Advances in Polymer Nanocomposites for Drilling Fluids: A Review

Abstract

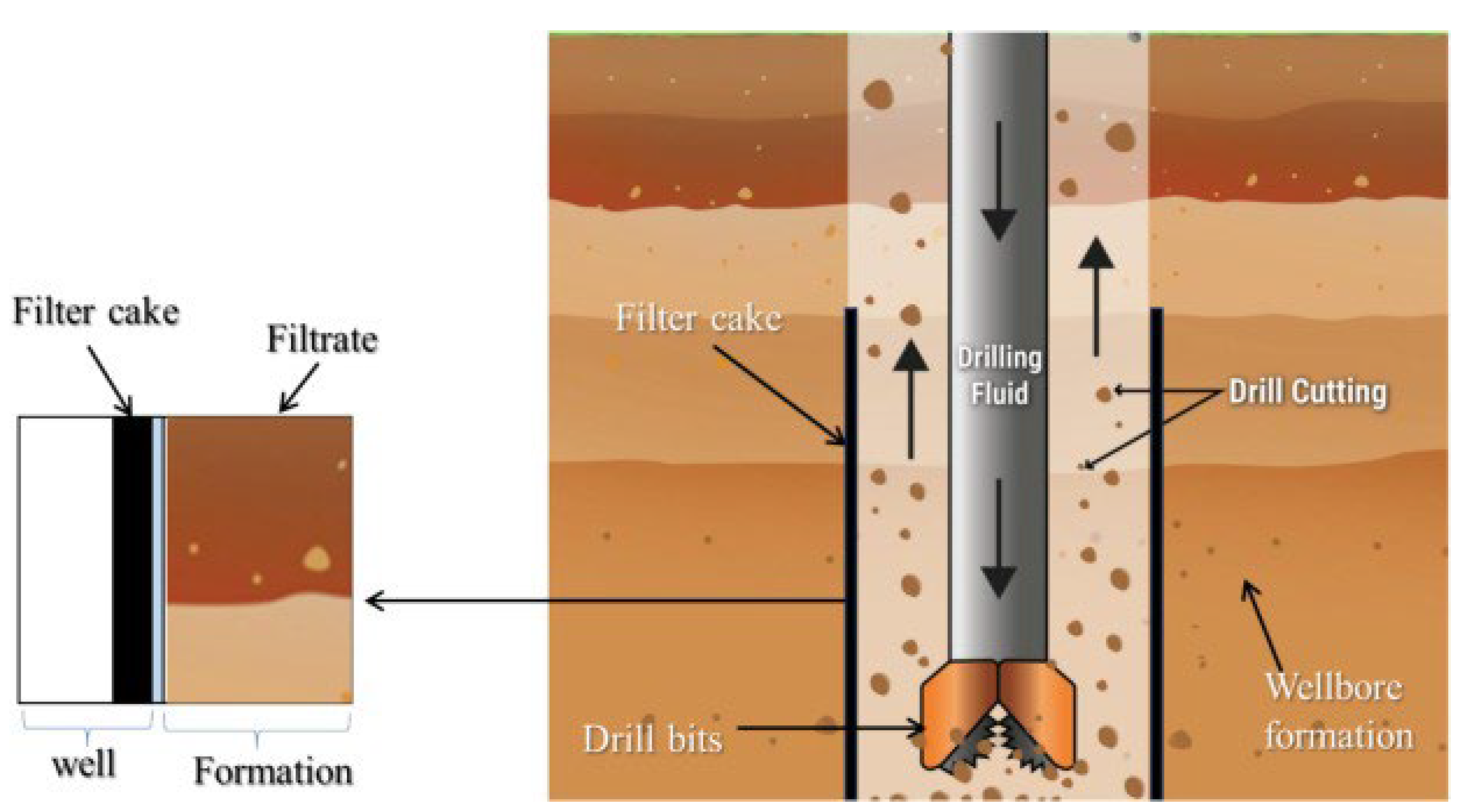

1. Introduction

2. Overview of PNCs

2.1. Fundamentals and Preparation of PNCs

2.1.1. Strategic Integration of Polymers and Nanoparticles for Advanced Drilling Fluids

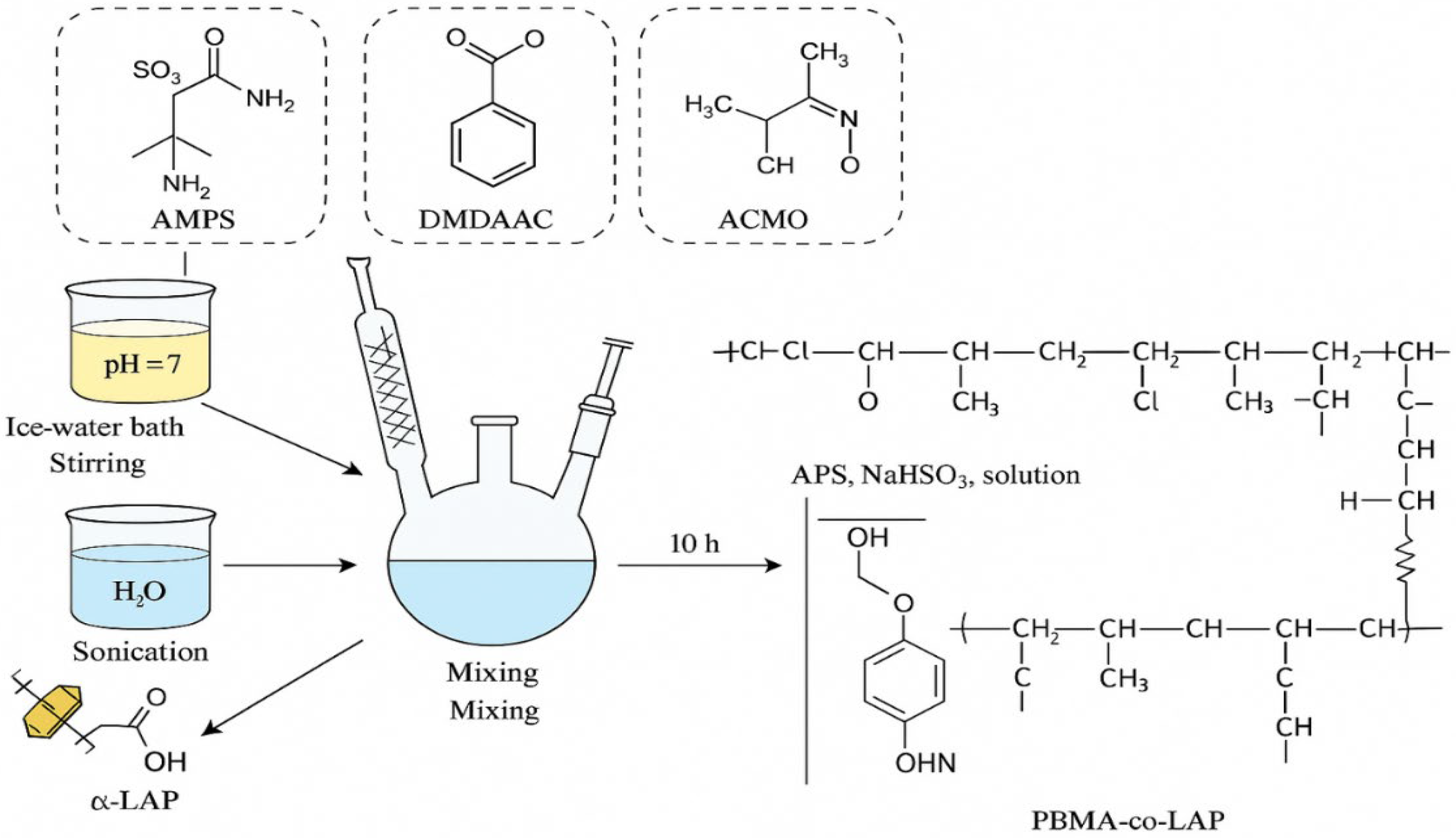

2.1.2. PNCs Made of Polymers and Inorganic NPS

2.1.3. PNCs Made of Polymers and Metal NPS or Metal Oxide NPS

2.1.4. Properties and Advantages of PNCs

2.2. PNCs in Drilling Fluids

2.2.1. PNCs for Improving Rheological Properties

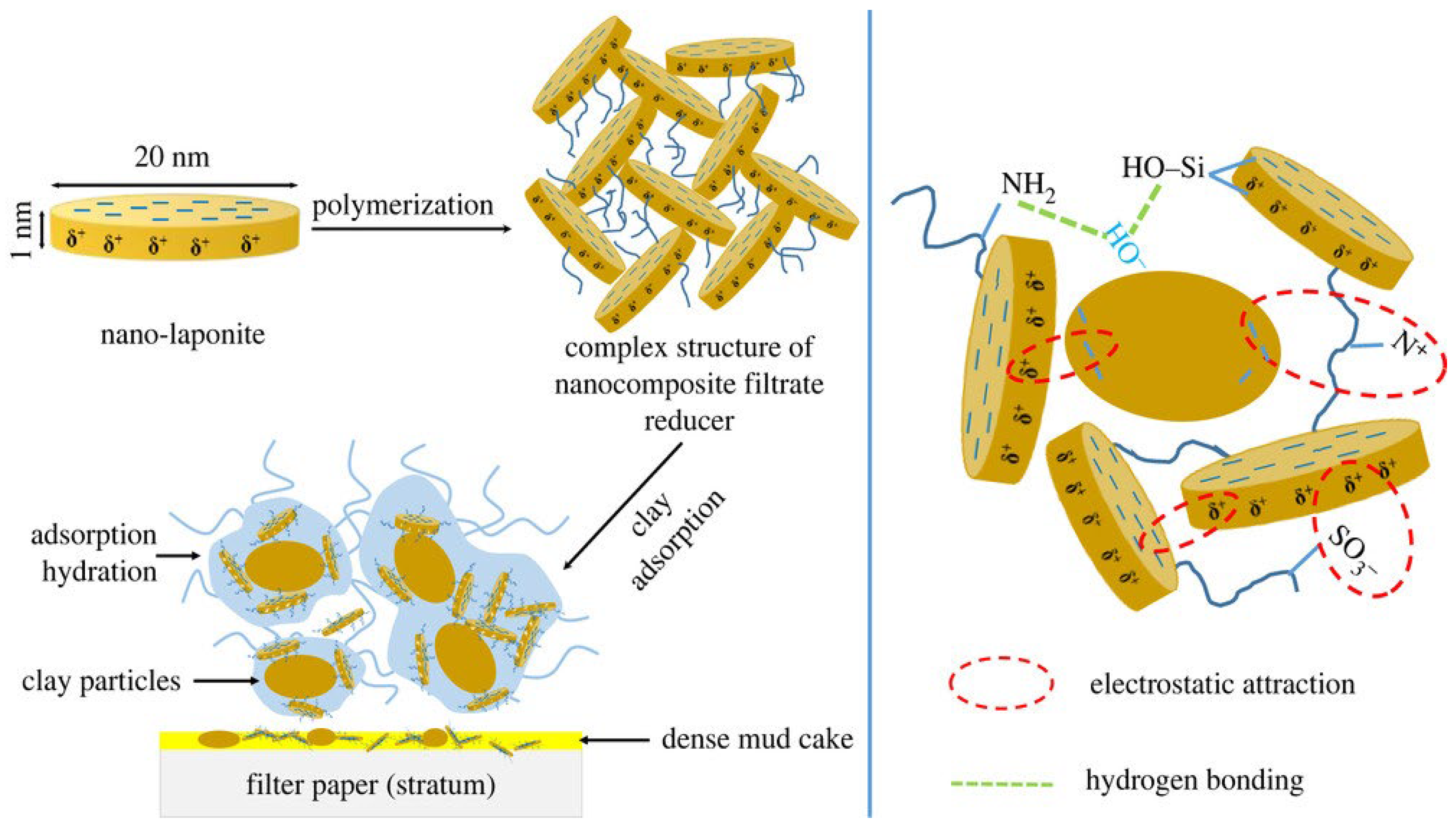

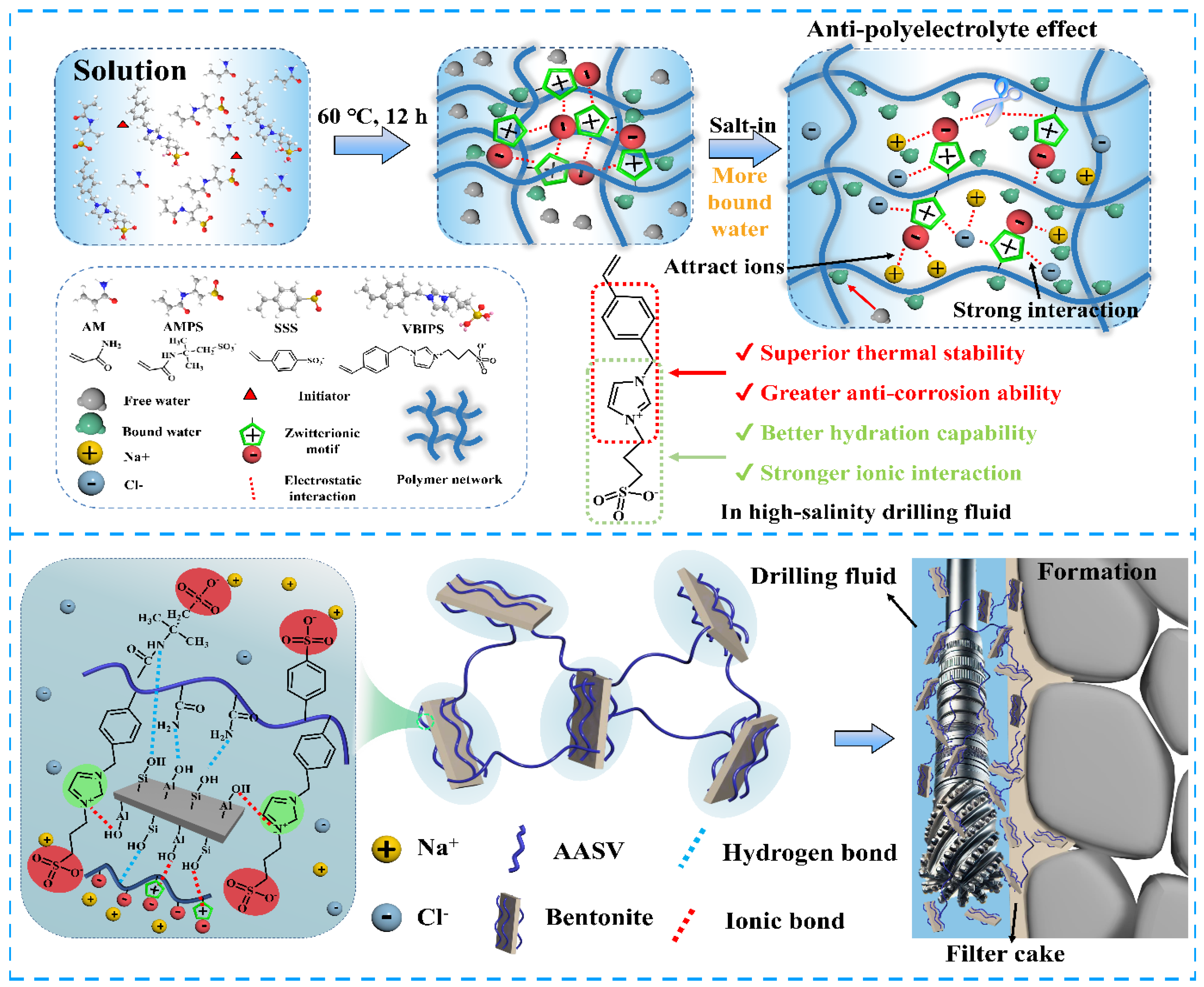

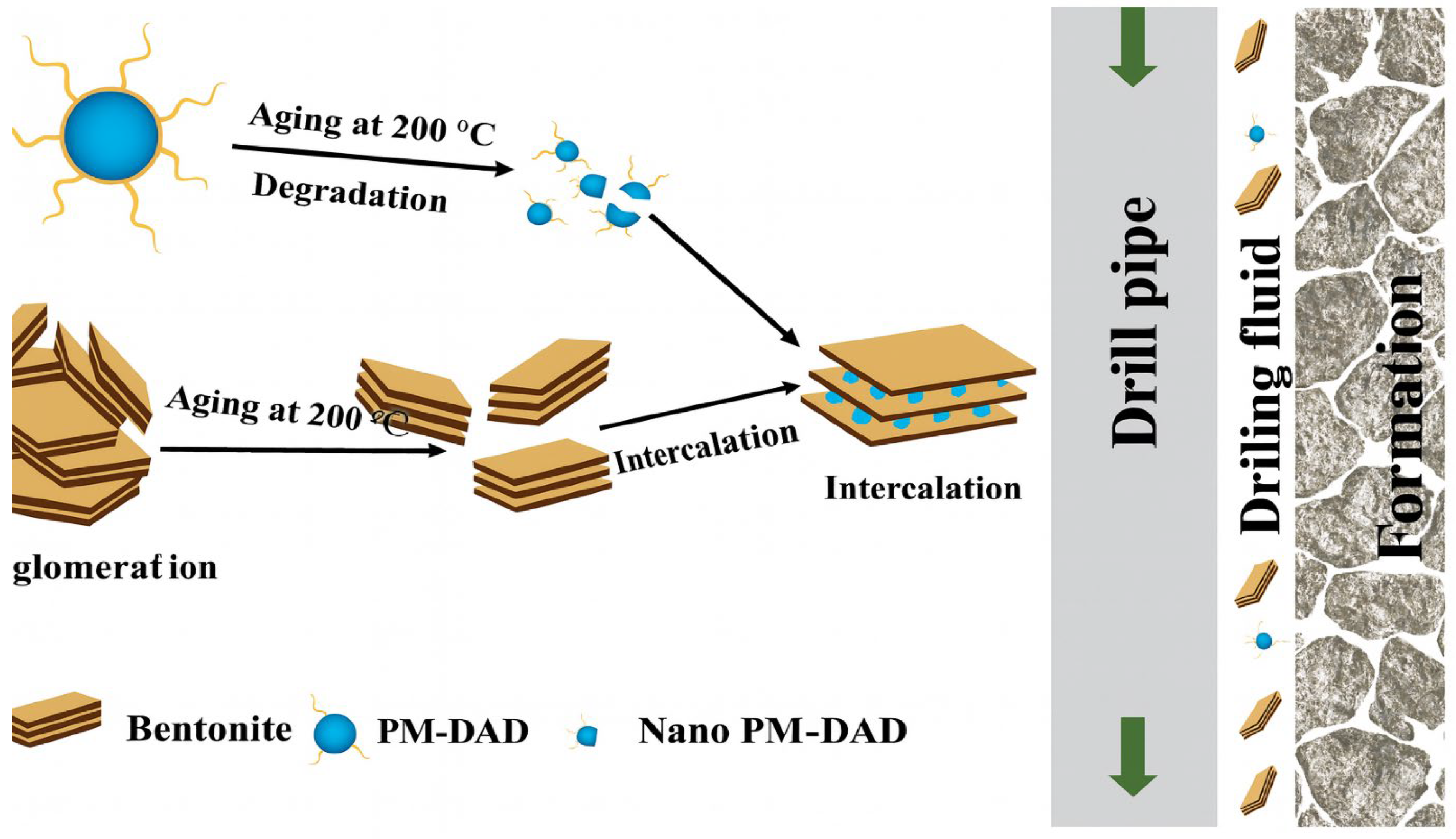

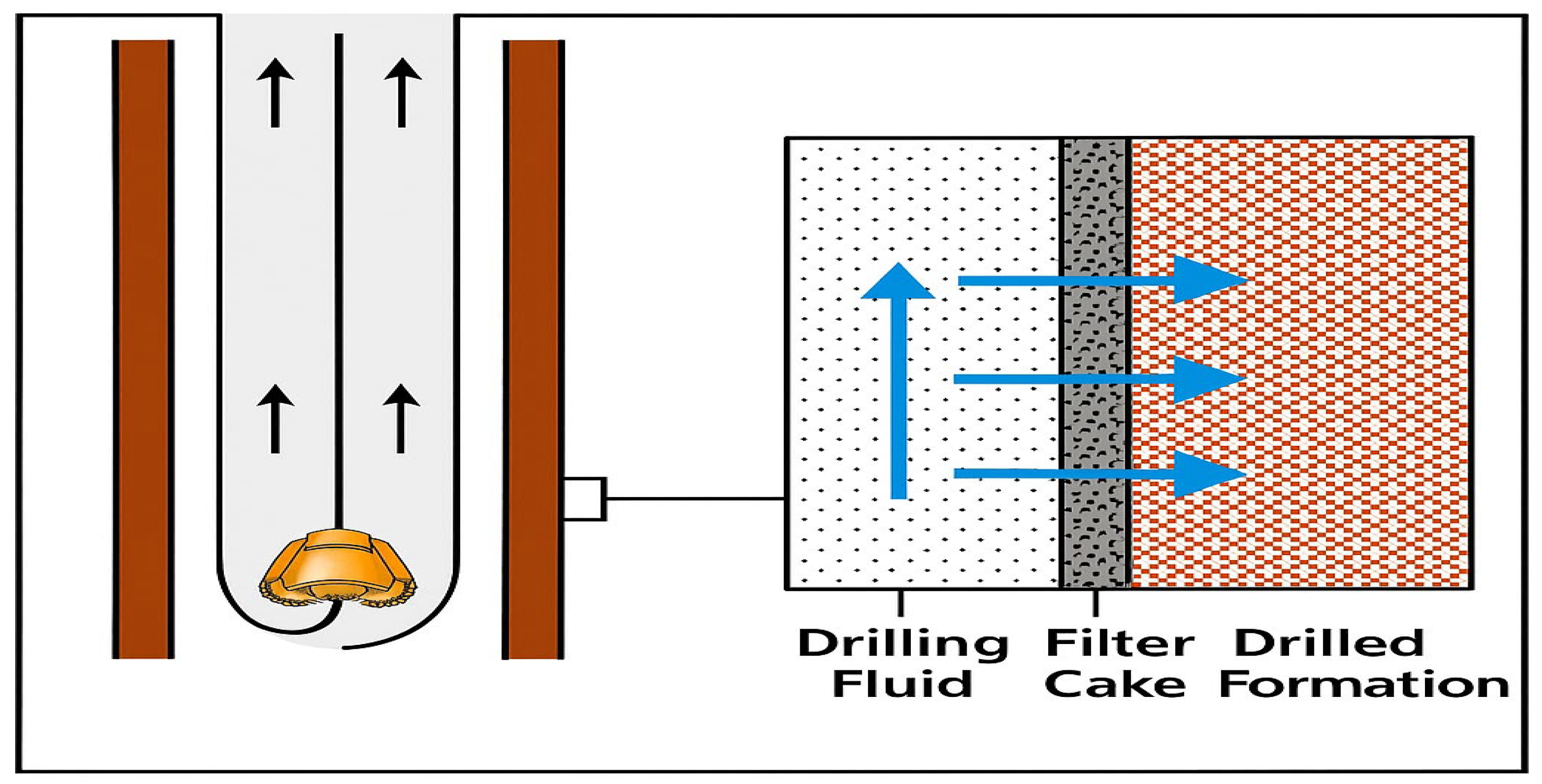

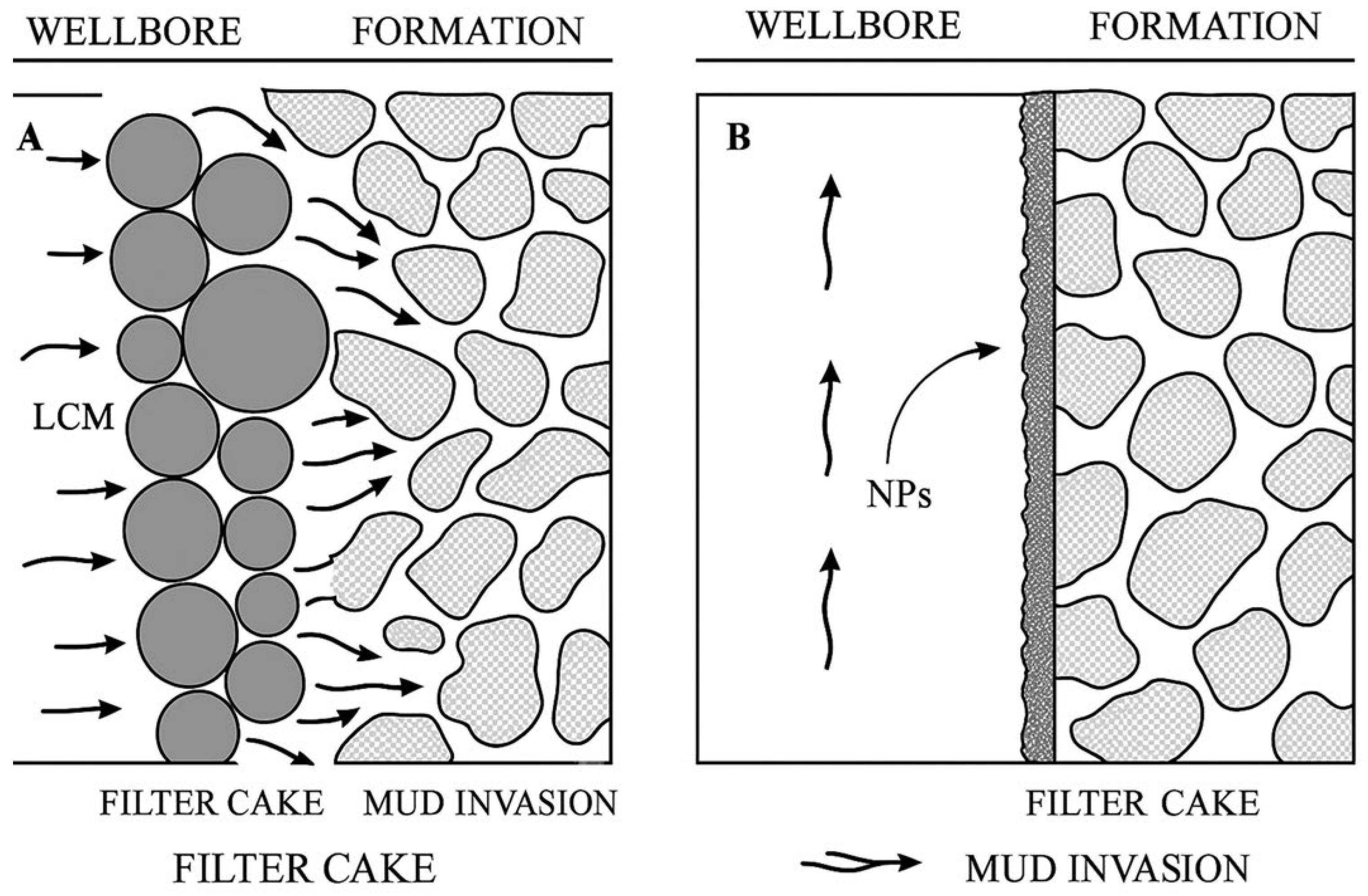

2.2.2. PNCs for Controlling Filtrate Loss

2.2.3. PNCs for Inhibiting Shale Swelling

Shale Swelling Mechanisms and Mineralogical Basis

Mechanism of Shale Swelling

| Material Used (PNCs) | Polymer Used | Nanofillers Used | Thermal Stability Threshold (°C) | Swelling Inhibition/Shale Recovery Metrics | Key Findings | Shale Inhibition Mechanism | Reference |

