Residual Stresses in Metal Manufacturing: A Bibliometric Review

Abstract

1. Introduction

1.1. Residual Stresses in Metal Manufacturing

1.2. Process-Induced Residual Stresses: Sources and Mechanisms

1.3. Scientific Challenges and Rationale for a Bibliometric Review

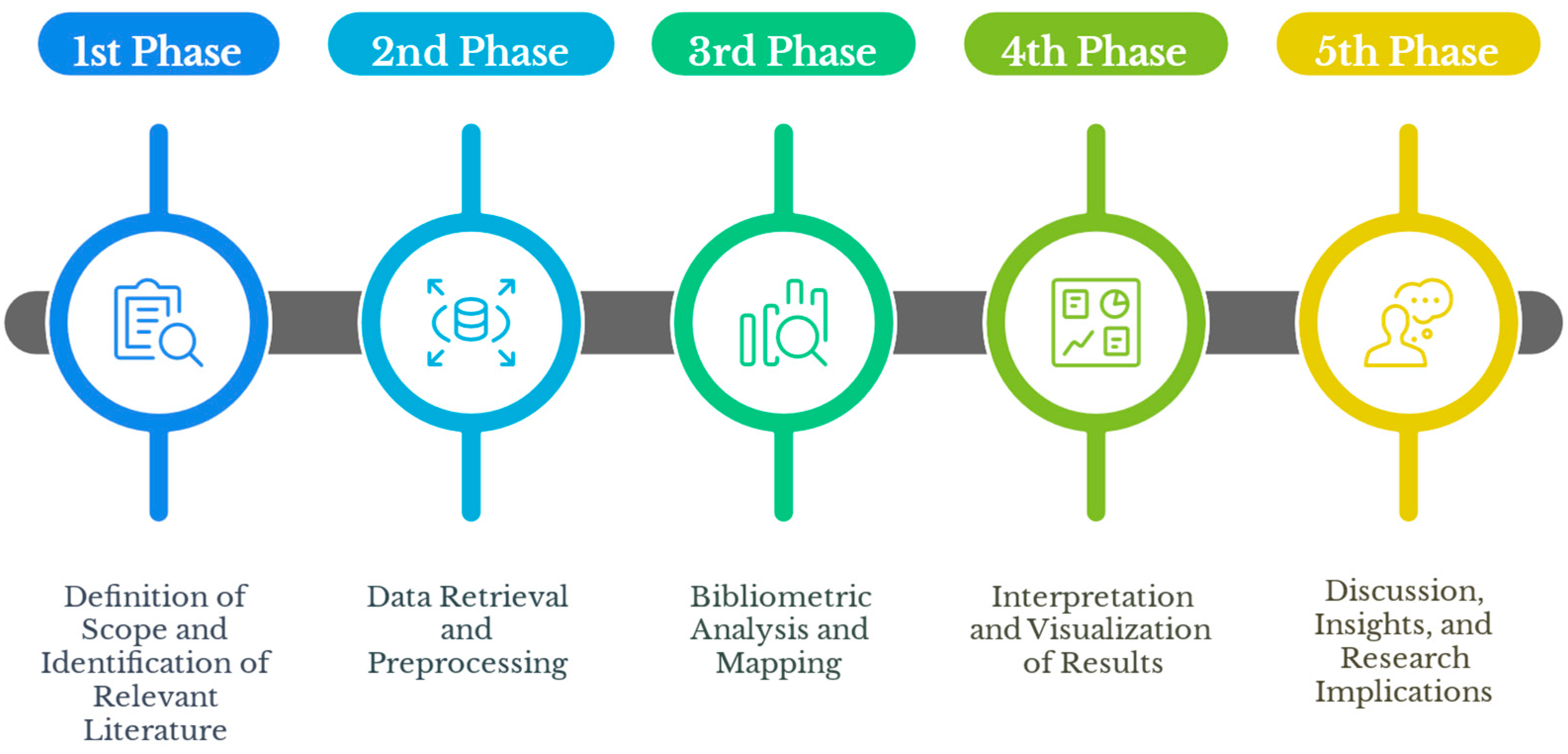

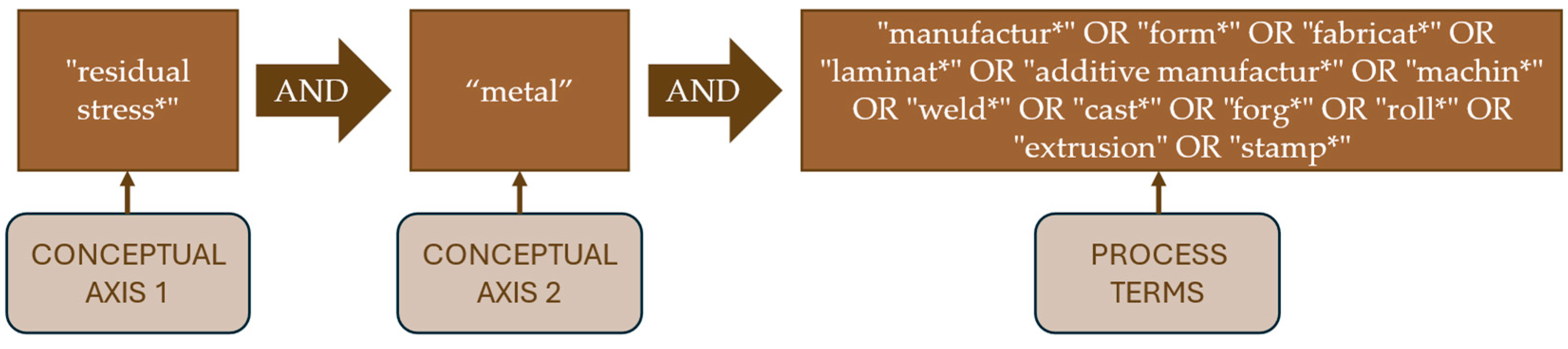

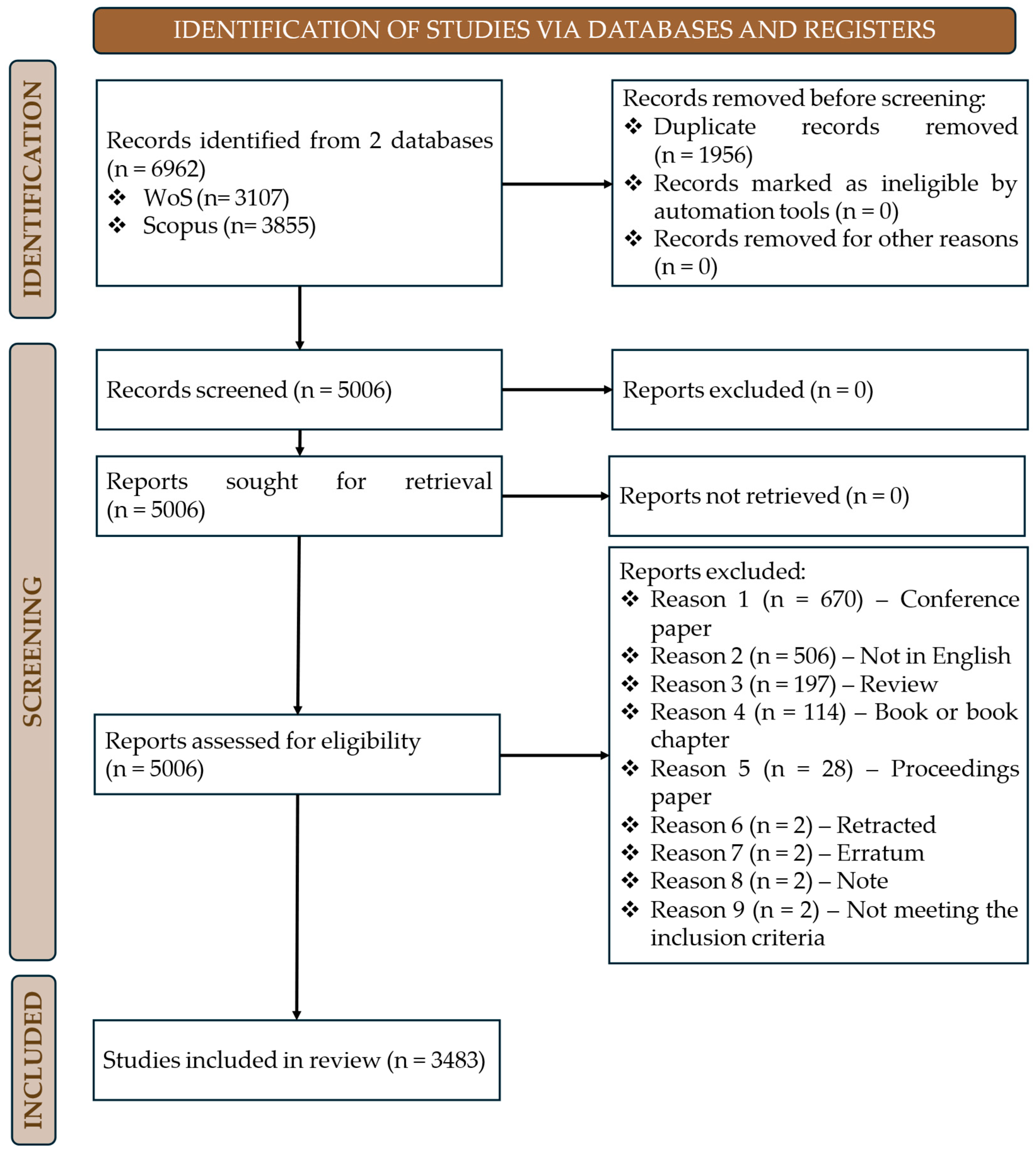

2. Methods

3. Results

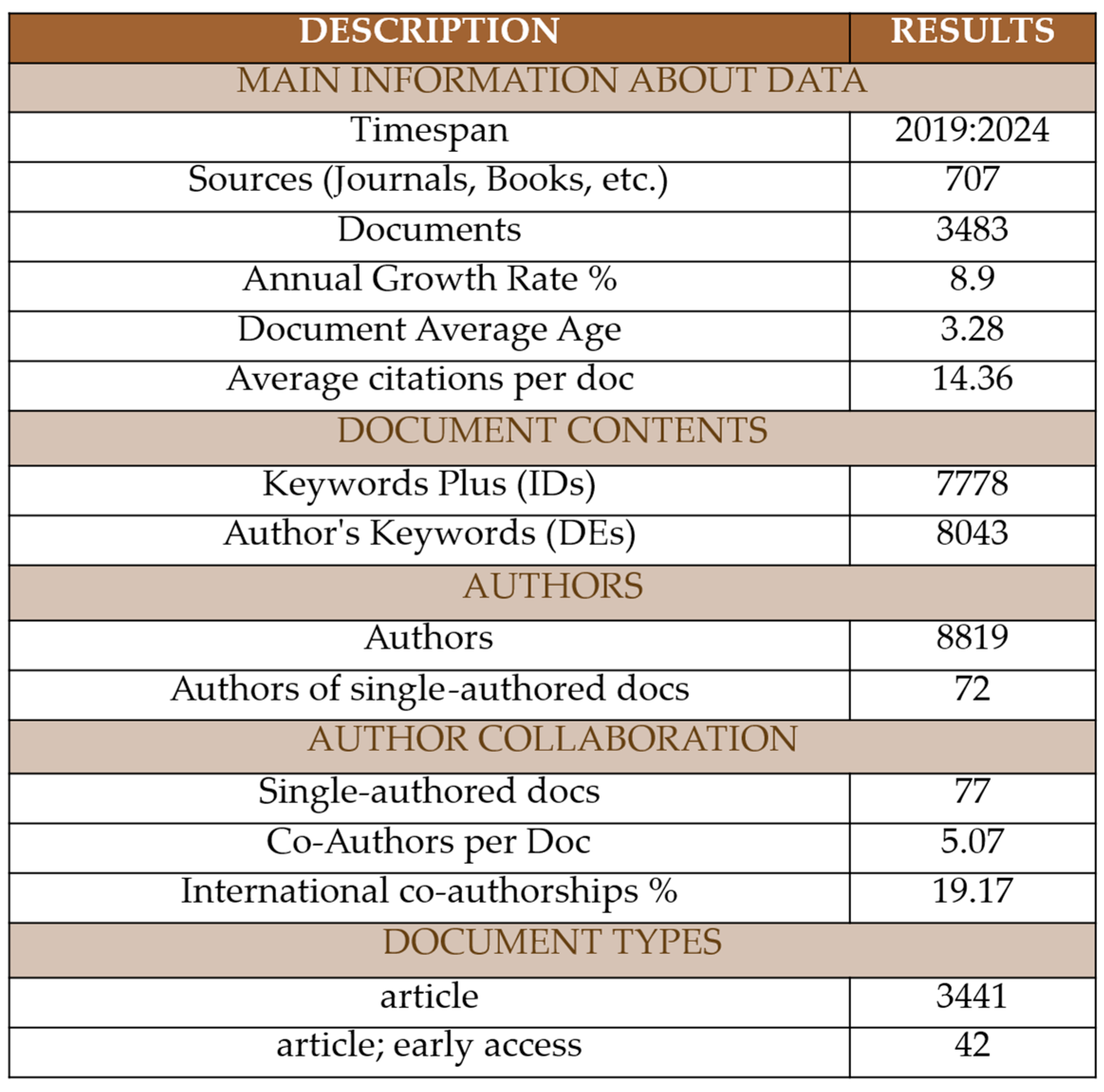

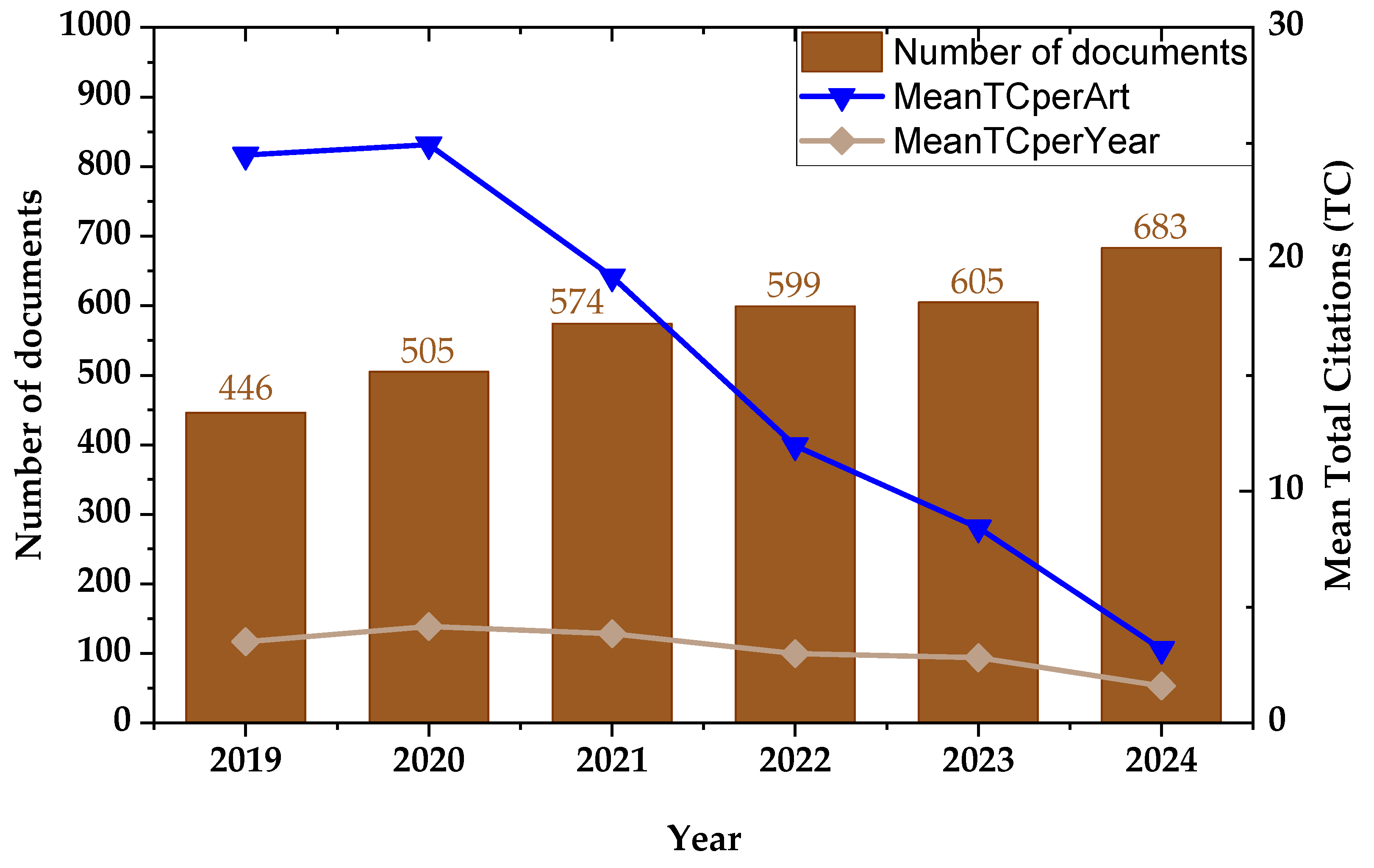

3.1. Descriptive Overview of the Bibliographic Dataset

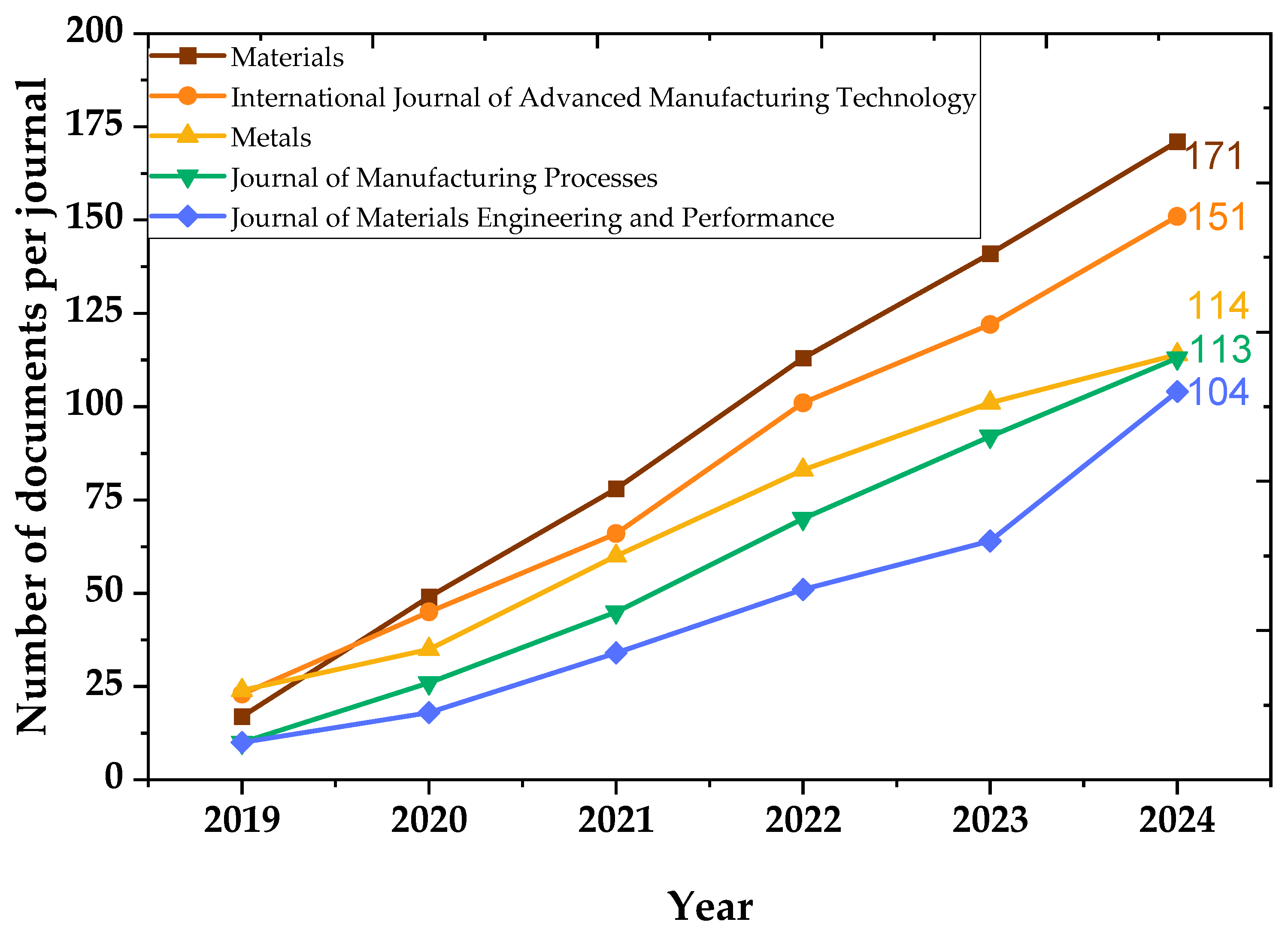

3.2. Analysis of Core and Impactful Journals

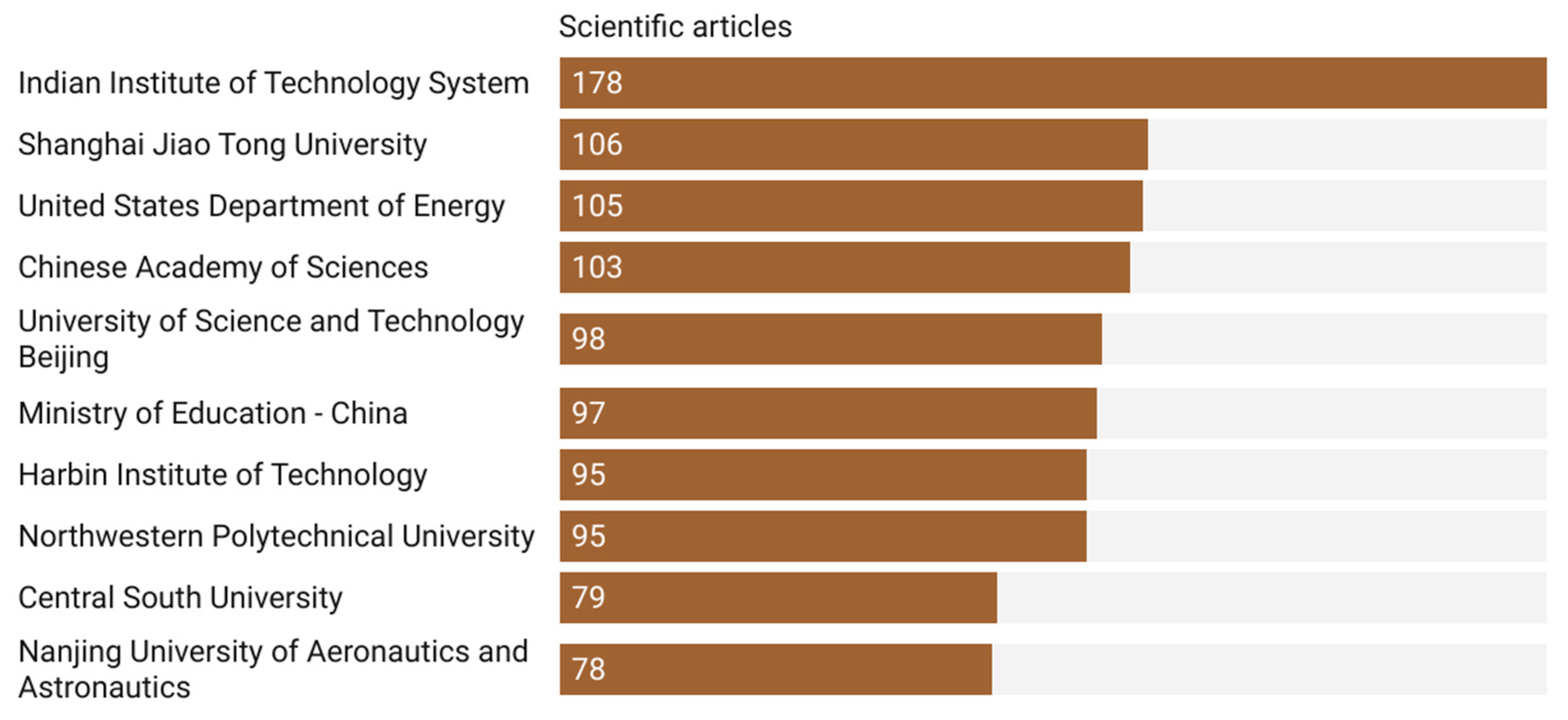

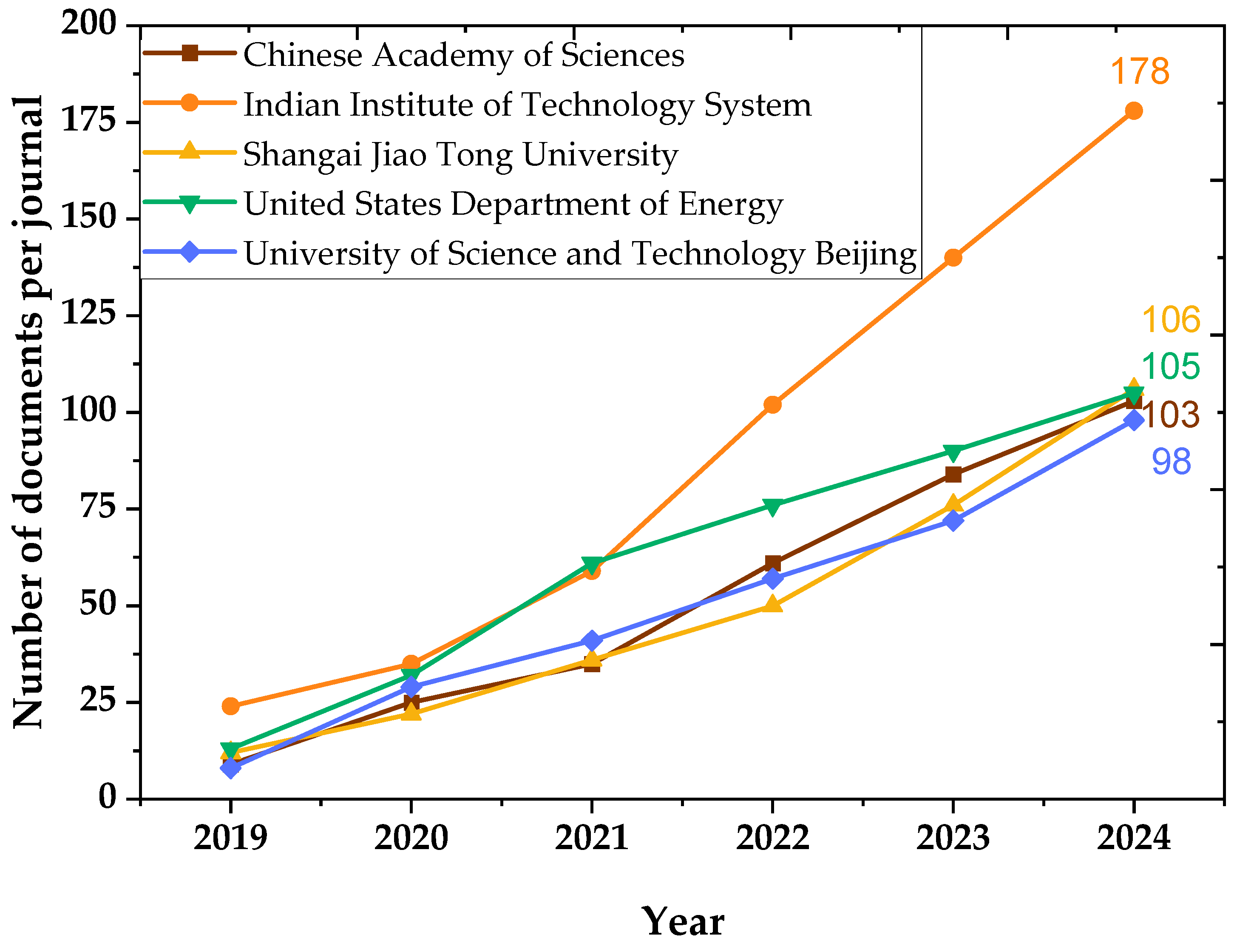

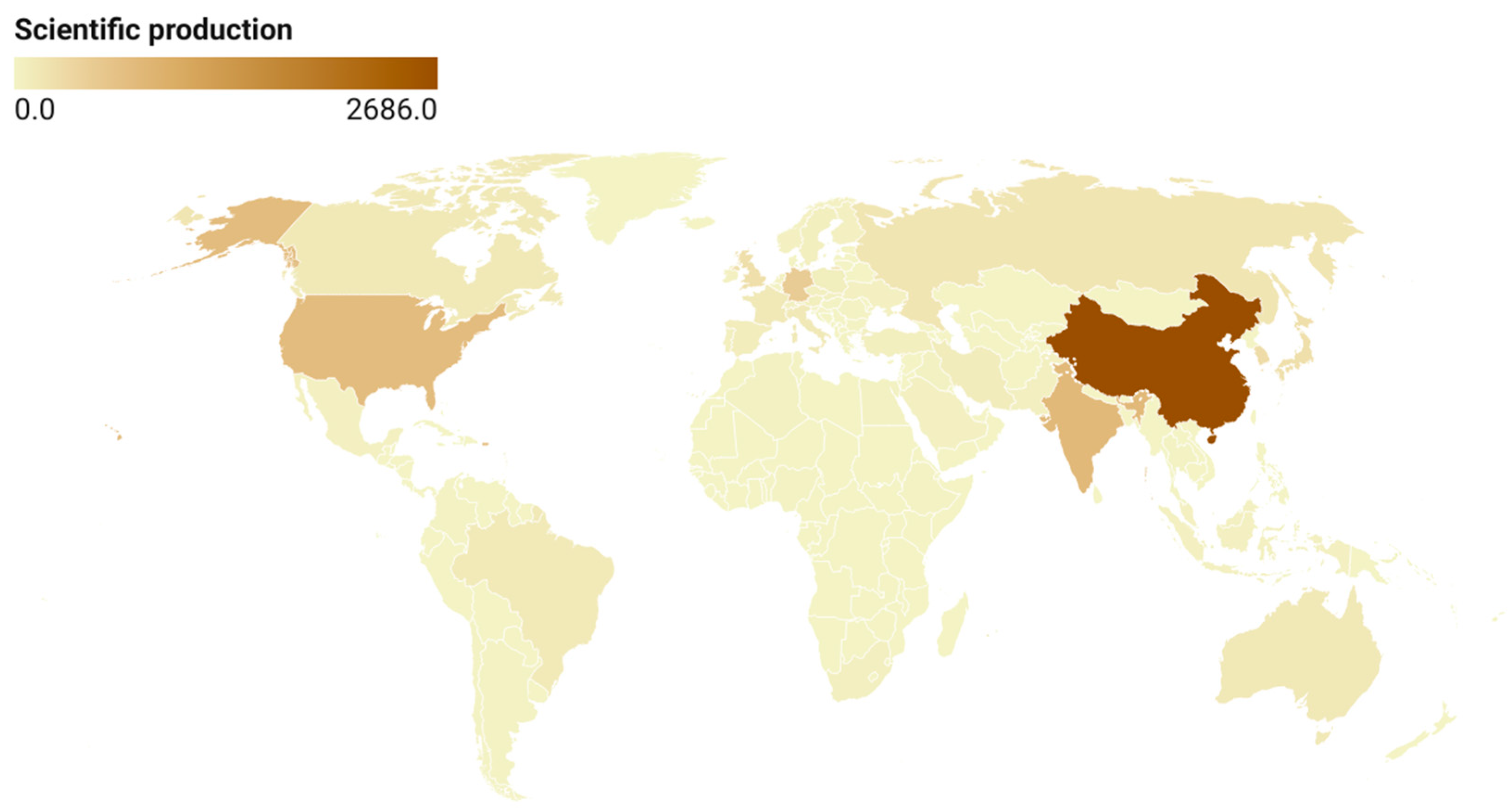

3.3. Institutional and National Contributions

3.4. Most Influential Scientific Articles

4. Discussion

