Comparative Study on Mechanical Performance and Toughness of High-Performance Self-Compacting Concrete with Polypropylene and Basalt Fibres

Abstract

1. Introduction

2. Materials and Methods

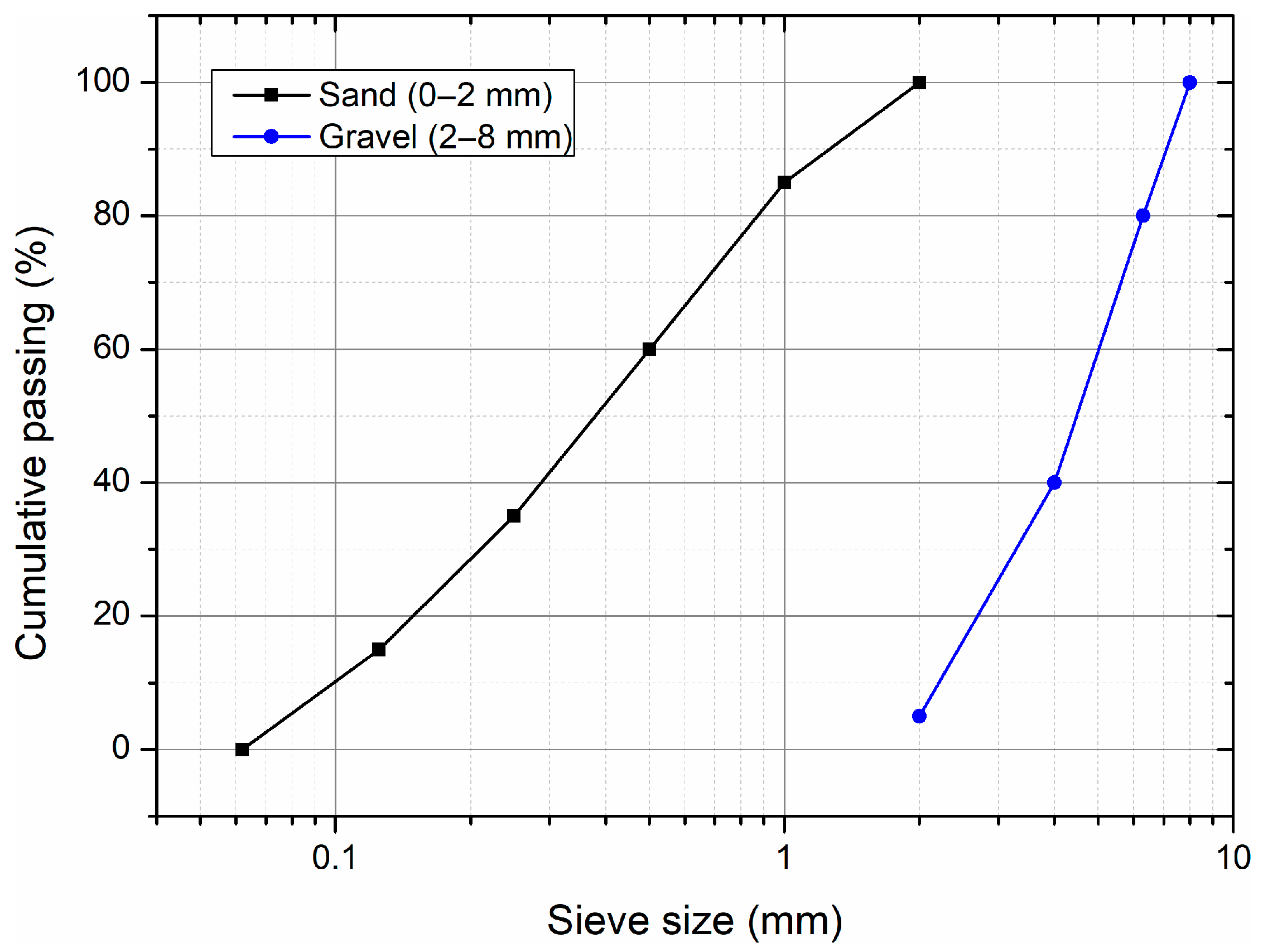

2.1. Materials

2.2. Mix Proportions

2.3. Mixing Procedure

2.4. Testing Procedure

3. Results

3.1. Properties of Fresh Mixes

