Hydration, Soundness, and Strength of Low Carbon LC3 Mortar Using Waste Brick Powder as a Source of Calcined Clay

Abstract

1. Introduction

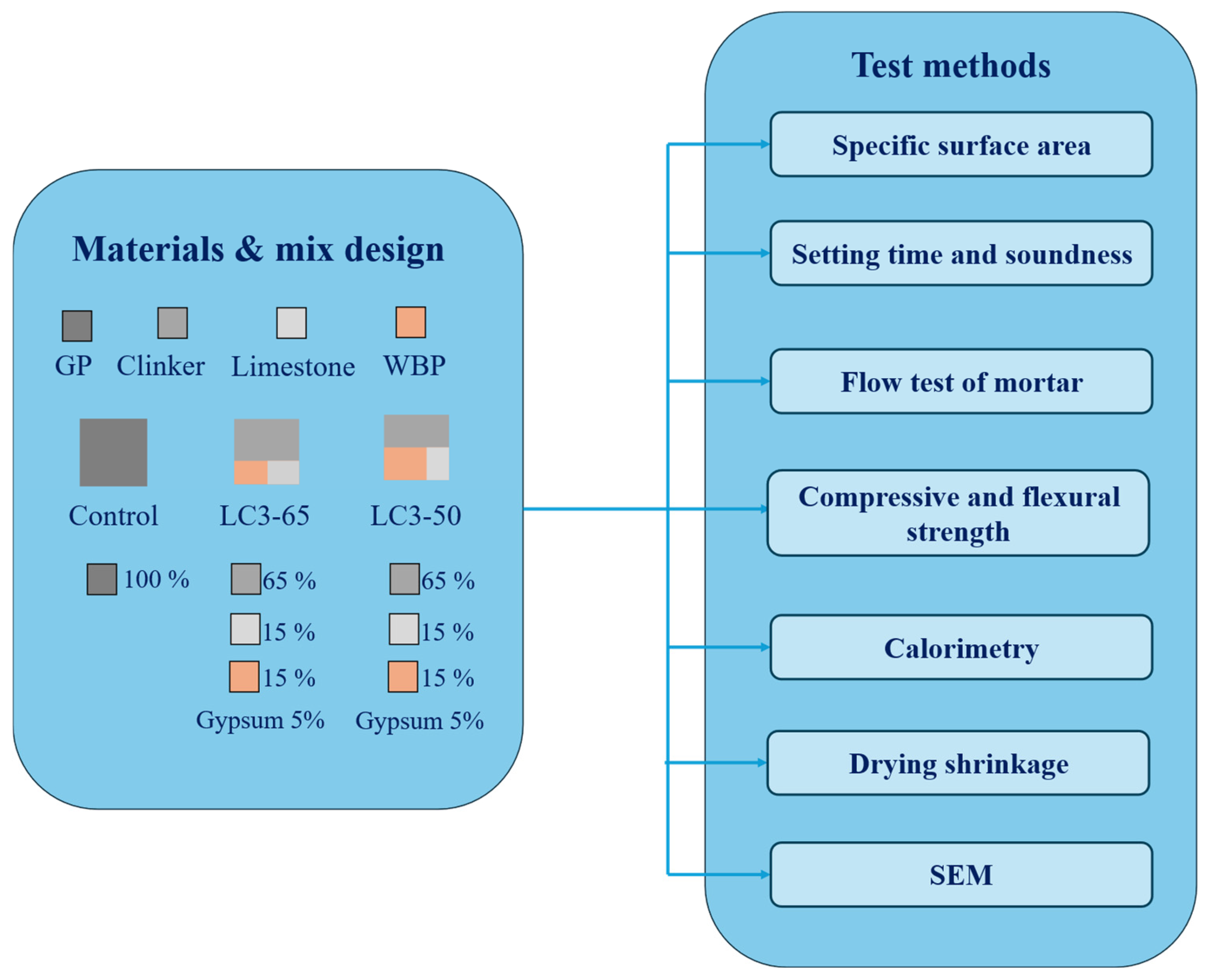

2. Materials and Methods

2.1. Materials

2.2. Preparation of LC3 Binder and the Mix Proportions

| Ingredient | C3S | C2S | C4AF | CaO | SiO2 | CaCO3 | Al2O3 | Fe2O3 | CaSO4 |

|---|---|---|---|---|---|---|---|---|---|

| Clinker | 67.5 | 16 | 8.5 | 2 | 0.5 | - | - | - | - |

| Limestone | - | - | - | - | 1.5 | 95 | 0.75 | 0.5 | - |

| Gypsum | - | - | - | - | 1.5 | - | - | - | 97 |

| Cement | - | - | - | 63.1 | 20.7 | - | 5.70 | 2.90 | - |

| WBP [28] | - | - | - | 2.06 | 66.21 | - | 18.86 | 6.4 | - |

| Binder Mix ID | Clinker | Waste Brick Powder | Limestone | Gypsum |

|---|---|---|---|---|

| LC3-50 | 50 | 30 | 15 | 5 |

| LC3-65 | 65 | 15 | 15 | 5 |

2.3. Test Methods

2.3.1. Blaine’s Fineness Test

2.3.2. Setting Time and Soundness Test of Binder Paste

2.3.3. Flow Test of Mortar

2.3.4. Compressive and Flexure Strength Tests

2.3.5. Calorimetry Test

2.3.6. Drying Shrinkage Test

2.3.7. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Specific Surface Area of Binders

