Effect of Rubber Particle Size and Content on the Mechanical Properties of Rubber–Clay Mixtures Solidified by EICP

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

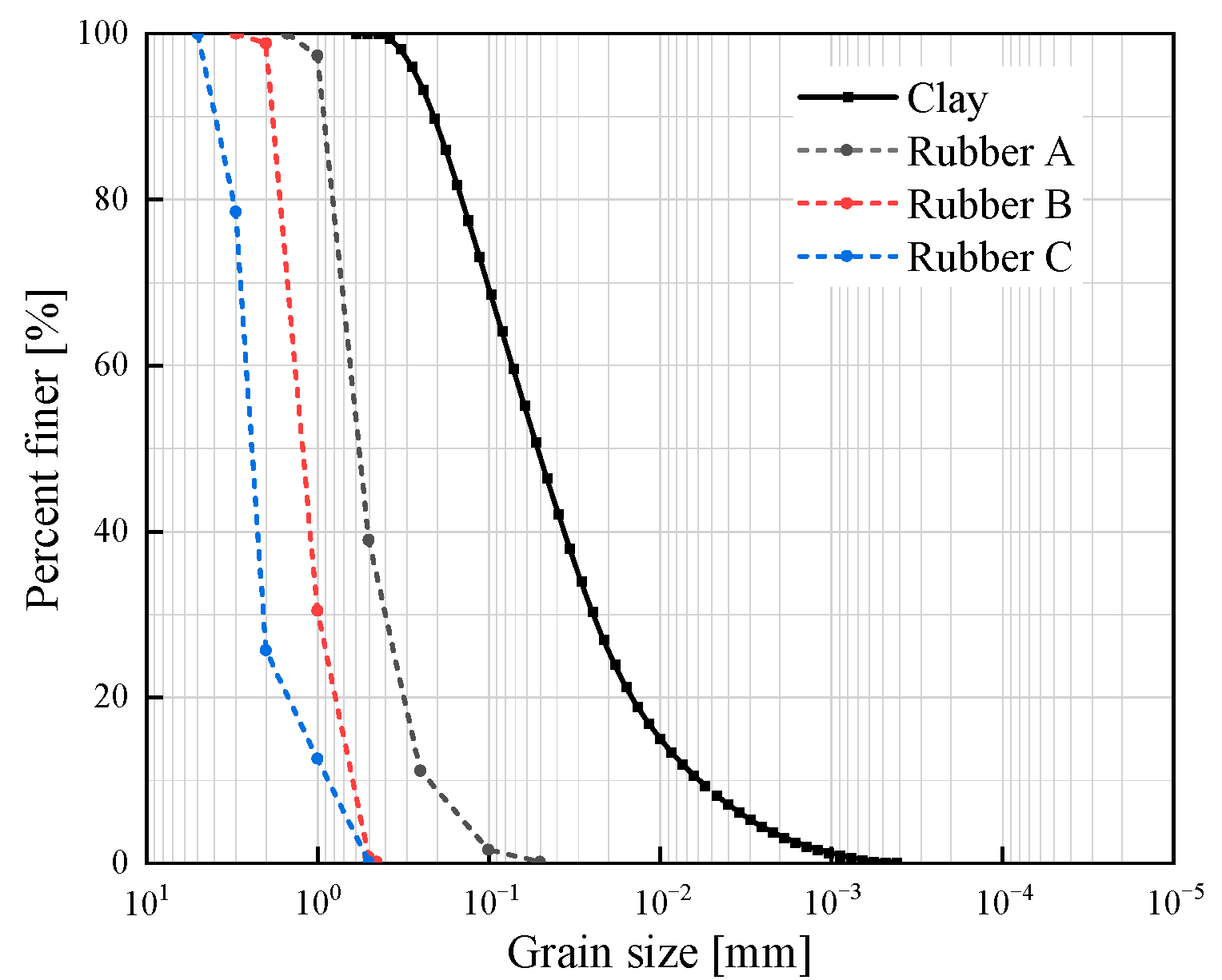

2.1.1. Soil

2.1.2. Rubber Particle

2.1.3. EICP Solution

2.2. Specimen Preparation

2.3. Test Methods

2.3.1. Determination of Calcium Carbonate Content

2.3.2. Triaxial Compressive Test

2.3.3. Oedometer Test

2.3.4. Permeability Test

2.3.5. Nuclear Magnetic Resonance Test

3. Results and Discussion

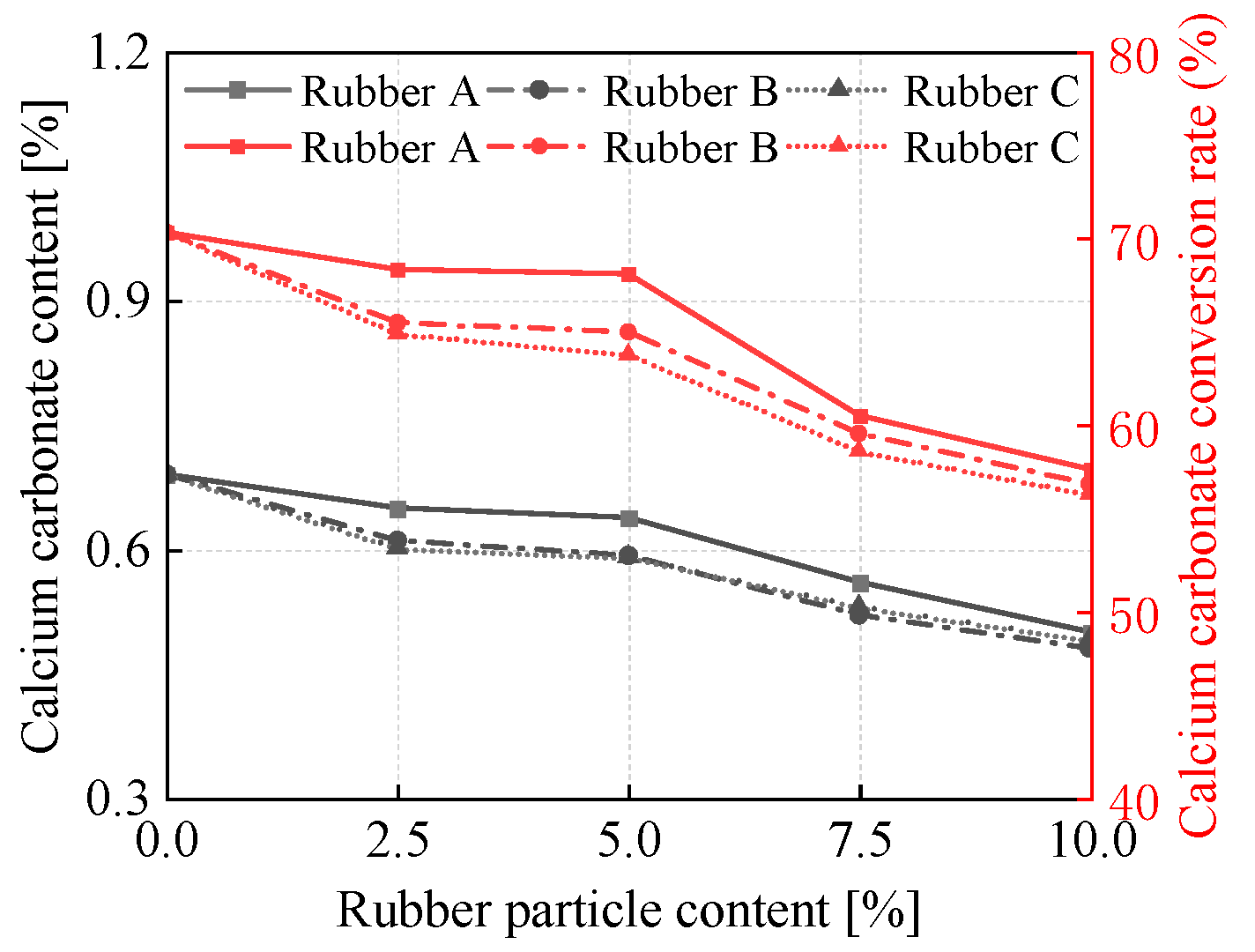

3.1. Effect of Rubber Particle Sizes and Content on Calcium Carbonate Content

