Multiscale Finite Element Analysis of Warping Suppression in Microelectronics with Graded SiC/Al Composites

Highlights

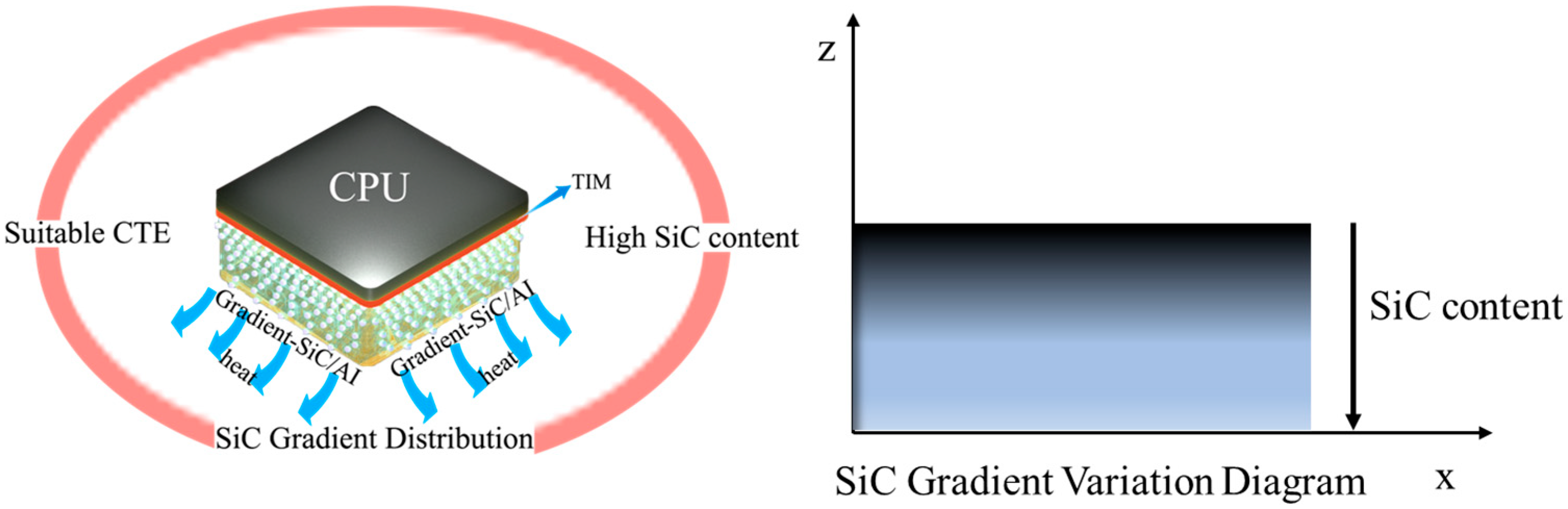

- Graded SiC/Al enables adaptive chip-heatsink thermal expansion matching.

- 42.5% lower peak stress and 52% reduced warpage vs. Cu-based materials.

- Gradient CTE suppresses interfacial strain jumps, enabling 125 °C operation.

- Multi-scale modeling reveals dislocation suppression mechanism.

