Composition-Dependent Creep Resistance and Strain Rate Sensitivity of BCC Mg-Sc Alloy Studied via Nano-Indentation on Diffusion Couple

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Diffusion Couple

2.2. Nano-Indentation Creep Deformation and Continuous Stiffness Tests

2.3. Data Analyses of Nano-Indentation Creep Deformation Test

2.4. Data Analyses of Nano-Indentation Continuous Stiffness Measurement

3. Results and Discussion

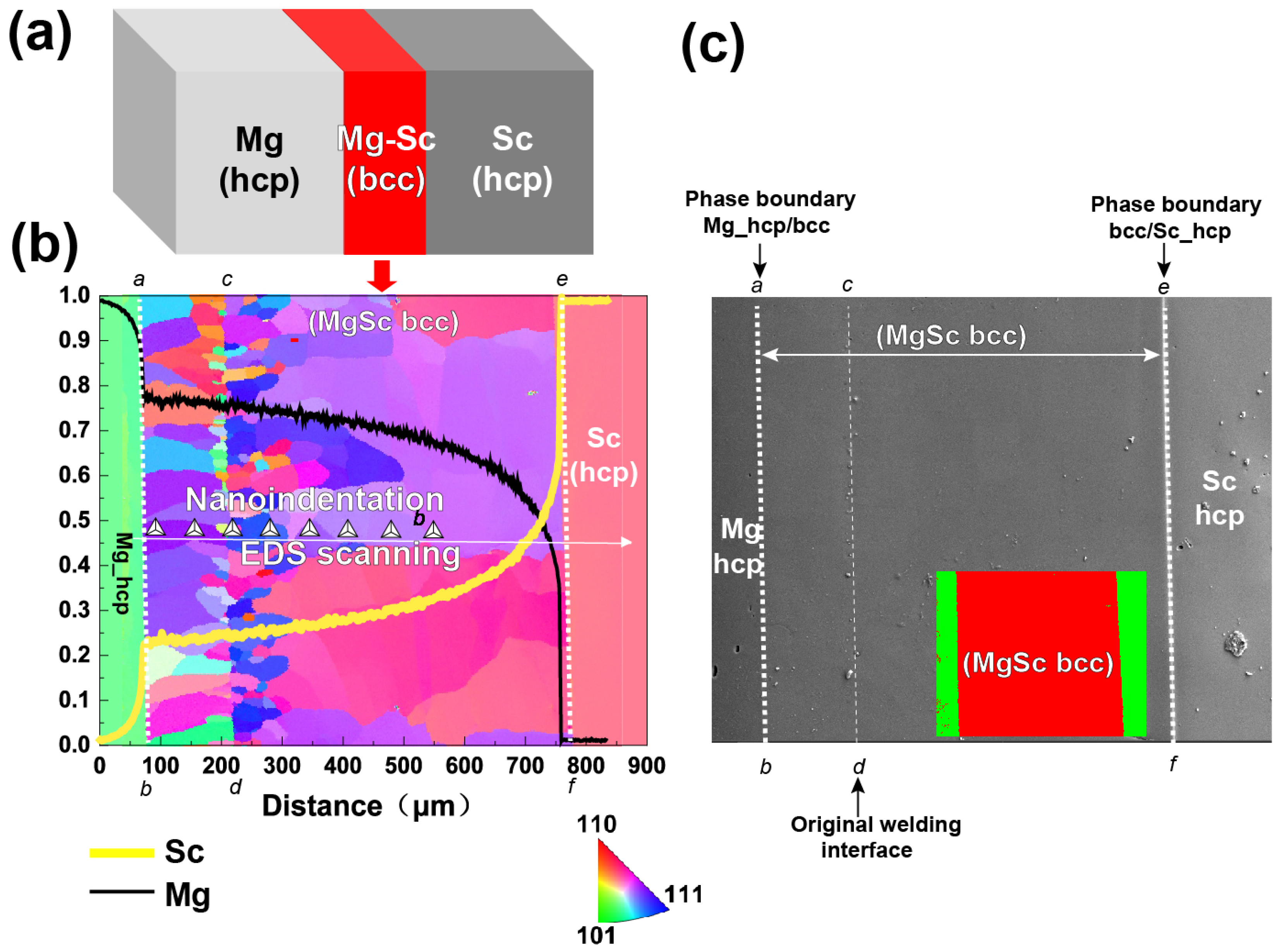

3.1. Microstructural Characterization

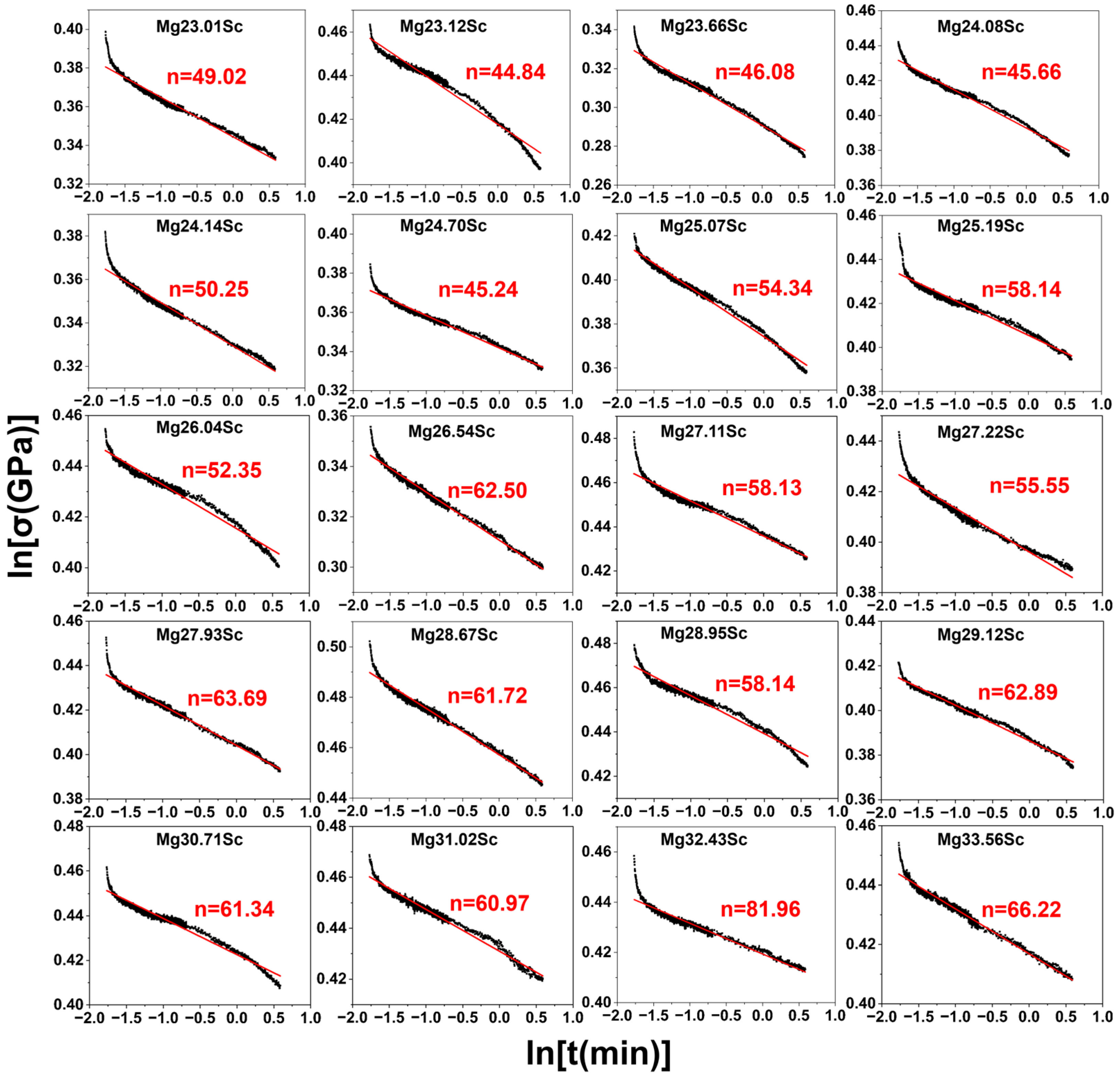

3.2. Nano-Indentation Creep Behavior

3.3. Nanometer Indentation Strain Rate Sensitivity

4. Limitations

- Only the material intrinsic creep resistance, the stress exponent, and the intrinsic strain rate sensitivity at room temperature, which are purely influenced by the chemical composition of Sc, have been studied. The creep deformation behaviors at elevated temperatures, which are activated by thermal physics, and the mechanisms of grain boundary sliding and grain boundary diffusion have not been considered yet. They are left for future works.

- Strain rate range constraint: The nano-indentation creep tests were conducted within a defined strain rate range of 0.01 s−1 to 0.1 s−1. While appropriate for probing local creep resistance, this relatively narrow window may restrict the comprehensive quantification of the strain rate sensitivity exponent (m), potentially limiting the resolution of its composition-dependent evolution.

