1. Introduction

Traditionally, internal components and frames of automobiles have been made from metals. The usage of metals for the internal components and frames tends to increase the overall weight of an automobile. In order to reduce the overall weight of automobiles, fiber-reinforced composites are being developed as a replacement. The main characteristic of these fiber-reinforced composites is that they are light weight and also offer a high degree of stiffness. Thus, it can be observed that the extensive use of these composite materials in the transportation industry can help achieve a high degree of mechanical performance along with improving the efficiency of vehicles due to the reduction in weight they offer [

1]. Over the last decade, an increase in the interest shown towards improving the environmental impact of the materials used in making these composites has led to the development of sustainable and eco-friendly composite materials which incorporate natural fibers as reinforcing materials [

2,

3,

4], and composite materials in general offer an uncanny advantage where the properties of the materials used can be modified in order to meet the various requirements of the applications [

1].

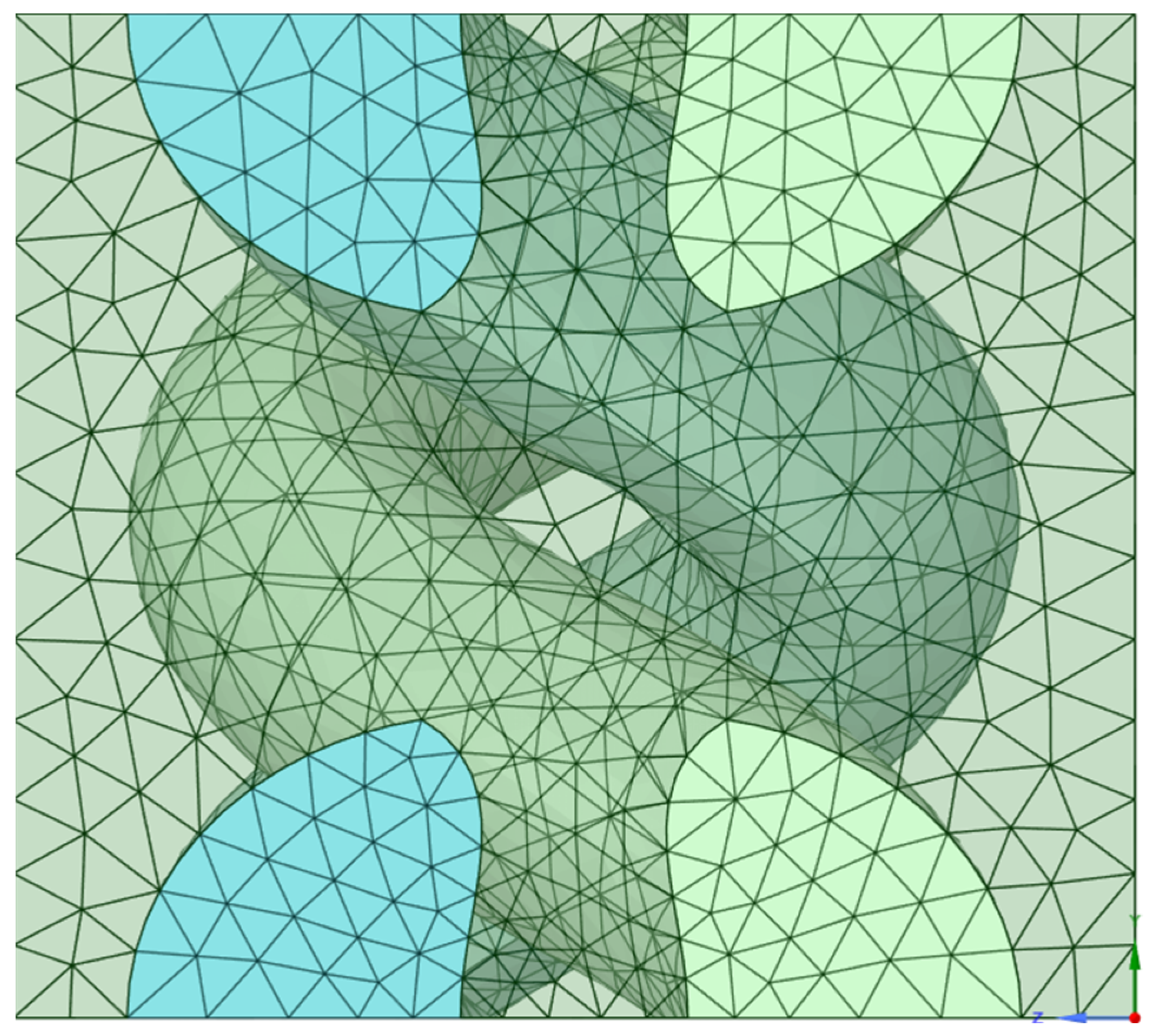

The ultimate microstructure of the composite, which is a result of compaction, partially dictates the mechanical properties of a composite [

5,

6]; along with this, the mechanical properties of the yarn utilized, which are dependent on the cross section of the yarn, are also responsible for the mechanical properties of the composite material [

1]. The mechanical properties of fiber-reinforced composites are dependent on the yarn fiber volume ratio, which has a range of 0.76 to 0.9; for the case of an ideal structure with unidirectional hexagonal packing, the yarn fiber volume ratio is found to be 0.98 [

7,

8]. The macroscopic behavior of the heterogenous fiber-reinforced composite is dictated by the geometrical arrangement of the phases and the properties of the interface [

9]. The fiber volume fraction is an important parameter which has a greater influence on the mechanical properties of the fiber-reinforced composites, as seen by the studies conducted by some researchers on the fiber packing density of idealized yarn constructions and the distribution of fibers in the cross section [

8,

10,

11,

12]. Hybrid composites have been front and center on the world stage in recent years due to their versatility and the range of applications for which they can be utilized, as well as the fact that the properties of the composites can be easily modified to satisfy the requirements of potential applications. The rise in environmental awareness, as mentioned earlier, has led to the development of sustainable and eco-friendly composites. These composites are made from a combination of high-performance fibers like carbon, Kevlar, glass, etc. with natural fibers like sisal, jute, hemp, flax, etc. [

13]. It is evidently clear that the mechanical performance of the natural fibers when compared with the mechanical performance of the high-performance fibers is lower; however, we can utilize the high-performance fibers as the outer layers of the composite while utilizing the natural fibers as the inner layers of the composite, thus creating a hybrid composite which is sustainable and ecofriendly in nature with multiple reinforcements [

14]. These hybrid composites can be utilized in the marine, automotive and aviation sectors, as well as for with manufacturing blades for turbines and producing numerous household items.

The frames and components which are made from traditional materials can be replaced by components and frames made from high performance materials like basalt, carbon, Kevlar, etc. These components or frames can be converted into composites using resins. The frames and components made from these materials are ultra-light weight in nature and are mechanically sturdy; to predict the performance of these frames and components, advanced computational tools can be used [

15,

16,

17,

18,

19,

20,

21,

22]. Zero toxicity, nonabrasive nature, biodegradability, lower costs and ease of manufacturing are some of the advantages that the natural fibers offer over the synthetic fibers [

23,

24,

25,

26,

27,

28]. Usually, natural fiber-based reinforced composites are made from plant fibers such as hemp, jute, sisal, flax, banana, etc. [

29,

30]. Investigations into the physical and mechanical properties of natural fiber-based composites made from sisal, hemp, jute, coir, arrowroot, kenaf, pinecone and bamboo have been conducted in detail by various authors [

31,

32,

33,

34,

35,

36]. The thermal and mechanical properties of the hybrid composites can be increased significantly when synthetic fibers or high-performance fibers are added along with the natural fibers. The tensile properties [

37,

38,

39,

40], flexural [

41], impact strength [

42,

43,

44,

45], damping [

46] and interlaminar shear strength [

41] of the hybrid composites have been investigated to determine the effect of hybridization.

The eco-friendliness, ease of handling, biodegradability, carbon neutral nature, cost effectiveness, higher specific strength and excellent mechanical properties are some of the properties exhibited by flax fibers, and this has led to the extensive research that has been conducted on flax-based composites. The composites made from flax and other natural fiber-based composites have a wide range of applications in the automotive sector, the biomedical sector, the production of turbine blades, the marine industry, the aerospace industry, printed circuit boards and the construction industry [

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57,

58,

59,

60,

61,

62,

63].

The mechanical properties of composites due to hybridization were studied by several researchers [

46]. Vacuum assisted transfer molding process was utilized to produce the composite samples. Flax, carbon and glass were used as reinforcing fibers in the composites and the main reason for the integration of flax was to make the composite environmentally friendly. Tensile strength, impact strength, flexural strength, interlaminar shear strength and dampening properties were studied in this study. The results obtained from the impact tests revealed that the hybrid composites which had reinforcing fibers of flax and glass had the highest impact strength when compared to the other composite samples tested.

A study conducted by researchers [

64] dealt with the effects of stacking sequence on the mechanical properties like tensile strength, flexural strength and impact strength. The hybrid composites were prepared with kenaf fiber fabrics and glass fiber fabrics. The results obtained from the impact tests revealed that the hybrid composites had a superior performance where there was an improvement in the impact strength in the edgewise orientation of 8.6% and an improvement of 51.9% was shown in the flatwise orientation.

The tensile, flexural and impact strengths of flax and hemp-based hybrid composites when exposed to a cryogenic treatment were evaluated and compared with composite samples which were exposed to a cryogenic treatment [

65]. The composites were prepared using the hand lay-up method and the fibers used in the preparation of the composites were treated with NaOH solution to increase their interfacial adhesion. The results of the experiments conducted showed that the impact strength of the composite samples decreased with the increase in the immersion time in the liquid nitrogen which was used to administer the cryogenic treatment.

Researchers conducted experimental investigations for the usage of hemp fiber-based hybrid composites for automotive applications [

66]. The hemp fibers were integrated with glass fiber reinforced composites. Both treated and untreated fibers were integrated with the glass fiber reinforced composite. The treated fibers were treated with NaOH and the mechanical properties like tensile strength, impact strength and hardness were tested. The samples were fabricated using the hand lay-up method. The results obtained from the impact tests show that the hybrid composites have good impact strength when compared to the glass epoxy composites.

The effect of stacking sequence on the mechanical and thermal properties of flax, Kevlar, carbon and carbon–Kevlar hybrid epoxy composites were studied [

67]. In the study, tensile strength, flexural strength, interlaminar shear strength, impact strength, thermal behaviors, water absorption and contact angle were evaluated. The composites produced had four layers and were produced using the hand lay-up method. The impact tests revealed that the performance of the hybrid composites were better than the other samples showing an impact strength of 13.86 MPa. The structural integrity and the strength of the composite materials can be significantly diminished due to the damage caused by drop-weight impacts, and visual inspection of these damages may not be enough to detect them. This is due to the fact that the damages induced by these impacts occur internally and may increase when minor delamination of the composite occurs. Thus, it is of paramount importance to study the behavior of these laminated composites upon impact [

68]. It has been seen that the composites made from woven fabrics exhibit superior resistance to impact damage owing to the fact that there are interlacing fiber tows present in two directions, and along with this they are easy to manufacture, exhibit high toughness and have better damage tolerance [

69].