3.2. Setting Time and Soundness

3.3. Workability of Mortars

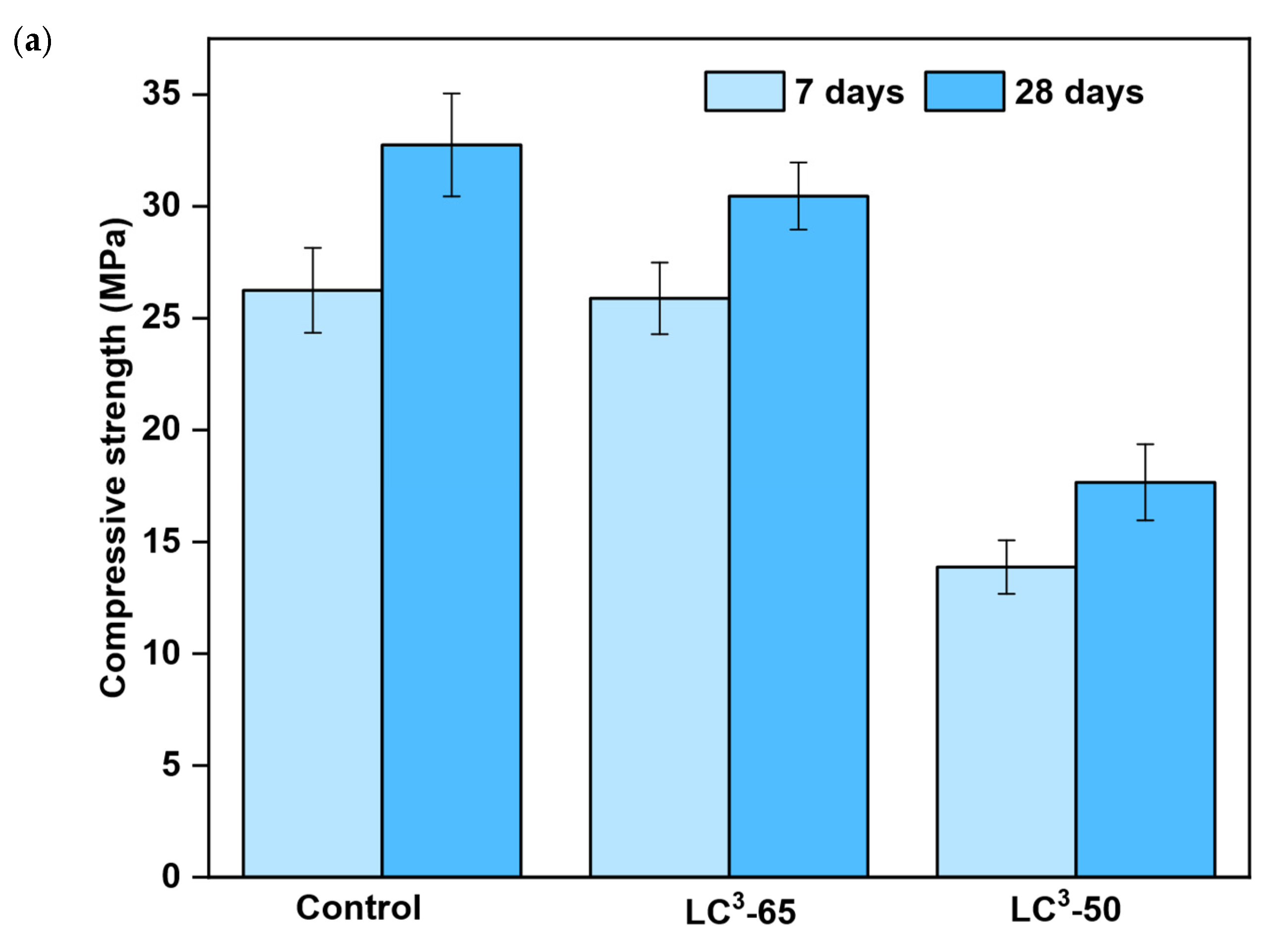

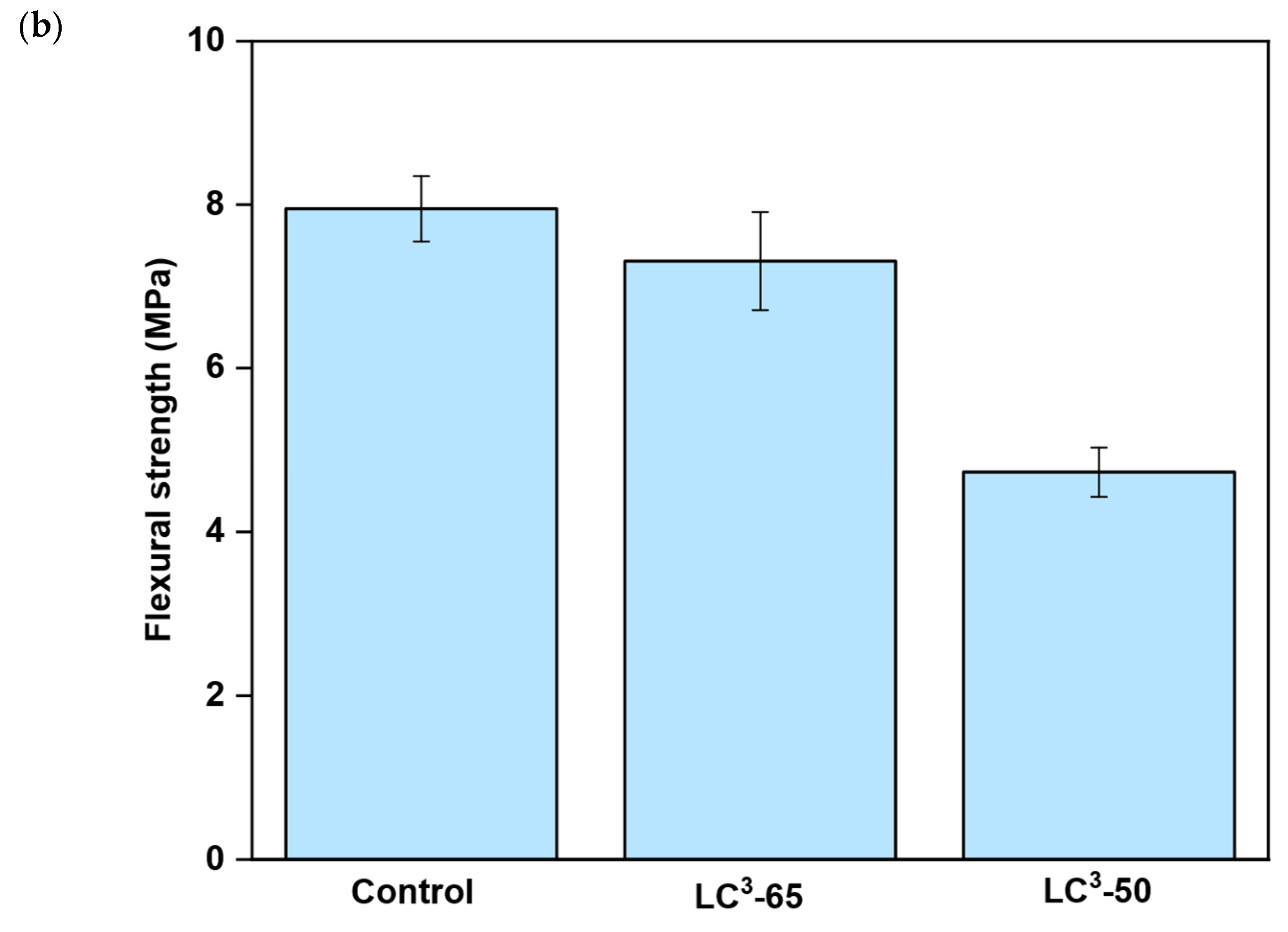

3.4. Compressive and Flexure Strengths

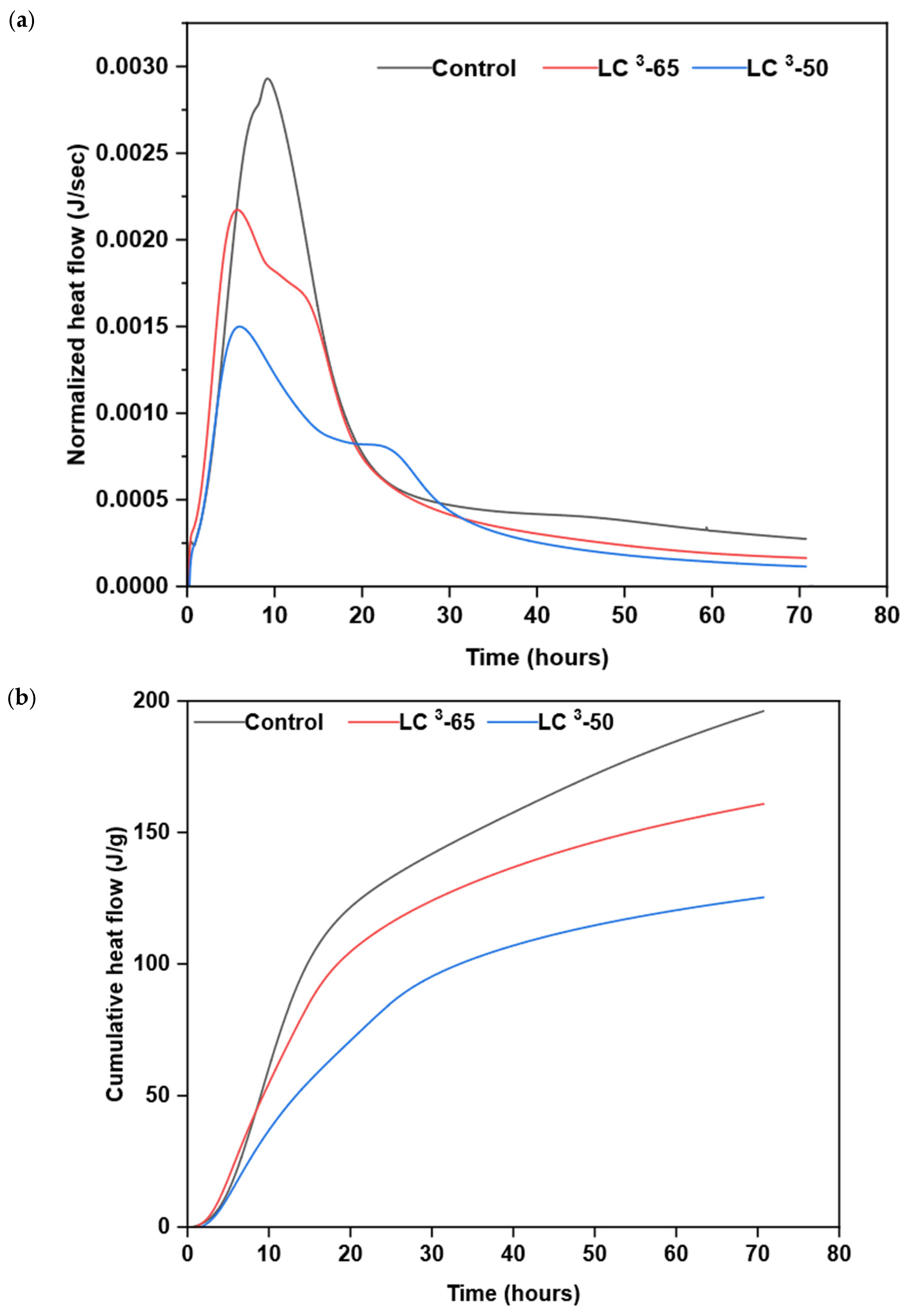

3.5. Calorimetry

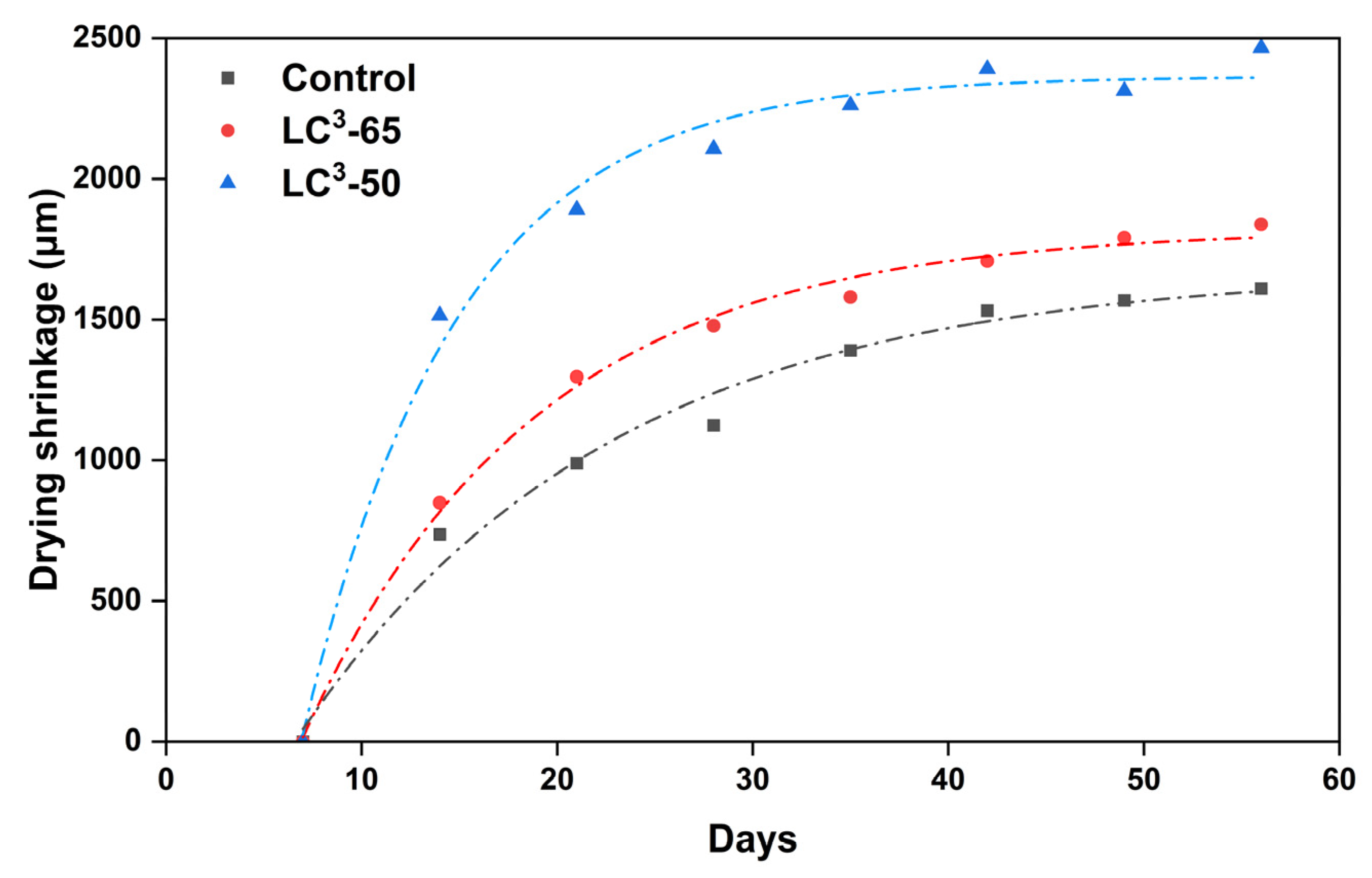

3.6. Drying Shrinkage

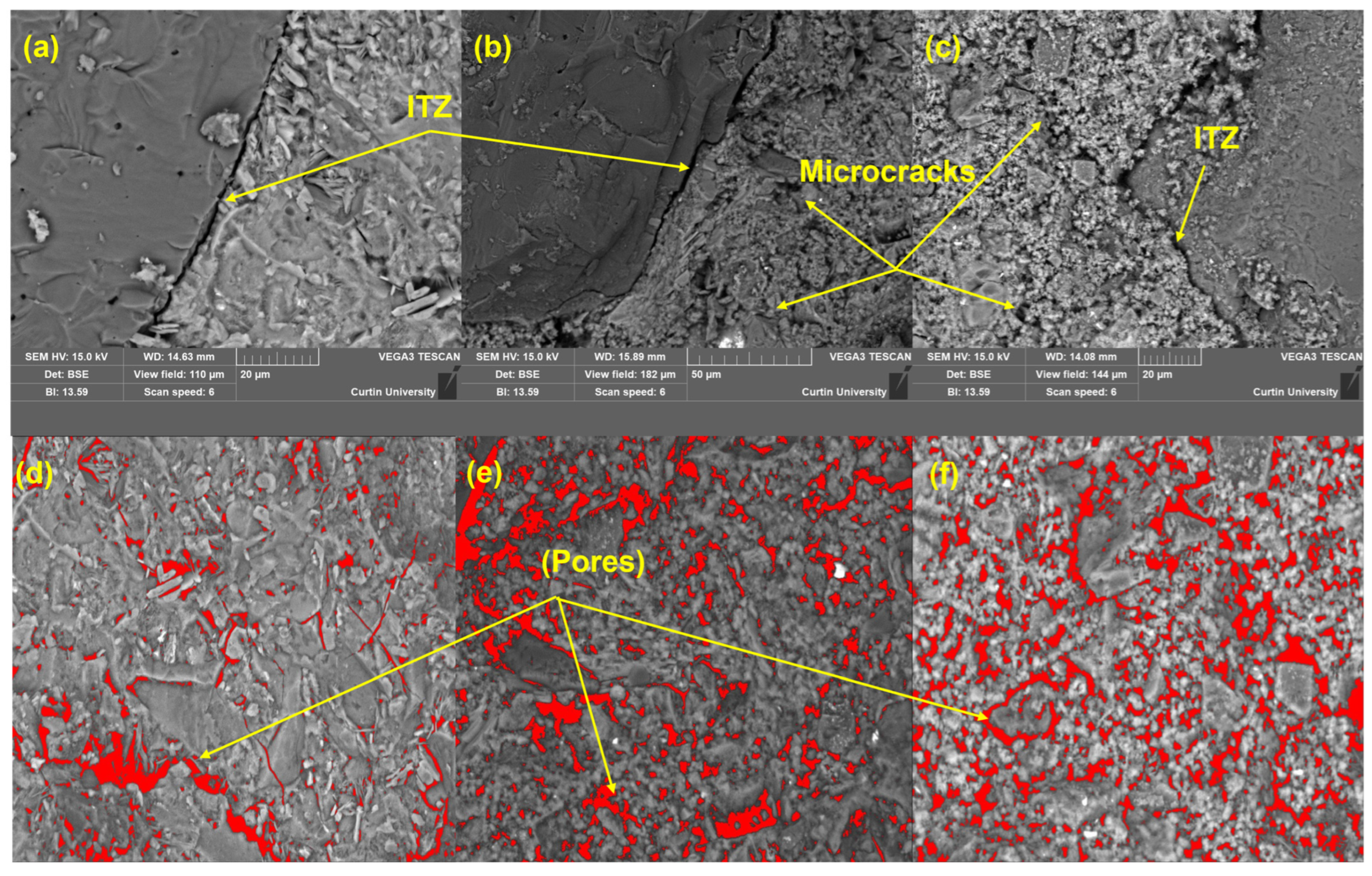

3.7. Microstructure

4. Conclusions

- The compressive strength results showed that at 7 days, mortars LC3-65 and LC3-50 were 1.5% and 47% weaker than the control mix, respectively. The 28-day compressive strengths of the LC3 mixtures were 7% and 46% lower than those of the control mix. Similarly, the 28-day flexural strengths were 8% and 40% lower.

