Effects of EOGO in Metakaolin-Based Geopolymer

Abstract

1. Introduction

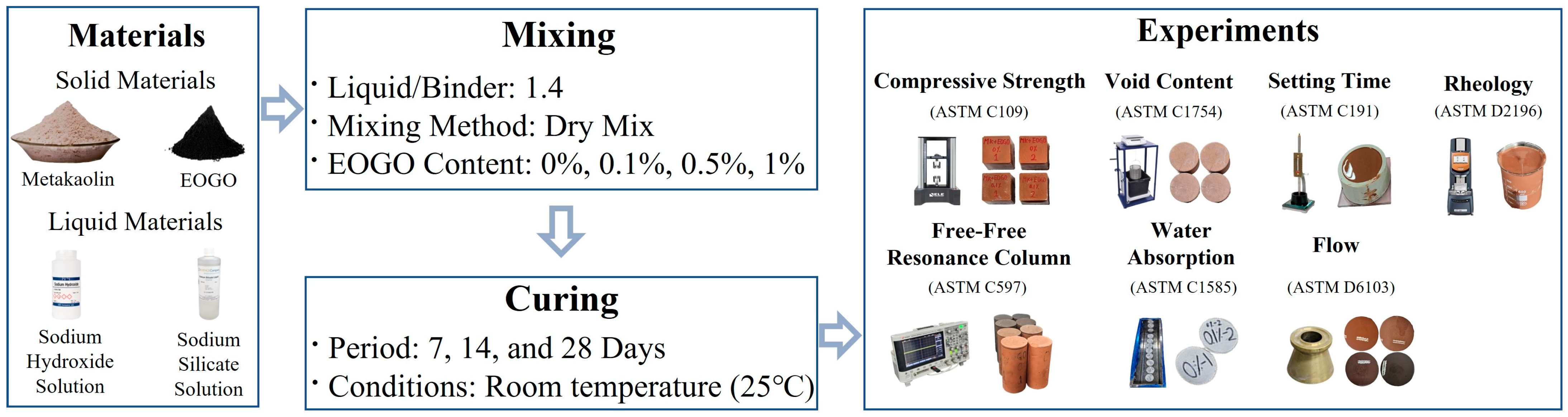

2. Materials and Methods

2.1. Materials

2.1.1. Metakaolin

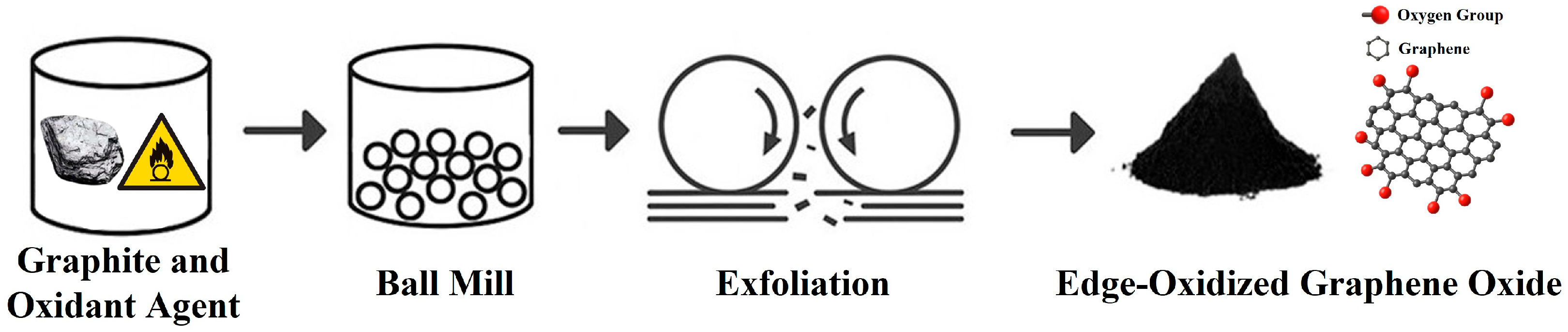

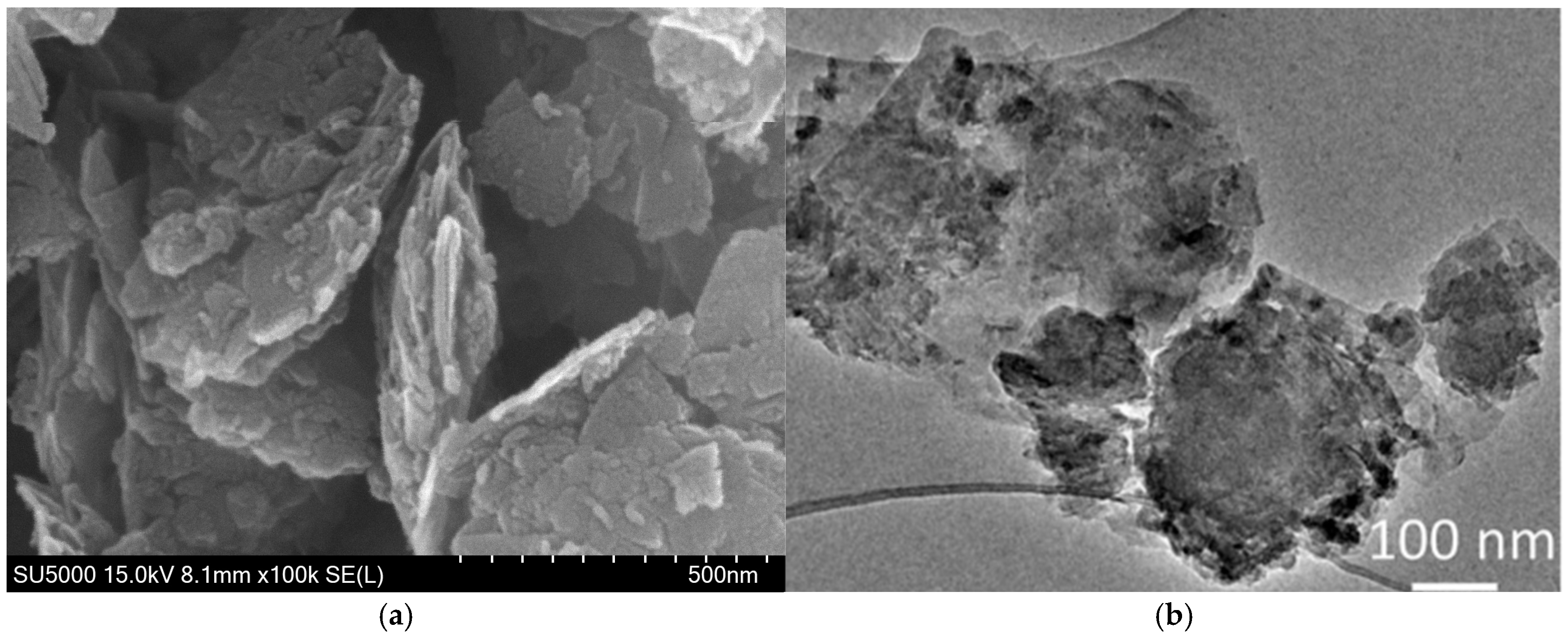

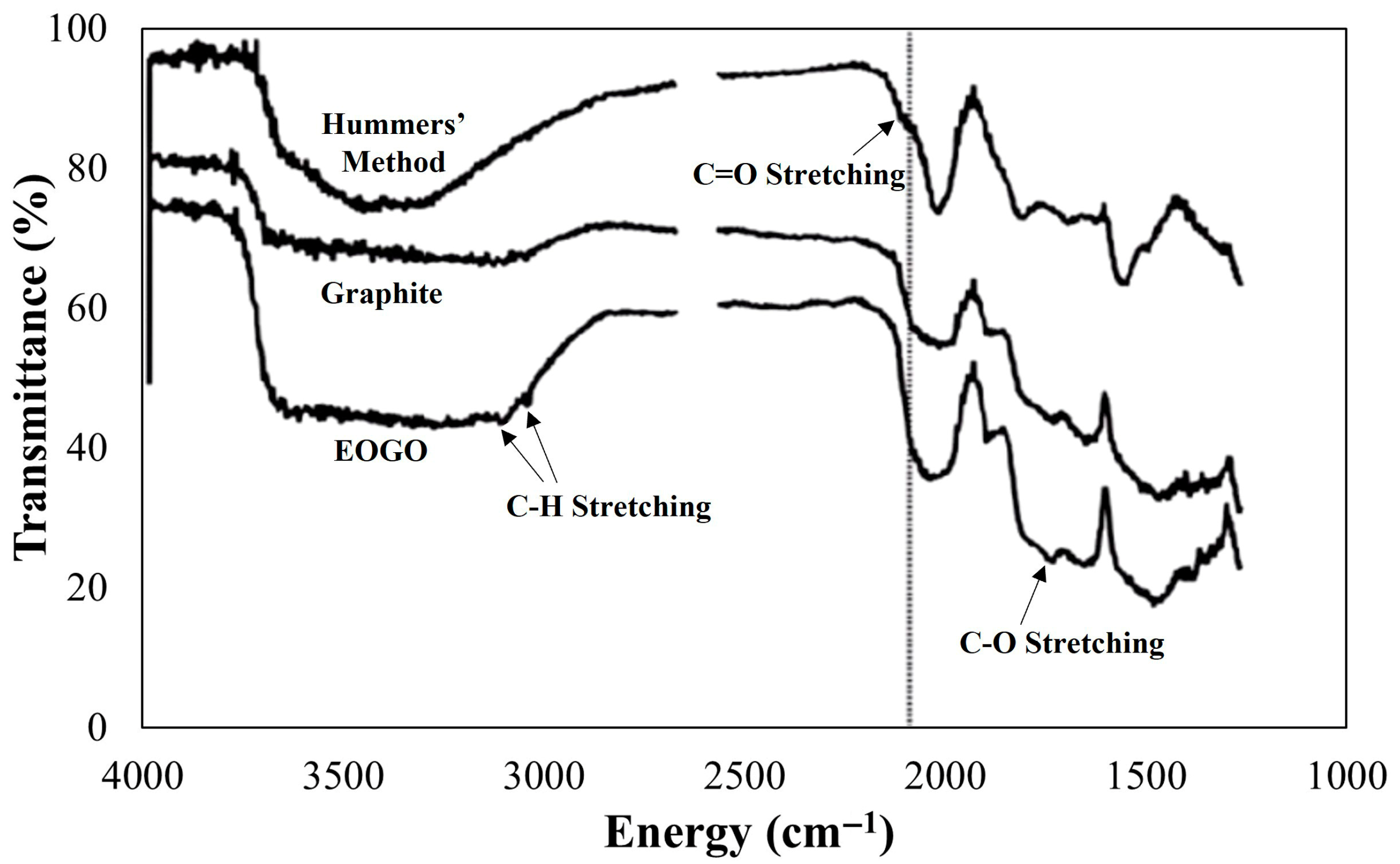

2.1.2. Edge-Oxidized Graphene Oxide (EOGO)

2.2. Preparation of MKGO Paste and Specimens

2.3. Test Methods

2.3.1. Compressive Strength

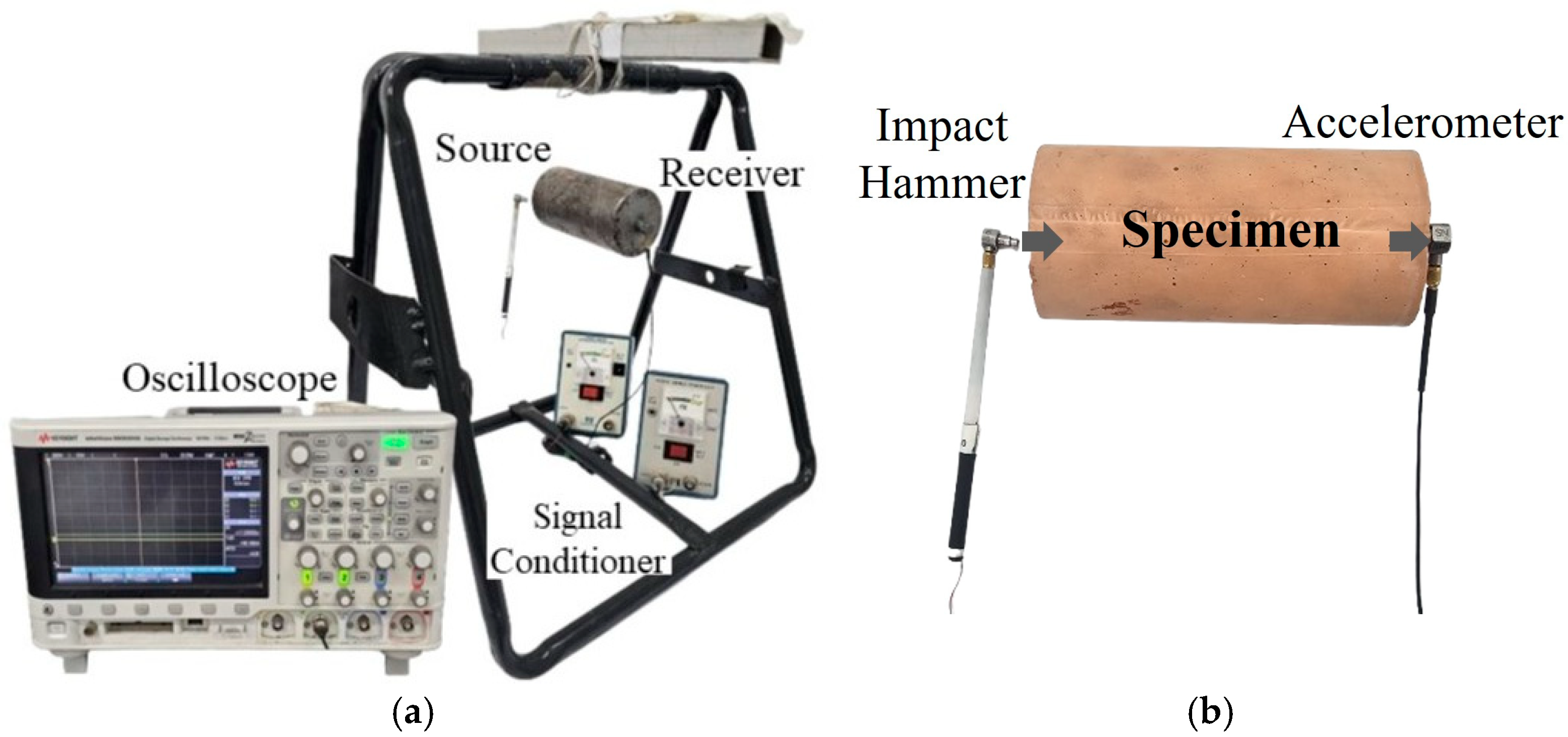

2.3.2. Free–Free Resonant Column (FFRC)

2.3.3. Void Content

2.3.4. Water Absorption

2.3.5. Setting Time

2.3.6. Flow

2.3.7. Rheology

3. Results

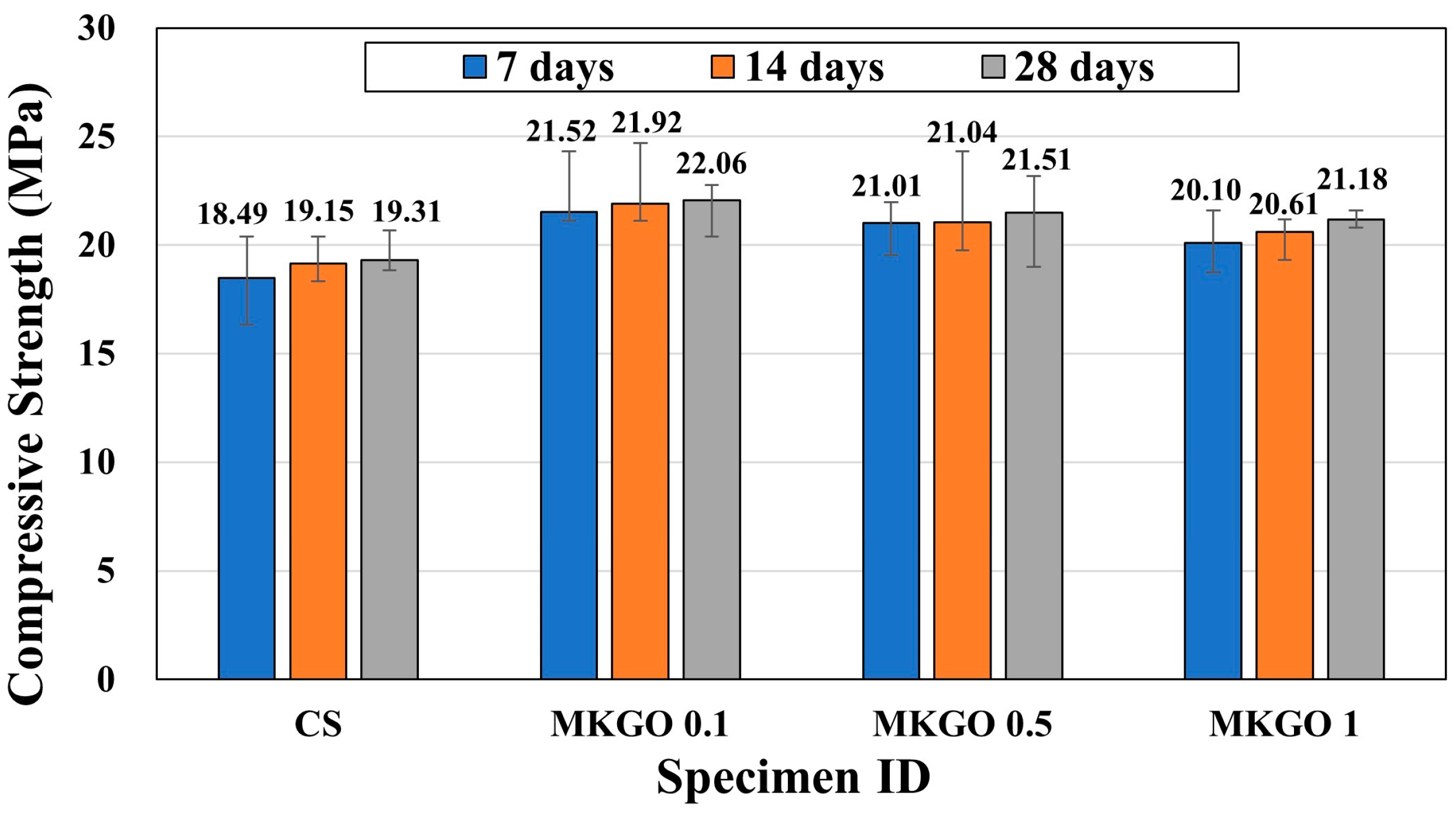

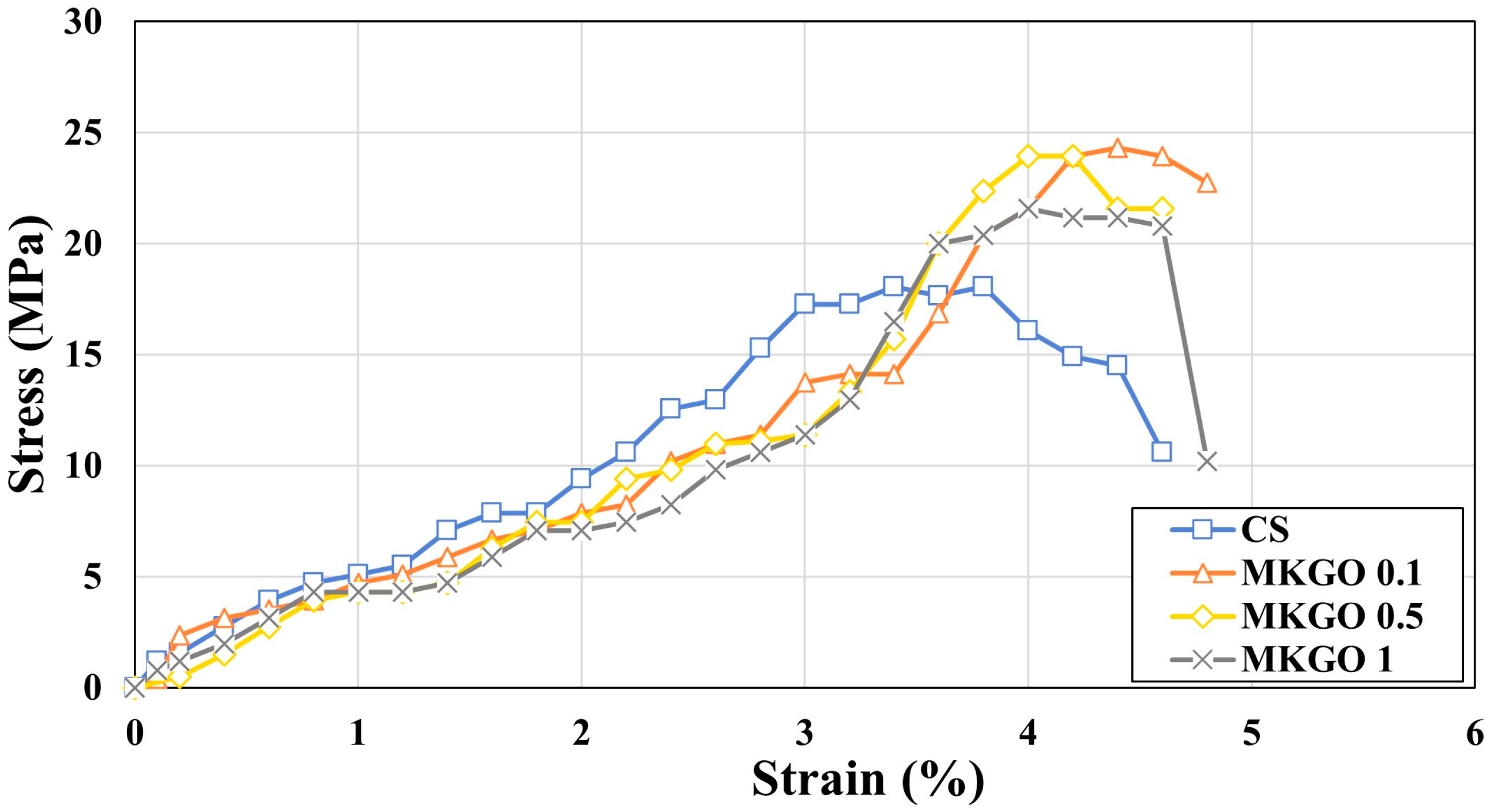

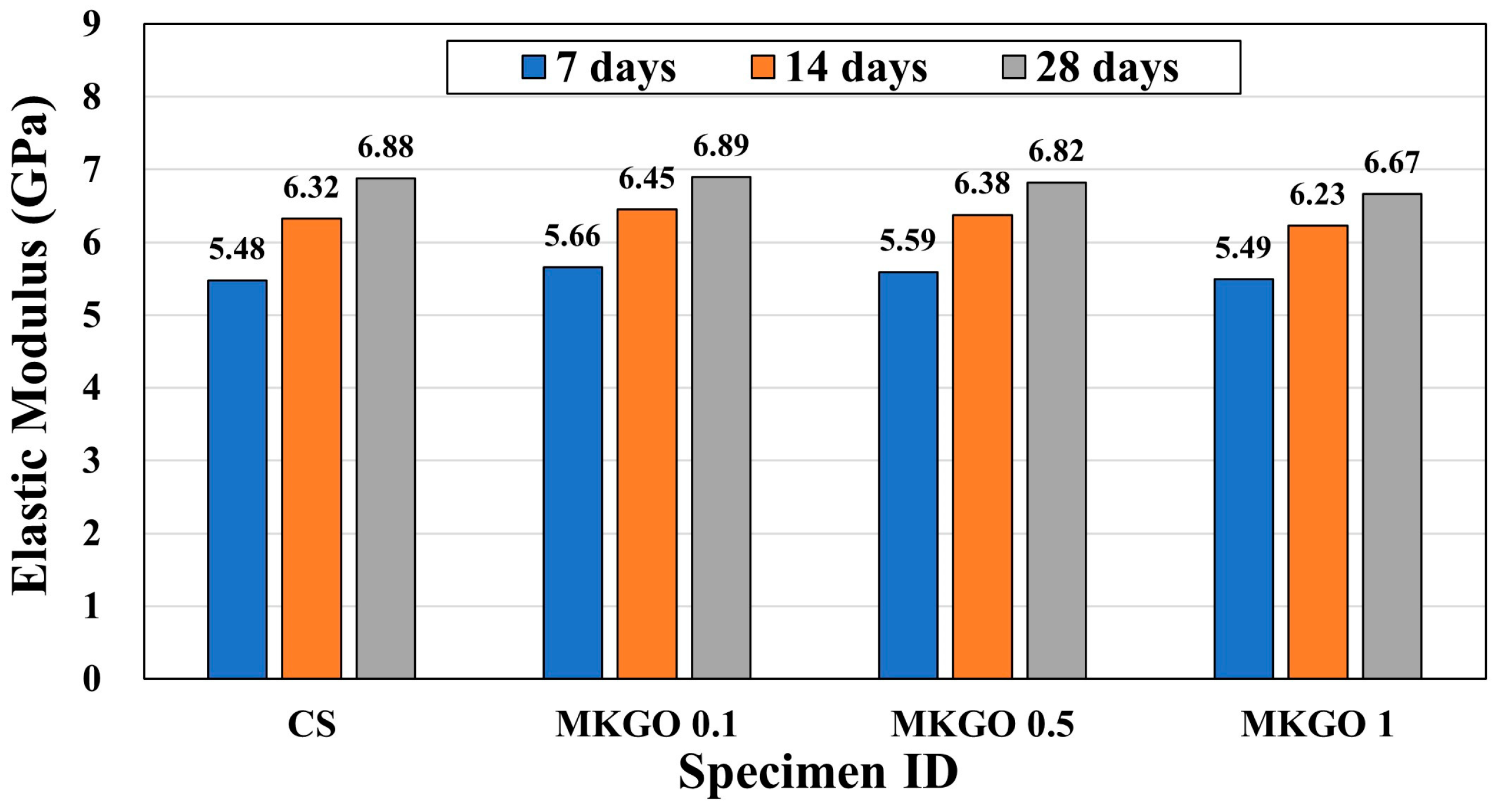

3.1. Effects of EOGO on Mechanical Properties of Metakaolin-Based Geopolymer

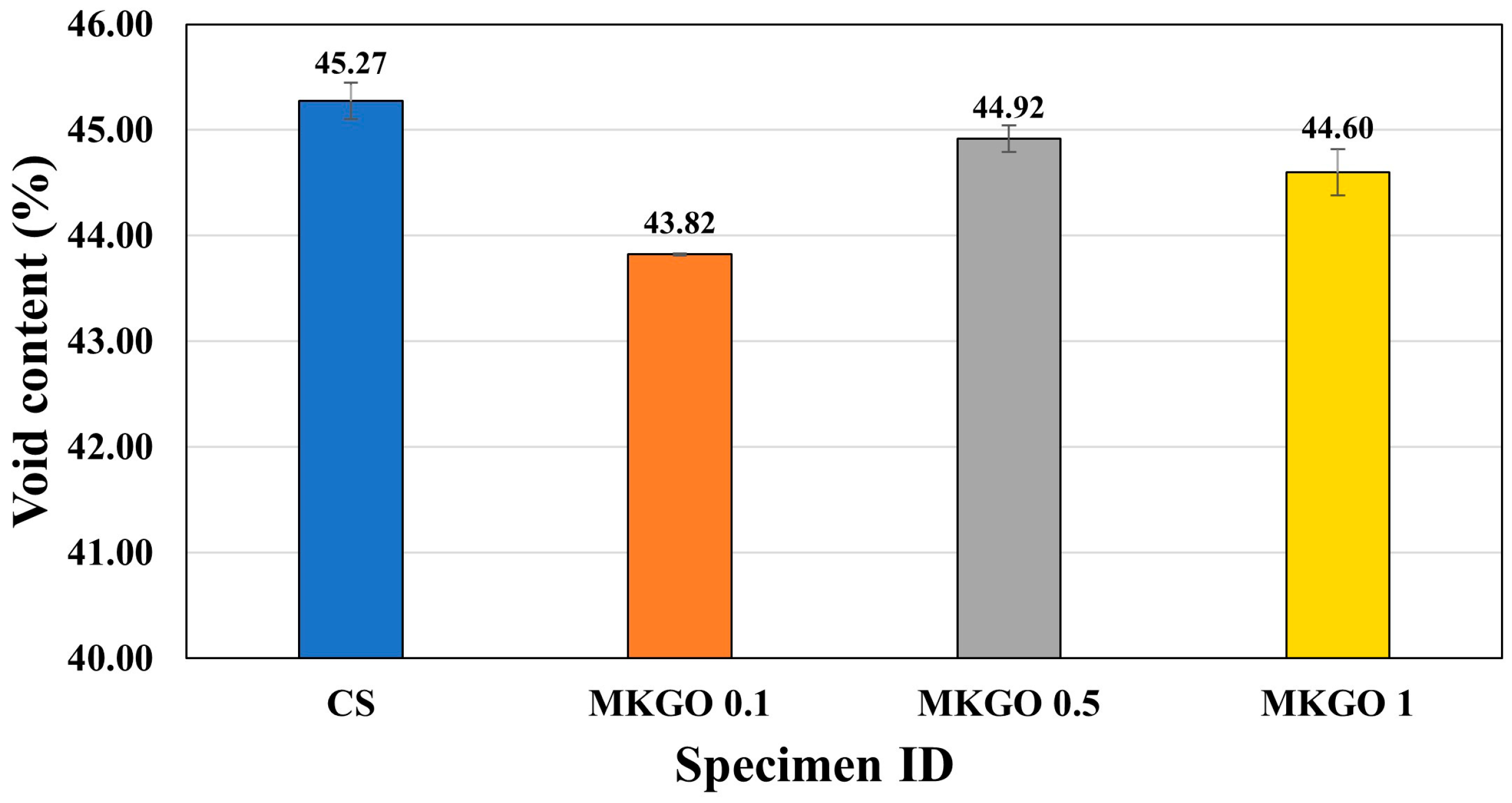

3.2. Effects of EOGO on Void Content of Metakaolin-Based Geopolymer

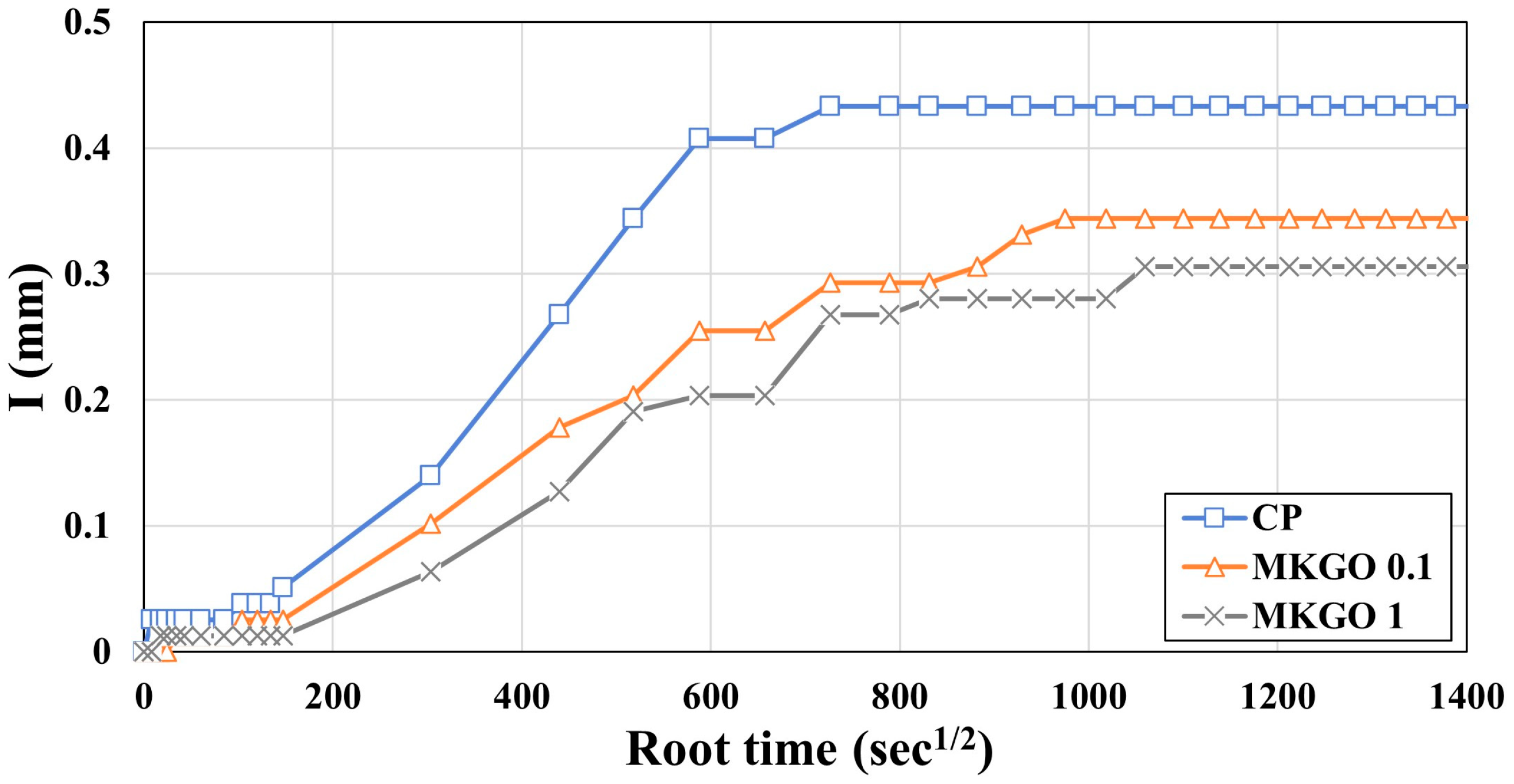

3.3. Effects of EOGO on Water Absoption of Metakaolin-Based Geopolymer

