Thermal Treatment Prevents Effects of Downward Loads on the Screw-In Force Generation and Canal-Centering Ability of Nickel–Titanium Rotary Instruments

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Size Estimation

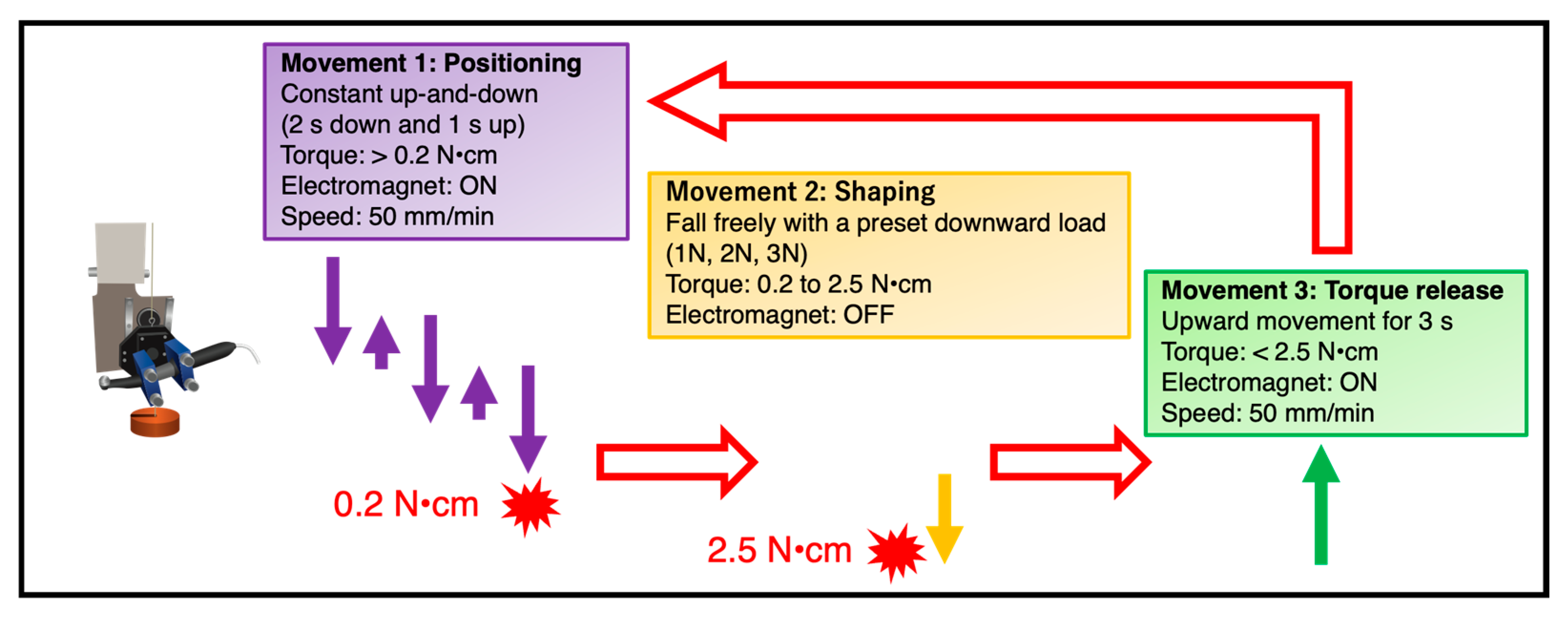

2.2. Automated Root Canal Instrumentation Device

2.3. Root Canal Instrumentation

2.4. Assessment of the Instrumentation Time and Canal-Centering Ratio

2.5. Statistical Analysis

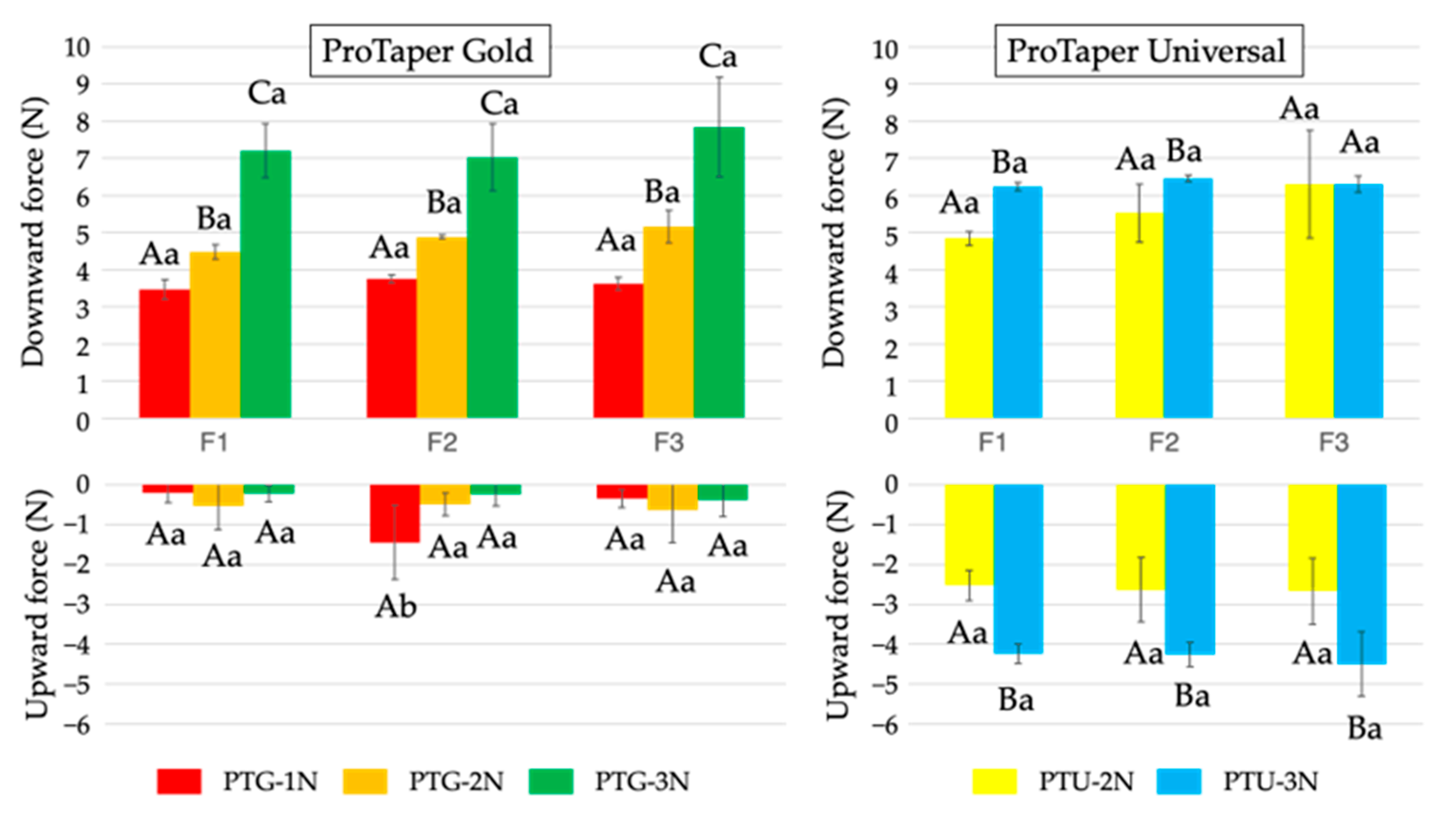

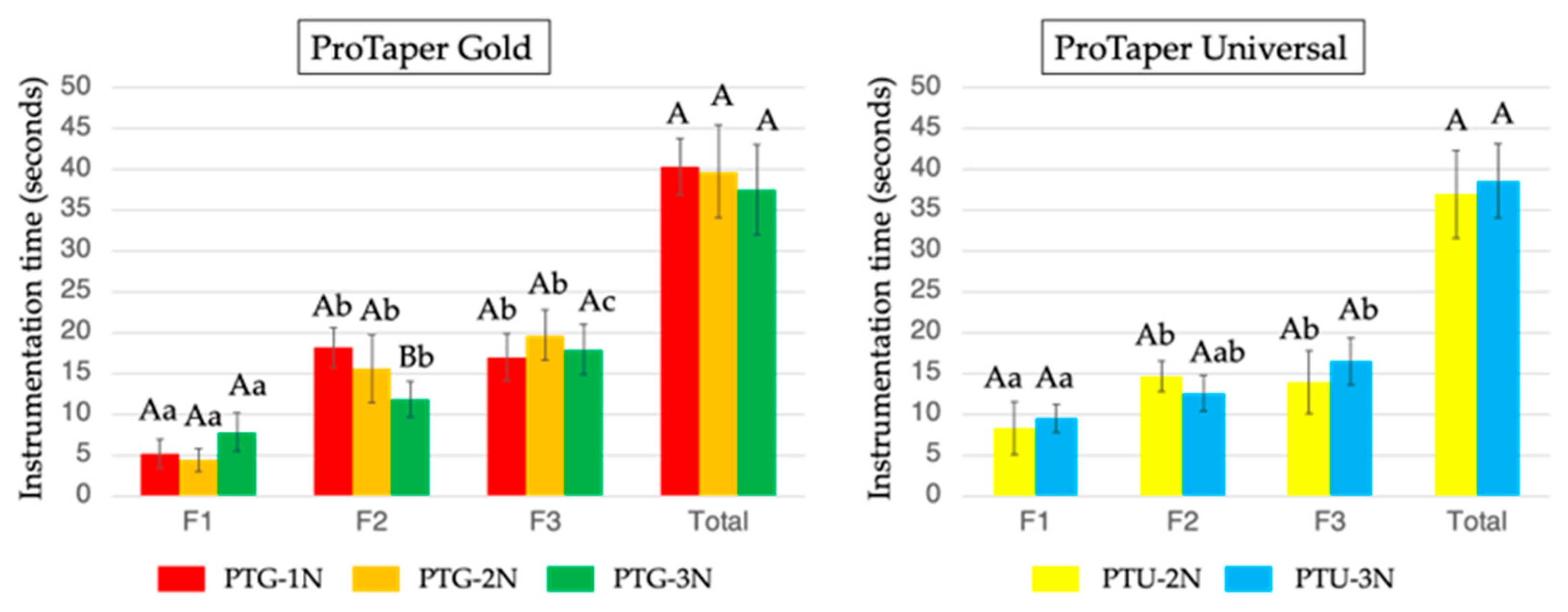

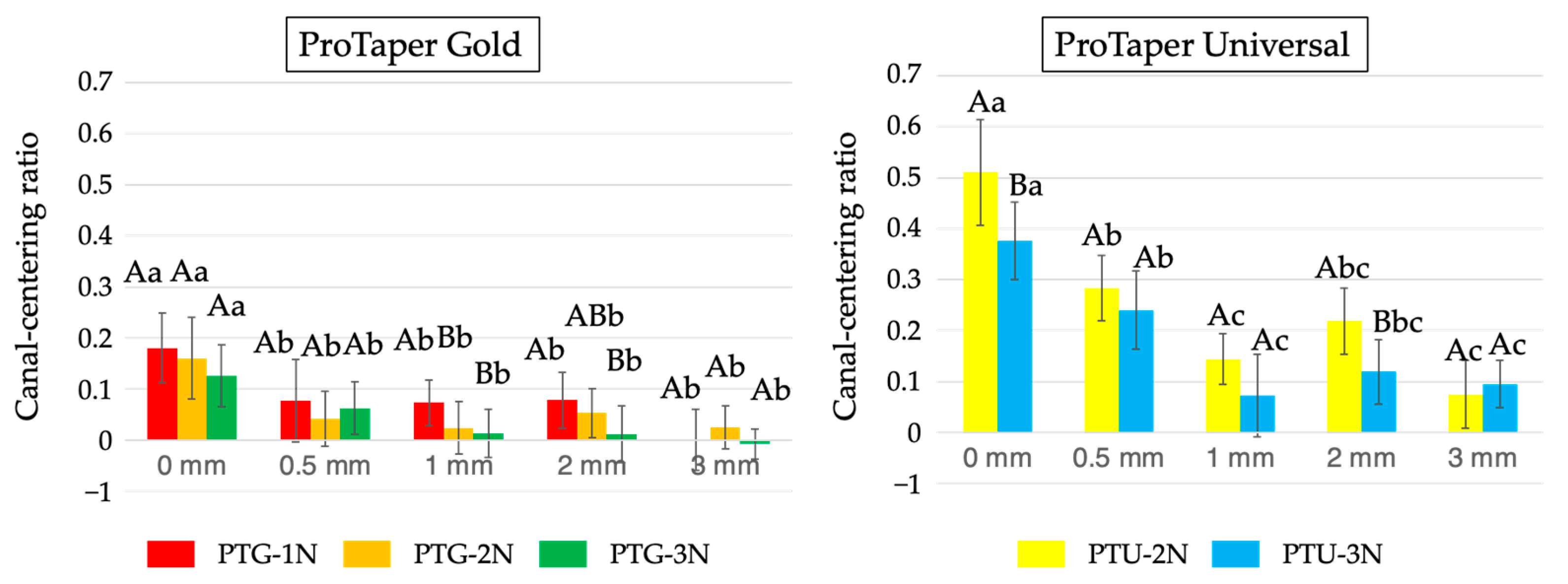

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siqueira, J.F., Jr.; Silva, W.O.; Romeiro, K.; Gominho, L.F.; Alves, F.R.F.; Rôças, I.N. Apical root canal microbiome associated with primary and posttreatment apical periodontitis: A systematic review. Int. Endod. J. 2024, 57, 1043–1058. [Google Scholar] [CrossRef]

