A Study on the Road Performance of the Self-Healing Microcapsule for Asphalt Pavement

Abstract

1. Introduction

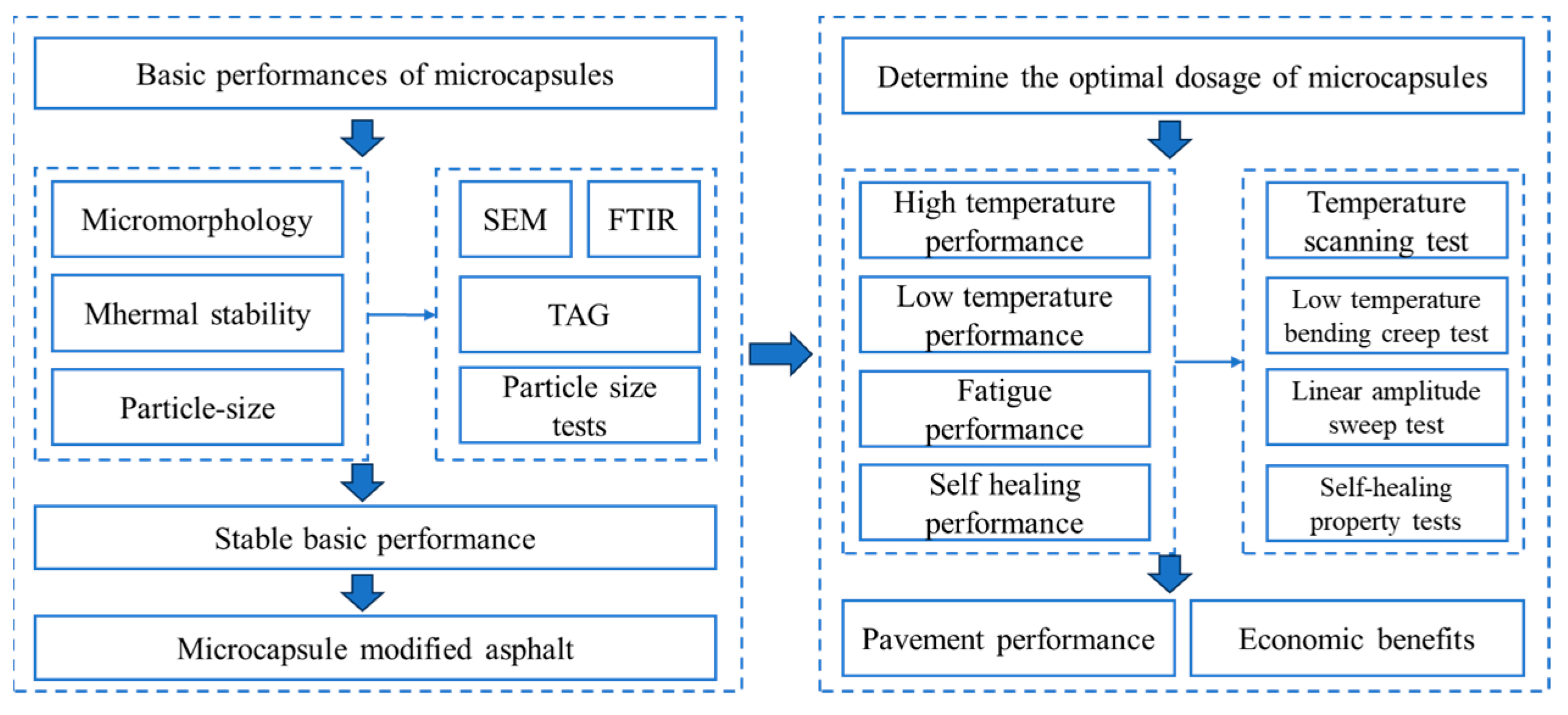

2. Test Materials and Methods

2.1. Test Materials

2.1.1. Asphalt

2.1.2. Microcapsules

- (1)

- Core Material

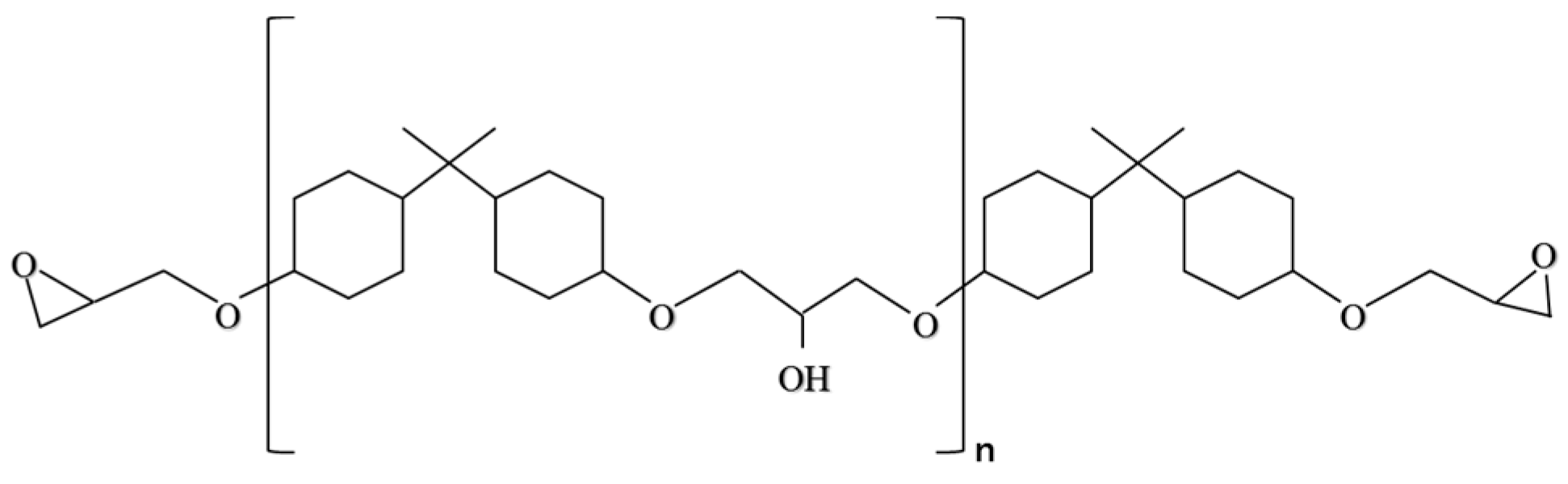

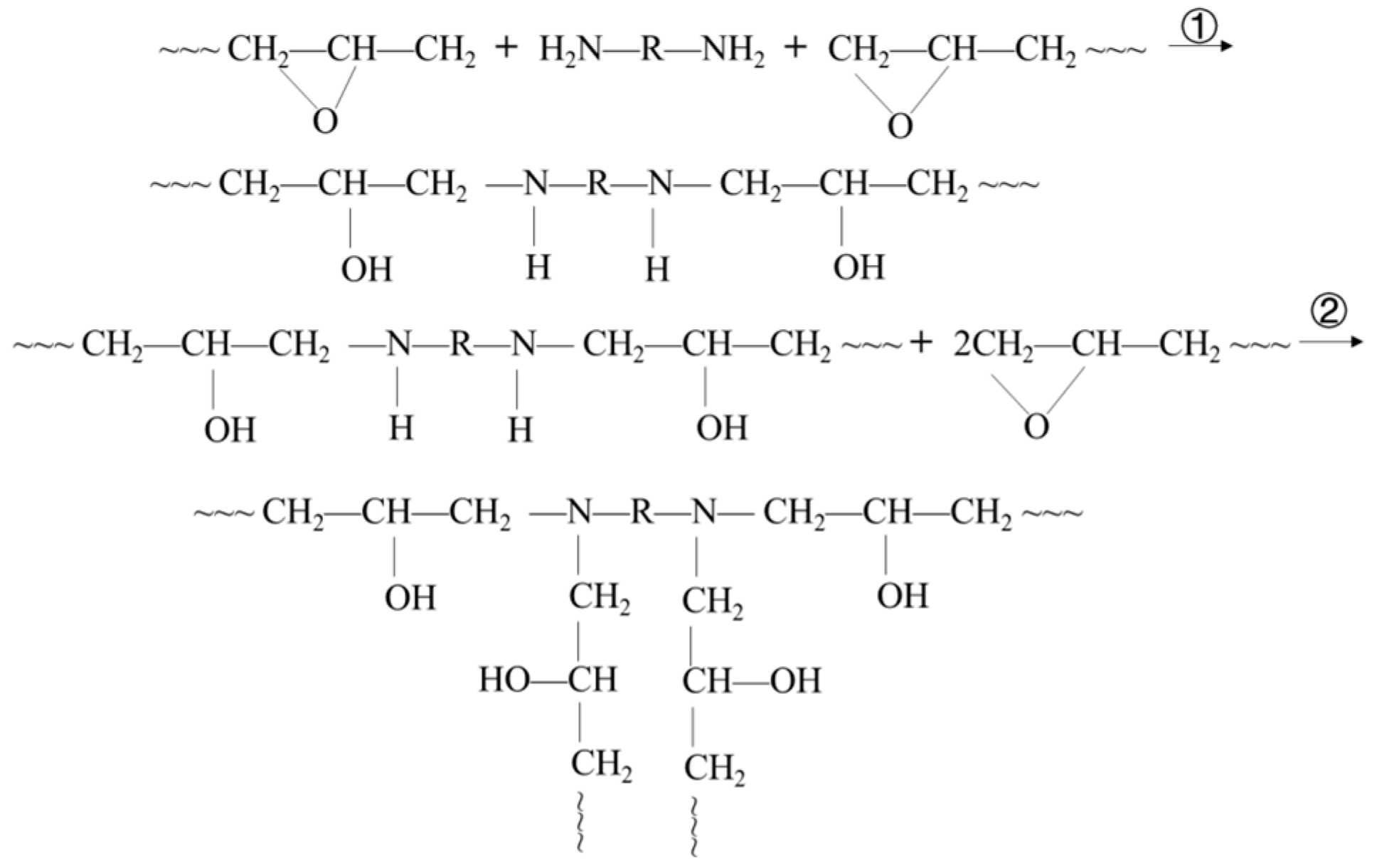

- (2)

