Damage Diagnosis Framework for Composite Structures Based on Multi-Dimensional Signal Feature Space and Neural Network

Abstract

1. Introduction

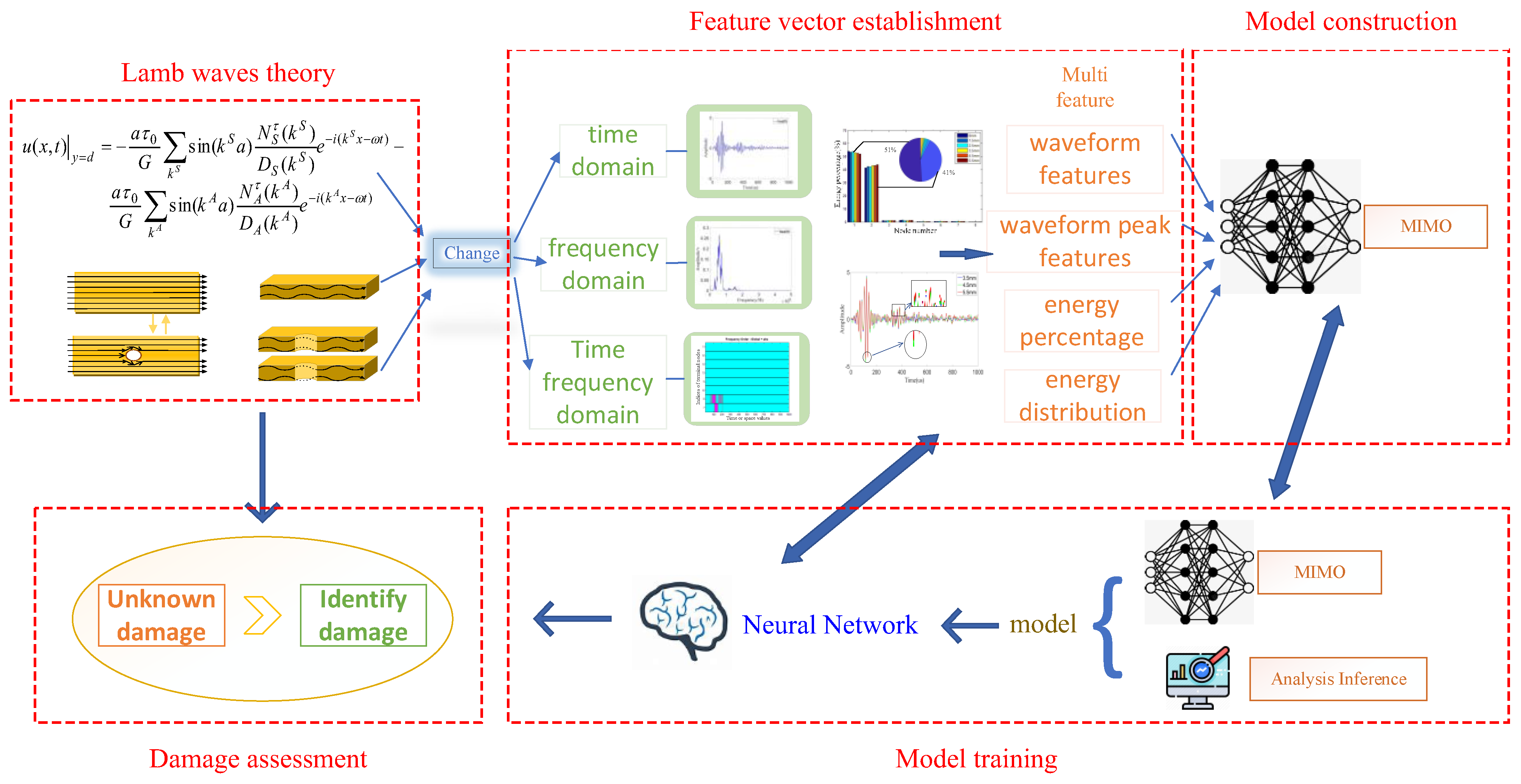

2. Fundamental Analysis and Overview

3. Multi-Dimensional Signal Feature Space-Based Damage Monitoring and Assessment

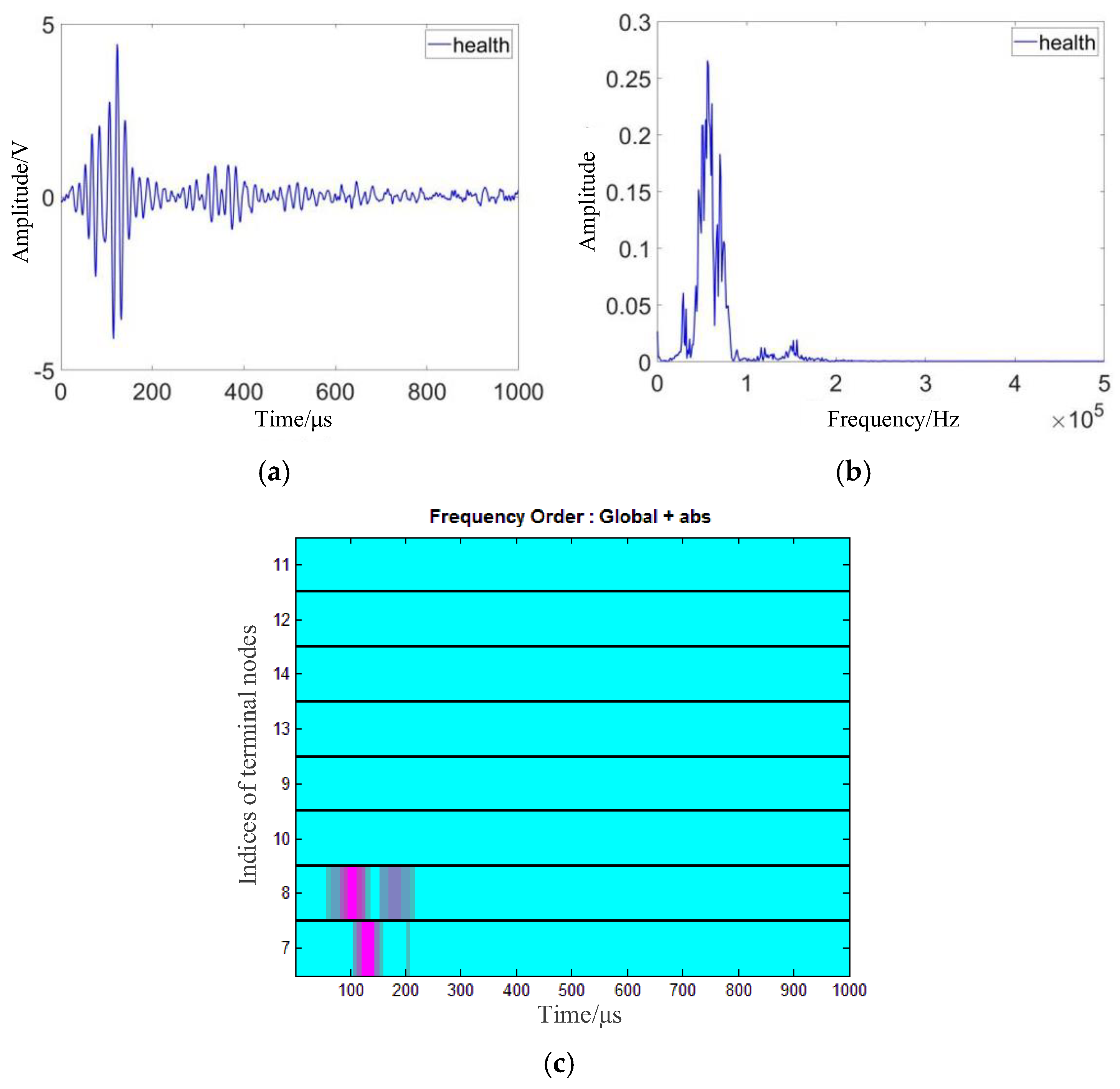

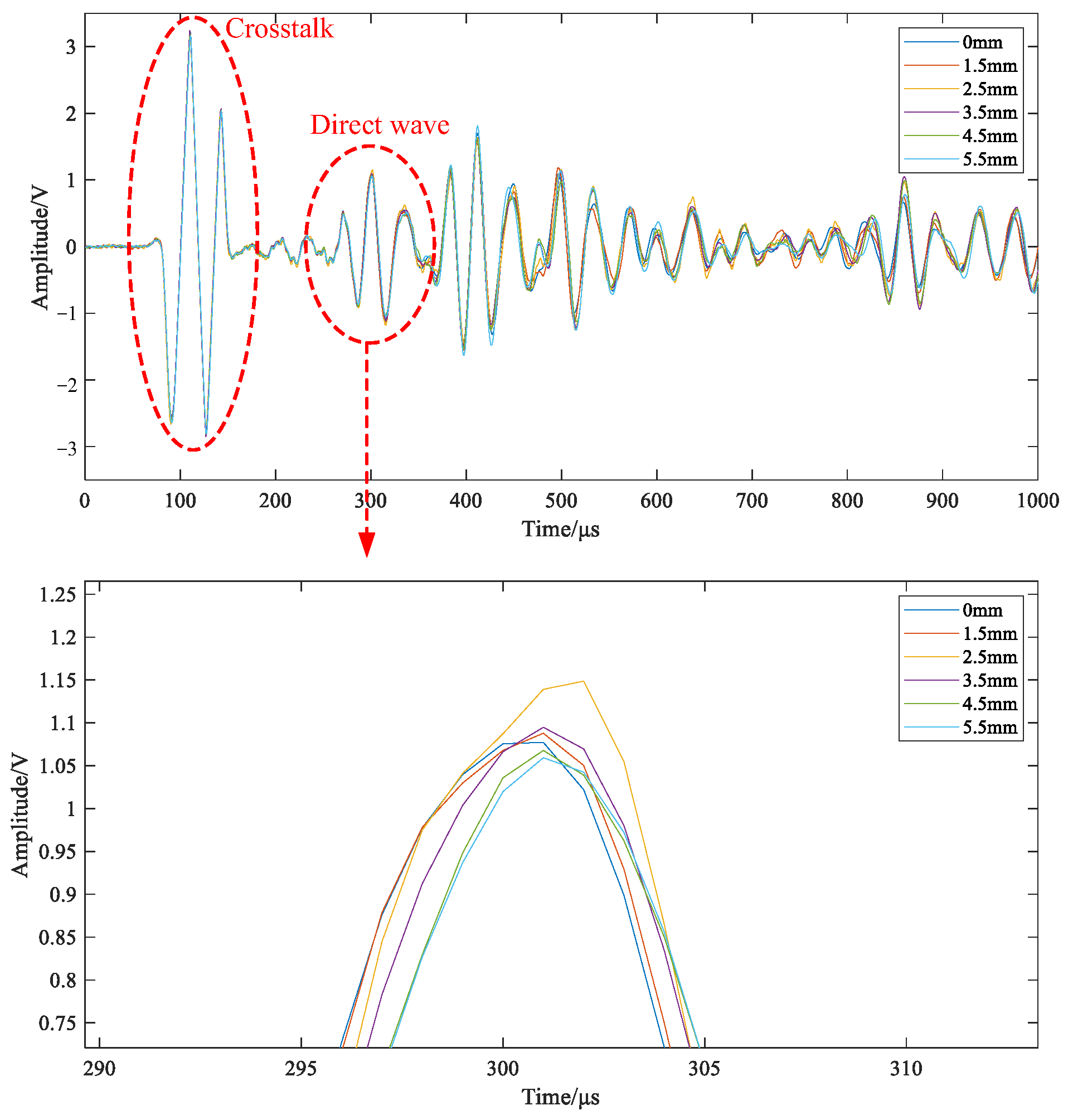

3.1. Analysis of Lamb Wave Structural Response

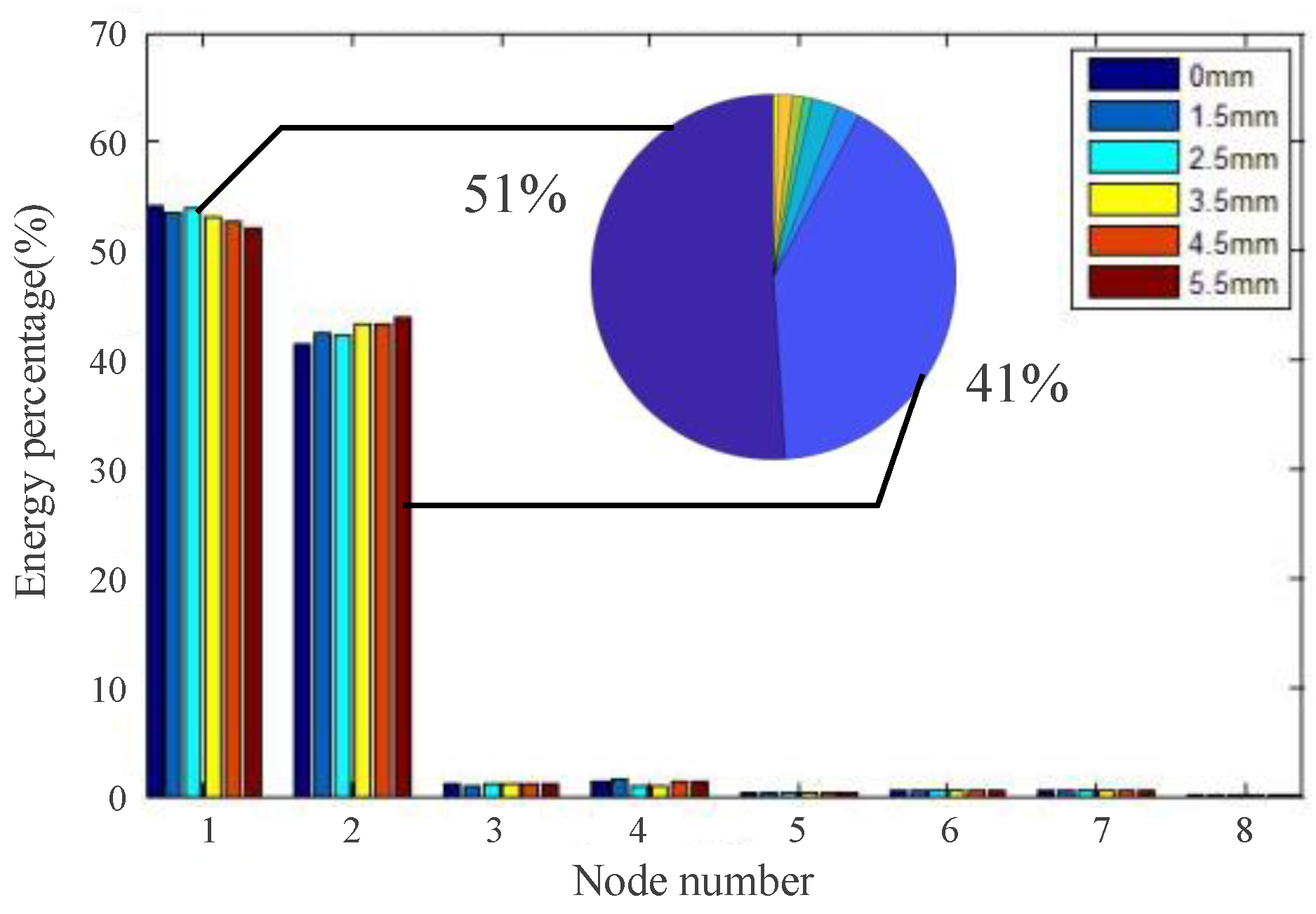