4.1. Analysis of the Most Impactful Documents and Citation Trends

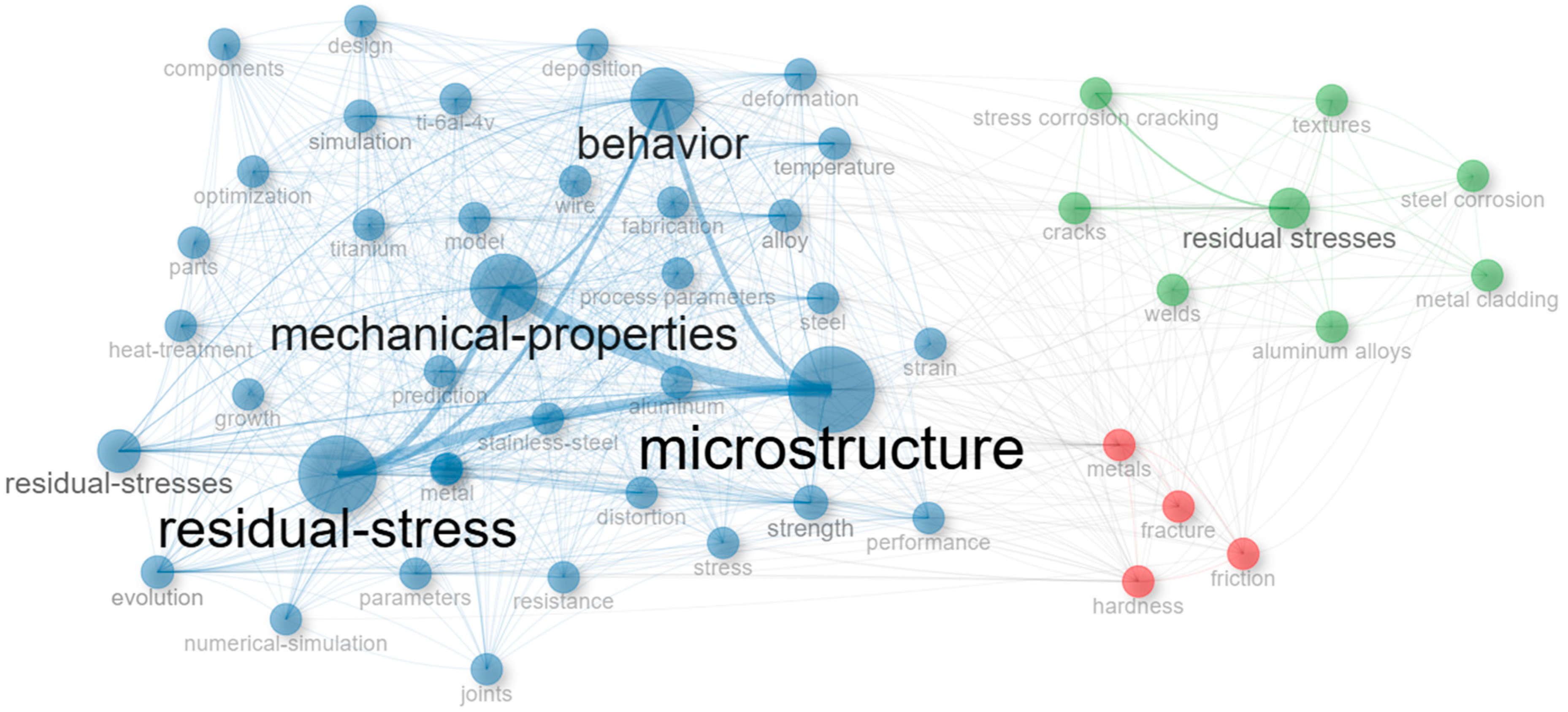

4.2. Analysis of Most Frequent Keywords and Word Analysis

4.3. Thematic Structure and Strategic Diagram

4.4. Dominant Processing Techniques

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tabatabaeian, A.; Ghasemi, A.R.; Shokrieh, M.M.; Marzbanrad, B.; Baraheni, M.; Fotouhi, M. Residual Stress in Engineering Materials: A Review. Adv. Eng. Mater. 2022, 24, 2100786. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of Measuring Residual Stresses in Components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Chen, S.; Gao, H.; Zhang, Y.; Wu, Q.; Gao, Z.; Zhou, X. Review on Residual Stresses in Metal Additive Manufacturing: Formation Mechanisms, Parameter Dependencies, Prediction and Control Approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An Overview of Residual Stresses in Metal Powder Bed Fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- James, M.N. Residual Stress Influences on Structural Reliability. Eng. Fail. Anal. 2011, 18, 1909–1920. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Li, Y.; Gan, W.; Zhou, W.; Li, D. Review on Residual Stress and Its Effects on Manufacturing of Aluminium Alloy Structural Panels with Typical Multi-Processes. Chin. J. Aeronaut. 2023, 36, 96–124. [Google Scholar] [CrossRef]

- Carpenter, K.; Tabei, A. On Residual Stress Development, Prevention, and Compensation in Metal Additive Manufacturing. Materials 2020, 13, 255. [Google Scholar] [CrossRef]

- Pereira, H.B.; Echeverri, E.A.A.; Alves, L.H.D.; Goldenstein, H. Evaluation of the Effect of Heat Input and Cooling Rate of Rail Flash-Butt Welding Using Finite Element Method Simulation. Soldag. Inspeção 2022, 27, e2701. [Google Scholar] [CrossRef]

- Ariza, E.A.; Tschiptschin, A.P.; Azevedo, C.R.F. Failure Analysis of a Martensitic Stainless Steel (CA-15M) Roll Manufactured by Centrifugal Casting. Part II: Thermal Stress Analysis by FEA. Eng. Fail. Anal. 2015, 48, 78–93. [Google Scholar] [CrossRef]

- Bastola, N.; Jahan, M.P.; Rangasamy, N.; Rakurty, C.S. A Review of the Residual Stress Generation in Metal Additive Manufacturing: Analysis of Cause, Measurement, Effects, and Prevention. Micromachines 2023, 14, 1480. [Google Scholar] [CrossRef]

- Akhtar, W.; Lazoglu, I.; Liang, S.Y. Prediction and Control of Residual Stress-Based Distortions in the Machining of Aerospace Parts: A Review. J. Manuf. Process. 2022, 76, 106–122. [Google Scholar] [CrossRef]

- Jovani, T.; Chanal, H.; Blaysat, B.; Grédiac, M. Direct Residual Stress Identification during Machining. J. Manuf. Process. 2022, 82, 678–688. [Google Scholar] [CrossRef]