3.2. Compressive Strength

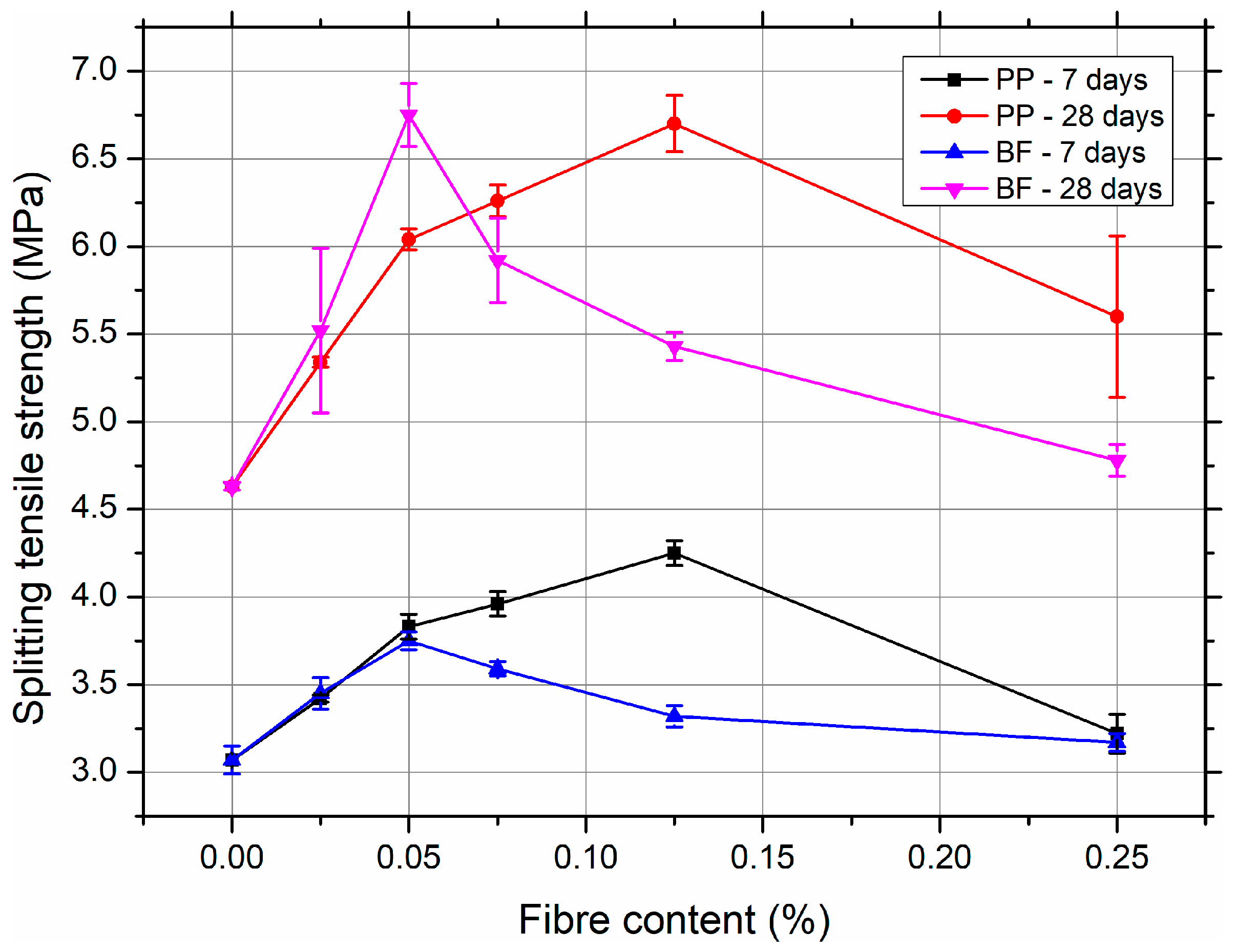

3.3. Splitting Tensile Strength

3.4. Flexural Strength

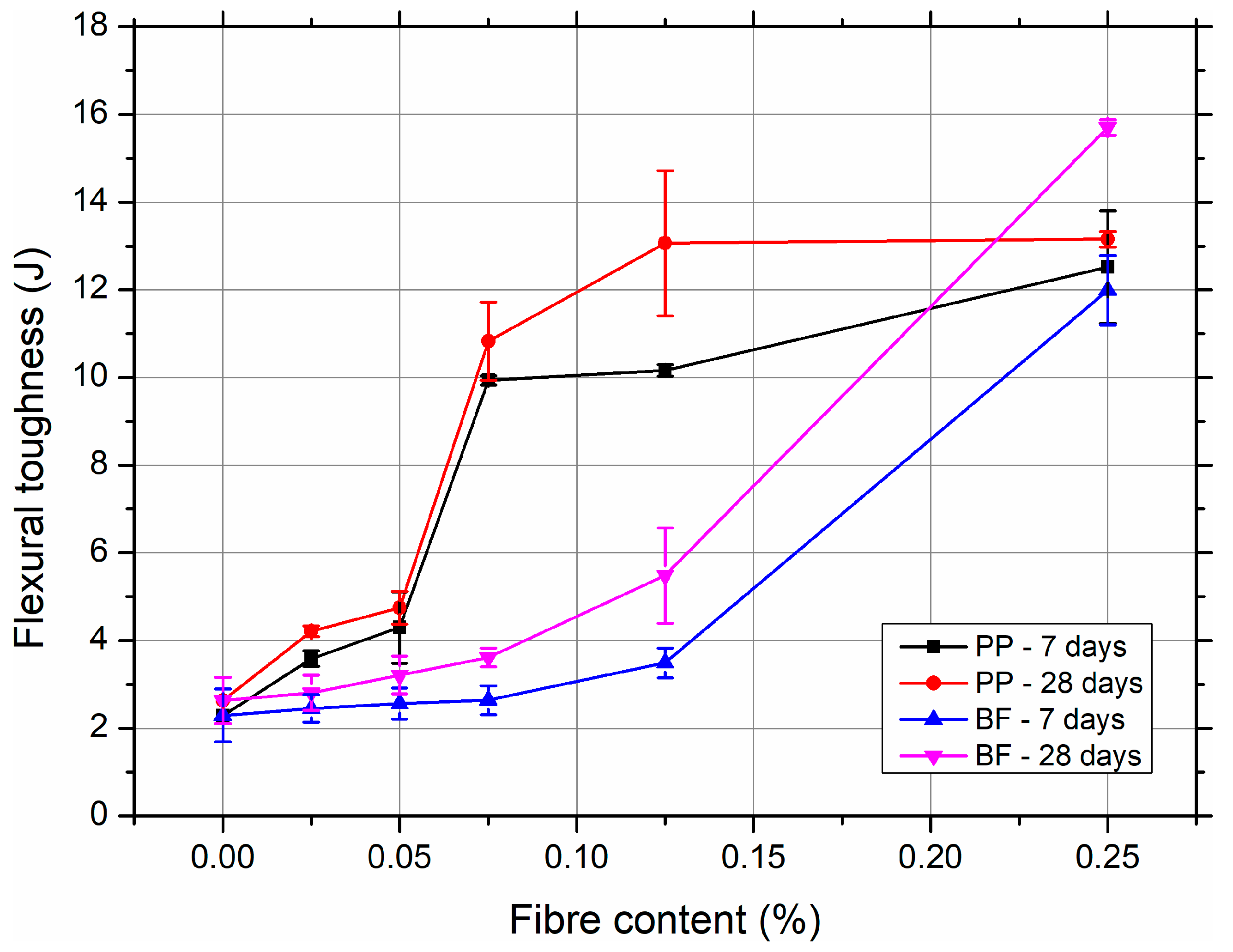

3.5. Load–Displacement Behaviour and Flexural Toughness

4. Statistical Analysis

4.1. Statistical Analysis of Compressive Strength

4.2. Statistical Analysis of Splitting Tensile Strength

4.3. Statistical Analysis of Flexural Strength

4.4. Statistical Analysis of Flexural Toughness

5. Discussion

6. Conclusions

- Both PP and BF fibres significantly improved the splitting tensile strength, flexural strength, and flexural toughness of SCC, with the extent of improvement depending on the type of fibre and dosage.

