Comprehensive Evaluation and Analysis of Aging Performance of Polymer-Rich Anchoring Adhesives

Abstract

1. Introduction

2. Experimental Section

2.1. Experimental Materials

2.2. Experimental Instruments

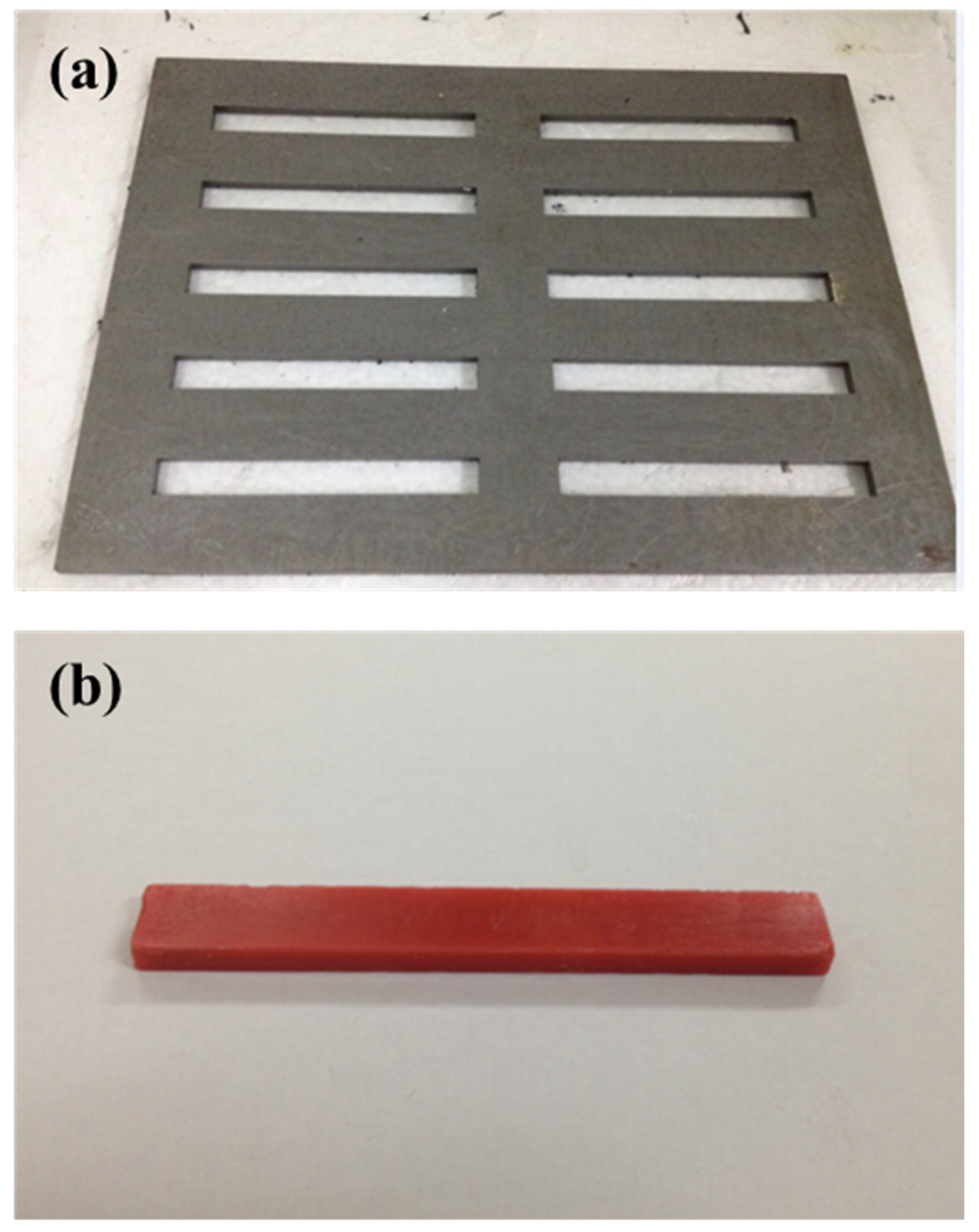

2.3. Experimental Preparation

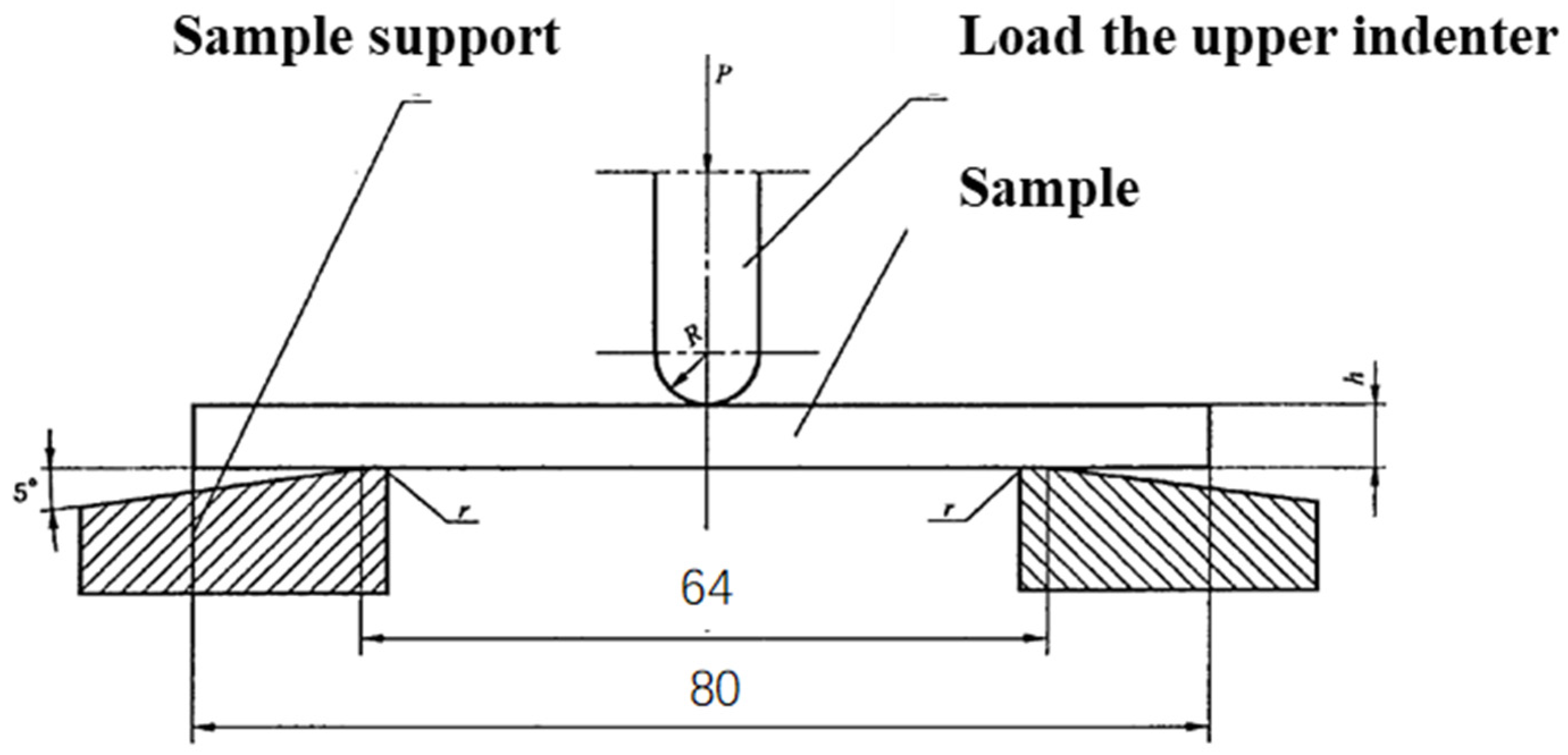

2.4. Testing and Characterization

- (1)

- Bending property test of adhesive

- (2)

- Dynamic thermomechanical analysis test

- (3)