- The isothermal calorimetry results showed 33% and 50% lower peak heat flow rates for LC3-65 and LC3-50 compared to the control paste. Additionally, the cumulative heat flow values of the LC3 mixes were 15% and 34% less than the control, respectively. This result supports the lower strengths of LC3-50 and LC3-65 due to the slower hydration caused by increasing clinker replacement.

- Both LC3 mixtures passed the soundness test showing minimal expansion in the Le Chatelier apparatus. The 56-day drying shrinkage of the control mortar was 1610 micro strains. In contrast, mortars LC3-65 and LC3-50 exhibited 14% and 53% increases in drying shrinkage compared to the control, respectively.

- The SEM analysis revealed fewer microcracks and lower porosity in the control sample compared to the LC3 samples. The porosity values of the control mix, LC3-65, and LC3-50 were found to be 7%, 11%, and 15%, respectively.

- The reduction in strength in the LC3 mixtures is attributed to their slower hydration rate and increased porosity compared to the control. Nevertheless, the results indicate that the performance of LC3-65 was close to that of the control mix, supporting the potential use of WBP as a low-carbon partial replacement of clinker in LC3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al Khaffaf, I.; Hawileh, R.A.; Sahoo, S.; Abdalla, J.A.; Kim, J.H. Toward carbon- neutral construction: A review of zero-carbon concrete. J. Build. Eng. 2025, 99, 111578. [Google Scholar] [CrossRef]

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry: Technology Assessment for Full Decarbonisation of the Industry by 2050; ETH Zurich: Zürich, Switzerland, 2018. [Google Scholar]

- Barbhuiya, S.; Nepal, J.; Das, B.B. Properties, compatibility, environmental benefits and future directions of limestone calcined clay cement (LC3) concrete: A review. J. Build. Eng. 2023, 79, 107794. [Google Scholar] [CrossRef]

- Gartner, E.; Sui, T. Alternative cement clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Bishnoi, S.; Maity, S.; Mallik, A.; Joseph, S.; Krishnan, S. Pilot scale manufacture of limestone calcined clay cement: The Indian experience. Indian Concr. J. 2014, 7, 22–28. [Google Scholar]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Guo, L.; Liu, J.; Xi, Y.; Cheng, H.; Chen, D. Effect of slag on the hydration mechanism of limestone calcined clay cement (LC3). Constr. Build. Mater. 2025, 477, 141357. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Di Bella, C.; Sirtoli, D.; Toropovs, N.; Lura, P. Plastic shrinkage of concrete made with calcined clay-limestone cement. Cem. Concr. Res. 2025, 189, 107784. [Google Scholar] [CrossRef]