- Franceschi, A.; Stahl, J.; Kock, C.; Selbmann, R.; Ortmann-Ishkina, S.; Jobst, A.; Merklein, M.; Kuhfuß, B.; Bergmann, M.; Behrens, B.A.; et al. Strategies for Residual Stress Adjustment in Bulk Metal Forming. Arch. Appl. Mech. 2021, 91, 3557–3577. [Google Scholar] [CrossRef]

- Gruening, A.; Lebsanft, M.; Scholtes, B. Residual Stress State in Tools Used for Thermo-Mechanical Metal Forming Processes. Conf. Proc. Soc. Exp. Mech. Ser. 2011, 8, 39–45. [Google Scholar] [CrossRef]

- Muramulla, N.; Kumar, G.; Tiwari, K.; Baral, A.; Akinlabi, S.A.; Fatoba, O.S.; Mashinini, P.M.; Akinlabi, E.T. Investigating Resulting Residual Stresses during Mechanical Forming Process. IOP Conf. Ser. Mater. Sci. Eng. 2018, 328, 012012. [Google Scholar] [CrossRef]

- Toribio, J.; Lorenzo, M.; Vergara, D.; Aguado, L. Residual Stress Redistribution Induced by Fatigue in Cold-Drawn Prestressing Steel Wires. Constr. Build. Mater. 2016, 114, 317–322. [Google Scholar] [CrossRef]