- Microstructural correlation gap: The conclusions regarding strengthening mechanisms are based solely on mechanical property measurements (n, m). The absence of complementary microstructural characterization (e.g., TEM for dislocation substructures or precipitate analysis) prevents a definitive mechanistic interpretation of the observed composition–property relationships. Future work integrating microstructural probes is essential to elucidate the underlying mechanisms driving the enhanced creep resistance.

5. Conclusions

- Sc significantly improves the room-temperature creep resistance of BCC-structured MgSc alloys. The creep displacement Δh decreases from 17.26 nm to 11.75 nm, while the stress exponent n increases from 49.02 to 66.22 as the Sc content rises from 23.01 at.% to 33.56 at.%. The composition variations in creep displacement and creep stress exponent indicate a better creep resistance of a Mg-Sc binary alloy at high-Sc compositions in comparison with low-Sc compositions. TEM characterization reveals that this enhancement originates from Sc-induced ordered structures, which act as practical barriers to dislocation motion through dynamic drag effects during creep deformation.

- While the stabilized hardness remains at approximately 2 GPa across all compositions, the strain rate sensitivity index m increases from 0.02 to 0.11 with a higher Sc content at room temperature. This phenomenon is attributed to the proliferation of short-range obstacles (e.g., ordered structure) that amplify the activation barriers for dislocation glide under strain rate variations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, H.; Tan, J.; Geng, T.; Wang, H.; Shi, H.; Lin, Y.; Jiang, B.; Eckert, J. Advances in high-strength and high-thermal conductivity cast magnesium alloys: Strategies for property optimization. J. Alloys Compd. 