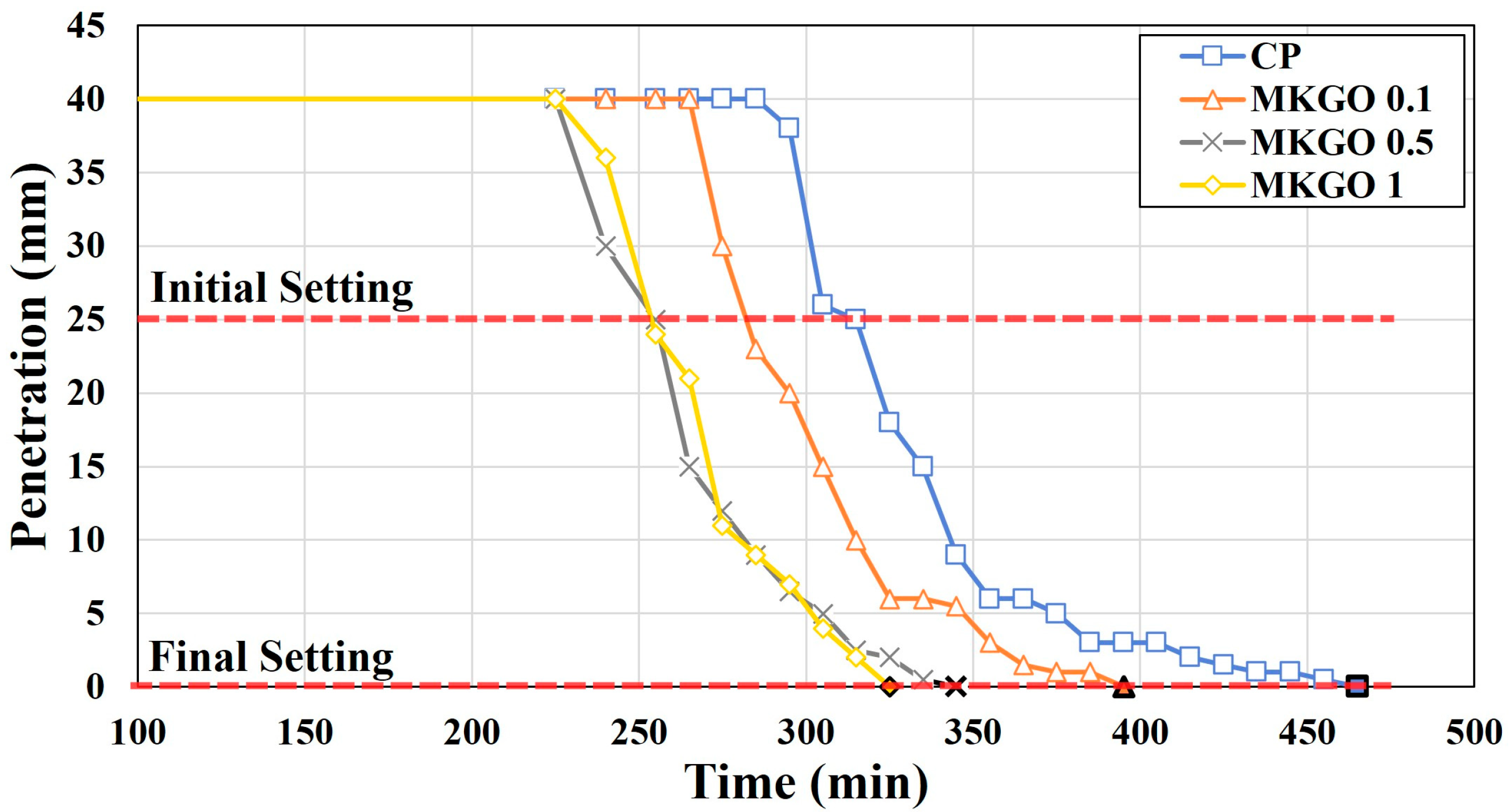

3.4. Effects of EOGO on Setting Time of Metakaolin-Based Geopolymer

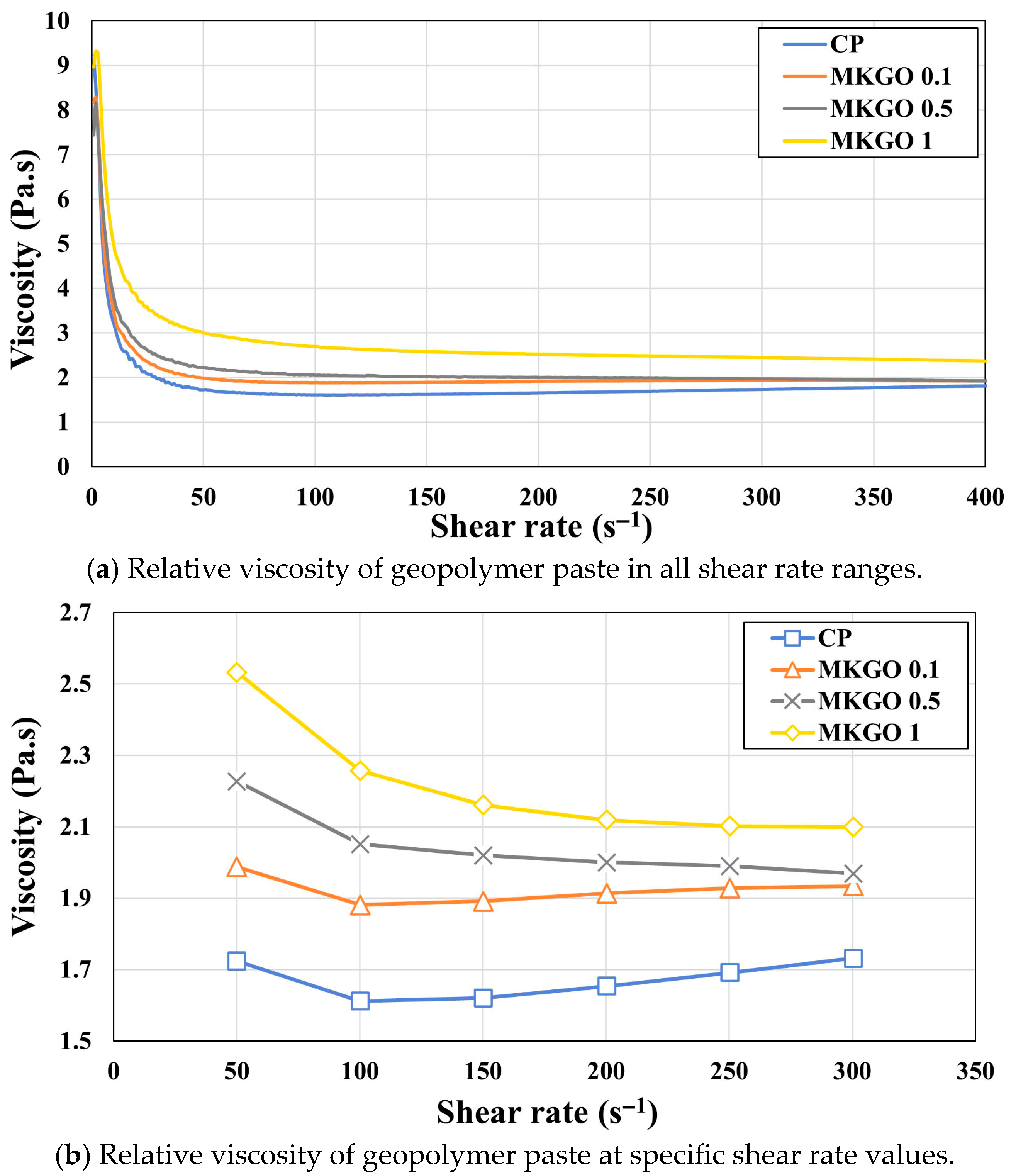

3.5. Effects of EOGO on Rheological Properties of Metakaolin-Based Geopolymer

4. Discussions

5. Conclusions

- Through compressive strength and FFRC tests, we found that the metakaolin-based geopolymer had higher strength and stiffness with an increased curing period. The strength and stiffness increased with the addition of EOGO, and the highest strength and stiffness were achieved at 0.1% EOGO due to the bridging effect, pore filling effect, and the formation of a more cross-linked N-A-S-H gel. Compared to the control specimen, 0.1% EOGO increased the strength by an average of 15% and the stiffness by 1.78%. However, at high concentrations of EOGO (0.5% or more), agglomerated regions interrupted the continuity of the N-A-S-H gel network and reduced the matrix cohesion.

