Effect of Heat Treatment on Microstructures and Mechanical Properties of TC4 Alloys Prepared by Selective Laser Melting

Abstract

1. Introduction

2. Experimental Section

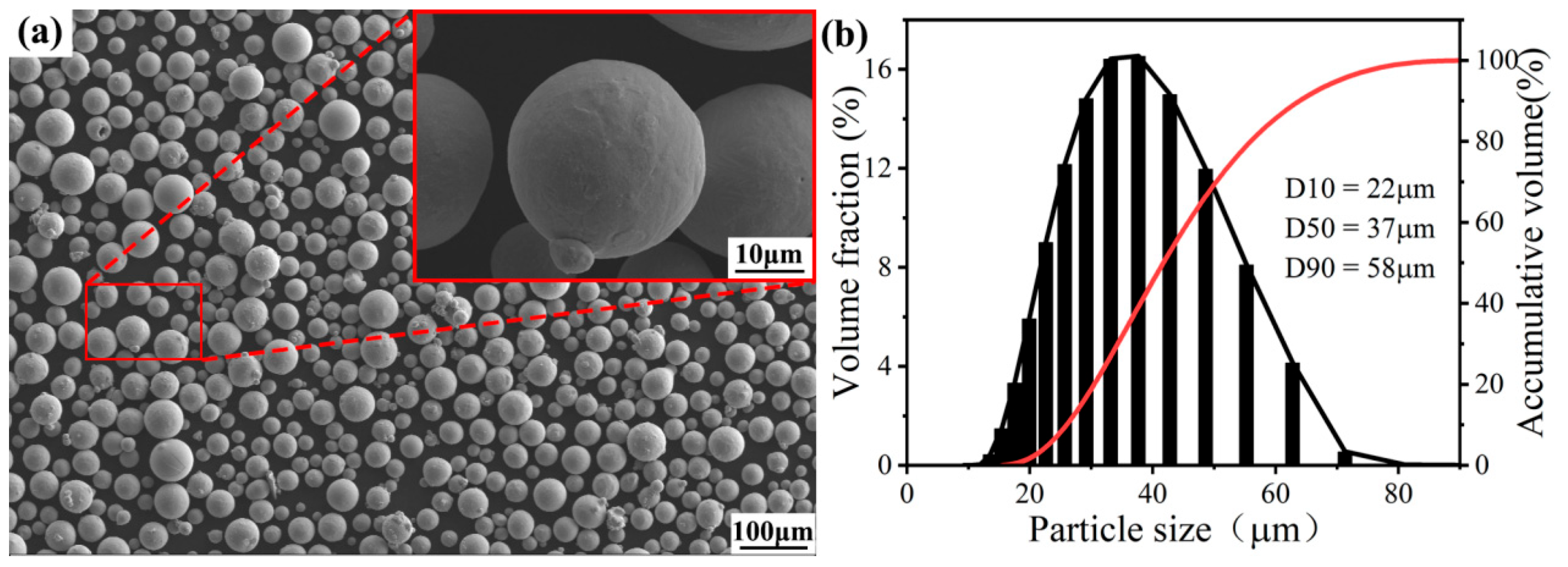

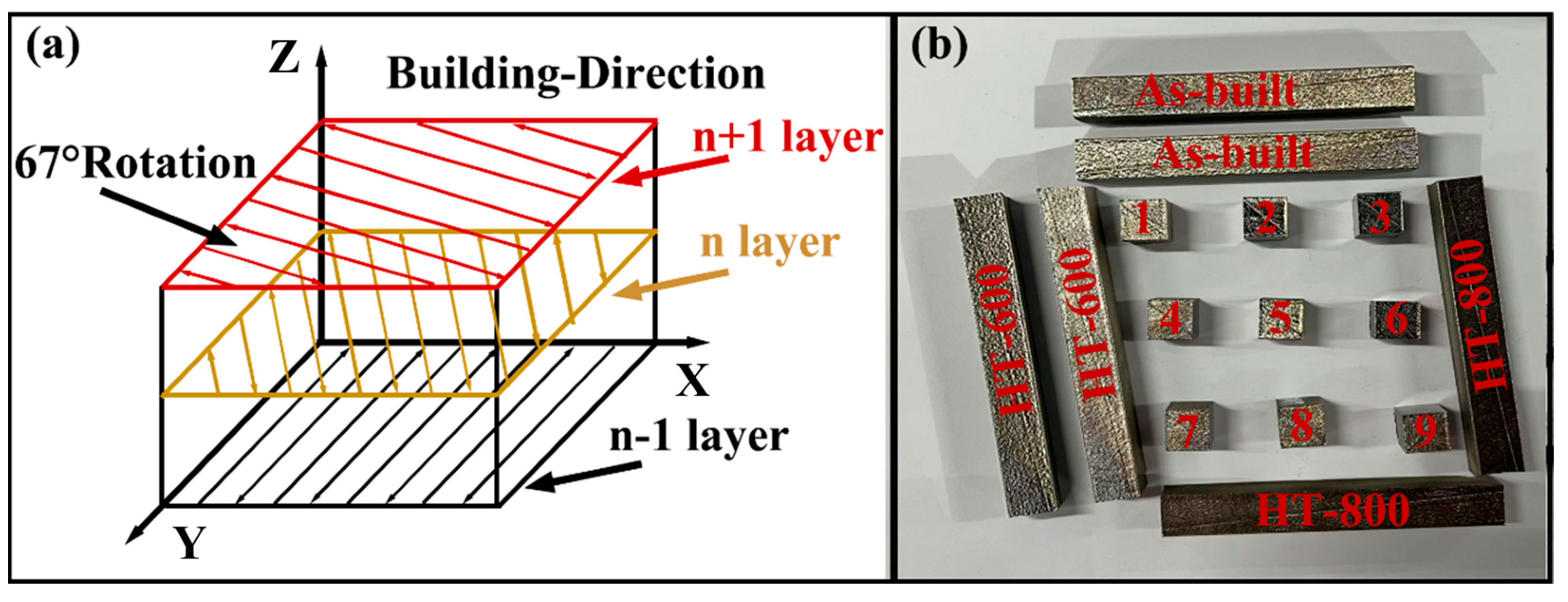

2.1. Materials and Processing