- Infrared spectroscopy analysis test

3. Results and Discussion

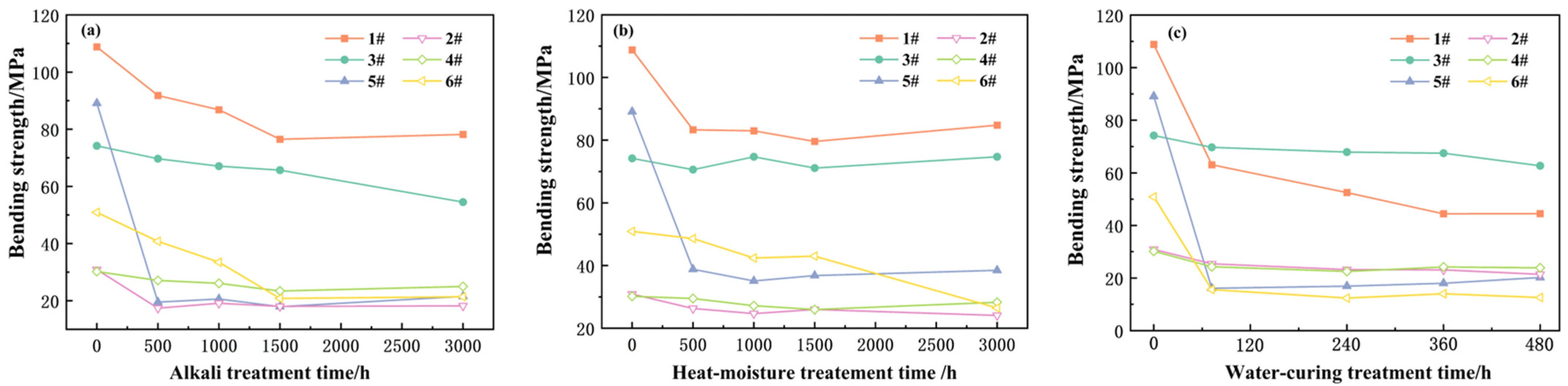

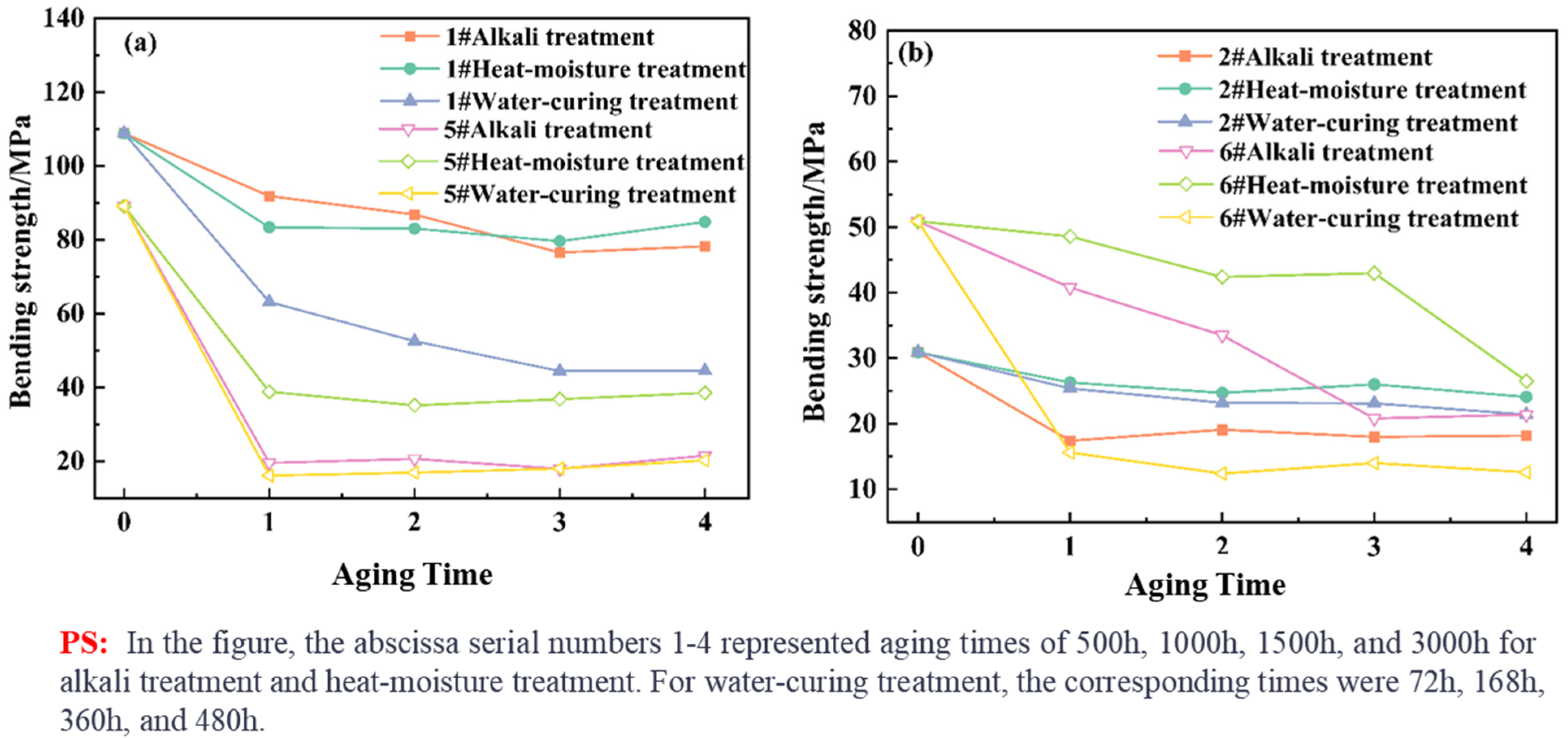

3.1. Test Results of Physical Performance

3.2. Test Results of Dynamic Thermomechanical Analysis