Abstract

1. Introduction

2. Simulation and Computational Methods

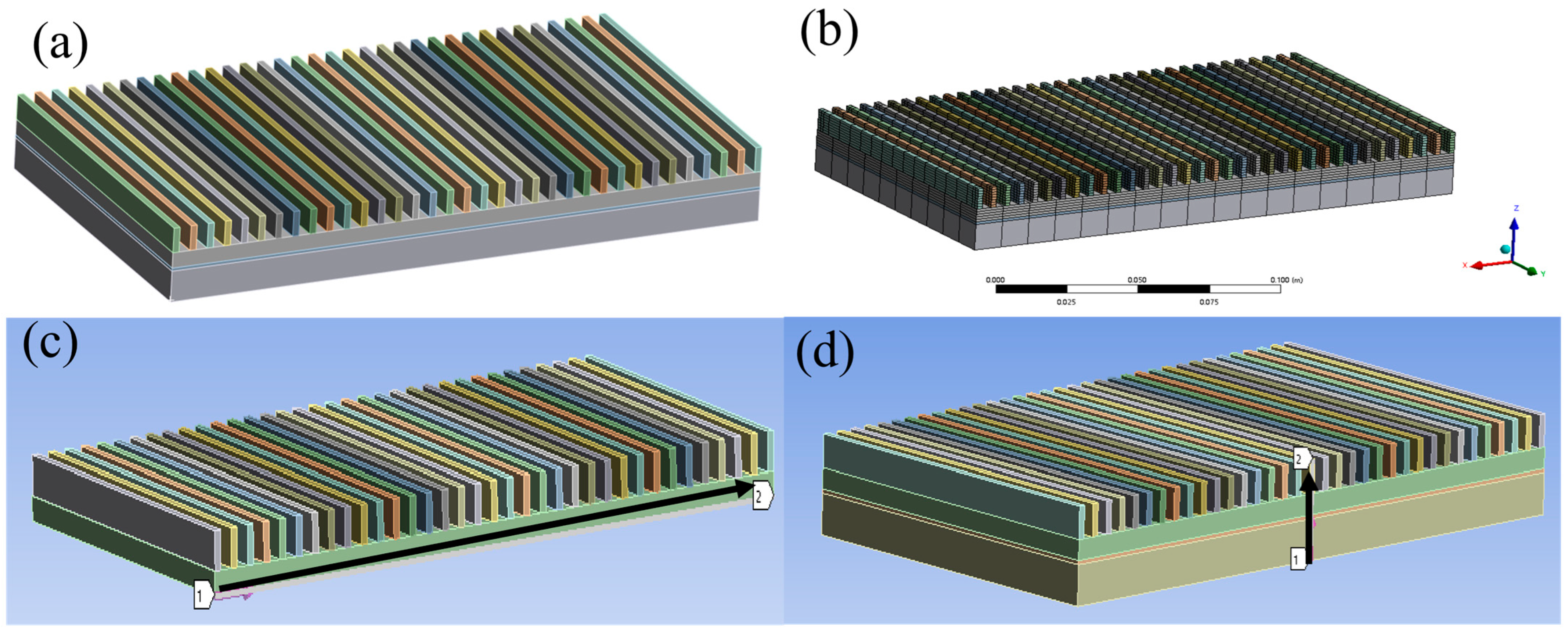

2.1. Definition of Numerical Model

2.2. Finite Element Simulation

3. Simulation and Discussion