|---|---|---|---|---|---|---|---|

| PEI–Gr NC | Polyethyleneimine (PEI) | Graphene (Gr) | 180 °C | Shale recovery 65%; swelling reduction ≈ 45% vs. base mud | Maintained stability under HPHT; enhanced hydrophobic sealing | PEI interacts with –OH groups on the shale surface; Gr creates a barrier layer blocking microcracks | [115] |

| Glu–Gr NC | Glutamic acid (Glu) | Graphene (Gr) | 200 °C | Swelling reduction ≈ 52%; shale recovery 70% | Long-term shale stability after 48 h aging at 150 °C | Hydrogen bonding binds Gr to shale; intercalation prevents water penetration into nanopores | [116] |

| PNS Latex | Polymer (PNS) | Latex NPs | 160 °C | API FL reduced from 24 mL to 10.8 mL; shale recovery ≈ 60% | Greater thermal resistance and filtrate control under HPHT conditions | Adsorbs on shale microstructures, plugging cracks and pores | [117] |

| PAM–SiO2 NC | Polyacrylamide (PAM) | SiO2 | 210 °C | Swelling inhibition ≈ 70%; recovery 86.6% over 48 h | Outperformed commercial inhibitors (KCl 49.2%, base mud 74.7%) | Physical blocking of nanopores and hydrogen bond disruption by SiO2–OH groups | [118] |