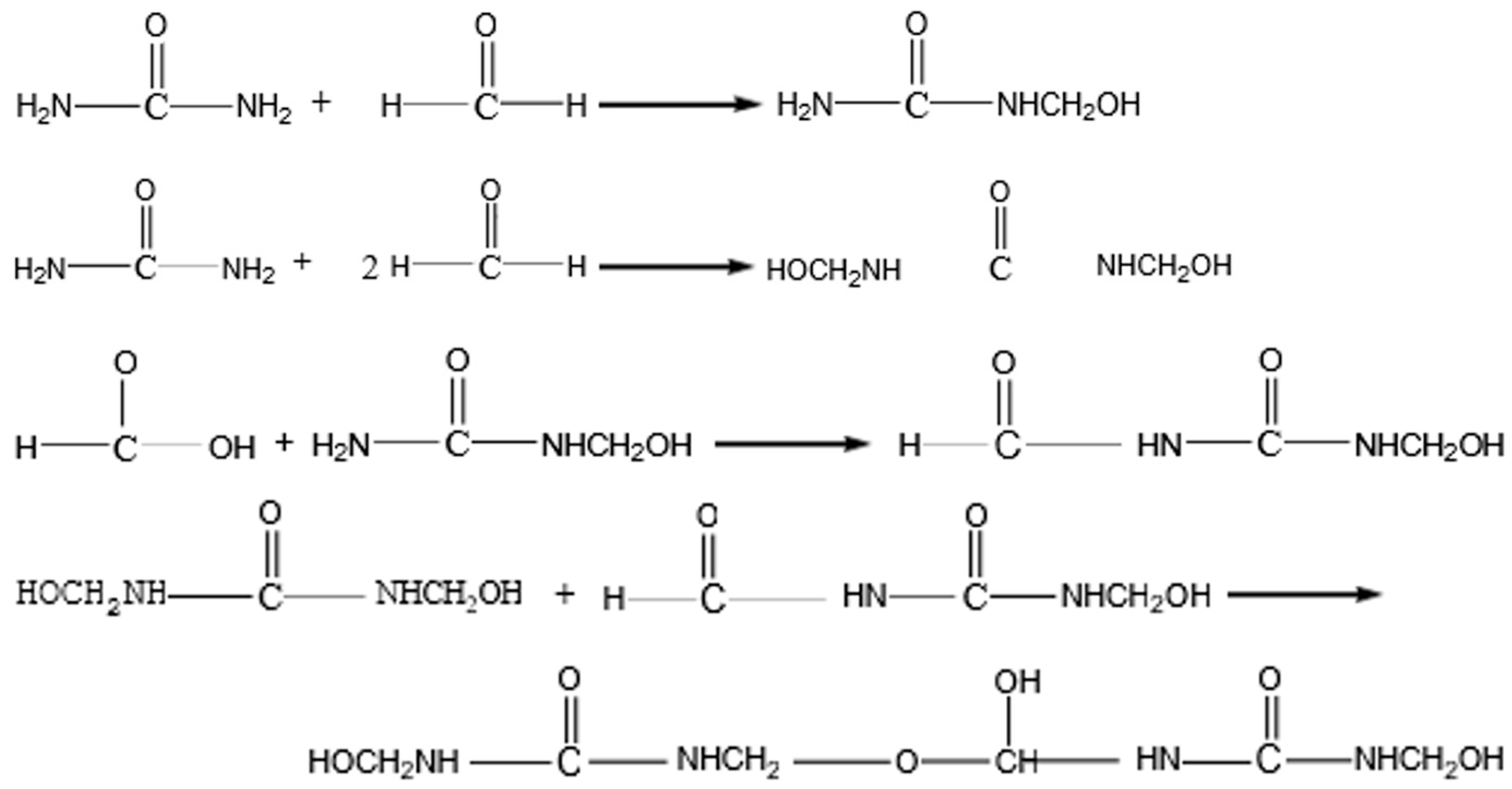

- Shell Material

- (3)

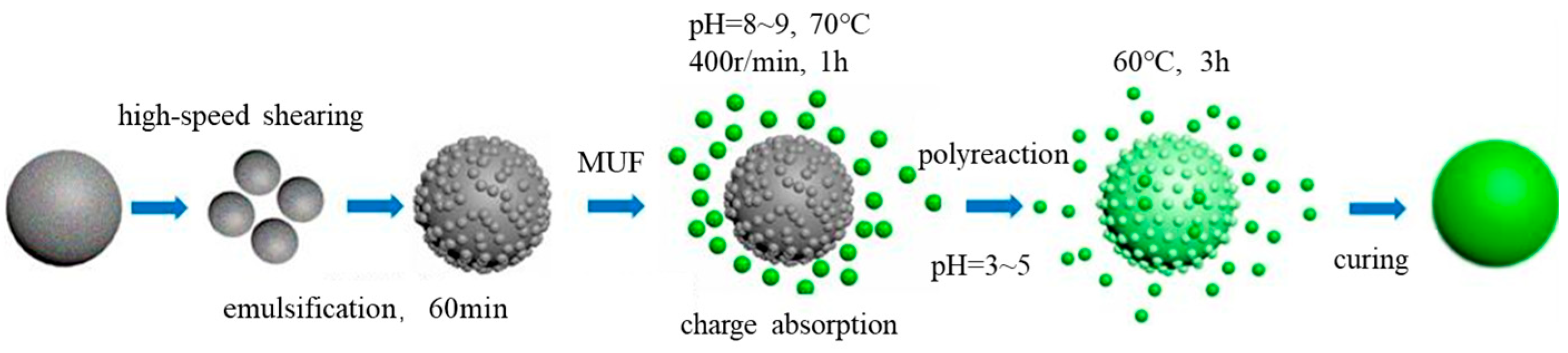

- Preparation of Microcapsules

2.1.3. Microcapsule/Asphalt

2.2. Test Methods

2.2.1. Performance Tests of the Microcapsule

- (1)

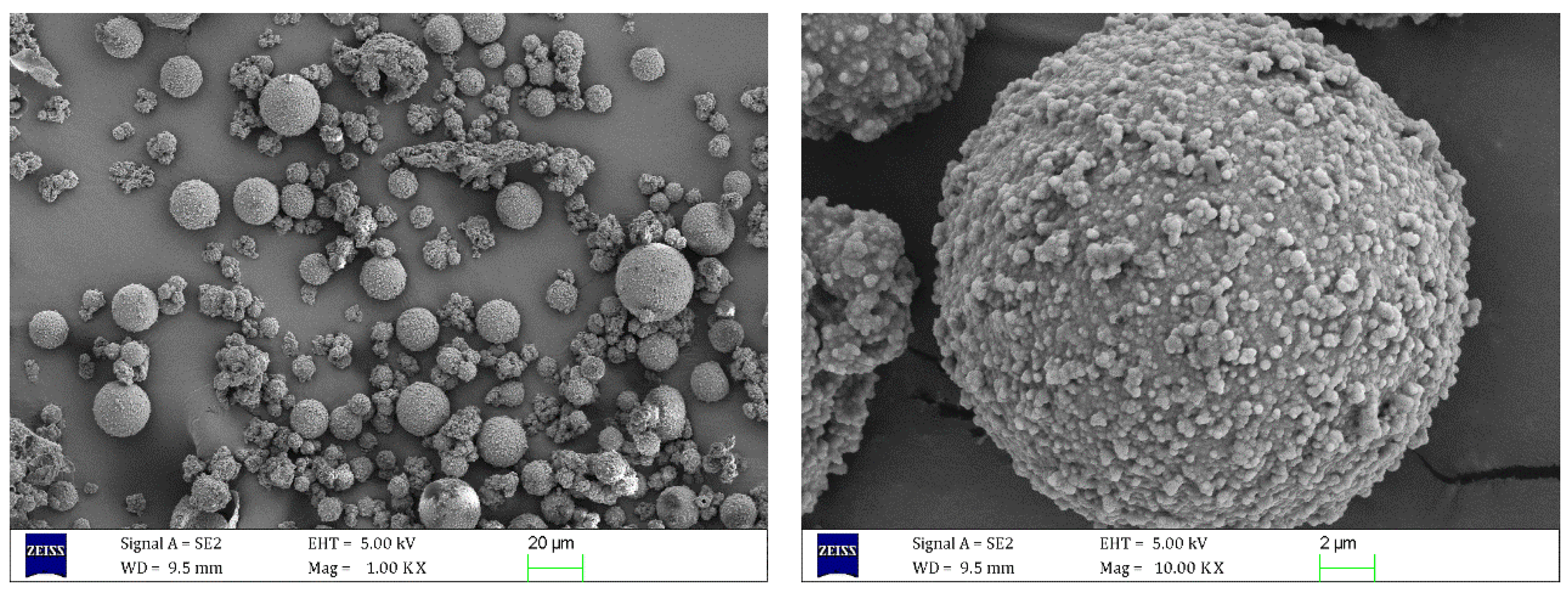

- Micromorphology and Microstructure Tests

- (2)

- Particle Size Tests

- (3)

- Thermogravimetric Analysis (TGA) Tests

- (4)