3.3. Test Results of Infrared Spectroscopy Analysis

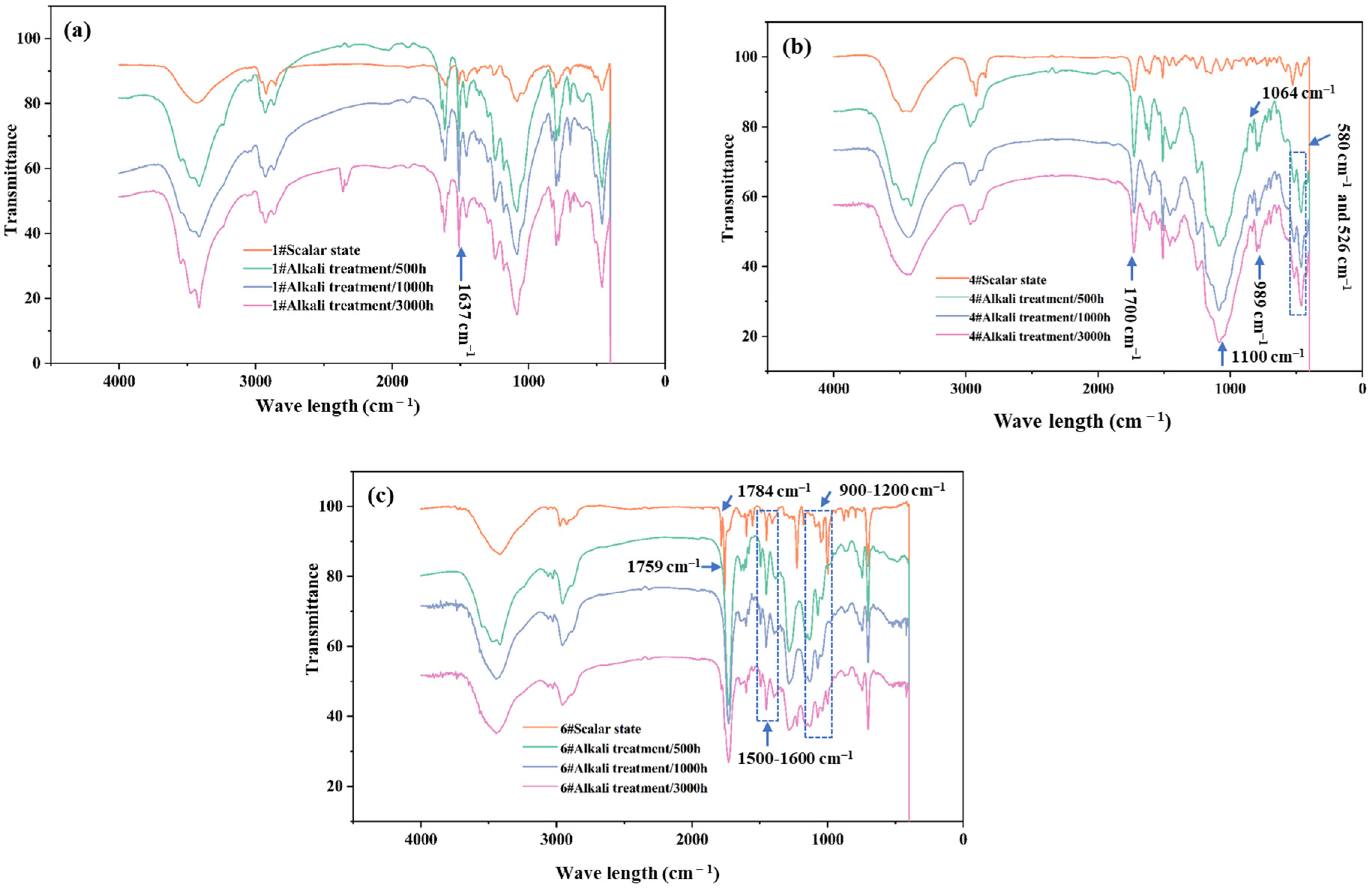

3.3.1. Results of Alkali Treatment

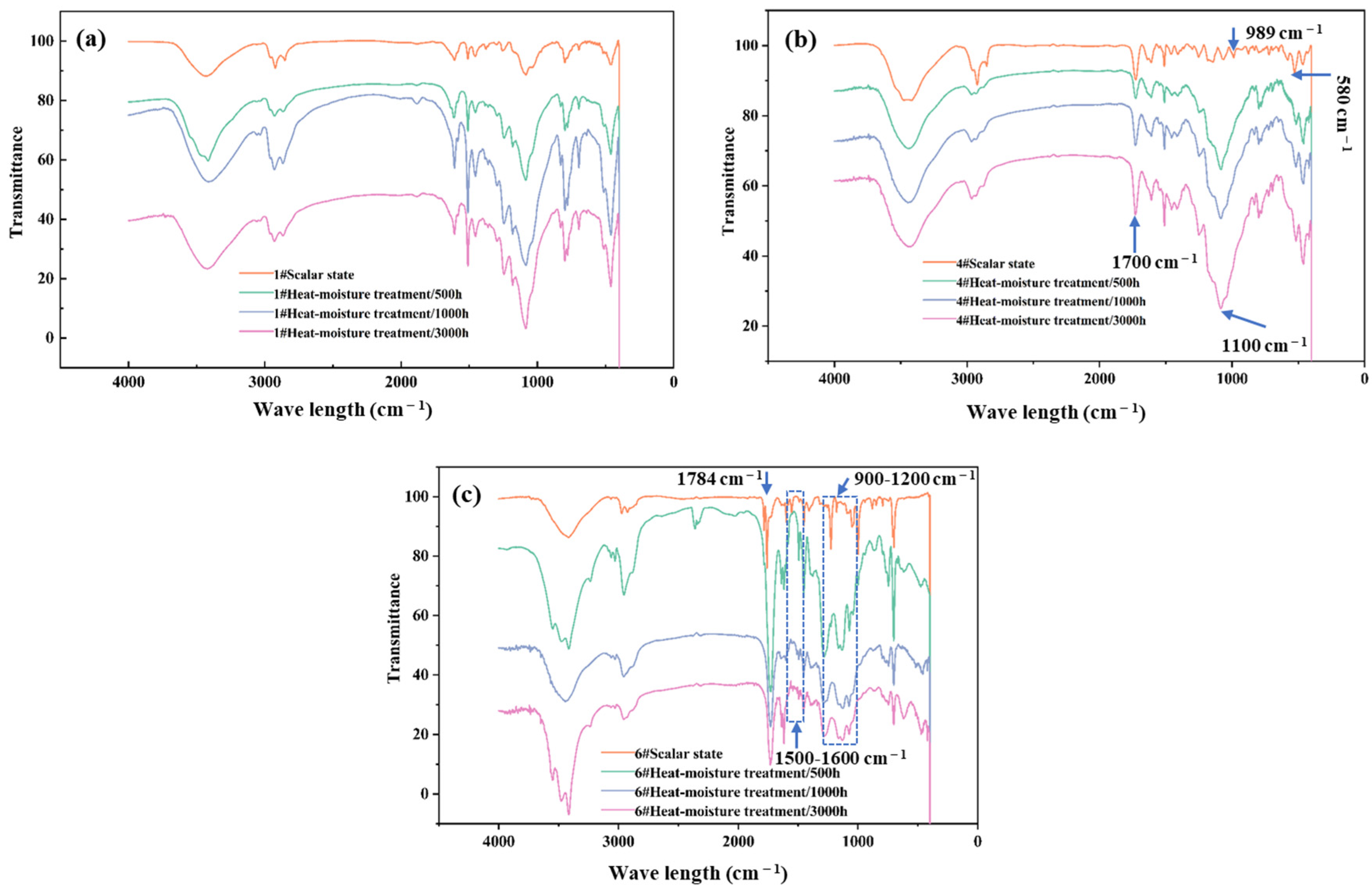

3.3.2. Results of Heat–Moisture Treatment

3.3.3. Results of Water-Curing Treatment

3.4. Comparison of Results of Three Test Methods

- Chemical bond changes dominate performance evolution: The extent of ester group (C=O and C-O) cleavage directly determines the adhesive’s anti-aging ability. Sample 6# has the most severe ester group damage and the most significant performance decline.

