Experimental Investigation of Mechanical Properties and Microstructure in Cement–Soil Modified with Waste Brick Powder and Polyvinyl Alcohol Fibers

Abstract

1. Introduction

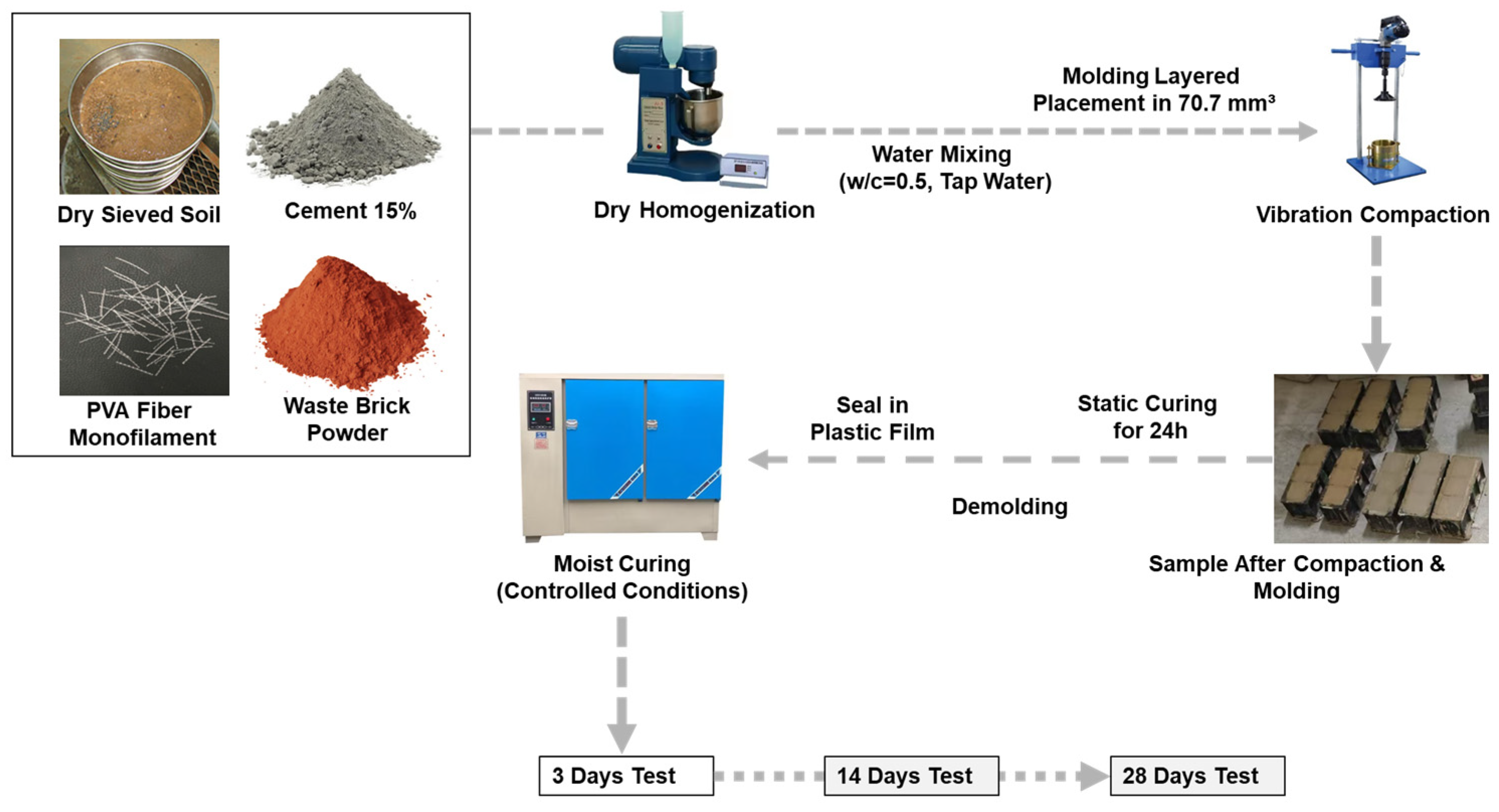

2. Materials and Testing Methods

2.1. Materials Specification

2.1.1. Soil Sourcing and Characterization

2.1.2. Cement

2.1.3. Polyvinyl Alcohol Fiber

2.1.4. Waste Brick Powder

2.2. Experimental Design

2.3. Mix Proportion

2.4. Experimental Methods

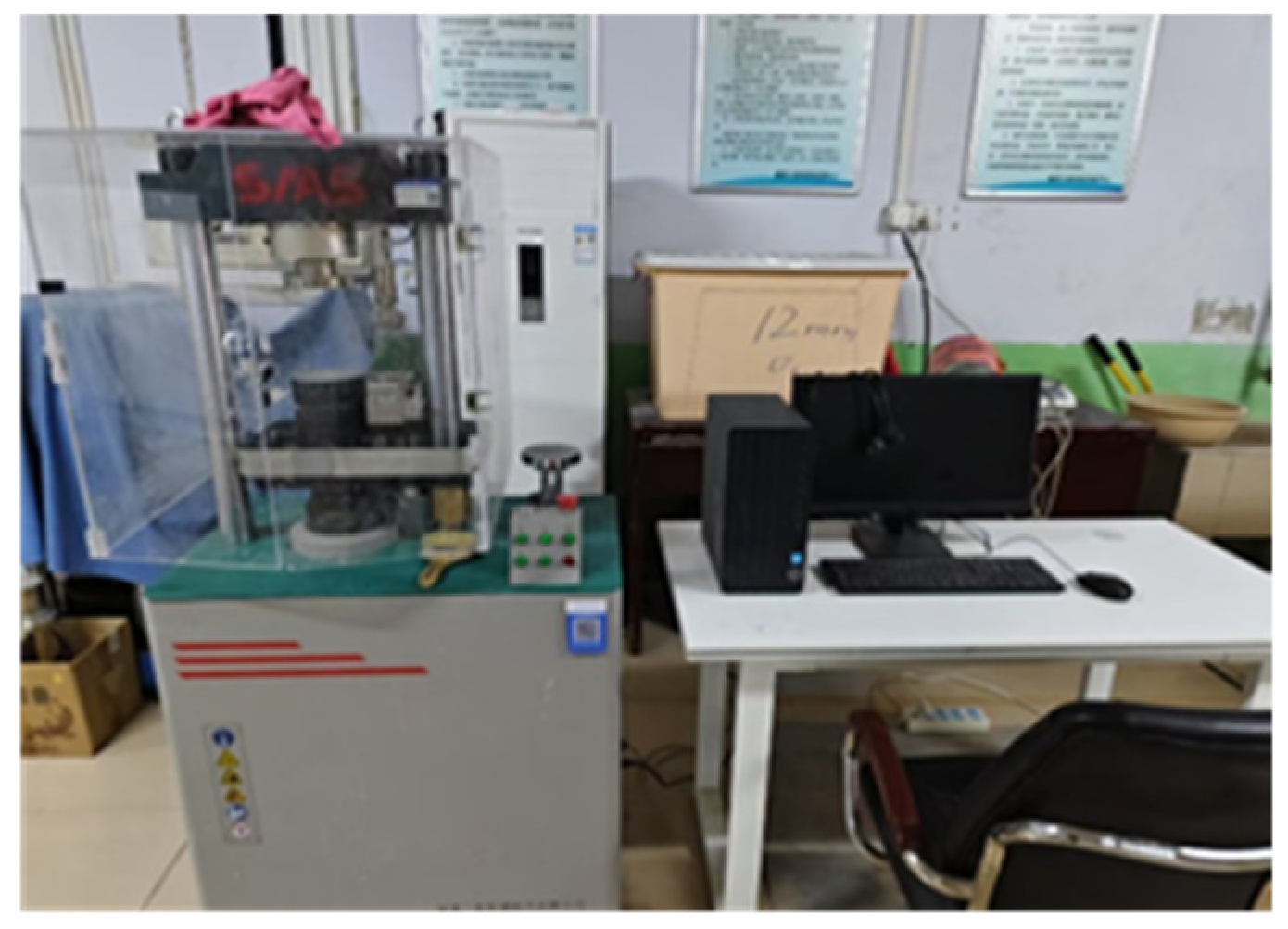

2.4.1. Unconfined Compressive Strength (UCS)

2.4.2. Splitting Tensile Strength (STS)

2.4.3. Scanning Electron Microscopy (SEM)

3. Results

3.1. Unconfined Compressive Strength Test

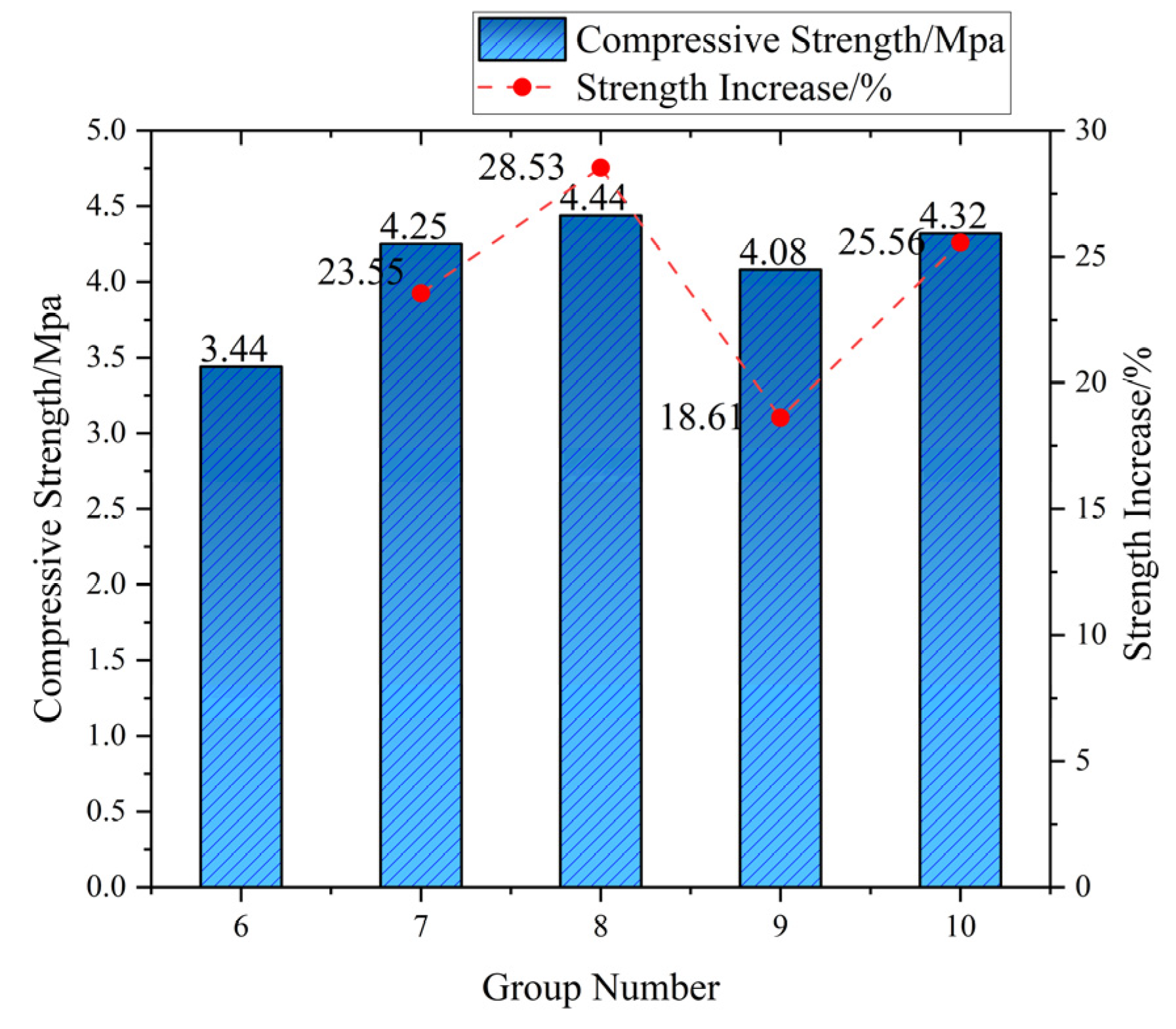

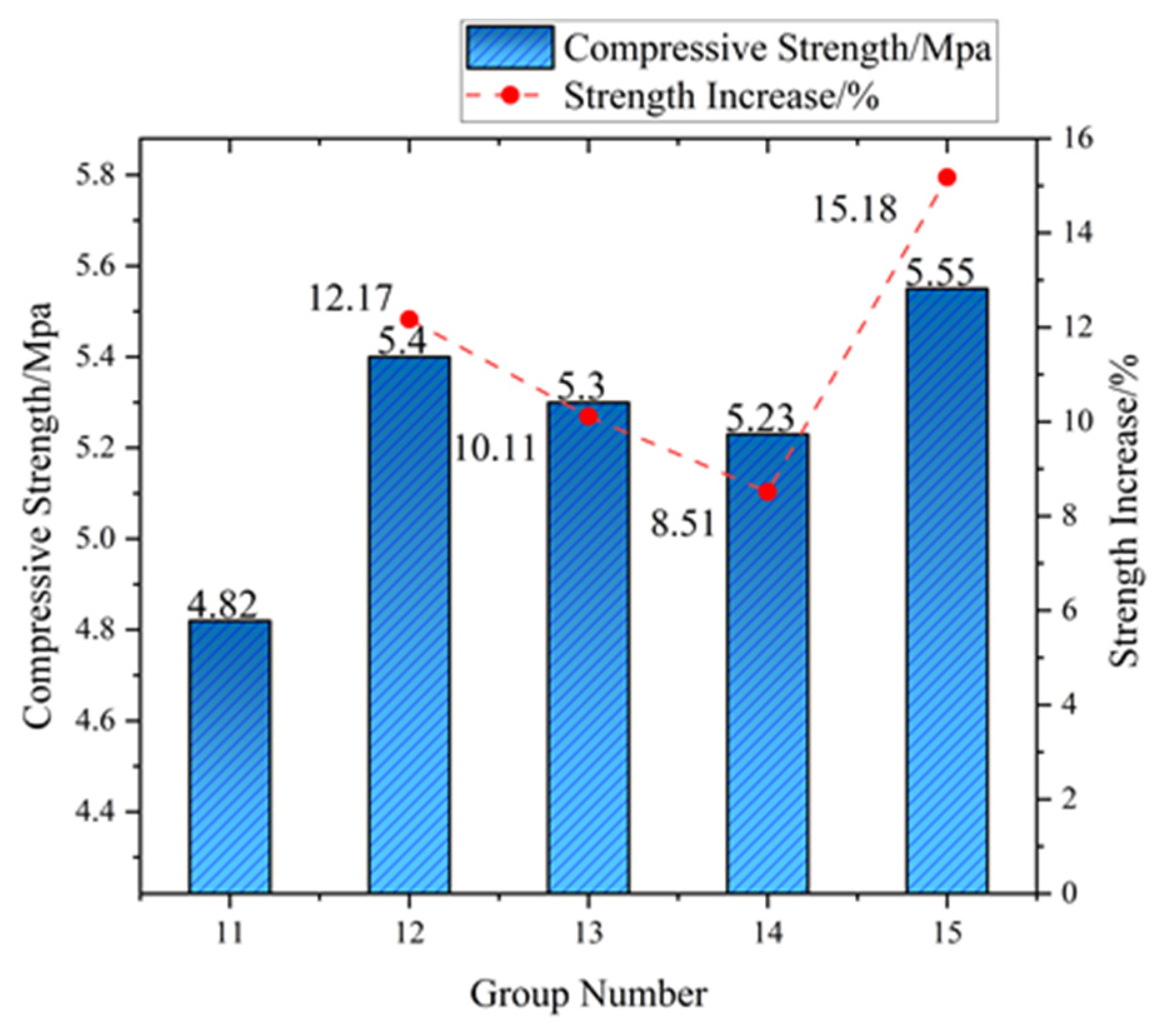