| C-g-AA–NH2 NC | Acrylic acid (AA) | Aminomethyl, Amyl | 190 °C | Anti-swelling ratio 95.2%; recovery > 80% | Effective plugging and surface adsorption at moderate HPHT | Carbon-core nanopore plugging and strong polymer–shale adsorption | [119] |

| AP–ZnO NC | Acrylic Polymer (AP) | ZnO | 220 °C | Swelling rate reduced from 14.3% to 6.7%; recovery 97% | Good thermal endurance and inhibition under saline conditions | ZnO plugs pores and cracks; AP encapsulates the shale surface and reduces water contact | [120] |

| GO–PAM NC | Polyacrylamide (PAM) | GO | 230 °C | Swelling reduction ≈ 60%; shale recovery 90% | Retained integrity after 150 °C aging; thin filter cake formation | GO sheets provide a hydrophobic barrier and improve shale cohesion | [121] |

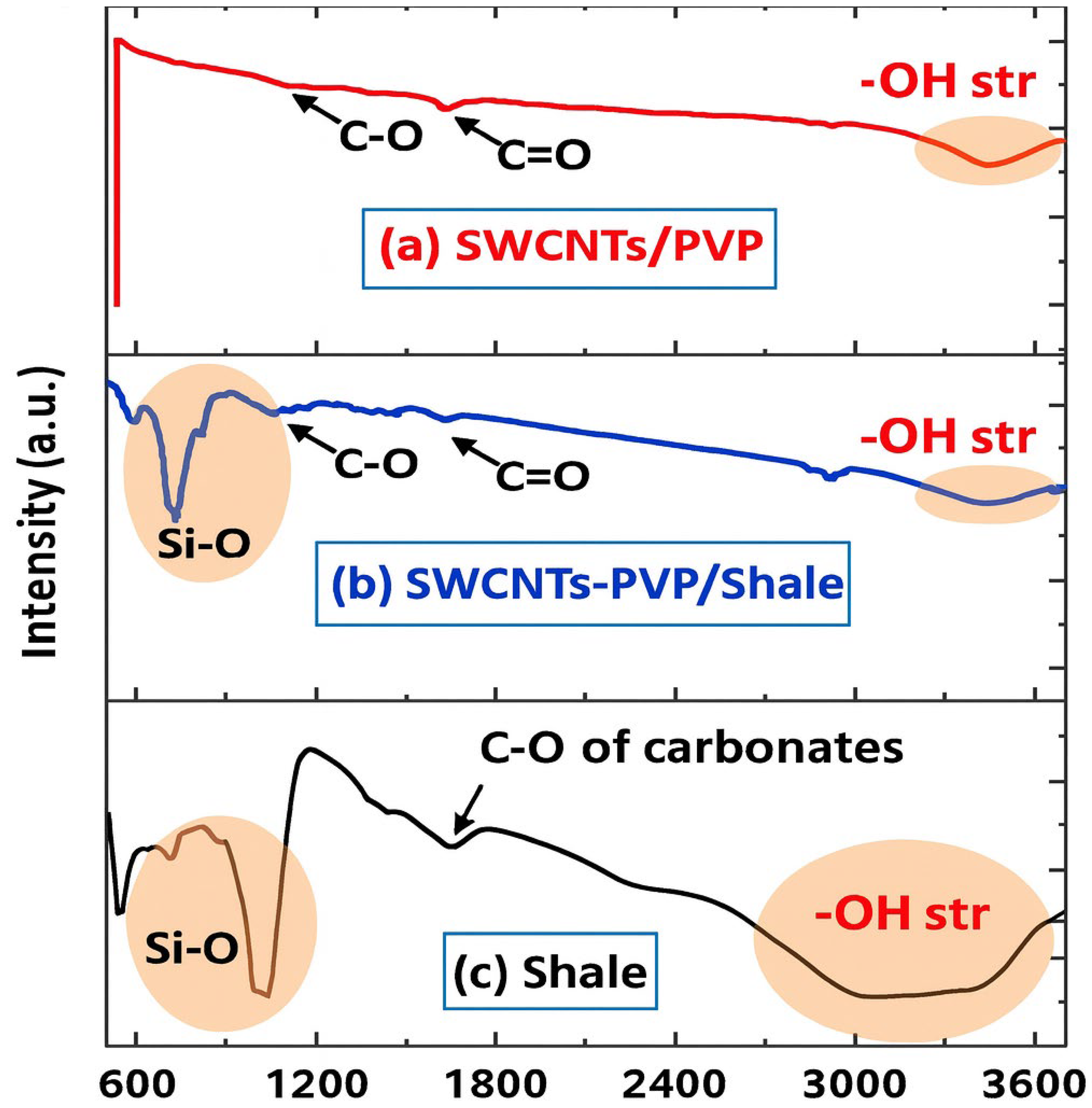

| SWCNTs/PVP NC | Polyvinylpyrrolidone (PVP) | SWCNTs | 240 °C | Swelling reduction ≈ 68%; FTIR shows reduced –OH absorption | Outstanding shear and thermal resilience under HPHT conditions | Hydrophobic shield and micro-pore plugging mechanism | [122] |