- Toribio, J.; Lorenzo, M.; Vergara, D.; Kharin, V. Hydrogen Degradation of Cold-Drawn Wires: A Numerical Analysis of Drawing-Induced Residual Stresses and Strains. Corrosion 2011, 67, 075001-1–075001-8. [Google Scholar] [CrossRef]

- Keste, A.A.; Gawande, S.H.; Sarkar, C. Design Optimization of Precision Casting for Residual Stress Reduction. J. Comput. Des. Eng. 2016, 3, 140–150. [Google Scholar] [CrossRef]

- Tognan, A.; Sandnes, L.; Totis, G.; Sortino, M.; Berto, F.; Grong, Ø.; Salvati, E. Evaluation and Origin of Residual Stress in Hybrid Metal and Extrusion Bonding and Comparison with Friction Stir Welding. Int. J. Mech. Sci. 2022, 218, 107089. [Google Scholar] [CrossRef]

- Ariza, E.A.; Martorano, M.A.; De Lima, N.B.; Tschiptschin, A.P. Numerical Simulation with Thorough Experimental Validation to Predict the Build-up of Residual Stresses during Quenching of Carbon and Low-Alloy Steels. ISIJ Int. 2014, 54, 1396–1405. [Google Scholar] [CrossRef]

- Dattoma, V.; De Giorgi, M.; Nobile, R. On the Evolution of Welding Residual Stress after Milling and Cutting Machining. Comput. Struct. 2006, 84, 1965–1976. [Google Scholar] [CrossRef]

- Johnson, C.A.; Ruud, J.A.; Bruce, R.; Wortman, D. Relationships between Residual Stress, Microstructure and Mechanical Properties of Electron Beam–Physical Vapor Deposition Thermal Barrier Coatings. Surf. Coat. Technol. 1998, 108–109, 80–85. [Google Scholar] [CrossRef]

- Yang, J.; Bu, K.; Zhou, Y.; Song, K.; Huang, T.; Peng, X.; Liu, H.; Du, Y. Microstructure, Residual Stress, and Mechanical Properties Evolution of a Cu–Fe–P Alloy under Different Conditions. J. Mater. Res. Technol. 2023, 24, 7896–7909. [Google Scholar] [CrossRef]

- Yang, Y.P.; Jamshidinia, M.; Boulware, P.; Kelly, S.M. Prediction of Microstructure, Residual Stress, and Deformation in Laser Powder Bed Fusion Process. Comput. Mech. 2018, 61, 599–615. [Google Scholar] [CrossRef]

- Thibault, D.; Bocher, P.; Thomas, M. Residual Stress and Microstructure in Welds of 13%Cr–4%Ni Martensitic Stainless Steel. J. Mater. Process. Technol. 2009, 209, 2195–2202. [Google Scholar] [CrossRef]

- Xiu, S.; Shi, X. Transformation Mechanism of Microstructure and Residual Stress within Hardening Layer in PSHG. J. Adv. Mech. Des. Syst. Manuf. 2015, 9, JAMDSM0038. [Google Scholar] [CrossRef]

- Huang, W.; Garmestani, H.; Liang, S.Y. Microstructure Evolution and the Influence on Material Properties of Residual Stress in Additive Manufacturing with Analytics for a Green Future. In TMS Annual Meeting & Exhibition; Springer Nature: Cham, Switzerland, 2025; pp. 244–253. [Google Scholar] [CrossRef]

- Li, J.; Zheng, J.; Jia, L.; Li, H. Residual Stress and Microstructure Evolution of 7075 Aluminum Induced by Ultrasonic Surface Rolling Coupled with Cavitation. J. Mater. Eng. Perform. 2025, 1–13. [Google Scholar] [CrossRef]

- Yue, Q.; Li, Y.; Liang, C.; Wang, Y.; He, Y. Quantitative Evaluation of Residual Stress and Microstructural Effects on the Surface Hardness of Machined Ti-6Al-4 V Alloy with Microscopic Characterization Techniques. J. Mater. Process. Technol. 2024, 327, 118382. [Google Scholar] [CrossRef]

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.D.; Fabijanic, D. The Effect of Post-Processing Heat Treatment on the Microstructure, Residual Stress and Mechanical Properties of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2021, 821, 141611. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, S.; Yang, Q.; Yuan, W. Influence of Precompression Deformation on the Residual Stress, Microstructure, and Mechanical Properties of Aluminum–Lithium Alloys. Mater. Charact. 2025, 220, 114721. [Google Scholar] [CrossRef]

- Dive, V.; Lakade, S. Recent Research Progress on Residual Stress Measurement Using Non-Destructive Testing. Mater. Today Proc. 2021, 47, 3282–3287. [Google Scholar] [CrossRef]

- Felhő, C.; Varga, G. 2D FEM Investigation of Residual Stress in Diamond Burnishing. J. Manuf. Mater. Process. 2022, 6, 123. [Google Scholar] [CrossRef]

- Peng, Z.; Zhou, H.; Li, G.; Zhang, L.; Zhou, T.; Fu, Y. A Detected-Data-Enhanced FEM for Residual Stress Reconstruction and Machining Deformation Prediction. Alex. Eng. J. 2024, 91, 334–347. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Wu, H.; Miao, K.; Wu, H.; Li, R.; Liu, C.; Fang, W.; Fan, G. Research Progress of Residual Stress Measurement Methods. Heliyon 2024, 10, e28348. [Google Scholar] [CrossRef]

- Wang, Q.; Maryum, P.; Liu, Y.; Wang, Q.; Maryum, P.; Liu, Y. An Overview of Techniques for Measuring Residual Stress in Metal Matrix Composites. J. Mater. Sci. Chem. Eng. 2022, 10, 59–77. [Google Scholar] [CrossRef]

- Shao, Z.; Zhang, C.; Li, Y.; Shen, H.; Zhang, D.; Yu, X.; Zhang, Y. A Review of Non-Destructive Evaluation (NDE) Techniques for Residual Stress Profiling of Metallic Components in Aircraft Engines. Aerospace 2022, 9, 534. [Google Scholar] [CrossRef]

- Alipooramirabad, H.; Kianfar, S.; Paradowska, A.; Ghomashchi, R. Residual Stress Measurement in Engine Block—An Overview. Int. J. Adv. Manuf. Technol. 2024, 131, 1–27. [Google Scholar] [CrossRef]

- Soyama, H.; Chighizola, C.R.; Hill, M.R. Effect of Compressive Residual Stress Introduced by Cavitation Peening and Shot Peening on the Improvement of Fatigue Strength of Stainless Steel. J. Mater. Process. Technol. 2021, 288, 116877. [Google Scholar] [CrossRef]

- Dong, W.; Jimenez, X.A.; To, A.C. Temperature-Dependent Modified Inherent Strain Method for Predicting Residual Stress and Distortion of Ti6Al4V Walls Manufactured by Wire-Arc Directed Energy Deposition. Addit. Manuf. 2023, 62, 103386. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Wei, X.; Gan, J.; Jiang, C. The Effect of Warm Shot Peening on Microstructure Evolution and Residual Stress in Gradient Nanostructured Mg-8Gd-3Y-0.4Zr Alloys. Coatings 2025, 15, 316. [Google Scholar] [CrossRef]

- Li, H.; Zhang, J.; Ao, N.; Xu, J.; Ji, D. Influence of Residual Stress and Its Relaxation on the Corrosion Bending Fatigue Resistance of EA4T Axle Steel Treated by Ultrasonic Surface Rolling. Int. J. Fatigue 2023, 170, 107561. [Google Scholar] [CrossRef]

- Akinwamide, S.O.; Venter, A.; Akinribide, O.J.; Babalola, B.J.; Andrews, A.; Olubambi, P.A. Residual Stress Impact on Corrosion Behaviour of Hot and Cold Worked 2205 Duplex Stainless Steel: A Study by X-Ray Diffraction Analysis. Eng. Fail. Anal. 2022, 131, 105913. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, L.; Peng, X.; Dai, S.; Ou, Y.; Pang, P.; Chen, L.; Jin, X.; Zhang, X.; Liao, B.; et al. Relationship between Residual Stress and Tribocorrosion Behavior of High Quality DLC Coatings Prepared by FCVA with HVP Technology. Ceram. Int. 2025, 51, 3062–3074. [Google Scholar] [CrossRef]