With low energy impacts on rectangular woven E-glass polyester composites of varying thickness, researchers have shown that complex, multiple damages occur [

70]. Several researchers also conducted a study using finite element analysis in ABAQUS version 2025X FD01 for low velocity impacts on thin composite laminates [

71]. In a study, the energy-based damage mechanics were evaluated using DYNA3D version R14.1.0 to study the effect of impact on carbon fabric composite laminates [

72]. To obtain a clear picture of the damage caused due to impacts, it is also necessary to compare results obtained after simulation with the experimental results. A study was conducted where energy absorption and impact damage resistance for unidirectional, 2D plane woven and single-ply 3D orthogonal fabric laminates were analyzed. The results of the analysis indicated that the single-ply 3D orthogonal fabric laminate had a greater level of impact damage resistance and higher energy absorption capability when compared with the other two type of fabric laminates [

73].

Traditionally, the models used for the analysis of impact damage have relied heavily on experimental data or analytical calculations. It has been observed that the analytical results are overly simple and unreliable, and it tends to become very expensive to conduct tests for each and every design, with the testing being complex and time consuming. Thus, the virtual testing of the desired sample using numerical simulation is catching on for engineering development. As a result, various geometries, laminate configurations and loading conditions can easily simulated and their effects can be analyzed.

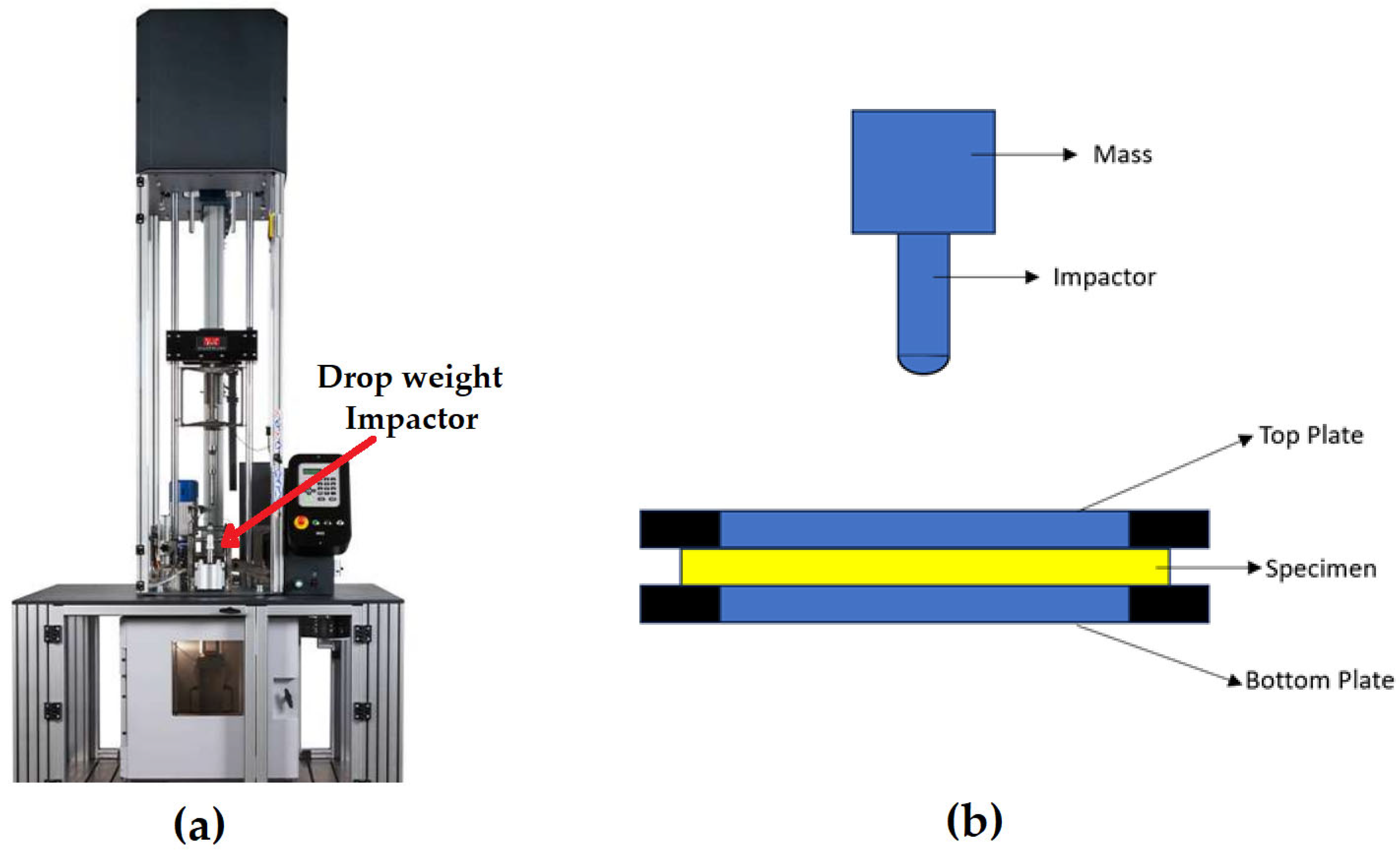

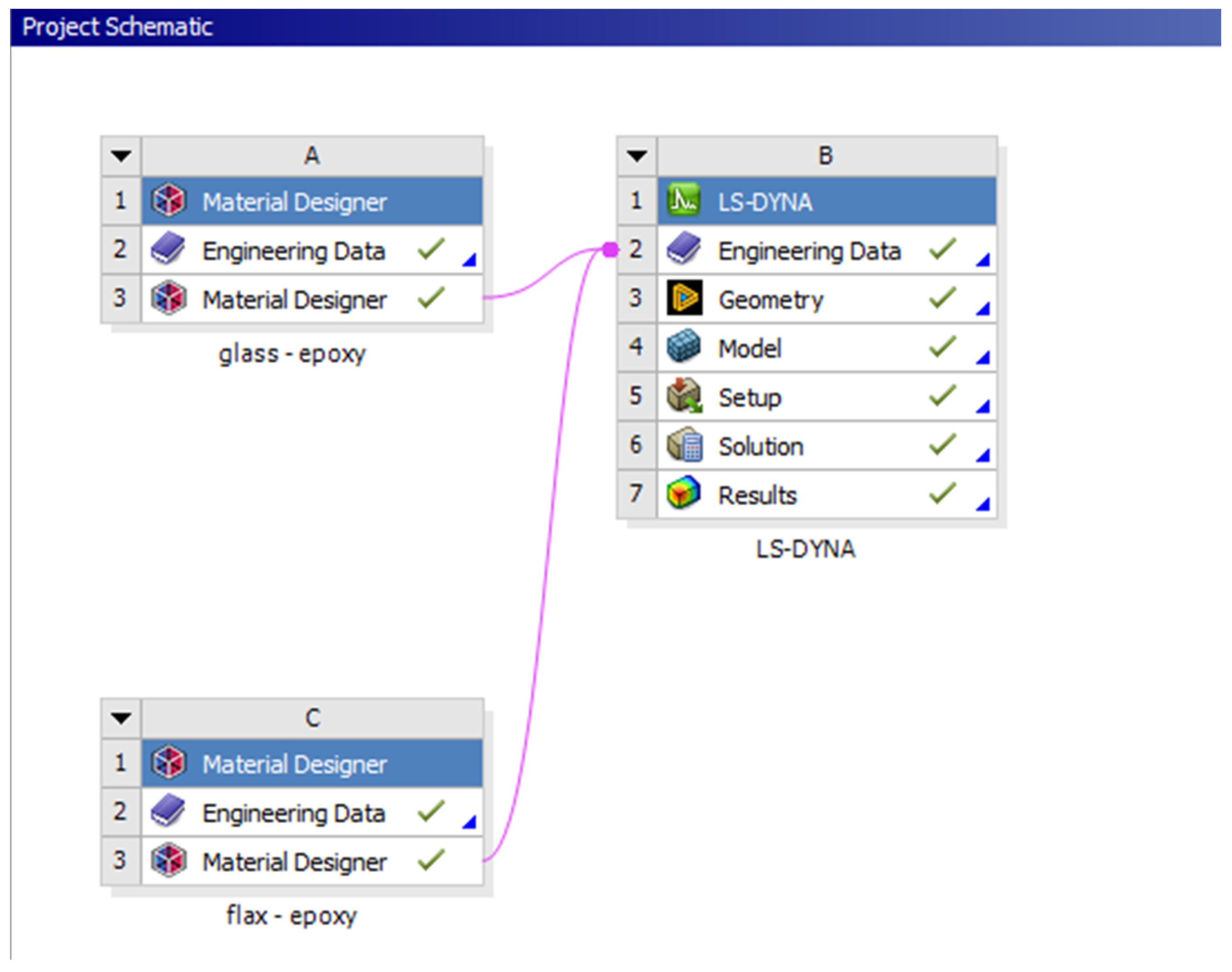

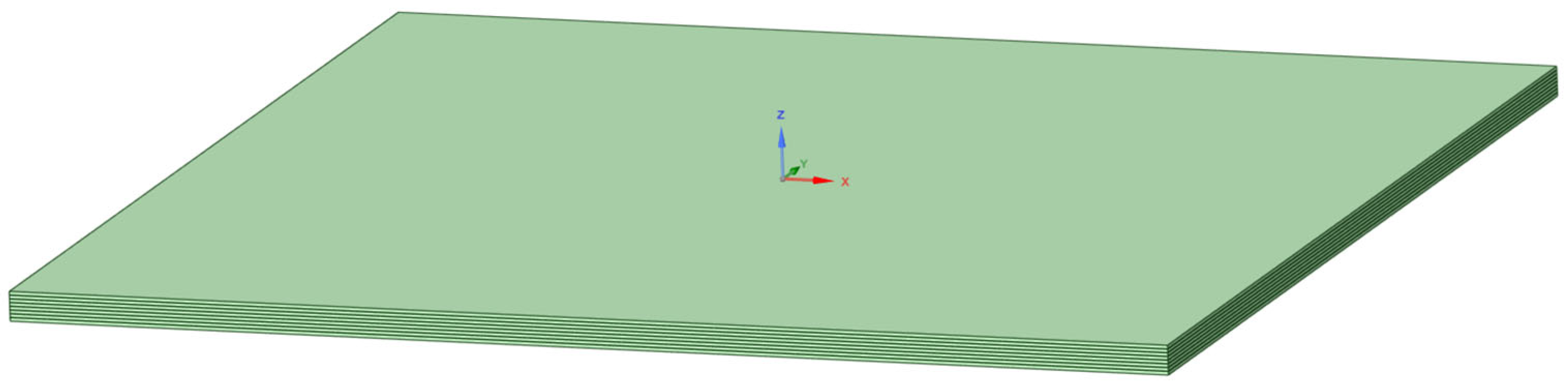

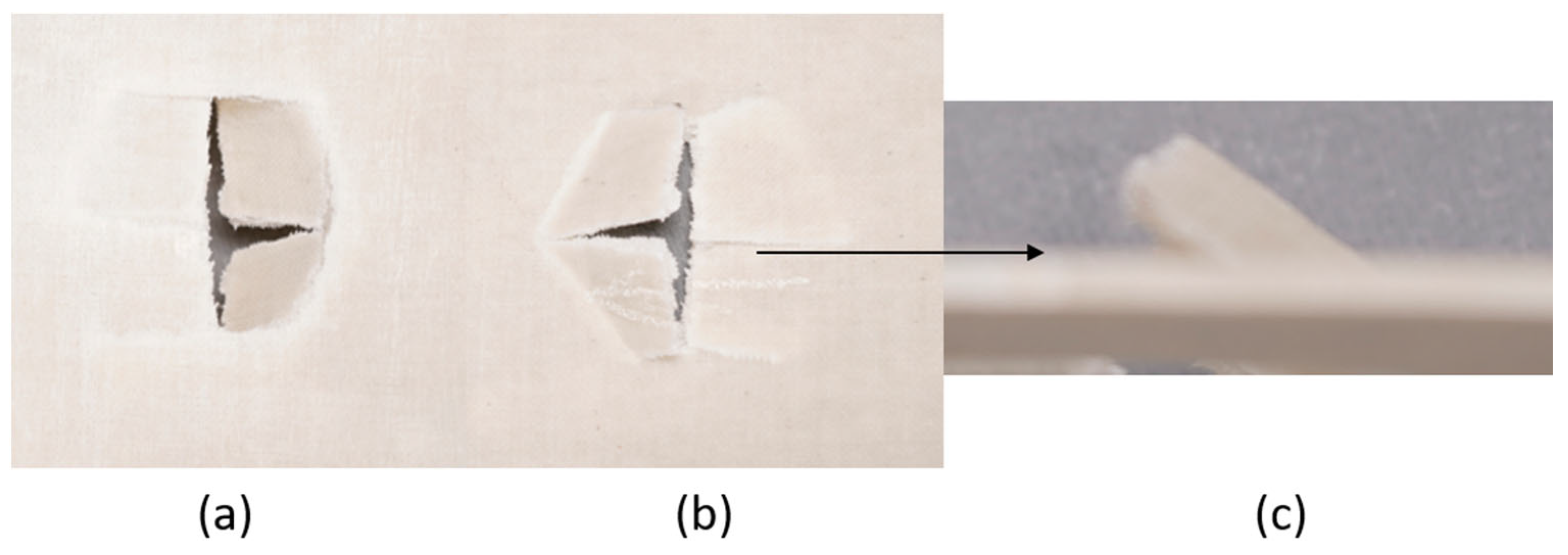

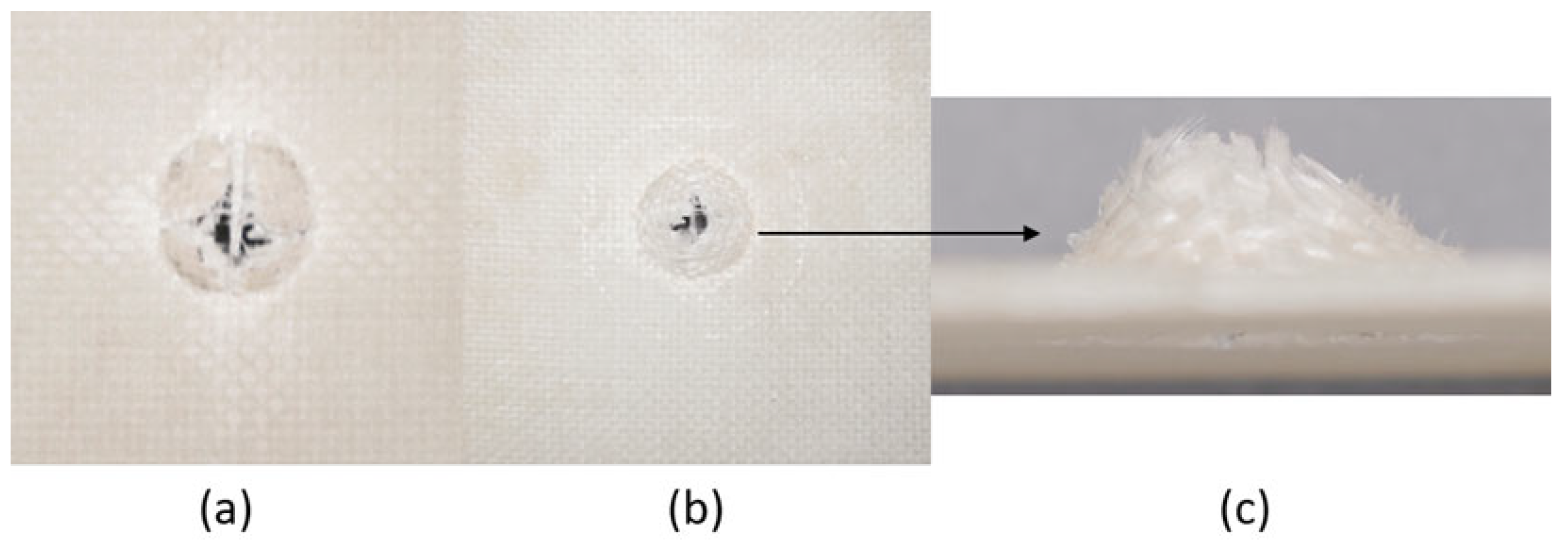

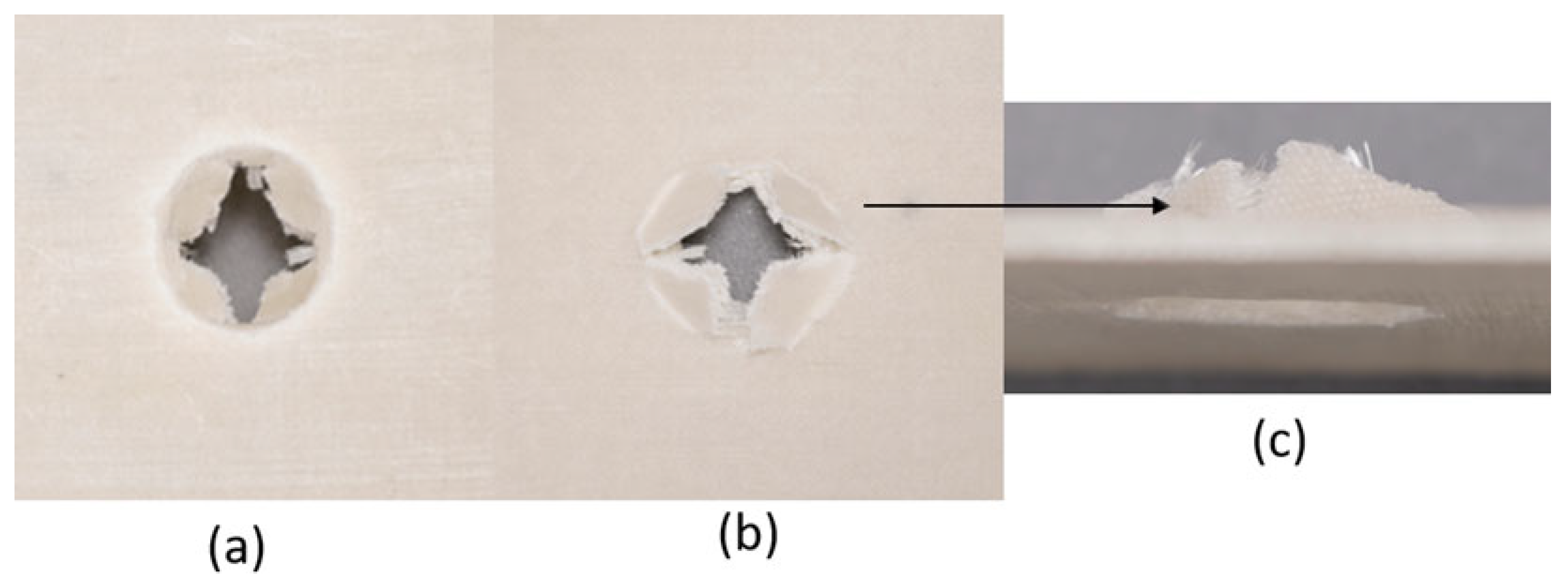

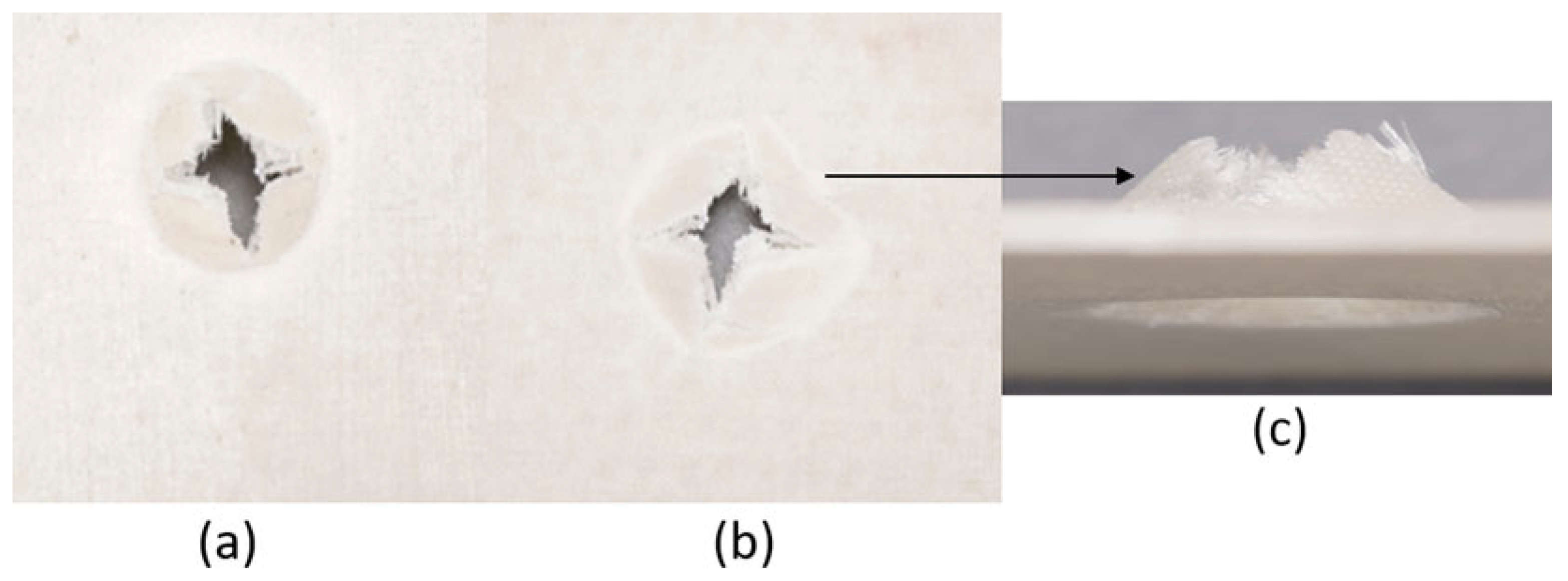

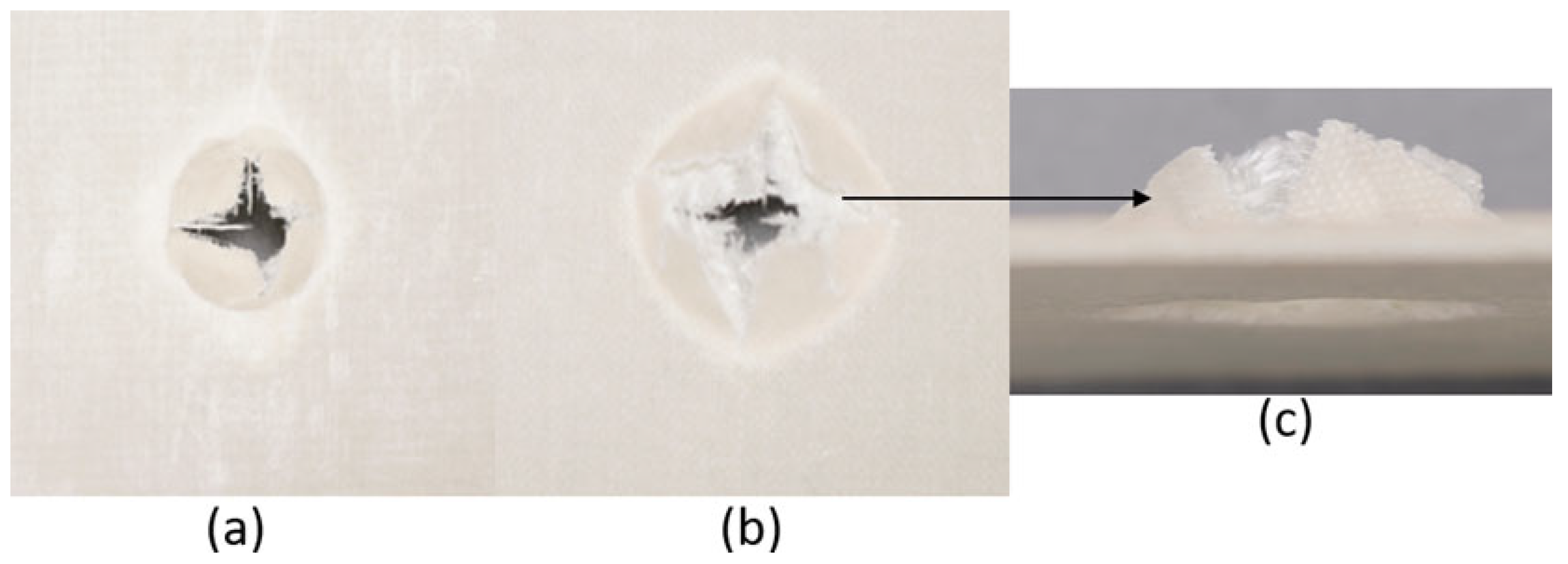

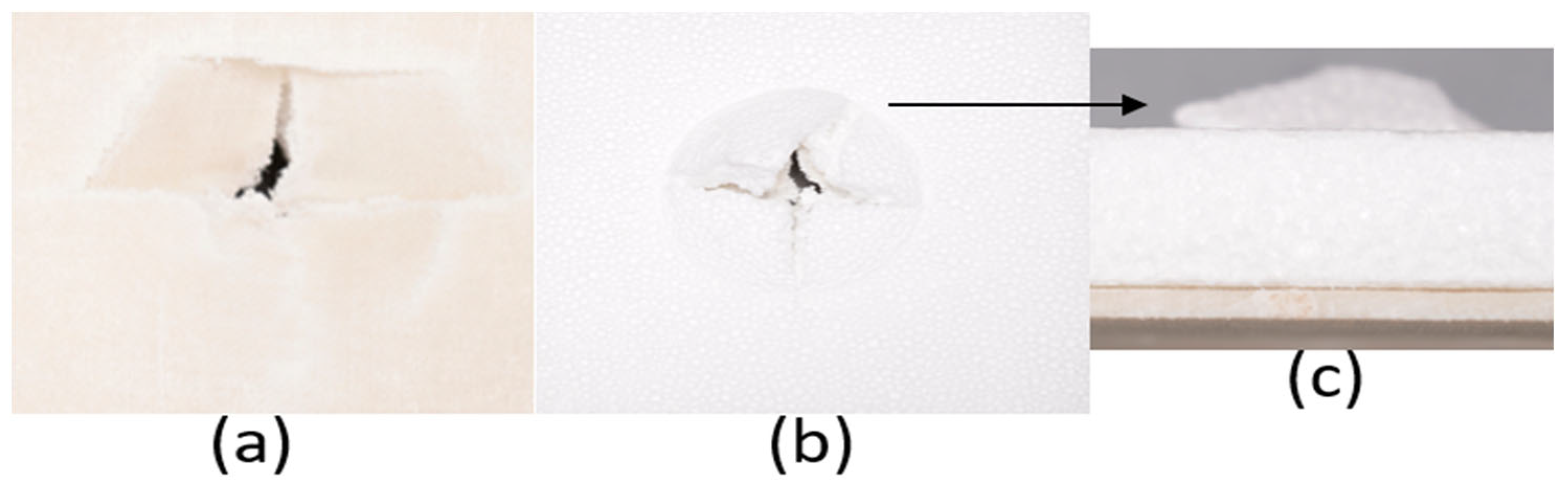

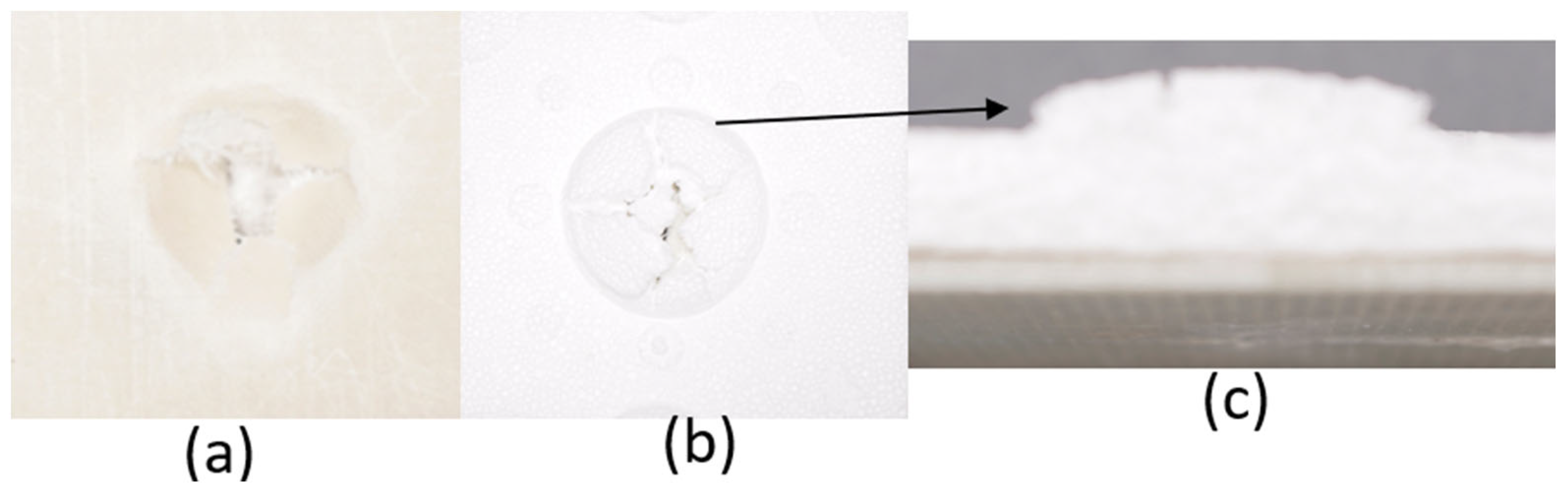

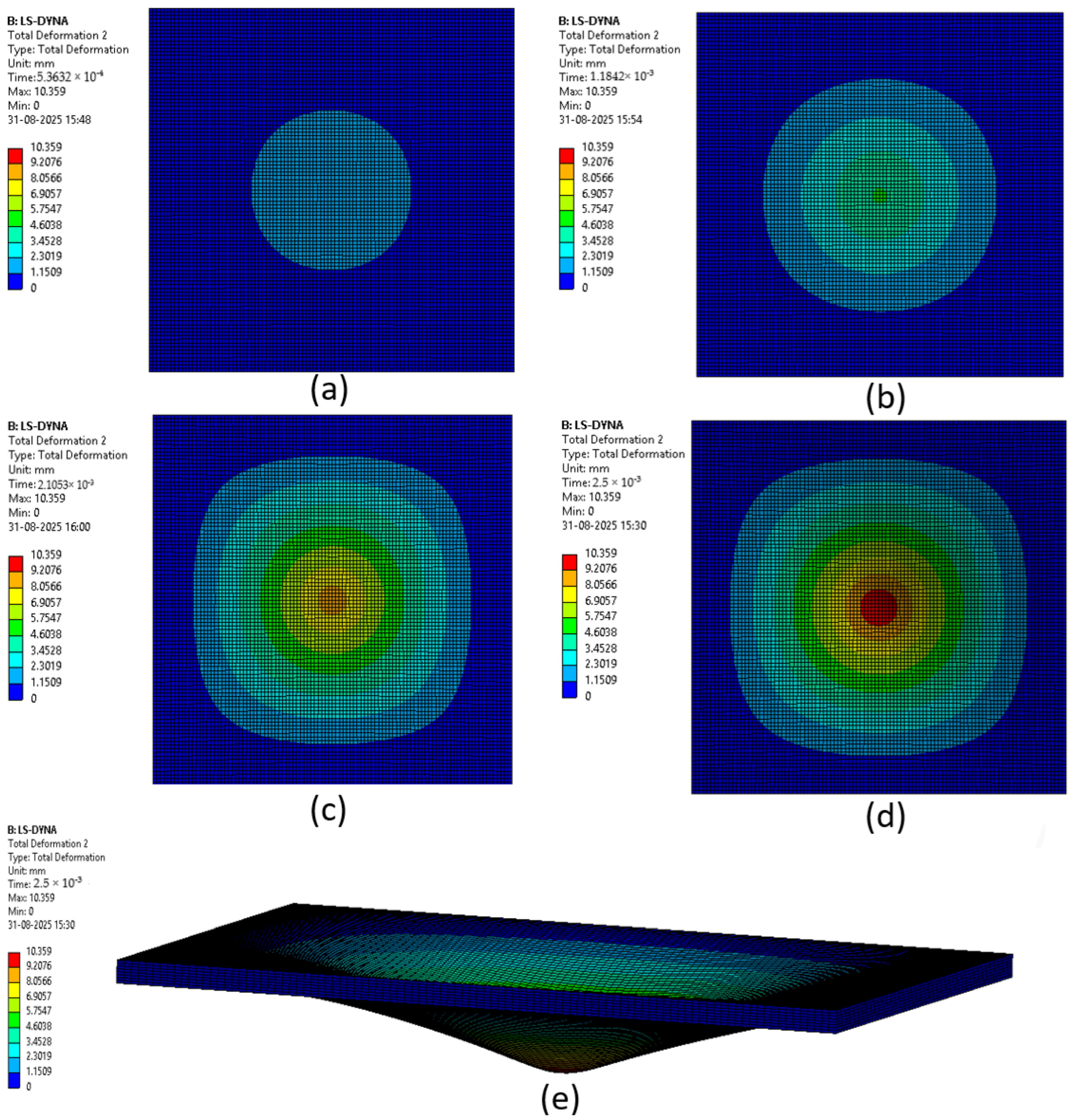

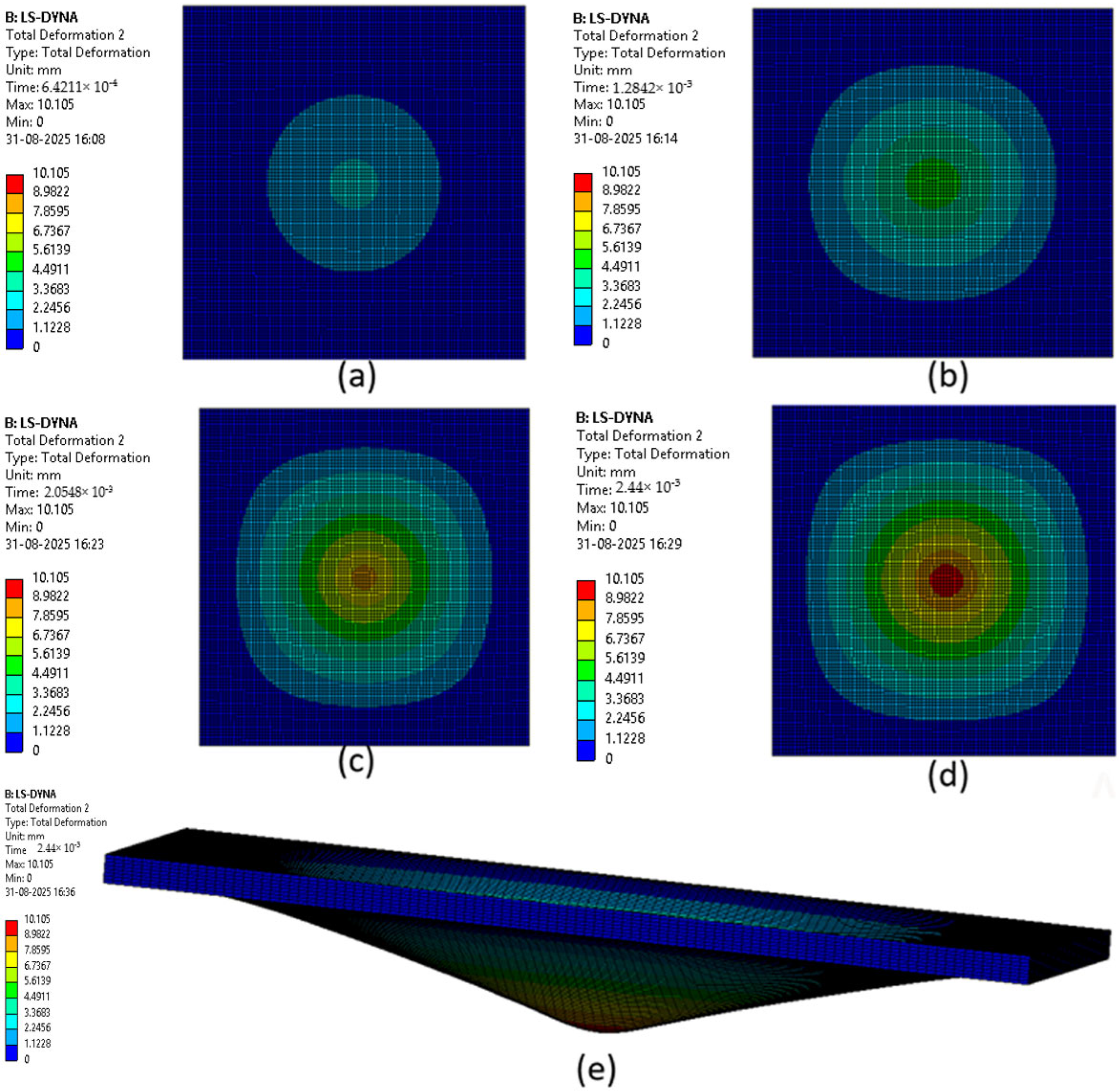

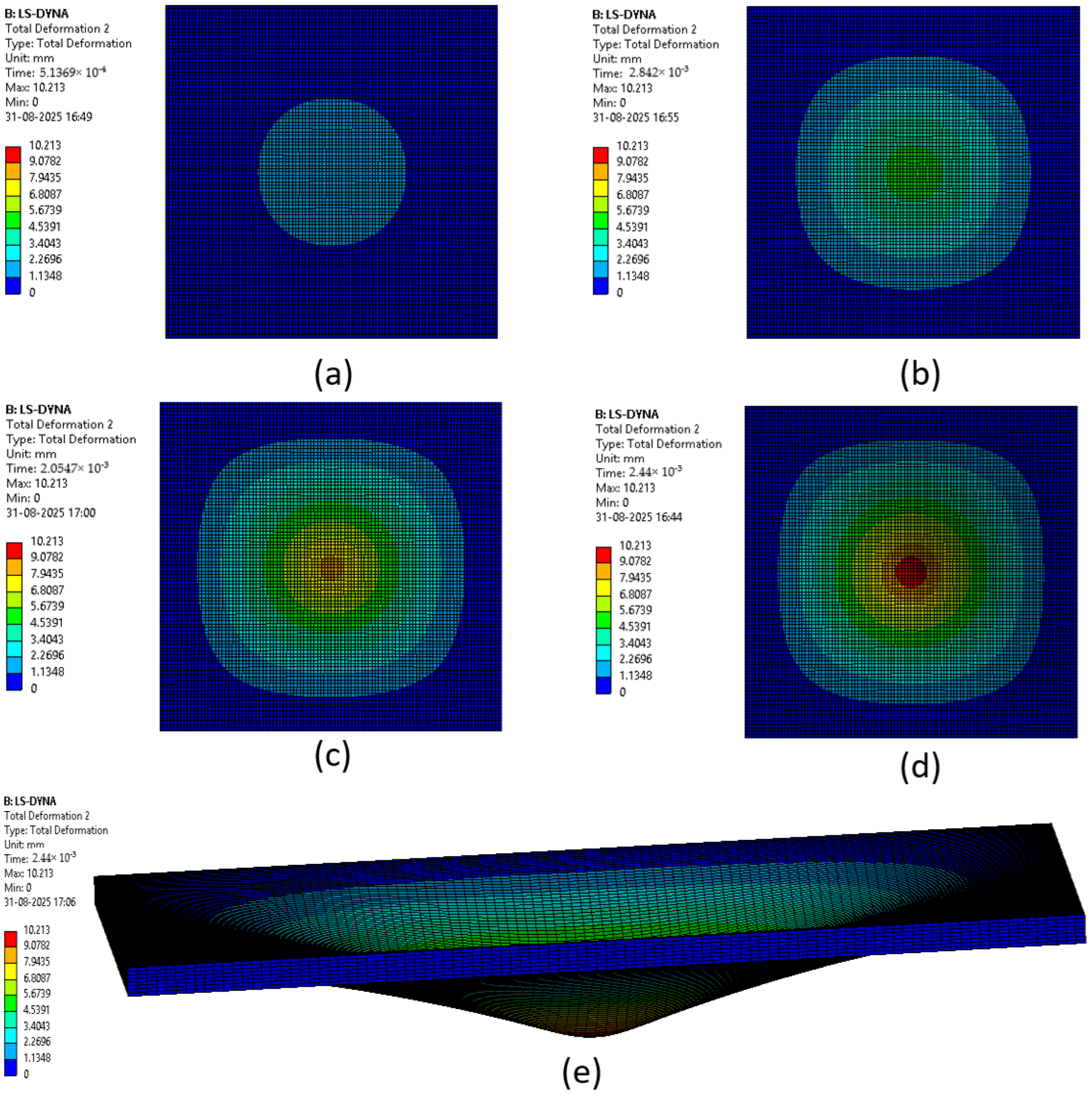

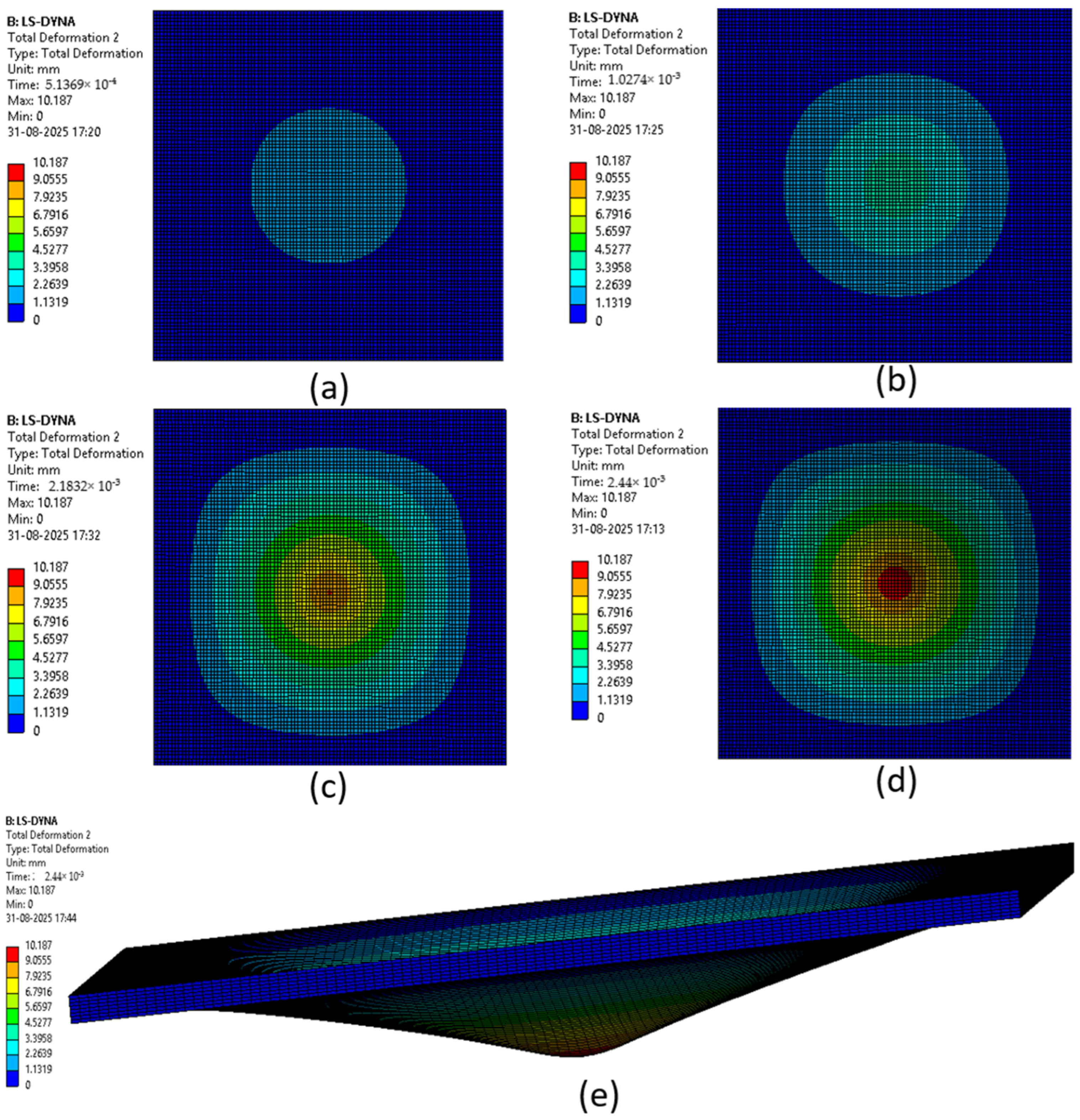