- Void content measurement showed that nano-sized EOGO had the effect of filling the pores of geopolymers and reducing the void content. In particular, the greatest decrease was observed at 0.1% EOGO, at which the void content was 3.2% lower than that of the control specimen. EOGO levels of 0.5% and 1% had a higher void content than 0.1% EOGO, which was due to the creation of larger pores caused by the agglomeration and non-uniform dispersion of EOGO.

- Due to the high surface area and hydrophilic properties of EOGO due to the oxygen-containing functional groups on its surface, the free moisture in the paste was adsorbed by EOGO. This phenomenon shortened the setting time of the geopolymer paste and reduced its fluidity. In particular, the reduction effect was the greatest at 0.1% EOGO. These results suggest that a metakaolin geopolymer with EOGO is a good cement substitute that can reduce carbon dioxide emissions and that it has the potential to become a construction material with excellent performance through the optimization of the properties of the geopolymer through further research.

- Although this study focused on microstructural and short-term durability indicators such as the void content and water absorption, long-term durability aspects such as the drying shrinkage, sulfate resistance, and environmental degradation were not directly assessed. Future research should include these parameters to fully understand the aging behavior and service life performance of EOGO-enhanced geopolymer composites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Zhang, D.W.; Wang, D.M.; Liu, Z.; Xie, F.Z. Rheology, agglomerate structure, and particle shape of fresh geopolymer pastes with different NaOH activators content. Constr. Build. Mater. 2018, 187, 674–680. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Ye, N.; Yang, J.; Ke, X.; Zhu, J.; Li, Y.; Xiang, C.; Xiao, B. Synthesis and characterization of geopolymer from Bayer red mud with thermal pretreatment. J. Am. Ceram. Soc. 2014, 97, 1652–1660. [Google Scholar] [CrossRef]