2025, 1029, 180843. [Google Scholar] [CrossRef]

- Friedrich, H.; Schumann, S. Research for a “new age of magnesium” in the automotive industry. J. Mater. Process. Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, C.; Cheng, W.; Bian, L.; Wang, H.; Xu, C. High-strength Mg93.96Zn2Y4Sr0.04 alloy with long-period stacking ordered structure. Mater. Sci. Eng. A 2013, 559, 416–420. [Google Scholar] [CrossRef]

- Bamberger, M.; Dehm, G. Trends in the development of new Mg alloys. Annu. Rev. Mater. Res. 2008, 38, 505–533. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, Z.; Han, S.; Gu, Y.; Zhu, Z.; Zhang, H. Evolution, limitations, advantages, and future challenges of magnesium alloys as materials for aerospace applications. J. Alloys Compd. 2024, 176707. [Google Scholar] [CrossRef]

- Froes, F.; Eliezer, D.; Aghion, E. The science, technology, and applications of magnesium. JOM 1998, 50, 30–34. [Google Scholar] [CrossRef]

- Tan, J.; Ramakrishna, S. Applications of magnesium and its alloys: A review. Appl. Sci. 2021, 11, 6861. [Google Scholar] [CrossRef]

- Wang, S.; Zha, M.; Jia, H.; Yang, Y.; Wang, D.; Wang, C.; Gao, Y.; Wang, H. A review of superplastic magnesium alloys: Focusing on alloying strategy, grain structure control and deformation mechanisms. J. Mater. Sci. Technol. 2025, 211, 303–319. [Google Scholar] [CrossRef]