2.2. Heat Treatment Processes

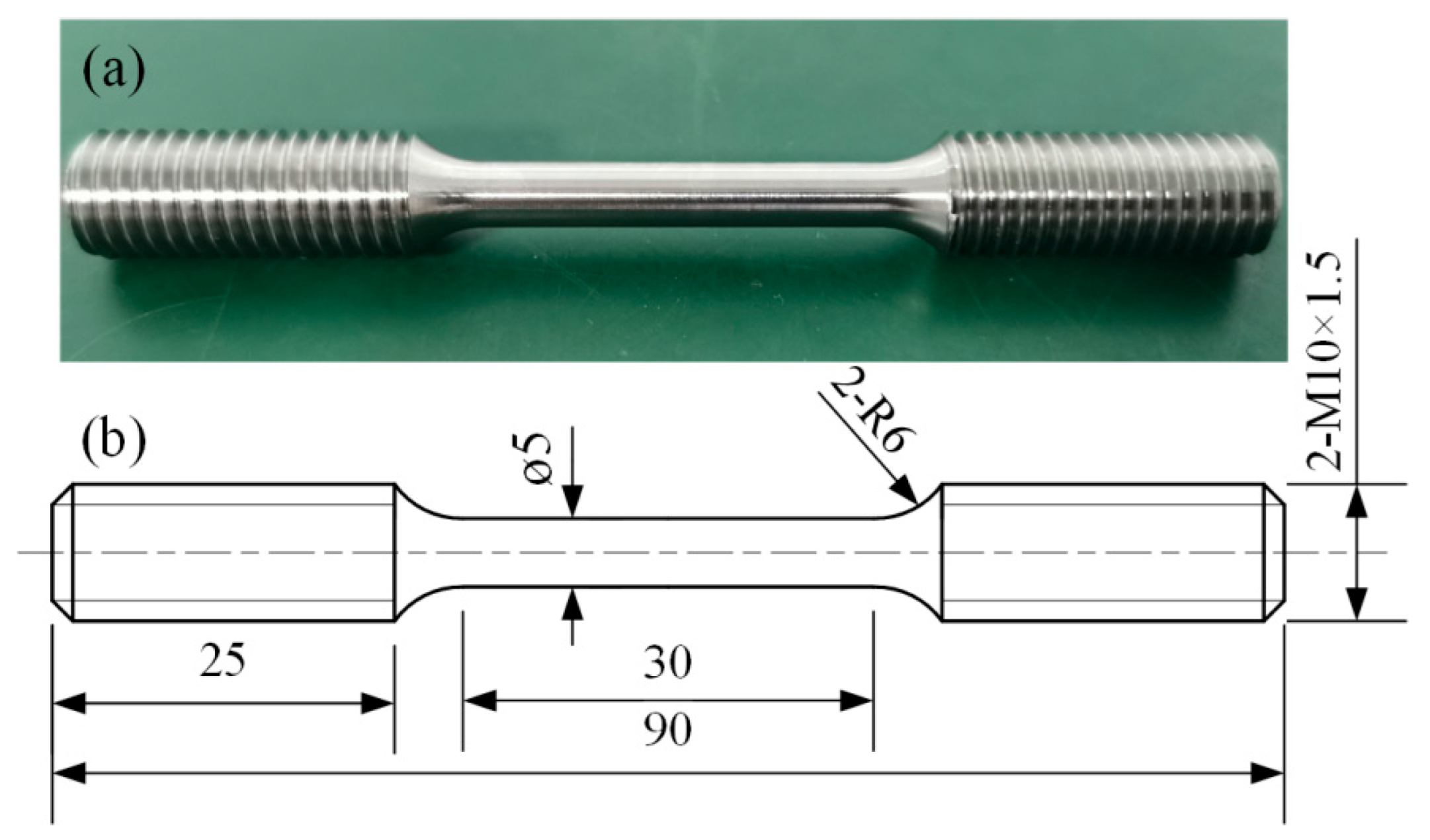

2.3. Microstructure Characterization and Mechanical Test

3. Results and Discussion

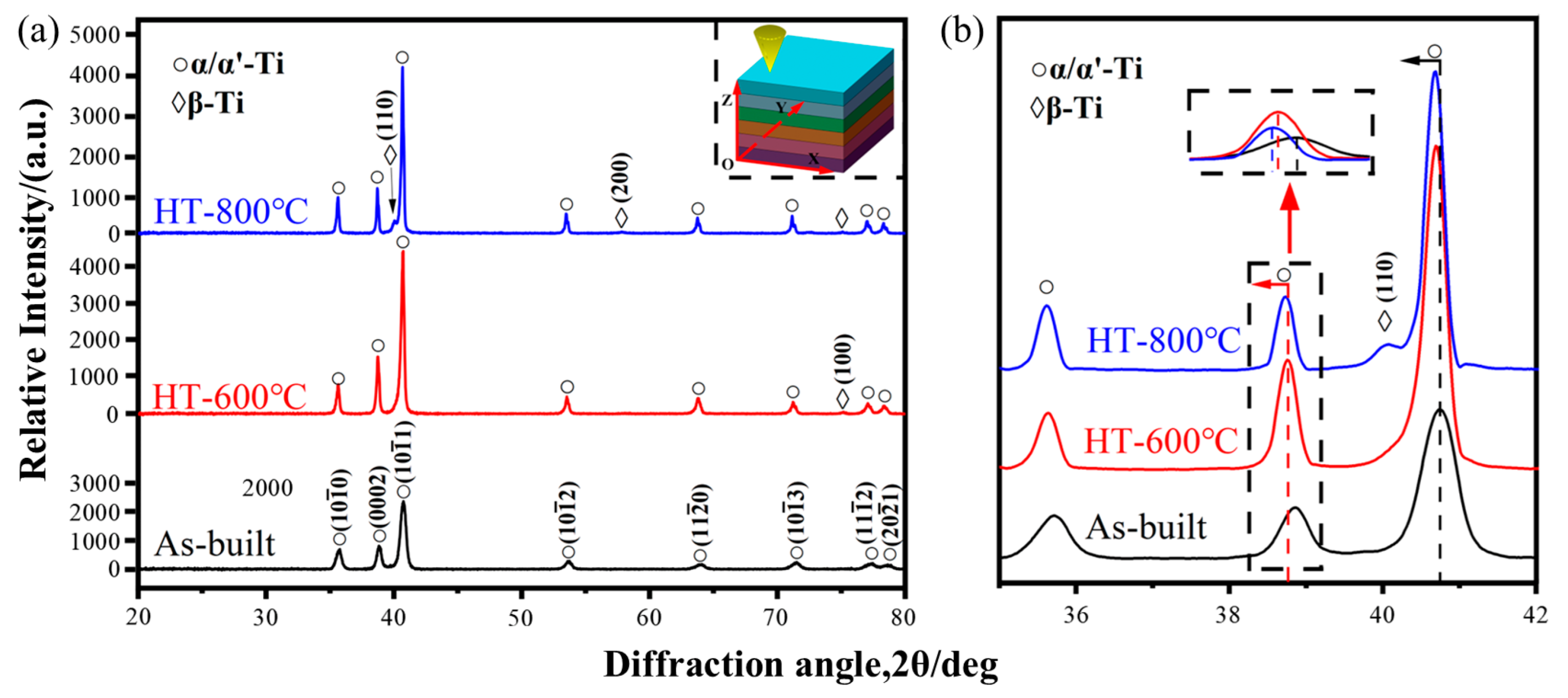

3.1. Phase Analysis

3.2. Microstructures

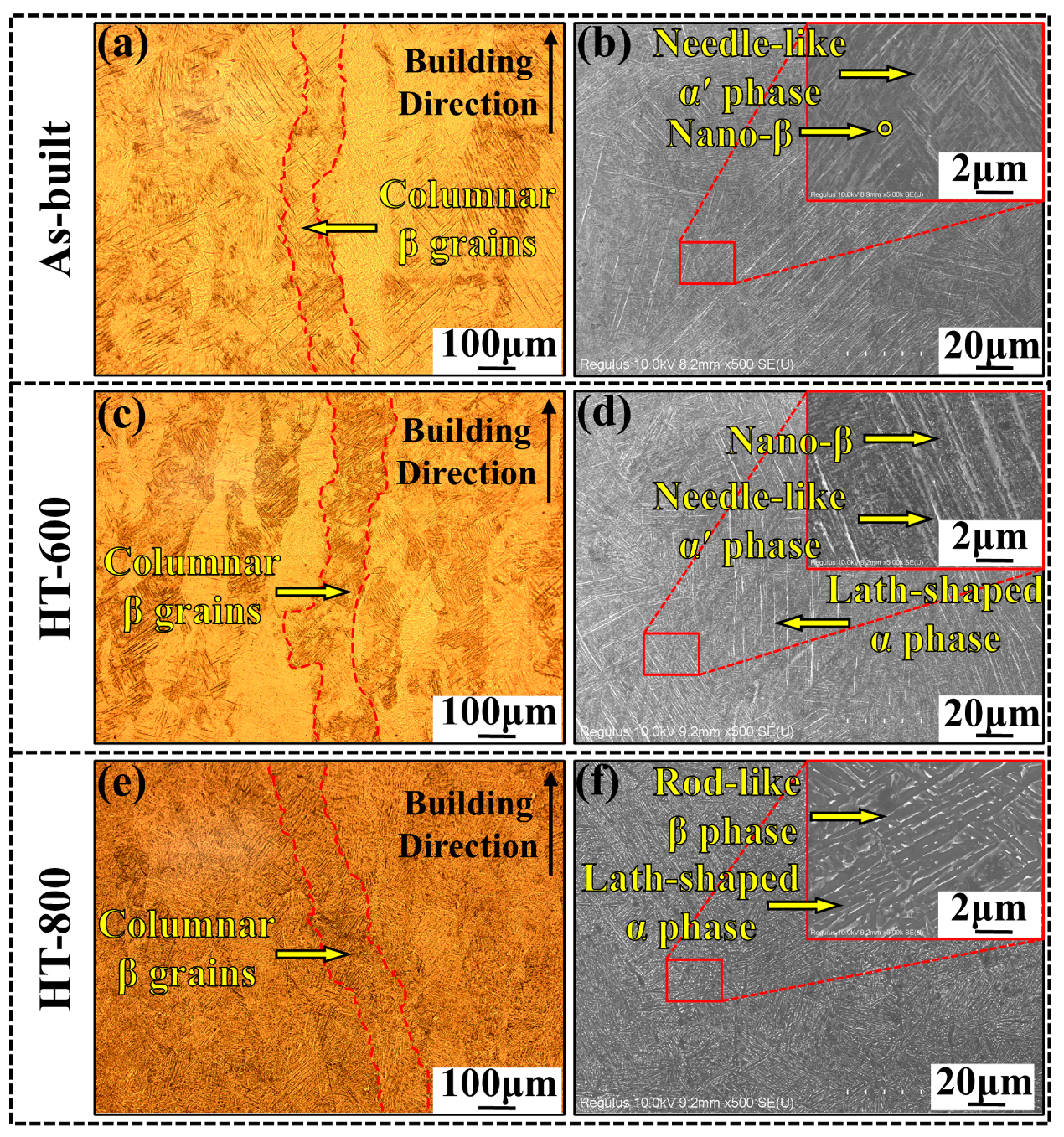

3.2.1. Microstructural Morphology