- PP fibres proved to be more effective in the early ages (7 days), particularly at 0.05–0.125% volume, by controlling microcrack development and improving tensile stress distribution. The peak tensile strength increase reached 45% compared to the control mix.

- BF fibres offered superior post-cracking performance and toughness, especially at 28 days. Optimal performance was observed at 0.125–0.25% volume, where toughness increased by over 500% relative to the plain SCC.

- Excessive fibre content (≥0.25%) led to reduced workability and greater variability in results, indicating the need for dosage optimisation.

- Statistical evaluation using ANOVA and Tukey’s test confirmed significant differences between mixtures and validated observed trends.

- For practical design, PP fibres are suitable for improving early-age cracking resistance, while BF fibres are recommended for applications that require enhanced post-crack load-bearing capacity and energy absorption.

- The findings suggest that the hybridisation of PP and BF fibres could offer complementary benefits, and further studies on long-term durability, rheological effects, and hybrid systems are encouraged.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The European Guidelines for Self-Compacting Concrete; Specification, Production and Use; The SCC European Project Group: BIBM, CEMBUREAU, ERMCO, EFCA, EFNARC: Brussels, Belgium, 2005.

- Mohamed, O.A.; Najm, O.F. Compressive strength and stability of sustainable self-consolidating concrete containing fly ash, silica fume, and GGBS. Front. Struct. Civ. Eng. 2016, 11, 406–411. [Google Scholar] [CrossRef]

- El-Chabib, H.; Syed, A. Properties of self-consolidating concrete made with high volumes of supplementary cementitious materials. J. Mat. Civ. Eng. 2013, 25, 1579–1586. [Google Scholar] [CrossRef]

- Guo, K.; Dong, H.; Zhang, J.; Zhang, L.; Li, Z. Experimental Study of Alkali-Activated Cementitious Materials Using Thermally Activated Red Mud: Effect of the Si/Al Ratio on Fresh and Mechanical Properties. Buildings 2025, 15, 565. [Google Scholar] [CrossRef]

- Kodur, V.K.R. Spalling in high strength concrete exposed to fire: Concerns, causes, critical parameters and cures. Adv. Technol. Struct. Eng. 2002, 103, 1–9. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Harlow, UK, 2011. [Google Scholar]

- Çelik, Z.; Bingöl, A.F. Mechanical properties and postcracking behavior of self-compacting fiber reinforced concrete. Struct. Concr. 2019, 21, 2124–2133. [Google Scholar] [CrossRef]

- Smarzewski, P. Flexural toughness of high-performance concrete with basalt and polypropylene short fibres. Adv. Civ. Eng. 2018, 2018, 5024353. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Qi, C.; Weiss, J.; Olek, J. Characterization of plastic shrinkage cracking in fiber reinforced concrete using image analysis and a modified Weibull function. Mater. Struct. 2003, 36, 386–395. [Google Scholar] [CrossRef]

- Alhozaimy, M.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Smarzewski, P. Influence of basalt-polypropylene fibres on fracture properties of high performance concrete. Compos. Struct. 2019, 209, 23–33. [Google Scholar] [CrossRef]

- Smarzewski, P. Fibre Reinforced Concrete: Improvements and Innovations II; RILEM Bookseries; Springer: Cham, Switzerland, 2022; Volum 36, pp. 186–197. [Google Scholar] [CrossRef]

- Smarzewski, P. Fresh and Mechanical Properties of High-Performance Self-Compacting Concrete Containing Ground Granulated Blast Furnace Slag and Polypropylene Fibres. Appl. Sci. 2023, 13, 1975. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Pickel, D.J.; West, J.F.; Alaskar, A. Use of basalt fibres in fibre-reinforced concrete. ACI Mater. J. 2019, 115, 867–876. [Google Scholar]

- Algin, Z.; Ozen, M. The properties of chopped basalt fibre reinforced self-compacting concrete. Constr. Build. Mater. 2018, 186, 678–685. [Google Scholar] [CrossRef]