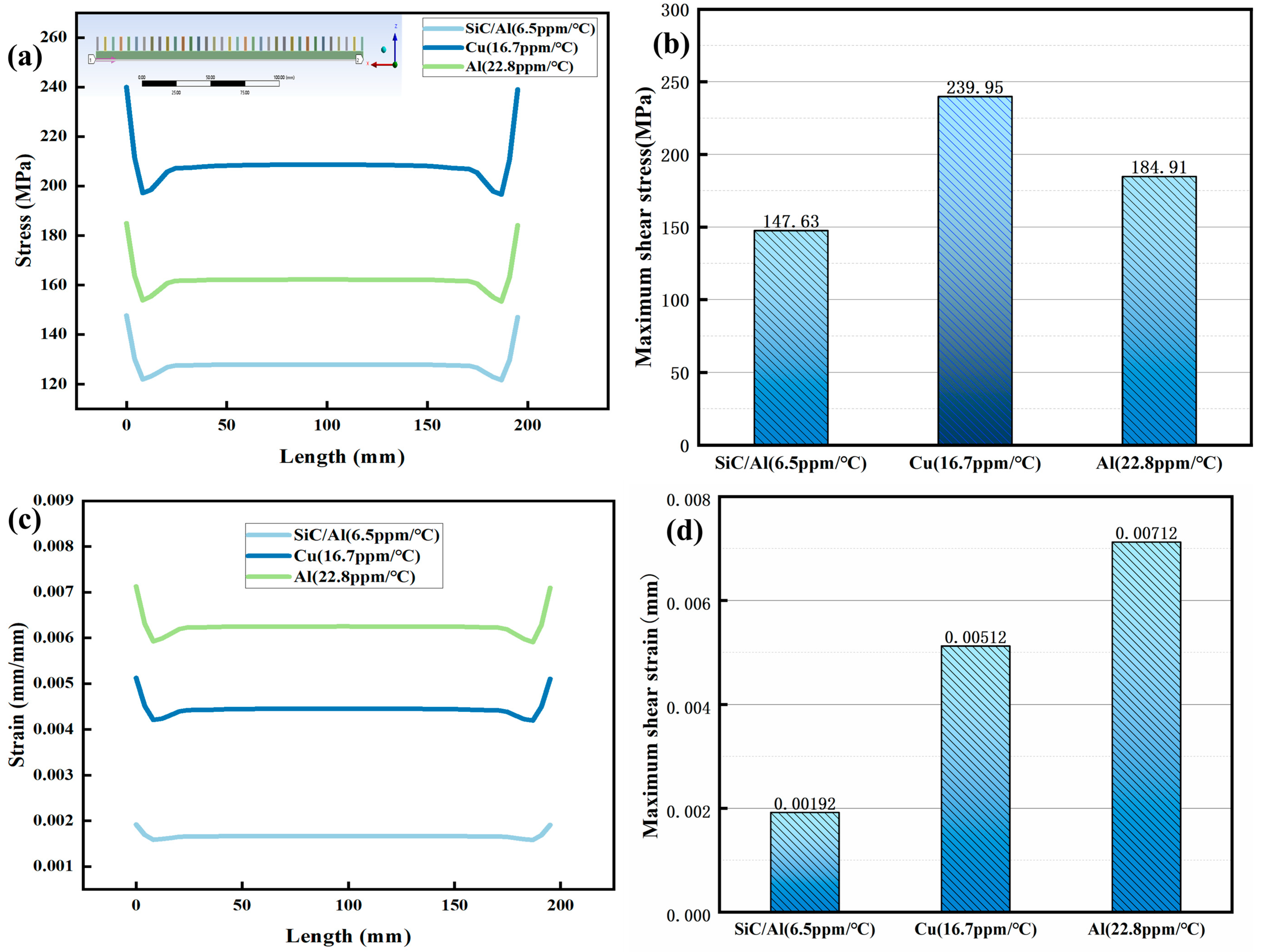

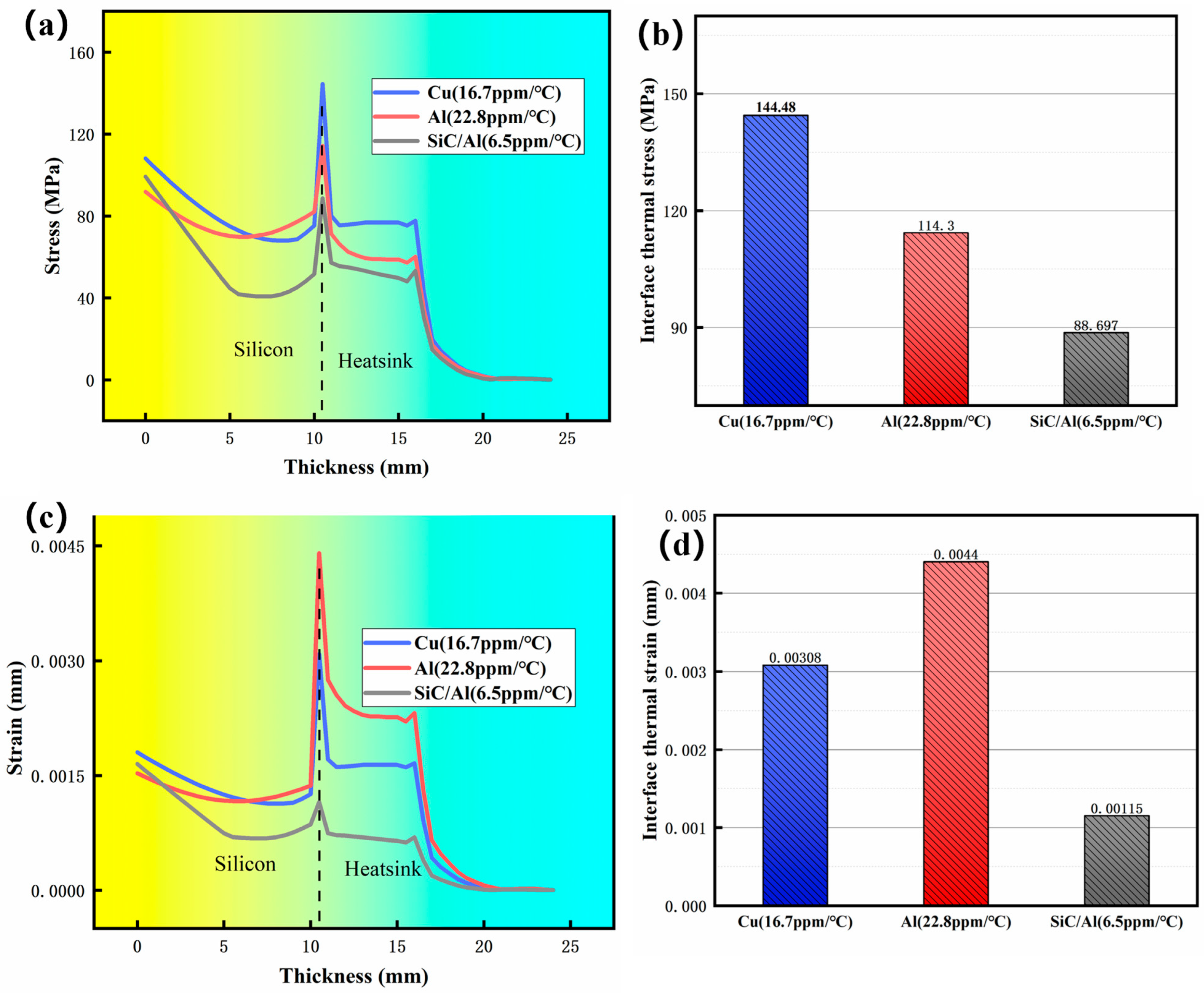

3.1. Thermal and Mechanical Behavior of Homogeneous Materials

- (1)

- Thermal Performance Analysis

- (2)

- Thermomechanical Stress Behavior

- (3)