- Luo, X.; Feng, Z.; Yu, T.; Luo, J.; Huang, T.; Wu, G.; Hansen, N.; Huang, X. Transitions in mechanical behavior and in deformation mechanisms enhance the strength and ductility of Mg-3Gd. Acta Mater. 2020, 183, 398–407. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Yu, K.; Rupert, T.J.; Mahajan, S.; Lavernia, E.J.; Schoenung, J.M.; Beyerlein, I.J. Manipulating deformation mechanisms with Y alloying of Mg. Mater. Sci. Eng. A 2021, 817, 141373. [Google Scholar] [CrossRef]

- Mo, N.; McCarroll, I.; Tan, Q.; Ceguerra, A.; Cairney, J.; Dieringa, H.; Huang, Y.; Jiang, B.; Pan, F.; Bermingham, M.; et al. Roles of Nd and Mn in a new creep-resistant magnesium alloy. Mater. Sci. Eng. A 2020, 779, 139152. [Google Scholar] [CrossRef]

- Wang, J.; Xu, G.; Zeng, X.; Llorca, J.; Cui, Y. Exploring the correlation between solvent diffusion and creep resistance of Mg–Ga HCP alloys from high throughput liquid-solid diffusion couple. Mater. Des. 2021, 197, 109243. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Q.; Tan, J.; Dong, Q.; Lv, H.; Wang, F.; Tang, A.; Eckert, J.; Pan, F. Enhancing the room-temperature plasticity of magnesium alloys: Mechanisms and strategies. J. Magnes. Alloys 2024, 12, 4741–4767. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, M.; Xu, C.; Guo, S.; Ning, Z.; Cao, F.; Huang, Y.; Sun, J.; Yi, J. Creep behaviors of a Mg–Li based alloy at elevated temperatures. Mater. Sci. Eng. A 2021, 827, 142063. [Google Scholar] [CrossRef]

- Kang, Y.; Pelton, A.; Chartrand, P.; Fuerst, C. Critical evaluation and thermodynamic optimization of the Al–Ce, Al–Y, Al–Sc and Mg–Sc binary systems. Calphad 2008, 32, 413–422. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Somekawa, H.; Koike, J. Martensitic transformation in a β-type Mg–Sc alloy. Shap. Mem. Superelast. 2018, 4, 167–173. [Google Scholar] [CrossRef]

- Liu, J.; Lin, Y.; Bian, D.; Wang, M.; Lin, Z.; Chu, X.; Li, W.; Liu, Y.; Shen, Z.; Liu, Y.; et al. In vitro and in vivo studies of Mg-30Sc alloys with different phase structure for potential usage within bone. Acta Biomater. 2019, 98, 50–66. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Ji, Y.; Tang, J.; Otsuka, K.; Wang, Y.; Hou, M.; Hao, Y.; Ren, S.; Luo, P.; Ma, T.; et al. A lightweight strain glass alloy showing nearly temperature-independent low modulus and high strength. Nat. Mater. 2022, 21, 1003–1007. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.; Kula, A.; Mishra, R.; Niewczas, M. The effect of Sc on plastic deformation of Mg–Sc binary alloys under tension. J. Alloys Compd. 2018, 761, 58–70. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. A lightweight shape-memory magnesium alloy. Science 2016, 353, 368–370. [Google Scholar] [CrossRef]

- Yamagishi, K.; Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. Room temperature superelasticity in a lightweight shape memory Mg alloy. Scr. Mater. 2019, 168, 114–118. [Google Scholar] [CrossRef]

- Ando, D.; Ogawa, Y.; Suzuki, T.; Sutou, Y.; Koike, J. Age-hardening effect by phase transformation of high Sc containing Mg alloy. Mater. Lett. 2015, 161, 5–8. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. Aging effect of Mg–Sc alloy with α+β two phase microstructure. Mater. Trans. 2016, 57, 1119–1123. [Google Scholar] [CrossRef]