- Minamizawa, K.; Arakawa, J.; Akebono, H.; Nambu, K.; Nakamura, Y.; Hayakawa, M.; Kikuchi, S. Fatigue Limit Estimation for Carburized Steels with Surface Compressive Residual Stress Considering Residual Stress Relaxation. Int. J. Fatigue 2022, 160, 106846. [Google Scholar] [CrossRef]

- Qin, Y.; Ma, C.; Mei, L. Prediction of Weld Residual Stresses Based on Numerical Simulation and Machine Learning: A Review. Int. J. Adv. Manuf. Technol. 2025, 138, 2731–2779. [Google Scholar] [CrossRef]

- Falodun, O.; Oke, S.; Bodunrin, M. A Comprehensive Review of Residual Stresses in Carbon Steel Welding: Formation Mechanisms, Mitigation Strategies, and Advanced Post-Weld Heat Treatment Techniques. Int. J. Adv. Manuf. Technol. 2025, 136, 4107–4140. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J.; Wang, Y. Evolution, Control, and Mitigation of Residual Stresses in Additively Manufactured Metallic Materials: A Review. Adv. Eng. Mater. 2023, 25, 2300489. [Google Scholar] [CrossRef]

- Rizwee, M.; Kumar, D. Evaluating Residual Stresses in Metal Additive Manufacturing: A Comprehensive Review of Detection Methods, Impact, and Mitigation Strategies. Int. J. Mater. Form. 2024, 17, 53. [Google Scholar] [CrossRef]

- Bian, P.; Jammal, A.; Xu, K.; Ye, F.; Zhao, N.; Song, Y. A Review of the Evolution of Residual Stresses in Additive Manufacturing During Selective Laser Melting Technology. Materials 2025, 18, 1707. [Google Scholar] [CrossRef] [PubMed]

- Gurmesa, F.D.; Lemu, H.G.; Adugna, Y.W.; Harsibo, M.D. Residual Stresses in Wire Arc Additive Manufacturing Products and Their Measurement Techniques: A Systematic Review. Appl. Mech. 2024, 5, 420–449. [Google Scholar] [CrossRef]

- Han, Z.; Jiang, H.; Dong, C.; Zhang, L.; Peng, G.; Zhang, T. Instrumented Indentation Methods for Measurement of Residual Stresses in Thin Films/Coatings: A Review. J. Coat. Technol. Res. 2025, 22, 581–603. [Google Scholar] [CrossRef]

- del Bosque, A.; Lampropoulos, G.; Vergara, D. Nanocomposites for Multifunctional Sensors: A Comprehensive Bibliometric Exploration. Nanomaterials 2024, 15, 34. [Google Scholar] [CrossRef]

- del Bosque, A.; Vergara, D.; Lampropoulos, G.; Fernández-Arias, P. Energy Storage in Carbon Fiber-Based Batteries: Trends and Future Perspectives. Appl. Sci. 2024, 14, 10034. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Haddaway, N.R.; Page, M.J.; Pritchard, C.C.; McGuinness, L.A. PRISMA2020: An R Package and Shiny App for Producing PRISMA 2020-Compliant Flow Diagrams, with Interactivity for Optimised Digital Transparency and Open Synthesis. Campbell Syst. Rev. 2022, 18, e1230. [Google Scholar] [CrossRef] [PubMed]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing Parameters in Laser Powder Bed Fusion Metal Additive Manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of Functionally Graded Materials: An Overview of Manufacturing Methods, Applications and Future Challenges. Compos. B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Fu, J.; Li, H.; Song, X.; Fu, M.W. Multi-Scale Defects in Powder-Based Additively Manufactured Metals and Alloys. J. Mater. Sci. Technol. 2022, 122, 165–199. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding Melt Pool Characteristics in Laser Powder Bed Fusion: An Overview of Single- and Multi-Track Melt Pools for Process Optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.J.; Gibson, I. Wire and Arc Additive Manufacturing: Opportunities and Challenges to Control the Quality and Accuracy of Manufactured Parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Liao, Z.; la Monaca, A.; Murray, J.; Speidel, A.; Ushmaev, D.; Clare, A.; Axinte, D.; M’Saoubi, R. Surface Integrity in Metal Machining—Part I: Fundamentals of Surface Characteristics and Formation Mechanisms. Int. J. Mach. Tools Manuf. 2021, 162, 103687. [Google Scholar] [CrossRef]

- Tong, Z.; Ren, X.; Jiao, J.; Zhou, W.; Ren, Y.; Ye, Y.; Larson, E.A.; Gu, J. Laser Additive Manufacturing of FeCrCoMnNi High-Entropy Alloy: Effect of Heat Treatment on Microstructure, Residual Stress and Mechanical Property. J. Alloys Compd. 2019, 785, 1144–1159. [Google Scholar] [CrossRef]

- Becker, T.H.; Kumar, P.; Ramamurty, U. Fracture and Fatigue in Additively Manufactured Metals. Acta Mater. 2021, 219, 117240. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. Density and Mechanical Properties in Selective Laser Melting of Invar 36 and Stainless Steel 316L. J. Mater. Process. Technol. 2019, 266, 397–420. [Google Scholar] [CrossRef]

- Bhanu, V.; Pandey, S.M.; Gupta, A.; Pandey, C. Dissimilar Weldments of P91 and Incoloy 800HT: Microstructure, Mechanical Properties, and Residual Stresses. Int. J. Press. Vessel. Pip. 2022, 199, 104782. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the Microstructure, Mechanical Property and Residual Stress of SLM Inconel-718 Alloy Manufactured by Differing Island Scanning Strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Saboori, A.; Piscopo, G.; Lai, M.; Salmi, A.; Biamino, S. An Investigation on the Effect of Deposition Pattern on the Microstructure, Mechanical Properties and Residual Stress of 316L Produced by Directed Energy Deposition. Mater. Sci. Eng. A 2020, 780, 139179. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, S.; Zhao, Z.; Chen, T.; Zeng, J. Numerical Simulation of Residual Stresses in Aluminum Alloy Welded Joints. J. Manuf. Process. 2020, 50, 380–393. [Google Scholar] [CrossRef]

- Song, X.; Feih, S.; Zhai, W.; Sun, C.N.; Li, F.; Maiti, R.; Wei, J.; Yang, Y.; Oancea, V.; Romano Brandt, L.; et al. Advances in Additive Manufacturing Process Simulation: Residual Stresses and Distortion Predictions in Complex Metallic Components. Mater. Des. 2020, 193, 108779. [Google Scholar] [CrossRef]

- Oh, G.; Akiniwa, Y. Mean and Residual Stress Effects on Fatigue Behavior in a Pre-Strained Corner of Stainless Steel Sheet. Int. J. Fatigue 2021, 145, 106125. [Google Scholar] [CrossRef]

- Ahmed, I.I.; Adebisi, J.A.; Abdulkareem, S.; Sherry, A.H. Investigation of Surface Residual Stress Profile on Martensitic Stainless Steel Weldment with X-Ray Diffraction. J. King Saud Univ.—Eng. Sci. 2018, 30, 183–187. [Google Scholar] [CrossRef]

- He, Y.; Xiao, G.; Li, W.; Huang, Y. Residual Stress of a TC17 Titanium Alloy after Belt Grinding and Its Impact on the Fatigue Life. Materials 2018, 11, 2218. [Google Scholar] [CrossRef]

- Teixeira, Ó.; Silva, F.J.G.; Ferreira, L.P.; Atzeni, E. A Review of Heat Treatments on Improving the Quality and Residual Stresses of the Ti–6Al–4V Parts Produced by Additive Manufacturing. Metals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Strantza, M.; Vrancken, B.; Prime, M.B.; Truman, C.E.; Rombouts, M.; Brown, D.W.; Guillaume, P.; Van Hemelrijck, D. Directional and Oscillating Residual Stress on the Mesoscale in Additively Manufactured Ti-6Al-4V. Acta Mater. 2019, 168, 299–308. [Google Scholar] [CrossRef]

