Tribology of MXene Materials: Advances, Challenges, and Future Directions

Abstract

1. Introduction

1.1. Overview of MXenes

1.2. Scope and Objectives of the Review

1.3. Tunability of MXenes for Lubricant Additive Applications

2. Structure and Properties of MXenes

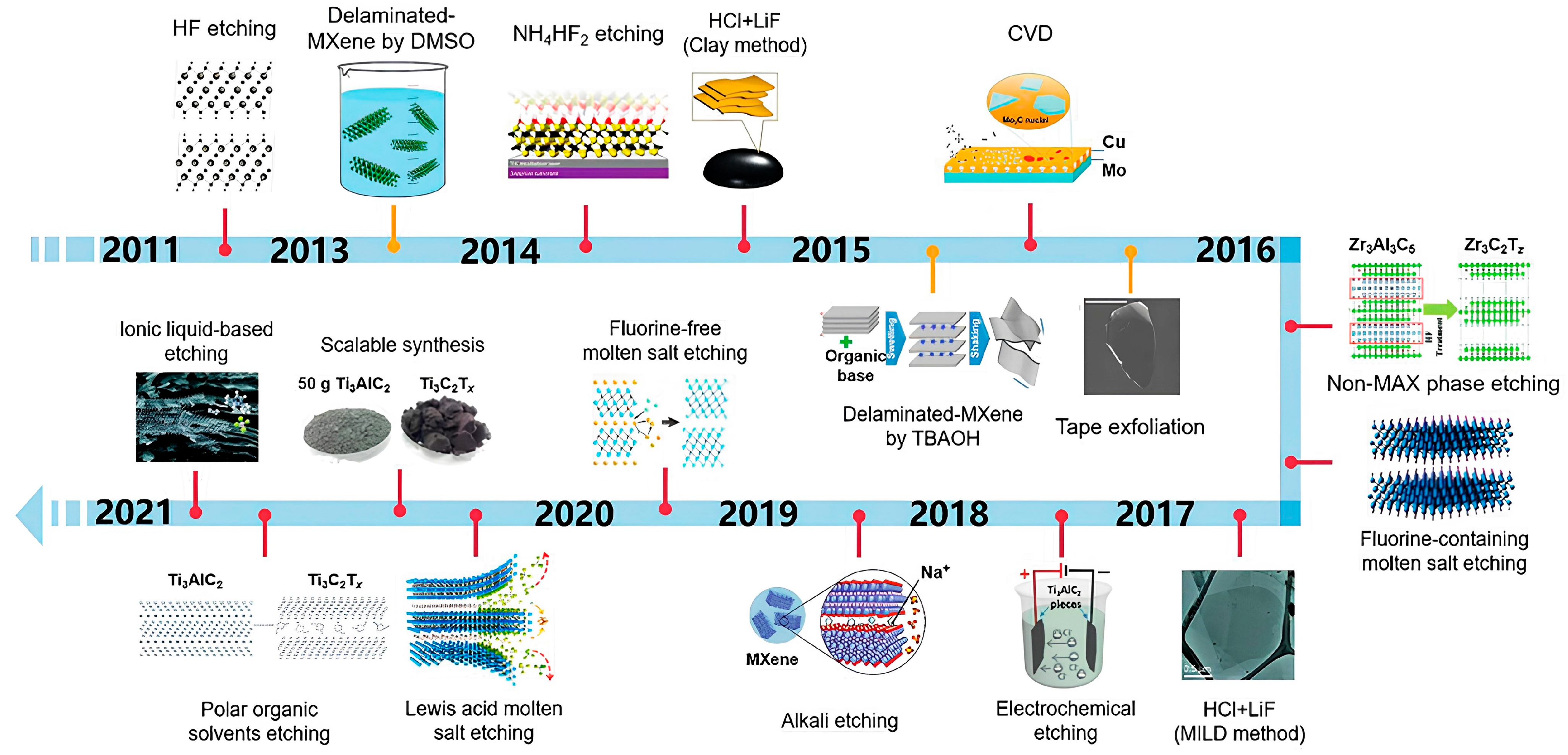

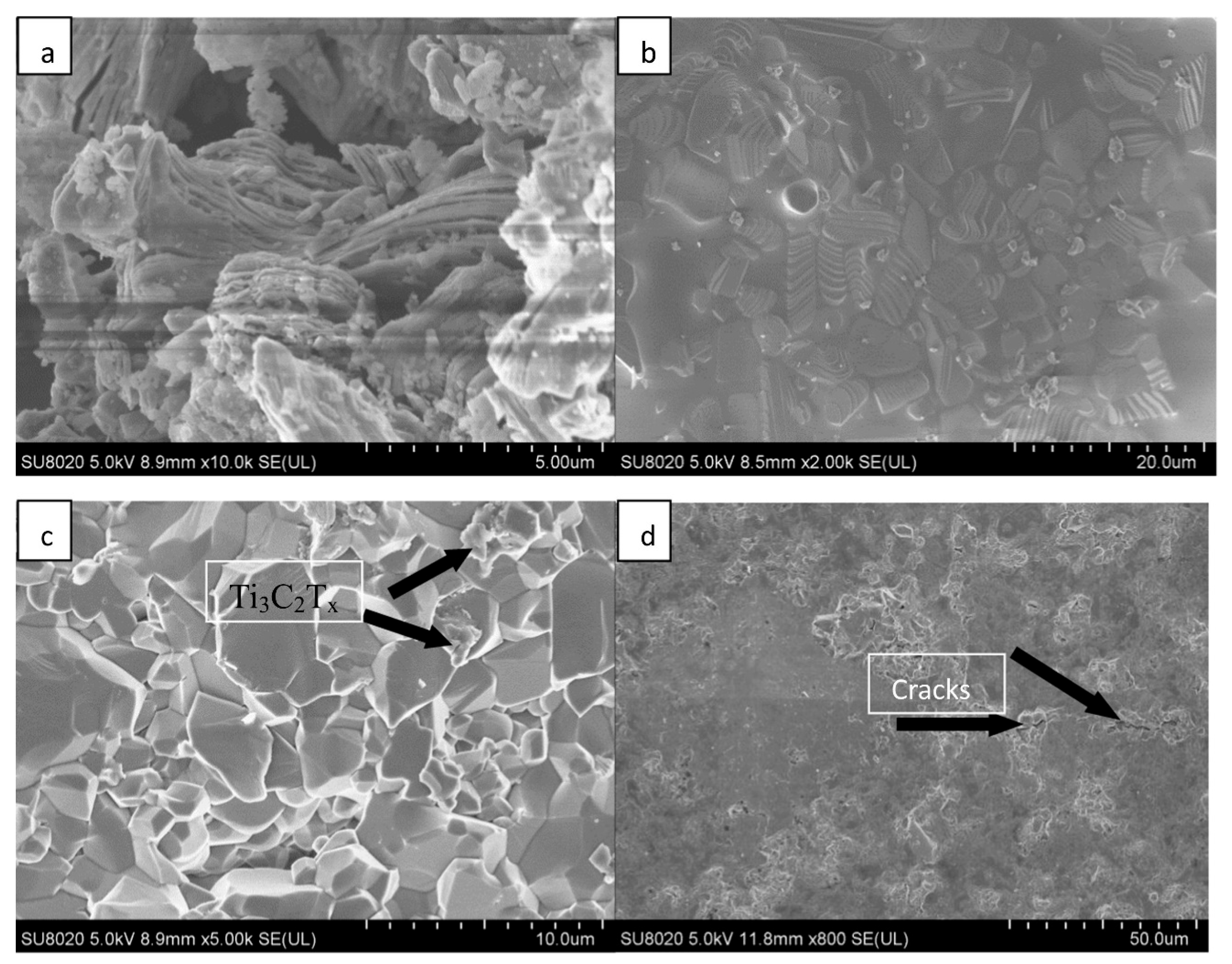

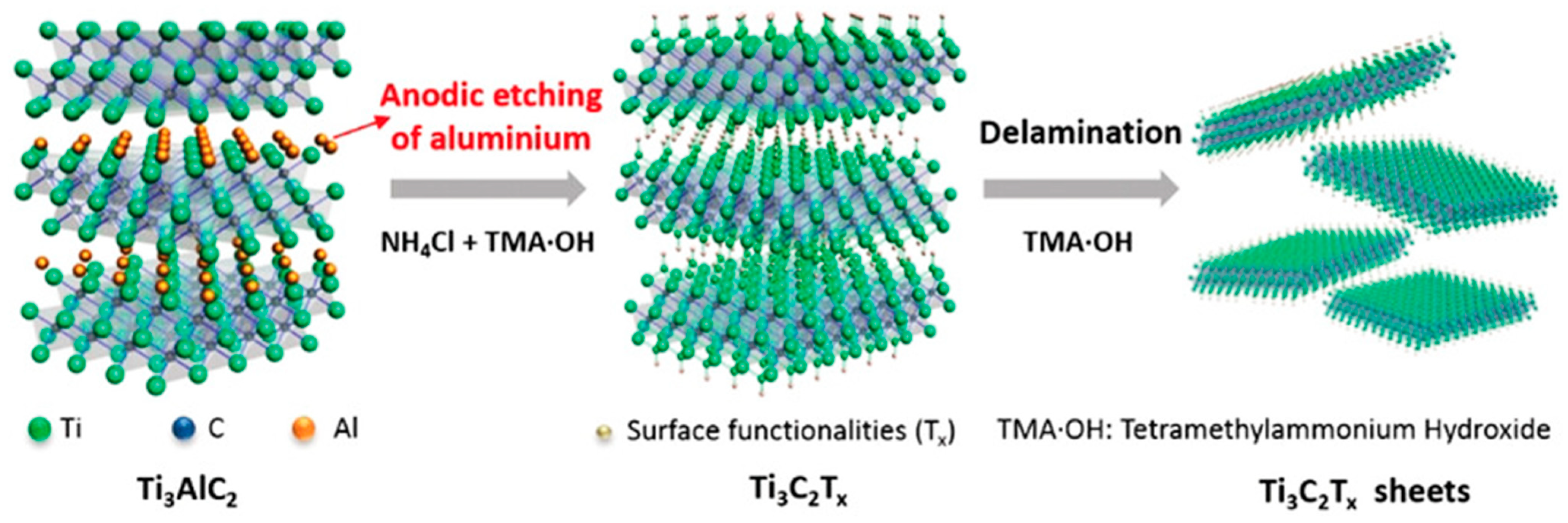

2.1. Synthesis and Chemical Composition

2.2. Mechanical, Thermal, and Electrical Properties

3. Tribological Performance of MXenes

3.1. MXenes as Solid Lubricants

3.2. Friction and Wear Behavior in Various Environments

3.3. Role of Surface Terminations on Tribological Properties

4. Applications of MXenes in Tribology

4.1. Lubrication in Micro and Nano-Scale Systems

4.2. Additives for Lubricants and Greases

4.3. Tribological Coatings and Thin Films

5. Expanding the Role of MXene-Based Composites

5.1. Polymer-MXene Composites

5.2. Metal Matrix MXene Composites

5.3. Synergistic Effects with Other 2D Materials

6. Experimental Techniques in Tribological Studies of MXenes

6.1. Measurement of Friction and Wear

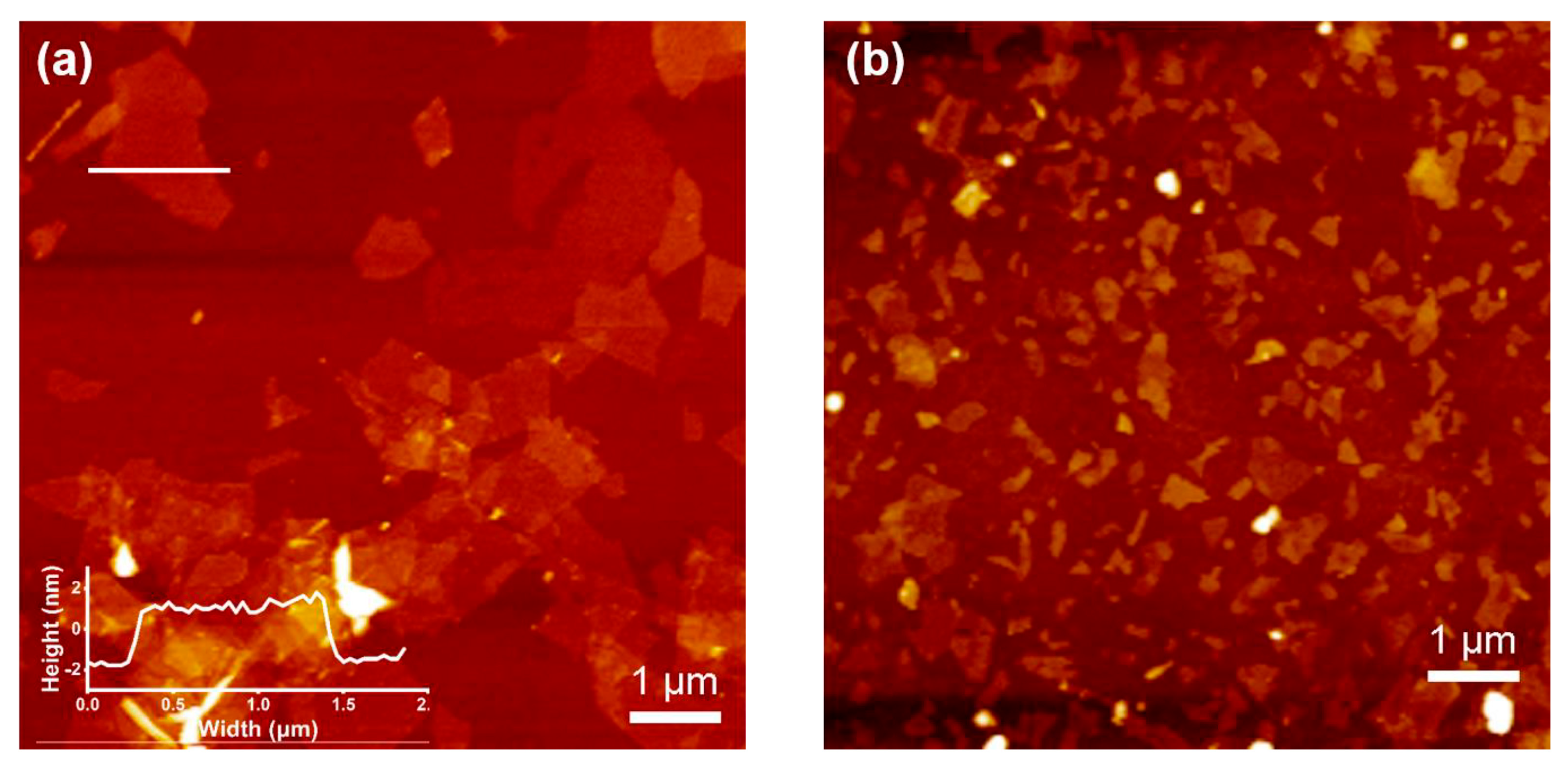

6.2. Surface Characterization Techniques

6.3. High-Temperature and Harsh Environment Performance

7. Computational Studies and Modeling in MXene Tribology