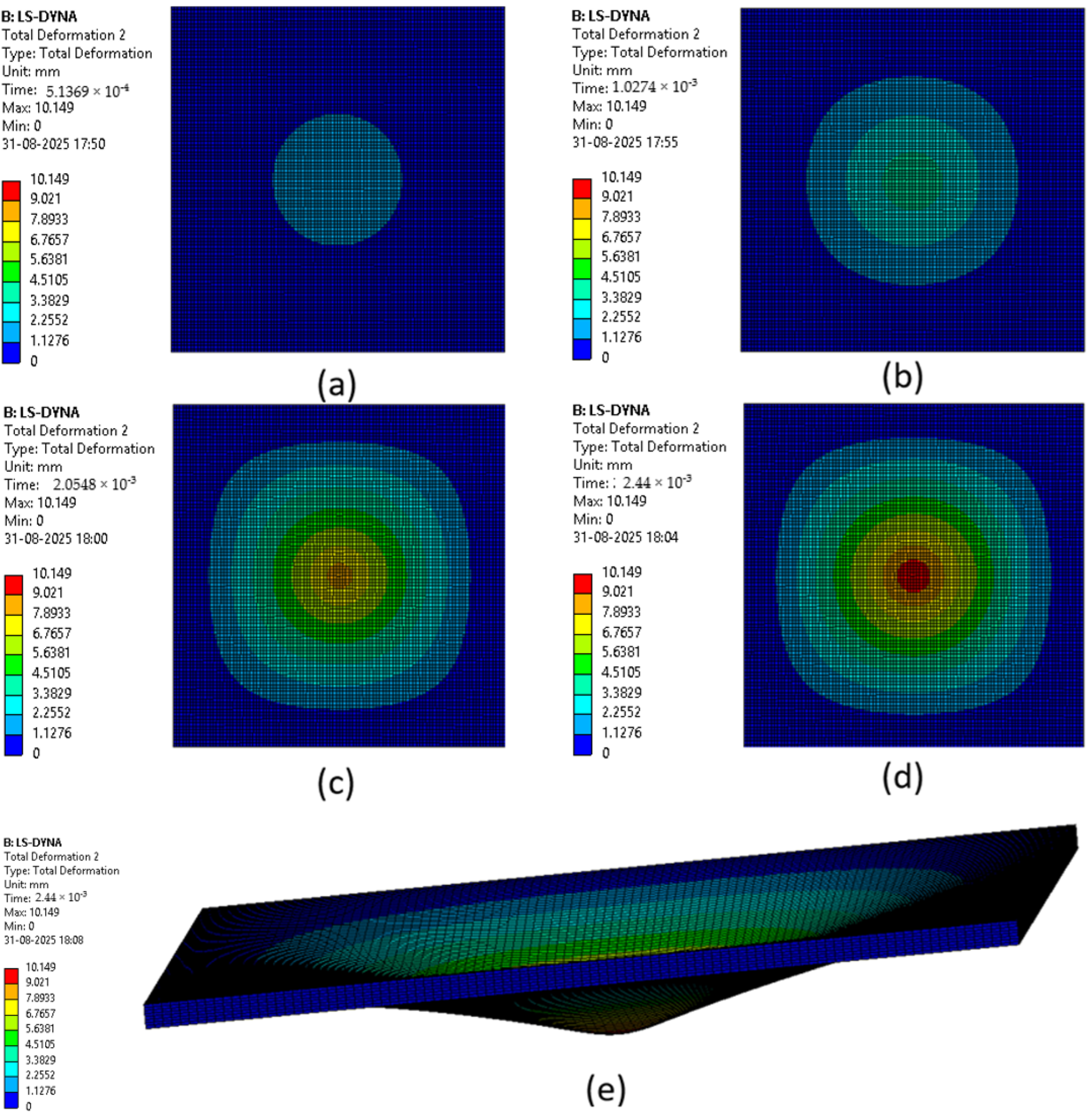

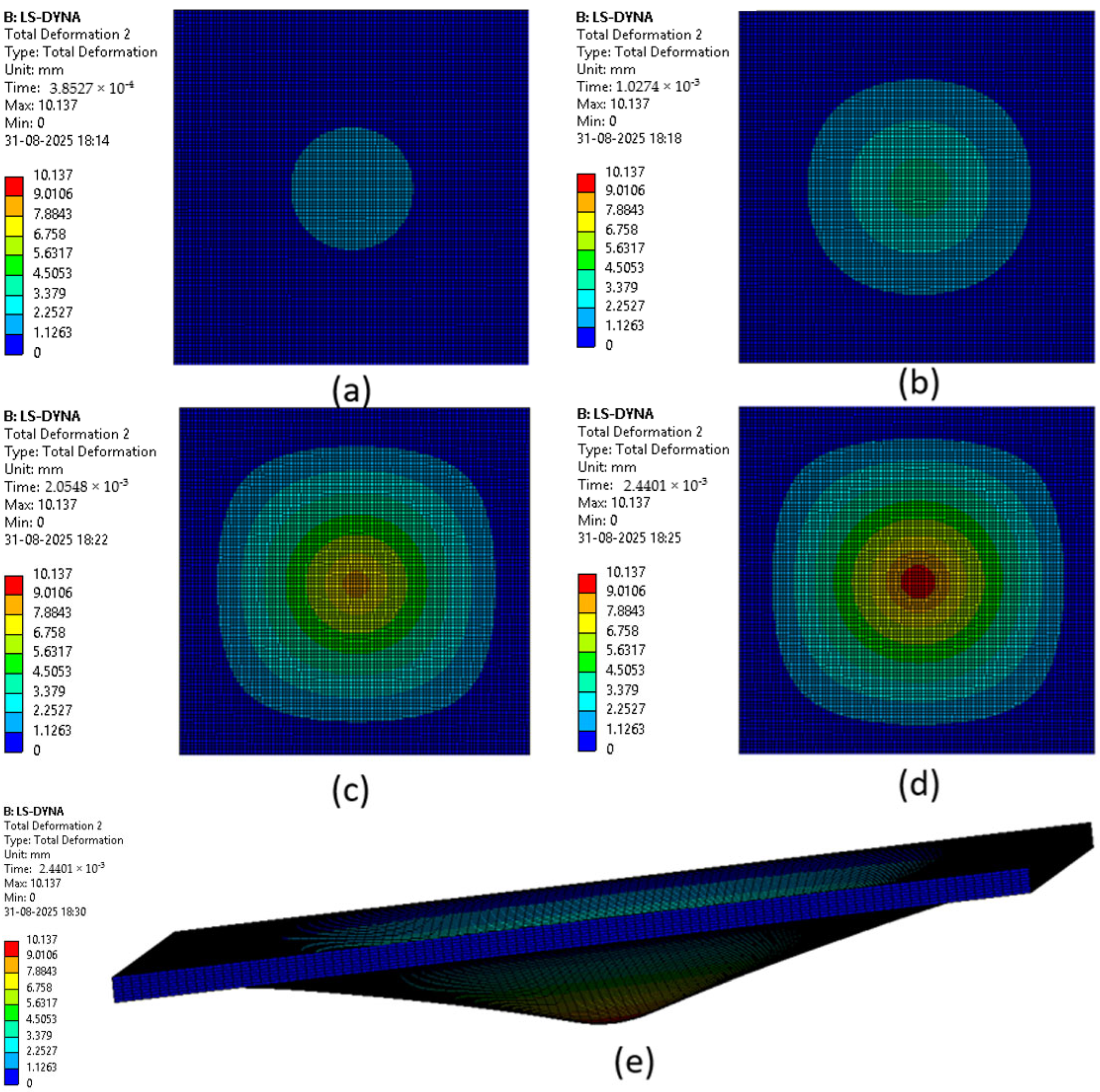

Based on the research gap evident from the available literature, the impact performance of laminated hybrid composites was the focus of this investigation. In this study, the behavior of hybrid polymer composites made from glass fiber and natural fiber-based flax fabric, when subjected to low velocity drop-weight impacts. The effect of the low velocity impact might not be apparent as the energy would be transmitted through the material, leading to the formation of minute cracks or deformations which over time could grow in size and affect the structural integrity of the part, and ultimately to a catastrophic failure of the component. In this work, tests have been conducted to determine the maximum force which the composite can withstand before experiencing a failure. The experimental tests were carried out according to ASTM standards with a drop-weight impact testing machine. Simulations were done to replicate the same using explicit finite element software LS-DYNA version R14.1.0. The results obtained from the experimental tests were compared with the simulated results in order to determine the error of prediction. Additionally, composite laminates lined with a layer of EPS (expanded polystyrene) foam were tested and compared with composite laminates which were not lined with the foam. An improvement in the performance of the composite laminates lined with the EPS foam was expected.