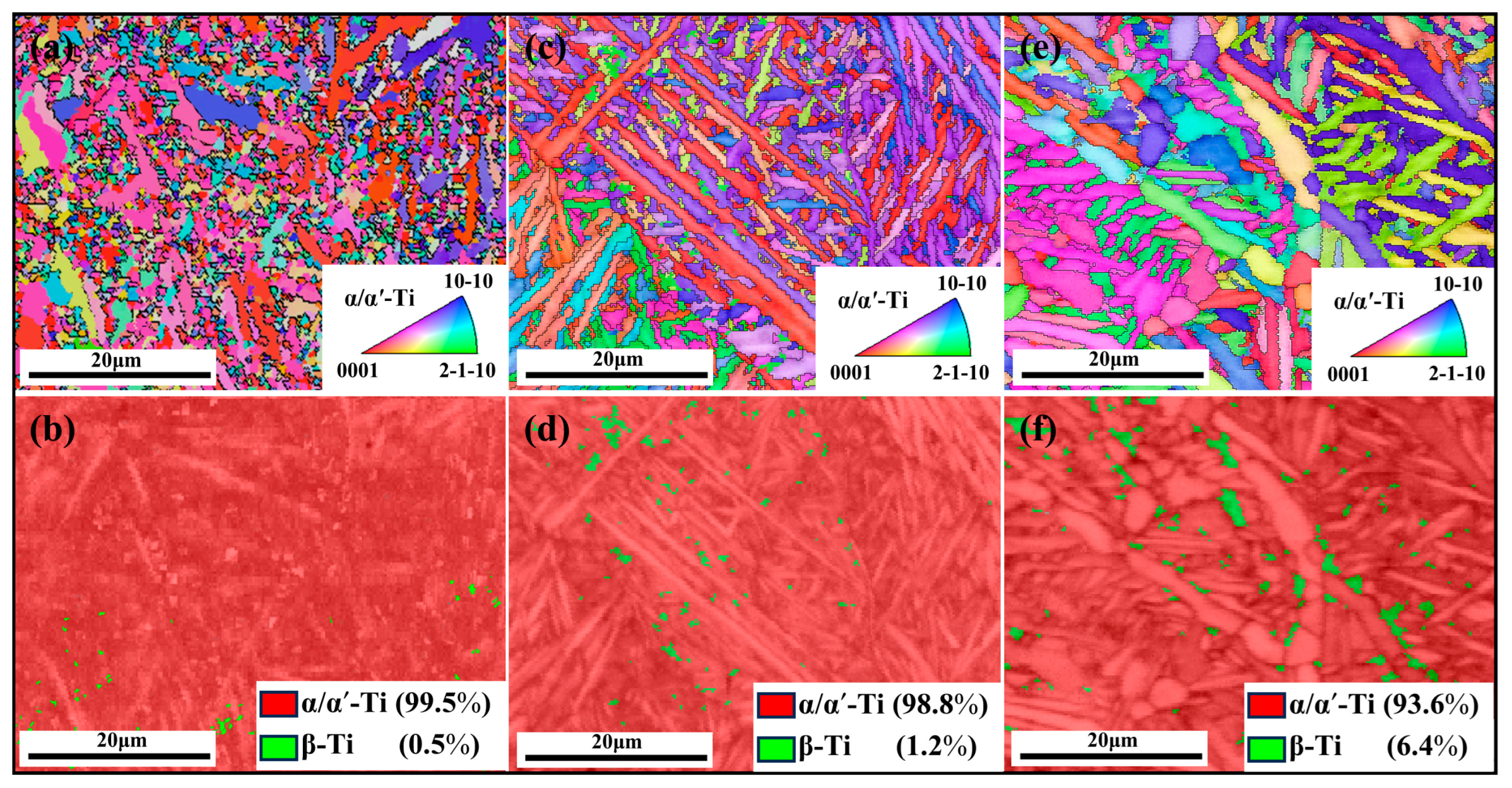

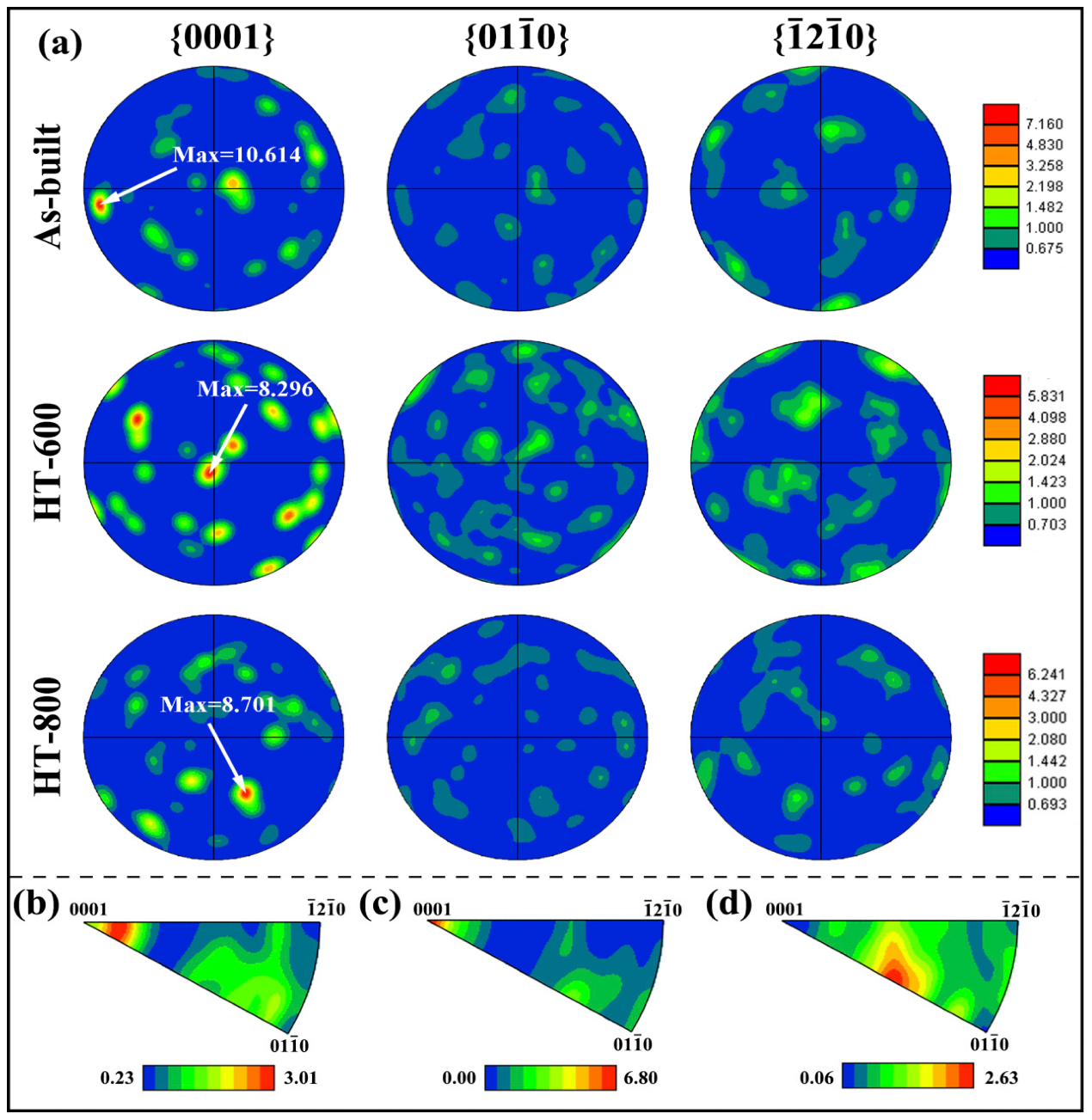

3.2.2. Grain Orientation and Distribution

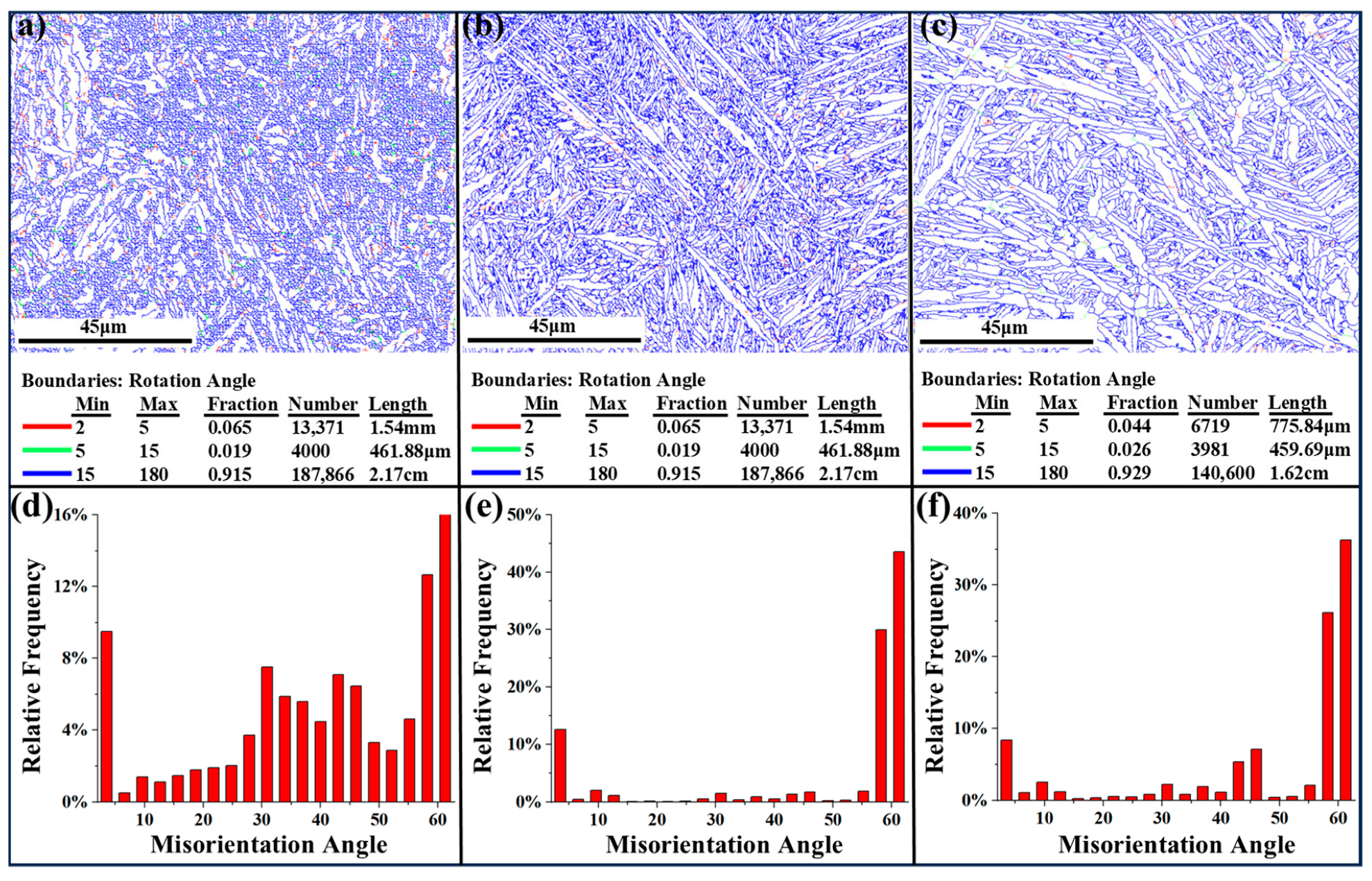

3.2.3. Grain Boundary Distribution and Dislocation Density

3.3. Mechanical Properties

3.3.1. Microhardness

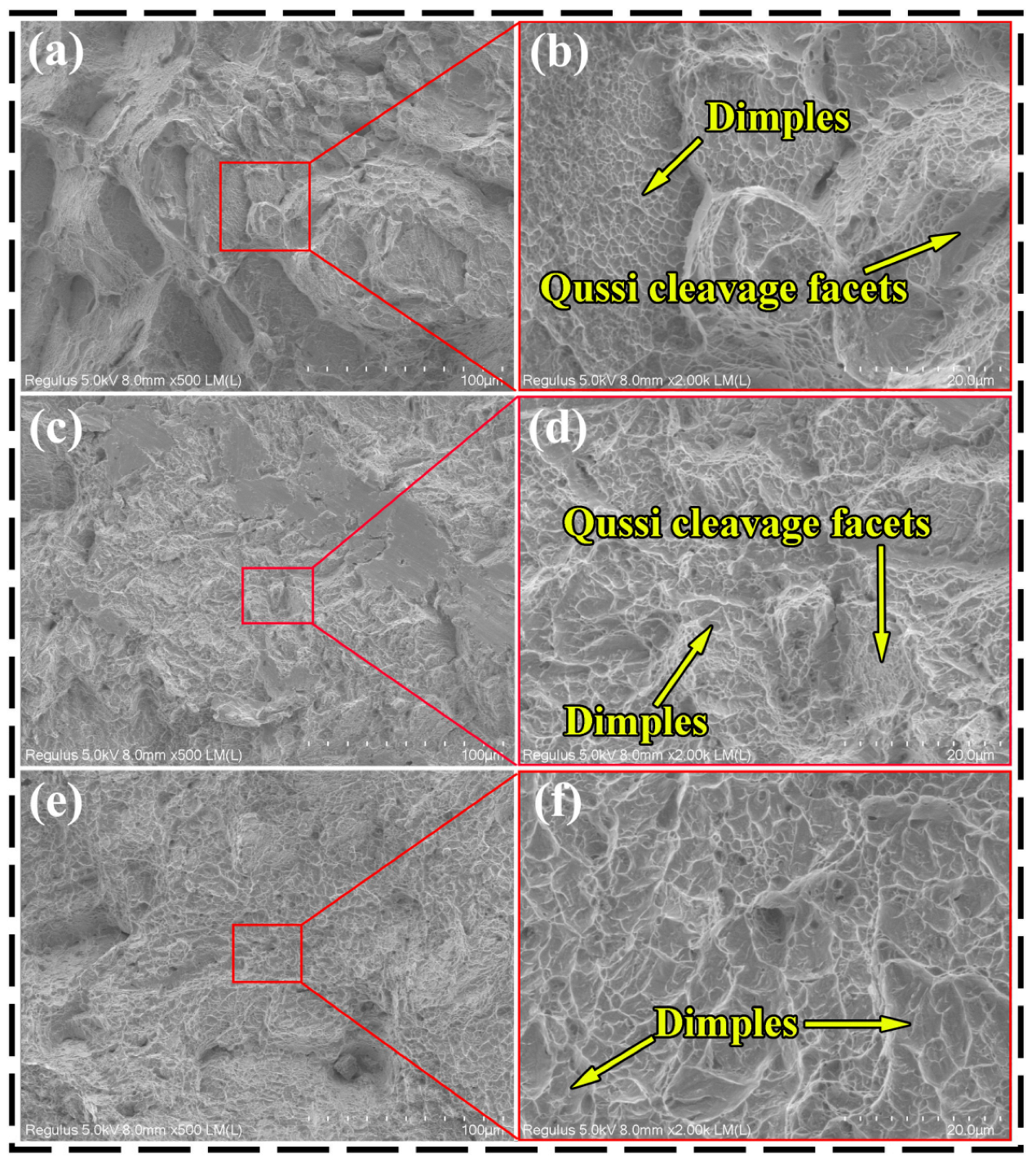

3.3.2. Tensile Property and Fracture Mechanism

4. Conclusions

- (1)

- Microstructure control mechanism: The SLM microstructure of TC4 is mainly needle-like α′ martensite, with a small amount of nano-β phase (volume fraction 0.5%) distributed at the boundary, and the texture is mainly <0001>. The decomposition of the α′ phase part into lath-shaped α and nano-β phases and an increase in the β phase content are triggered by annealing at 600 °C. After heat treatment at 800 °C (above the α′ decomposition temperature of 760 °C), the brittle α′ phase almost completely transforms into stable lath-shaped α and short rod-like β phases. Meanwhile, the volume fraction of the β phase increases to 6.4%. The texture shifts towards the <01-10> direction, where the slip system is more active, achieving the regulation of the microstructure from being brittle-dominant to being tough-dominant.