- Ricucci, D.; Siqueira, J.F., Jr.; Bate, A.L.; Pitt Ford, T.R. Histologic investigation of root canal-treated teeth with apical periodontitis: A retrospective study from twenty-four patients. J. Endod. 2009, 35, 493–502. [Google Scholar] [CrossRef]

- Schilder, H. Cleaning and shaping the root canal. Dent. Clin. N. Am. 1974, 18, 269–296. [Google Scholar] [CrossRef]

- Sjögren, U.; Hagglund, B.; Sundqvist, G.; Wing, K. Factors affecting the long-term results of endodontic treatment. J. Endod. 1990, 16, 498–504. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef]

- Gambill, J.M.; Alder, M.; del Rio, C.E. Comparison of nickel-titanium and stainless steel hand-file instrumentation using computed tomography. J. Endod. 1996, 22, 369–375. [Google Scholar] [CrossRef] [PubMed]

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef]

- Glossen, C.R.; Haller, R.H.; Dove, S.B.; del Rio, C.E. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J. Endod. 1995, 21, 146–151. [Google Scholar] [CrossRef] [PubMed]

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef]

- McGuigan, M.B.; Louca, C.; Duncan, H.F. Endodontic instrument fracture: Causes and prevention. Br. Dent. J. 2013, 214, 341–348. [Google Scholar] [CrossRef]

- Maki, K.; Ebihara, A.; Kimura, S.; Nishijo, M.; Tokita, D.; Okiji, T. Effect of different speeds of up-and-down motion on canal centering ability and vertical force and torque generation of nickel-titanium rotary instruments. J. Endod. 2019, 45, 68–72. [Google Scholar] [CrossRef]

- Maki, K.; Ebihara, A.; Unno, H.; Omori, S.; Nakatsukasa, T.; Kimura, S.; Okiji, T. Effect of different downward loads on canal centering ability, vertical force, and torque generation during nickel-titanium rotary instrumentation. Materials 2022, 15, 2724. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Kwak, S.W.; Sigurdsson, A.; Chang, S.W.; Kim, S.K.; Kim, H.C. Stress generation during pecking motion of rotary nickel-titanium instruments with different pecking depth. J. Endod. 2017, 43, 1688–1691. [Google Scholar] [CrossRef] [PubMed]

- Hirano, K.; Kimura, S.; Maki, K.; Omori, S.; Ebihara, A.; Okiji, T. Impact of varying amplitudes of upward and downward motion on the torque/force generation, canal-centering ability, and cyclic fatigue resistance of nickel–titanium reciprocating instrument. Appl. Sci. 2025, 15, 288. [Google Scholar] [CrossRef]

- Pedullà, E.; Carlesi, T.; Pappalardo, A.; Canova, F.S.; Malagnino, V.A.; La Sora, G.R.M.; Generali, L. Impact of pecking amplitude on cyclic fatigue of new nickel-titanium files. Clin. Exp. Dent. Res. 2024, 10, e811. [Google Scholar] [CrossRef]