- Çelik, Z.; Bingöl, A.F. Fracture properties and impact resistance of self-compacting fiber reinforced concrete (SCFRC). Mater. Struct. 2020, 53, 50. [Google Scholar] [CrossRef]

- Arslan, M.E. Effects of basalt and glass chopped fibres addition on fracture energy and mechanical properties of ordinary concrete: CMOD measurement. Constr. Build. Mater. 2016, 114, 383–391. [Google Scholar] [CrossRef]

- Borhan, T.M. Properties of glass concrete reinforced with short basalt fibre. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fibre with different lengths and dosages. Compos. Part B 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Smarzewski, P. Flexural toughness evaluation of basalt fibre reinforced HPC beams with and without initial notch. Compos. Struct. 2020, 235, 111769. [Google Scholar] [CrossRef]

- Smarzewski, P. Study of bond strength of steel bars in basalt fibre reinforced high performance concrete. Crystals 2020, 10, 436. [Google Scholar] [CrossRef]

- PN-EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 12390-3:2019-07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 12390-6:2011; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN 12390-5:2019-08; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- ASTM C1609/C1609M-19; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- Chen, Y.; Ul Haq, S.; Iqbal, S.; Khan, I.; Room, S.; Khan, S.A. Performance Evaluation of Indented Macro Synthetic Polypropylene Fibers in High Strength Self-Compacting Concrete (SCC). Sci. Rep. 2024, 14, 20844. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Fang, C.; Chang, Y.; Nie, J. Influence of Basalt Fiber and Polypropylene Fiber on the Mechanical and Durability Properties of Cement-Based Composite Materials. J. Build. Eng. 2024, 90, 109335. [Google Scholar] [CrossRef]

- Hussein, I.A.; Ghalehnovi, M. The Impact of Colloidal Nano Silica (CNS) and Polypropylene Fibers (PP) on the Properties of Recycled Concrete Aggregate Self-Compacting Concrete (SCC). Case Stud. Constr. Mater. 2025, 22, e04424. [Google Scholar] [CrossRef]

- Katebi, A.; Asadollahfardi, G.; Salehi, A.; Ahmadi, G.; Soleymani-Tushmanlo, A. Investigation of the Properties of Self-Compacting Concrete Using Treated Rubber Powder, Polypropylene Fibers, and Wash Water. Case Stud. Constr. Mater. 2025, 22, e04443. [Google Scholar] [CrossRef]

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of Low-Modulus Polypropylene Fiber on Physical and Mechanical Properties of Self-Compacting Concrete. Case Stud. Constr. Mater. 2022, 16, e00814. [Google Scholar] [CrossRef]

- Olive Sharon, R.P.; SenthilPandian, M. Interactive Influence of Basalt Fibres and Pozzolanic Additives on the Mechanical and Microstructural Properties of Self-Compacting Concrete. Case Stud. Constr. Mater. 2025, 22, e04650. [Google Scholar] [CrossRef]

- Al-Rousan, E.T.; Khalid, H.R.; Rahman, M.K. Fresh, mechanical and durability properties of basalt fiber-reinforced concrete (BFRC): A review. Develop. Built Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Guler, S. Structural Self-Compacting Lightweight Concrete: Effects of Fly Ash and Basalt Fibers on Workability, Thermal and Mechanical Properties under Ambient Conditions and High Temperatures. Constr. Build. Mater. 2025, 481, 141658. [Google Scholar] [CrossRef]

- Sathe, S.; Kolte, D.A. Enhancing concrete performance with hybrid basalt–polypropylene fibers: Experimental and numerical evaluation. Innov. Infrastruct. Solut. 2025, 10, 204. [Google Scholar] [CrossRef]

- Xue, Z.; Qi, P.; Yan, Z.; Pei, Q.; Zhong, J.; Zhan, Q. Mechanical Properties and Crack Resistance of Basalt Fiber Self-Compacting High Strength Concrete: An Experimental Study. Materials 2023, 16, 4374. [Google Scholar] [CrossRef] [PubMed]