7.1. Density Functional Theory (DFT) Studies on MXene Interactions

7.2. Modeling of Tribological Behavior at Macro and Nano Scales

8. Challenges and Limitations in MXene Tribology

8.1. Stability and Scalability of MXene Materials

8.2. Hydrolysis and Oxidation: Mechanisms of MXene Degradation

8.3. Challenges in Large-Scale Applications

9. Future Directions and Opportunities

9.1. Innovations in MXene Functionalization for Improved Tribology

9.2. MXenes for Green and Sustainable Tribological Applications

9.3. Emerging Applications in Space and Extreme Conditions

10. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Antony Jose, S.; Ralls, A.M.; Kasar, A.K.; Antonitsch, A.; Neri, D.C.; Image, J.; Meyer, K.; Zhang, G.; Menezes, P.L. MXenes: Manufacturing, Properties, and Tribological Insights. Materials 2025, 18, 3927. [Google Scholar] [CrossRef]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten Years of Progress in the Synthesis and Development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Park, J.; Kim, M.; Lee, S.; Heo, J.M.; Jin, Y.H.; Chae, Y.; Han, J.; Wang, J.; Seok, S.; et al. Ultrahigh Conductive MXene Films for Broadband Electromagnetic Interference Shielding. Adv. Mater. 2025, 37, 2502443. [Google Scholar] [CrossRef]