- Molecular chain movement ability reflects aging state: The change in loss factor reveals the variation in molecular chain segment movement ability. An initially high loss factor (such as in epoxy resin) indicates the free movement of molecular chain segments. A decrease in the loss factor after aging indicates an increase in molecular chain rigidity, which is directly related to the decline in flexural strength.

- Microscopic explanation of the performance stabilization period: When the IR spectrum indicates that the main functional groups no longer change significantly and the DMA loss factor stabilizes, the adhesive network structure reaches a new equilibrium state, which is macroscopically manifested by the flexural strength no longer declining.

4. Conclusions

- Aging Rate and Performance Evaluation

- 2.

- Suggestions Related to the Effectiveness of Testing Methods and Test Duration

- 3.

- Significance of Testing Methods for Research and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Contrafatto, L.; Cosenza, R. Behaviour of post-installed adhesive anchors in natural stone. Constr. Build. Mater. 2014, 68, 355–369. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H.; Almashagbeh, H. Effect of carbon nanotubes on strengthening of RC beams retrofitted with carbon fiber/epoxy composites. Mater. Des. 2016, 89, 225–234. [Google Scholar] [CrossRef]

- Mabaya, M.; Aguiar, R.A.A.; Costa, H.R.M.; de Barros, A.L.F.; Reis, J.M.L.; Souza, J.P.B. Improvements in the thermal, mechanical and electrical conductivity properties of a structural adhesive. A preliminary study. Int. J. Adhes. Adhes. 2023, 122, 103317. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build. Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Szewczak, A. Influence of Epoxy Glue Modification on the Adhesion of CFRP Tapes to Concrete Surface. Materials 2021, 14, 6339. [Google Scholar] [CrossRef] [PubMed]

- Zhai, L.L.; Ling, G.P.; Wang, Y.W. Effect of nano-Al2O3 on adhesion strength of epoxy adhesive and steel. Int. J. Adhes. Adhes. 2008, 28, 23–28. [Google Scholar] [CrossRef]

- Yan, L.; Kou, K.; Ji, T.; Liang, G.; Ha, E. Application of a new modified epoxy adhesive for bonding fluorine rubber to metal. J. Adhes. Sci. Technol. 2007, 21, 1483–1496. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Kampa, Ł.; Chowaniec, A.; Królicka, A.; Żak, A.; Abdoulpour, H.; Vantadori, S. Enhanced adhesive performance of epoxy resin coating by a novel bonding agent. Constr. Build. Mater. 2021, 301, 124078. [Google Scholar] [CrossRef]

- Niu, P.; Xu, D.; Zhu, J.; Zhao, Z.; Sun, A.; Wei, L.; Li, Y. Polyurethane-modified room-temperature curing epoxy super adhesive for artifact restoration and light emitting diode encapsulation. Mater. Des. 2024, 248, 113480. [Google Scholar] [CrossRef]

- Li, J.; Huan, X.; Wang, S.; Sheng, Y.; Xu, D.; You, Z. Performance of optimized composition of epoxy resin adhesive used in High Friction Surface Treatment. Case Stud. Constr. Mater. 2024, 21, e03431. [Google Scholar] [CrossRef]

- Shi, C.; Jin, S.; Jin, K.; Yang, Y.; Xu, L. Improving bonding behavior between basalt fiber-reinforced polymer sheets concrete using multi-wall carbon nanotubes modified epoxy, compos. C. Stud. Constr. Mater. 2023, 18, e02216. [Google Scholar]

- Nourizadeh, H.; Mirzaghorbanali, A.; McDougall, K.; Jeewantha, L.H.J.; Craig, P.; Motallebiyan, A.; Shokri, B.J.; Rastegarmanesh, A.; Aziz, N. Characterization of mechanical bonding properties of anchoring resins under elevated temperature, Intern. J. Rock Mech. Min. Sci. 2023, 170, 105506. [Google Scholar] [CrossRef]

- Afzal, A.; Kausar, A.; Siddiq, M. Role of polymeric composite in civil engineering applications: A review. Polym-Plast. Technol. Mater. 2020, 59, 1023–1040. [Google Scholar]

- Al-Mosawe, A.; Al-Mahaidi, R. Temperature Effects on the Fatigue Life and Tensile Strength of Structural Adhesives. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012104. [Google Scholar] [CrossRef]