3.1.1. PVA Fiber Dosage Effects on Compressive Strength

3.1.2. Curing Age–Strength Relationship

3.2. Splitting Tensile Strength Test

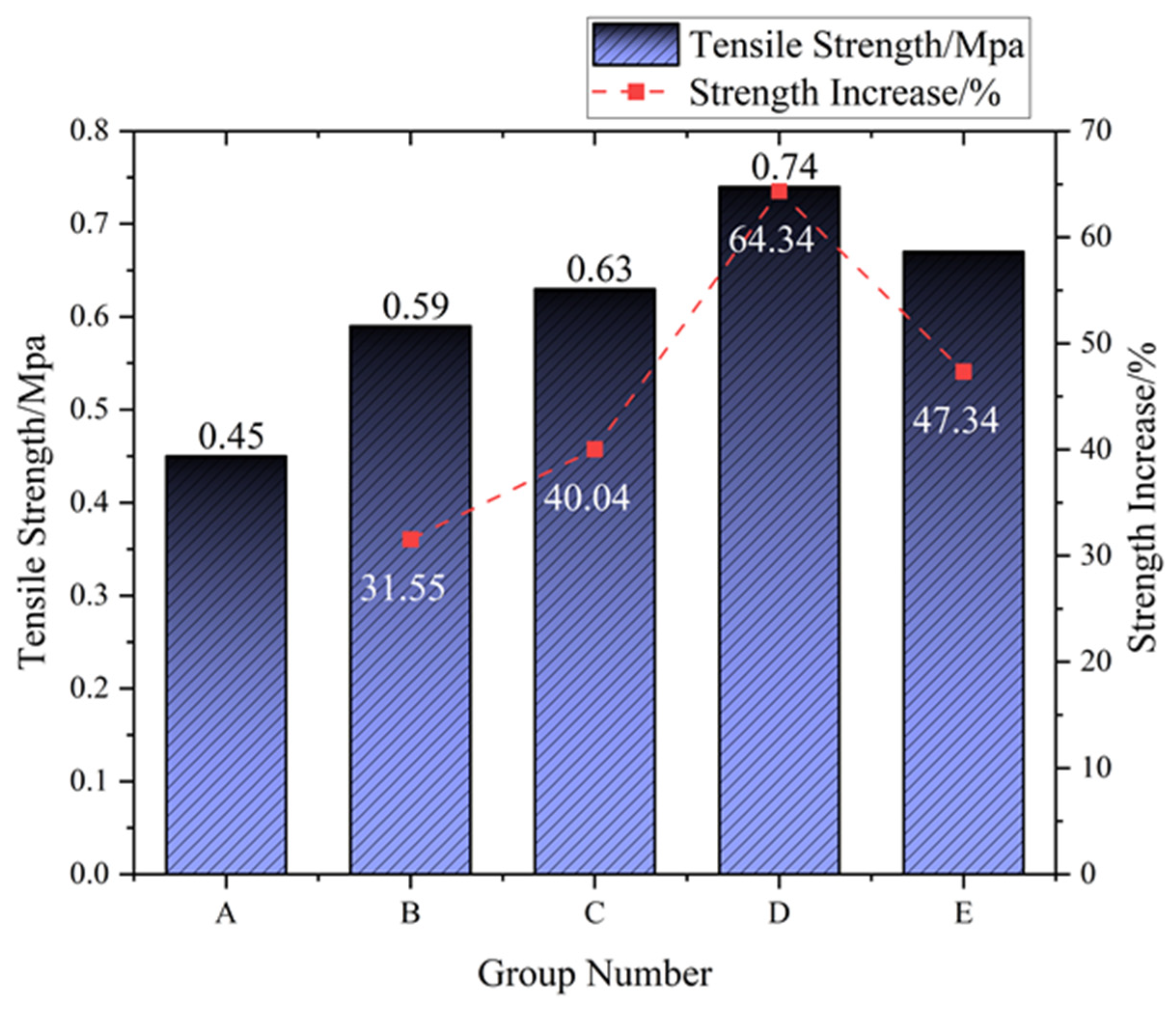

PVA Fiber Dosage Effects on Tensile Strength

3.3. Scanning Electron Microscopy (SEM) Analysis

3.3.1. Microstructure Analysis of WBP

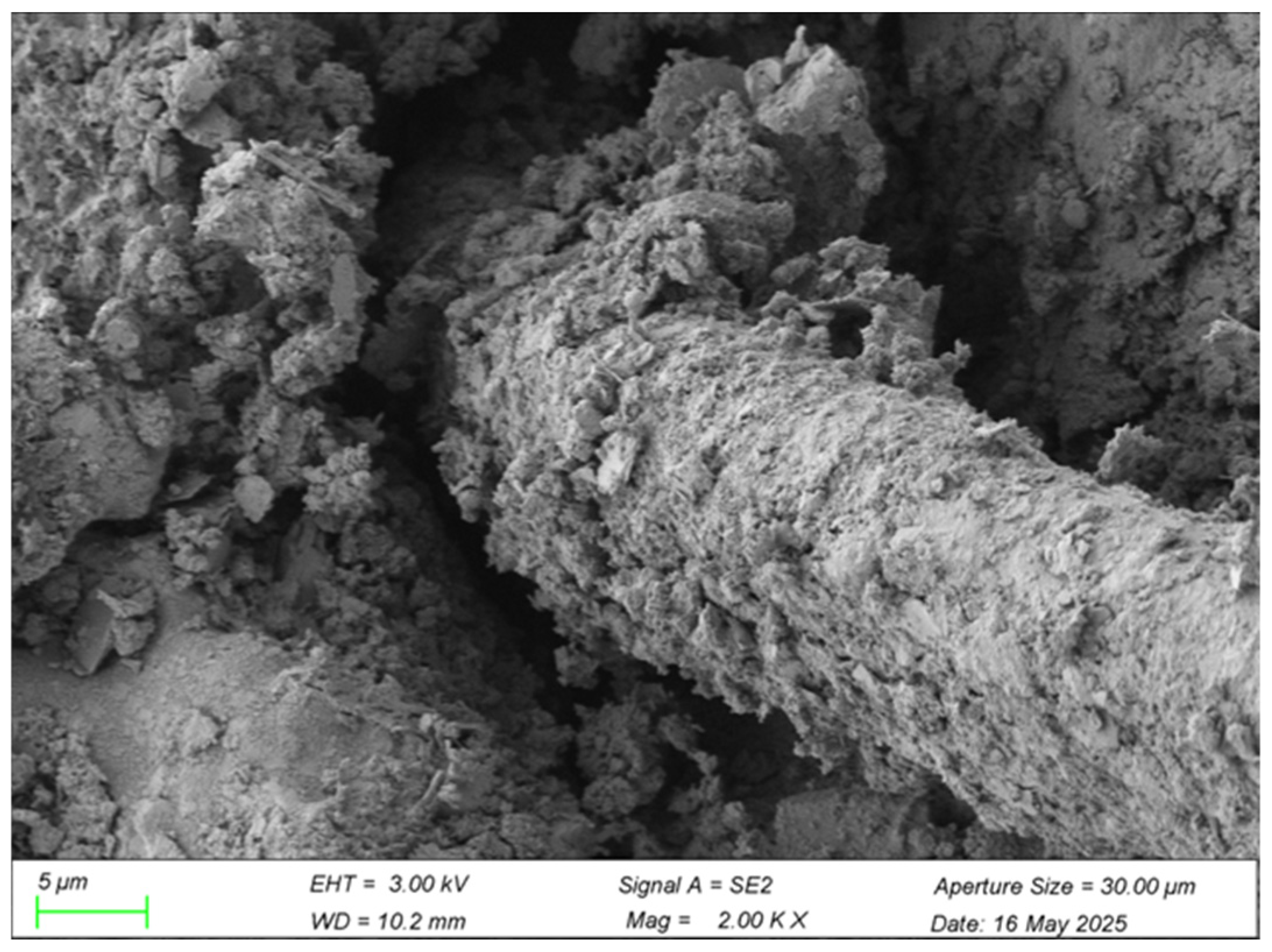

3.3.2. Microstructure Analysis of PVA Fibers

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Zhang, H.; Zhang, Z. Experimental Study on Mechanics and Water Stability of High Liquid Limit Soil Stabilized by Compound Stabilizer: A Sustainable Construction Perspective. Sustainability 2021, 13, 5681. [Google Scholar] [CrossRef]

- Alhassani, A.M.J.; Kadhim, S.M.; Fattah, A.A. Stabilization of Clayey Soil Using Cement Kiln Dust as Sustainable Material. IOP Conf. Ser. Earth Environ. Sci. 2021, 856, 12038. [Google Scholar] [CrossRef]