- Fourier Transform Infrared Spectroscopy (FTIR) Tests

2.2.2. Temperature Scanning (TS) Test

2.2.3. Low-Temperature Bending Creep Stiffness Test

2.2.4. Linear Amplitude Sweep (LAS) Test

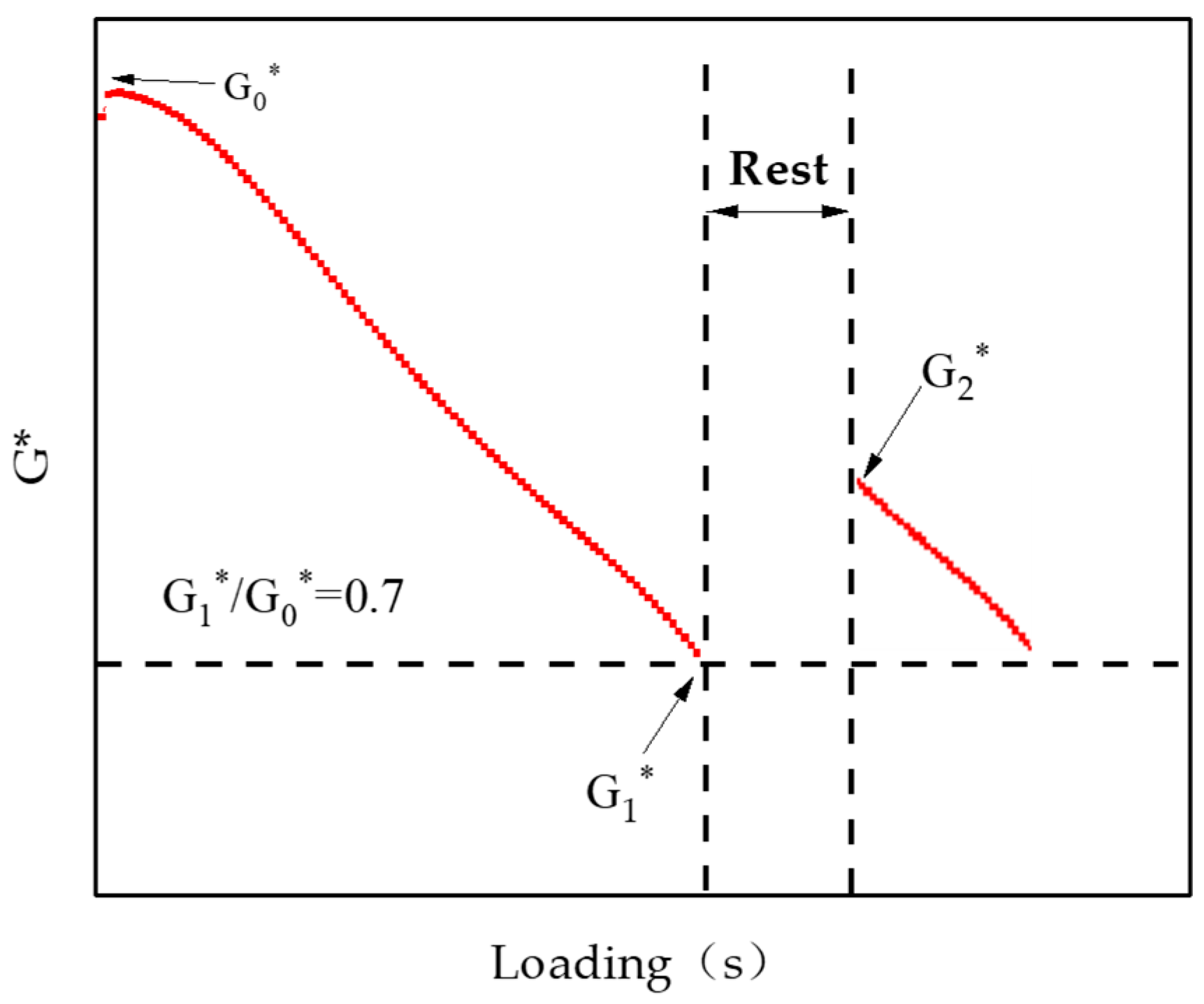

2.2.5. Self-Healing Property Tests

3. Results and Discussions