- Rong, C.; Su, T.; Li, Z.; Chu, T.; Zhu, M.; Yan, Y.; Zhang, B.; Xuan, F.-Z. Elastic Properties and Tensile Strength of 2D Ti3C2Tx MXene Monolayers. Nat. Commun. 2024, 15, 1566. [Google Scholar] [CrossRef]

- Anasori, B.; Gogotsi, Y. (Eds.) 2D Metal Carbides and Nitrides (MXenes): Structure, Properties and Applications; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-19025-5. [Google Scholar]

- Huang, Y.; Spiece, J.; Parker, T.; Lee, A.; Gogotsi, Y.; Gehring, P. Violation of the Wiedemann–Franz Law and Ultralow Thermal Conductivity of Ti3C2Tx MXene. ACS Nano 2024, 18, 32491–32497. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of Tribology on Global Energy Consumption, Costs and Emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications to Tribology: Bhushan/Introduction; John Wiley & Sons, Ltd.: West Sussex, UK, 2013; ISBN 978-1-118-40302-0. [Google Scholar]

- Sose, A.T.; Joshi, S.Y.; Kunche, L.K.; Wang, F.; Deshmukh, S.A. A Review of Recent Advances and Applications of Machine Learning in Tribology. Phys. Chem. Chem. Phys. 2023, 25, 4408–4443. [Google Scholar] [CrossRef] [PubMed]

- Takadoum, J.; Takadoum, J. Materials and Surface Engineering in Tribology; ISTE: London, UK; Wiley: Hoboken, NJ, USA, 2008; ISBN 978-1-84821-067-7. [Google Scholar]

- Ralls, A.M.; Kumar, P.; Menezes, P.L. Tribological Properties of Additive Manufactured Materials for Energy Applications: A Review. Processes 2020, 9, 31. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Righi, M.C.; Sumant, A.V.; Anasori, B.; Mochalin, V.N. Perspectives of 2D MXene Tribology. Adv. Mater. 2023, 35, 2207757. [Google Scholar] [CrossRef] [PubMed]

- Parra-Muñoz, N.; Soler, M.; Rosenkranz, A. Covalent Functionalization of MXenes for Tribological Purposes—A Critical Review. Adv. Colloid Interface Sci. 2022, 309, 102792. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Chung, K.-H. Assessment of Tribological Properties of Ti3C2 as a Water-Based Lubricant Additive. Materials 2020, 13, 5545. [Google Scholar] [CrossRef]

- Marquis, E.; Cutini, M.; Anasori, B.; Rosenkranz, A.; Righi, M.C. Nanoscale MXene Interlayer and Substrate Adhesion for Lubrication: A Density Functional Theory Study. ACS Appl. Nano Mater. 2022, 5, 10516–10527. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Shekhirev, M.; Anayee, M.; Gogotsi, Y. Multi-Year Study of Environmental Stability of Ti3C2Tx MXene Films. Graphene 2D Mater. 2024, 9, 77–85. [Google Scholar] [CrossRef]

- Gao, J.; Du, C.-F.; Zhang, T.; Zhang, X.; Ye, Q.; Liu, S.; Liu, W. Dialkyl Dithiophosphate-Functionalized Ti3C2Tx MXene Nanosheets as Effective Lubricant Additives for Antiwear and Friction Reduction. ACS Appl. Nano Mater. 2021, 4, 11080–11087. [Google Scholar] [CrossRef]

- Guo, J.; Zeng, C.; Wu, P.; Liu, G.; Zhou, F.; Liu, W. Surface-Functionalized Ti3C2Tx MXene as a Kind of Efficient Lubricating Additive for Supramolecular Gel. ACS Appl. Mater. Interfaces 2022, 14, 52566–52573. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Li, Z.; Liu, S.; Wang, J.; Yang, S. MXenes in Tribology: Current Status and Perspectives. Adv. Powder Mater. 2023, 2, 100092. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the Synthesis of 2D MXenes. Adv. Mater. 2021, 33, 2103148. [Google Scholar] [CrossRef]

- Yu, L.; Xu, L.; Lu, L.; Alhalili, Z.; Zhou, X. Thermal Properties of MXenes and Relevant Applications. ChemPhysChem 2022, 23, e202200203. [Google Scholar] [CrossRef]

- Ibragimova, R.; Erhart, P.; Rinke, P.; Komsa, H.-P. Surface Functionalization of 2D MXenes: Trends in Distribution, Composition, and Electronic Properties. J. Phys. Chem. Lett. 2021, 12, 2377–2384. [Google Scholar] [CrossRef]

- Perera, A.A.P.R.; Madhushani, K.A.U.; Punchihewa, B.T.; Kumar, A.; Gupta, R.K. MXene-Based Nanomaterials for Multifunctional Applications. Materials 2023, 16, 1138. [Google Scholar] [CrossRef] [PubMed]

- Salim, O.; Mahmoud, K.A.; Pant, K.K.; Joshi, R.K. Introduction to MXenes: Synthesis and Characteristics. Mater. Today Chem. 2019, 14, 100191. [Google Scholar] [CrossRef]

- Li, X.; Sun, M.; Shan, C.; Chen, Q.; Wei, X. Mechanical Properties of 2D Materials Studied by In Situ Microscopy Techniques. Adv. Mater. Interfaces 2018, 5, 1701246. [Google Scholar] [CrossRef]

- Falin, A.; Holwill, M.; Lv, H.; Gan, W.; Cheng, J.; Zhang, R.; Qian, D.; Barnett, M.R.; Santos, E.J.G.; Novoselov, K.S.; et al. Mechanical Properties of Atomically Thin Tungsten Dichalcogenides: WS2, WSe2, and WTe2. ACS Nano 2021, 15, 2600–2610. [Google Scholar] [CrossRef]