4. Conclusions

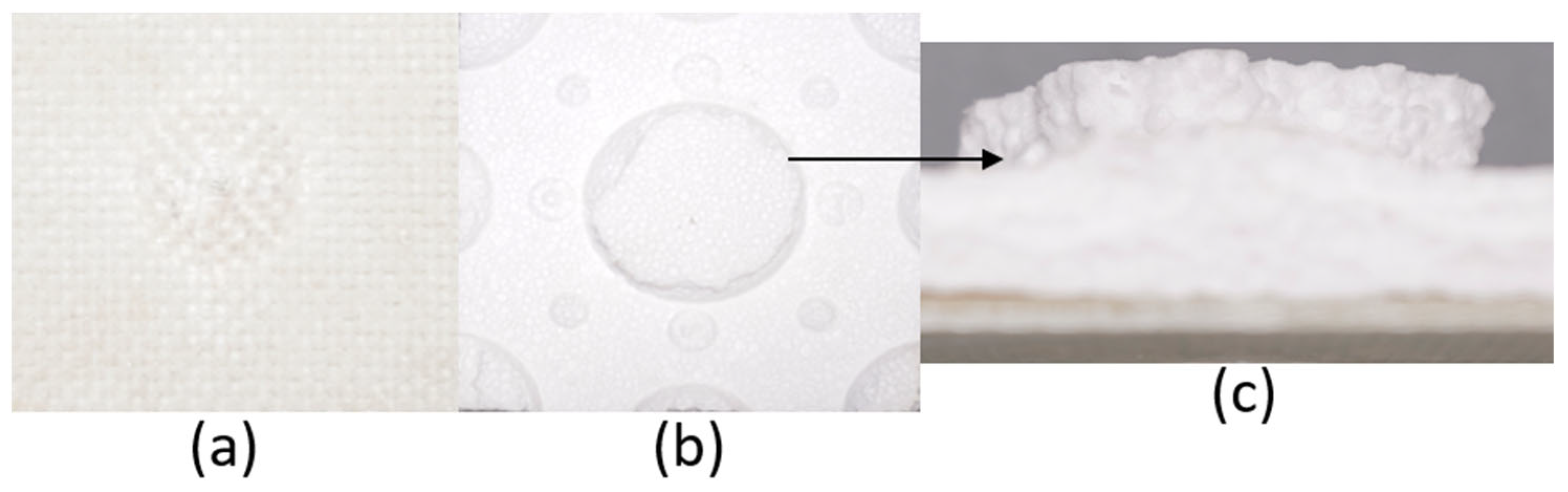

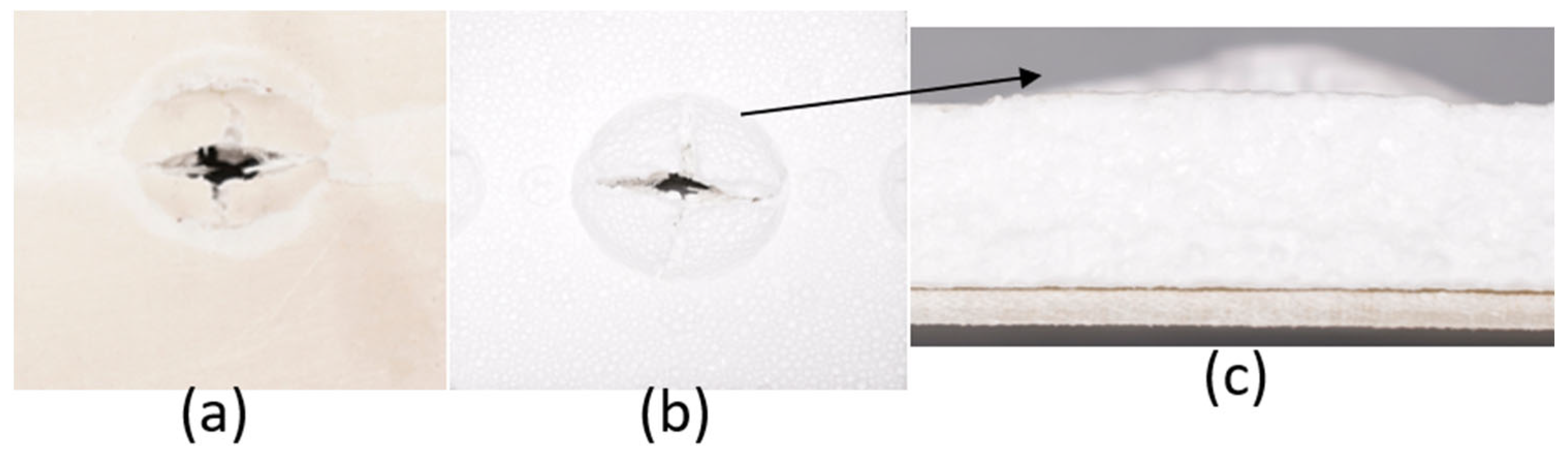

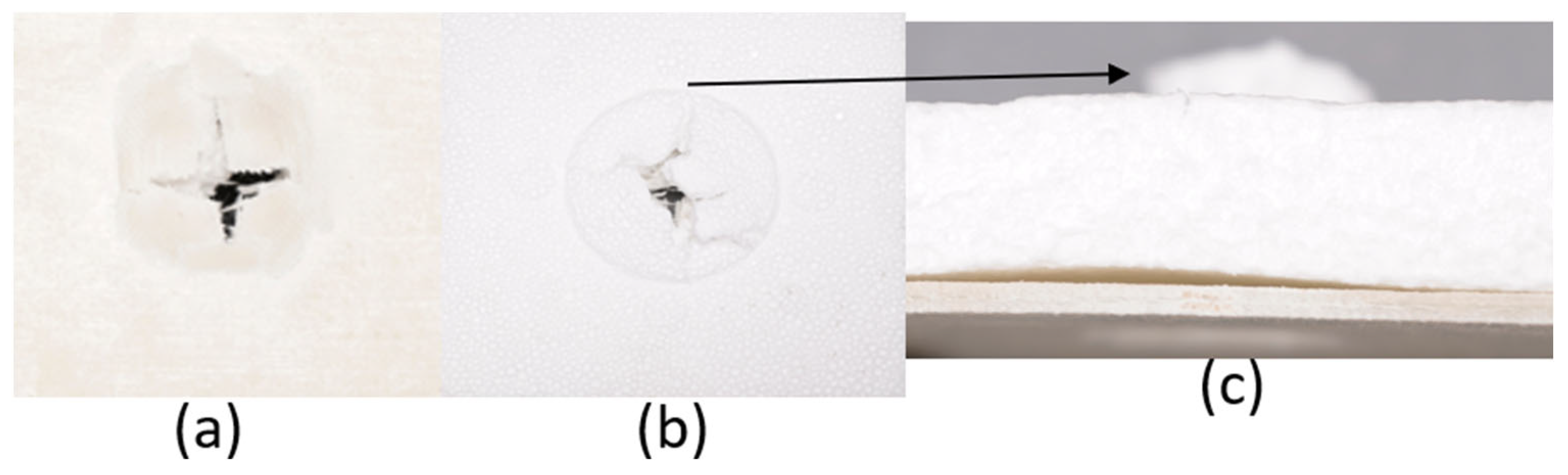

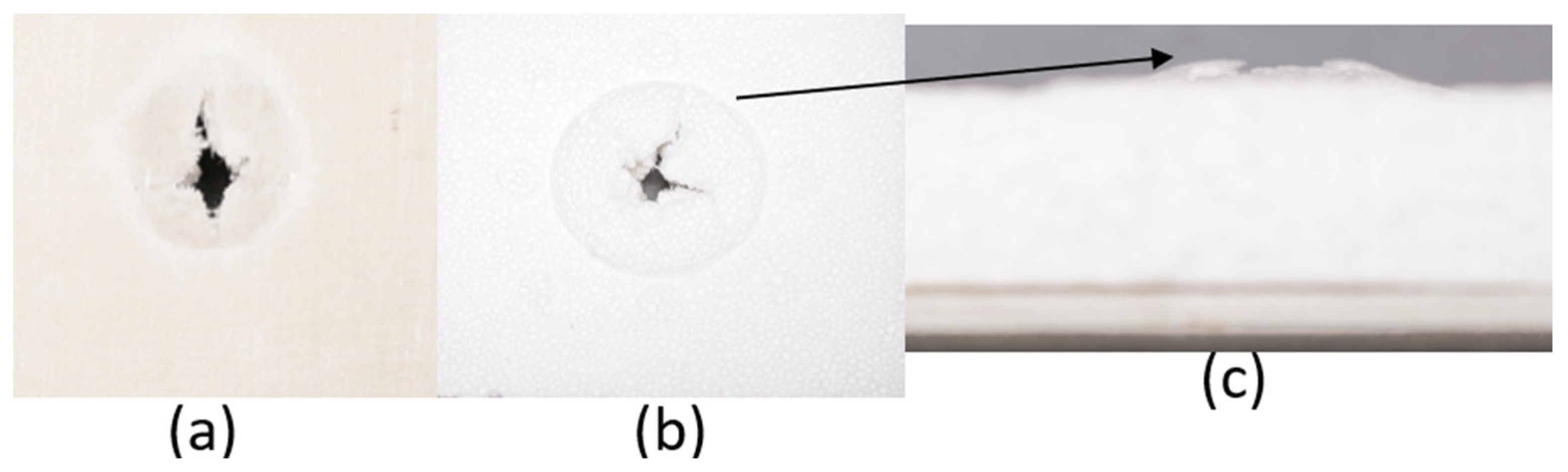

Numerous studies have been performed on the effect of low impact on composites made from glass or carbon fiber. In this study, pure laminates made from glass and flax fabrics, along with hybrid composites made using a combination of flax fabrics and glass fabrics, lined with EPS foam and not lined with EPS foam were tested at room temperature. The results obtained by testing the composite laminates not lined with EPS foam were compared with simulated results obtained from simulating the composite laminates not lined with EPS foam.