3.1. Basic Performances of Microcapsules

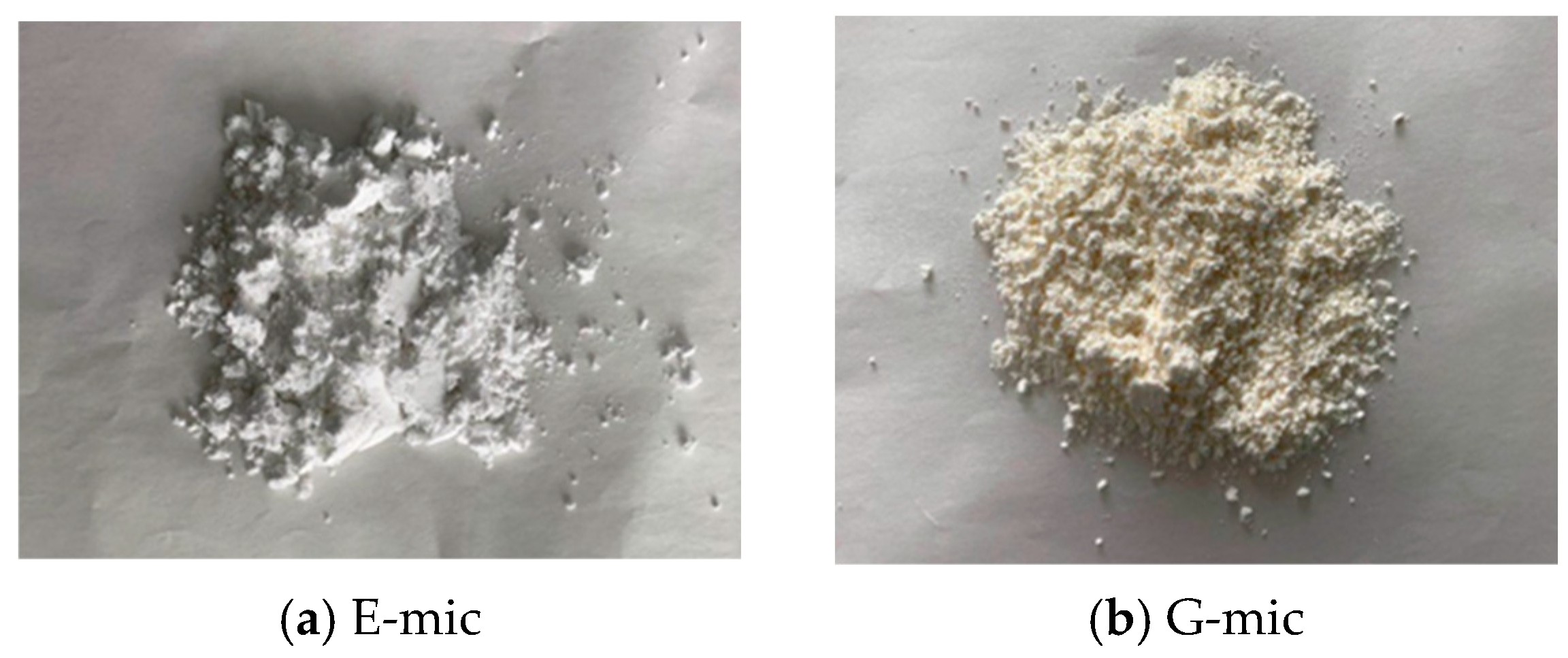

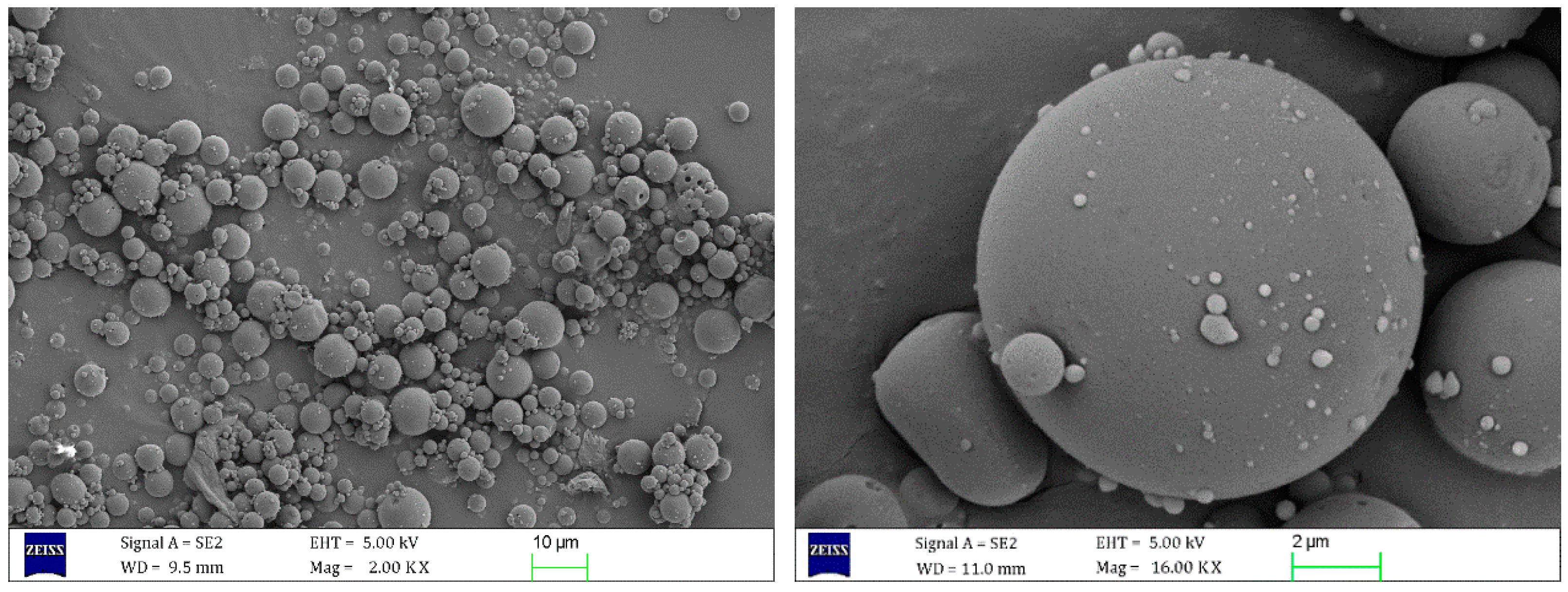

3.1.1. Micromorphology and Microstructure Tests

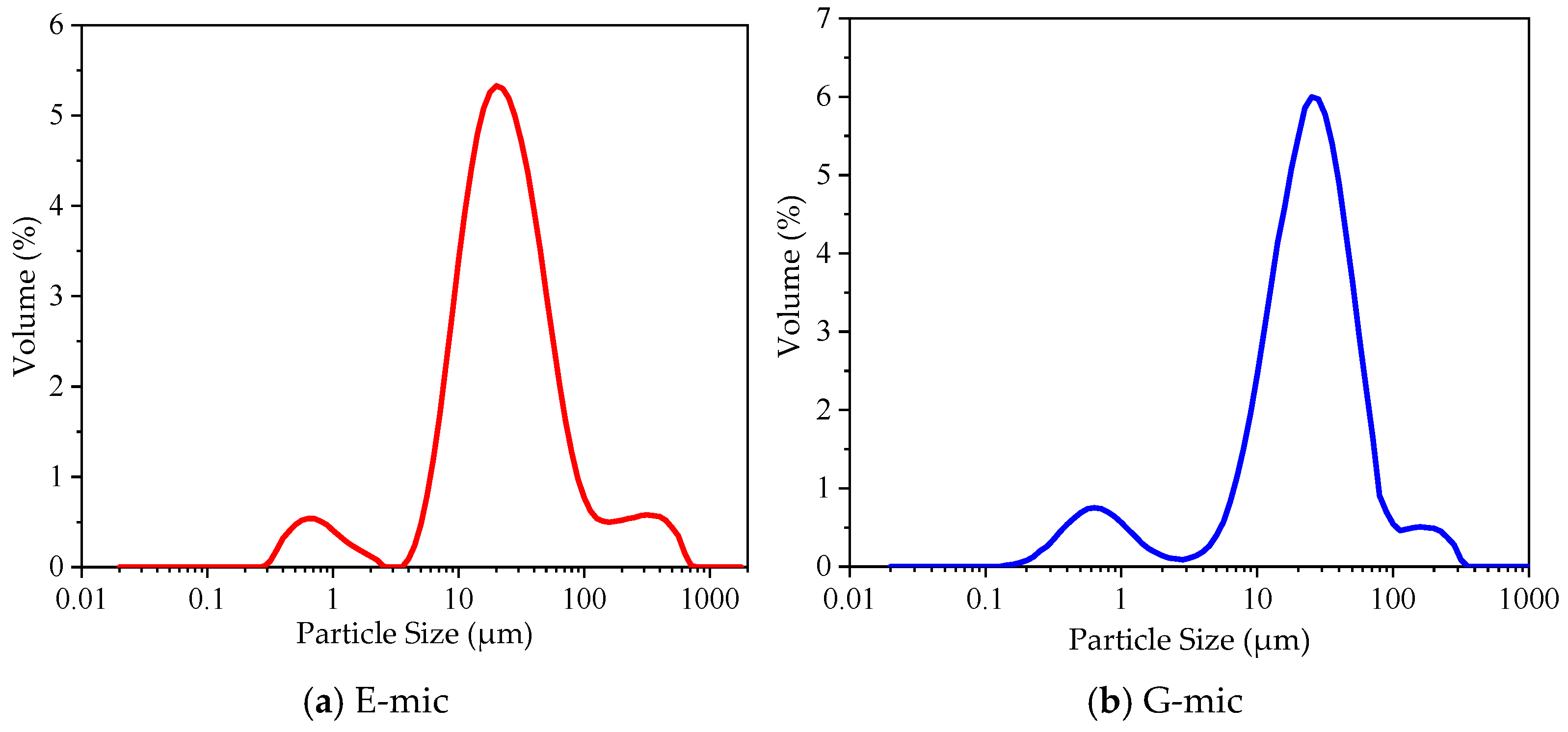

3.1.2. Particle Size Analysis

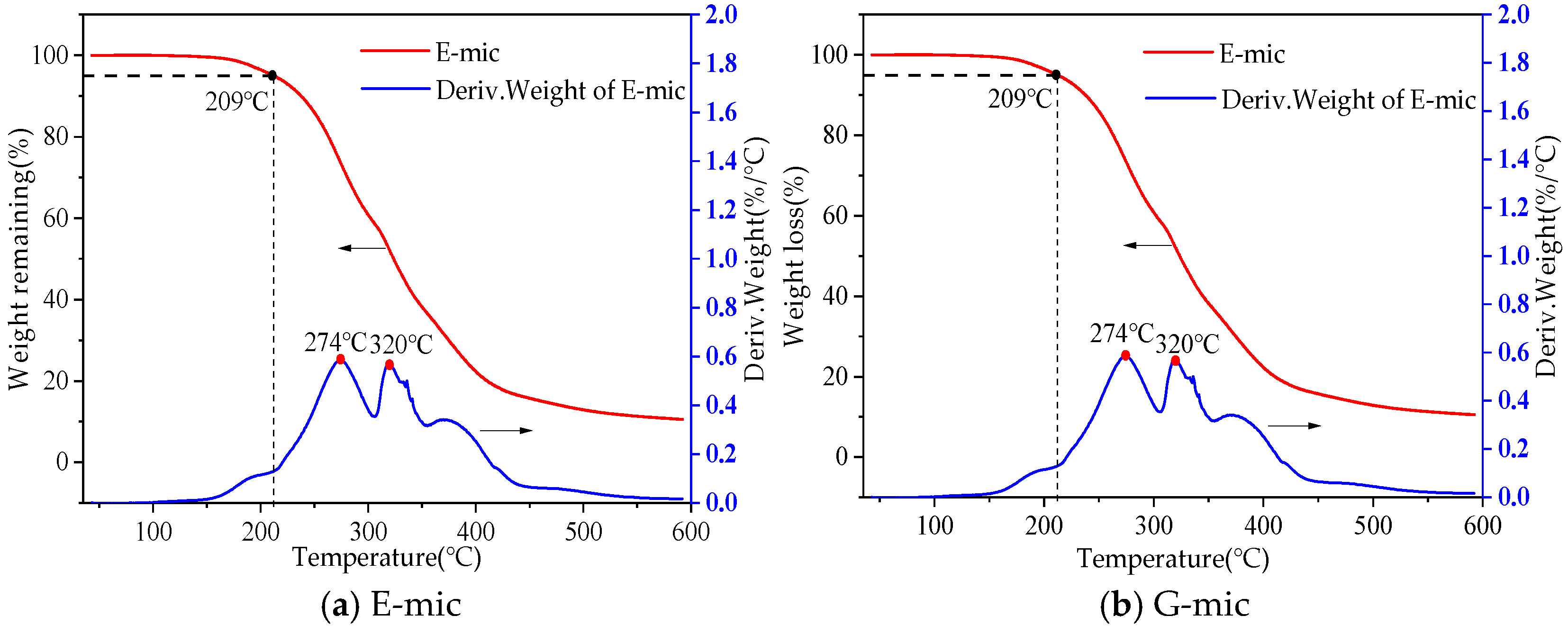