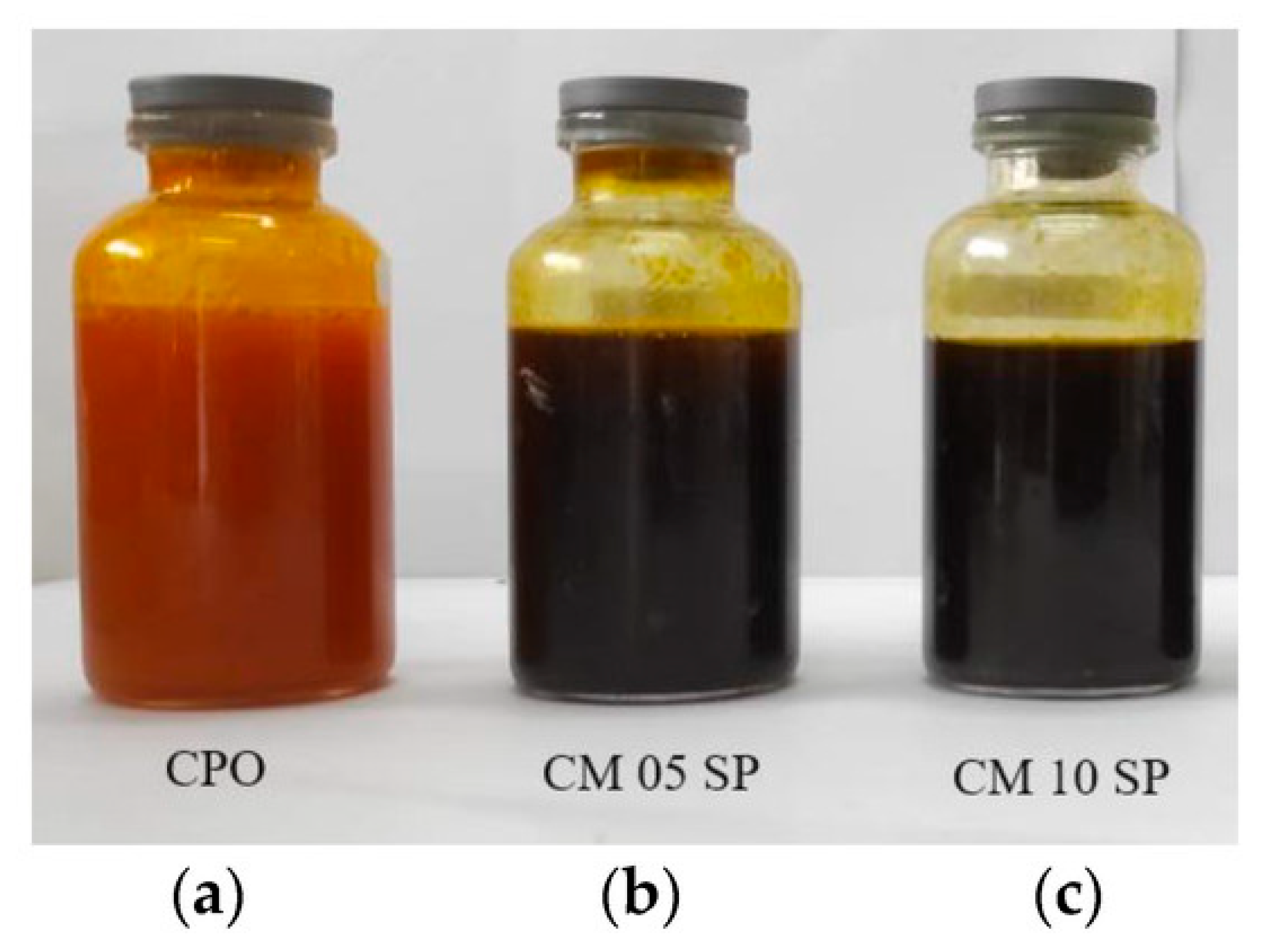

- Samylingam, L.; Aslfattahi, N.; Saidur, R.; Yahya, S.M.; Afzal, A.; Arifutzzaman, A.; Tan, K.H.; Kadirgama, K. Thermal and Energy Performance Improvement of Hybrid PV/T System by Using Olein Palm Oil with MXene as a New Class of Heat Transfer Fluid. Sol. Energy Mater. Sol. Cells 2020, 218, 110754. [Google Scholar] [CrossRef]

- Marian, M.; Tremmel, S.; Wartzack, S.; Song, G.; Wang, B.; Yu, J.; Rosenkranz, A. Mxene Nanosheets as an Emerging Solid Lubricant for Machine Elements—Towards Increased Energy Efficiency and Service Life. Appl. Surf. Sci. 2020, 523, 146503. [Google Scholar] [CrossRef]

- Aigner, B.; Boidi, G.; Rosenkranz, A.; Grützmacher, P.G.; Varga, M.; Gachot, C. MXene and MXene/MoS2 Solid Lubricant Coatings in Journal Bearings. ACS Appl. Nano Mater. 2025, 8, 4608–4616. [Google Scholar] [CrossRef]

- Kozak, A.; Hofbauerová, M.; Halahovets, Y.; Pribusová-Slušná, L.; Precner, M.; Mičušík, M.; Orovčík, L.; Hulman, M.; Stepura, A.; Omastová, M.; et al. Nanofriction Properties of Mono- and Double-Layer Ti3C2Tx MXenes. ACS Appl. Mater. Interfaces 2022, 14, 36815–36824. [Google Scholar] [CrossRef]

- Fan, B.; Zhao, X.; Zhang, P.; Wei, Y.; Qiao, N.; Yang, B.; Soomro, R.A.; Zhang, R.; Xu, B. Effect of Sodium Dodecyl Sulfate on Stability of MXene Aqueous Dispersion. Adv. Sci. 2023, 10, 2300273. [Google Scholar] [CrossRef]

- Tan, J.; Fan, B.; Zhang, P.; Wei, Y.; Soomro, R.A.; Zhao, X.; Kumar, J.; Qiao, N.; Xu, B. Ultralong Stability of Ti3 C2 Tx-MXene Dispersion Through Synergistic Regulation of Storage Environment and Defect Capping with Tris-HCl Buffering. Small Methods 2024, 8, 2301689. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, K.; Xu, Q.; Zhang, J.; Hu, Y.; Ma, T.; Zheng, Q.; Luo, J. Superlubricity between Graphite Layers in Ultrahigh Vacuum. ACS Appl. Mater. Interfaces 2020, 12, 43167–43172. [Google Scholar] [CrossRef] [PubMed]

- Jelenc, J.; Remskar, M. Friction on a Single MoS2 Nanotube. Nanoscale Res. Lett. 2012, 7, 208. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Wei, X.; Huang, Y.; Wang, F.; Yan, P. High-Temperature Friction and Wear Properties of NiCr/hBN Self-Lubricating Composites. Metals 2019, 9, 356. [Google Scholar] [CrossRef]

- Dolz, D.; Morales-García, Á.; Viñes, F.; Illas, F. Exfoliation Energy as a Descriptor of MXenes Synthesizability and Surface Chemical Activity. Nanomaterials 2021, 11, 127. [Google Scholar] [CrossRef]

- Boidi, G.; Zambrano, D.; Ripoll, M.R.; Rosenkranz, A. Humidity-Dependent Tribological Performance of Ti3C2Tx/MoS2 Nanosheet-Based Hybrid Coatings. ACS Appl. Nano Mater. 2024, 7, 24947–24957. [Google Scholar] [CrossRef]

- Liu, N.; Li, Q.; Wan, H.; Chang, L.; Wang, H.; Fang, J.; Ding, T.; Wen, Q.; Zhou, L.; Xiao, X. High-Temperature Stability in Air of Ti3C2Tx MXene-Based Composite with Extracted Bentonite. Nat. Commun. 2022, 13, 5551. [Google Scholar] [CrossRef]

- Boidi, G.; Zambrano, D.F.; Jogl, C.; Rodríguez Ripoll, M.; Varga, M.; Rosenkranz, A. Vacuum Tribology of Multi-Layer Ti3C2Tx and Ti3C2T/MoS2 Hybrid Coatings. Appl. Mater. Today 2024, 38, 102180. [Google Scholar] [CrossRef]

- Arole, K.; Tajedini, M.; Sarmah, A.; Athavale, S.; Green, M.J.; Liang, H. Effects of Ti3C2Tz MXene Nanoparticle Additive on Fluidic Properties and Tribological Performance. J. Mol. Liq. 2023, 386, 122435. [Google Scholar] [CrossRef]

- Sun, W.; Song, Q.; Liu, K.; Zhang, Q.; Tao, Z.; Ye, J. Comparative Study on Boundary Lubrication of Ti3C2Tx MXene and Graphene Oxide in Water. Friction 2023, 11, 1641–1659. [Google Scholar] [CrossRef]

- Yang, Q.; Eder, S.J.; Martini, A.; Grützmacher, P.G. Effect of Surface Termination on the Balance between Friction and Failure of Ti3C2Tx MXenes. npj Mater. Degrad. 2023, 7, 6. [Google Scholar] [CrossRef]

- Björk, J.; Rosen, J. Functionalizing MXenes by Tailoring Surface Terminations in Different Chemical Environments. Chem. Mater. 2021, 33, 9108–9118. [Google Scholar] [CrossRef]

- Chircov, C.; Grumezescu, A.M. Microelectromechanical Systems (MEMS) for Biomedical Applications. Micromachines 2022, 13, 164. [Google Scholar] [CrossRef]

- Rasheed, T.; Sorour, A.A. Unveiling the Power of MXenes: Solid Lubrication Perspectives and Future Directions. Adv. Colloid Interface Sci. 2024, 329, 103186. [Google Scholar] [CrossRef]

- Ramezanpour, J.; Ramezanzadeh, B.; Mohammadloo, H.E. Tribological Applications of MXenes as Surface-Active Advanced Materials. In MXenes as Surface-Active Advanced Materials; Elsevier: Amsterdam, The Netherlands, 2024; pp. 209–230. ISBN 978-0-443-13589-7. [Google Scholar]