- Vedhasakthi, K.; Chithra, R. Strength Attributes and Microstructural Characterization of Basalt Fibre Incorporated Self-Compacting Concrete. J. Build. Eng. 2023, 78, 107592. [Google Scholar] [CrossRef]

- Liang, N.; Ren, L.; Tian, S.; Liu, X.; Zhong, Z.; Deng, Z.; Yan, R. Study on the Fracture Toughness of Polypropylene–Basalt Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2021, 15, 35. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Xu, W.; Zhao, X.; Zhang, L.; Wang, Y.; Niu, D. Flexural Behavior and Prediction Model of Basalt Fiber/Polypropylene Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2022, 16, 31. [Google Scholar] [CrossRef]

- Ashteyat, A.; Obaidat, A.T.; Qerba’a, R.; Abdel-Jaber, M. Influence of Basalt Fiber on the Rheological and Mechanical Properties and Durability Behavior of Self-Compacting Concrete (SCC). Fibers 2024, 12, 52. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Liang, N.; de la Fuente, A.; Peng, H. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers 2021, 9, 43. [Google Scholar] [CrossRef]

- Chia, E.; Nguyen, H.B.; Le, K.N.; Bi, K.; Pham, T.M. Performance of Hybrid Basalt-Recycled Polypropylene Fibre Reinforced Concrete. Structures 2025, 75, 108711. [Google Scholar] [CrossRef]

- Zhang, M.; Li, B.; Zheng, Z.; Zhang, J. Experimental Study on Impact Performance of Basalt-Polypropylene Fiber Reinforced High-Performance Concrete. Materials 2024, 17, 3253. [Google Scholar] [CrossRef] [PubMed]

| Compound | Cement | GGBS |

|---|---|---|

| SiO2 | 20.19 | 33.14 |

| Al2O3 | 4.30 | 13.55 |

| Fe2O3 | 3.25 | 1.30 |

| CaO | 64.61 | 43.36 |

| MgO | 1.41 | 6.48 |

| SO3 | 2.96 | 0.29 |

| K2O | 2.59 | 0.31 |

| Na2O | 0.26 | 0.29 |

| Cl | 0.111 | 0.006 |

| LOI | 3.41 | 0.76 |

| Insoluble matter | 0.48 | 0.31 |

| Property | Polypropylene Fibres | Basalt Fibres |

|---|---|---|

| Density [kg/m3] | 910 | 2700 |

| Length [mm] | 12 | 12 |

| Diameter [μm] | 25 | 13 |

| Tensile strength [MPa] | 305 | 1700 |

| Elastic modulus [GPa] | 35 | 70 |

| Elongation at break [%] | 10 | 2.4 |

| Mix ID | Cement [kg/m3] | GGBFS [kg/m3] | Fine Aggregate [kg/m3] | Coarse Aggregate [kg/m3] | Water [kg/m3] | SUPERPLASTICIZER [% Binder] | Fibres Type | Fibre Content [% Vol.] |

|---|---|---|---|---|---|---|---|---|

| SCC-REF | 350 | 300 | 980 | 400 | 210 | 3 | None | 0 |

| SCC-PP-0.025 | 350 | 300 | 980 | 400 | 210 | 3 | Polypropylene | 0.025 |

| SCC-PP-0.05 | 350 | 300 | 980 | 400 | 210 | 3 | Polypropylene | 0.05 |

| SCC-PP-0.075 | 350 | 300 | 980 | 400 | 210 | 3 | Polypropylene | 0.075 |

| SCC-PP-0.125 | 350 | 300 | 980 | 400 | 210 | 3 | Polypropylene | 0.125 |

| SCC-PP-0.25 | 350 | 300 | 980 | 400 | 210 | 3 | Polypropylene | 0.25 |

| SCC-BF-0.025 | 350 | 300 | 980 | 400 | 210 | 3 | Basalt | 0.025 |

| SCC-BF-0.05 | 350 | 300 | 980 | 400 | 210 | 3 | Basalt | 0.05 |

| SCC-BF-0.075 | 350 | 300 | 980 | 400 | 210 | 3 | Basalt | 0.075 |

| SCC-BF-0.125 | 350 | 300 | 980 | 400 | 210 | 3 | Basalt | 0.125 |

| SCC-BF-0.25 | 350 | 300 | 980 | 400 | 210 | 3 | Basalt | 0.25 |

| Mix ID | Fibre Type | Fibre Content [% Vol.] | Slump Flow [mm] | T500 [s] | L-Box, PA [—] |

