Sustainable Use of Volcanic Ash in Mortars as a Replacement for Cement or Sand: Shrinkage and Physical and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

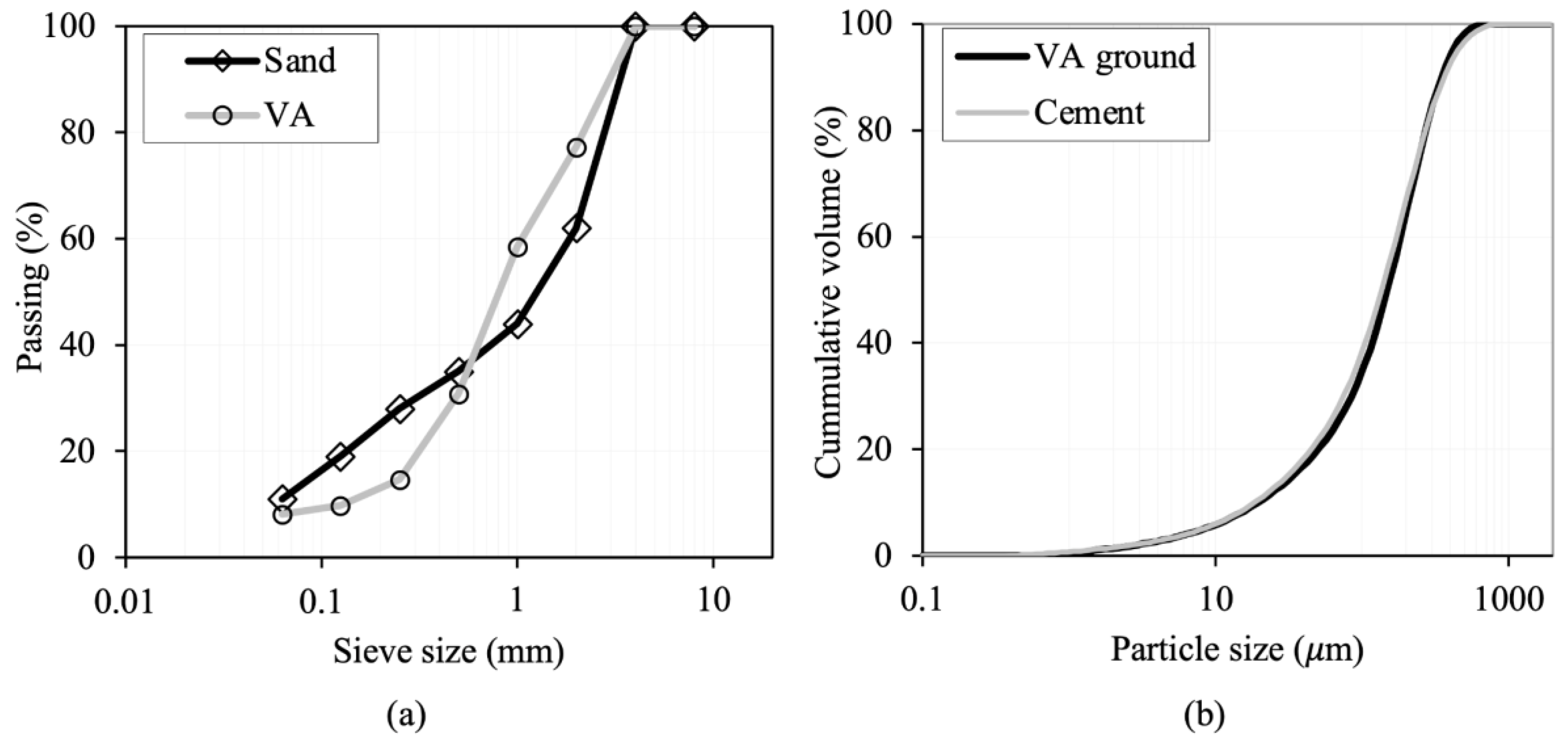

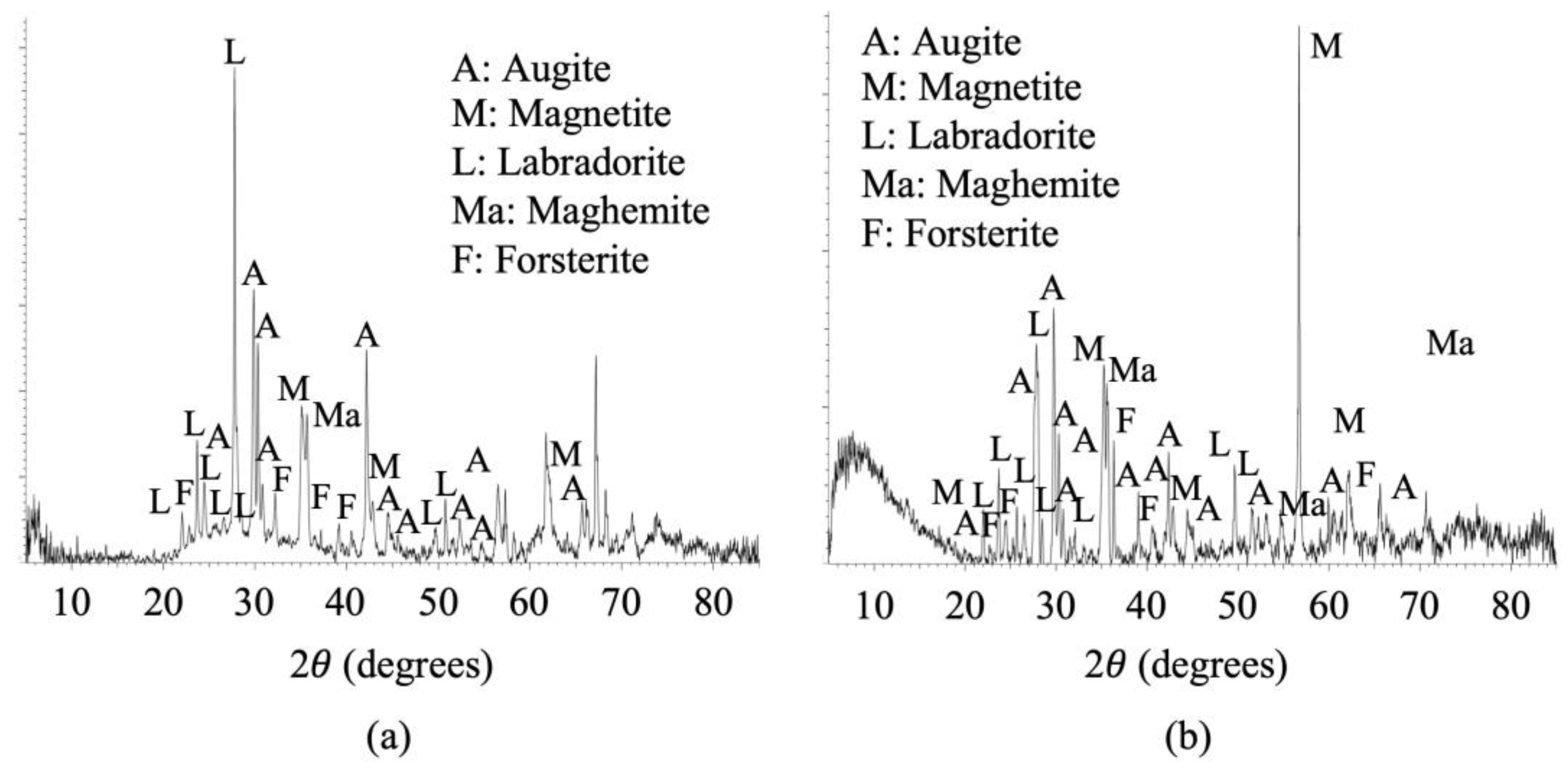

2.1. Raw Materials

2.2. Mixture Proportions and Mixing Procedure

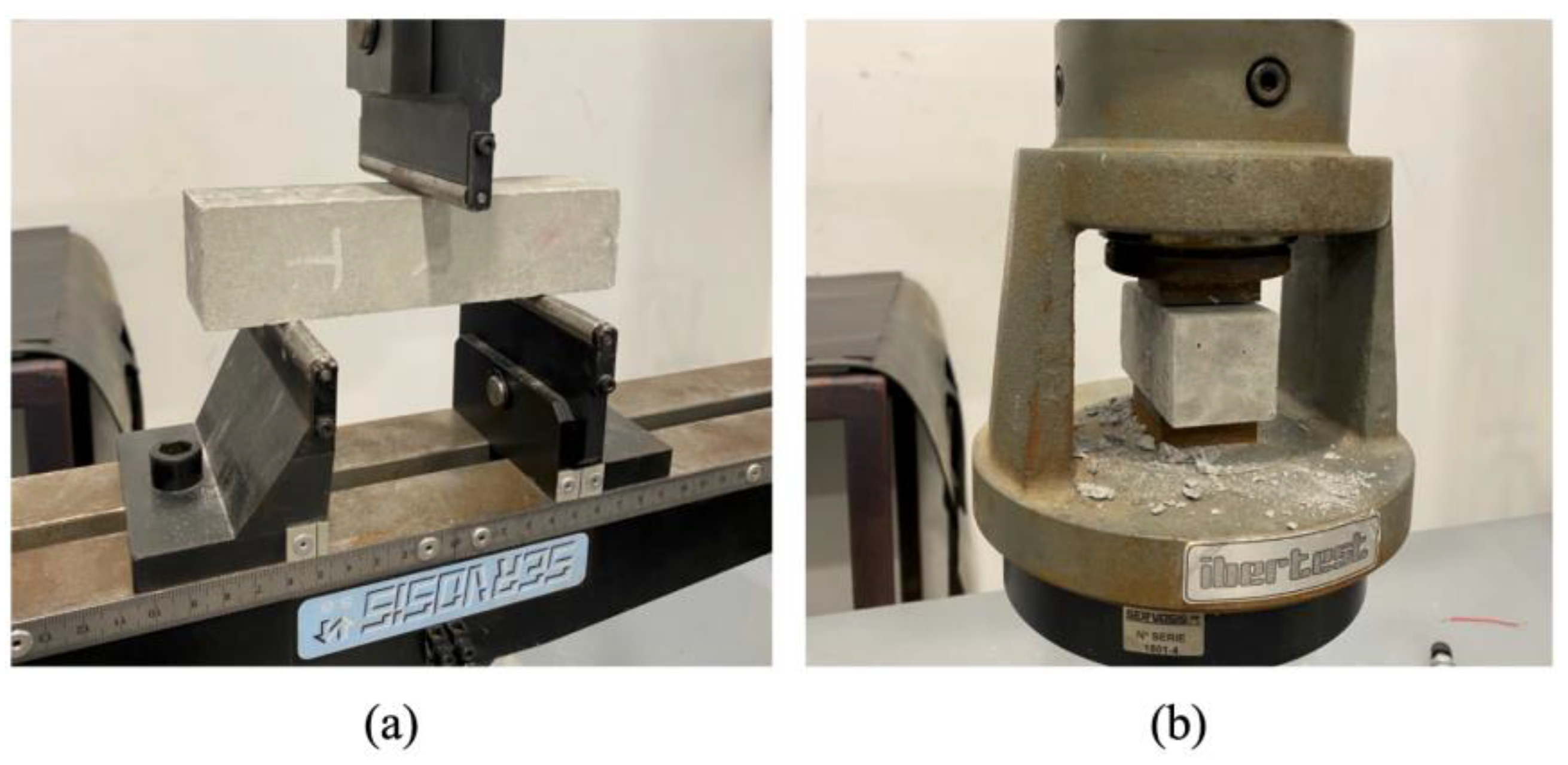

2.3. Tests Performed

3. Results and Discussion

3.1. Mechanical Strength

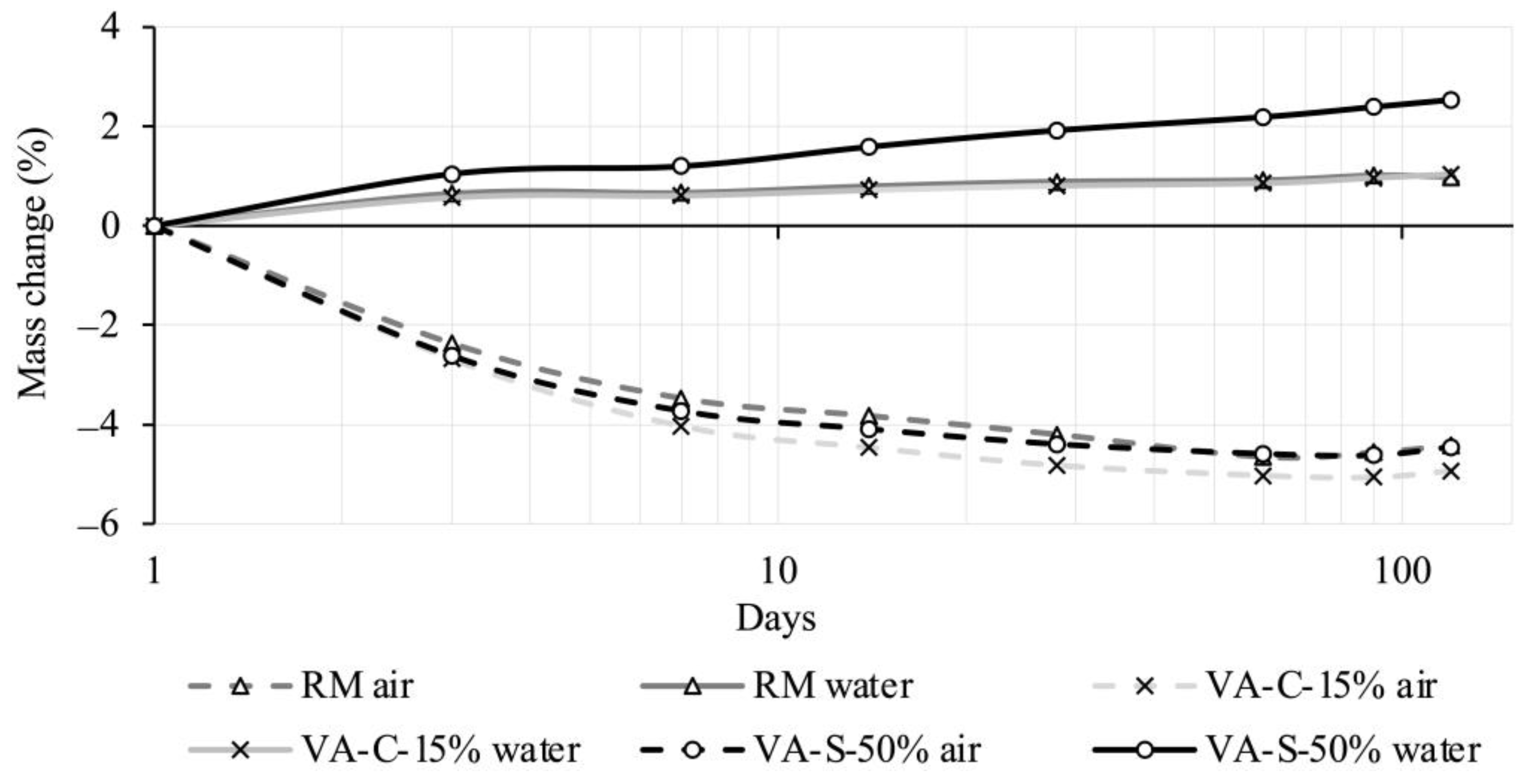

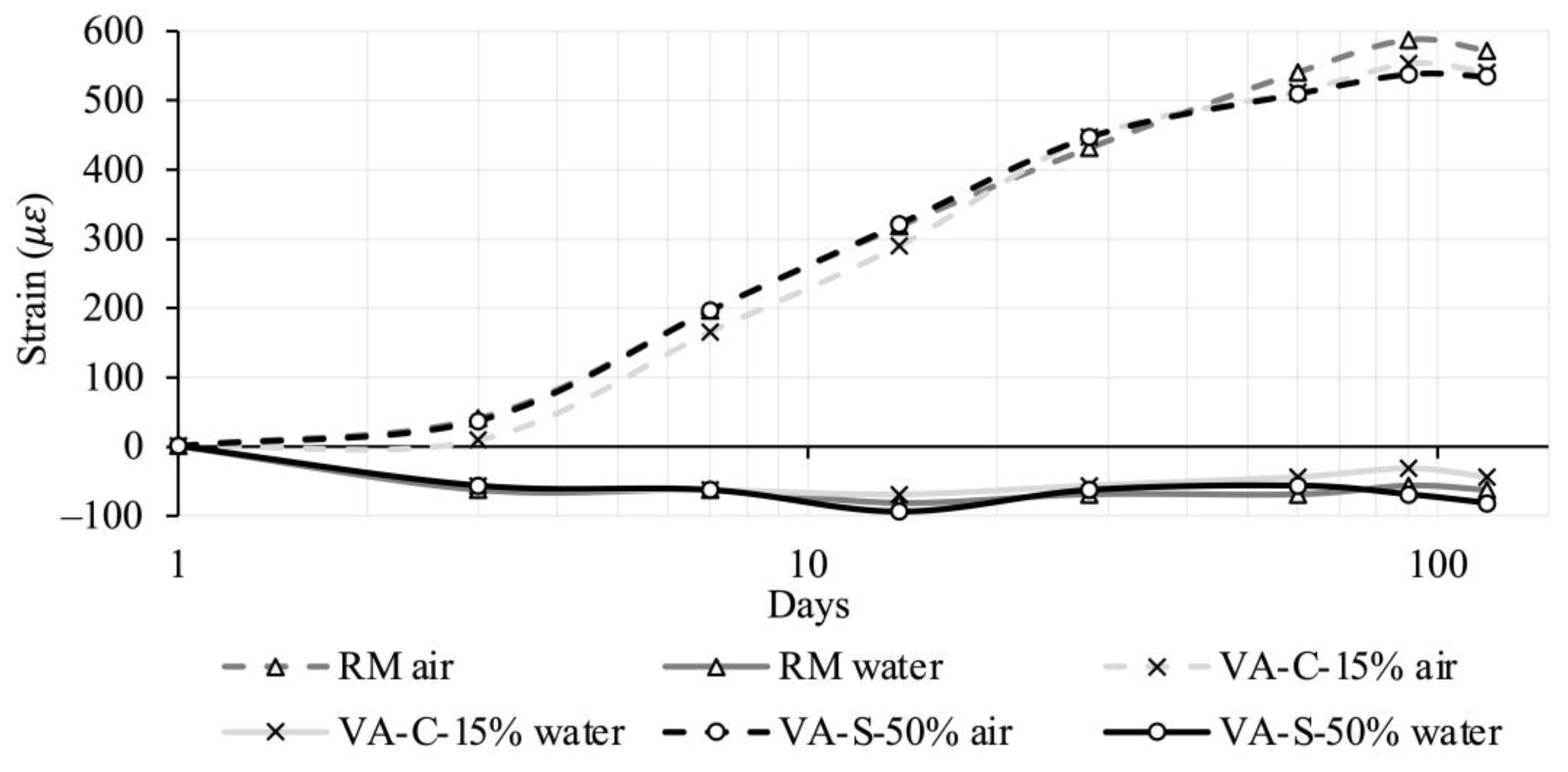

3.2. Shrinkage

3.3. Physical Properties of Mortar Mixes

3.3.1. Bulk Density and Flowability

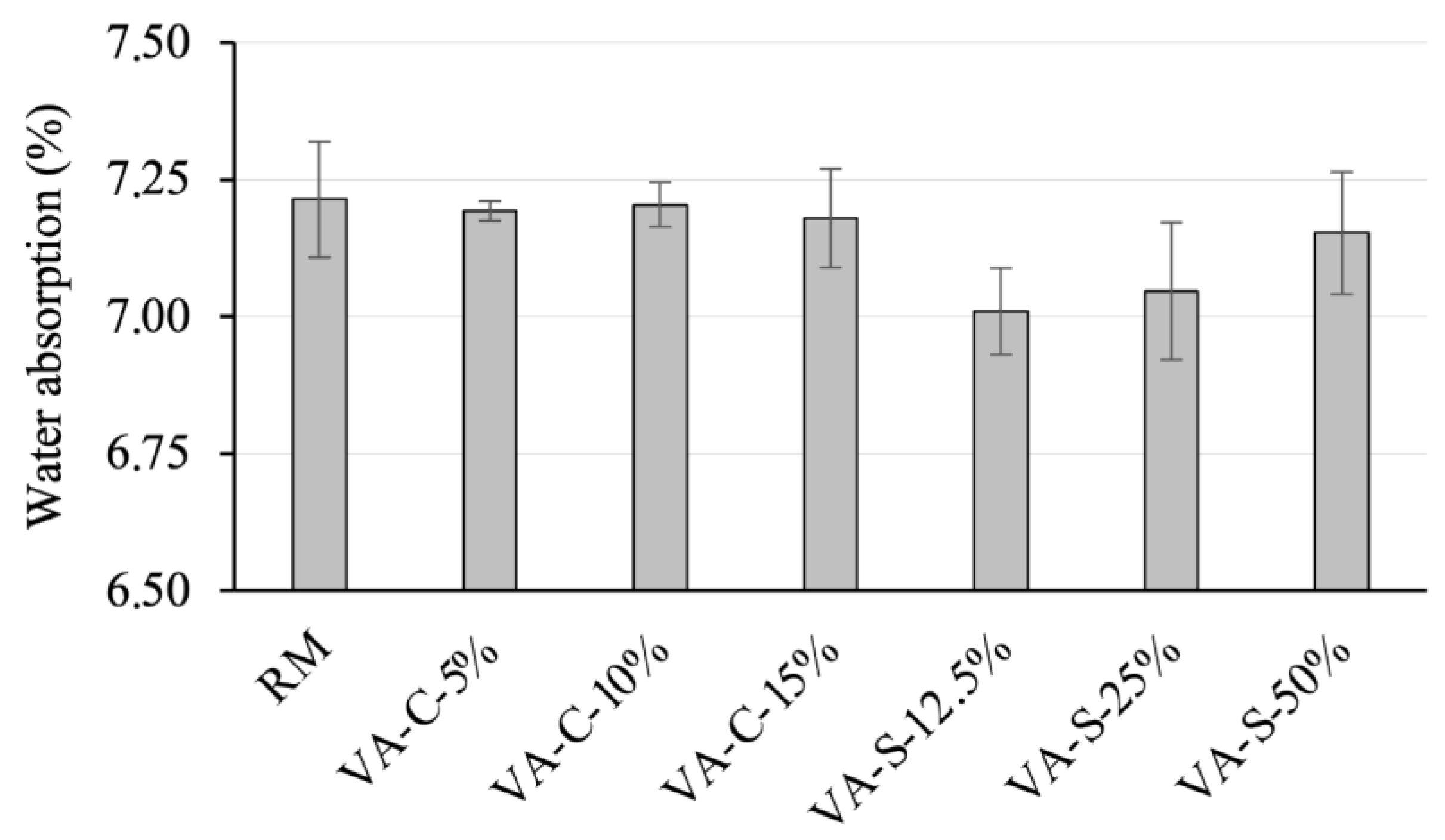

3.3.2. Water Absorption

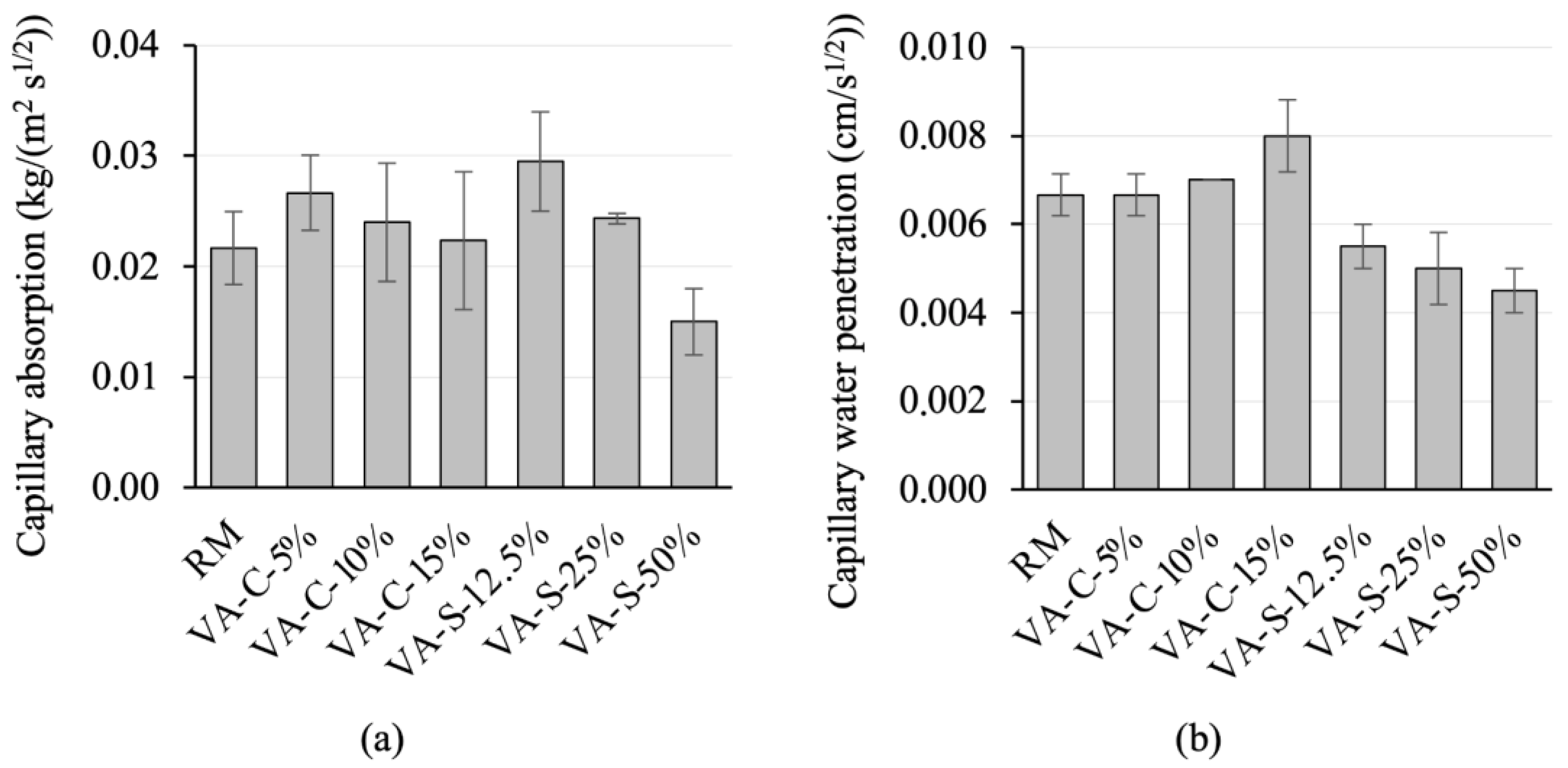