3.1.3. Microcapsule Thermal Stability Analysis

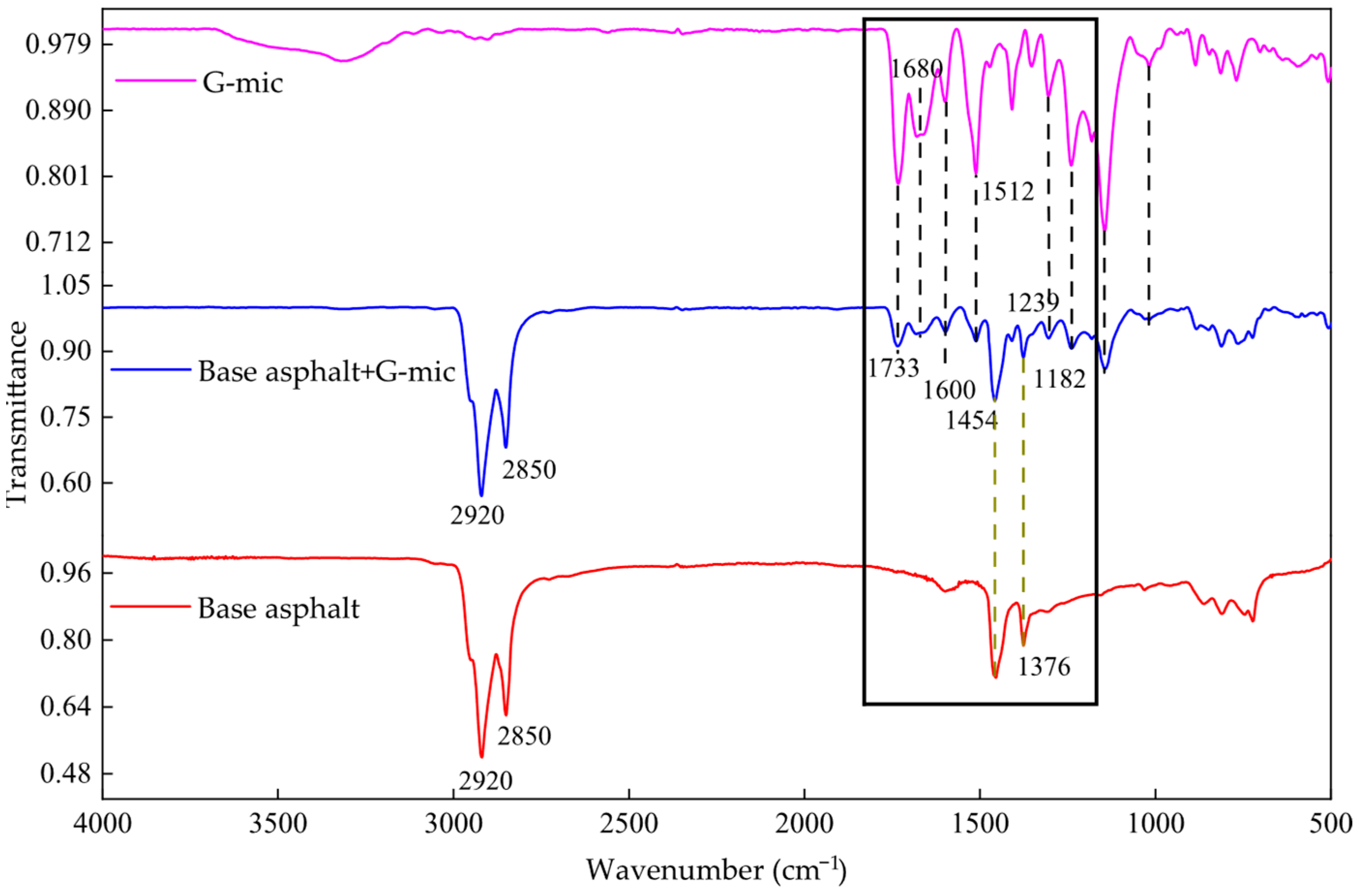

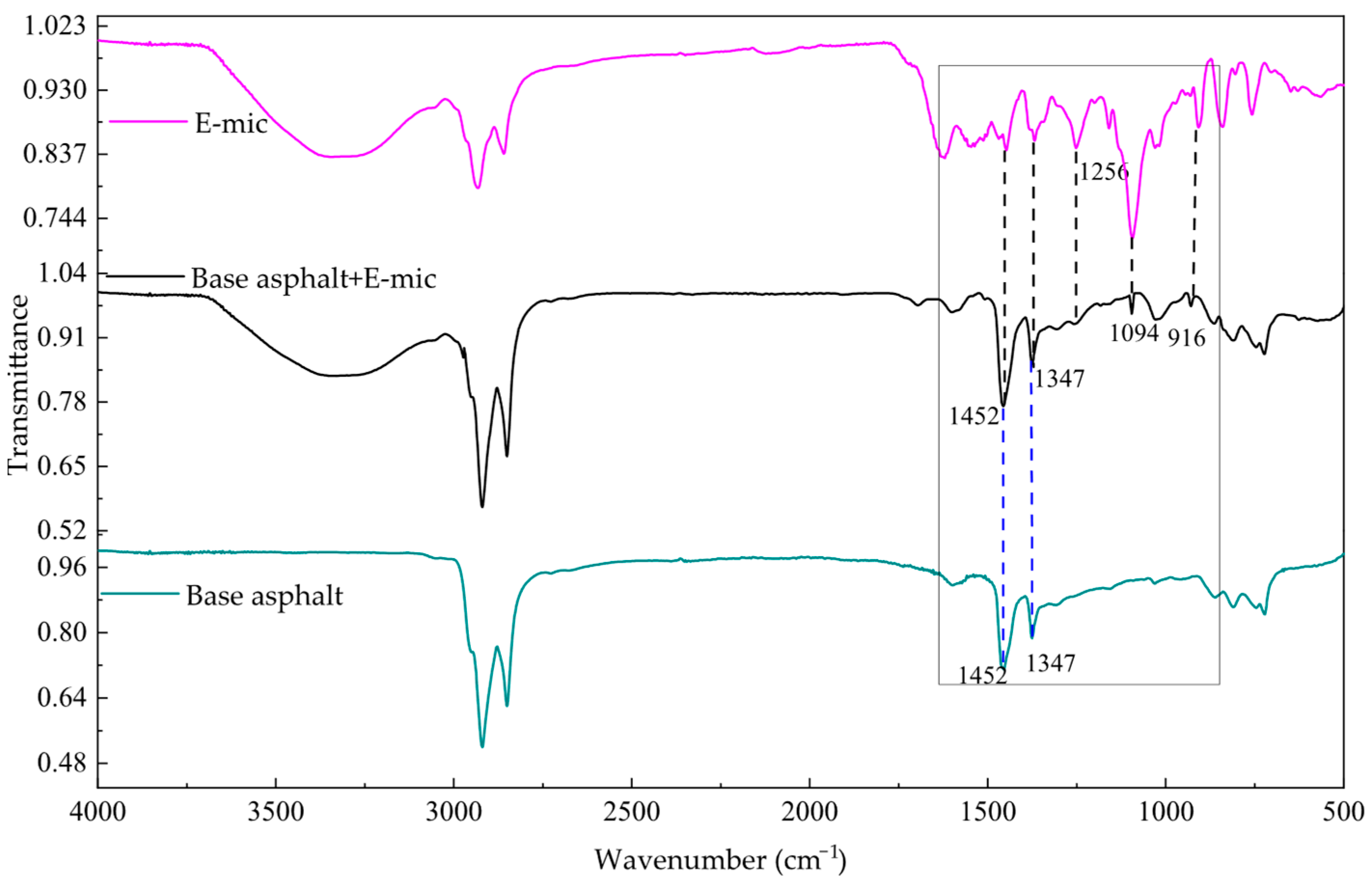

3.1.4. Analysis of Interaction Mechanism Between Microcapsules and Asphalt

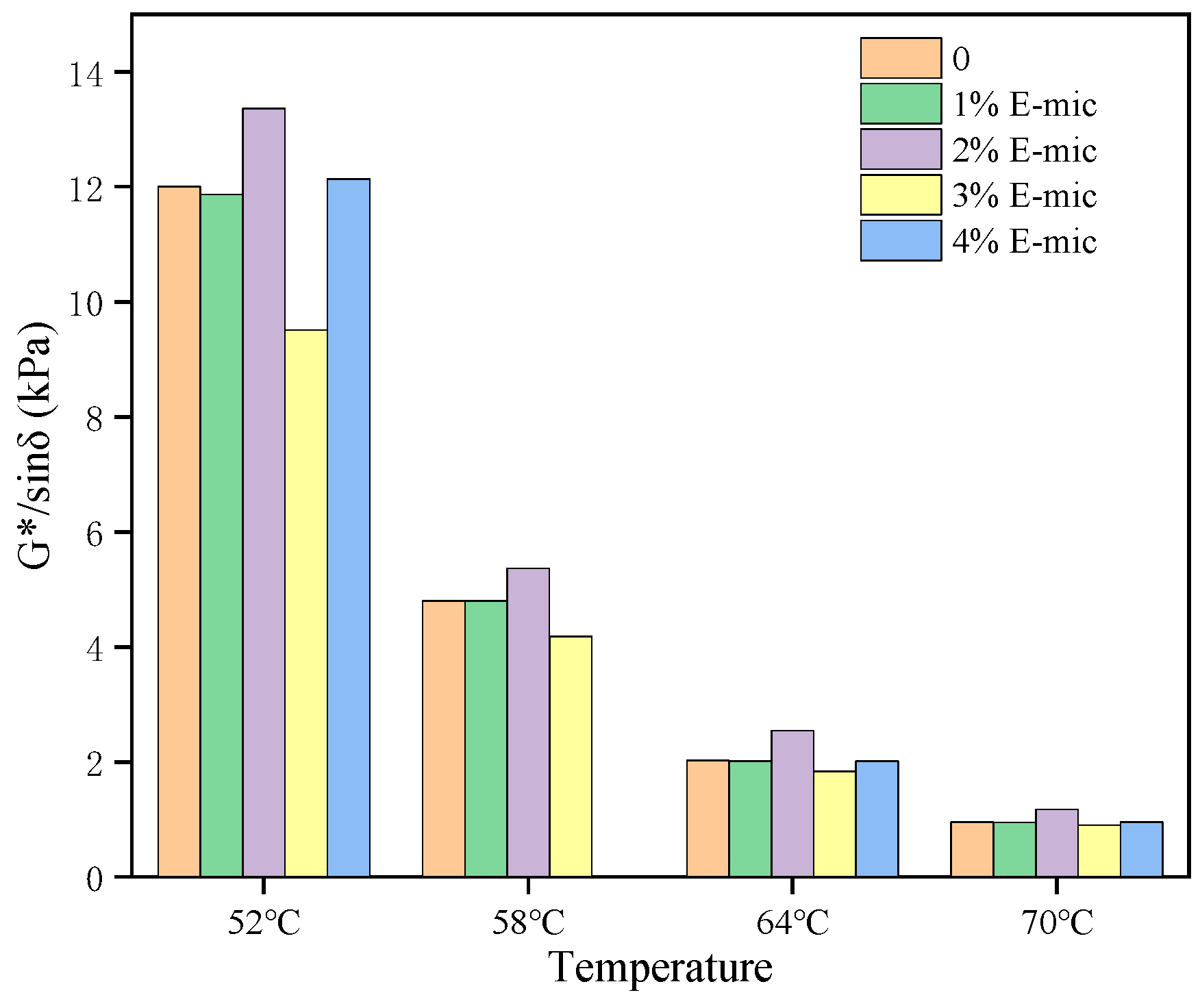