|---|---|---|---|---|---|

| SCC-REF | None | 0 | 722.5 | 4.1 | 0.94 |

| SCC-PP-0.025 | Polypropylene | 0.025 | 715 | 4.3 | 0.90 |

| SCC-PP-0.05 | Polypropylene | 0.05 | 705.5 | 4.5 | 0.88 |

| SCC-PP-0.075 | Polypropylene | 0.075 | 580.5 | 4.8 | 0.85 |

| SCC-PP-0.125 | Polypropylene | 0.125 | 570 | 5.0 | 0.82 |

| SCC-PP-0.25 | Polypropylene | 0.25 | 485 | — | 0.63 |

| SCC-BF-0.025 | Basalt | 0.025 | 680 | 4.4 | 0.89 |

| SCC-BF-0.05 | Basalt | 0.05 | 613.5 | 5.0 | 0.87 |

| SCC-BF-0.075 | Basalt | 0.075 | 575 | 5.5 | 0.84 |

| SCC-BF-0.125 | Basalt | 0.125 | 552 | 5.9 | 0.81 |

| SCC-BF-0.25 | Basalt | 0.25 | 478.5 | — | 0.61 |

| Source | Sum Sq | df | F | p-Value |

|---|---|---|---|---|

| Fibre type | 1218.59 | 2 | 580.96 | <0.001 |

| Fibre content (vol. %) | 4933.93 | 5 | 940.89 | <0.001 |

| Interaction (type × content) | 586.63 | 10 | 55.93 | <0.001 |

| Residual | 41.95 | 40 | — | — |

| Source | Sum Sq | df | F | p-Value |

|---|---|---|---|---|

| Fibre type | 0.834 | 2 | 8.66 | 0.0054 |

| Fibre content (vol. %) | 34.003 | 5 | 141.22 | <0.0001 |

| Interaction (type × content) | 11.774 | 10 | 24.39 | <0.0001 |

| Residual | 1.926 | 40 | — | — |

| Source | Sum Sq | df | F | p-Value |

|---|---|---|---|---|

| Fibre type | 0.102 | 2 | 0.253 | 0.3201 |

| Fibre content (vol. %) | 55.989 | 5 | 55.633 | <0.0001 |

| Interaction (type × content) | 22.772 | 10 | 211.314 | <0.0001 |

| Residual | 4.428 | 22 | — | — |

| Source | Sum Sq | df | F | p-Value |

|---|---|---|---|---|

| Fibre type | 150.06 | 2 | 156.11 | <0.0001 |

| Fibre content (vol. %) | 1209.39 | 5 | 503.25 | <0.0001 |

| Interaction (type × content) | 361.17 | 10 | 75.15 | <0.0001 |

| Residual | 12.02 | 25 | — | — |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smarzewski, P.; Jancy, A. Comparative Study on Mechanical Performance and Toughness of High-Performance Self-Compacting Concrete with Polypropylene and Basalt Fibres. Materials 2025, 18, 3833. https://doi.org/10.3390/ma18163833

Smarzewski P, Jancy A. Comparative Study on Mechanical Performance and Toughness of High-Performance Self-Compacting Concrete with Polypropylene and Basalt Fibres. Materials. 2025; 18(16):3833. https://doi.org/10.3390/ma18163833

Chicago/Turabian StyleSmarzewski, Piotr, and Anna Jancy. 2025. "Comparative Study on Mechanical Performance and Toughness of High-Performance Self-Compacting Concrete with Polypropylene and Basalt Fibres" Materials 18, no. 16: 3833. https://doi.org/10.3390/ma18163833

APA StyleSmarzewski, P., & Jancy, A. (2025). Comparative Study on Mechanical Performance and Toughness of High-Performance Self-Compacting Concrete with Polypropylene and Basalt Fibres. Materials, 18(16), 3833. https://doi.org/10.3390/ma18163833