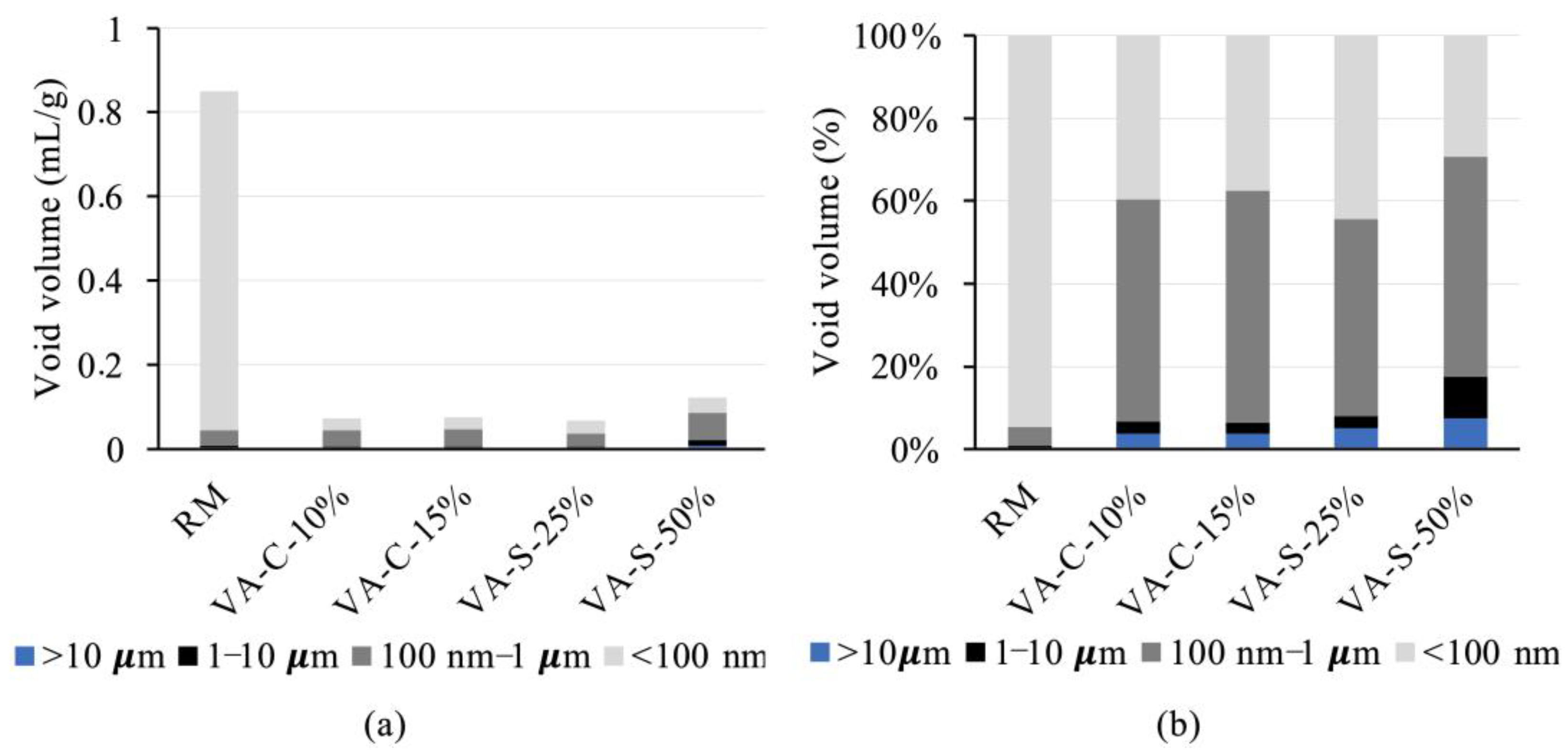

3.3.3. Porosity

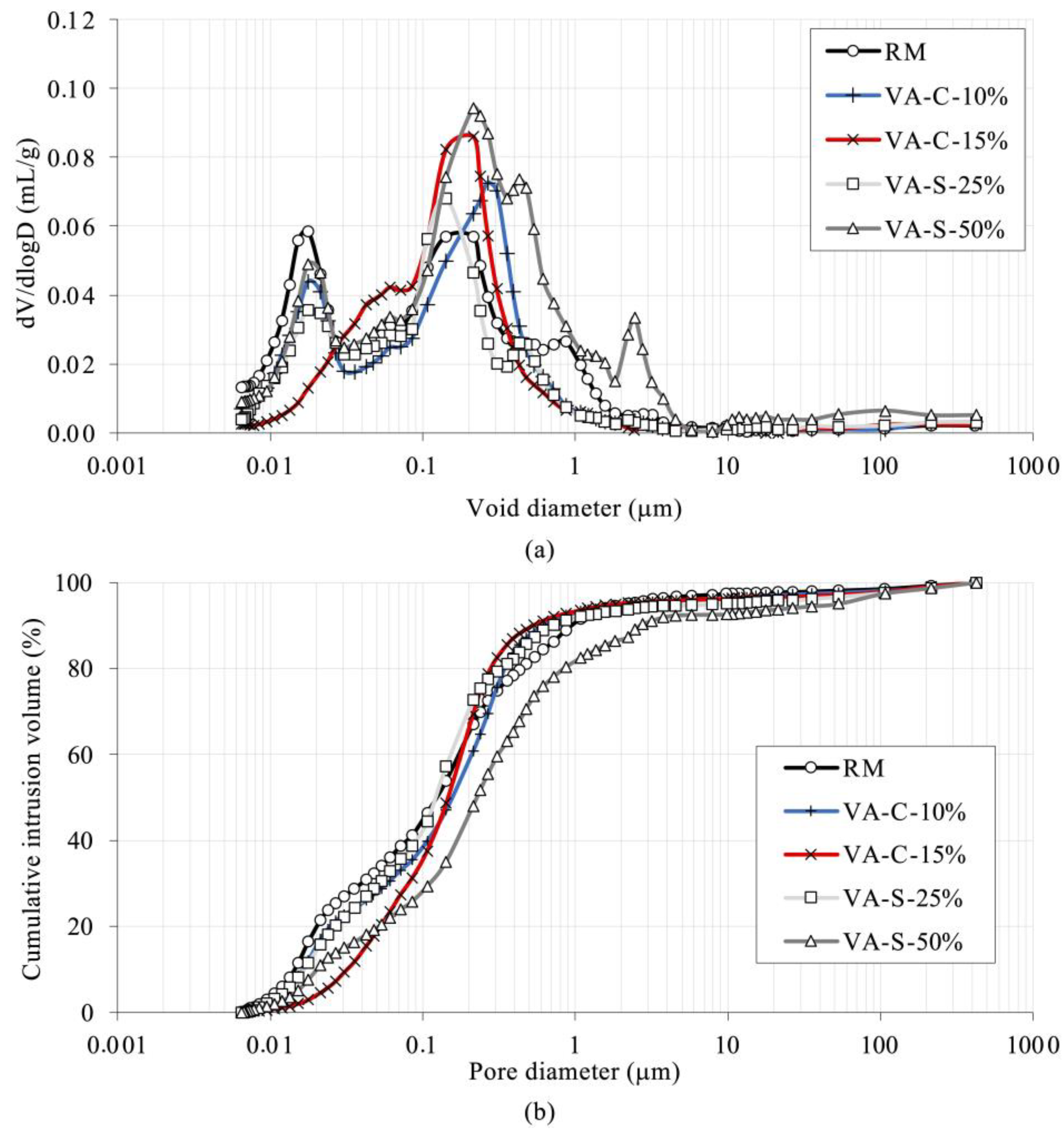

3.4. Microstructure of the Mortar Mixtures

4. Conclusions

- The workability of the VA-C series was similar to RM, while the VA-S series were classified as stiff mortars.

- The influence of replacing cement with ground VA on water absorption was negligible. Water absorption appeared to be more sensitive to the replacement of sand with VA, resulting in lower values than RM. A governing factor for absorption depends on the structure of the capillary of the material: the smaller the capillary network, the lower the absorption of the mortar.