3.2. High-Temperature Rheological Analysis

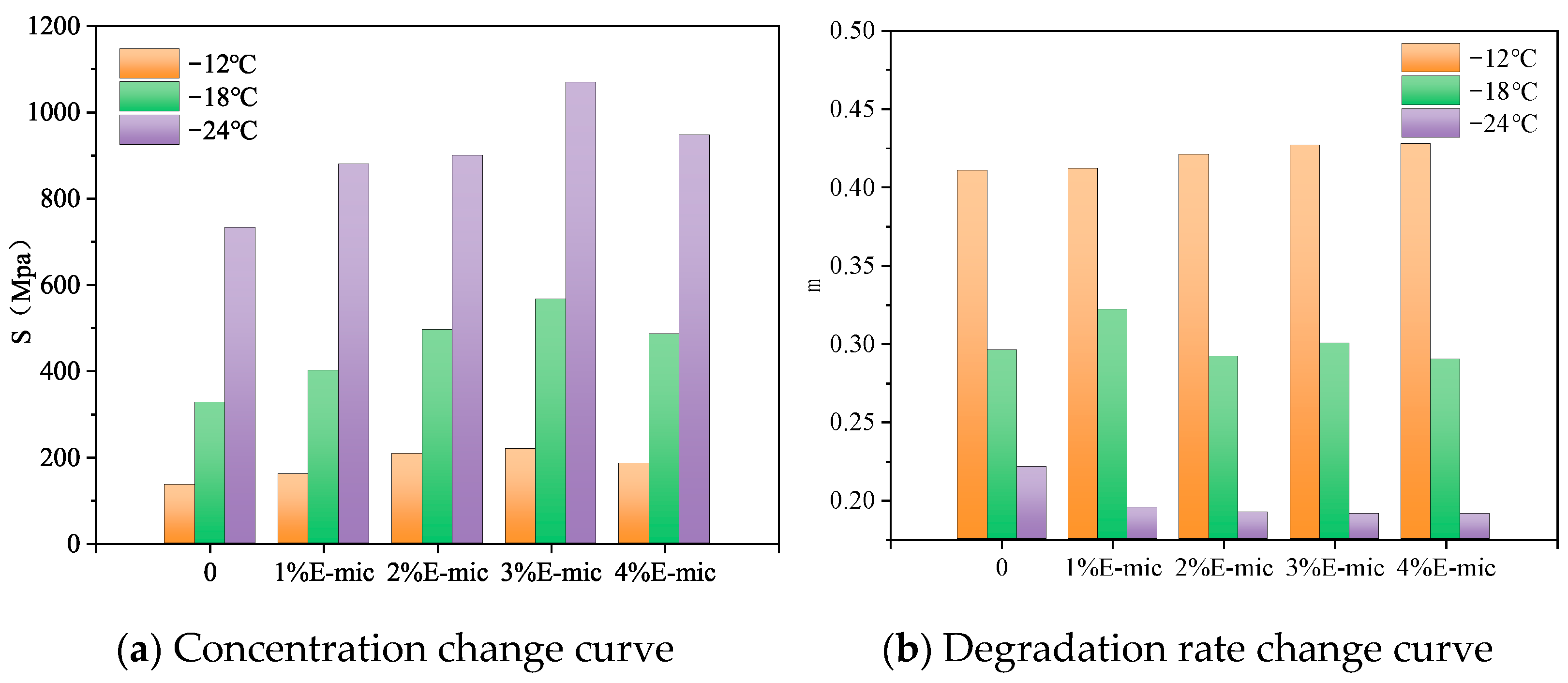

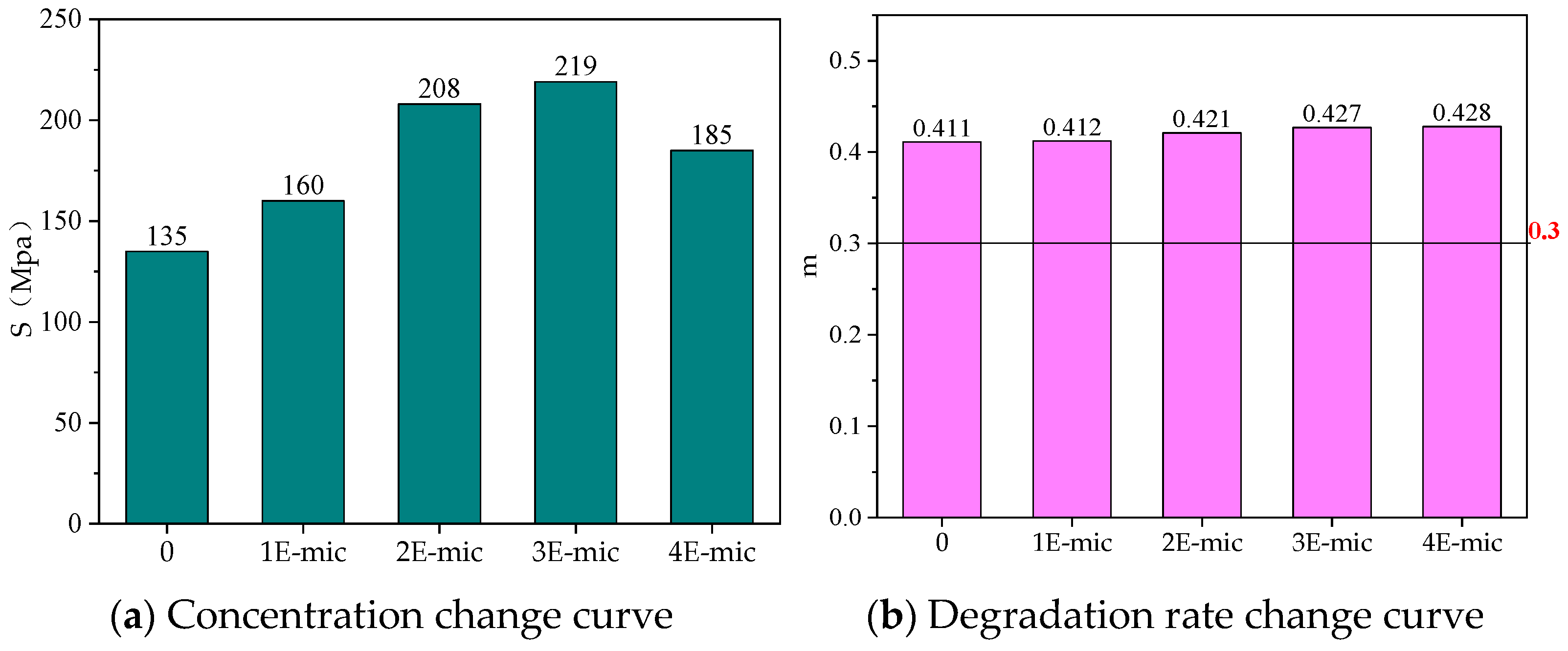

3.3. Low-Temperature Crack Resistance Analysis

3.4. Fatigue Resistance Analysis

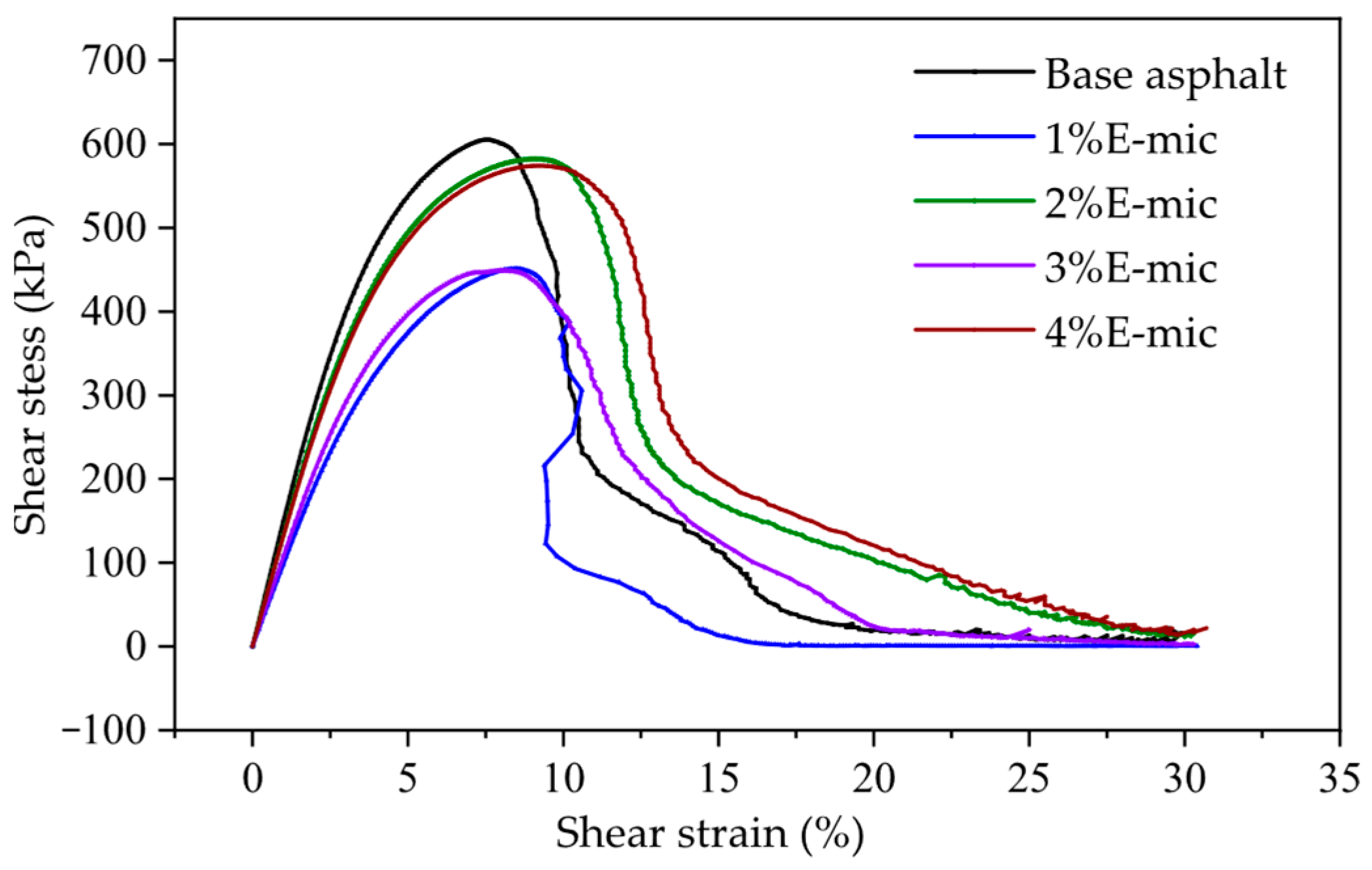

- (1)

- The Stress–Strain Analysis

- (2)