- La Rosa, G.R.M.; Canova, F.S.; Generali, L.; Pedullà, E. The role of pecking motion depths in dynamic cyclic fatigue resistance: In vitro study. Int. Dent. J. 2024, 74, 855–861. [Google Scholar] [CrossRef]

- Chicon, J.B.; Fernandes Pavão, V.M.; Gonçalves Cunha, M.H.; Frozoni, M. Influence of the brushing motions on the dynamic cyclic fatigue resistance of the reciproc blue instrument: In vitro study. J. Endod. 2024, 50, 1340–1345. [Google Scholar] [CrossRef] [PubMed]

- Romeiro, K.; Brasil, S.C.; Souza, T.M.; Gominho, L.F.; Pérez, A.R.; Perez, R.; Alves, F.R.F.; Rôças, I.N.; Siqueira, J.F., Jr. Influence of brushing motions on the shaping of oval canals by rotary and reciprocating instruments. Clin. Oral Investig. 2023, 27, 3973–3981. [Google Scholar] [CrossRef]

- Yanık, D.; Özel, Ş.; Dağlı Taşman Cömert, F. Brushing motion caused no microcracks: A micro-computed tomography study. Clin. Oral Investig. 2025, 29, 173. [Google Scholar] [CrossRef]

- Ha, J.H.; Cheung, G.S.; Versluis, A.; Lee, C.J.; Kwak, S.W.; Kim, H.C. ‘Screw-in’ tendency of rotary nickel-titanium files due to design geometry. Int. Endod. J. 2015, 48, 666–672. [Google Scholar] [CrossRef]

- Ha, J.H.; Kwak, S.W.; Kim, S.K.; Kim, H.C. Screw-in forces during instrumentation by various file systems. Restor. Dent. Endod. 2016, 41, 304–309. [Google Scholar] [CrossRef]

- Maki, K.; Ebihara, A.; Kimura, S.; Nishijo, M.; Tokita, D.; Miyara, K.; Okiji, T. Enhanced root canal-centering ability and reduced screw-in force generation of reciprocating nickel-titanium instruments with a post-machining thermal treatment. Dent. Mater. J. 2020, 39, 251–255. [Google Scholar] [CrossRef]

- Plotino, G.; Ahmed, H.M.; Grande, N.M.; Cohen, S.; Bukiet, F. Current assessment of reciprocation in endodontic preparation: A comprehensive review–part II: Properties and effectiveness. J. Endod. 2015, 41, 1939–1950. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.Y.; Kim, H.C.; Kim, E. Kinematic effects of nickel-titanium instruments with reciprocating or continuous rotation motion: A systematic review of in vitro studies. J. Endod. 2016, 42, 1009–1017. [Google Scholar] [CrossRef]

- Omori, S.; Ebihara, A.; Hirano, K.; Kasuga, Y.; Unno, H.; Nakatsukasa, T.; Kimura, S.; Maki, K.; Hanawa, T.; Okiji, T. Effect of rotational modes on torque/force generation and canal centering ability during rotary root canal instrumentation with differently heat-treated nickel-titanium instruments. Materials 2022, 15, 6850. [Google Scholar] [CrossRef] [PubMed]

- Yahata, Y.; Yoneyama, T.; Hayashi, Y.; Ebihara, A.; Doi, H.; Hanawa, T.; Suda, H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 2009, 42, 621–626. [Google Scholar] [CrossRef]

- Hieawy, A.; Haapasalo, M.; Zhou, H.; Wang, Z.J.; Shen, Y. Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J. Endod. 2015, 41, 1134–1138. [Google Scholar] [CrossRef] [PubMed]

- Kaval, M.E.; Capar, I.D.; Ertas, H. Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J. Endod. 2016, 42, 1840–1843. [Google Scholar] [CrossRef]

- Pessoa, O.F.; da Silva, J.M.; Gavini, G. Cyclic fatigue resistance of rotary NiTi instruments after simulated clinical use in curved root canals. Braz. Dent. J. 2013, 24, 117–120. [Google Scholar] [CrossRef]

- Uygun, A.D.; Kol, E.; Topcu, M.K.; Seckin, F.; Ersoy, I.; Tanriver, M. Variations in cyclic fatigue resistance among ProTaper Gold, ProTaper Next and ProTaper Universal instruments at different levels. Int. Endod. J. 2016, 49, 494–499. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 2016, 49, 1073–1078. [Google Scholar] [CrossRef]