- The capillary absorption coefficient and water penetration coefficient were not significantly affected by the replacement of cement with VA. In contrast, when sand was substituted by VA, it had a greater influence on both parameters. The VA-S series showed a lower water penetration coefficient than RM. The capillary absorption coefficient was highly influenced by the amount of sand replaced by VA. Both coefficients tended to decrease as the amount of VA increases.

- Total porosity was quite similar across all the series, with the exception of VA-S-50%, which exhibited a significantly higher value than the other series. The microstructures of VA-S-50% mortars were less refined than the other series.

- The VA-C series showed lower compressive strength after being cured for 28, 90, and 200 days when compared to RM. Conversely, the VA-S-12.5% and VA-S-25% mixtures exhibited higher compressive strengths. VA-S-75% is not recommended because of its low compressive and flexural strengths. A similar pattern was observed with flexural strength. Most of the mixtures showed gained greater flexural and compressive strengths over time than RM when comparing the 28-day results with the 200-day results.

- Regarding shrinkage, there were no significant deviations in the mixes with maximum replacement levels, VA-C-15% and VA-S-50% mixtures, when compared to the reference mixture (in both air-cured and immersed specimens).

- Based on the SEM/EDS analysis, the introduction of ground VA as a cement replacement led to a homogeneous matrix, similar to RM. When sand was replaced by VA, the paste-aggregate interface in VA was very similar to that of natural aggregates.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Longpré, M.A.; Felpeto, A. Historical Volcanism in the Canary Islands; Part 1: A Review of Precursory and Eruptive Activity, Eruption Parameter Estimates, and Implications for Hazard Assessment. J. Volcanol. Geotherm. Res. 2021, 419, 107363. [Google Scholar] [CrossRef]

- Fernández, J.; Escayo, J.; Hu, Z.; Camacho, A.G.; Samsonov, S.V.; Prieto, J.F.; Tiampo, K.F.; Palano, M.; Mallorquí, J.J.; Ancochea, E. Detection of Volcanic Unrest Onset in La Palma, Canary Islands, Evolution and Implications. Sci. Rep. 2021, 11, 2540. [Google Scholar] [CrossRef] [PubMed]

- Sanjuán, M.A.; Frías, M.; Monasterio, M.; García-Giménez, R.; Virgil de la Villa, R.; Álamo, M. Volcanic Ash from La Palma (Canary Islands, Spain) as Portland Cement Constituent. J. Build. Eng. 2023, 78, 107641. [Google Scholar] [CrossRef]

- Informe Sobre Las Actuaciones y Medidas Emprendidas Tras La Erupción Del Volcán de Cumbre Vieja (La Palma), Seis Meses Después Del Inicio de La Emergencia; Joint Commission for Reconstruction, Recovery, and Support of La Palma, Gobierno de España, Agencia Estatal Boletín Ofcial del Estado: Madrid, Spain, 2022; pp. 1–54.