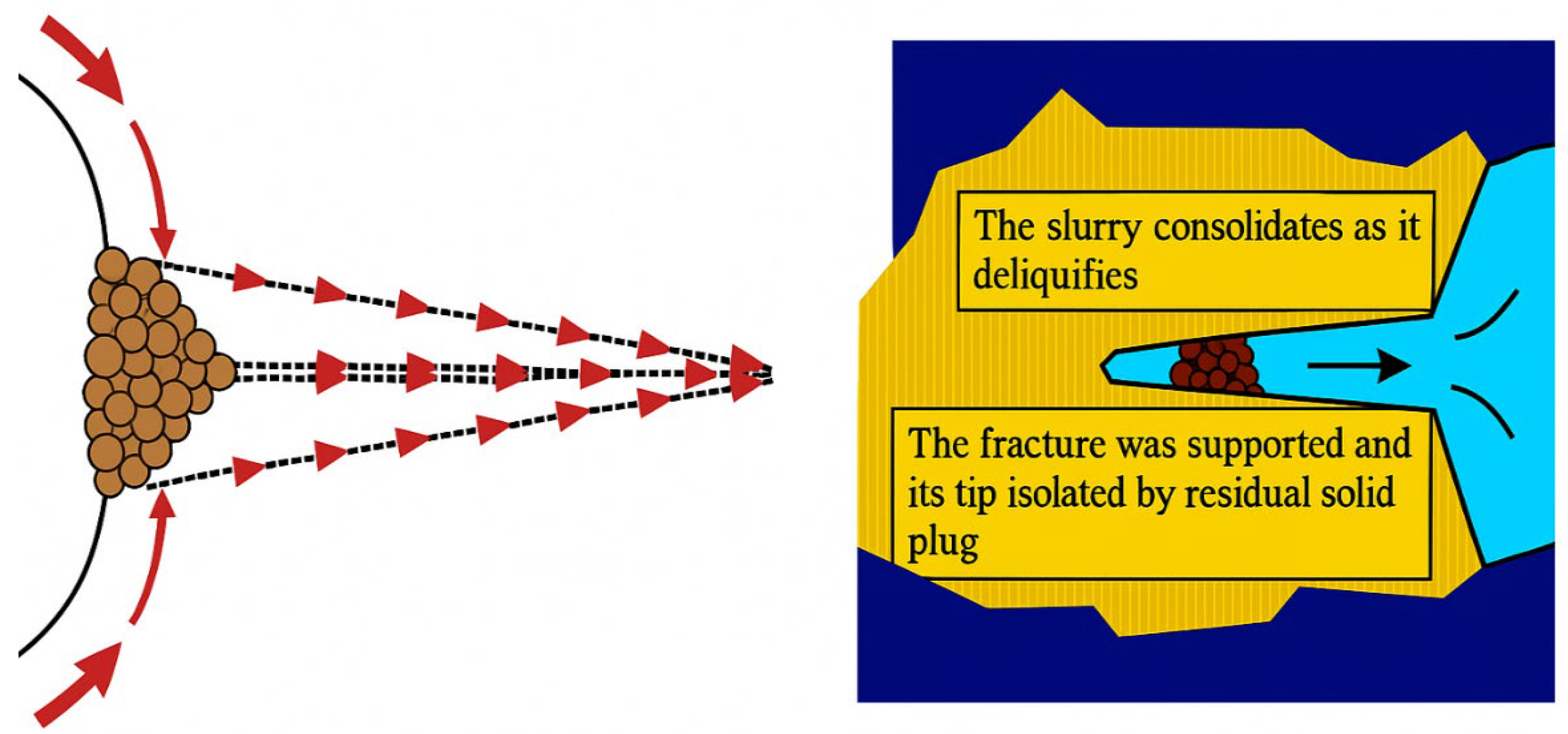

2.2.4. PNCs for Stabilizing the Wellbore

3. Conclusions and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AV | Apparent Viscosity |

| CMC | Carboxymethyl Cellulose |

| CNT | Carbon Nanotube |

| FCT | Filter Cake Thickness |

| GG | Guar Gum |

| GS | Gel Strength |

| HPAM | Hydrolyzed Polyacrylamide |

| HPHT | High-Pressure High-Temperature |

| HEC | Hydroxyethyl Cellulose |

| LCM | Lost Circulation Material |

| NP(s) | Nanoparticle(s) |

| OBM | Oil-Based Mud |

| PAC | Polyanionic Cellulose |

| PAM | Polyacrylamide |

| PHPA | Partially Hydrolyzed Polyacrylamide |

| PNC(s) | Polymer Nanocomposite(s) |

| PV | Plastic Viscosity |

| ROP | Rate of Penetration |

| SiO2 | Silica |

| WBM | Water-Based Mud |

| XG | Xanthan Gum |

| WBMs | Water-Based Muds |

| OBMs | Oil-Based Muds |

| PNCs | Polymer Nanocomposites |

| HPHT | High-Pressure & High-Temperature |

| KPAM | Potassium Polyacrylamide |

| YP | Yield Point |

| CoF | Coefficient of Friction |

| GO | Graphene Oxide |

| CNTs | Carbon Nanotubes |

| Gr | Graphene |

| QDs | Quantum Dots |

| MSNs | Mesoporous Silica Nanoparticles |

| FESEM | Field-Emission Scanning Electron Microscopy |

| FTIR | Fourier-Transform Infrared Spectroscopy |

References

- Chen, H.; Xu, C. The impact of cryptocurrencies on China’s carbon price variation during COVID-19: A quantile perspective. Technol. Forecast. Soc. Change 2022, 183, 121933. [Google Scholar] [CrossRef]

- Saba, C.S.; Ngepah, N. The impact of artificial intelligence (AI) on employment and economic growth in BRICS: Does the moderating role of governance Matter? Res. Glob. 2024, 8, 100213. [Google Scholar] [CrossRef]

- Yan, L.; Wang, C.; Xu, B.; Sun, J.; Yue, W.; Yang, Z. Preparation of a novel amphiphilic comb-like terpolymer as viscosifying additive in low-solid drilling fluid. Mater. Lett. 2013, 105, 232–235. [Google Scholar] [CrossRef]

- Li, X.; Ju, Y.; Jia, Y.; Liu, F.; Liu, G.; Wang, S.; Wang, H.; Mao, S.; Yang, J.; Du, G. Design of novel temperature-resistant and salt-tolerant acrylamide-based copolymers by aqueous dispersion polymerization. Des. Monomers Polym. 2022, 25, 220–230. [Google Scholar] [CrossRef]

- He, Y.; Gou, S.; Zhou, Y.; Zhou, L.; Tang, L.; Liu, L.; Fang, S. Thermoresponsive behaviors of novel polyoxyethylene-functionalized acrylamide copolymers: Water solubility, rheological properties and surface activity. J. Mol. Liq. 2020, 319, 114337. [Google Scholar] [CrossRef]

- Saleh, T.A.; Rana, A.; Arfaj, M.K.; Ibrahim, M.A. Hydrophobic polymer-modified nanosilica as effective shale inhibitor for water-based drilling mud. J. Pet. Sci. Eng. 2022, 209, 109868. [Google Scholar] [CrossRef]

- Borisov, A.S.; Husein, M.; Hareland, G. A field application of nanoparticle-based invert emulsion drilling fluids. J. Nanoparticle Res. 2015, 17, 340. [Google Scholar] [CrossRef]

- Boyou, N.V.; Ismail, I.; Sulaiman, W.R.W.; Haddad, A.S.; Husein, N.; Hui, H.T.; Nadaraja, K. Experimental investigation of hole cleaning in directional drilling by using nano-enhanced water-based drilling fluids. J. Pet. Sci. Eng. 2019, 176, 220–231. [Google Scholar] [CrossRef]

- Boudouh, D.; Ikram, R.; Jan, B.M.; Metselaar, H.S.C.; Hamana, D.; Kenanakis, G. Synthesis, characterization and filtration properties of ecofriendly Fe3O4 nanoparticles derived from olive leaves extract. Materials 2021, 14, 4306. [Google Scholar] [CrossRef]

- Hajiabadi, S.H.; Aghaei, H.; Kalateh-Aghamohammadi, M.; Shorgasthi, M. An overview on the significance of carbon-based nanomaterials in upstream oil and gas industry. J. Pet. Sci. Eng. 2020, 186, 106783. [Google Scholar] [CrossRef]

- Gbadamosi, A.; Yusuff, A.; Agi, A.; Muruga, P.; Junin, R.; Jeffrey, O. Mechanistic study of nanoparticles-assisted xanthan gum polymer flooding for enhanced oil recovery: A comparative study. J. Pet. Explor. Prod. Technol. 2022, 12, 207–213. [Google Scholar] [CrossRef]

- Hoelscher, K.P.; De Stefano, G.; Riley, M.; Young, S. Application of nanotechnology in drilling fluids. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012; SPE: Richardson, TX, USA, 2012; p. SPE-157031. [Google Scholar]

- Cheraghian, G.G.; Afrand, M. Nanotechnology for drilling operations. In Emerging Nanotechnologies for Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2021; pp. 135–148. [Google Scholar]

- Vargas, J.; Roldán, L.J.; Lopera, S.H.; Cardenas, J.C.; Zabala, R.D.; Franco, C.A.; Cortés, F.B. Effect of silica nanoparticles on thermal stability in bentonite free water-based drilling fluids to improve its rheological and filtration properties after aging process. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 29–31 October 2019; OTC: Boca Raton, FL, USA, 2019; p. D011S007R003. [Google Scholar]

- Rowan, N.J. The role of digital t1chnologies in supporting and improving fishery and aquaculture across the supply chain–Quo Vadis? Aquac. Fish. 2023, 8, 365–374. [Google Scholar] [CrossRef]

- Li, M.-C.; Wu, Q.; Song, K.; De Hoop, C.F.; Lee, S.; Qing, Y.; Wu, Y. Cellulose nanocrystals and polyanionic cellulose as additives in bentonite water-based drilling fluids: Rheological modeling and filtration mechanisms. Ind. Eng. Chem. Res. 2015, 55, 133–143. [Google Scholar] [CrossRef]

- Mao, H.; Qiu, Z.; Shen, Z.; Huang, W. Hydrophobic associated polymer based silica nanoparticles composite with core–shell structure as a filtrate reducer for drilling fluid at utra-high temperature. J. Pet. Sci. Eng. 2015, 129, 1–14. [Google Scholar] [CrossRef]

- Abdollahi, M.; Pourmahdi, M.; Nasiri, A.R. Synthesis and characterization of lignosulfonate/acrylamide graft copolymers and their application in environmentally friendly water-based drilling fluid. J. Pet. Sci. Eng. 2018, 171, 484–494. [Google Scholar] [CrossRef]

- Nooripoor, V.; Nazemi, R.; Hashemi, A. Employing nano-sized additives as filtration control agent in water-based drilling fluids: Study on barium sulfate, bentonite, surface-modified bentonite, titanium oxide, and silicon oxide. Energy Sources Part A Recover. Util. Environ. Eff. 2024, 46, 13806–13822. [Google Scholar] [CrossRef]

- Nooripoor, V.; Hashemi, A. Effect of a modified nano clay and nano graphene on rheology, stability of water-in-oil emulsion, and filtration control ability of oil-based drilling fluids: A comparative experimental approach. Oil Gas Sci. Technol. d’IFP Energies Nouv. 2020, 75, 40. [Google Scholar] [CrossRef]

- GB/T 16783.1-2006; Petroleum and Natural Gas Industries―Field Testing of Drilling Fluids―Part 1: Water-Based Fluids. SAC: Shenzhen, China, 2016.

- Gao, J.; Zhang, G.; Wang, L.; Ding, L.; Shi, H.; Lai, X.; Wen, X.; Ma, S.; Huang, C. Rheological properties of an ultra-high salt hydrophobic associated polymer as a fracturing fluid system. RSC Adv. 2019, 9, 15246–15256. [Google Scholar] [CrossRef]

- Mohamed, A.; Elkatatny, S.; Al-Majed, A. Removal of calcium carbonate water-based filter cake using a green biodegradable acid. Sustainability 2020, 12, 994. [Google Scholar] [CrossRef]

- Koh, J.K.; Lai, C.W.; Johan, M.R.; Gan, S.S.; Chua, W.W. Recent advances of modified polyacrylamide in drilling technology. J. Pet. Sci. Eng. 2022, 215, 110566. [Google Scholar] [CrossRef]

- Liu, J.; Dai, Z.; Xu, K.; Yang, Y.; Lv, K.; Huang, X.; Sun, J. Water-based drilling fluid containing bentonite/poly (sodium 4-styrenesulfonate) composite for ultrahigh-temperature ultradeep drilling and its field performance. SPE J. 2020, 25, 1193–1203. [Google Scholar] [CrossRef]

- Growcock, F.; Harvey, T. Drilling fluids. In Drilling Fluids Processing Handbook; Elsevier: Burlington, MA, USA, 2005; Volume 1. [Google Scholar]

- Bergane, C.; Hammadi, L. Impact of organophilic clay on rheological properties of gasoil-based drilling muds. J. Pet. Explor. Prod. Technol. 2020, 10, 3533–3540. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Lv, K.; Ji, Y.; Ji, J.; Liu, J. Nano-modified polymer gels as temperature-and salt-resistant fluid-loss additive for water-based drilling fluids. Gels 2022, 8, 547. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Chenevert, M.E.; Sharma, M.M.; Friedheim, J. Decreasing Water Invasion into Atoka Shale Using Non-modified Silica Nanoparticles. SPE Drill. Compl. 2011, 27, 103–112. [Google Scholar] [CrossRef]