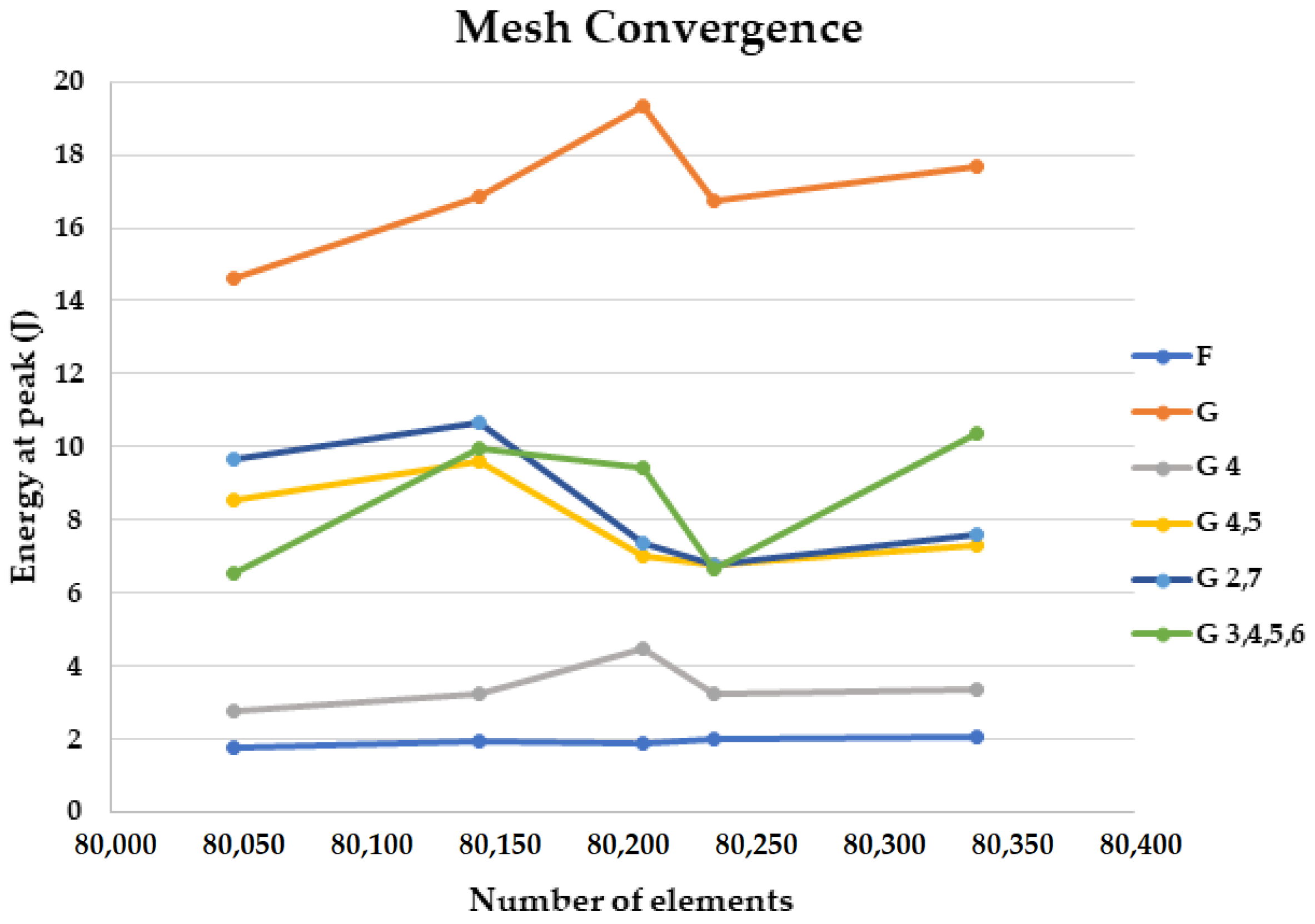

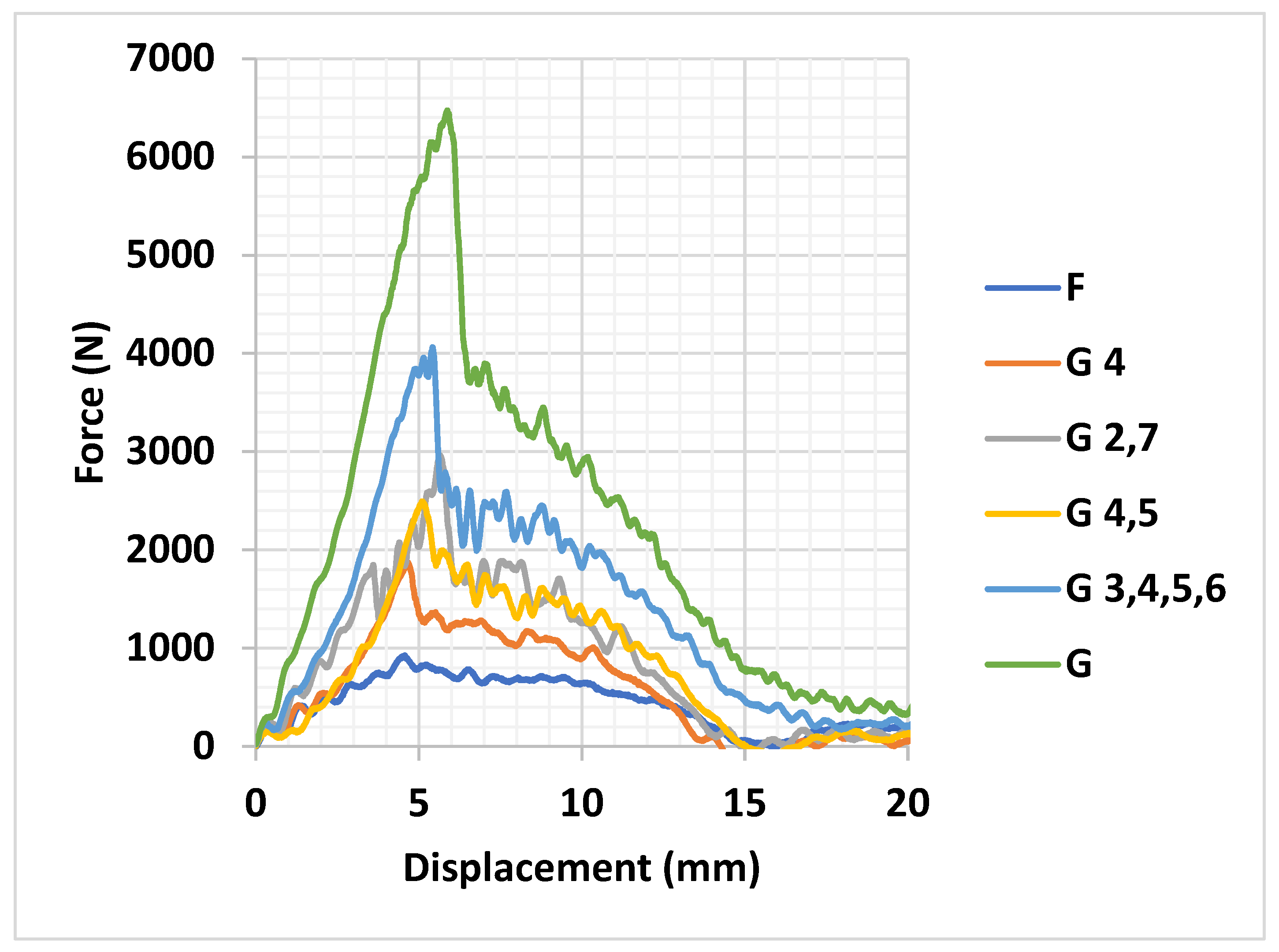

Upon comparing the results of laminates lined with EPS foam and laminates not lined with EPS foam, it can be seen clearly that the energy at peak for the laminates lined with EPS foam is higher. This is because the energy applied to the laminate is transferred through the various layers of the composite and then to the layer of foam, and the foam absorbs the energy applied to a certain degree. From

Table 7, it can be clearly seen that by applying a lining of foam to the laminate which absorbed the least amount of energy (Sample1: F), the amount of energy absorbed by the laminate has increased by a percentage of 82.95. When we shine a light onto the percentage increase in the displacement at peak, it can be observed that the displacements at peak endured by the composite laminates lined with EPS foam are significantly higher than displacements at peak for the composite laminates not lined with EPS foam. This increase in displacement at peak also lends a hand in corroborating that applying a lining of EPS foam on the composite laminates helps in increasing the energy absorbed at peak. This is again reinforced when we examine the energy at puncture values for both the laminate sets. A clear increase in the energy at puncture values for the laminates lined with EPS foam is shown when compared with the values obtained for the laminates not lined with EPS foam. When we compare the values obtained in

Table 3 and

Table 4, we see that the samples containing glass fibers show a decrease in the peak force; this can be attributed to the fact that foam can reduce the contact stiffness, and upon impact the instantaneous peak force is lower as the foam gets crushed and dissipates the energy leading to higher absorption of energy up to the point of puncture. Thus, it can be said that by applying a lining of foam on the composite laminates, the amount of energy absorbed by the laminates can be increased, which would prove to be beneficial when used as a structural component.

All the results obtained for the composite laminates not lined with EPS foam and laminates lined with EPS foam from experimental test and simulations pointed towards one observation, that the energy at peak, displacement at peak, force at peak and energy at puncture increased as the number of layers of glass fabric increased. This increase can be attributed to the fact that the strength of the glass fiber is inherently greater than that of the flax fiber. Thus, it can be concluded that the increase in the number of glass fabric layers leads to improved mechanical performance of the composite laminates. Apart from this, we can also observe that the effect of the stacking sequence also plays a role. It is evident from the results obtained that the samples which have two layers of glass fabrics achieve almost similar results to the sample containing four layers of glass. The effect of the stacking of glass fabrics in different positions can be studied further. This also shows that if we study the effect of the stacking, we can achieve the desired levels of mechanical properties while utilizing lower number of glass layers, thus playing into the fact that we are trying to make the composites more environmentally friendly.

Since the multilayered samples used in this research were specially designed with a combination of eight layers of flax and glass fabrics in different stacking sequences, no comparable data could be found from existing publications. When the results obtained via simulations were compared with the tested results, it was be seen that the error in deformation varies between 3.32% to 10.73% and the error in the force at peak varies from 0.06% to 17.14%. This variation in the values between the tested and simulated samples may be a result of boundary condition and loading configuration applied during simulations, which could affect the distribution of force and the contact time. On the other hand, the of presence of voids in the composite laminates, the variation of the diameter of the natural fibers used, and their morphology may also contribute to the variations in the results which have been observed.

It is necessary to consider the design aspects (e.g., dimension, shape, curvature, geometry, location and joining elements) while designing such composites in specific machine elements in automotives (e.g., bumper, spring, battery box, storage cabinet or other interior components).