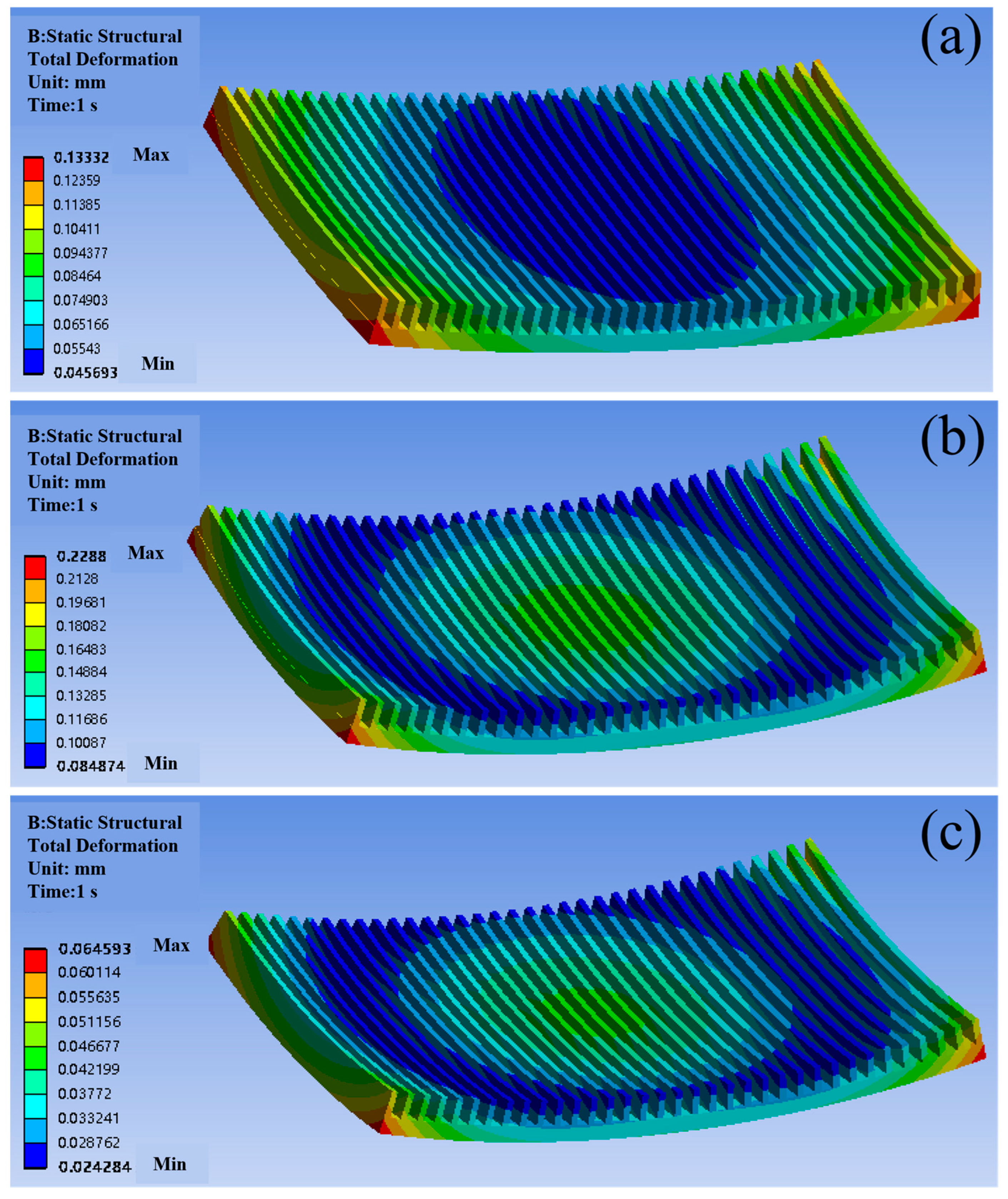

- Warping Deformation Mechanisms

3.2. Performance Enhancement via Gradient