- Shatto, C.; Weiser, F.; Walentowitz, A.; Stahlmann, R.; Shrestha, S.; Guerrero-Campos, M.; Medina, F.M.; Nogales, M.; Jentsch, A.; Beierkuhnlein, C. Volcanic Tephra Deposition Dataset Based on Interpolated Field Measurements Following the 2021 Tajogaite Eruption on La Palma, Canary Islands, Spain. Data Br. 2024, 52, 109949. [Google Scholar] [CrossRef]

- Rodríguez-Pérez, M.C.; Ferrer, M.E.F.; Boada, L.D.; Pérez, A.D.A.; Aguilar, M.C.D.; Jerónimo, J.F.F.; Talavera, I.G.; Gangotena, L.V.; de la Torre, A.H.; Simbaña-Rivera, K.; et al. Health Impact of the Tajogaite Volcano Eruption in La Palma Population (ISVOLCAN Study): Rationale, Design, and Preliminary Results from the First 1002 Participants. Environ. Heal. A Glob. Access Sci. Source 2024, 23, 19. [Google Scholar] [CrossRef]

- Tesone, A.I.; Lasagni Vitar, R.M.; Tau, J.; Maglione, G.A.; Llesuy, S.; Tasat, D.R.; Berra, A. Volcanic Ash from Puyehue-Cordón Caulle Volcanic Complex and Calbuco Promote a Differential Response of pro-Inflammatory and Oxidative Stress Mediators on Human Conjunctival Epithelial Cells. Environ. Res. 2018, 167, 87–97. [Google Scholar] [CrossRef]

- Cultrone, G. The Use of Mount Etna Volcanic Ash in the Production of Bricks with Good Physical-Mechanical Performance: Converting a Problematic Waste Product into a Resource for the Construction Industry. Ceram. Int. 2022, 48, 5724–5736. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Wang, K.-T.; Tang, Q.; Nzeukou, A.N.; Billong, N.; Melo, U.C.; Cui, X.-M. Review on the Use of Volcanic Ashes for Engineering Applications. Resour. Conserv. Recycl. 2018, 137, 177–190. [Google Scholar] [CrossRef]

- Abdulmalek, N.A.; Chakkamalayath, J. Cost-Benefit Analysis of Vibrated Concrete and Self–Compacting Concrete Containing Recycled Aggregates and Natural Pozzolana. J. Eng. Res. 2023, 11, 156–168. [Google Scholar] [CrossRef]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.H.; Mehta, P.K.; Monteiro, P.J.M. High-Volume Natural Volcanic Pozzolan and Limestone Powder as Partial Replacements for Portland Cement in Self-Compacting and Sustainable Concrete. Cem. Concr. Compos. 2014, 45, 136–147. [Google Scholar] [CrossRef]

- Cabrera, A.J. Ecomaterials for Reconstruction and Recovery or Road Infrastructure in Volcanic Environments. Transp. Res. Procedia 2023, 71, 101–108. [Google Scholar] [CrossRef]

- Játiva, A.; Corominas, A.; Etxeberria, M. Durable Mortar Mixes Using 50% of Activated Volcanic Ash as A Binder. Materials 2025, 18, 1777. [Google Scholar] [CrossRef] [PubMed]

- Játiva, A.; Etxeberria, M. Exploring the Utilization of Activated Volcanic Ash as a Substitute for Portland Cement in Mortar Formulation: A Thorough Experimental Investigation. Materials 2024, 17, 1123. [Google Scholar] [CrossRef] [PubMed]

- Tremiño, R.M.; Real-Herraiz, T.; Letelier, V.; Ortega, J.M. Microstructure and Durability Performance of Mortars with Volcanic Powder from Calbuco Volcano (Chile) after 4 Hardening Years. Materials 2021, 14, 1751. [Google Scholar] [CrossRef]

- Presa, L.; Rosado, S.; Peña, C.; Martín, D.A.; Costafreda, J.L.; Astudillo, B.; Parra, J.L. Volcanic Ash from the Island of La Palma, Spain: An Experimental Study to Establish Their Properties as Pozzolans. Processes 2023, 11, 657. [Google Scholar] [CrossRef]

- Jubera-Pérez, F.J.; Jaizme-Vega, E.; Rosa-Orihuela, R.; Damas-Montesdeoca, R.; Hernández-Díaz, C.; Rodríguez-Díaz, J.; González-Díaz, E. Pozzolanic Activity of Volcanic Ashes Produced by the Eruption of the Tajogaite Volcano in La Palma, Canary Islands. Constr. Build. Mater. 2024, 419, 135498. [Google Scholar] [CrossRef]

- Martín-Rodriguez, P.; Fernández-Jiménez, A.; del Mar Alonso, M.; Palomo, A.; García-Lodeiro, I. Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements. Materials 2024, 17, 242. [Google Scholar] [CrossRef]

- Játiva, A.; Ruales, E.; Etxeberria, M. Volcanic Ash as a Sustainable Binder Material: An Extensive Review. Materials 2021, 14, 1302. [Google Scholar] [CrossRef]

- Tashima, M.M.; Soriano, L.; Borrachero, M.V.; Monzó, J.; Payá, J. Towards the Valorization of Cumbre Vieja Volcanic Ash—Production of Alternative Cements. Constr. Build. Mater. 2023, 370, 130635. [Google Scholar] [CrossRef]

- Mañosa, J.; Serrano-Conte, J.; Maldonado-Alameda, A.; Aulinas, M.; Chimenos, J.M. Pyroclastic Volcanic Ash as a Potential Precursor of Alkali-Activated Binders—A Case Study from Tajogaite (La Palma, Canary Islands) Volcano Eruption. J. Build. Eng. 2023, 72, 106623. [Google Scholar] [CrossRef]

- Lemougna, P.N.; MacKenzie, K.J.D.; Melo, U.F.C. Synthesis and Thermal Properties of Inorganic Polymers (Geopolymers) for Structural and Refractory Applications from Volcanic Ash. Ceram. Int. 2011, 37, 3011–3018. [Google Scholar] [CrossRef]

- James Olawuyi, B.; Kolapo, O. Compressive Strength of Volcanic Ash/Ordinary Portland Cement Laterized Concrete. Civ. Eng. Dimens. 2010, 12, 23–28. [Google Scholar] [CrossRef][Green Version]

- Hammat, S.; Menadi, B.; Kenai, S.; Thomas, C.; Kirgiz, M.S.; Sousa Galdino, A.G. de The Effect of Content and Fineness of Natural Pozzolana on the Rheological, Mechanical, and Durability Properties of Self-Compacting Mortar. J. Build. Eng. 2021, 44, 103276. [Google Scholar] [CrossRef]

- Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Effect of Processed Volcanic Ash as Active Mineral Addition for Cement Manufacture. Materials 2022, 15, 6305. [Google Scholar] [CrossRef]

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption. Comité Européen de Normalisation: Brussels, Belgium, 2013.

- ASTM-C618-23; Standard Specification for Coal Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- EN 196-1; Methods of Testing Cement. Part 1: Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2018.

- EN 1015-3; Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Comité Européen de Normalisation: Brussels, Belgium, 2000.

- EN 1015-11; Methods of Test for Mortar for Masonry. Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Comité Européen de Normalisation: Brussels, Belgium, 2020.

- LNEC-E-394; Betões–Determinação Da Absorção de Água Por Imersão. Laboratorio Nacional de Engenharia Civil: Lisboa, Portugal, 1993.