- Lees, D.E.; Hutchinson, A.R. Mechanical characteristics of some cold-cured structural adhesives. Intern. J. Adhes. Adhes 1992, 12, 197–205. [Google Scholar] [CrossRef]

- Sullivan, K.; Peterman, K.D. A review of adhesive steel-to-steel connections for use in heavy construction. J. Constr. Steel Res. 2024, 213, 108405. [Google Scholar] [CrossRef]

- Qin, Q.; Wei, D.; Gan, J.; Gong, Y.; Jin, T. Preparation of environmental-benign castor oil-derived polyurethane thermal conductive structural adhesives with superior strength. Polymer 2024, 298, 126831. [Google Scholar] [CrossRef]

- Manalo, A.; Maranan, G.; Benmokrane, B.; Cousin, P.; Alajarmeh, O.; Ferdous, W.; Liang, R.; Hota, G. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Liu, L.; Sun, W.; Xiao, J.; Li, W.; Jian, L.; Zhang, Q. Bond behavior between high-strength grout and rebar after exposure to elevated temperatures. Structures 2024, 69, 107308. [Google Scholar] [CrossRef]

- Hashemi, N.; Hassanpour, S.; Vatani Oskoei, A. The Effect of Rebar Embedment and CFRP Confinement on the Compressive Strength of Low-Strength Concrete. Int. J. Concr. Struct. Mater. 2022, 16, 17. [Google Scholar] [CrossRef]

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S. Durability of an epoxy adhesive used in civil structural applications. Constr. Build. Mater. 2018, 161, 618–633. [Google Scholar] [CrossRef]

- Hong, B.; Xian, G.; Li, H. Effects of water or alkali solution immersion on the water uptake and physicomechanical properties of polyurethane. Polym. Eng. Sci. 2018, 58, 2276–2287. [Google Scholar] [CrossRef]

- Moon, D.Y.; Ou, Y.C.; Roh, H. Interlaminar shear capacity of thermally damaged GFRP bars under alkaline concrete environment. Constr. Build. Mater. 2017, 152, 105–114. [Google Scholar] [CrossRef]

- Su, Y.; Wu, L.; He, X.; Zheng, Z.; Tan, H.; Yang, J.; Ma, Q.; Ding, J.; Bao, M. A novel early strength agent prepared by wet-grinding concrete waste slurry and its effect on early hydration and mechanical properties of cement based materials. Constr. Build. Mater. 2023, 362, 129673. [Google Scholar] [CrossRef]

- Ding, K.; Wang, K.; Liu, Y. Effects of Hygrothermal Environment on Tensile Capacity of Adhesive-injected Anchor Bolt of ALC Panel and ETICS. KSCE J. Civ. Eng. 2023, 27, 1107–1117. [Google Scholar] [CrossRef]

- Hao, X.; Xian, G.; Huang, X.; Xin, M.; Shen, H. Effects of Adhesive Coating on the Hygrothermal Aging Performance of Pultruded CFRP Plates. Polymers 2020, 12, 491. [Google Scholar] [CrossRef]

- Ascione, F.; Granata, L.; Guadagno, L.; Naddeo, C. Hygrothermal durability of epoxy adhesives used in civil structural applications. Compos. Struct. 2021, 265, 113591. [Google Scholar] [CrossRef]

- Benzarti, K.; Chataigner, S.; Quiertant, M.; Marty, C.; Aubagnac, C. Accelerated ageing behaviour of the adhesive bond between concrete specimens and CFRP overlays. Constr. Build. Mater. 2011, 25, 523–538. [Google Scholar] [CrossRef]

- Norazwani Muhammad, Z.; Ahmad, S.H.; Ali, E.S. Durability of green polyurethane adhesive bonded aluminum alloy in dry and hydrothermal ageing conditions. J. Appl. Polym. Sci. 2015, 131, 205–212. [Google Scholar]

- Lai, W.L.; Kou, S.C.; Poon, C.S.; Tsang, W.F.; Lai, C.C. Effects of elevated water temperatures on interfacial delaminations, failure modes and shear strength in externally-bonded CFRP-concrete beams using infrared thermography, gray-scale images and direct shear test. Constr. Build. Mater. 2009, 23, 3152–3160. [Google Scholar] [CrossRef]

- GB/T 2567-2021; Test methods for properties of resin castings. Domestic-National Standards-State Administration for Market Regulation: Beijing, China, 2021.