- Chmielewska, I.; Gosk, W. Sustainable soil stabilization: The use of waste materials to improve the engineering properties of soft soils. Inżynieria Bezpieczeństwa Obiektów Antropog. 2022, 3, 34–41. [Google Scholar] [CrossRef]

- Odeh, N.A.; Al-Rkaby, A.H. Strength, Durability, and Microstructures characterization of sustainable geopolymer improved clayey soil. Case Stud. Constr. Mater. 2022, 16, e00988. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, J.; Gong, X.; El Naggar, M.H.; Zhang, R. The effect of cemented soil strength on the frictional capacity of precast concrete pile–cemented soil interface. Acta Geotech. 2020, 15, 3271–3282. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Wu, H.; Wang, W.; Wang, L.; Yao, C.; Wu, J. Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials. Constr. Build. Mater. 2021, 274, 122113. [Google Scholar] [CrossRef]

- Liang, L.; Xu, Y.; Hu, S. Bending and Crack Evolution Behaviors of Cemented Soil Reinforced with Surface Modified PVA Fiber. Materials 2022, 15, 4799. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, S.; Chen, F.; Wang, C.; Chen, Q. Research Progress and Performance Evaluation of Polyvinyl Alcohol Fiber Engineered Cementitious Composites. Sustainability 2023, 15, 10991. [Google Scholar] [CrossRef]

- Yao, X.; Huang, G.; Wang, M.; Dong, X. Mechanical Properties and Microstructure of PVA Fiber Reinforced Cemented Soil. KSCE J. Civ. Eng. 2021, 25, 482–491. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.-F.; Wang, J.; Shi, Y.; Ling, Y.