3.2. Feature Extraction

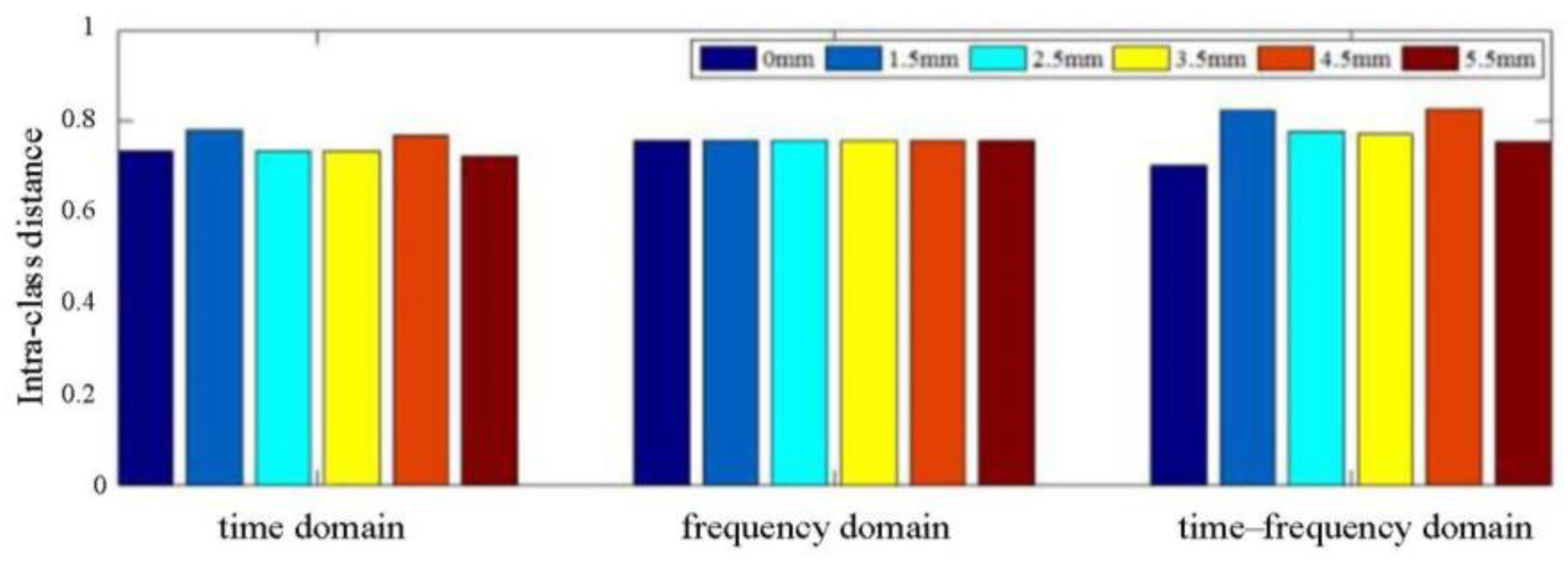

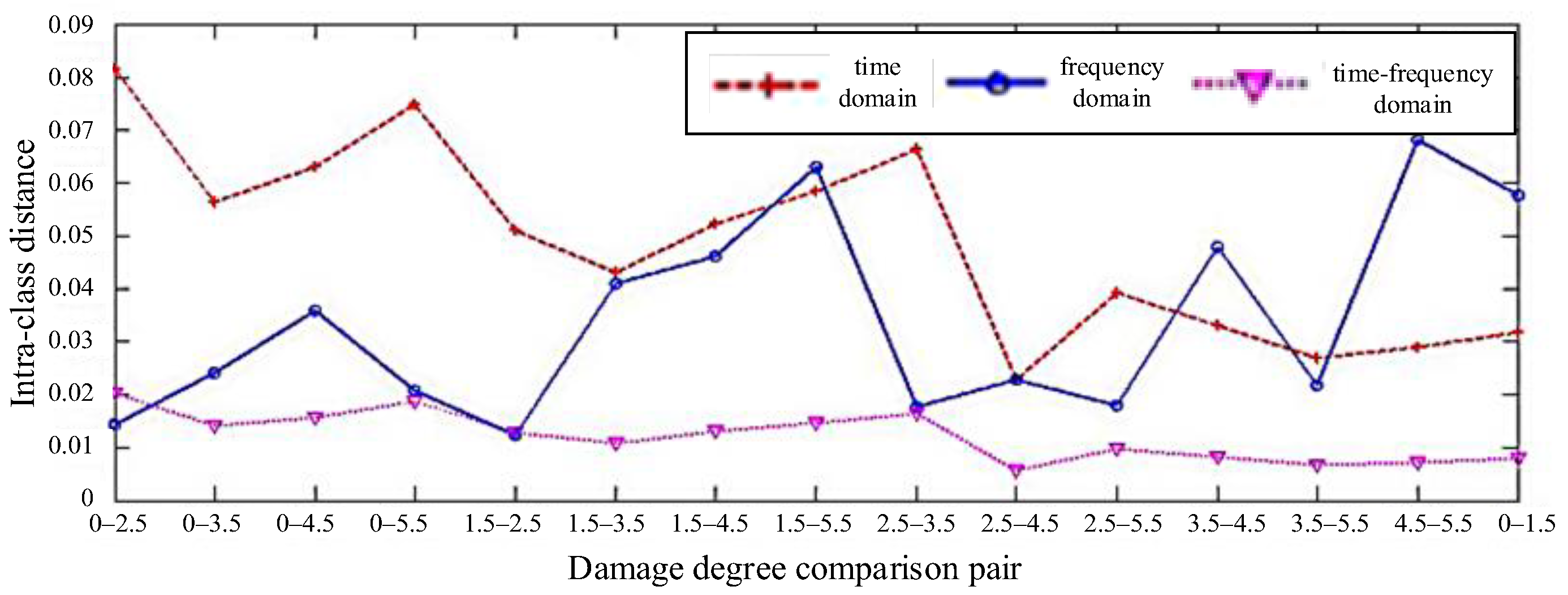

3.3. Separability Comparison of Feature Parameters

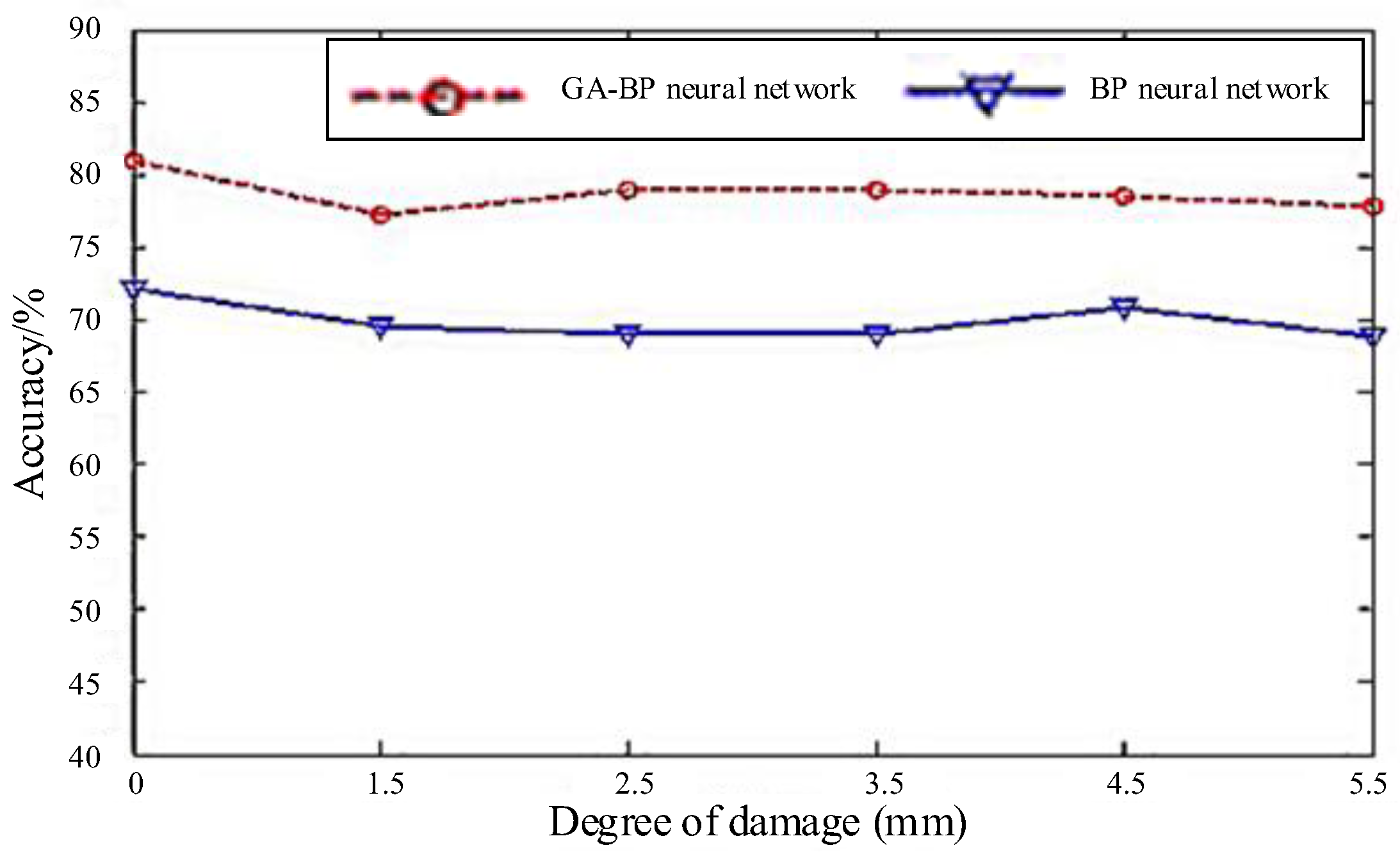

3.4. Assessment of Damage Degree

4. Experimental Verification and Result Analysis

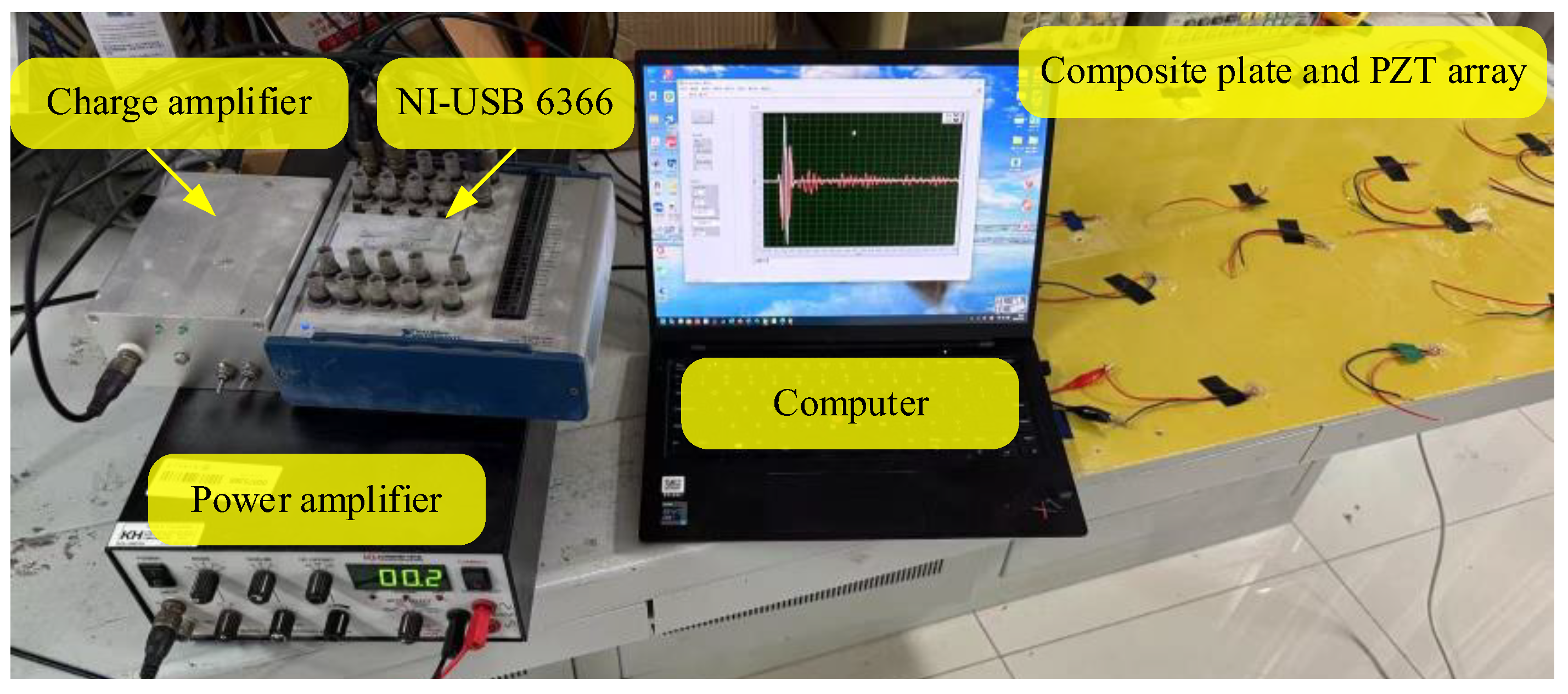

4.1. Design of Damage Assessment System

4.2. Design of Experimental Scheme

4.3. Analysis of Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Surace, C. Special issue on novel