SiC/Al Composites

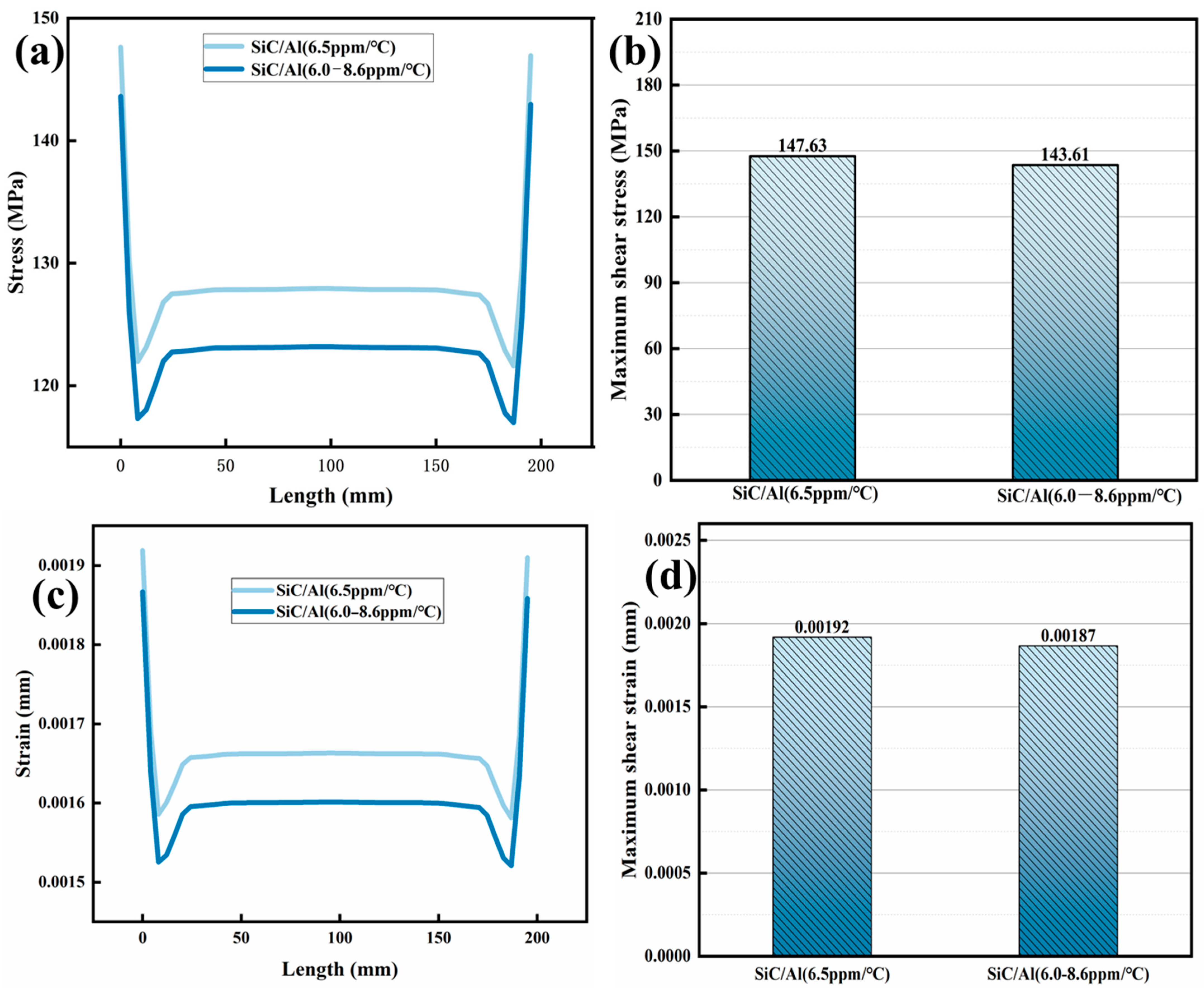

- (1)

- Axial Stress–Strain Optimization

- (2)