-F. Effect of PVA fiber on durability of cementitious composite containing nano-SiO2. Nanotechnol. Rev. 2019, 8, 116–127. [Google Scholar] [CrossRef]

- Hata, T.; Saracho, A.C.; GuhaRay, A.; Haigh, S.K. Strength characterization of cohesionless soil treated with cement and polyvinyl alcohol. Soils Found. 2022, 62, 101238. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Alemi, M.P. Micro-structural and mechanical properties of PVA fiber reinforced engineered cementitious composite incorporating natural and artificial pozzolanic materials under different temperatures. Constr. Build. Mater. 2022, 346, 128180. [Google Scholar] [CrossRef]

- Sun, M.; Zhu, J.; Sun, T.; Chen, Y.; Li, X.; Yin, W.; Han, J. Multiple effects of nano-CaCO3 and modified polyvinyl alcohol fiber on flexure–tension-resistant performance of engineered cementitious composites. Constr. Build. Mater. 2021, 303, 124426. [Google Scholar] [CrossRef]

- Li, Y.; Thielemans, W.; Yuan, Q.; Li, J. PVA fiber reinforced cement composites with calcined cutter soil mixing residue as a partial cement replacement. Constr. Build. Mater. 2022, 326, 126924. [Google Scholar] [CrossRef]

- Tamassoki, S.; Daud, N.N.N.; Nejabi, M.N.; Roshan, M.J. Fibre-Reinforced Soil Mixed Lime/Cement Additives: A Review. Pertanika J. Sci. Technol. 2022, 31, 217–235. [Google Scholar] [CrossRef]

- Mei, L.; Dong, X.; Yang, S.; Deng, J.; Heidarzadeh, A. Experimental Study on Mechanical Properties of Cement-Solidified Remolded Soil Reinforces by Polyvinyl Alcohol Fiber. Adv. Mater. Sci. Eng. 2022, 2022, 5169404. [Google Scholar] [CrossRef]