- (2)

- Performance optimization rule: The tensile strength of the SLM-formed TC4 reaches 1381 MPa, but the elongation is only 5.22%. After heat treatment at 600 °C, the performance changes are relatively small, and the fracture is still mainly a mixture of brittleness and toughness. After heat treatment at 800 °C, the strength decreased by 18% (to 1027 MPa), but the elongation increased to 11.43%, achieving a balance between strength and plasticity. It meets the requirements of grade F-5 in ASTM B381-13 (R2019) standard. The fracture mechanism is transformed into a ductile fracture. This optimization stems from the synergistic effects of the α′ → α + β phase transition in reducing brittle phases, β phase toughening, and texture optimization.

- (3)

- Engineering guidance value: This study clarifies the quantitative influence of heat treatment temperature on the microstructure and properties of SLM-fabricated TC4. Meanwhile, it is proposed that the performance could be further optimized by regulating the holding temperature (such as optimizing the β phase content at 800 °C) and the cooling rate (refining the α/β phase distribution). A basis is provided for heat treatment process design for applications in load-bearing components in aerospace and other fields. However, the heat treatment temperature range of this study is limited (it does not cover higher temperatures or more temperature values). Additionally, the performance is only evaluated through “horizontal” stretched parts (with the length direction perpendicular to the forming direction), without a comprehensive analysis of the tensile performance in different directions. There are certain limitations. In the future, systematic research will be carried out on the above aspects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Song, C.; Wang, A.; Wu, Z.; Chen, Z.; Yang, Y.; Wang, D. The design and manufacturing of a titanium alloy beak for Grus japonensis using additive manufacturing. Mater. Des. 2017, 117, 410–416. [Google Scholar] [CrossRef]

- Yang, L.; Zhicong, P.; Ming, L.; Yonggang, W.; Di, W.; Changhui, S.; Shuxin, L. Investigation into the dynamic mechanical properties of selective laser melted Ti-6Al-4V alloy at high strain rate tensile loading. Mater. Sci. Eng. A 2019, 745, 440–449. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, D.; Su, S.; Chen, A. Experimental study of effect of post processing on fracture toughness and fatigue crack growth performance of selective laser melting Ti-6Al-4V. Chin. J. Aeronaut. 2019, 32, 2383–2393. [Google Scholar] [CrossRef]

- Ming, W.; Chen, J.; An, Q.; Chen, M. Dynamic mechanical properties and machinability characteristics of selective laser melted and forged Ti6Al4V. J. Mech. Work. Technol. 2019, 271, 284–292. [Google Scholar] [CrossRef]

- Chang, K.; Liang, E.; Huang, W.; Zhang, X.; Chen, Y.; Dong, J.; Zhang, R. Microstructural feature and mechanical property in different building directions of additive manufactured Ti6Al4V alloy. Mater. Lett. 2020, 267, 127516. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Mechanical properties of a Ti6Al4V porous structure produced by selective laser melting. Mater. Des. 2013, 49, 545–552. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Li, C.-L.; Hong, J.-K.; Narayana, P.L.; Choi, S.-W.; Lee, S.W.; Park, C.H.; Yeom, J.-T.; Mei, Q. Realizing superior ductility of selective laser melted Ti-6Al-4V through a multi-step heat treatment. Mater. Sci. Eng. A 2021, 799, 140367. [Google Scholar] [CrossRef]

- Zhang, X.-Y.; Fang, G.; Leeflang, S.; Böttger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloys Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Sun, Q.-D.; Sun, J.; Guo, K.; Waqar, S.; Liu, J.-W.; Wang, L.-S. Influences of processing parameters and heat treatment on microstructure and mechanical behavior of Ti-6Al-4V fabricated using selective laser melting. Adv. Manuf. 2022, 10, 520–540. [Google Scholar] [CrossRef]

- Grell, W.; Solis-Ramos, E.; Clark, E.; Lucon, E.; Garboczi, E.; Predecki, P.; Loftus, Z.; Kumosa, M. Effect of powder oxidation on the impact toughness of electron beam melting Ti-6Al-4V. Addit. Manuf. 2017, 17, 123–134. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ren, J.; Xin, C.; Sang, B.; Chen, D.; Lu, X.; Zhang, L.; Zhang, Y. Charpy impact behaviors of metastable β-Ti alloys: Transformation induce plasticity versus twining induce plasticity. Mater. Sci. Eng. A 2023, 867, 144753. [Google Scholar] [CrossRef]

- Hrabe, N.; White, R.; Lucon, E. Effects of internal porosity and crystallographic texture on Charpy absorbed energy of electron beam melting titanium alloy (Ti-6Al-4V). Mater. Sci. Eng. A 2019, 742, 269–277. [Google Scholar] [CrossRef]

- Sharma, D.; Hiremath, S.S.; Kenchappa, N.B. Effect of heat treatment on the variable amplitude fatigue life and microstructure of the novel bioinspired Ti-6Al-4V thin tubes fabricated using Selective Laser Melting process. Fatigue Fract. Eng. Mater. Struct. 2022, 46, 975–986. [Google Scholar] [CrossRef]