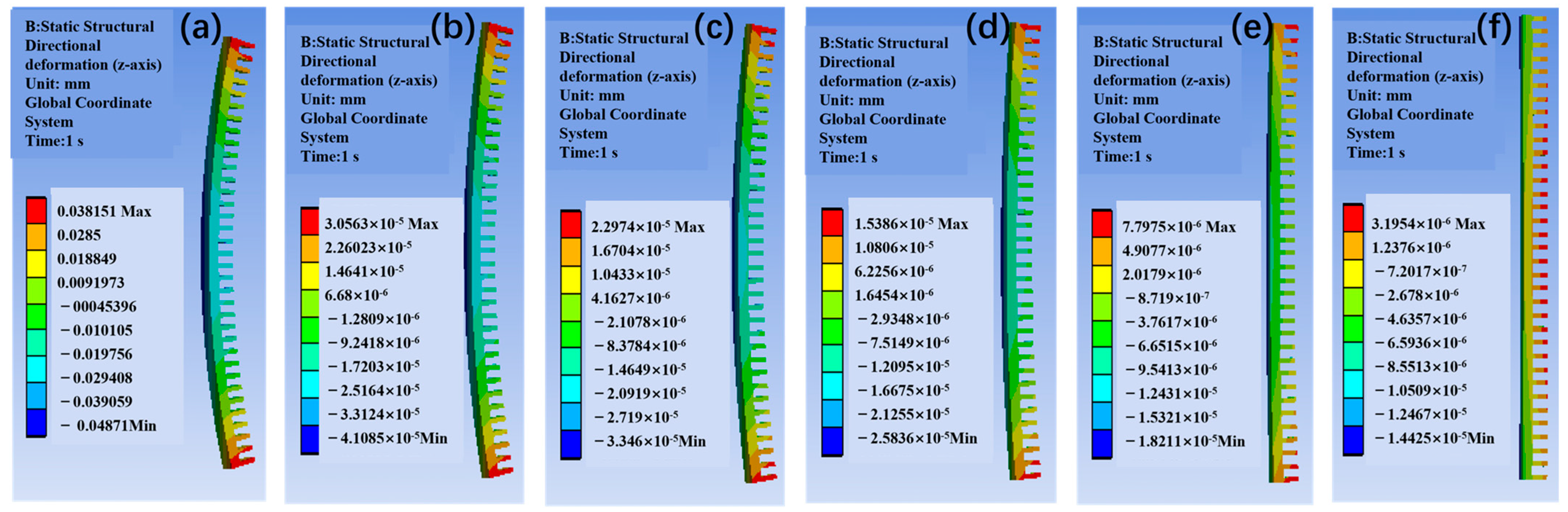

- Warping Deformation Optimization

- (3)