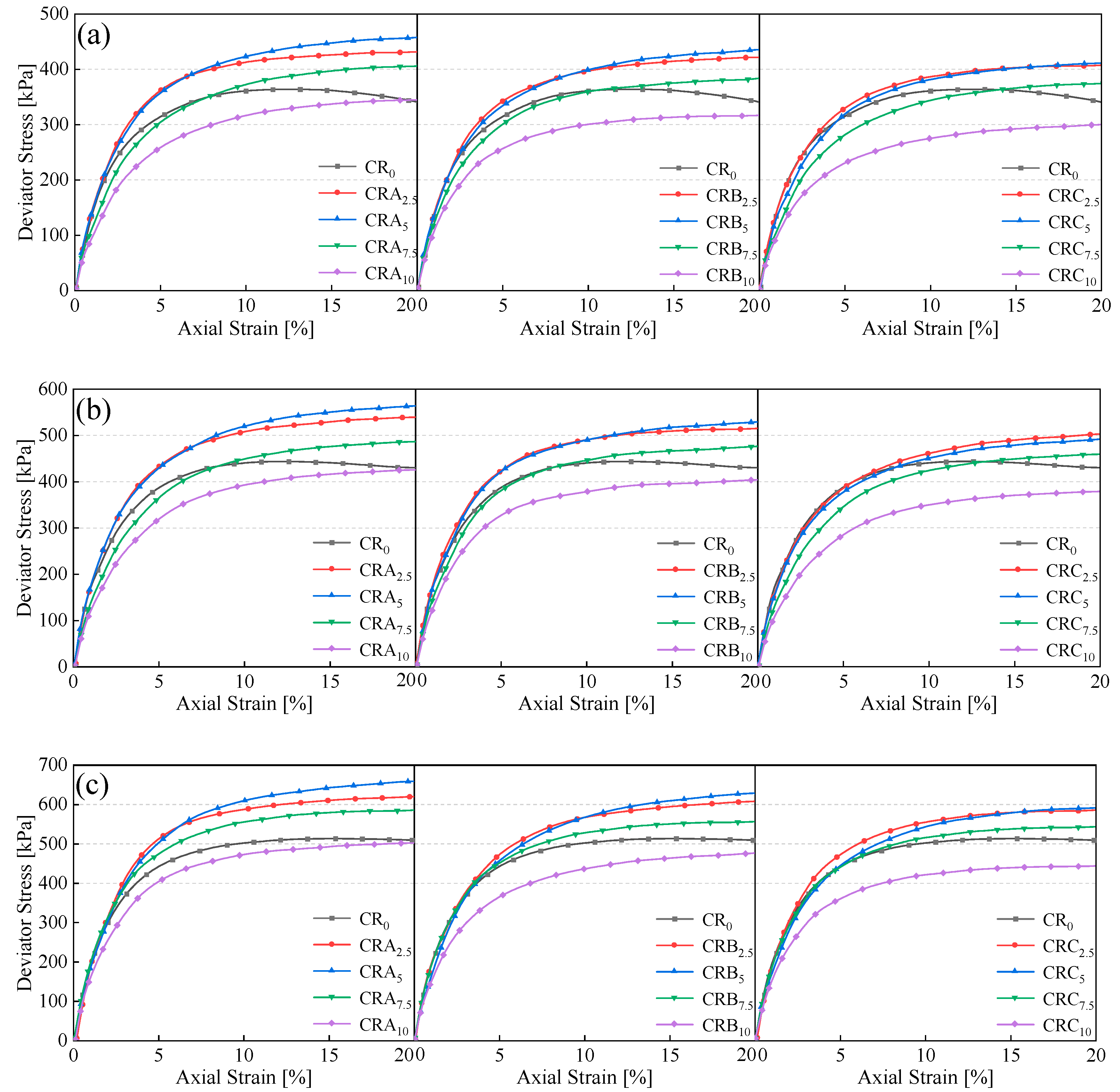

3.2. Triaxial Compression Test

3.2.1. Stress–Strain Relationship

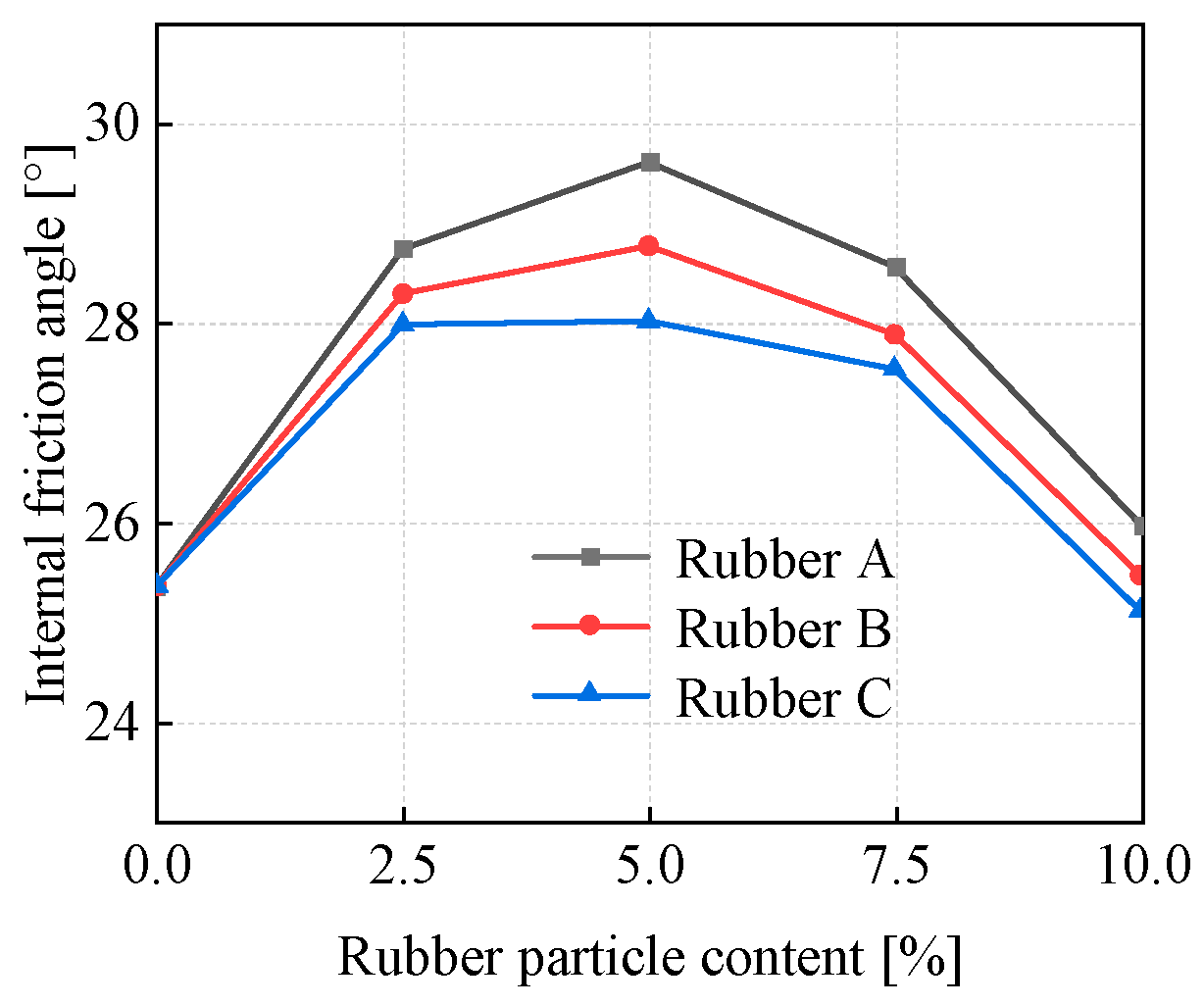

3.2.2. Cohesion and Internal Friction Angle

3.3. Oedometer Test

3.3.1. Stress–Strain Relationship

3.3.2. Compressibility

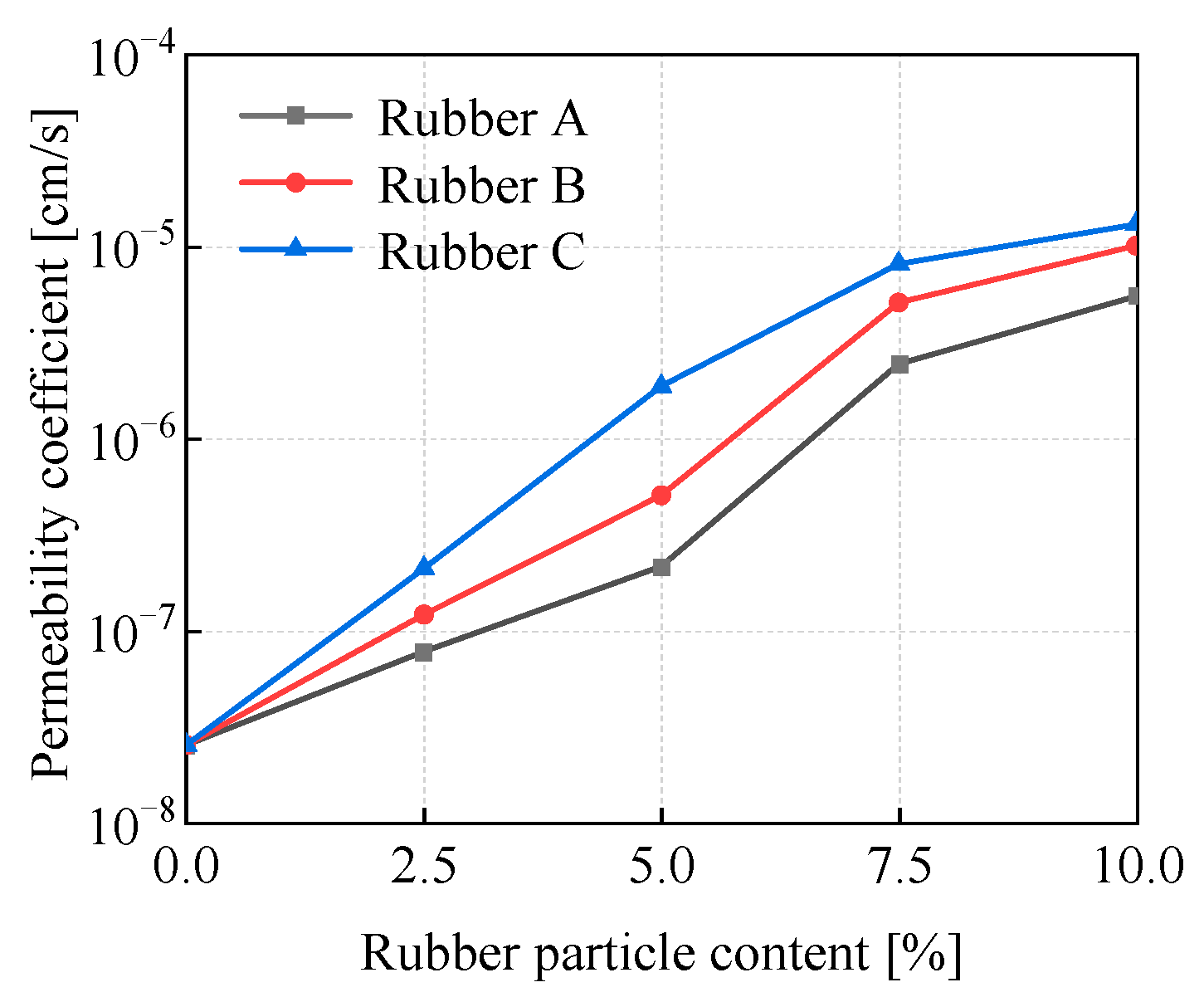

3.4. Effect of Rubber Particle Size and Content on Permeability

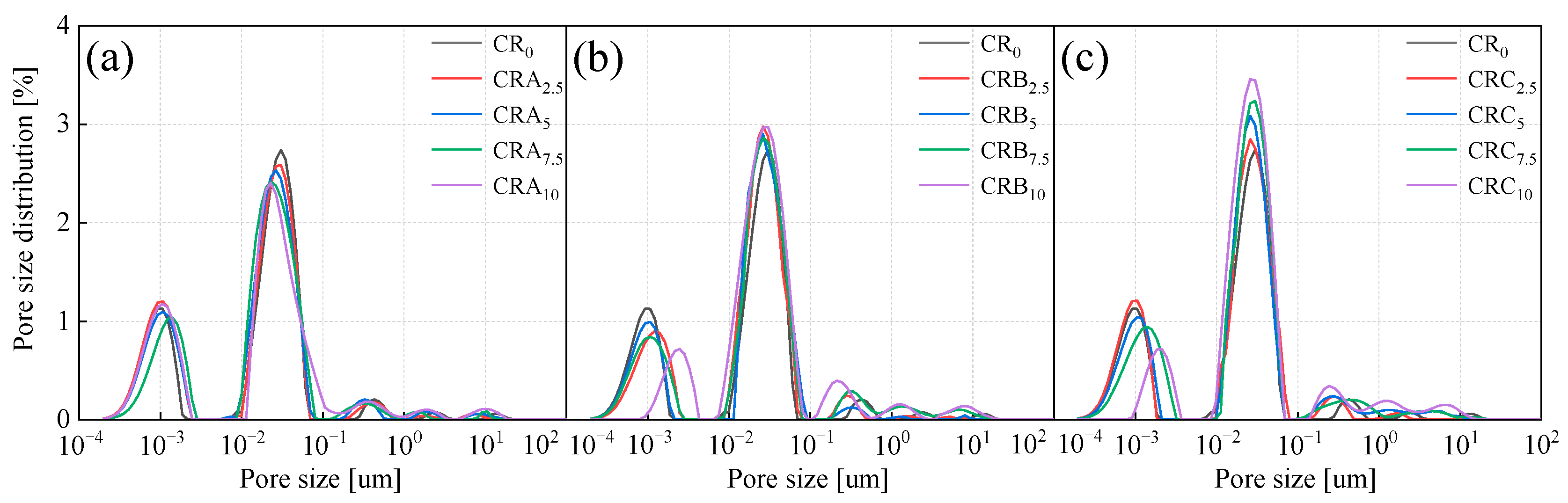

3.5. Nuclear Magnetic Resonance Analysis

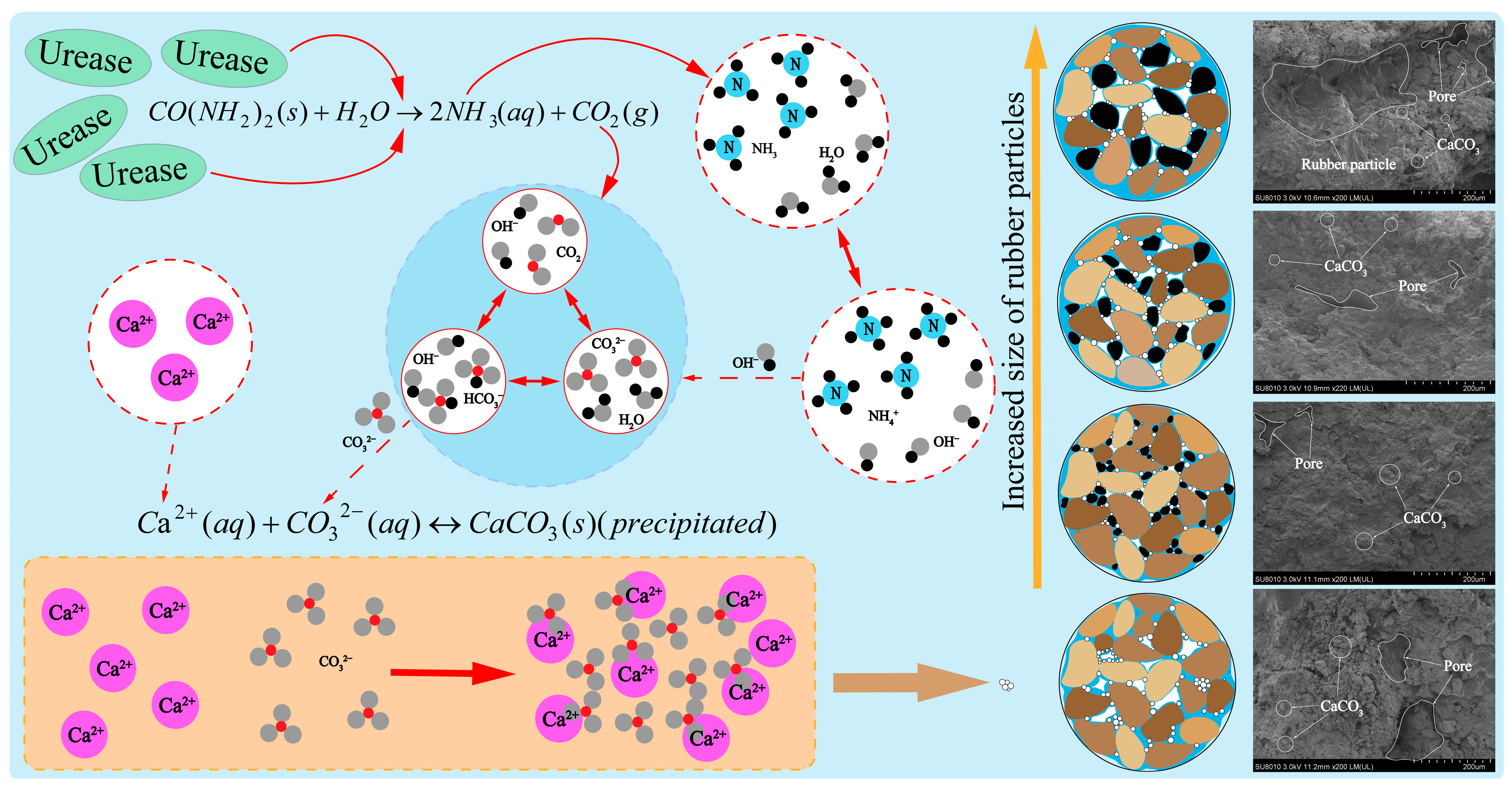

3.6. Microstructure Change Process

4. Conclusions

- (1)