- Zhang, K.; Tang, H.; Shi, X.; Xue, Y.; Huang, Q. Effect of Ti3C2 MXenes Additive on the Tribological Properties of Lithium Grease at Different Temperatures. Wear 2023, 526, 204953. [Google Scholar] [CrossRef]

- Ma, W.; Li, T.; Li, W.; Tang, H.; Zhang, L.; Yu, Y.; Qiao, Z. Ti3C2Tx MXenes—An Effective and Long-Storable Oil Lubricant Additive. Tribol. Int. 2023, 180, 108273. [Google Scholar] [CrossRef]

- Zaharin, H.A.; Ghazali, M.J.; Khalid, M.; Nagarajan, T.; Pin, W.W.; Ezzah, F.; Gerard, O.; Walvekar, R.; Rasheed, A.K. Tribological, Oxidation and Thermal Analysis of Advanced Microwave–Hydrothermal Synthesised Ti3C2Tx MXene as Additives in Outboard Engine Oil. Lubricants 2023, 11, 264. [Google Scholar] [CrossRef]

- Gasni, D.; Rahmadiawan, D.; Irwansyah, R.; Khalid, A.E. Composite of Carboxymethyl Cellulose/MXene and Span 60 as Additives to Enhance Tribological Properties of Bio-Lubricants. Lubricants 2024, 12, 78. [Google Scholar] [CrossRef]

- Chen, H.; Zheng, Z.; Yu, H.; Qiao, D.; Feng, D.; Song, Z.; Zhang, J. Preparation and Tribological Properties of MXene-Based Composite Films. Ind. Eng. Chem. Res. 2021, 60, 11128–11140. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Liang, F.; Zhang, H.; Wang, B.; Li, X.; Lin, Z.; Lin, Y.; Chen, X. Tailoring Tribological Characteristics in Titanium Alloys by Laser Surface Texturing and 2D Ti3C2Tx MXene Nanocoating. Adv. Funct. Mater. 2024, 34, 2401231. [Google Scholar] [CrossRef]

- Chhattal, M.; Rosenkranz, A.; Kaihuan, Y.; Grützmacher, P.G.; Gong, Z.; Zhang, J. Comparative Analysis of the Solid Lubrication Performance—Ti3AlC2 versus Ti3C2T Coatings. Ceram. Int. 2024, 50, 26391–26401. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Ayyagari, A.; Shevchenko, E.; Berman, D. MXene/Graphene Oxide Nanocomposites for Friction and Wear Reduction of Rough Steel Surfaces. Sci. Rep. 2023, 13, 11057. [Google Scholar] [CrossRef] [PubMed]

- Echols, I.J.; Yun, J.; Cao, H.; Thakur, R.M.; Sarmah, A.; Tan, Z.; Littleton, R.; Radovic, M.; Green, M.J.; Lutkenhaus, J.L. Conformal Layer-by-Layer Assembly of Ti3C2Tz MXene-Only Thin Films for Optoelectronics and Energy Storage. Chem. Mater. 2022, 34, 4884–4895. [Google Scholar] [CrossRef]

- Collini, P.; Kota, S.; Dillon, A.D.; Barsoum, M.W.; Fafarman, A.T. Electrophoretic Deposition of Two-Dimensional Titanium Carbide (MXene) Thick Films. J. Electrochem. Soc. 2017, 164, D573–D580. [Google Scholar] [CrossRef]

- Gao, C.; Chen, Q.; Feng, J.; Xu, Z. Optimizing Surface Texture Through Ion Induction for High Areal Capacitance and Enhanced Stability in MXene Electrodes. Adv. Funct. Mater. 2025, 35, 2413425. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, X.; Schubert, D.W.; Liu, X. Review on Polymer/MXene Composites for Electromagnetic Interference Shielding Applications. Adv. Nanocomposites 2024, 1, 52–76. [Google Scholar] [CrossRef]

- Qin, L.; Tao, Q.; Liu, X.; Fahlman, M.; Halim, J.; Persson, P.O.Å.; Rosen, J.; Zhang, F. Polymer-MXene Composite Films Formed by MXene-Facilitated Electrochemical Polymerization for Flexible Solid-State Microsupercapacitors. Nano Energy 2019, 60, 734–742. [Google Scholar] [CrossRef]

- Kumar, S.; Zain Mehdi, S.M.; Taunk, M.; Kumar, S.; Aherwar, A.; Singh, S.; Singh, T. Synergistic Effects of Polymer Integration on the Properties, Stability, and Applications of MXenes. J. Mater. Chem. A 2025, 13, 11050–11113. [Google Scholar] [CrossRef]

- Aakyiir, M.; Kingu, M.S.; Araby, S.; Meng, Q.; Shao, J.; Amer, Y.; Ma, J. Stretchable, Mechanically Resilient, and High Electromagnetic Shielding Polymer/MXene Nanocomposites. J. Appl. Polym. Sci. 2021, 138, 50509. [Google Scholar] [CrossRef]

- Jin, L.; Wang, X.; Huang, Y.; Chen, G.; Pang, H.; Yin, X.; Chai, C. Lubrication Mechanism of Polyimide/V2CTx MXene Composites Based on Surface Chemistry. Polym. Compos. 2023, 44, 8075–8084. [Google Scholar] [CrossRef]

- Wyatt, B.C.; Nemani, S.K.; Anasori, B. 2D Transition Metal Carbides (MXenes) in Metal and Ceramic Matrix Composites. Nano Converg. 2021, 8, 16. [Google Scholar] [CrossRef]

- Fei, M.; Lin, R.; Lu, Y.; Zhang, X.; Bian, R.; Cheng, J.; Luo, P.; Xu, C.; Cai, D. MXene-Reinforced Alumina Ceramic Composites. Ceram. Int. 2017, 43, 17206–17210. [Google Scholar] [CrossRef]

- Fan, Y.; Mei, X.; Liu, B.; Wang, J.; Ye, L.; Zhang, Y.; Li, X. Effect of Size-Variant 2D MXene on Strengthening Mechanism in Metal Matrix Composites. J. Alloys Compd. 2024, 978, 173423. [Google Scholar] [CrossRef]

- Khan, M.U.; Du, L.; Fu, S.; Wan, D.; Bao, Y.; Feng, Q.; Grasso, S.; Hu, C. Preparations and Applications of MXene–Metal Composites: A Review. Coatings 2022, 12, 516. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, X.; Pei, W.; Liu, N.; Zhao, J. Heterostructures of MXenes and N-Doped Graphene as Highly Active Bifunctional Electrocatalysts. Nanoscale 2018, 10, 10876–10883. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, Y.; Ding, B.; Hao, X.; Dou, H.; Zhang, X. Layer-by-Layer Self-Assembled Two-Dimensional MXene/Layered Double Hydroxide Composites as Cathode for Alkaline Hybrid Batteries. J. Power Sources 2018, 390, 208–214. [Google Scholar] [CrossRef]

- Mohajer, F.; Ziarani, G.M.; Badiei, A.; Iravani, S.; Varma, R.S. MXene-Carbon Nanotube Composites: Properties and Applications. Nanomaterials 2023, 13, 345. [Google Scholar] [CrossRef]

- Pan, F.; Yu, L.; Xiang, Z.; Liu, Z.; Deng, B.; Cui, E.; Shi, Z.; Li, X.; Lu, W. Improved Synergistic Effect for Achieving Ultrathin Microwave Absorber of 1D Co Nanochains/2D Carbide MXene Nanocomposite. Carbon 2021, 172, 506–515. [Google Scholar] [CrossRef]

- Dwivedi, N.; Dhand, C.; Kumar, P.; Srivastava, A.K. Emergent 2D Materials for Combating Infectious Diseases: The Potential of MXenes and MXene–Graphene Composites to Fight against Pandemics. Mater. Adv. 2021, 2, 2892–2905. [Google Scholar] [CrossRef]

- Jin, L.; Cao, W.; Wang, P.; Song, N.; Ding, P. Interconnected MXene/Graphene Network Constructed by Soft Template for Multi-Performance Improvement of Polymer Composites. Nano-Micro Lett. 2022, 14, 133. [Google Scholar] [CrossRef] [PubMed]