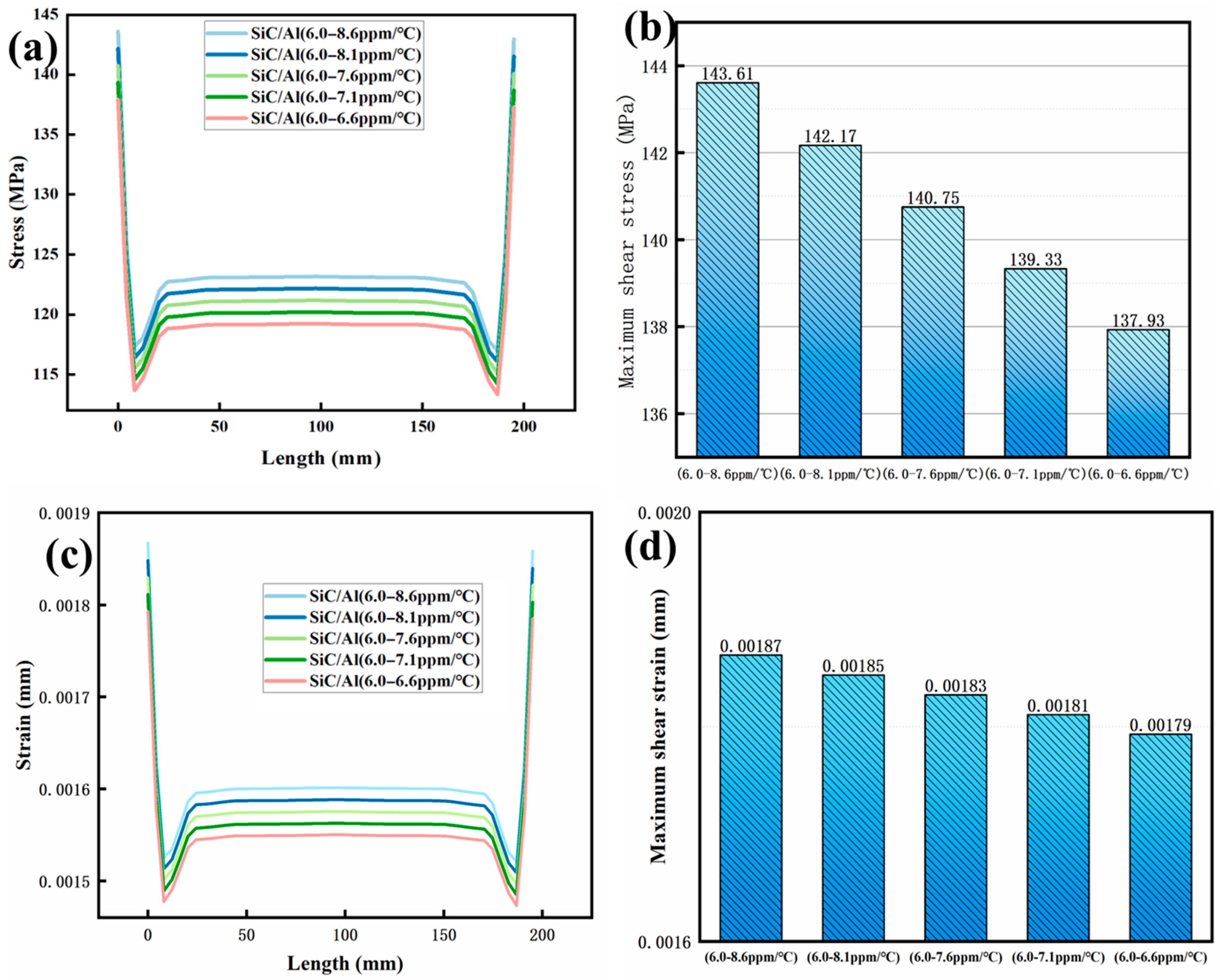

- Thermal Expansion Gradient Engineering

- (4)

- Integrated Analysis and Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Das Sharma, D.; Pasdast, G.; Tiagaraj, S.; Aygün, K. High-performance, power-efficient three-dimensional system-in-package designs with universal chiplet interconnect express. Nat. Electron. 2024, 7, 244–254. [Google Scholar] [CrossRef]

- Wen, Y.; Chen, C.; Ye, Y.; Xue, Z.; Liu, H.; Zhou, X.; Zhang, Y.; Li, D.; Xie, X.; Mai, Y.W. Advances on thermally conductive epoxy-based composites as electronic packaging underfill materials—A review. Adv. Mater. 2022, 34, 2201023. [Google Scholar] [CrossRef] [PubMed]

- Pathak, S.K.; Sharma, P.O.; Goel, V.; Bhattacharyya, S.; Aybar, H.Ş.; Meyer, J.P. A detailed review on the performance of photovoltaic/thermal system using various cooling methods. Sustain. Energy Technol. Assess. 2022, 51, 101844. [Google Scholar] [CrossRef]

- Liao, K.; Zhong, Y.; Du, Z.; Liu, G.; Li, C.; Wu, X.; Deng, C.; Lu, C.; Wang, X.; Chan, C.T. On-chip integrated exceptional surface microlaser. Sci. Adv. 2023, 9, eadf3470. [Google Scholar] [CrossRef] [PubMed]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Kukkapalli, V.K.; Kim, S.; Thomas, S.A. Thermal Management Techniques in Metal Hydrides for Hydrogen Storage Applications: A Review. Energies 2023, 16, 3444. [Google Scholar] [CrossRef]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Sun, J.; Jing, Q.; Lei, L.; Zhang, J. Compositional gradient affects the residual stress distribution in Si3N4/SiC functionally graded materials. Ceram. Int. 2023, 49, 19281–19289. [Google Scholar] [CrossRef]

- Zhang, C.; Qu, Z.; Fang, X.; Feng, X.; Hwang, K.-C. Digital gradient sensing method to evaluate thermal stress at elevated temperatures. Exp. Mech. 2016, 56, 1123–1132. [Google Scholar] [CrossRef]

- Yang, K.; Jiang, G.-H.; Qu, Q.; Peng, H.-F.; Gao, X.-W. A new modified conjugate gradient method to identify thermal conductivity of transient non-homogeneous problems based on radial integration boundary element method. Int. J. Heat Mass Transf. 2019, 133, 669–676. [Google Scholar] [CrossRef]