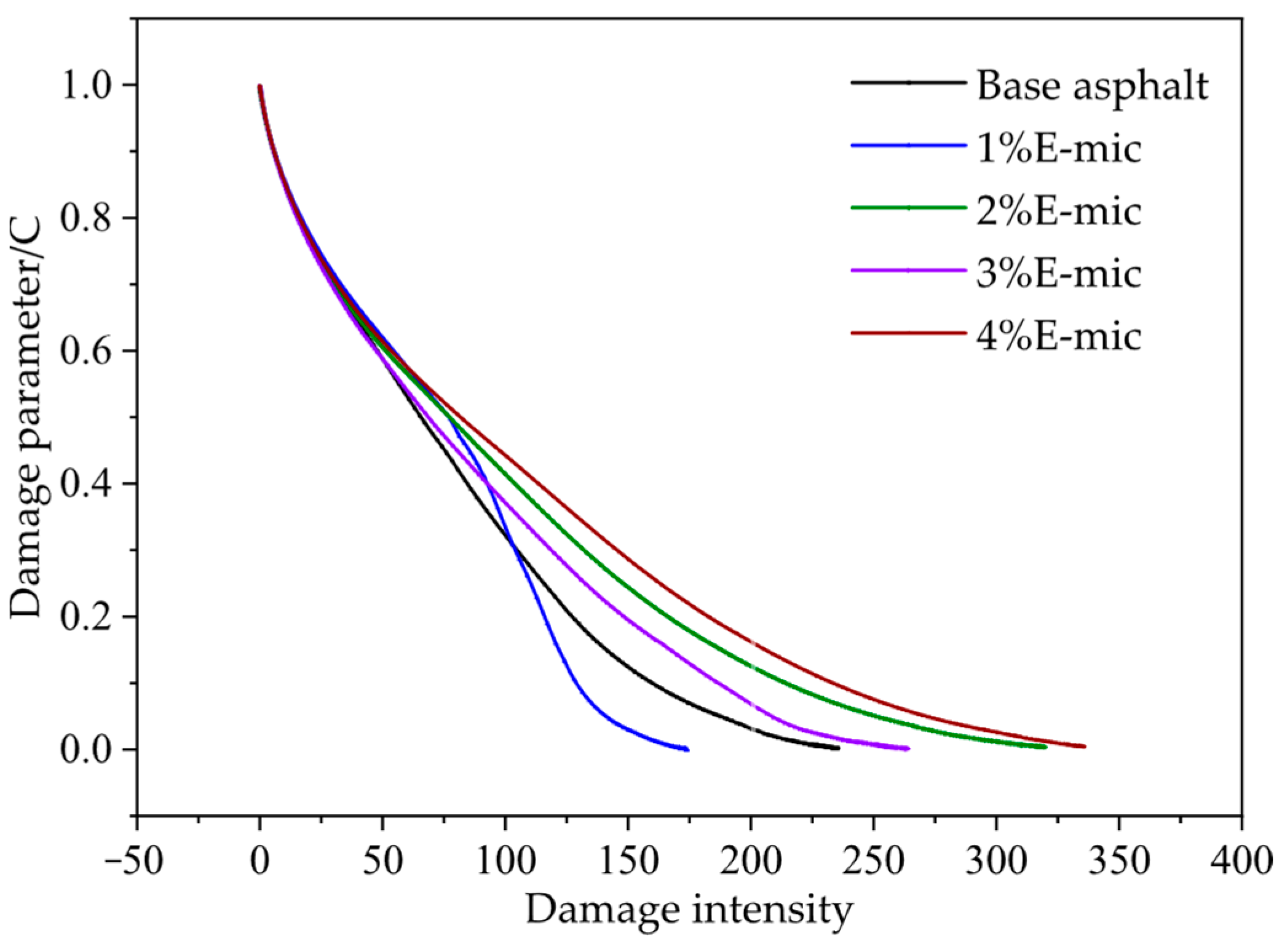

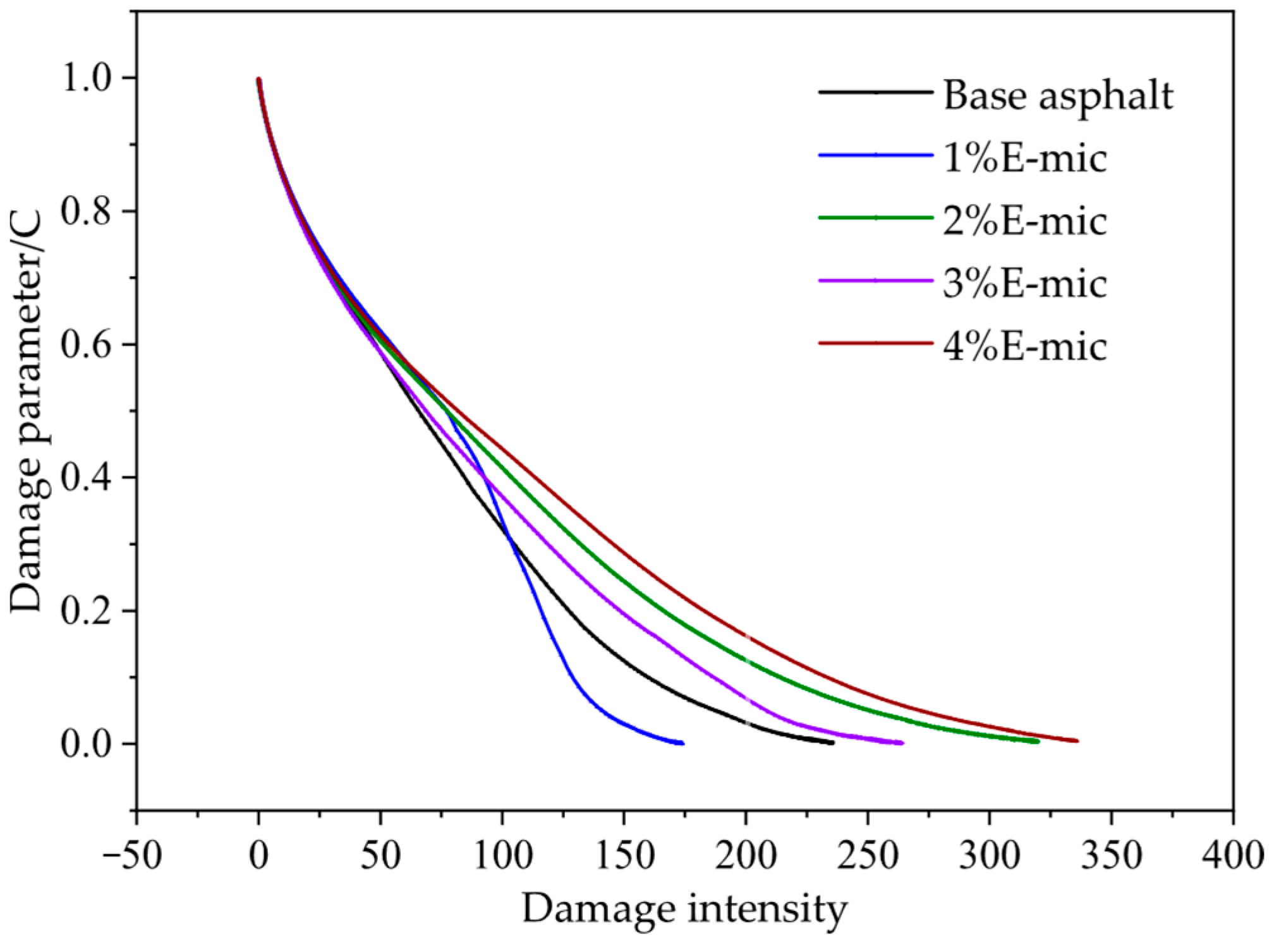

- Fatigue Damage Analysis

- (3)

- Fatigue Life Analysis

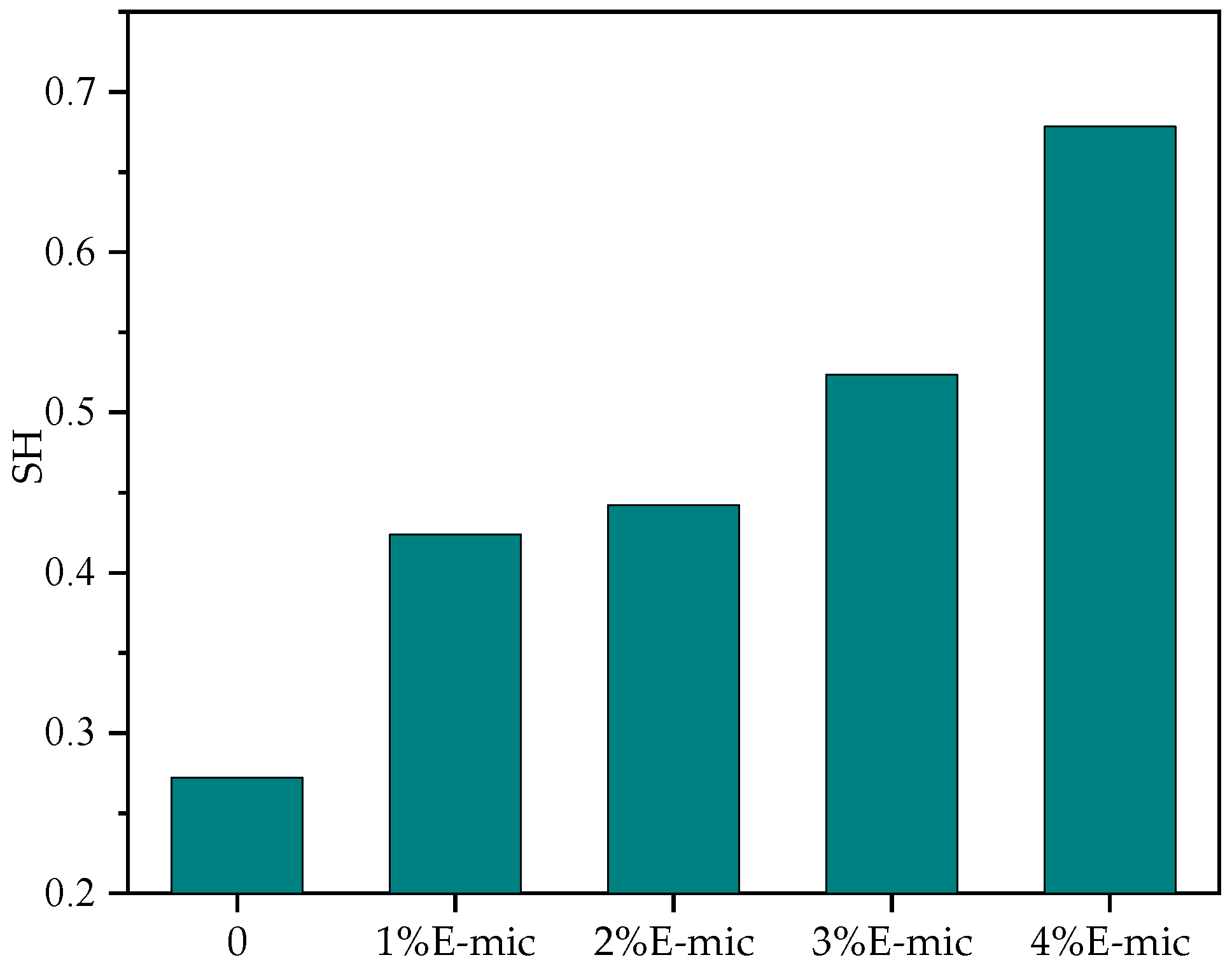

3.5. Self-Healing Property Analysis

3.6. The Recommended Dosage of the Microcapsule

4. Conclusions

- For spherical micron-sized particles with a uniform shape and particle size, the average particle size of the E-mic was 23.582 μm, and that of the G-mic was 22.440 μm, showing a good normal distribution. In addition, they could maintain good stability at high temperatures.

- The TS tests indicated that the rutting resistance of the base asphalt gradually decreases with the increase in the temperature, while the high-temperature deformation resistance showed a better performance when the microcapsule dosage was 2% and 4%.

- The low-temperature bending creep stiffness test demonstrated that the addition of microcapsules increased the stiffness modulus of the base asphalt, but the creep rate was not obvious. At −12 °C, the low-temperature crack resistance and stress relaxation of all specimens were better. The microcapsule can slightly improve the stress relaxation at low temperatures.

- The stress–strain curve of LAS shows that yield stress is greater than that of base asphalt except when the microcapsule dosage is 3%. The fatigue damage curve of the LAS shows that at the range of 100–200, the microcapsule/asphalt fatigue damage rate is lower than that of the base asphalt, except for the microcapsule dosage of 1%; that is, the corresponding fatigue life will be better. The microcapsules can effectively improve the anti-fatigue performance of the base asphalt at high strain levels, and microcapsules/asphalt with a microcapsule dosage of 4% also have a higher anti-fatigue performance at low strain levels.

- Considering the high-temperature deformation resistance, the low-temperature crack resistance, the fatigue resistance, and the self-healing property of asphalt, the optimal dosage of the microcapsules is recommended to be 4%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| E | Modified epoxy resin |

| G | Curing agent |

| MUF | Melamine modified urea–formaldehyde resin |

| E-mic | Modified epoxy resin microcapsule |

| G-mic | Curing agent microcapsule |

References

- Wang, L.; Cheng, P.; Zhao, Q. Research on Fatigue–Healing Performance of Asphalt Mixture Based on the Semicircular Bending Test. Materials 2023, 16, 6382. [Google Scholar] [CrossRef] [PubMed]

- Ameri, M.; Sadeghiavaz, M. Microwave Healing Properties and Moisture Sensitivity of Asphalt Mixture Containing Iron Powder Filler. Sci. Rep. 2024, 14, 23154. [Google Scholar] [CrossRef] [PubMed]

- Diao, H.; Ling, T.; Zhang, Z.; Peng, B.; Huang, Q. Multiscale Fatigue Performance Evaluation of Hydrated Lime and Basalt Fiber Modified Asphalt Mixture. Materials 2023, 16, 3608. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Xu, W.; Cao, K.; Li, K. Self-Healing Behavior of Recycled Asphalt Prepared by Residue Oil of Straw Liquefaction Based on Molecular Dynamics Simulation. Sci. Rep. 2022, 12, 2718. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Fini, E.; Jia, X.; Song, B.; Wang, Y. Effect of Aging on Healing Capacity of Bituminous Composites Containing Polyphosphoric Acid. Materials 2023, 16, 3333. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yao, T.; Cheng, F. Road Performance and Self-Healing Property of Bituminous Mixture Containing Urea–Formaldehyde Microcapsules. Materials 2024, 17, 943. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Miao, Y.; Zhao, H.; Chen, J.; Qing, L.; Mu, R.; Chen, X.; Li, Z. Study on the Self-Healing Performance of Microcapsules and Microcapsule-Containing Asphalt. Sustainability 2022, 14, 12231. [Google Scholar] [CrossRef]