- Shi, Q.J.; Bai, C. Carbon Emission Efficiency in the Construction Industry and Its Carbon Emission Control Measures: A Case Study of Henan Province, China. Nat. Environ. Pollut. Technol. 2020, 19, 791–797. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- Caldas, L.R.; de Araujo, A.F.; Hasparyk, N.P.; Tiecher, F.; Amantino, G.; Filho, R.D.T. Circular economy in concrete production: Greenhouse Gas (GHG) emissions assessment of rice husk bio-concretes. Rev. IBRACON Estrut. Mater. 2022, 15, e15602. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, W.; Zheng, S.; Xing, F.; Guo, M.; Zhu, Z. Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate. Polymers 2023, 15, 2701. [Google Scholar] [CrossRef]

- Deng, M.; Dong, Z.; Zhang, C. Experimental investigation on tensile behavior of carbon textile reinforced mortar (TRM) added with short polyvinyl alcohol (PVA) fibers. Constr. Build. Mater. 2020, 235, 117801. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr. Build. Mater. 2018, 193, 631–642. [Google Scholar] [CrossRef]

- Liu, M.; Dai, W.; Li, M.; Jin, W.; Yang, X.; Han, Y.; Huang, M. Mechanism of interface performance enhancement of nano-SiO2 modified polyvinyl alcohol fiber reinforced geopolymer concrete: Experiments, microscopic characterization, and molecular simulation. J. Build. Eng. 2024, 98, 111062. [Google Scholar] [CrossRef]

- Jain, N.; Singh, V.K.; Chauhan, S. A review on mechanical and water absorption properties of polyvinyl alcohol based composites/films. J. Mech. Behav. Mater. 2017, 26, 213–222. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Ma, Z. Properties of the foam concrete containing waste brick powder derived from construction and demolition waste. J. Build. Eng. 2020, 32, 101509. [Google Scholar] [CrossRef]

- Pongsivasathit, S.; Horpibulsuk, S.; Piyaphipat, S. Assessment of mechanical properties of cement stabilized soils. Case Stud. Constr. Mater. 2019, 11, e00301. [Google Scholar] [CrossRef]

- Aldaood, A.; Khalil, A.; Bouasker, M.; Al-Mukhtar, M. Experimental Study on the Mechanical Behavior of Cemented Soil Reinforced with Straw Fiber. Geotech. Geol. Eng. 2021, 39, 2985–3001. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Guo, Z.; Luo, X. Reusing waste clay brick powder for low-carbon cement concrete and alkali-activated concrete: A critical review. J. Clean. Prod. 2024, 449, 141755. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, T.; Castel, A. Damage of non-steam-cured UHPC under axial compression with and without short-term sustained loading history. Structures 2022, 38, 1066–1078. [Google Scholar] [CrossRef]

- Gebresamuel, H.T.; Melese, D.T.; Boru, Y.T.; Legese, A.M. Effect of Specimens’ Height to Diameter Ratio on Unconfined Compressive Strength of Cohesive Soil. Stud. Geotech. Mech. 2023, 45, 112–132. [Google Scholar] [CrossRef]

- Huang, T.; Gao, J.; Sun, Q.; Zeng, D.; Su, X.; Liu, W.K.; Chen, W. Stochastic nonlinear analysis of unidirectional fiber composites using image-based microstructural uncertainty quantification. Compos. Struct. 2021, 260, 113470. [Google Scholar] [CrossRef]

- Okuda, M.; Matsuyama, T.; Tsuji, K. X-ray fluorescence analysis using ultrasonic levitation technique. X-Ray Spectrom. 2023, 52, 364–370. [Google Scholar] [CrossRef]

- Zhang, J.; Shu, Y. Effect of fiber content on mechanical parameters and crack development of two kinds of reinforced cement soil. Mater. Res. Express 2023, 10, 75301. [Google Scholar] [CrossRef]

- Hioe, Y.; Orth, F.; Wilkowski, G.; Brust, F.; Bagnoli, K. Initial Experimental and Analytical Efforts to Predict Sustained Load Crack Growth During a Hydrotest and Subsequent Fatigue Crack Growth During Pressure Cycling. In Proceedings of the 2022 14th International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2022. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Tortai, J.-H.; Abaidi, M.; Schiavone, P.; Behringer, U.F.; Finders, J. FEM simulation of charging effect during SEM metrology. In Proceedings of the 34th European Mask and Lithography Conference, Grenoble, France, 19 September 2018. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, C.-T.; Xu, Q.; Lou, Z.; Xu, Z.; Thierry, B.; Gu, N. Gold Nanoparticle Probe-Assisted Antigen-Counting Chip Using SEM. ACS Appl. Mater. Interfaces 2019, 11, 6769–6776. [Google Scholar] [CrossRef]