- Haruna, M.A.; Pervaiz, S.; Hu, Z.; Nourafkan, E.; Wen, D. Improved rheology and high-temperature stability of hydrolyzed polyacrylamide using graphene oxide nanosheet. J. Appl. Polym. Sci. 2019, 136, 47582. [Google Scholar] [CrossRef]

- Bavoh, C.B.; Ofei, T.N.; Lal, B.; Sharif, A.M.; Shahpin, M.H.B.A.; Sundramoorthy, J.D. Assessing the impact of an ionic liquid on NaCl/KCl/polymer water-based mud (WBM) for drilling gas hydrate-bearing sediments. J. Mol. Liq. 2019, 294, 111643. [Google Scholar] [CrossRef]

- Lalji, S.M.; Ali, S.I.; Ahmed, R.; Hashmi, S.; Awan, Z.U.H.; Qazi, S.W.A. Influence of graphene oxide on salt-polymer mud rheology and Pakistan shale swelling inhibition behavior. Arab. J. Geosci. 2022, 15, 612. [Google Scholar] [CrossRef]

- Chen, Y.; Yin, Q.; Zhang, X.; Xue, X.; Jia, H. The crystallization behaviors and rheological properties of polypropylene/graphene nanocomposites: The role of surface structure of reduced graphene oxide. Thermochim. Acta 2018, 661, 124–136. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Lv, K.; Liu, J.; Shen, H.; Zhang, F. Application of core-shell structural acrylic resin/nano-SiO2 composite in water based drilling fluid to plug shale pores. J. Nat. Gas Sci. Eng. 2018, 55, 418–425. [Google Scholar] [CrossRef]

- Akhtarmanesh, S.; Shahrabi, M.J.A.; Atashnezhad, A. Improvement of wellbore stability in shale using nanoparticles. J. Pet. Sci. Eng. 2013, 112, 290–295. [Google Scholar] [CrossRef]

- Morgani, M.S.; Saboori, R.; Sabbaghi, S. Hydrogen sulfide removal in water-based drilling fluid by metal oxide nanoparticle and ZnO/TiO2 nanocomposite. Mater. Res. Express 2017, 4, 75501. [Google Scholar] [CrossRef]

- Naheed, Z.; Nasreen, S.; Tiwari, A.K.; Arsh, S. Analyzing the effectiveness of energy aid for driving the transition towards energy decarbonization; Evidence from Asian developing countries. J. Environ. Manag. 2024, 360, 121125. [Google Scholar] [CrossRef]

- Aftab, A.; Ismail, A.R.; Khokhar, S.; Ibupoto, Z.H. Novel zinc oxide nanoparticles deposited acrylamide composite used for enhancing the performance of water-based drilling fluids at elevated temperature conditions. J. Pet. Sci. Eng. 2016, 146, 1142–1157. [Google Scholar] [CrossRef]

- Ruan, Y.; Wang, W.; Abubakar, M.; Ahmad, N. Global Economic Resilience: Developing Green Growth Strategies, Renewable Energy Integration, and Environmental Economics for Sustainability. Renew. Energy 2025, 251, 123341. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, L.; Luo, P.; Li, X.; Ren, W.; Yi, T. Polymer-laponite composites as filtrate reducer for high temperature and salt resistant drilling fluid: Characterization and performance evaluation. Colloids Surf. A Physicochem. Eng. Asp. 2024, 688, 133679. [Google Scholar] [CrossRef]

- Ezell, R.G.; Ezzat, A.M.; Turner, J.K.; Wu, J.J. New filtration-control polymer for improved brine-based reservoir drilling-fluids performance at temperatures in excess of 400 F and high pressure. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10–12 February 2010; SPE: Richardson, TX, USA, 2010; p. SPE-128119. [Google Scholar]

- Tavakkoli, O.; Kamyab, H.; Shariati, M.; Mohamed, A.M.; Junin, R. Effect of nanoparticles on the performance of polymer/surfactant flooding for enhanced oil recovery: A review. Fuel 2022, 312, 122867. [Google Scholar] [CrossRef]

- Peng, H.; Chen, H.; Sun, Y.; Zhang, X.; Abubakar, M. Environmental economics of green recovery in mineral extraction: Balancing production and conservation. Resour. Policy 2024, 96, 105202. [Google Scholar] [CrossRef]

- Needaa, A.-M.; Pourafshary, P.; Hamoud, A.-H.; Jamil, A. Controlling bentonite-based drilling mud properties using sepiolite nanoparticles. Pet. Explor. Dev. 2016, 43, 717–723. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Synthetic polymers: A review of applications in drilling fluids. Pet. Sci. 2024, 21, 475–518. [Google Scholar] [CrossRef]

- Hayati, M.M.; Aminlou, A.; Abapour, M.; Shafie-khah, M.; Shahinzadeh, H.; Gharehpetian, G.B. 18 The Power-to-X (PtX) Effect in Ancillary Service Markets. In Power-to-X in Regional Energy Systems; CRC Press: Boca Raton, FL, USA, 2025; p. 432. [Google Scholar]

- Li, M.-C.; Tang, Z.; Liu, C.; Huang, R.; Koo, M.S.; Zhou, G.; Wu, Q. Water-redispersible cellulose nanofiber and polyanionic cellulose hybrids for high-performance water-based drilling fluids. Ind. Eng. Chem. Res. 2020, 59, 14352–14363. [Google Scholar] [CrossRef]

- Aftab, A.; Ali, M.; Sahito, M.F.; Mohanty, U.S.; Jha, N.K.; Akhondzadeh, H.; Azhar, M.R.; Ismail, A.; Keshavarz, A.; Iglauer, S. Environmental friendliness and high performance of multifunctional tween 80/ZnO-nanoparticles-added water-based drilling fluid: An experimental approach. ACS Sustain. Chem. Eng. 2020, 8, 11224–11243. [Google Scholar] [CrossRef]

- Pandey, A.; Chaturvedi, K.R.; Sharma, T. Assessment of polymer based carbonation in weak/strong alkaline media for energy production and carbon storage: An approach to address carbon emissions. J. Clean. Prod. 2021, 328, 129628. [Google Scholar] [CrossRef]

- Chaturvedi, K.R.; Trivedi, J.; Sharma, T. Evaluation of polymer-assisted carbonated water injection in sandstone reservoir: Absorption kinetics, rheology, and oil recovery results. Energy Fuels 2019, 33, 5438–5451. [Google Scholar] [CrossRef]

- Chen, Y.; Shull, K.R. Thermothickening behavior of self-stabilized colloids formed from associating polymers. Macromolecules 2019, 52, 4926–4933. [Google Scholar] [CrossRef]

- Bayat, A.E.; Harati, S.; Kolivandi, H. Evaluation of rheological and filtration properties of a polymeric water-based drilling mud in presence of nano additives at various temperatures. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127128. [Google Scholar] [CrossRef]

- Dong, X.; Sun, J.; Huang, X.; Lv, K.; Zhou, Z.; Gao, C. Nano-laponite/polymer composite as filtration reducer on water-based drilling fluid and mechanism study. R. Soc. Open Sci. 2022, 9, 220385. [Google Scholar] [CrossRef] [PubMed]

- Awaysheh, A.; Heron, R.A.; Perry, T.; Wilson, J.I. On the relation between corporate social responsibility and financial performance. Strateg. Manag. J. 2020, 41, 965–987. [Google Scholar] [CrossRef]

- Belu, C.; Manescu, C. Strategic corporate social responsibility and economic performance. Appl. Econ. 2013, 45, 2751–2764. [Google Scholar] [CrossRef]

- Aramburu, I.A.; Pescador, I.G. The effects of corporate social responsibility on customer loyalty: The mediating effect of reputation in cooperative banks versus commercial banks in the Basque country. J. Bus. Ethics 2019, 154, 701–719. [Google Scholar] [CrossRef]

- Ahamed, M.M.; Luintel, K.B.; Mallick, S.K. Does local knowledge spillover matter for firm productivity? The role of financial access and corporate governance. Res. Policy 2023, 52, 104837. [Google Scholar] [CrossRef]

- Ai, Y.; Chi, Z.; Sun, G.; Zhou, H.; Kong, T. The research on non-linear relationship between enterprise digital transformation and stock price crash risk. N. Am. J. Econ. Financ. 2023, 68, 101984. [Google Scholar] [CrossRef]

- Liu, Y.; Bian, Y.; Zhang, W. How does enterprises’ digital transformation impact the educational structure of employees? Evidence from China. Sustainability 2022, 14, 9432. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Yu, W. Opportunity or challenge? Research on the influence of digital finance on digital transformation of agribusiness. Sustainability 2023, 15, 1072. [Google Scholar] [CrossRef]

- Lu, Z.; Li, H. Does environmental information disclosure affect green innovation? Econ. Anal. Policy 2023, 80, 47–59. [Google Scholar] [CrossRef]

- Liao, F.; Hu, Y.; Chen, M.; Xu, S. Digital transformation and corporate green supply chain efficiency: Evidence from China. Econ. Anal. Policy 2024, 81, 195–207. [Google Scholar] [CrossRef]

- Li, S.; Wang, Q. Green finance policy and digital transformation of heavily polluting firms: Evidence from China. Financ. Res. Lett. 2023, 55, 103876. [Google Scholar] [CrossRef]

- Li, R.; Rao, J.; Wan, L. The digital economy, enterprise digital transformation, and enterprise innovation. Manag. Decis. Econ. 2022, 43, 2875–2886. [Google Scholar] [CrossRef]

- Li, M.; Jiang, A.; Ma, J. Digital transformation and income inequality within enterprises–Evidence from listed companies in China. Pac. Basin Financ. J. 2023, 81, 102133. [Google Scholar] [CrossRef]

- Krishnamurti, C.; Shams, S.; Pensiero, D.; Velayutham, E. Socially responsible firms and mergers and acquisitions performance: Australian evidence. Pac. Basin Financ. J. 2019, 57, 101193. [Google Scholar] [CrossRef]

- Ko, K.-C.; Nie, J.; Ran, R.; Gu, Y. Corporate social responsibility, social identity, and innovation performance in China. Pac. Basin Financ. J. 2020, 63, 101415. [Google Scholar] [CrossRef]

- Guo, L.; Xu, L. The effects of digital transformation on firm performance: Evidence from China’s manufacturing sector. Sustainability 2021, 13, 12844. [Google Scholar] [CrossRef]

- Eller, R.; Alford, P.; Kallmünzer, A.; Peters, M. Antecedents, consequences, and challenges of small and medium-sized enterprise digitalization. J. Bus. Res. 2020, 112, 119–127. [Google Scholar] [CrossRef]

- Cui, L.; Wang, Y. Can corporate digital transformation alleviate financial distress? Financ. Res. Lett. 2023, 55, 103983. [Google Scholar] [CrossRef]

- Cui, D.; Ding, M.; He, Z.; Shen, M. Restricted shares and CSR: Evidence from foreign strategic investors in China. Pac. Basin Financ. J. 2022, 76, 101865. [Google Scholar] [CrossRef]

- El-Khayat, H.M.M.; Gaber, H.S.; Helal, N.S.; Zayed, K.M.; Flefel, H.E.; Mohammed, W.A.; Sayed, S.S.M. Comparative study on Lake Manzala in Egypt after and before development and purifications: Ecosystem and biomarkers; biochemical, histopathological and immunohistochemical. Environ. Pollut. 2023, 339, 122741. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Zhang, M.; Zhang, Y.; Zhou, M.; Peng, L.; He, A.; Zhang, X.; Yan, X.; Wang, Y.; et al. In vitro lung and gastrointestinal bioaccessibility of potentially toxic metals in Pb-contaminated alkaline urban soil: The role of particle size fractions. Ecotoxicol. Environ. Saf. 2020, 190, 110151. [Google Scholar] [CrossRef]