- Ogawa, Y.; Sutou, Y.; Ando, D.; Koike, J. Aging precipitation kinetics of Mg–Sc alloy with bcc+hcp two-phase. J. Alloys Compd. 2018, 747, 854–860. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Yoshimi, K.; Koike, J. Determination of α/β phase boundaries and mechanical characterization of Mg–Sc binary alloys. Mater. Sci. Eng. A 2016, 670, 335–341. [Google Scholar] [CrossRef]

- Buch, F.; Mordike, B. Microstructure, mechanical properties and creep resistance of binary and more complex magnesium scandium alloys. In Magnesium Alloys and Their Applications; Kainer, K.U., Ed.; Wiley-VCH: Weinheim, Germany, 1998; pp. 145–150. [Google Scholar]

- Mordike, B. Development of highly creep resistant magnesium alloys. J. Mater. Process. Technol. 2001, 117, 391–394. [Google Scholar] [CrossRef]

- Mordike, B.; Ebert, T. Magnesium: Properties, applications and potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Mordike, B. Creeperesistant magnesium alloys. Mater. Sci. Eng. A 2002, 324, 103–112. [Google Scholar] [CrossRef]

- Mordike, B.; Stulikova, I.; Smola, B. Mechanisms of creep deformation in Mg–Sc based alloys. Metall. Mater. Trans. A 2005, 36, 1729–1736. [Google Scholar] [CrossRef]

- Durst, K.; Maier, V. Dynamic nanoindentation testing for studying thermally activated processes from single to nanocrystalline metals. Curr. Opin. Solid State Mater. Sci. 2015, 19, 340–353. [Google Scholar] [CrossRef]

- Vagarali, S.S.; Langdon, T.G. Deformation mechanisms in hcp metals at elevated temperatures—I. Creep behavior of magnesium. Acta Metall. 1981, 29, 1969–1982. [Google Scholar] [CrossRef]

- Staroselsky, A.; Anand, L. A constitutive model for hcp materials deforming by slip and twinning: Application to magnesium alloy AZ31B. Int. J. Plast. 2003, 19, 1843–1864. [Google Scholar] [CrossRef]

- Ahmad, M.; Sosa, J.C.; Rongong, J. Characterisation of creep behaviour using the power law model in copper alloy. J. Mech. Eng. Sci. 2017, 11, 2503–2510. [Google Scholar] [CrossRef]

- Mao, J.; Liu, W.; Li, D.; Zhang, C.; Ma, Y. The Strain Rate Sensitivity and Creep Behavior for the Tripler Plane of Potassium Dihydrogen Phosphate Crystal by Nanoindentation. Micromachines 2021, 12, 369. [Google Scholar] [CrossRef]

- Viespoli, L.M.; Johanson, A.; Alvaro, A.; Nyhus, B.; Sommacal, A.; Berto, F. Tensile characterization of a lead alloy: Creep induced strain rate sensitivity. Mater. Sci. Eng. A 2019, 744, 365–375. [Google Scholar] [CrossRef]

- Alkorta, J.; Martínez-Esnaola, J.M.; Sevillano, J.G. Critical examination of strain-rate sensitivity measurement by nanoindentation methods: Application to severely deformed niobium. Acta Mater. 2008, 56, 884–893. [Google Scholar] [CrossRef]

- Somekawa, H.; Mukai, T. Nanoindentation creep behavior of grain boundary in pure magnesium. Philos. Mag. Lett. 2010, 90, 883–890. [Google Scholar] [CrossRef]

- Han, L.; Northwood, D.O.; Nie, X.; Hu, H. The effect of cooling rates on the refinement of microstructure and the nanoscale indentation creep behavior of Mg–Al–Ca alloy. Mater. Sci. Eng. A 2009, 512, 58–66. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, W.; Bi, G.; Lu, J.; Huo, W.; Zhang, Y. Nanoindentation creep behavior of coarse-grained and ultrafine-grained pure magnesium and AZ31 alloy. Mater. Sci. Eng. A 2017, 698, 348–355. [Google Scholar] [CrossRef]