- Wu, S.Q.; Lu, Y.J.; Gan, Y.L.; Huang, T.T.; Zhao, C.Q.; Lin, J.J.; Guo, S.; Lin, J.X. Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; Humbeeck, J.V. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Gerrit, M.; Ter, H.; Thorsten, H.B. Selective Laser Melting Produced Ti-6Al-4V: Post-Process Heat Treatments to Achieve Superior Tensile Properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef]

- Ju, J.; Li, J.; Yang, C.; Wang, K.; Kang, M.; Wang, J. Evolution of the microstructure and optimization of the tensile properties of the Ti–6Al–4V alloy by selective laser melting and heat treatment. Mater. Sci. Eng. A 2021, 802, 140673. [Google Scholar] [CrossRef]

- Seo, Y.; Woo, S.-C.; Kim, T.-W.; Lee, Y.-S. Influence of heat treated microstructures on the dynamic deformation characteristics of Ti-6Al-4V alloy. J. Mech. Sci. Technol. 2015, 29, 5223–5232. [Google Scholar] [CrossRef]

- Funch, C.V.; Palmas, A.; Somlo, K.; Valente, E.H.; Cheng, X.; Poulios, K.; Villa, M.; Somers, M.A.; Christiansen, T.L. Targeted heat treatment of additively manufactured Ti-6Al-4V for controlled formation of Bi-lamellar microstructures. J. Mater. Sci. Technol. 2021, 81, 67–76. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Peng, B.; Wang, X.; Li, S.; Wang, Q.; Li, Z.; Wang, Y. Effect of heating treatment on the microstructural evolution and dynamic tensile properties of Ti-6Al-4V alloy produced by selective laser melting. J. Manuf. Process. 2022, 74, 244–255. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, J.; Liu, J.; Wang, J.; Niu, L.; Chen, Y. Effect of volume energy density on microstructure and mechanical properties of TC4 alloy by selective laser melting. J. Alloys Compd. 2023, 968, 171769. [Google Scholar] [CrossRef]

- Liang, Z.; Sun, Z.; Zhang, W.; Wu, S.; Chang, H. The effect of heat treatment on microstructure evolution and tensile properties of selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2019, 782, 1041–1048. [Google Scholar] [CrossRef]

- Lu, W.; Shi, Y.; Lei, Y.; Li, X. Effect of electron beam welding on the microstructures and mechanical properties of thick TC4-DT alloy. Mater. Des. 2012, 34, 509–515. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- Yu, H.; Li, W.; Li, S.; Zou, H.; Zhai, T.; Liu, L. Study on Transformation Mechanism and Kinetics of α′ Martensite in TC4 Alloy Isothermal Aging Process. Crystals 2020, 10, 229. [Google Scholar] [CrossRef]

- Li, P.-H.; Guo, W.-G.; Huang, W.-D.; Su, Y.; Lin, X.; Yuan, K.-B. Thermomechanical response of 3D laser-deposited Ti–6Al–4V alloy over a wide range of strain rates and temperatures. Mater. Sci. Eng. A 2015, 647, 34–42. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wei, L.; He, S.; Cuiuri, D.; Li, H. Introduction of ternary alloying element in wire arc additive manufacturing of titanium aluminide intermetallic. Addit. Manuf. 2019, 27, 236–245. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Effect of heat treatment on microstructure and mechanical properties of the selective laser melting processed Ti-5Al-2.5Sn α titanium alloy. Mater. Sci. Eng. A 2018, 709, 301–311. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the Texture Formation of Selective Laser Melted Ti-6Al-4V. Met. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Shimagami, K.; Ito, T.; Toda, Y.; Yumoto, A.; Yamabe-Mitarai, Y. Effects of Zr and Si addition on high-temperature mechanical properties and microstructure in Ti-10Al-2Nb-based alloys. Mater. Sci. Eng. A 2019, 756, 46–53. [Google Scholar] [CrossRef]

- ASTM B381-13(R2019); Standard Specification for Titanium and Titanium Alloy Forgings. ASTM International: West Conshohocken, PA, USA, 2013.

| Elements | |||||||

|---|---|---|---|---|---|---|---|

| Al | V | Fe | C | N | H | O | Ti |

| 5.5–6.5 | 3.4–4.5 | ≤0.25 | ≤0.08 | ≤0.03 | ≤0.012 | ≤0.1 | Bal |

| Sample | Temperature (°C) | Time (h) | Cooling |

|---|---|---|---|

| As-built | None | None | None |

| HT-600 | 600 | 2 | FC |

| HT-800 | 800 | 2 | FC |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Shi, Y.; Shen, S.; Zhang, S.; Ding, H.; Pan, X. Effect of Heat Treatment on Microstructures and Mechanical Properties of TC4 Alloys Prepared by Selective Laser Melting. Materials 2025, 18, 4126. https://doi.org/10.3390/ma18174126

Zhang J, Shi Y, Shen S, Zhang S, Ding H, Pan X. Effect of Heat Treatment on Microstructures and Mechanical Properties of TC4 Alloys Prepared by Selective Laser Melting. Materials. 2025; 18(17):4126. https://doi.org/10.3390/ma18174126

Chicago/Turabian StyleZhang, Jian, Yuhuan Shi, Su Shen, Shengdong Zhang, Honghui Ding, and Xiaoming Pan. 2025. "Effect of Heat Treatment on Microstructures and Mechanical Properties of TC4 Alloys Prepared by Selective Laser Melting" Materials 18, no. 17: 4126. https://doi.org/10.3390/ma18174126

APA StyleZhang, J., Shi, Y., Shen, S., Zhang, S., Ding, H., & Pan, X. (2025). Effect of Heat Treatment on Microstructures and Mechanical Properties of TC4 Alloys Prepared by Selective Laser Melting. Materials, 18(17), 4126. https://doi.org/10.3390/ma18174126