- Lu, X.; Yang, Q.; Wang, H.; Zhu, Y. A global meta-analysis of the correlation between soil physicochemical properties and lead bioaccessibility. J. Hazard. Mater. 2023, 453, 131440. [Google Scholar] [CrossRef]

- Ağbulut, Ü. Turkey’s electricity generation problem and nuclear energy policy. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 2281–2298. [Google Scholar] [CrossRef]

- Roy, S.; Singha, N.; Bose, A.; Basak, D.; Chowdhury, I.R. Multi-influencing factor (MIF) and RS–GIS-based determination of agriculture site suitability for achieving sustainable development of Sub-Himalayan region, India. Environ. Dev. Sustain. 2023, 25, 7101–7133. [Google Scholar] [CrossRef]

- Liu, G.N.; Wu, Y.; Wang, S.C.; Liao, J.; Yu, S.W. The Main Water Environmental Issues and Assessment-zonation of Eco-environmental Geology Risks for Typical River-lake-wetland Systems in the Central Yangtze River. S. China Geol. 2022, 38, 226–239. [Google Scholar]

- Jin, X.; Wei, L.; Wang, Y.; Lu, Y. Construction of ecological security pattern based on the importance of ecosystem service functions and ecological sensitivity assessment: A case study in Fengxian County of Jiangsu Province, China. Environ. Dev. Sustain. 2021, 23, 563–590. [Google Scholar] [CrossRef]

- Pata, U.K.; Kartal, M.T.; Adebayo, T.S.; Ullah, S. Enhancing environmental quality in the United States by linking biomass energy consumption and load capacity factor. Geosci. Front. 2023, 14, 101531. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, S.; Zhang, Q. The relationship of renewable energy consumption to financial development and economic growth in China. Renew. Energy 2021, 170, 897–904. [Google Scholar] [CrossRef]

- Zhang, Q.; Shah, S.A.R.; Yang, L. Modeling the effect of disaggregated renewable energies on ecological footprint in E5 economies: Do economic growth and R&D matter? Appl. Energy 2022, 310, 118522. [Google Scholar] [CrossRef]

- Tkalec, Ž.; Antignac, J.-P.; Bandow, N.; Béen, F.M.; Belova, L.; Bessems, J.; Le Bizec, B.; Brack, W.; Cano-Sancho, G.; Chaker, J.; et al. Innovative analytical methodologies for characterizing chemical exposure with a view to next-generation risk assessment. Environ. Int. 2024, 186, 108585. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, Y.; Yang, X.; Guo, Y.; Xiang, T.; Wang, Y.; Yan, Y.; Li, D.; Nie, T.; Li, Z.; et al. Effect-directed analysis for revealing aryl hydrocarbon receptor agonists in sediment samples from an electronic waste recycling town in China. Environ. Pollut. 2022, 308, 119659. [Google Scholar] [CrossRef]

- Ma, Q.; Yang, X.; Guo, Y.; Wang, Y.; Liu, Y.; Zhang, S.; Xie, H.Q.; Xiang, T.; Li, Z.; Nie, T.; et al. Effect-directed analysis of estrogenic chemicals in sediments from an electronic-waste recycling area. Environ. Pollut. 2022, 306, 119369. [Google Scholar] [CrossRef]

- Shui, Y.; Zhong, J.; Yang, Y.; Zeng, Y.; Liu, S. Employment Transfer of Rural Female Labor and Family Welfare Effect in Mountainous Areas: An Empirical Analysis Based on Panel Data. Land 2022, 11, 2134. [Google Scholar] [CrossRef]

- Xin-gang, Z.; Jin, Z. Industrial restructuring, energy consumption and economic growth: Evidence from China. J. Clean. Prod. 2022, 335, 130242. [Google Scholar] [CrossRef]

- Su, Y.; Fan, Q. Renewable energy technology innovation, industrial structure upgrading and green development from the perspective of China’s provinces. Technol. Forecast. Soc. Change 2022, 180, 121727. [Google Scholar] [CrossRef]

- Shang, J.; Wang, Z.; Li, L.; Chen, Y.; Li, P. A study on the correlation between technology innovation and the new-type urbanization in Shaanxi province. Technol. Forecast. Soc. Change 2018, 135, 266–273. [Google Scholar] [CrossRef]

- Xu, H.; Jiao, M. City size, industrial structure and urbanization quality—A case study of the Yangtze River Delta urban agglomeration in China. Land Use Policy 2021, 111, 105735. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, C. Innovative low-carbon city: Carbon emission performance evaluation of innovative city construction. S. China J. Econ. 2021, 3, 36–53. [Google Scholar]

- Zhang, C.; Yao, Y.; Zhou, H. External technology dependence and manufacturing TFP: Evidence from China. Res. Int. Bus. Financ. 2023, 64, 101885. [Google Scholar] [CrossRef]

- Gao, S.; Lin, D.; Li, A.; Deng, L.; Dong, A.; Zhang, J. A zwitterionic polymer filtrate reducer with enhanced anti-polyelectrolyte effect for high-temperature and high-salinity conditions. Chem. Eng. J. 2025, 508, 161087. [Google Scholar] [CrossRef]

- Nathaniel, S.; Anyanwu, O.; Shah, M. Renewable energy, urbanization, and ecological footprint in the Middle East and North Africa region. Environ. Sci. Pollut. Res. 2020, 27, 14601–14613. [Google Scholar] [CrossRef]

- Cheraghian, G. Application of nano-particles of clay to improve drilling fluid. Int. J. Nanosci. Nanotechnol. 2017, 13, 177–186. [Google Scholar]

- Movahedi, H.; Jamshidi, S.; Hajipour, M. New insight into the filtration control of drilling fluids using a graphene-based nanocomposite under static and dynamic conditions. ACS Sustain. Chem. Eng. 2021, 9, 12844–12857. [Google Scholar] [CrossRef]

- Aghayan, S.K. Moghadas hosseinzadeh F. The impact of traveling on infectious diseases transmission with a focus on air travel: A Narrative Review. Int. J. Travel. Med. Glob. Health 2025, 13, 33–41. [Google Scholar]

- Ma, J.; Pang, S.; Zhang, Z.; Xia, B.; An, Y. Experimental study on the polymer/graphene oxide composite as a fluid loss agent for water-based drilling fluids. ACS Omega 2021, 6, 9750–9763. [Google Scholar] [CrossRef]

- Medhi, S.; Chowdhury, S.; Gupta, D.K.; Mazumdar, A. An investigation on the effects of silica and copper oxide nanoparticles on rheological and fluid loss property of drilling fluids. J. Pet. Explor. Prod. Technol. 2020, 10, 91–101. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chowdhury, A.; Hossain, M.M.; Hossain, M.K. Applications, drawbacks, and future scope of nanoparticle-based polymer composites. In Nanoparticle-Based Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 243–275. [Google Scholar]

- Davoodi, S.; SA, A.R.; Soleimanian, A.; Jahromi, A.F. Application of a novel acrylamide copolymer containing highly hydrophobic comonomer as filtration control and rheology modifier additive in water-based drilling mud. J. Pet. Sci. Eng. 2019, 180, 747–755. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose nanomaterial reinforced polymer nanocomposites. Curr. Opin. Colloid Interface Sci. 2017, 29, 1–8. [Google Scholar] [CrossRef]

- Elochukwu, H.; Gholami, R.; Dol, S.S. An approach to improve the cuttings carrying capacity of nanosilica based muds. J. Pet. Sci. Eng. 2017, 152, 309–316. [Google Scholar] [CrossRef]

- Kafashi, S.; Rasaei, M.; Karimi, G. Effects of sugarcane and polyanionic cellulose on rheological properties of drilling mud: An experimental approach. Egypt. J. Pet. 2017, 26, 371–374. [Google Scholar] [CrossRef]

- Villada, Y.; Gallardo, F.; Erdmann, E.; Casis, N.; Olivares, L.; Estenoz, D. Functional characterization on colloidal suspensions containing xanthan gum (XGD) and polyanionic cellulose (PAC) used in drilling fluids for a shale formation. Appl. Clay Sci. 2017, 149, 59–66. [Google Scholar] [CrossRef]

- Agwu, O.E.; Okon, A.N.; Akpanika, O.I. Activation of local bentonitic clays for use as viscosifiers in water-based drilling fluids. J. Sci. Res. Rep. 2016, 12, 1–11. [Google Scholar] [CrossRef]

- Chimanowsky, J.P., Jr.; Neto, R.P.C.; Tavares, M.I.B. NMR evaluation of polystyrene nanocomposites degradated by repeated extrusion processing. Polym. Degrad. Stab. 2015, 118, 178–187. [Google Scholar] [CrossRef]

- Alizadeh, S.; Sabbaghi, S.; Soleymani, M. Synthesis of Alumina/Polyacrylamide nanocomposite and its influence on viscosity of drilling fluid. Int. J. Nano Dimens. 2015, 6, 271–276. [Google Scholar]

- Aghdam, S.B.; Moslemizadeh, A.; Kowsari, E.; Asghari, N. Synthesis and performance evaluation of a novel polymeric fluid loss controller in water-based drilling fluids: High-temperature and high-salinity conditions. J. Nat. Gas Sci. Eng. 2020, 83, 103576. [Google Scholar] [CrossRef]

- Lin, Z.; Li, F.; Liu, X.; Su, J. High temperature degradable pullulan microsphere/polymer composite for filtration loss control of water-based drilling fluids. Geoenergy Sci. Eng. 2024, 243, 213362. [Google Scholar] [CrossRef]

- Zhao, D.; Gao, Y.; Wu, Z.; Shabaz, M. Harnessing robotics for environmental economics and energy strategy: Advancing global economic policies towards green growth. Energy Strateg. Rev. 2024, 55, 101504. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Wang, S.; Li, H. Artificial intelligence of robotics and green transformation: Evidence from Chinese manufacturing firms. Environ. Dev. Sustain. 2025, 1–27. [Google Scholar] [CrossRef]

- Elaf, R.; Ali, A.B.; Saad, M.; Hussein, I.A.; Bai, B. Development of eco-friendly chitosan-g-polyacrylamide preformed particle gel for conformance control in high-temperature and high-salinity reservoirs. Geoenergy Sci. Eng. 2023, 230, 212136. [Google Scholar] [CrossRef]

- Sun, J.; Peng, Y.; Liang, Z.; Zhou, Y.; Li, L. AI-Driven Synergies: The Role of Artificial Intelligence in Enhancing Green Product Innovation for Environmental and Organizational Performance in China’s Petrochemical Industry. Open Access Libr. J. 2025, 12, 1–15. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Feng, C. Artificial intelligence, institutional environment, and corporate green transformation: Evidence from China’s resource-based sector. Int. Rev. Econ. Financ. 2025, 103, 104473. [Google Scholar] [CrossRef]

- Gao, J.; Zheng, M.; Yuan, H.; Yang, Y.; Chen, H.; Fan, Y.; Shen, W. Nano-blade structured hematite/magnetite heterojunction with ZnO cocatalyst and plasmon Au adornment for improvement in solar water splitting. J. Alloys Compd. 2025, 1037, 182416. [Google Scholar] [CrossRef]

- Barry, M.M.; Jung, Y.; Lee, J.-K.; Phuoc, T.X.; Chyu, M.K. Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J. Pet. Sci. Eng. 2015, 127, 338–346. [Google Scholar] [CrossRef]

- Mohammed, R.K.; Farzaneh, H. Power-to-X in Southern Iraq: Techno-economic assessment of solar-powered hydrogen electrolysis combined with carbon capture and storage for sustainable energy solutions. Energy Convers. Manag. X 2025, 26, 100918. [Google Scholar] [CrossRef]

- Obobisa, E.S.; Ahakwa, I. Stimulating the adoption of green technology innovation, clean energy resources, green finance, and environmental taxes: The way to achieve net zero CO2 emissions in Europe? Technol. Forecast. Soc. Change 2024, 205, 123489. [Google Scholar] [CrossRef]