- Fang, L.; Wang, J.; Xu, C.; He, X.; Xu, G.; Tao, X.; Ouyang, Y.; Du, Y. Interdiffusion behaviors and mechanical properties in Zr–Nb–Hf system. Calphad 2023, 83, 102634. [Google Scholar] [CrossRef]

- Haußmann, L.; Neumeier, S.; Bresler, J.; Keim, S.; Pyczak, F.; Göken, M. Influence of Nb, Ta and Zr on the Interdiffusion Coefficients and Solid Solution Strengthening of γ-TiAl Single Phase Alloys. Metals 2022, 12, 752. [Google Scholar] [CrossRef]

- Mao, S.; Wang, C.; Li, N.; Wang, J.; Chen, Y.; Xu, G.; Guo, Y.; Cui, Y. Kinetic diffusion multiple: A high-throughput approach to screening the composition-microstructure-micromechanical properties relationships. Calphad 2018, 61, 219–226. [Google Scholar] [CrossRef]

- Conrad, H. Thermally activated deformation of metals. JOM 1964, 16, 582–588. [Google Scholar] [CrossRef]

- Dong, R.; Xu, G.; Ko, W.; Wang, J.; Tao, X.; Cui, Y. Diffusion behaviors and atomic mobilities in Mg–Sc hcp and bcc alloys: Investigation via single-phase and multi-phase diffusion couples. Calphad 2021, 72, 102228. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, Z.; Tao, X.; Wang, J.; Xu, G.; Cui, Y. Measurement of the diffusion coefficient in Mg–Sn and Mg–Sc binary alloys. Int. J. Mater. Res. 2022, 113, 391–399. [Google Scholar] [CrossRef]

- Li, N.; Li, Y.; Yang, L.; Wang, C. High-throughput investigation of temperature-dependent creep mechanisms in Mg–Zn alloys using nanoindentation. Phys. Scr. 2025, 100, 055933. [Google Scholar] [CrossRef]

- Choi, I.-C.; Yoo, B.-G.; Kim, Y.-J.; Jang, J. Indentation creep revisited. J. Mater. Res. 2012, 27, 3–11. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, Z.; Huang, P. Diffusion quadruples for the determination of quaternary phase diagrams applied to FeCoNiCr system. Scr. Metall. 1988, 22, 1825–1829. [Google Scholar] [CrossRef]

- Cheng, K.; Xu, H.; Ma, B.; Zhou, J.; Tang, S.; Liu, Y.; Sun, C.; Wang, N.; Wang, M.; Zhang, L.; et al. An in-situ study on the diffusion growth of intermetallic compounds in the Al–Mg diffusion couple. J. Alloys Compd. 2019, 810, 151878. [Google Scholar] [CrossRef]

- Long, X.; Shen, Z.; Jia, Q.; Li, J.; Dong, R.; Su, Y.; Yang, X.; Zhou, K. Determine the unique constitutive properties of elastoplastic materials from their plastic zone volution under nanoindentation. Mech. Mater. 2022, 175, 104485. [Google Scholar] [CrossRef]

- Robertson, C.; Poissonnet, S.; Boulanger, L. Plasticity in ion-irradiated austenitic stainless steels. J. Mater. Res. 1998, 13, 2123–2131. [Google Scholar] [CrossRef]

- Chiang, S.; Marshall, D.; Evans, A. The response of solids to elastic/plastic indentation. Proc. R. Soc. Lond. 2013, 53, 298–311. [Google Scholar]

- Baker, S.; Liu, J. Nanoindentation Techniques, Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Zhang, Z.; Li, Y.; Wu, W. Effects of loading rate and peak load on nanoindentation creep behavior of DD407Ni-base single crystal superalloy. Trans. Nonferrous Met. Soc. China 2022, 32, 206–216. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Ma, Y.; Huang, Y.; Tang, Y.; Cheng, F.; Yu, Q. Indentation size effect and micromechanics characterization of intermetallic compounds in the Au–Sn system. Mater. Sci. Eng. A 2014, 610, 161–170. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, G.; Wang, D.; Liu, Y.; Zeng, X.; Knezevic, M. Creep strength of Mg–Y–Zn alloys containing long-period stacking ordered structures. J. Alloys Compd. 2025, 1024, 180110. [Google Scholar] [CrossRef]