- Liang, L.; Ding, Y.; Nishiwaki, T.; Nikolayevich, K.S.; Cai, Z.; Yu, K. Limestone calcined clay-based engineered cementitious composites (LC3-ECC) with recycled sand: Macro performance and micro mechanism. Constr. Build. Mater. 2024, 453, 139036. [Google Scholar] [CrossRef]

- Farhan, Z.; Gul, W. Impact of metakaolin on cement mortar and concrete: A review. Int. J. Civ. Eng. Technol. 2017, 8, 2157–2172. [Google Scholar]

- Li, L.G.; Lin, Z.H.; Chen, G.M.; Kwan, A.K. Reutilizing clay brick dust as paste substitution to produce environment-friendly durable mortar. J. Clean. Prod. 2020, 274, 122787. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Abdellatief, M.; Salah, A.; Youssf, O. Valorization of recycled concrete powder, clay brick powder, and volcanic pumice powder in sustainable geopolymer concrete. Sci. Rep. 2025, 15, 11049. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Li, X.; Lei, B. Properties of waste brick powder-based artificial fine aggregate and its application in concrete. J. Build. Eng. 2024, 98, 111466. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Wu, H.; Wang, W.; Wang, L.; Yao, C.; Wu, J. Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials. Constr. Build. Mater. 2021, 274, 122113. [Google Scholar] [CrossRef]

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Qian, X.; Cao, K.; Xu, Y.; Fang, Y.; Cui, L. Hydration, Compressive Strength and Durability of Eco-friendly Cement Mortars Containing Recycled Brick Powder and Metakaolin. KSCE J. Civ. Eng. 2022, 26, 4023–4037. [Google Scholar] [CrossRef]

- AS 3972-2010; General Purpose and Blended Cements. Standards Australia: Sydney, Australia, 2010.

- AS 1672.1—1997; Limes and Limestones Part 1: Limes for Building. Standards Australia: Sydney, Australia, 1997.

- AS 2758.1:2014; Aggregates and Rock for Engineering Purposes, Part 1: Concrete Aggregates. Standards Australia: Sydney, Australia, 2014.

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2019, 7, 3–14. [Google Scholar] [CrossRef]

- AS 1012.8.3:2015; Methods of Testing Concrete, Method 8.3: Methods of Making and Curing Concrete Mortar and Grout Specimens. Standards Australia: Sydney, Australia, 2015.

- Sharmin, S.; Sarker, P.K.; Biswas, W.K.; Abousnina, R.M.; Javed, U. Characterization of waste clay brick powder and its effect on the mechanical properties and microstructure of geopolymer mortar. Constr. Build. Mater. 2024, 412, 134848. [Google Scholar] [CrossRef]

- AS/NZS 2350.8:2006; Methods of Testing Portland, Blended and Masonry Cements, Method 8: Fineness Index by Air Permeability Method. Standards Australia: Sydney, Australia, 2006.

- Dhers, S.; Mueller, A.; Guggenberger, R.; Freimut, D.; Weldert, K.; Sachsenhauser, B.; Yermakou, V.; Mikanovic, N.; Schwesig, P. On the relationship between superplasticizer demand and specific surface area of calcined clays in LC3 systems. Constr. Build. Mater. 2024, 411, 134467. [Google Scholar] [CrossRef]

- Ober, S.S.; Frederick, K.J. A Study of the Blaine Fineness Tester and A Determination of Surface Area From Air Permeability Data. In Proceedings of the Symposium on Particle Size Measurement, Boston, MA, USA, 26–27 June 1958; ASTM International: West Conshohocken, PA, USA, 1959. [Google Scholar]

- AS/NZS 2350.4:2006; Methods of Testing Portland and Blended Cements Method 4: Setting Time. Standards Australia: Sydney, Australia, 2006.

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Setting time and standard consistency of quaternary binders: The influence of cementitious material addition and mixing. Int. J. Sustain. Built Environ. 2017, 6, 30–36. [Google Scholar] [CrossRef]

- AS/NZS 2350.5:2006; Methods of Testing Portland, Blended and Masonry Cements—Determination of Soundness. Standards Australia: Sydney, Australia, 2006.

- AS 2701-2001; Methods of Sampling and Testing Mortar for Masonry Construction. Standards Australia: Sydney, Australia, 2001.