- Kanugrahan, S.P.; Hakam, D.F.; Nugraha, H. Techno-Economic Analysis of Indonesia Power Generation Expansion to Achieve Economic Sustainability and Net Zero Carbon 2050. Sustainability 2022, 14, 9038. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, X.H.; Lau, C.K.M.; Cai, Y. The causal relationship between green finance and geopolitical risk: Implications for environmental management. J. Environ. Manag. 2023, 327, 116949. [Google Scholar] [CrossRef] [PubMed]

- Zheng, N.; Zhu, J.; Zhu, H.; Xuan, J.; Xu, H.; Ni, M. Toward a circular carbon economy: Production of green C1 compounds through high-temperature CO2 electrolysis. Nexus 2025, 2, 100053. [Google Scholar] [CrossRef]

- Afrane, S.; Ampah, J.D.; Yusuf, A.A.; Jinjuan, Z.; Yang, P.; Chen, J.L.; Mao, G. Role of negative emission technologies in South Africa’s pathway to net zero emissions by 2050. Energy Sustain. Dev. 2024, 79, 101401. [Google Scholar] [CrossRef]

- Peecock, A.; Hull-Bailey, B.; Hastings, A.; Martinez-Felipe, A.; Wilcox, L.B. Techno-economic assessment of liquid carrier methods for intercontinental shipping of hydrogen: A case study. Int. J. Hydrogen Energy 2024, 94, 971–983. [Google Scholar] [CrossRef]

- Zhang, J.; Raza, S.M.F.; Huang, Y.; Wang, C. What affect energy poverty in China? A path towards sustainable development. Econ. Res. Istraz. 2023, 36, 2111316. [Google Scholar] [CrossRef]

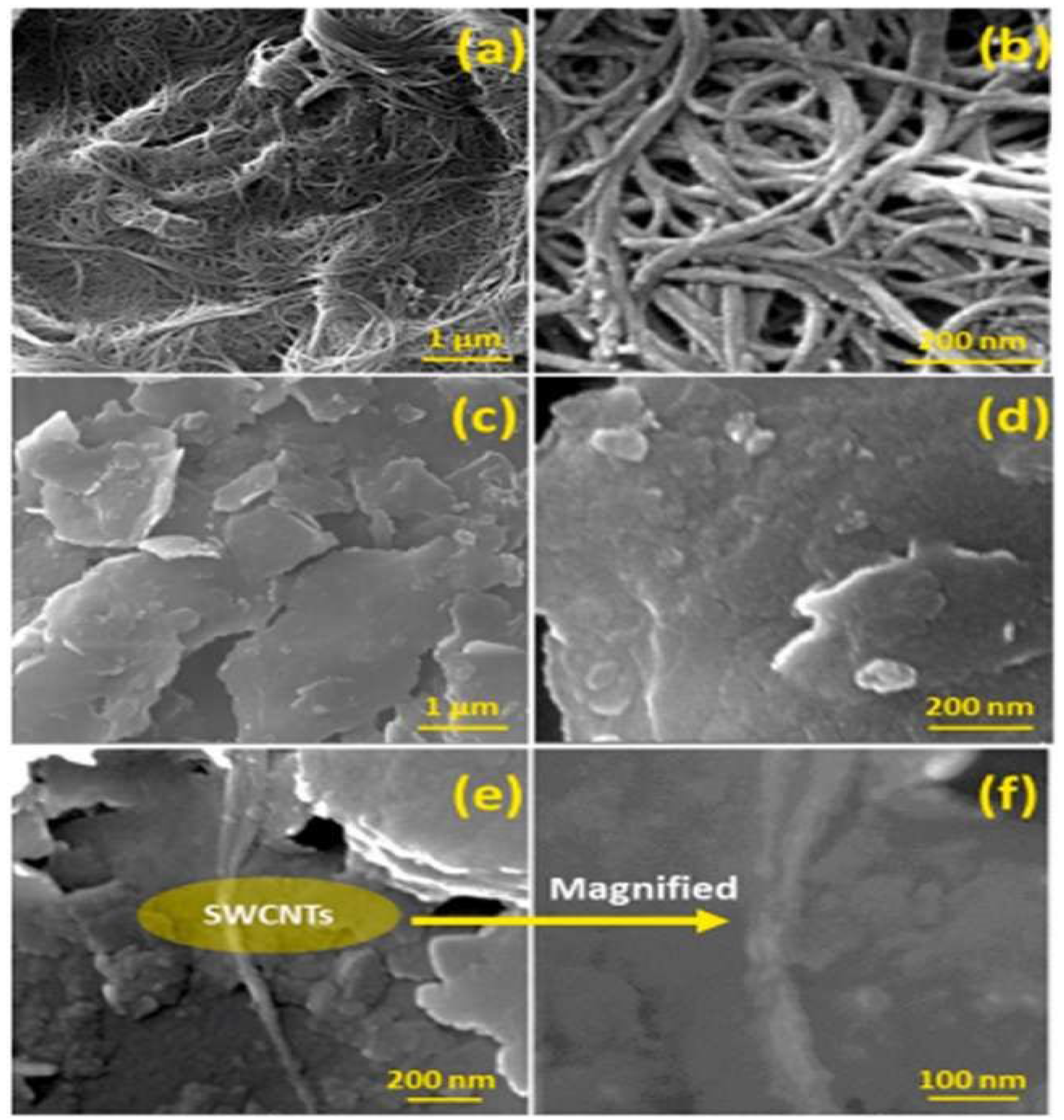

- Ahmad, H.M.; Kamal, M.S.; Al-Harthi, M.A.; Elkatatny, S.M.; Murtaza, M.M. Synthesis and experimental investigation of novel CNT-polymer nanocomposite to enhance borehole stability at high temperature drilling applications. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018; SPE: Richardson, TX, USA, 2018; p. SPE-192352. [Google Scholar]

- Oseh, J.O.; Mohd, N.M.N.A.; Gbadamosi, A.O.; Agi, A.; Blkoor, S.O.; Ismail, I.; Igwilo, K.C.; Igbafe, A.I. Polymer nanocomposites application in drilling fluids: A review. Geoenergy Sci. Eng. 2023, 222, 211416. [Google Scholar] [CrossRef]

- Bayat, A.E.; Moghanloo, P.J.; Piroozian, A.; Rafati, R. Experimental investigation of rheological and filtration properties of water-based drilling fluids in presence of various nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 256–263. [Google Scholar] [CrossRef]

- Rana, A.; Arfaj, M.K.; Saleh, T.A. Graphene grafted with glucopyranose as a shale swelling inhibitor in water-based drilling mud. Appl. Clay Sci. 2020, 199, 105806. [Google Scholar] [CrossRef]

- Blkoor, S.O.; Norddin, M.N.A.M.; Ismail, I.; Oseh, J.O.; Agi, A.; Gbadamosi, A.O.; Okoli, N.O.; Onyejekwe, I.M.; Risal, A.R. Amphipathic anionic surfactant modified hydrophilic polyethylene glycol-nanosilica composite as effective viscosifier and filtration control agent for water-based drilling muds. Arab. J. Chem. 2022, 15, 103741. [Google Scholar] [CrossRef]

- Ikram, R.; Jan, B.M.; Vejpravova, J.; Choudhary, M.I.; Chowdhury, Z.Z. “Recent advances of graphene-derived nanocomposites in water-based drilling fluids. Nanomaterials 2020, 10, 2004. [Google Scholar] [CrossRef]

- Ahmad, H.M.; Iqbal, T.; Al Harthi, M.A.; Kamal, M.S. Synergistic effect of polymer and nanoparticles on shale hydration and swelling performance of drilling fluids. J. Pet. Sci. Eng. 2021, 205, 108763. [Google Scholar] [CrossRef]

| Polymer | Primary Functions in WBDFs | Advantages | Limitations/Challenges |

|---|---|---|---|

| Xanthan Gum (XG) | Viscosifier, suspension aid, improves gel strength | Exceptional rheology control at low shear rates; eco-friendly and biodegradable | Thermal degradation above 150 °C; viscosity loss in high-salinity environments |

| Polyanionic Cellulose (PAC) | Fluid-loss reducer, filtrate-control agent | Maintains stable filter cake; good salt tolerance; improves wellbore stability | Sensitive to Ca2+/Mg2+ contamination; limited performance above 160 °C |

| Carboxymethyl Cellulose (CMC) | Filtrate control and rheology modifier | Biodegradable; forms thin, low-permeability filter cakes | Degrades above 150 °C; reduced efficiency in highly saline systems |

| Partially Hydrolyzed Polyacrylamide (PHPA) | Shale encapsulation, viscosity enhancement | Provides very good cutting suspension and shale inhibition | Decomposes under HPHT; limited solids tolerance |

| Hydrolyzed Polyacrylamide (HPAM) | Rheology enhancer and clay stabilizer | High viscosity at low dosage; improves drilling rate | Mechanically unstable under shear; acrylamide monomer toxicity concerns |

| Polyanionic Starch (PAS) / Modified Starch | Filtrate-loss control and wellbore stabilization | Cost-effective; biodegradable; good salt tolerance | Loses structure above 180 °C without crosslinking or nanofiller support |

| Guar Gum (GG) | Viscosifier and lubricity enhancer | Provides high viscosity at low concentrations; bio-based and renewable | Poor thermal stability (>150 °C); bacterial degradation risk |

| Scleroglucan/Welan Gum | Rheology modifier for HPHT wells | High shear and thermal resistance; stable gel formation | Costly; susceptible to oxidation in long-term storage |

| Chitosan Derivatives | Rheology and fluid-loss modifier | Biodegradable; enhances thixotropy and film-forming capability | Thermal degradation above 160 °C; limited salt tolerance |

| Potassium Polyacrylamide (KPAM) | Shale-inhibiting polymer, viscosity enhancer | Improves wellbore stability; effective in low-solids muds | Overuse increases yield stress and pumping energy |

| Acrylamide-co-AMPS Copolymer | HPHT filtrate-control additive | Good thermal (≥200 °C) and salt resistance; stable in brine | Relatively expensive; requires dispersion control |

| Polysaccharide–Nanocomposite Blends (e.g., XG–SiO2) | Combined rheology and filtrate control | Enhanced thermal stability (>200 °C) and improved shale inhibition | Preparation complexity; dispersion stability must be maintained |

| Method | Polymer Type | Nanoparticle Compatibility | Dispersion Quality | Scalability | Impact on Stability & Shale Inhibition |

|---|---|---|---|---|---|

| Solution Mixing | Water-soluble polymers (PAM, PAC, CMC) | SiO2, TiO2, GO | Good at lab scale; solvent removal may cause agglomeration | Moderate | Ensures high uniformity; improved filtrate control, but limited long-term NP stability |

| Melt Mixing | Thermoplastics and modified gums | SiO2, ZnO, CNTs | Good physical dispersion; thermal shear may cause NP clustering | High | Produces durable, temperature-resistant composites; effective for rheology but moderate shale inhibition |

| In situ Polymerization | Acrylamide, AMPS, or acrylic copolymers | TiO2, ZnO, GO, α-LAP | Higher chemical bonding and NP immobilization | Moderate to high | Best dispersion and stability; strong barrier formation and shale inhibition under HPHT |

| Polymer Used | Nanofiller Used | Tested Rheology Parameters | Test Conditions | Main Findings | Benefits | Reference |

|---|---|---|---|---|---|---|

| ANDP (AM, AMPS, DMDAAC) | SiO2, Metal Oxides | PV, AV, YP, GS | 150–200 °C, 500 psi | At 200 °C, ANDP improved AV, PV, and YP over the base fluid. | High thermal stability and salt resistance prevent clay aggregation. | [54] |

| C-g-AA-NH2 | KCl | PV, AV, YP | 25 °C, 100 psi | 2 wt% AA-C-g-AA-NH2 outperformed 10 wt% KCl in rheology. | Effective KCl replacement at a lower dosage. | [55] |

| SP-GO | GO | PV, AV, YP, GS | 78–250 °F | 0.4 wt% gave best performance; improved PV and YP. | Lubricates and enhances rheology in salty, high-temp conditions. | [56] |