- The addition of rubber particles exerts a certain influence on the degree of the EICP reaction. As the rubber particle content rises, the calcium carbonate content in the samples generally shows a downward trend. Nevertheless, the inclusion of rubber particles is capable of enhancing the shear strength of the specimens. Specifically, both the cohesion and the angle of internal friction of the EICP-RC solidified clay increase as the rubber particle content increases. For a specific rubber particle size, the most significant improvement occurs when the rubber particle content reaches 5%. Moreover, for any fixed rubber particle content, smaller-sized rubber particles demonstrate a more pronounced improvement effect.

- (2)

- According to the findings of the odometer test, as the rubber particle content in the specimen augmented, its deformation also increased, accompanied by the growth of both the Cc and Cs. When the rubber particle content remained constant, the samples treated with large-sized rubber particles exhibited a larger Cc and Cs. The results of the permeability test indicated that the permeability coefficient of the samples rose with the increase in rubber particle content. The size of the rubber particles had a notable impact on the permeability of the samples. Generally, the permeability coefficients of the samples modified with large-sized rubber particles were higher than those of the samples modified with small-sized rubber particles.

- (3)

- Incorporating large-sized rubber particles into cemented soils modifies the soil’s pore structure by increasing both the size and number of mesopores and macropores. Conversely, adding small-sized rubber particles has minimal impact on overall pore structure but effectively fills mesopores and macropores. The synergistic effect between EICP and rubber particles can more effectively solidify the soil structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yadav, J.S.; Tiwari, S.K. Behaviour of cement stabilized treated coir fibre-reinforced clay-pond ash mixtures. J. Build. Eng. 2016, 8, 131–140. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Zhang, J.; Su, P.; Wen, K.; Li, Y.; Li, L. Environmental impact and mechanical improvement of microbially induced calcium carbonate precipitation-treated coal fly ash–soil mixture. Environ. Geotech. 2024, 11, 29–39. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, N.; Cai, G.; Jin, Y.; Ding, N.; Shen, D. Review of ground improvement using microbial induced carbonate precipitation (MICP). Mar. Georesources Geotechnol. 2017, 35, 1135–1146. [Google Scholar] [CrossRef]