approaches for structural health monitoring. Appl. Sci. 2021, 11, 7210. [Google Scholar] [CrossRef]

- Hou, J.; Xu, D.; Jankowski, U. Structural modal parameter identification with the Power-Exponential window function. Mech. Syst. Signal Process. 2025, 222, 111771. [Google Scholar] [CrossRef]

- Henrique, T.; Ferreira, W.; Martins, C. Fast tool for structural monitoring of a pier after impact of a very large vessel using ambient vibration analysis. J. Mar. Sci. Appl. 2021, 1, 1–8. [Google Scholar] [CrossRef]

- Wang, X.Y.; Li, L.F.; Tian, W.; Du, Y.; Hou, R.R.; Xia, Y. Unsupervised one-class classification for condition assessment of bridge cables using Bayesian factor analysis. Smart Struct. Syst. 2022, 29, 41–51. [Google Scholar]

- Barchi, F.; Zanatta, L.; Parisi, E.; Burrello, A.; Brunelli, D.; Bartolini, A.; Acquaviva, A. Spiking neural network-based near-sensor computing for damage detection in structural health monitoring. Future Internet 2021, 13, 219. [Google Scholar] [CrossRef]

- Su, Z.Q.; Lin, Y.; Ye, L. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Dao, P.B. Lamb wave-based structural damage detection: A time series approach using cointegration. Materials 2023, 16, 6894. [Google Scholar] [CrossRef]

- He, M.; Dong, C.; Sun, X.; He, J. Fatigue Crack Monitoring Method Based on the Lamb Wave Damage Index. Materials 2024, 17, 3836. [Google Scholar] [CrossRef] [PubMed]

- Migot, A.; Saaudi, A.; Giurgiutiu, V. Delamination depth detection in composite plates using the Lamb wave technique based on convolutional neural networks. Sensors 2024, 24, 3118. [Google Scholar] [CrossRef]

- Bolourani, A.; Bitaraf, M.; Tak, A.N. Structural health monitoring of harbor caissons using support vector machine and principal component analysis. Structures 2021, 33, 4501–4513. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoon, S.; Kim, B.; Gwon, G.H.; Kim, I.H.; Jung, H.J. A new image-quality evaluating and enhancing methodology for bridge inspection using an unmanned aerial vehicle. Smart Struct. Syst. 2021, 27, 209–226. [Google Scholar]

- Wang, P.; Shi, Q. Damage identification in structures based on energy curvature difference of wavelet packet transform. Shock Vib. 2018, 2, 1–13. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, L.; Zhang, L. Local damage identification method using finite element model updating based on a new wavelet damage function. Adv. Struct. Eng. 2018, 21, 1482–1494. [Google Scholar] [CrossRef]