- Li, H.; Luo, Y.; Hu, D.; Jiang, D. Effect of hydrothermal aging on the dynamic mechanical performance of the room temperature-cured epoxy adhesive. Rheol. Acta. 2019, 58, 9–19. [Google Scholar] [CrossRef]

- Koliolios, E.; Nakano, S.; Kawamura, T.; Busfield, J.J.C. Elucidation of smear wear layer structure and ageing mechanisms of filled tyre tread compounds. Polymer 2024, 300, 126982. [Google Scholar] [CrossRef]

- Liu, X.; Huang, H.; Xie, Z.; Zhang, Y.; Zhang, Y.; Sun, K.; Min, L. EPDM/polyamide TPV compatibilized by chlorinated polyethyl. Poly. Test. 2003, 22, 9–16. [Google Scholar] [CrossRef]

- Motevalizadeh, S.M.; Mollenhauer, K. Exploration of chemical changes in bituminous mastics induced by aging Insights from FTIR spectroscopy, DSR measurements, and machine learning. Int. J. Pavement Eng. 2024, 25, 2418927. [Google Scholar] [CrossRef]

- Lei, Z.; Li, Z.; Zhang, X.; Shi, X. Durability of CFRP-wrapped concrete in cold regions: A laboratory evaluation of montmorillonite nanoclay-modified siloxane epoxy adhesive. Constr. Build. Mater. 2021, 290, 123253. [Google Scholar] [CrossRef]

- Niu, R.; Yang, Y.; Lin, Y.; Liu, Z.; Fan, Y. Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling. Polymers 2023, 15, 3949. [Google Scholar] [CrossRef]

- Liu, T.; Chen, Z.; Ma, Y.; Ren, Y.; Tan, J.; Cheng, Z.; Zhu, X. Preparation and Properties of Epoxy Adhesives with Fast Curing at Room Temperature and Low-Temperature Resistance. ACS Omega 2024, 9, 22186–22195. [Google Scholar] [CrossRef]

- Shi, M.; Zhixiong, H.; Guorui, Y.; Li, Y. Effects of Accelerated Thermo-Oxidative Aging on Properties of a Damped-Encapsulating Epoxy Adhesive. Poly-Plast. Technol. Eng. 2008, 47, 180–185. [Google Scholar] [CrossRef]

| Test Instrument | Manufacturer |

|---|---|

| 401 Type Thermal Aging Test Chamber | Shanghai Experimental Instrument General Factory, Shanghai, China |

| SDH001U Type Damp-Heat Aging Test Chamber | Chongqing Wanda Instrument Co., Ltd., Chongqing, China |

| Single-row Two-hole Water Bath Test Chamber | Beijing Zhongxing Weiye Instrument Co., Ltd., Beijing, China |

| AG—IS 100kN Universal Testing Machine | Shimadzu Corporation, Kyoto, Japan |

| DMA 242C Type Dynamic Mechanical Analyzer | NETZSCH Group, Selb, Germany |

| TENSOR 27 Type Fourier Transform Attenuated Total Reflection Infrared Spectrometer | BRUKER OPTIK GMBH, Ettlingen, Germany |

| Sample Number | Alkali Treatment | Heat–Moisture Treatment | Water-Curing Treatment |

|---|---|---|---|

| Aging time | 3000 h | 3000 h | 480 h |

| 1# | 28 | 20 | 59 |

| 2# | 40 | 16 | 30 |

| 3# | 27 | 0 | 15 |

| 4# | 19 | 1 | 22 |

| 5# | 70 | 51 | 77 |

| 6# | 58 | 49 | 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, B.; Wu, S.; Yao, S. Comprehensive Evaluation and Analysis of Aging Performance of Polymer-Rich Anchoring Adhesives. Materials 2025, 18, 3484. https://doi.org/10.3390/ma18153484

Zeng B, Wu S, Yao S. Comprehensive Evaluation and Analysis of Aging Performance of Polymer-Rich Anchoring Adhesives. Materials. 2025; 18(15):3484. https://doi.org/10.3390/ma18153484

Chicago/Turabian StyleZeng, Bing, Shuo Wu, and Shufang Yao. 2025. "Comprehensive Evaluation and Analysis of Aging Performance of Polymer-Rich Anchoring Adhesives" Materials 18, no. 15: 3484. https://doi.org/10.3390/ma18153484

APA StyleZeng, B., Wu, S., & Yao, S. (2025). Comprehensive Evaluation and Analysis of Aging Performance of Polymer-Rich Anchoring Adhesives. Materials, 18(15), 3484. https://doi.org/10.3390/ma18153484