- Meng, H.; Shu, S.; Gao, Y.; Yan, B.; He, J. Multiple-phase enzyme-induced carbonate precipitation (EICP) method for soil improvement. Eng. Geol. 2021, 294, 106374. [Google Scholar] [CrossRef]

- Almajed, A.; Khodadadi Tirkolaei, H.; Kavazanjian, E. Baseline Investigation on Enzyme-Induced Calcium Carbonate Precipitation. J. Geotech. Geoenviron. Eng. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Ando, Y. Distribution of mineralized carbonate and its quantification method in enzyme mediated calcite precipitation technique. Soils Found. 2015, 55, 447–457. [Google Scholar] [CrossRef]

- Oliveira, P.J.V.; Freitas, L.D.; Carmona, J.P.S.F. Effect of Soil Type on the Enzymatic Calcium Carbonate Precipitation Process Used for Soil Improvement. J. Mater. Civ. Eng. 2017, 29, 04016263. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, K.; Zhang, C.; Zhao, Z. Mechanical properties of Na-montmorillonite-modified EICP-treated silty sand. Environ. Sci. Pollut. Res. 2022, 29, 10332–10344. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, V.; Khodadadi Tirkolaei, H.; Martin, K.; Hamdan, N.; Van Paassen, L.A.; Kavazanjian, E., Jr. Variability in the Unconfined Compressive Strength of EICP-Treated “Standard” Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 06021001. [Google Scholar] [CrossRef]

- Hamdan, N.; Zhao, Z.; Mujica, M.; Kavazanjian, E.; He, X. Hydrogel-Assisted Enzyme-Induced Carbonate Mineral Precipitation. J. Mater. Civ. Eng. 2016, 28, 04016089. [Google Scholar] [CrossRef]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based methods for ecofriendly stabilization of different types of natural sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Hosseinpour, I.; Almeida, M.S.S.; Riccio, M.; Baroni, M. Strength and Compressibility Characteristics of a Soft Clay Subjected to Ground Treatment. Geotech. Geol. Eng. 2017, 35, 1051–1066. [Google Scholar] [CrossRef]

- Rezaei, M.; Ajalloeian, R.; Ghafoori, M. Geotechnical Properties of Problematic Soils Emphasis on Collapsible Cases. Int. J. Geosci. 2012, 3, 105–110. [Google Scholar] [CrossRef]

- Yilmaz, I.; Civelekoglu, B. Gypsum: An additive for stabilization of swelling clay soils. Appl. Clay Sci. 2009, 44, 166–172. [Google Scholar] [CrossRef]

- Tang, A.; Cui, Y.; Trinh, V.; Szerman, Y.; Marchadier, G. Analysis of the railway heave induced by soil swelling at a site in southern France. Eng. Geol. 2009, 106, 68–77. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Lu, L.; Fan, W.; Ge, S.; Liew, R.K.; Shi, Y.; Dou, H.; Wang, S.; Lam, S.S. Progress in recycling and valorization of waste silk. Sci. Total Environ. 2022, 830, 154812. [Google Scholar] [CrossRef] [PubMed]

- Tajdini, M.; Nabizadeh, A.; Taherkhani, H.; Zartaj, H. Effect of Added Waste Rubber on the Properties and Failure Mode of Kaolinite Clay. Int. J. Civ. Eng. 2017, 15, 949–958. [Google Scholar] [CrossRef]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, J.; Chen, X.; Wang, X.; Jia, Y. Experimental investigation on static and dynamic characteristics of granulated rubber-sand mixtures as a new railway subgrade filler. Constr. Build. Mater. 2021, 273, 121955. [Google Scholar] [CrossRef]

- Ho, M.-H.; Chan, C.-M.; Bakar, I. One Dimensional Compressibility Characteristics of Clay Stabilised with Cement-Rubber Chips. Int. J. Sustain. Constr. Eng. Technol. 2010, 1, 91–104. [Google Scholar]

- Cui, M.J.; Zheng, J.J.; Dahal, B.K.; Lai, H.J.; Huang, Z.F.; Wu, C.C. Effect of waste rubber particles on the shear behaviour of bio-cemented calcareous sand. Acta Geotech. 2021, 16, 1429–1439. [Google Scholar] [CrossRef]

- Chen, Y.; Chai, S.; Cai, D.; Wang, W.; Li, X.; Liu, J. Experimental study on shear mechanical properties of improved loess based on rubber particle incorporation and EICP technology. Front. Earth Sci. 2023, 11, 1270102. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E.; Hamdan, N. Enzyme Induced Biocementated Sand with High Strength at Low Carbonate Content. Sci. Rep. 2019, 9, 1135. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, R.; Pires, I.; Duarte, S.O.D.; Monteiro, G.A. Effects of clay’s chemical interactions on biocementation. Appl. Clay Sci. 2018, 156, 96–103. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Choi, S.; Park, S.; Wu, S.; Chu, J. Methods for Calcium Carbonate Content Measurement of Biocemented Soils. J. Mater. Civ. Eng. 2017, 29, 06017015. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- ASTM D7181; Standard Test Method for Consolidated Drained Triaxial Compression Test for Soils. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM: West Conshohocken, PA, USA, 2011.