- Sun, Y.; Huo, Y.; Yu, W.; Yan, Z.; Wang, Z.; Li, Z.; Wang, Z.; Chen, H.; Jiang, A.; Wang, X. Microstructure and nanoindentation creep behavior of NiAlCrFeMo high-entropy alloy. J. Alloys Compd. 2025, 1020, 179330. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Zhang, Z.; Xu, C.; Nie, K.; Niu, X. A high strength and good ductility Mg–Y–NI–TI alloy with long period stacking ordered structure processed by hot rolling and aging treatment. Mater. Sci. Eng. A 2015, 648, 134–139. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.; Minor, A. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef] [PubMed]

| No. | Sc at.% | a | b | k | R2 |

|---|---|---|---|---|---|

| 1 | 23.01 | 4.3149 | 0.3175 | −0.0147 | 0.9946 |

| 2 | 23.12 | 3.4316 | 0.2821 | 0.0158 | 0.9935 |

| 3 | 23.66 | 1.9768 | 0.3581 | 0.0189 | 0.9932 |

| 4 | 24.08 | 2.6334 | 0.2431 | 0.0586 | 0.9923 |

| 5 | 24.14 | 3.0238 | 0.3142 | 0.0428 | 0.9937 |

| 6 | 24.70 | 4.4832 | 0.2188 | 0.0221 | 0.9810 |

| 7 | 25.07 | 2.4008 | 0.3014 | 0.0320 | 0.9903 |

| 8 | 25.19 | 2.7927 | 0.2506 | 0.0495 | 0.9884 |

| 9 | 26.04 | 3.0589 | 0.2039 | 0.0589 | 0.9902 |

| 10 | 26.54 | 4.1954 | 0.2437 | 0.0271 | 0.9926 |

| 11 | 27.11 | 4.5016 | 0.2236 | 0.0183 | 0.9843 |

| 12 | 27.22 | 4.1373 | 0.3185 | −0.0115 | 0.9959 |

| 13 | 27.93 | 2.9581 | 0.3583 | −0.0067 | 0.9953 |

| 14 | 28.67 | 3.7173 | 0.2733 | 0.0547 | 0.9945 |

| 15 | 28.95 | 3.6620 | 0.3489 | −0.0441 | 0.9937 |

| 16 | 29.12 | 2.4741 | 0.3439 | 0.0481 | 0.9969 |

| 17 | 30.71 | 4.0704 | 0.2161 | 0.0065 | 0.9854 |

| 18 | 31.02 | 2.6011 | 0.2266 | 0.1001 | 0.9959 |

| 19 | 32.43 | 3.0927 | 0.3041 | 0.0183 | 0.9941 |

| 20 | 33.56 | 2.5880 | 0.3196 | 0.0068 | 0.9901 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Xu, G.; Chen, F. Composition-Dependent Creep Resistance and Strain Rate Sensitivity of BCC Mg-Sc Alloy Studied via Nano-Indentation on Diffusion Couple. Materials 2025, 18, 3828. https://doi.org/10.3390/ma18163828

Liu C, Xu G, Chen F. Composition-Dependent Creep Resistance and Strain Rate Sensitivity of BCC Mg-Sc Alloy Studied via Nano-Indentation on Diffusion Couple. Materials. 2025; 18(16):3828. https://doi.org/10.3390/ma18163828

Chicago/Turabian StyleLiu, Chenyue, Guanglong Xu, and Fuwen Chen. 2025. "Composition-Dependent Creep Resistance and Strain Rate Sensitivity of BCC Mg-Sc Alloy Studied via Nano-Indentation on Diffusion Couple" Materials 18, no. 16: 3828. https://doi.org/10.3390/ma18163828

APA StyleLiu, C., Xu, G., & Chen, F. (2025). Composition-Dependent Creep Resistance and Strain Rate Sensitivity of BCC Mg-Sc Alloy Studied via Nano-Indentation on Diffusion Couple. Materials, 18(16), 3828. https://doi.org/10.3390/ma18163828