| PEG-SiO2 NC + SDS | SiO2, SDS | PV, AV, YP, GS | 78–250 °F, 500 psi | At 1.5 g, boosted PV by 75%, YP by 100%, and AV by 81.8%. | SDS enhances dispersion and thermal stability. | [57] |

| PEG–SiO2 | SiO2 | PV, AV, YP, GS | 78–250 °F, 500 psi | Slight decrease in AV/PV vs. base fluid, but good thermal performance. | Stable rheology at high temperature and pressure; compatible with mud systems. | [58] |

| PAAG NC | SiO2 | PV, AV, YP | 25–180 °C, 500 psi | 1.0 wt% improved rheology by 46–80%. | Good salt resistance and thermal stability up to 240 °C. | [59] |

| Hydrophobic polymer NC | Bentonite | PV, YP, GS | 25 °C, 100 psi | PNCs improved viscosity and structure due to the interaction with bentonite. | Promotes uniform dispersion and consistent fluid behavior. | [60] |

| PP-SiO2 vs. PHPA | SiO2 | AV, PV, YP, GS | 25–150 °C, 500 psi | PNCs exhibited greater YP and thermal performance compared to PHPA. | Sustains properties under heat without degradation. | [61] |

| PVP/SWCNTS | CNTs | AV, PV, YP, GS | 25 °C, 100 psi | Small drops in AV and PV; shear-thinning behavior. | Good mud stability with little performance change. | [62] |

| CuO/PAM NC | ZnO | AV, PV, YP, GS | 25 °C, 100 psi | Big rheology improvements in fresh and salt water. | Stable and effective across fluid types. | [63] |

| XG–SiO2 | SiO2 | AV, PV, YP, GS | 25–120 °C, 500 psi | Outperformed XG and other base muds. | Strong rheological performance even at HPHT. | [64] |

| PP-SiO2–NH2 | SiO2 | AV, PV, YP, GS | 25 °C, 100 psi | Improved PV from 11 to 15 mPa·s and YP from 9 to 14 Pa. | Good thermal resistance and rheology stability. | [65] |

| PSt MMA nano clay | Clay (Laponite) | AV, PV, YP, GS | 25 °C, 100 psi | AV/PV increased by 44–51%. | Stable up to 120 °C; enhances mud rheology. | [66] |

| Nano-LS-g-PAM-AMPS | SiO2 | AV, PV, YP, GS | 200 °C, 600 psi | Strong AV/PV/YP increase with thermal/salt resistance. | Durable at high temperatures and salinity. | [67] |

| Laponite NC polymer | Laponite | AV, PV, YP, GS | Up to 260 °C | Maintains viscosity after 72 h of aging. | Extreme thermal stability. | [68] |

| Laponite copolymer | Laponite | AV, PV, YP | 210 °C, 500 psi | Stable AV (19 cP), PV (15 cP), YP (8 lbf). | High-temp stability. | [69] |

| PEG–NS | SiO2 | PV, YP, GS | 78 °F | PV improved by 14% and YP by 50%. | Stable up to 200 °C. | [70] |

| SMA/SiO2 | SiO2 | PV, YP, GS | 78 °F | Minor rheology change; filtration control improved. | Reasonable fluid loss control. | [71] |

| CNT/ZnO/polymers | CNTs, ZnO | AV, PV, YP, GS | Up to 400 °F | Rheology remained stable post-aging. | High-temp durability. | [72] |

| Core–shell NC | SiO2 | PV, AV, GS | 120 °C, 100 psi | Rheology close to commercial CMC. | Reasonable control and competitiveness. | [73] |

| MES/Polystyrene NC | Polystyrene | PV, AV, GS | 150 °C, 500 psi | Exhibits shear thinning and uniform velocity. | Stable thermal and flow behavior. | [74] |

| TiN NPs in KCl | Titanium Nitride (TiN) | Cof, AV, PV, YP, GS | 25 °C | YP improved by 122%, PV by 17%. | Good cutting, transport, and hole cleaning. | [75] |

| Hydrophobic PEG–SiO2 | SiO2 | PV, YP, GS | 250 °F | AV/YP/PV all increased. | Improved NPs integration and fluid loss control. | [76] |

| PAM–PEG–SiO2 | SiO2 | PV, YP, GS | 95 °C, 500 psi | AV and YP improved greatly. | Enhances stability up to 95 °C. | [77] |

| PAM–ZnO NC | ZnO | AV, PV, YP, GS | 80–150 °F | 18–17% increases in PV and YP. | Works well even at low dosages. | [78] |

| EDA–G graphene NC | Gr | PV, AV, YP, GS | 150 °C, 500 psi | Good rheology; salt- and calcium-resistant. | Effective in extreme salinity. | [79] |

| SFDL core–shell NC | SiO2 | PV, AV, YP, GS, Cof | Up to 446 °F | Massive gains in AV, PV, and YP; Cof dropped significantly. | Prevents polymer breakdown at very high temperatures. | [80] |

| TiO2–PAM NC | Titanium Dioxide TiO2 | PV, AV, YP, GS | 25 °C | 273% PV increase with 14 g PNCs. | Good cross-linking and high stability. | [81] |

| PAM/Al2O3 NC | Alumina (Al2O3) | PV, YP, AV, GS | 150 °C, 500 psi | PV exceeded 300 cp at a 4 wt% concentration. | Long-term mud stability and compatibility. | [82] |

| ZnO–Clay NC | ZnO, Clay | PV, YP, AV, GS | 110–370 °F, up to 18,500 psi | PV and YP were greatly enhanced at 370 °F. | Good under extreme HPHT. | [83] |

| Material Used (PNCs) | Polymer Used | Nanofillers Used | Key Findings | Shale Inhibition Mechanism | Reference |

|---|---|---|---|---|---|

| PNSC + NH2 | PNSC | Nanohydroxide (NH2) | The percentage of shale retained after the hydration test was 75.3% with PNSC + NH2, compared to 33.6% with base mud and 58.4% with KCl. | Uses physical plugging and hydrogen bonding to reduce water contact between the shale and the fluid. | [87] |

| PEG-NS | Polyethylene glycol (PEG) | SiO2 | PEG-NS exhibited larger plugging capacity and retarded shale hydration, with slower pressure growth than JHC. | Physical plugging and disruption of hydrogen bonds to reduce shale hydration and water absorption. | [88] |

| AR/SiO2 NC | Acrylic Resin (AR) | SiO2 | Reduced API FL by 53.6% and API FCT by 23.1%, proving effective in inhibiting shale hydration. | Forms substantial physical barriers by sealing microcracks and nanopores in shale through AR/SiO2’s core–shell structure. | [89] |

| Materials Used | Test Conditions | Main Results | Reference |

|---|---|---|---|

| Used a polymer mix (AM, AMPS, DMDAAC) with nano-laponite | Tested in both freshwater and saltwater mud at 150–200 °C | 2% PNCs reduced fluid loss in saltwater mud from 280 mL to 72 mL after heating for 16 h. | [92] |

| Combined salt-based polymer with GO | Concentrations of 0.1–0.5% at 78 and 250 °F | The blend improved fluid filtration performance at both temperatures. | [93] |

| Mixed polypropylene beads with silica | Used 8 g PP and 1 g silica at 78 and 250 °F | Reduced fluid loss by 24% and slightly decreased filter cake thickness. | [94] |

| Created a nanocomposite using AM, AMPS, NVP, and GO | Evaluated at 25, 150, and 180 °C | 1% dosage maintained strong filtration control even with high salt content (up to 25%). | [23] |

| Blended PVP with CNTs | Tested 1% and 5% at 25 °C | Achieved 18–23% reduction in fluid loss. | [95] |

| Used polypropylene and PHPA with modified silica | Tested at 25 and 120 °C | Improved high-temperature stability and reduced fluid loss by about 18%. | [51] |

| Combined PAM-AMPS with nano-lignite | LPLT: 78 °F/HPHT: 356 °F | Aging produced good fluid loss results (7.1 mL LPLT, 30 mL HPHT) | [96] |

| Used PSt MMA and nano-clay | Tested at 78 and 250 °F | Reduced fluid loss by up to 65% under high-temperature conditions. | [97] |

| Developed a copolymer with laponite | HPHT at 356 °F and 500 psi | Halved the fluid loss from 34 mL to 16 mL. | [8] |

| Combined PAM with copper oxide | Used 1–10 g doses at 25 and 120 °C | Lowered fluid loss and produced a thinner filter cake. | [98] |

| Created a nanocomposite with PEG and nano-silica | 1% tested at 78°f | Cut fluid loss by over 15%. | [34] |

| Mixed methyl ester sulfonate with nano-polystyrene | Tested at both low (78 °F) and high (250 °F) temperatures | Reduced fluid loss by 22% at LPLT and 61% at HPHT due to a synergistic effect. | [34] |

| Blended SMA with silica | 2% tested at 78 °F | Reduced API fluid loss by 22%. | [99] |

| Combined CNT, ZnO, and synthetic polymers | Tested up to 400 °F | Maintained stable mud and created thin, less permeable filter cakes. | [100] |

| Used carboxymethyl cellulose with polystyrene | LPLT test at 25 °C | It resulted in the lowest fluid loss volume in this category. | [101] |

| Combined PEG and silica | Tested at 78 and 250 °F | 2% dosage performed well even after thermal aging. | [102] |

| Used PAM with ZnO | Tested at 78 °F and 150 °F | Reduced fluid loss by 12.7% (LPLT) and 23% (HPHT). | [21] |

| Created PAM-silica nanocomposite | 0.1–1.0% tested at up to 203 °F | 0.7% dosage provided stable and effective filtration. | [103] |

| Used AM, AMPS, MA, and St with silica | Tested from 78 °F to 446 °F | Withstood extreme conditions and effectively controlled fluid loss. | [104] |

| Blended PAM with titanium dioxide | Doses from 1–14 g at 25 °C | Reduced fluid loss from 53 mL to 19 mL at the highest dose. | [105] |

| Material Used (PNCs) | Polymer Used | Nanofillers Used | Key Findings | Shale Inhibition Mechanism | Reference |

|---|---|---|---|---|---|

| PAM-SiO2 NC | PAM | SiO2 | Achieved the highest shale stability (86.6%) over 48 h, outperforming commercial inhibitors (74.7%) and KCl (49.2%). | Disrupts hydrogen bonds in water through PAM-SiO2 NC’s OH groups and physically blocks microcracks and nanopores in shale. | [109] |

| C-g-AA-NH2 | Acrylic acid (AA) | Aminomethyl, Amyl | Achieved a high anti-swelling ratio of 95.2% with AA-AAm-C-Amyl, surpassing KCl (55.4%). | Combines carbon core nanopore plugging and strong polymer adsorption to inhibit swelling. | [110] |

| AP-ZnO NC | Acrylic Polymer (AP) | ZnO | Shale recovery improved to 97% with AP-ZnO NC compared to 81% with BF; the swelling rate reduced from 14.29% to 6.69%. | ZnO reduces mud invasion by plugging pores and cracks, while AP encapsulates the shale surface, preventing water interaction. | [111] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wakeel, S.; Aslam, A.; Zhang, J. Advances in Polymer Nanocomposites for Drilling Fluids: A Review. Materials 2025, 18, 4809. https://doi.org/10.3390/ma18204809

Wakeel S, Aslam A, Zhang J. Advances in Polymer Nanocomposites for Drilling Fluids: A Review. Materials. 2025; 18(20):4809. https://doi.org/10.3390/ma18204809

Chicago/Turabian StyleWakeel, Shahbaz, Ammara Aslam, and Jianhua Zhang. 2025. "Advances in Polymer Nanocomposites for Drilling Fluids: A Review" Materials 18, no. 20: 4809. https://doi.org/10.3390/ma18204809

APA StyleWakeel, S., Aslam, A., & Zhang, J. (2025). Advances in Polymer Nanocomposites for Drilling Fluids: A Review. Materials, 18(20), 4809. https://doi.org/10.3390/ma18204809