- Ahmadullah, T.; Chrysochoou, M. Relationship between strength development and pozzolanic reactions in lime stabilized kaolinite. Int. J. Geo-Eng. 2024, 15, 11. [Google Scholar] [CrossRef]

- Karimi, S.; Farshbaf Aghajani, H. The strength and microstructure of cemented sand-gravel (CSG) mixture containing fine-grained particles. Int. J. Geo-Eng. 2023, 14, 5. [Google Scholar] [CrossRef]

- Sierra, K.; An, J.; Shamet, R.; Chen, J.; Kim, Y.J.; Nam, B.H.; Park, P. A review of geopolymer binder as a grouting material. Int. J. Geo-Eng. 2024, 15, 21. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef]

- Rashad, A.M. Alkali-activated metakaolin: A short guide for civil Engineer–An overview. Constr. Build. Mater. 2013, 41, 751–765. [Google Scholar] [CrossRef]

- Pouhet, R. Formulation and Durability of Metakaolin-Based Geopolymers. Ph.D. Dissertation, Université Paul Sabatier-Toulouse III, Toulouse, France, 2015. Available online: https://theses.hal.science/tel-01297848 (accessed on 11 August 2025).

- Pelisser, F.; Guerrino, E.L.; Menger, M.; Michel, M.D.; Labrincha, J.A. Micromechanical characterization of metakaolin-based geopolymers. Constr. Build. Mater. 2013, 49, 547–553. [Google Scholar] [CrossRef]

- Belmokhtar, N.; Ammari, M.; Brigui, J. Comparison of the microstructure and the compressive strength of two geopolymers derived from Metakaolin and an industrial sludge. Constr. Build. Mater. 2017, 146, 621–629. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y.; Li, M.; Jiang, J.; Guo, L.; Wang, W.; Duan, P. Effects of graphene oxide on microstructure and mechanical properties of graphene oxide-geopolymer composites. Constr. Build. Mater. 2020, 247, 118544. [Google Scholar] [CrossRef]

- Suo, Y.; Guo, R.; Xia, H.; Yang, Y.; Zhou, B.; Zhao, Z. A review of graphene oxide/cement composites: Performance, functionality, mechanisms, and prospects. J. Build. Eng. 2022, 53, 104502. [Google Scholar] [CrossRef]

- Maglad, A.M.; Zaid, O.; Arbili, M.M.; Ascensão, G.; Șerbănoiu, A.A.; Grădinaru, C.M.; de Prado-Gil, J. A study on the properties of geopolymer concrete modified with nano graphene oxide. Buildings 2022, 12, 1066. [Google Scholar] [CrossRef]

- Ho, V.D.; Gholampour, A.; Losic, D.; Ozbakkaloglu, T. Enhancing the performance and environmental impact of alkali-activated binder-based composites containing graphene oxide and industrial by-products. Constr. Build. Mater. 2021, 284, 122811. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.; Liu, Y.; Ge, C.; Guo, L.; Shu, X.; Liu, J. Synergistic effects of silica nanoparticles/polycarboxylate superplasticizer modified graphene oxide on mechanical behavior and hydration process of cement composites. RSC Adv. 2017, 7, 16688–16702. [Google Scholar] [CrossRef]

- Khawaji, M.; Cho, B.H.; Nam, B.H.; Alharbi, Y.; An, J. Edge-oxidized graphene oxide as additive in fiber-reinforced concrete: Effects on fresh and hardened properties. J. Mater. Civ. Eng. 2020, 32, 04020028. [Google Scholar] [CrossRef]

- Chuah, S.; Li, W.; Chen, S.J.; Sanjayan, J.G.; Duan, W.H. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments. Constr. Build. Mater. 2018, 161, 519–527. [Google Scholar] [CrossRef]