- AS 1012.9:2014; Methods of Testing Concrete, Method 9: Compressive Strength Tests—Concrete, Mortar and Grout Specimens. Standards Australia: Sydney, Australia, 2014.

- AS 1012.11-2000; Methods of Testing Concrete, Method 11: Determination of the Modulus of Rupture. Standards Australia: Sydney, Australia, 2000.

- Atiş, C.D.; Bilim, C.; Çelik, Ö.; Karahan, O. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar] [CrossRef]

- ASTM C1679-22; Standard Practice for Measuring Hydration Kinetics of Hydraulic Cementitious Mixtures Using Isothermal Calorimetry. ASTM International: West Conshohocken, PA, USA, 2022.

- Bissonnette, B.; Pierre, P.; Pigeon, M. Influence of key parameters on drying shrinkage of cementitious materials. Cem. Concr. Res. 1999, 29, 1655–1662. [Google Scholar] [CrossRef]

- AS 1012.13:2015; Methods of Testing Concrete Method 13: Determination of the Drying Shrinkage of Concrete for Samples Prepared in the Field or in the Laboratory. Standards Australia: Sydney, Australia, 2015.

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical Properties of Macro Polypropylene Fibre-Reinforced Concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Abousnina, R.M.; Manalo, A.; Lokuge, W. Physical and Mechanical Properties of Cement Mortar Containing Fine Sand Contaminated with Light Crude Oil. Procedia Eng. 2016, 145, 250–258. [Google Scholar] [CrossRef]

- Tay, J.H.; Show, K.Y. Properties of Cement Made from Sludge. J. Environ. Eng. 1991, 117, 236–246. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M. Assessment of pore structure evolution in the limestone calcined clay cementitious system and its implications for performance. Cem. Concr. Compos. 2017, 84, 36–47. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Sree, S.K.; Rao, B.C.; Yadav, M.J.; Giri, P.S. Experimental studies on mechanical and durability characteristics of lc3 concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1091, 012075. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Kim, T.; Castel, A. Mitigation of alkali-silica reaction by limestone calcined clay cement (LC3). Cem. Concr. Res. 2020, 137, 106176. [Google Scholar] [CrossRef]

- Dixit, A.; Du, H.; Dai Pang, S. Performance of mortar incorporating calcined marine clays with varying kaolinite content. J. Clean. Prod. 2021, 282, 124513. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Diaz, A.A.; Haha, M.B.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Afroz, S.; Zhang, Y.; Kim, T.; Li, W.; Castel, A. Autogenous and total shrinkage of limestone calcined clay cement (LC3) concretes. Constr. Build. Mater. 2022, 314, 125720. [Google Scholar] [CrossRef]

- Juenger, M.C.; Winnefeld, F.; Provis, J.L.; Ideker, J.H. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Brooks, J.J.; Johari, M.M. Effect of metakaolin on creep and shrinkage of concrete. Cem. Concr. Compos. 2001, 23, 495–502. [Google Scholar] [CrossRef]

- Dhir, R.K.; Limbachiya, M.C.; McCarthy, M.J.; Chaipanich, A. Evaluation of Portland limestone cements for use in concrete construction. Mater. Struct. 2007, 40, 459–473. [Google Scholar] [CrossRef]

- Bederina, M.; Makhloufi, Z.; Bouziani, T. Effect of Limestone Fillers the Physic-Mechanical Properties of Limestone Concrete. Phys. Procedia 2011, 21, 28–34. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Humagain, S.; Shrestha, G.; Madhavan, M.K.; Sarker, P.K. Hydration, Soundness, and Strength of Low Carbon LC3 Mortar Using Waste Brick Powder as a Source of Calcined Clay. Materials 2025, 18, 3697. https://doi.org/10.3390/ma18153697

Humagain S, Shrestha G, Madhavan MK, Sarker PK. Hydration, Soundness, and Strength of Low Carbon LC3 Mortar Using Waste Brick Powder as a Source of Calcined Clay. Materials. 2025; 18(15):3697. https://doi.org/10.3390/ma18153697

Chicago/Turabian StyleHumagain, Saugat, Gaurab Shrestha, Mini K. Madhavan, and Prabir Kumar Sarker. 2025. "Hydration, Soundness, and Strength of Low Carbon LC3 Mortar Using Waste Brick Powder as a Source of Calcined Clay" Materials 18, no. 15: 3697. https://doi.org/10.3390/ma18153697

APA StyleHumagain, S., Shrestha, G., Madhavan, M. K., & Sarker, P. K. (2025). Hydration, Soundness, and Strength of Low Carbon LC3 Mortar Using Waste Brick Powder as a Source of Calcined Clay. Materials, 18(15), 3697. https://doi.org/10.3390/ma18153697