- Gagliardi, J.; Versiani, M.A.; de Sousa-Neto, M.D.; Plazas-Garzon, A.; Basrani, B. Evaluation of the shaping characteristics of ProTaper Gold, ProTaper NEXT, and ProTaper Universal in curved canals. J. Endod. 2015, 41, 1718–1724. [Google Scholar] [CrossRef]

- Vasconcelos, R.A.; Arias, A.; Peters, O.A. Lateral and axial cutting efficiency of instruments manufactured with conventional nickel-titanium and novel gold metallurgy. Int. Endod. J. 2018, 51, 577–583. [Google Scholar] [CrossRef]

- Ha, J.H.; Kwak, S.W.; Versluis, A.; Lee, C.J.; Park, S.H.; Kim, H.C. The geometric effect of an off-centered cross-section on nickel-titanium rotary instruments: A finite element analysis study. J. Dent. Sci. 2017, 12, 173–178. [Google Scholar] [CrossRef] [PubMed]

- de Cristofaro Almeida, G.; Aun, D.P.; Resende, P.D.; Peixoto, I.F.; Viana, A.C.; Buono, V.T.; de Azevedo Bahia, M.G. Comparative analysis of torque and apical force to assess the cutting behaviour of ProTaper Next and ProTaper Universal endodontic instruments. Aust. Endod. J. 2020, 46, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.C.; Cheung, G.S.; Lee, C.J.; Kim, B.M.; Park, J.K.; Kang, S.I. Comparison of forces generated during root canal shaping and residual stresses of three nickel-titanium rotary files by using a three-dimensional finite-element analysis. J. Endod. 2008, 34, 743–747. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E. Laboratory comparison of the mechanical properties of TRUShape with several nickel-titanium rotary instruments. Int. Endod. J. 2017, 50, 805–812. [Google Scholar] [CrossRef] [PubMed]

- Kyaw, M.S.; Ebihara, A.; Kasuga, Y.; Maki, K.; Kimura, S.; Htun, P.H.; Nakatsukasa, T.; Okiji, T. Influence of rotational speed on torque/force generation and shaping ability during root canal instrumentation of extracted teeth with continuous rotation and optimum torque reverse motion. Int. Endod. J. 2021, 54, 1614–1622. [Google Scholar] [CrossRef]

- Lim, K.C.; Webber, J. The validity of simulated root canals for the investigation of the prepared root canal shape. Int. Endod. J. 1985, 18, 240–246. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maki, K.; Ebihara, A.; Luo, Y.; Kasuga, Y.; Unno, H.; Omori, S.; Kimura, S.; Okiji, T. Thermal Treatment Prevents Effects of Downward Loads on the Screw-In Force Generation and Canal-Centering Ability of Nickel–Titanium Rotary Instruments. Materials 2025, 18, 3610. https://doi.org/10.3390/ma18153610

Maki K, Ebihara A, Luo Y, Kasuga Y, Unno H, Omori S, Kimura S, Okiji T. Thermal Treatment Prevents Effects of Downward Loads on the Screw-In Force Generation and Canal-Centering Ability of Nickel–Titanium Rotary Instruments. Materials. 2025; 18(15):3610. https://doi.org/10.3390/ma18153610

Chicago/Turabian StyleMaki, Keiichiro, Arata Ebihara, Yanshan Luo, Yuka Kasuga, Hayate Unno, Satoshi Omori, Shunsuke Kimura, and Takashi Okiji. 2025. "Thermal Treatment Prevents Effects of Downward Loads on the Screw-In Force Generation and Canal-Centering Ability of Nickel–Titanium Rotary Instruments" Materials 18, no. 15: 3610. https://doi.org/10.3390/ma18153610

APA StyleMaki, K., Ebihara, A., Luo, Y., Kasuga, Y., Unno, H., Omori, S., Kimura, S., & Okiji, T. (2025). Thermal Treatment Prevents Effects of Downward Loads on the Screw-In Force Generation and Canal-Centering Ability of Nickel–Titanium Rotary Instruments. Materials, 18(15), 3610. https://doi.org/10.3390/ma18153610