- Ding, X.; Cui, Y.; Ma, T.; Ye, F. Multiscale-Mechanical Analysis on Self-Healing Microcapsules Under Asphalt Pavement. Constr. Build. Mater. 2024, 443, 137670. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, R.; Sun, B.; Liu, J.; Hao, P. Microcapsule Synthesis and Evaluation on Fatigue and Healing of Microcapsule-Based Asphalt by the Entropy and TOPSIS Method. Int. J. Pavement Eng. 2022, 23, 4610–4621. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, R.; Cheng, F. Study on the Properties and Self-Healing Ability of Asphalt and Asphalt Mixture Containing Methanol-Modified Melamine-Formaldehyde Microcapsules. Mater. Today Commun. 2024, 41, 111007. [Google Scholar] [CrossRef]

- Xu, X.; Yuan, L.; Cong, P.; Wang, Z.; Guo, H.; Zhou, X.; Shao, T. Rheological and Healing Properties of Bitumen Containing Carbon Black Microcapsules. Fuel 2024, 373, 132399. [Google Scholar] [CrossRef]

- Chen, B.; Liu, D.; Chen, A.; Wang, Y. Influence of Microcapsules on Self-Healing Performance and Road Performance of Dense-Graded Asphalt Mixture. IOP Conf. Ser. Earth Environ. Sci. 2021, 768, 12020. [Google Scholar] [CrossRef]

- Xu, X.; Cong, P.; Wang, Z.; Zhang, T.; Zhou, X.; Yang, Q.; Zhao, Y.; Zhang, T. Application of Microencapsulated Waste Cooking Oil in Bitumen: Responsiveness and Bitumen Performance Changes. Fuel 2025, 402, 136026. [Google Scholar] [CrossRef]

- Lu, T.; Hofko, B.; Sun, D.; Mirwald, J.; Eberhardsteiner, L.; Hu, M. Microscopic and Rheologic Characterization of Third Generation Self-Repairing Microcapsule Modified Asphalt. Constr. Build. Mater. 2023, 400, 132841. [Google Scholar] [CrossRef]

- Wen, Y.; Ma, F.; Fu, Z.; Li, C.; Shi, K.; Dai, J.; Zhu, C. Evaluation of the Microcapsules on the Rheological and Self-Healing Performance of Asphalt. Constr. Build. Mater. 2023, 409, 133982. [Google Scholar] [CrossRef]

- Yang, S.; Ji, J.; Tao, H.; Muhammad, Y.; Huang, J.; Wang, S.; Wei, Y.; Li, J. Fabrication of Urea Formaldehyde–Epoxy Resin Microcapsules for the Preparation of High Self-Healing Ability Containing SBS Modified Asphalt. Polym. Compos. 2021, 42, 4128–4137. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Tan, Y.-Q.; Lv, H.-J.; Han, M.-Z. Evaluation of Rheological and Self-Healing Properties of Asphalt Containing Microcapsules Modified with Graphene. Constr. Build. Mater. 2022, 357, 129287. [Google Scholar] [CrossRef]

- Ma, E.; Chen, X.; Lai, J.; Kong, X.; Guo, C. Self-Healing of Microcapsule-Based Materials for Highway Construction: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 368–384. [Google Scholar] [CrossRef]

- Wen, Y.; Ma, F.; Fu, Z.; Dong, W.; Jia, M.; Dai, J.; Hou, Y.; Jiang, X.; Hao, Y. Influence of Hybrid Microcapsules on the Low-Temperature Cracking Resistance of Asphalt Binder. Constr. Build. Mater. 2025, 480, 141525. [Google Scholar] [CrossRef]

- Ren, Y.; Hao, P. Modification Mechanism and Enhanced Low-Temperature Performance of Asphalt Mixtures with Graphene-Modified Phase-Change Microcapsules. Constr. Build. Mater. 2022, 320, 126301. [Google Scholar] [CrossRef]

- Tao, M.; Xu, T. Development and Properties of Bio-Based Rice Oil Microcapsule and Its Dispersibility in Emulsified Asphalt. J. Ind. Eng. Chem. 2024, 131, 503–513. [Google Scholar] [CrossRef]

- Xu, X.; Yuan, L.; Cong, P.; Wang, Z.; Zhou, X.; Wang, J.; Liu, J. Self-Healing Microcapsule Properties Improvement Technology: Key Challenges and Solutions for Application in Asphalt Materials. Constr. Build. Mater. 2024, 439, 137298. [Google Scholar] [CrossRef]

- Tian, Y.; Zheng, M.; Li, P.; Zhang, J.; Qiao, R.; Cheng, C.; Xu, H. Preparation and Characterization of Self-Healing Microcapsules of Asphalt. Constr. Build. Mater. 2020, 263, 120174. [Google Scholar] [CrossRef]

- Pei, Z.; Yi, J.; Xu, M.; Ai, X.; Cao, J.; Hu, W.; Gao, L.; Feng, D. Exploration of the Design Theory of Crack-Resistant Rejuvenator for Warm-Mix Recycled Asphalt Mixtures with High RAP Contents. J. Clean. Prod. 2023, 388, 135855. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Q.; Bi, Y.; Yu, B.; Zhang, J. Self-Healing Effect of Various Capsule-Core Materials on Asphalt Materials. Adv. Civ. Eng. 2022, 2022, 5372501. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Arteaga-Perez, L.E.; Guadarrama-Lezama, A.Y.; Briones, R.; Vivanco, J.F.; Gonzalez-Torre, I. Microencapsulated Bio-Based Rejuvenators for the Self-Healing of Bituminous Materials. Materials 2020, 13, 1446. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Li, H.; Feng, L.; Li, F. Effect of UV Light on the Barrier Performance of Aluminum Powder/Epoxy Coating. Polymers 2022, 14, 2405. [Google Scholar] [CrossRef] [PubMed]

- Yalikun, N.; Yu, S.; Yang, H.; Liu, C.; Zhang, H.; Wang, Q.; Zhang, Y.; Chen, F. Preparation and Performance Study of Oxidized CR/SBS Composite Modified Asphalt. J. Environ. Chem. Eng. 2025, 13, 117094. [Google Scholar] [CrossRef]

- Wen, D.; Ge, D.; Wang, Y.; Lv, S.; Liu, Q.; Liu, S. Effectiveness of Different Categories of Light Oils in Partially Reactive Crumb Rubber-Modified Asphalt. Materials 2025, 18, 1871. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Ma, S.; Zhu, S.; Fan, L.; Liu, P.; Lin, J.; Li, Y. Comparison and Analysis of Testing Methods for Storage Stability of Sbs Modified Asphalt. Highw. Eng. 2023, 48, 173–178. [Google Scholar]

- AASHTO TP 101-14; Standard Method of Test for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- Sun, D.; Pang, Q.; Zhu, X.; Tian, Y.; Lu, T.; Yang, Y. Enhanced Self-Healing Process of Sustainable Asphalt Materials Containing Microcapsules. ACS Sustain. Chem. Eng. 2017, 5, 9881–9893. [Google Scholar] [CrossRef]

- Ābele, A.; Merijs-Meri, R.; Bērziņa, R.; Zicāns, J.; Haritonovs, V.; Ivanova, T. Effect of Bio-Oil on Rheological and Calorimetric Properties of RTFOT Aged Bituminous Compositions. Int. J. Pavement Res. Technol. 2021, 14, 537–542. [Google Scholar] [CrossRef]

| Indicators | Unit | Measured Value | Specified Value |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 66.7 | 60–80 |

| Ductility (5 cm/min) | cm | >100 | ≥100 |

| Softening point | °C | 46.7 | ≥42/43 |

| Viscosity (135 °C) | mPa s | 475 | - |

| Viscosity/mPa·s/25 °C | Epoxy Equivalent/ g·eq−1 | Color/Max, G | Performance Overview |

|---|---|---|---|

| 2300 | 215 | 1 | Obtained by hydrogenation modification of bisphenol A type, colorless and transparent, weather-resistant, and yellowing-resistant. |

| Material | Molecular Formula | Specification |

|---|---|---|

| Melamine (M) | C3N3(NH2)3 | AR |

| Urea (U) | CH4N2O | AR |

| Formaldehyde (F) | CH2O | AR |

| Samples | D(10) (μm) | D(50) (μm) | D(90) (μm) | Span | Consistency | Shading Degree |

|---|---|---|---|---|---|---|

| E-mic | 7.096 | 23.582 | 87.440 | 1.113 | 0.343 | 10.93% |

| G-mic | 4.477 | 22.440 | 63.246 | 1.157 | 0.355 | 12.90% |

| Content | Rutting Factor (64 °C)/kPa | Creep Stiffness Modulus (−12 °C) | Change Rate (−12 °C) | Self-Healing Rate |

|---|---|---|---|---|

| 0 | 2.02 | 135 | 0.411 | 0.27 |

| 1 | 2.02 | 160 | 0.412 | 0.42 |

| 2 | 2.55 | 208 | 0.421 | 0.44 |

| 3 | 1.84 | 219 | 0.427 | 0.52 |

| 4 | 2.02 | 185 | 0.428 | 0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Ji, R.; Zhang, C.; Xu, J.; Zheng, M.; Song, X. A Study on the Road Performance of the Self-Healing Microcapsule for Asphalt Pavement. Materials 2025, 18, 3483. https://doi.org/10.3390/ma18153483

Li P, Ji R, Zhang C, Xu J, Zheng M, Song X. A Study on the Road Performance of the Self-Healing Microcapsule for Asphalt Pavement. Materials. 2025; 18(15):3483. https://doi.org/10.3390/ma18153483

Chicago/Turabian StyleLi, Pei, Rongyi Ji, Chenlong Zhang, Jinghan Xu, Mulian Zheng, and Xinghan Song. 2025. "A Study on the Road Performance of the Self-Healing Microcapsule for Asphalt Pavement" Materials 18, no. 15: 3483. https://doi.org/10.3390/ma18153483

APA StyleLi, P., Ji, R., Zhang, C., Xu, J., Zheng, M., & Song, X. (2025). A Study on the Road Performance of the Self-Healing Microcapsule for Asphalt Pavement. Materials, 18(15), 3483. https://doi.org/10.3390/ma18153483