- Venkateshalu, S.; Tomboc, G.M.; Nagalingam, S.P.; Kim, J.; Sawaira, T.; Sehar, K.; Pollet, B.G.; Kim, J.Y.; Nirmala Grace, A.; Lee, K. Synergistic MXene/LDH Heterostructures with Extensive Interfacing as Emerging Energy Conversion and Storage Materials. J. Mater. Chem. A 2023, 11, 14469–14488. [Google Scholar] [CrossRef]

- Le, T.A.; Bui, Q.V.; Tran, N.Q.; Cho, Y.; Hong, Y.; Kawazoe, Y.; Lee, H. Synergistic Effects of Nitrogen Doping on MXene for Enhancement of Hydrogen Evolution Reaction. ACS Sustain. Chem. Eng. 2019, 7, 16879–16888. [Google Scholar] [CrossRef]

- White, K.E.; Chu, Y.Z.; Gani, G.; Ippolito, S.; Barr, K.K.; Thomas, J.C.; Weber-Bargioni, A.; Lau, K.C.; Gogotsi, Y.; Weiss, P.S. Atomic-Scale Investigations of Ti3C2T MXene Surfaces. Matter 2024, 7, 2609–2618. [Google Scholar] [CrossRef]

- Rodriguez, A.; Jaman, M.S.; Acikgoz, O.; Wang, B.; Yu, J.; Grützmacher, P.G.; Rosenkranz, A.; Baykara, M.Z. The Potential of Ti3C2TX Nano-Sheets (MXenes) for Nanoscale Solid Lubrication Revealed by Friction Force Microscopy. Appl. Surf. Sci. 2021, 535, 147664. [Google Scholar] [CrossRef]

- Hou, K.; Yang, Y.; Zhou, H.; Chen, X.; Ge, S. Enhanced Yield of Large-Sized Ti3C2Tx MXene Polymers Nanosheets via Cyclic Ultrasonic-Centrifugal Separation. Polymers 2023, 15, 1330. [Google Scholar] [CrossRef]

- Jung, Y.; Seok, S.; Jung, K.; Park, J.; Kwon, S.; Choi, J. Nitrogen-Doped Titanium Carbide (Ti3C2Tx) MXene Nanosheet Stack For Long-Term Stability and Efficacy in Au and Ag Recovery. Small 2023, 19, 2305247. [Google Scholar] [CrossRef]

- Boidi, G.; Zambrano, D.; Schwarz, S.; Marquis, E.; Varga, M.; Ripoll, M.R.; Badisch, E.; Righi, M.C.; Gachot, C.; Grützmacher, P.G.; et al. Solid Lubrication Performance of Hybrid Ti3C2T/MoS2 Coatings. Carbon 2024, 225, 119067. [Google Scholar] [CrossRef]

- Chhattal, M.; Kaihuan, Y.; Grützmacher, P.G.; Zambrano, D.F.; Rosenkranz, A.; Ali, S.; Huang, Y.; Gong, Z.; Zhang, J. Solid Lubrication Performance of Multi-Layered V2CT Coatings. Carbon 2024, 226, 119168. [Google Scholar] [CrossRef]

- Boidi, G.; F. De Queiróz, J.C.; Profito, F.J.; Rosenkranz, A. Ti3C2Tx MXene Nanosheets as Lubricant Additives to Lower Friction under High Loads, Sliding Ratios, and Elevated Temperatures. ACS Appl. Nano Mater. 2023, 6, 729–737. [Google Scholar] [CrossRef]

- Guo, L.; Tao, L.; Wang, T. Improved Tribological Performance of MOF@MXene/PI under High Temperature. Langmuir 2024, 40, 8862–8871. [Google Scholar] [CrossRef] [PubMed]

- Singsen, S.; Untarabut, P.; Kaewraung, W.; Ngamwongwan, L.; Prasongkit, J.; Suthirakun, S. Strain and External Electric Field Engineering of S-Terminated MXene on Selective and Sensitive Detection of N-Containing Compound Gases: A Computational Study. Langmuir 2024, 40, 22693–22704. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Jin, H.; Li, H.; Mao, Z.; Tang, L.; Huang, D.; Liao, J.-H.; Zhang, J. Role of Surface Functional Groups to Superconductivity in Nb2C-MXene: Experiments and Density Functional Theory Calculations. Surf. Interfaces 2022, 29, 101711. [Google Scholar] [CrossRef]

- Yadav, A.; Dashora, A.; Patel, N.; Miotello, A.; Press, M.; Kothari, D.C. Study of 2D MXene Cr2C Material for Hydrogen Storage Using Density Functional Theory. Appl. Surf. Sci. 2016, 389, 88–95. [Google Scholar] [CrossRef]

- Li, R.; Sun, W.; Zhan, C.; Kent, P.R.C.; Jiang, D. Interfacial and Electronic Properties of Heterostructures of MXene and Graphene. Phys. Rev. B 2019, 99, 085429. [Google Scholar] [CrossRef]

- Abraham, B.M.; Sinha, P.; Halder, P.; Singh, J.K. Fusing a Machine Learning Strategy with Density Functional Theory to Hasten the Discovery of 2D MXene-Based Catalysts for Hydrogen Generation. J. Mater. Chem. A 2023, 11, 8091–8100. [Google Scholar] [CrossRef]

- Kim, H.-J.; Yoo, S.-S.; Kim, D.-E. Nano-Scale Wear: A Review. Int. J. Precis. Eng. Manuf. 2012, 13, 1709–1718. [Google Scholar] [CrossRef]

- Zhang, D.; Ashton, M.; Ostadhossein, A.; Van Duin, A.C.T.; Hennig, R.G.; Sinnott, S.B. Computational Study of Low Interlayer Friction in Tin+1Cn (n = 1, 2, and 3) MXene. ACS Appl. Mater. Interfaces 2017, 9, 34467–34479. [Google Scholar] [CrossRef]

- Hoque, M.A.; Yao, C.-W.; Khanal, M.; Lian, I. Tribocorrosion Behavior of Micro/Nanoscale Surface Coatings. Sensors 2022, 22, 9974. [Google Scholar] [CrossRef]

- Fang, H.; Thakur, A.; Zahmatkeshsaredorahi, A.; Fang, Z.; Rad, V.; Shamsabadi, A.A.; Pereyra, C.; Soroush, M.; Rappe, A.M.; Xu, X.G.; et al. Stabilizing Ti3C2Tx MXene Flakes in Air by Removing Confined Water. Proc. Natl. Acad. Sci. USA 2024, 121, e2400084121. [Google Scholar] [CrossRef]

- Mathis, T.S.; Maleski, K.; Goad, A.; Sarycheva, A.; Anayee, M.; Foucher, A.C.; Hantanasirisakul, K.; Shuck, C.E.; Stach, E.A.; Gogotsi, Y. Modified MAX Phase Synthesis for Environmentally Stable and Highly Conductive Ti3C2 MXene. ACS Nano 2021, 15, 6420–6429. [Google Scholar] [CrossRef]

- Bao, W.; Shen, H.; Zeng, G.; Zhang, Y.; Wang, Y.; Cui, D.; Xia, J.; Jing, K.; Liu, H.; Guo, C.; et al. Engineering the next Generation of MXenes: Challenges and Strategies for Scalable Production and Enhanced Performance. Nanoscale 2025, 17, 6204–6265. [Google Scholar] [CrossRef] [PubMed]

- Kruger, D.D.; García, H.; Primo, A. Molten Salt Derived MXenes: Synthesis and Applications. Adv. Sci. 2024, 11, 2307106. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.-Y.; Xiao, H.; Long, J.-J. Preparation, Structure, Property and Application of MXene in Fabricating Functional and Intelligent Textiles: A Comprehensive Review. Compos. Part B Eng. 2025, 301, 112461. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, Y.; Li, S.; Liu, X.; Zhang, J. Passivation of MXene via Atomic Layer Deposition of SnO2 to Achieve Improved NO2 Sensing. Appl. Phys. Lett. 2023, 123, 161902. [Google Scholar] [CrossRef]

- Natu, V.; Barsoum, M.W. MXene Surface Terminations: A Perspective. J. Phys. Chem. C 2023, 127, 20197–20206. [Google Scholar] [CrossRef]