- EN 15801:2009; Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- Ortega, J.M.; Branco, F.G.; Pereira, L.; Marques, L. Chloride Ingress Resistance, Microstructure and Mechanical Properties of Lightweight Mortars with Natural Cork and Expanded Clay Prepared Using Sustainable Blended Cements. J. Mar. Sci. Eng. 2022, 10, 1174. [Google Scholar] [CrossRef]

- Karolina, R.; Syahrizal, S.; Putra, M.A.; Prasetyo, T.A. Optimization of the Use of Volcanic Ash of Mount Sinabung Eruption as the Substitution for Fine Aggregate. Procedia Eng. 2015, 125, 669–674. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Yin, J.; Peng, Y.; Wang, Y.; Tang, S.; Shi, Y.; Wang, Y.; Wang, L. Thermodynamics-Based Simulations of the Hydration of Low-Heat Portland Cement and the Compensatory Effect of Magnesium Oxide Admixtures. J. Zhejiang Univ. Sci. A 2025, 26, 305–319. [Google Scholar] [CrossRef]

- Siddique, R. Effect of Volcanic Ash on the Properties of Cement Paste and Mortar. Resour. Conserv. Recycl. 2011, 56, 66–70. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Huang, M.; Yin, H.; Jiang, K.; Xiao, K.; Tang, S. Influence of Different Alkali Sulfates on the Shrinkage, Hydration, Pore Structure, Fractal Dimension and Microstructure of Low-Heat Portland Cement, Medium-Heat Portland Cement and Ordinary Portland Cement. Fractal Fract. 2021, 5, 79. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials; Prentice-Hall: Upper Saddle River, NJ, USA, 2013. [Google Scholar]

- Ortega, J.M.; Branco, F.G.; Pereira, L. Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements. Buildings 2023, 13, 1651. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G. The Pore Structure of Cement Paste Blended with Fly Ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | TiO2 | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| VA | 43.63 | 13.47 | 13.23 | 0.19 | 8.39 | 11.27 | 3.56 | 1.49 | 3.63 | 0.76 | 0.00 |

| Sand | 0.34 | 0.12 | 0.06 | <LLD | 21.46 | 31.58 | <LLD | 0.02 | 0.04 | <LLD | 46.05 |

| Cement | 39.59 | 14.62 | 14.91 | 0.20 | 6.20 | 11.36 | 5.56 | 1.77 | 4.20 | 0.82 | 0.00 |

| Sample | Sand | Cement | VA | Ground VA | Water |

|---|---|---|---|---|---|

| RM | 1350 | 450 | 0 | 0 | 225 |

| VA-C-5% | 1350 | 427.5 | 0 | 22.5 | 225 |

| VA-C-10% | 1350 | 405 | 0 | 45 | 225 |

| VA-C-15% | 1350 | 382.5 | 0 | 67.5 | 225 |

| VA-S-12.5% | 1181.3 | 450 | 168.75 | 0 | 225 |

| VA-S-25% | 1012.5 | 450 | 337.5 | 0 | 225 |

| VA-S-50% * | 675 | 450 | 675 | 0 | 225 |

| VA-S-75% * | 337.5 | 450 | 1012.5 | 0 | 225 |

| Mix | Bulk Density (g/cm3) | Flow (mm) | |

|---|---|---|---|

| Fresh | Hardened | ||

| RM | 2.45 ± 0.01 | 2.44 ± 0.02 | 163 ± 6 |

| VA-C-5% | 2.40 ± 0.05 | 2.39 ± 0.04 | 171 ± 4 |

| VA-C-10% | 2.38 ± 0.01 | 2.36 ± 0.03 | 168 ± 6 |

| VA-C-15% | 2.39 ± 0.03 | 2.38 ± 0.03 | 166 ± 4 |

| VA-S-12.5% | 2.36 ± 0.02 | 2.35 ± 0.02 | 153 ± 6 |

| VA-S-25% | 2.30 ± 0.01 | 2.25 ± 0.09 | 134 ± 10 |

| VA-S-50% | 2.18 ± 0.05 | 2.17 ± 0.04 | 135 ± 13 |

| VA-S-75% | 1.93 ± 0.03 | 1.92 ± 0.03 | 105 ± 7 |

| Specimen | Element (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|

| O | Mg | Al | Si | S | Cl | Ca | Fe | |

| RM | 35.67 | 1.52 | 1.26 | 10.95 | 1.12 | 0.17 | 46.72 | 2.59 |

| VA-C-10% | 35.77 | 2.45 | 1.18 | 10.70 | 1.16 | 0.19 | 46.79 | 1.76 |

| VA-C-15% | 34.80 | 1.46 | 0.94 | 9.44 | 0.93 | - | 51.82 | 0.61 |

| VA-S-25% | 33.32 | 0.78 | 1.07 | 6.85 | 1.14 | 0.25 | 54.46 | 2.13 |

| VA-S-50% | 36.31 | 2.07 | 2.01 | 11.69 | 1.18 | - | 46.87 | 0.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gil-Martín, L.M.; Oliveira, M.J.; Fernández-Ruiz, M.A.; Branco, F.G.; Hernández-Montes, E. Sustainable Use of Volcanic Ash in Mortars as a Replacement for Cement or Sand: Shrinkage and Physical and Mechanical Properties. Materials 2025, 18, 3694. https://doi.org/10.3390/ma18153694

Gil-Martín LM, Oliveira MJ, Fernández-Ruiz MA, Branco FG, Hernández-Montes E. Sustainable Use of Volcanic Ash in Mortars as a Replacement for Cement or Sand: Shrinkage and Physical and Mechanical Properties. Materials. 2025; 18(15):3694. https://doi.org/10.3390/ma18153694

Chicago/Turabian StyleGil-Martín, Luisa María, Miguel José Oliveira, Manuel Alejandro Fernández-Ruiz, Fernando G. Branco, and Enrique Hernández-Montes. 2025. "Sustainable Use of Volcanic Ash in Mortars as a Replacement for Cement or Sand: Shrinkage and Physical and Mechanical Properties" Materials 18, no. 15: 3694. https://doi.org/10.3390/ma18153694

APA StyleGil-Martín, L. M., Oliveira, M. J., Fernández-Ruiz, M. A., Branco, F. G., & Hernández-Montes, E. (2025). Sustainable Use of Volcanic Ash in Mortars as a Replacement for Cement or Sand: Shrinkage and Physical and Mechanical Properties. Materials, 18(15), 3694. https://doi.org/10.3390/ma18153694