- Gong, K.; Pan, Z.; Korayem, A.H.; Qiu, L.; Li, D.; Collins, F.; Duan, W.H. Reinforcing effects of graphene oxide on portland cement paste. J. Mater. Civ. Eng. 2015, 27, A4014010. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Yang, H.; Monasterio, M.; Cui, H.; Han, N. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite. Compos. Part A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- An, J.; Nam, B.H.; Alharbi, Y.; Cho, B.H.; Khawaji, M. Edge-oxidized graphene oxide (EOGO) in cement composites: Cement hydration and microstructure. Compos. Part B Eng. 2019, 173, 106795. [Google Scholar] [CrossRef]

- Cho, B.H.; Nam, B.H.; Khawaji, M. Flexural fatigue behaviors and damage evolution analysis of edge-oxidized graphene oxide (EOGO) reinforced concrete composites. Cem. Concr. Compos. 2021, 122, 104082. [Google Scholar] [CrossRef]

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of initial CaO/Al2O3 and SiO2/Al2O3 ratios on the properties of slag/fly ash-based geopolymer stabilized clay: Synergistic effects and stabilization mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Liu, F.; Tang, R.; Li, Q.; Wang, H.; Zou, Y.; Yuan, X. Improved thermal performance, frost resistance, and pore structure of cement–based composites by binary modification with mPCMs/nano–SiO2. Energy 2025, 332, 137166. [Google Scholar] [CrossRef]

- Available online: www.nycontech.com (accessed on 11 August 2025).

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- ASTM C 109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C 597; Standard Test Method for Ultrasonic Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Chen, Y.; Zhang, L.; Xu, L.; Zhou, S.; Luo, B.; Ding, K. In-situ investigation on dynamic response of highway transition section with foamed concrete. Earthq. Eng. Eng. Vib. 2025, 24, 547–563. [Google Scholar] [CrossRef]

- ASTM C 1754; Standard Test Method for Density and Void Content of Hardened Pervious Concrete (Withdrawn 2021). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C 1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C 191; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D 6103; Standard Test Method for Flow Consistency of Controlled Low Strength Material (CLSM). ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM D 2196; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 1986.

- Luo, Y.; Meng, J.; Wang, D.; Jiao, L.; Xue, G. Experimental study on mechanical properties and microstructure of metakaolin based geopolymer stabilized silty clay. Constr. Build. Mater. 2022, 316, 125662. [Google Scholar] [CrossRef]

- Ayeni, O.; Onwualu, A.P.; Boakye, E. Characterization and mechanical performance of metakaolin-based geopolymer for sustainable building applications. Constr. Build. Mater. 2021, 272, 121938. [Google Scholar] [CrossRef]

- Al-Swaidani, A.M.; Meziab, A.; Khwies, W.T.; Al-Bali, M.; Lala, T. Building MLR, ANN and FL models to predict the strength of problematic clayey soil stabilized with a combination of nano lime and nano pozzolan of natural sources for pavement construction. Int. J. Geo-Eng. 2024, 15, 2. [Google Scholar] [CrossRef]

- Alharbi, Y.; An, J.; Cho, B.H.; Khawaji, M.; Chung, W.; Nam, B.H. Mechanical and sorptivity characteristics of edge-oxidized graphene oxide (EOGO)-cement composites: Dry-and wet-mix design methods. Nanomaterials 2018, 8, 718. [Google Scholar] [CrossRef]

- Long, W.J.; Li, H.D.; Fang, C.L.; Xing, F. Uniformly dispersed and re-agglomerated graphene oxide-based cement pastes: A comparison of rheological properties, mechanical properties and microstructure. Nanomaterials 2018, 8, 31. [Google Scholar] [CrossRef]

- Lee, H.; Shin, J.; Cho, B.H.; Nam, B.H. Effect of Edge-Oxidized Graphene Oxide (EOGO) on Fly Ash Geopolymer. Materials 2025, 18, 3457. [Google Scholar] [CrossRef]

- Saafi, M.; Tang, L.; Fung, J.; Rahman, M.; Liggat, J. Enhanced properties of graphene/fly ash geopolymeric composite cement. Cem. Concr. Res. 2015, 67, 292–299. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Panesar, D.K. Impact of graphene oxide and highly reduced graphene oxide on cement based composites. Constr. Build. Mater. 2019, 206, 71–83. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, S.; Chen, W.; Wang, S.; Gao, Y. Kirigami structure enhancing the crack-bridging effects of graphene oxide on the calcium silicate hydrate. Mater. Des. 2025, 256, 114334. [Google Scholar] [CrossRef]

- Park, K.; Kim, J.H.; Shin, J.; Lee, H.; Nam, B.H. A Study on the Effect of Graphene Oxide on Geotechnical Properties of Soil. Materials 2024, 17, 6199. [Google Scholar] [CrossRef]

- Ding, X.H.; Luo, B.; Zhou, H.T.; Chen, Y.H. Generalized solutions for advection–dispersion transport equations subject to time-and space-dependent internal and boundary sources. Comput. Geotech. 2025, 178, 106944. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Physical Properties | ||||

|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | K2O + Na2O | Mean Particle Size (μm) | Specific Gravity |

| 49.1 | 43.2 | 1.32 | 0.57 | 11 | 2.6 |

| Oxygen | Non-Oxygen Composition | ||||||

|---|---|---|---|---|---|---|---|

| Carbon | Silicon | Sulfur | Potassium | Calcium | Chromium | Copper | |

| 5~10% | >99.8% | <40 ppm | <60 ppm | <5 ppm | <30 ppm | <125 ppm | <5 ppm |

| Paste ID | L/B Ratio | Metakaolin (g) | SSS (g) | SHS (g) | EOGO (%) | EOGO (g) |

|---|---|---|---|---|---|---|

| CP | 1.4 | 838 | 838 | 335 | 0 | 0 |

| MKGO 0.1 | 1.4 | 838 | 838 | 335 | 0.1 | 0.84 |

| MKGO 0.5 | 1.4 | 838 | 838 | 335 | 0.5 | 4.19 |

| MKGO 1 | 1.4 | 838 | 838 | 335 | 1 | 8.38 |

| Paste ID | Initial Setting Time (min) | Final Setting Time (min) |

|---|---|---|

| CP | 315 | 465 |

| MKGO 0.1 | 280 | 395 |

| MKGO 0.5 | 255 | 345 |

| MKGO 1 | 255 | 325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Lee, H.; An, J.; Nam, B.H. Effects of EOGO in Metakaolin-Based Geopolymer. Materials 2025, 18, 3864. https://doi.org/10.3390/ma18163864

Lee C, Lee H, An J, Nam BH. Effects of EOGO in Metakaolin-Based Geopolymer. Materials. 2025; 18(16):3864. https://doi.org/10.3390/ma18163864

Chicago/Turabian StyleLee, Chaewon, Hoyoung Lee, Jinwoo An, and Boo Hyun Nam. 2025. "Effects of EOGO in Metakaolin-Based Geopolymer" Materials 18, no. 16: 3864. https://doi.org/10.3390/ma18163864

APA StyleLee, C., Lee, H., An, J., & Nam, B. H. (2025). Effects of EOGO in Metakaolin-Based Geopolymer. Materials, 18(16), 3864. https://doi.org/10.3390/ma18163864