- Alexandrino, P.D.S.L.; Gomes, G.F.; Cunha, S.S., Jr. A robust optimization for damage detection using multiobjective genetic algorithm, neural network and fuzzy decision making. Inverse Probl. Sci. Eng. 2020, 28, 21–46. [Google Scholar] [CrossRef]

- Rautela, M.; Senthilnath, J.; Moll, J.; Gopalakrishnan, S. Combined two-level damage identification strategy using ultrasonic guided waves and physical knowledge assisted machine learning. Ultrasonics 2020, 115, 106472. [Google Scholar] [CrossRef]

- Sun, D.; Wang, Q.; Xue, X.; Zhang, S. Damage Degree Assessment Based on Lamb Wave and Wavelet Packet Transform. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 3179–3184. [Google Scholar]

- Giurgiutiu, V. Tuned lamb wave excitation and detection with piezoelectric wafer active sensors for structural health monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Gianesini, B.M.; Cortez, N.E.; Antunes, R.A.; Vieira Filho, J. Method for removing temperature effect in impedance-based structural health monitoring systems using polynomial regression. Struct. Health Monit. 2020, 20, 147592172091712. [Google Scholar] [CrossRef]

- Mousavi, M.; Gandomi, A.H. Structural health monitoring under environmental and operational variations using MCD prediction error. J. Sound Vib. 2021, 521, 116370–116382. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, K.; Cheng, H.; Gao, D.; Cai, K. Fatigue damage monitoring of composite structures based on lamb wave propagation and multi-feature fusion. J. Compos. Sci. 2024, 8, 423. [Google Scholar] [CrossRef]

- Deng, D.; Zeng, X.; Yang, Z.; Yang, Y.; Zhang, S.; Ma, S.; Xu, H.; Yang, L.; Wu, Z. Multi-frequency probabilistic imaging fusion for impact localization on aircraft composite structures. Struct. Health Monit. 2025, 24, 185–201. [Google Scholar] [CrossRef]

- Gao, G.; Chen, H.; Hu, N.; Deng, M. Experimental observation of static component generation by Lamb wave propagation in an elastic plate. Ultrasonics 2021, 36, 106537–106540. [Google Scholar] [CrossRef] [PubMed]

| ANNT * | TE | Accuracy of Ten Tests | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 1.5 | 2.5 | 3.5 | 4.5 | 5.5 | All | ||

| BPM | 0.44 | 72.1 | 69.6 | 69 | 69 | 70.9 | 68.9 | 69.9 |

| BPMSE | 0.11 | 8.0 | 8.3 | 11.2 | 10.4 | 7.52 | 10.0 | 8.93 |

| GABPM | 0.06 | 80.9 | 77.3 | 78.9 | 79.7 | 78.5 | 77.8 | 78.8 |

| GABPMSE | 0.06 | 9.6 | 6.6 | 10.9 | 6.9 | 8.2 | 11.9 | 8.7 |

| Degree of Damage | BP | GA-BP | ||||

|---|---|---|---|---|---|---|

| Test | Correct | Accuracy | Test | Correct | Accuracy | |

| 0% | 16 | 13 | 81.3% | 16 | 14 | 87.5% |

| 20% | 16 | 12 | 75% | 16 | 14 | 87.5% |

| 50% | 16 | 12 | 75% | 16 | 15 | 93.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, J.; Zhang, S.; Yuan, Q.; Lu, M.; Wang, Q. Damage Diagnosis Framework for Composite Structures Based on Multi-Dimensional Signal Feature Space and Neural Network. Materials 2025, 18, 3834. https://doi.org/10.3390/ma18163834

Wang J, Wang J, Zhang S, Yuan Q, Lu M, Wang Q. Damage Diagnosis Framework for Composite Structures Based on Multi-Dimensional Signal Feature Space and Neural Network. Materials. 2025; 18(16):3834. https://doi.org/10.3390/ma18163834

Chicago/Turabian StyleWang, Jian, Jing Wang, Shaodong Zhang, Qin Yuan, Minhua Lu, and Qiang Wang. 2025. "Damage Diagnosis Framework for Composite Structures Based on Multi-Dimensional Signal Feature Space and Neural Network" Materials 18, no. 16: 3834. https://doi.org/10.3390/ma18163834

APA StyleWang, J., Wang, J., Zhang, S., Yuan, Q., Lu, M., & Wang, Q. (2025). Damage Diagnosis Framework for Composite Structures Based on Multi-Dimensional Signal Feature Space and Neural Network. Materials, 18(16), 3834. https://doi.org/10.3390/ma18163834