- Tan, K.H.; Zaed, M.A.; Saidur, R.; Abdullah, N.; Ishak, N.A.I.M.; Cherusseri, J. Strategic Insights for Bulk Production of MXene: A Review. E3S Web Conf. 2024, 488, 01003. [Google Scholar] [CrossRef]

- Hart, J.L.; Hantanasirisakul, K.; Lang, A.C.; Anasori, B.; Pinto, D.; Pivak, Y.; van Omme, J.T.; May, S.J.; Gogotsi, Y.; Taheri, M.L. Control of MXenes’ Electronic Properties through Termination and Intercalation. Nat. Commun. 2019, 10, 522. [Google Scholar] [CrossRef]

- Yu, K.; Ren, J.; Liao, W.; Hu, B.; Bai, C.; Li, Z.; Zhang, X.; Chhattal, M.; Li, N.; Qiang, L. Maintaining the 2D Structure of MXene via Self-Assembled Monolayers for Efficient Lubrication in High Humidity. Small 2024, 20, 2402143. [Google Scholar] [CrossRef]

- Sa, N.; Wu, M.; Wang, H.-Q. Review of the Role of Ionic Liquids in Two-Dimensional Materials. Front. Phys. 2023, 18, 43601. [Google Scholar] [CrossRef]

- Fernandes, A.M.; Rocha, M.A.A.; Freire, M.G.; Marrucho, I.M.; Coutinho, J.A.P.; Santos, L.M.N.B.F. Evaluation of Cation−Anion Interaction Strength in Ionic Liquids. J. Phys. Chem. B 2011, 115, 4033–4041. [Google Scholar] [CrossRef]

- Huang, S.; Mutyala, K.C.; Sumant, A.V.; Mochalin, V.N. Achieving Superlubricity with 2D Transition Metal Carbides (MXenes) and MXene/Graphene Coatings. Mater. Today Adv. 2021, 9, 100133. [Google Scholar] [CrossRef]

- Amani, A.M.; Tayebi, L.; Vafa, E.; Abbasi, M.; Vaez, A.; Kamyab, H.; Chelliapan, S.; Azizli, M.J.; Bazargan-Lari, R. On the Horizon of Greener Pathways to Travel into a Greener Future Portal: Green MXenes, Environment-Friendly Synthesis, and Their Innovative Applications. J. Clean. Prod. 2024, 436, 140606. [Google Scholar] [CrossRef]

- Amrillah, T.; Abdullah, C.A.C.; Hermawan, A.; Sari, F.N.I.; Alvani, V.N. Towards Greener and More Sustainable Synthesis of MXenes: A Review. Nanomaterials 2022, 12, 4280. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, P.; Wang, F.; Ricciardulli, A.G.; Lohe, M.R.; Blom, P.W.M.; Feng, X. Fluoride-Free Synthesis of Two-Dimensional Titanium Carbide (MXene) Using A Binary Aqueous System. Angew. Chem. Int. Ed. 2018, 57, 15491–15495. [Google Scholar] [CrossRef]

- Cheng, H.; Zhao, W. Regulating the Nb2C Nanosheets with Different Degrees of Oxidation in Water Lubricated Sliding toward an Excellent Tribological Performance. Friction 2022, 10, 398–410. [Google Scholar] [CrossRef]

- Lei, C.; Zhang, Y.; Liu, D.; Wu, K.; Fu, Q. Metal-Level Robust, Folding Endurance, and Highly Temperature-Stable MXene-Based Film with Engineered Aramid Nanofiber for Extreme-Condition Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2020, 12, 26485–26495. [Google Scholar] [CrossRef] [PubMed]

- Irfan, M.S.; Ali, M.A.; Khan, T.; Anwer, S.; Liao, K.; Umer, R. MXene and Graphene Coated Multifunctional Fiber Reinforced Aerospace Composites with Sensing and EMI Shielding Abilities. Compos. Part Appl. Sci. Manuf. 2023, 165, 107351. [Google Scholar] [CrossRef]

| Material | Mechanical Strength (GPa) | Young’s Modulus (GPa) | Reference |

|---|---|---|---|

| Ti3C2Tx | 15.4 (tensile) | 484 ± 13 | [5] |

| MoS2 | 23 | 270 ± 100 | [26] |

| WS2 | 47.0 ± 8.6 | 302.4 ± 24.1 | [27] |

| WTe2 | 6.4 ± 3.3 | 149.1 ± 9.4 | [27] |

| Graphene | 130 | 1000 | [26] |

| MXene Coating | Application | Service Life Improvement Factor | Wear Reduction Factor | Reference |

|---|---|---|---|---|

| None (Reference) | Thrust Ball Bearing/Journal Bearing | 1.0 (Baseline) | 1.0 (Baseline) | |

| Ti3C2Tx | Thrust Ball Bearing | 2.1 | 2.9 | [29] |

| Ti3C2Tx | Journal Bearing | 4 | 68% | [30] |

| MoS2 | Journal Bearing | 11 | 82% | [30] |

| Ti3C2Tx/MoS2 (Hybrid) | Journal Bearing | 6 | 68% | [30] |

| Material | COF or Other Metric | Reference |

|---|---|---|

| MXenes | ||

| Ti3C2Tx monolayer (on SiO2) | 0.087 ± 0.002 | [31] |

| Ti3C2Tx double-layer (on SiO2) | 0.082 ± 0.003 | [31] |

| Ti3C2Tx aqueous dispersion with SDS stabilizer | ~213 days of minimal oxidation | [32] |

| Ti3C2Tx aqueous dispersion buffered with Tris-HCl | Maintained morphology, structure, and good dispersion for ~150 days | [33] |

| Non-MXene Layered Solids | ||

| Graphite layers sliding in Ultrahigh vacuum | ~0.0004 | [34] |

| MoS2 nanotube | 0.023 ± 0.005 | [35] |

| NiCr/hBN Self-Lubricating Composite | 0.28–0.63 depending on temperature | [36] |

| MXene | Exfoliation Energy (via DFT) | Reference |

|---|---|---|

| Ti2AlC | 2.76 | [37] |

| Ti3AlC2 | 2.63 | [37] |

| V2AlC | 3.28 | [37] |

| Nb2AlC | 2.87 | [37] |

| Environmental Factor | Tribological Effect | Optimal MXene Configuration | Reference |

|---|---|---|---|

| Elevated Humidity | Causes oxidation, leading to increased friction and wear | [38] | |

| High Temperature | Causes oxidation, leading to increased friction and wear | EB Nanosheet composites | [39] |

| Vacuum Conditions | Improve performance, but the effect is decreased | MXene/MoS2 hybrids | [40] |

| Oil Lubrication | Enhances tribological properties | Addition of <0.1 wt.% MXene as an oil additive | [41] |

| Aqueous Systems | Highly dependent on MXene configuration | MXene/GO composite | [42] |

| Termination Type | Mechanical Strength | Friction | Key Characteristics | References |

|---|---|---|---|---|

| -OH dominant | Weaker than -O at low pressure/temperature, but stronger under extreme conditions | Moderate | Strong hydrogen bonds resist sliding | [16,43] |

| -O dominant | Superior to -OH at low pressure/temperature, but weaker under extreme conditions | Low | Excellent tribofilm potential | [16,43] |

| -F dominant | Weaker than -O and -OH | High | Superior thermal conductivity | [16,43,44] |

| Hybrid | Tunable | Tunable | Often arise from standard etching methods | [44] |

| Formulation | Base Medium | Friction Reduction | Wear Improvement | Reference |

|---|---|---|---|---|

| Conventional | Lithium Grease | Baseline | Baseline | [48] |

| Ti3C2Tx-MLG | Lithium Grease | 56.7% | 26.6% | [48] |

| Ti3C2Tx-5750 | Synthetic Oil | 11.2% | 92.0% | [49] |

| Ti3C2Tx-ODPA | Supramolecular Gel | 46.32% | 81.18% | [19] |

| Ti3C2Tx | Outboard Engine Oil | 14.5% | 6.3% | [50] |

| Coating System | Substrate | Key Innovation | Friction Reduction | Reference |

|---|---|---|---|---|

| Si-MX/PDA-HOAC Composite | Silicon | Ternary nanocomposite design | Reduced friction and increased load-bearing capacity | [52] |