- Huang, H.; Ma, N.; Chen, J.; Feng, Z.; Murakawa, H. Toward Large-Scale Simulation of Residual Stress and Distortion in Wire and Arc Additive Manufacturing. Addit. Manuf. 2020, 34, 101248. [Google Scholar] [CrossRef]

- Yu, T.; Li, M.; Breaux, A.; Atri, M.; Obeidat, S.; Ma, C. Experimental and Numerical Study on Residual Stress and Geometric Distortion in Powder Bed Fusion Process. J. Manuf. Process. 2019, 46, 214–224. [Google Scholar] [CrossRef]

- Lu, X.; Lin, X.; Chiumenti, M.; Cervera, M.; Hu, Y.; Ji, X.; Ma, L.; Yang, H.; Huang, W. Residual Stress and Distortion of Rectangular and S-Shaped Ti-6Al-4V Parts by Directed Energy Deposition: Modelling and Experimental Calibration. Addit. Manuf. 2019, 26, 166–179. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, Z.; Lin, X.; Qiao, H.; Zhao, J.; Ding, W. Improving the Wear and Corrosion Resistance of Aeronautical Component Material by Laser Shock Processing: A Review. Materials 2023, 16, 4124. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.; Wu, Y.; Gong, H.; Peng, C.; He, Y. Experimental Analysis and Prediction Model of Milling- Induced Residual Stress of Aeronautical Aluminum Alloys. Appl. Sci. 2021, 11, 5881. [Google Scholar] [CrossRef]

- Luo, Y.; Gu, W.; Peng, W.; Jin, Q.; Qin, Q.; Yi, C. A Study on Microstructure, Residual Stresses and Stress Corrosion Cracking of Repair Welding on 304 Stainless Steel: Part I-Effects of Heat Input. Materials 2020, 13, 2416. [Google Scholar] [CrossRef] [PubMed]

- Mohtadi-Bonab, M.A. Effects of Different Parameters on Initiation and Propagation of Stress Corrosion Cracks in Pipeline Steels: A Review. Met. 2019, 9, 590. [Google Scholar] [CrossRef]

| Scientific Journal | Ranking | Frequency | Cumulative Frequency | Zone |

|---|---|---|---|---|

| Materials | 1 | 171 | 171 | Zone 1 |

| International Journal of Advanced Manufacturing Technology | 2 | 151 | 322 | Zone 1 |

| Metals | 3 | 114 | 436 | Zone 1 |

| Journal of Manufacturing Processes | 4 | 113 | 549 | Zone 1 |

| Journal of Materials Engineering and Performance | 5 | 104 | 653 | Zone 1 |

| Additive Manufacturing | 6 | 97 | 750 | Zone 1 |

| Journal of Materials Research and Technology | 7 | 72 | 822 | Zone 1 |

| Materials Science and Engineering A | 8 | 72 | 894 | Zone 1 |

| Journal of Alloys and Compounds | 9 | 53 | 947 | Zone 1 |

| Surface & Coatings Technology | 10 | 50 | 997 | Zone 1 |

| Scientific Journal | h-Index | g-Index | m-Index | Total Citations | Publications |

|---|---|---|---|---|---|

| Additive Manufacturing | 37 | 58 | 5.286 | 4014 | 97 |

| Journal of Manufacturing Processes | 29 | 40 | 4.143 | 2248 | 113 |

| Materials Science and Engineering A | 28 | 45 | 4.000 | 2281 | 72 |

| International Journal of Advanced Manufacturing Technology | 21 | 35 | 3.000 | 1746 | 151 |

| Journal of Alloys and Compounds | 21 | 34 | 3.000 | 1328 | 53 |

| Materials | 21 | 35 | 3.000 | 2035 | 171 |

| Journal of Materials Processing Technology | 20 | 34 | 2.857 | 1266 | 45 |

| Surface & Coatings Technology | 20 | 31 | 2.857 | 1099 | 50 |

| Materials & Design | 19 | 45 | 2.714 | 2108 | 46 |

| Journal of Materials Research and Technology | 18 | 24 | 3.000 | 928 | 72 |

| Country | Total Citations | Average Article Citations |

|---|---|---|

| China | 16,409 | 13.8 |

| United States | 6571 | 22.7 |

| India | 4212 | 11.7 |

| Germany | 2666 | 12.8 |

| United Kingdom | 2618 | 27.0 |

| Italy | 1496 | 22.0 |

| Singapore | 1326 | 55.2 |

| Japan | 1219 | 10.9 |

| Australia | 995 | 25.5 |

| Canada | 988 | 15.2 |

| Reference | Authors | Total Citations | Total Citations per Year | Normalized Total Citations |

|---|---|---|---|---|

| [59] | David Svetlizky et al. | 644 | 128.80 | 33.45 |

| [60] | João Pedro Oliveira et al. | 564 | 94.00 | 22.61 |

| [61] | Bassiouny Saleh et al. | 456 | 76.00 | 18.28 |

| [64] | Davoud Jafari et al. | 336 | 67.20 | 17.45 |

| [65] | Zhirong Liao et al. | 272 | 54.40 | 14.13 |

| [66] | Zhaopeng Tong et al. | 241 | 34.43 | 9.84 |

| [67] | Thorsten Hermann Becker et al. | 238 | 47.60 | 12.36 |

| [62] | Jin Fu et al. | 221 | 55.25 | 18.48 |

| [68] | Mostafa Yakout et al. | 199 | 28.43 | 8.12 |

| [63] | Jincheng Wang et al. | 194 | 64.67 | 23.03 |

| Words | Occurrences |

|---|---|

| residual * stress * | 1513 |

| microstructure | 772 |

| mechanical-properties | 565 |

| strength | 237 |

| simulation | 236 |

| alloy | 219 |

| temperature | 218 |

| model | 183 |

| distortion | 182 |

| parameters | 174 |

| steel | 169 |

| deformation | 164 |

| laser | 155 |

| stainless-steel | 146 |

| deposition | 119 |

| performance | 119 |

| heat-treatment | 116 |

| stress corrosion cracking | 116 |

| ti-6al-4v | 113 |

| resistance | 103 |

| design | 97 |

| titanium | 96 |

| hardness | 88 |

| cracks | 87 |

| process parameters | 84 |

| Processing Technique | Query Modification | Frequency | Percentage |

|---|---|---|---|

| Additive Manufacturing (AM) | AND (“additive manufactur *” OR “AM”) | 968 | 25.12% |

| Welding | AND (“weld *” OR “welding”) | 1360 | 35.35% |

| Machining | AND (“machin *” OR “milling” OR “turning”) | 679 | 17.64% |

| Casting | AND (“cast *” OR “casting”) | 210 | 5.46% |

| Forging | AND (“forg *” OR “forging”) | 80 | 2.08% |

| Rolling | AND (“roll *” OR “rolling”) | 339 | 8.81% |

| Extrusion | AND (“extrusion” OR “extrude *”) | 63 | 1.64% |

| Stamping | AND (“stamp *” OR “stamping”) | 36 | 0.94% |

| Laminating | AND (“laminat *” OR “lamination”) | 112 | 2.91% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vergara, D.; Fernández-Arias, P.; Ariza-Echeverri, E.A.; del Bosque, A. Residual Stresses in Metal Manufacturing: A Bibliometric Review. Materials 2025, 18, 3612. https://doi.org/10.3390/ma18153612

Vergara D, Fernández-Arias P, Ariza-Echeverri EA, del Bosque A. Residual Stresses in Metal Manufacturing: A Bibliometric Review. Materials. 2025; 18(15):3612. https://doi.org/10.3390/ma18153612

Chicago/Turabian StyleVergara, Diego, Pablo Fernández-Arias, Edwan Anderson Ariza-Echeverri, and Antonio del Bosque. 2025. "Residual Stresses in Metal Manufacturing: A Bibliometric Review" Materials 18, no. 15: 3612. https://doi.org/10.3390/ma18153612

APA StyleVergara, D., Fernández-Arias, P., Ariza-Echeverri, E. A., & del Bosque, A. (2025). Residual Stresses in Metal Manufacturing: A Bibliometric Review. Materials, 18(15), 3612. https://doi.org/10.3390/ma18153612