- Chen, T.-C.; Lin, W.-J.; Chen, D.-L. Effect of temperature gradient on simultaneously experimental determination of thermal expansion coefficients and elastic modulus of thin film materials. J. Appl. Phys. 2004, 96, 3800–3806. [Google Scholar] [CrossRef]

- Lutz, M.P.; Zimmerman, R.W. Thermal stresses and effective thermal expansion coefficient of a functionally gradient sphere. J. Therm. Stress. 1996, 19, 39–54. [Google Scholar] [CrossRef]

- Zhao, L.-H.; Wang, L.; Jin, Y.-F.; Ren, J.-W.; Wang, Z.; Jia, L.-C. Simultaneously improved thermal conductivity and mechanical properties of boron nitride nanosheets/aramid nanofiber films by constructing multilayer gradient structure. Compos. Part B Eng. 2022, 229, 109454. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Z.; Li, Q.; Wang, L. Fabrication of SiC/Al functionally graded materials via filtration extrusion. Adv. Eng. Mater. 2023, 25, 2300384. [Google Scholar] [CrossRef]

- Gao, Y.; Yi, J.; Lee, P.; Lindley, T. A micro-cell model of the effect of microstructure and defects on fatigue resistance in cast aluminum alloys. Acta Mater. 2004, 52, 5435–5449. [Google Scholar] [CrossRef]

- Xia, W.; Xiao, M.; Chen, Y.; Wu, F.; Liu, Z.; Fu, H. Thermal warpage analysis of PBGA mounted on PCB during reflow process by FEM and experimental measurement. Solder. Surf. Mt. Technol. 2014, 26, 162–171. [Google Scholar] [CrossRef]

- Chung, S.; Heo, G.; Kwak, J.; Oh, S.; Lee, Y.; Kang, C.; Lee, T. Development of PCB design guide and PCB deformation simulation tool for slim PCB quality and reliability. In Proceedings of the 2013 IEEE 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 2157–2162. [Google Scholar]

| Material | Si | Al | Cu | SiC/Al | |

|---|---|---|---|---|---|

| Properties | |||||

| Young’s modulus E (GPa) | 150 | 69 | 126 | 200 | |

| Poisson’s ratio (μ) | 0.25 | 0.33 | 0.345 | 0.3 | |

| Density (kg/m3) | 2330 | 2713 | 8942 | 2990 | |

| thermal expansion coefficient (ppm/°C) | 2.5 | 22.8 | 16.7 | 6.5 | |

| thermal conductivity (W/(m·°C)) | 148 | 155.3 | 396.7 | 160 | |

| specific heat capacity (J/(kg·°C)) | 712 | 915.7 | 383.3 | 951 | |

| Material | Max Temperature (°C) | Min Temperature (°C) | Heat Flux (W/mm2) |

|---|---|---|---|

| Cu | 92.188 | 75.398 | 1.0637 |

| Al | 98.991 | 64.923 | 0.92556 |

| SiC/Al | 98.692 | 65.344 | 0.93112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Zhang, J.; Su, H.; Zhang, Y.; Li, K.; Mei, H.; Wu, C.; Zhu, Q.; Gong, W. Multiscale Finite Element Analysis of Warping Suppression in Microelectronics with Graded SiC/Al Composites. Materials 2025, 18, 3788. https://doi.org/10.3390/ma18163788

Zhao J, Zhang J, Su H, Zhang Y, Li K, Mei H, Wu C, Zhu Q, Gong W. Multiscale Finite Element Analysis of Warping Suppression in Microelectronics with Graded SiC/Al Composites. Materials. 2025; 18(16):3788. https://doi.org/10.3390/ma18163788

Chicago/Turabian StyleZhao, Junfeng, Junliang Zhang, Hao Su, Yu Zhang, Kai Li, Haijuan Mei, Changwei Wu, Qingfeng Zhu, and Weiping Gong. 2025. "Multiscale Finite Element Analysis of Warping Suppression in Microelectronics with Graded SiC/Al Composites" Materials 18, no. 16: 3788. https://doi.org/10.3390/ma18163788

APA StyleZhao, J., Zhang, J., Su, H., Zhang, Y., Li, K., Mei, H., Wu, C., Zhu, Q., & Gong, W. (2025). Multiscale Finite Element Analysis of Warping Suppression in Microelectronics with Graded SiC/Al Composites. Materials, 18(16), 3788. https://doi.org/10.3390/ma18163788