- Chen, X.; Wen, K.; Wang, C.; Cheng, S.; Wang, S.; Ma, H.; Tian, H.; Zhang, J.; Li, X.; Shao, J. Enhancing mechanical strength of carbon fiber-epoxy interface through electrowetting of fiber surface. Compos. Part B Eng. 2022, 234, 109751. [Google Scholar] [CrossRef]

- Thang, N.C.; Van Tuan, N.; Dong, P.S.; Van Tham, V.; Tu, T.M. The influence of PVA content on the flexural behavior of engineered cementitious composite using local materials. J. Sci. Technol. Civ. Eng. 2022, 16, 55–64. [Google Scholar] [CrossRef]

| Soil Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) | Natural Moisture Content (%) | Moisture Content of Dry Soil (%) | Plasticity Index |

|---|---|---|---|---|---|

| 1.69 | 27.34 | 18 | 13.4 | 1.23 | 9.34 |

| Specific Surface Area (m2/kg) | Initial Setting Time (min) | Final Setting Time (min) | Stability | 3D Flexural Strength (MPa) | 3D Compressive Strength (MPa) | Loss on Ignition (%) |

|---|---|---|---|---|---|---|

| 350 | 195 | 250 | Qualified | 5.3 | 28.4 | 4.12 |

| Length (mm) | Type | Diameter (μm) | Elongation at Break (%) | Tensile Strength (MPa) | Density (g/cm3) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| 6 | Bundled monofilaments | 15.3 | 7 | 1830 | 1.29 | 40 |

| Specimen Count (n) | Fiber Length (mm) | Fiber Content (%) | Cement Content (%) | Dosage of Brick Powder (%) | Age (Days) |

|---|---|---|---|---|---|

| 1 | 6 | 0 | 15 | 5 | 3 |

| 2 | 6 | 0.25 | 15 | 5 | 3 |

| 3 | 6 | 0.5 | 15 | 5 | 3 |

| 4 | 6 | 0.75 | 15 | 5 | 3 |

| 5 | 6 | 1 | 15 | 5 | 3 |

| 6 | 6 | 0 | 15 | 5 | 14 |

| 7 | 6 | 0.25 | 15 | 5 | 14 |

| 8 | 6 | 0.5 | 15 | 5 | 14 |

| 9 | 6 | 0.75 | 15 | 5 | 14 |

| 10 | 6 | 1 | 15 | 5 | 14 |

| 11 | 6 | 0 | 15 | 5 | 28 |

| 12 | 6 | 0.25 | 15 | 5 | 28 |

| 13 | 6 | 0.5 | 15 | 5 | 28 |

| 14 | 6 | 0.75 | 15 | 5 | 28 |

| 15 | 6 | 1 | 15 | 5 | 28 |

| Group | Fiber Length (mm) | Fiber Content (%) | Cement Content (%) | Dosage of Brick Powder (%) | Age (Days) |

|---|---|---|---|---|---|

| A | 6 | 0 | 15 | 5 | 28 |

| B | 6 | 0.25 | 15 | 5 | 28 |

| C | 6 | 0.5 | 15 | 5 | 28 |

| D | 6 | 0.75 | 15 | 5 | 28 |

| E | 6 | 1 | 15 | 5 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Rahman, M.M.; Pan, H.; Ma, Y.; Sun, Y.; Wang, J. Experimental Investigation of Mechanical Properties and Microstructure in Cement–Soil Modified with Waste Brick Powder and Polyvinyl Alcohol Fibers. Materials 2025, 18, 3586. https://doi.org/10.3390/ma18153586

Yin X, Rahman MM, Pan H, Ma Y, Sun Y, Wang J. Experimental Investigation of Mechanical Properties and Microstructure in Cement–Soil Modified with Waste Brick Powder and Polyvinyl Alcohol Fibers. Materials. 2025; 18(15):3586. https://doi.org/10.3390/ma18153586

Chicago/Turabian StyleYin, Xiaosan, Md. Mashiur Rahman, Hongke Pan, Yongchun Ma, Yuzhou Sun, and Jian Wang. 2025. "Experimental Investigation of Mechanical Properties and Microstructure in Cement–Soil Modified with Waste Brick Powder and Polyvinyl Alcohol Fibers" Materials 18, no. 15: 3586. https://doi.org/10.3390/ma18153586

APA StyleYin, X., Rahman, M. M., Pan, H., Ma, Y., Sun, Y., & Wang, J. (2025). Experimental Investigation of Mechanical Properties and Microstructure in Cement–Soil Modified with Waste Brick Powder and Polyvinyl Alcohol Fibers. Materials, 18(15), 3586. https://doi.org/10.3390/ma18153586