| LST + MXene Nanocoating | Titanium Alloy | Laser-textured reservoirs | Reduced friction by 70% and resulted in minimal substrate wear | [53] |

| Ti3C2Tx | Stainless-steel | Comparison of MXenes to MAX phases | MXene coating surpassed MAX coating in friction reduction by 81.82% | [54] |

| MXene-Graphene Oxide Composite | Bearing steel | MXene-GO composites | Reduced friction coefficients by significantly more than MXene or GO alone | [55] |

| Application | Material System | Key Performance Metrics | Advantages over Conventional Materials | Reference |

|---|---|---|---|---|

| EMI Shielding | MXene/polymer film | EMI SE 57 dB Film thickness 9 µm | Lower reflection, higher absorption | [59] |

| Energy Storage | Polymer-MXene composite | 69.5 mF cm−2; 250.1 mWh cm−3; 10,000-cycle stability | Higher energy density, longer lifespan | [60] |

| Lubrication | Polyimide/V2CTx MXene composite | Wear rate reduced 43.2% at 0.8 wt.% Wear rate reduced 71.9% at 1.2 wt.% | Enhanced durability | [63] |

| Flexible Electronics | Elastomer-MXene film | EMI SE 49 dB Film thickness 1 mm, High elasticity | Combines flexibility with high shielding | [62] |

| Metal Matrix | MXene | Processing Method | Strength Enhancement | Reference |

|---|---|---|---|---|

| Al | Ti3C2Tx | SPS + extrusion | 66% (tensile) | [64] |

| Mg | Ti3C2Tx | SPS | 17.6% (CYS) | [66] |

| Cu | Ti3C2Tx | Hot pressing | 50% | [64] |

| Mg-Li Alloy | Ti3C2Tx | Molten Sonication | 128% (tensile YS) | [64] |

| Al | Ti3C2Tx | SPS + extrusion | UTS increased to ~217.9 MPa | [67] |

| Application | Hybrid System | Key Performance Metric | Improvement over MXene Alone | Reference |

|---|---|---|---|---|

| EMI Shielding | MXene/Co nanochains | −46.48 dB RL at 1.02 mm, 16.75 GHz | Improved wave absorption | [71] |

| Biomedical | MXene-Graphene | >99% antimicrobial efficiency | Improved conductivity | [72] |

| Mechanical Strength | MXene-Graphene | Young’s modulus 5.76 GPa | Improved mechanical strength | [73] |

| Energy Storage | MXene-NiCo-LDH | High electrical conductivity | Prevented Oxidation | [74] |

| ORR and HER | MXene and N-doped graphene | Overpotential of 0.36V | Much lower overpotentials | [75] |

| Technique | Purpose | MXene-Specific Consideration | Reference |

|---|---|---|---|

| Atomic Force Microscopy (AFM) | Nanoscale friction mapping | Friction responses are sensitive to surface chemistry | [76] |

| Friction Force Microscope (FFM) | Account for molecular forces during AFM | Friction responses are sensitive to surface chemistry | [77] |

| Environmental Control | Test under various humidity and temperature conditions | Accounts for thermal and oxidation effects | [13] |

| Layer-by-layer Coating Analysis | Ensure the durability and consistency of the material | Slight inconsistencies can significantly affect performance | [13] |

| Technique | Key Parameters | MXene-Specific Insights | Limitations | References |

|---|---|---|---|---|

| SEM | Morphology and surface topology | Observe flake structure and film thickness | No chemical composition insight | [81] |

| TEM | Internal structure, interlayer spacing | Chemical composition | Complex process, limited to small analysis areas | [77,81] |

| XPS | Surface chemical composition | Identify surface terminations, oxidation states, and surface groups | Surface sensitivity (limited depth profiling), ultra-high vacuum required | [77,81] |

| AFM | Surface topography, thickness mapping | Measure nanosheet thickness, visualize flake shapes | Limited to small scan areas, tip convolution | [77] |

| FFM | Nanoscale friction measurement | Nanoscale friction measurement | Influenced by humidity, tip convolution | [77] |

| MXene Type | Lubricant Base | Key Findings | Reference |

|---|---|---|---|

| Ti3C2Tx | Poly-(α)-olefin | Significant friction and wear reduction under high temperatures | [82] |

| Ti3C2Tx | Engine Oil | Improved oxidation and thermal conductivity | [50] |

| Ti3C2Tx | Polyimide Composites | Reduced friction and enhanced wear resistance under high temperatures | [83] |

| Scale | Technique/Model | Key Parameters | Findings/Performance Metrics | Reference |

|---|---|---|---|---|

| Nano | AFM/LFM + Arrhenius model | Surface chemistry | 0.082–0.087 COF | [31] |

| Nano | Archard’s Law | Load, hardness | Does not predict nano wear accurately | [89] |

| Macro | Ball-on-disk tribometry | Layer thickness, surface terminations | 4× reduction in friction, 10× reduction in wear | [31] |

| Macro | Tribocorrosion modeling | Electrochemical + mechanical wear | Nonlinear wear-corrosion relationship | [91] |

| Challenge | Technical Impact | Current Mitigation Strategies | Remaining Gaps | References |

|---|---|---|---|---|

| Surface Degradation | Termination loss due to repeated stress | Molten salt etching | Limited research on differing types of MXenes | [44,95] |

| Batch Inconsistency | Inconsistency in tribological performance | Advanced process monitoring | Lacking industry standards for QA | [96] |

| Defect Propagation | Higher wear rates in defective regions | Post-synthesis sorting techniques | Increased production cost | [96] |

| Scalability Limits | Limited applicability and higher costs | Advanced synthesis approaches | Mitigation strategies still in development | [94] |

| Challenge | Description | References |

|---|---|---|

| Toxic Etchants | HF poses severe health risks associated with its handling and disposal. The required precautions increase the cost of manufacturing, and safer alternatives are less efficient. | [94,99] |

| MAX Precursor Variability | Inconsistent purity reduces MXene quality and performance. | [99] |

| Oxidation Degradation | Degradation under certain conditions limits shelf and service life. | [94] |

| Application | MXene Configuration | Key Functionality | Performance Highlights | Reference |

|---|---|---|---|---|

| High-temperature environments | MXene/aramid nanofiber film | Thermal stability, EMI shielding, and mechanical strength | Strength 355 MPa @ −100 °C, 136 MPa @ 300 °C, >99% EMI shielding | [109] |

| Smart sensing in composite manufacturing | MXene-coated glass fiber-epoxy fabrics | In situ process monitoring | Resistance change tracked pressure and resin flow changes | [110] |

| Structural health monitoring | MXene-coated glass fiber-epoxy fabrics | Strain and bending tracking under mechanical loads | Reliable sensing after 100 flexural cycles | [110] |

| EMI shielding | MXene-coated glass fiber-epoxy fabrics | Protection of sensitive electronics | Higher EMI shielding than rGO-based composites | [110] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoll, J.L.; Paul, M.; Pritchett, L.; Snover, A.; Woods, L.; Antony Jose, S.; Menezes, P.L. Tribology of MXene Materials: Advances, Challenges, and Future Directions. Materials 2025, 18, 4767. https://doi.org/10.3390/ma18204767

Stoll JL, Paul M, Pritchett L, Snover A, Woods L, Antony Jose S, Menezes PL. Tribology of MXene Materials: Advances, Challenges, and Future Directions. Materials. 2025; 18(20):4767. https://doi.org/10.3390/ma18204767

Chicago/Turabian StyleStoll, Jonathan Luke, Mason Paul, Lucas Pritchett, Ashleigh Snover, Levi Woods, Subin Antony Jose, and Pradeep L. Menezes. 2025. "Tribology of MXene Materials: Advances, Challenges, and Future Directions" Materials 18, no. 20: 4767. https://doi.org/10.3390/ma18204767

APA StyleStoll, J. L., Paul, M., Pritchett, L., Snover, A., Woods, L., Antony Jose, S., & Menezes, P. L. (2025). Tribology of MXene Materials: Advances, Challenges, and Future Directions. Materials, 18(20), 4767. https://doi.org/10.3390/ma18204767