- ASTM D5084-16; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM: West Conshohocken, PA, USA, 2016.

- Kim, H.; Santamarina, J.C. Sand–rubber mixtures (large rubber chips). Can. Geotech. J. 2008, 45, 1457–1466. [Google Scholar] [CrossRef]

- Gao, M.; Jin, X.; Zhao, T.; Li, H.; Zhou, L. Study on the strength mechanism of red clay improved by waste tire rubber powder. Case Stud. Constr. Mater. 2022, 17, e01416. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. A study on the potential utilization of crumb rubber in cement treated soft clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Zhao, Y.; Meng, F.; Fan, P.; Li, H.; Niu, Y.; Liu, P. Surface improvement of scrap rubber by microbially induced carbonate precipitation and its effect on mechanical behavior of rubberised mortar. Constr. Build. Mater. 2022, 323, 126526. [Google Scholar] [CrossRef]

- Cui, M.; Zheng, J.; Zhang, R.; Lai, H.; Zhang, J. Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar] [CrossRef]

- An, R.; Gao, H.; Zhang, X.; Chen, X.; Wang, Y.; Xu, H. Mechanical behaviour and microstructure of granite residual bio-cemented soil by microbially induced calcite precipitation with different cementation–solution concentrations. Environ. Earth Sci. 2024, 83, 31. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Yin, Z.; Liang, Z. DEM modeling of large-scale triaxial test of rock clasts considering realistic particle shapes and flexible membrane boundary. Eng. Geol. 2020, 279, 105871. [Google Scholar] [CrossRef]

- Tajabadipour, M.; Marandi, M. Effect of Rubber Tire Chips-Sand Mixtures on Performance of Geosynthetic Reinforced Earth Walls. Period. Polytech. Civil Eng. 2016, 61, 322. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Effect of waste rubber fibres on the geotechnical properties of clay stabilized with cement. Appl. Clay Sci. 2017, 149, 97–110. [Google Scholar] [CrossRef]

- Yeo, J.Y.; Kim, S.Y.; Lee, J. Compressibility and small strain stiffness characteristics of silt-hematite mixtures. Eng. Geol. 2023, 325, 107282. [Google Scholar] [CrossRef]

- Soltani, A.; Taheri, A.; Deng, A.; O’Kelly, B.C. Improved Geotechnical Behavior of an Expansive Soil Amended with Tire-Derived Aggregates Having Different Gradations. Minerals 2020, 10, 923. [Google Scholar] [CrossRef]

- Lopera Perez, J.C.; Kwok, C.Y.; Senetakis, K. Micromechanical analyses of the effect of rubber size and content on sand-rubber mixtures at the critical state. Geotext. Geomembr. 2017, 45, 81–97. [Google Scholar] [CrossRef]

- Choo, H.; Burns, S.E. Shear wave velocity of granular mixtures of silica particles as a function of finer fraction, size ratios and void ratios. Granul. Matter 2015, 17, 567–578. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, J.; Hoang, Q.N.; Park, J. Effect of ocean environmental particles on compressibility, electrical resistivity, and stiffness characteristics of mixtures. Eng. Geol. 2022, 304, 106675. [Google Scholar] [CrossRef]

- Choo, H.; Hwang, J.; Choi, Y.; Lee, C.; Lee, W. Geotechnical Characteristics of Volcanic Beach Sands with Varying Iron Contents. Mar. Georesources Geotechnol. 2016, 34, 571–580. [Google Scholar] [CrossRef]

- Larrahondo, J.M.; Choo, H.; Burns, S.E. Laboratory-prepared iron oxide coatings on sands: Submicron-scale small-strain stiffness. Eng. Geol. 2011, 121, 7–17. [Google Scholar] [CrossRef]

- Kim, S.Y.; Hong, W.; Lee, J. Silt fraction effects of frozen soils on frozen water content, strength, and stiffness. Constr. Build. Mater. 2018, 183, 565–577. [Google Scholar] [CrossRef]

- Ajmera, B.; Tiwari, B.; Koirala, J.; Obaid, Z. Compaction Characteristics, Unconfined Compressive Strengths, and Coefficients of Permeability of Fine-Grained Soils Mixed with Crumb-Rubber Tire. J. Mater. Civ. Eng. 2017, 29, 04017148. [Google Scholar] [CrossRef]

- Kalkan, E. Preparation of scrap tire rubber fiber–silica fume mixtures for modification of clayey soils. Appl. Clay Sci. 2013, 80–81, 117–125. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, Y.; Liu, S.; Guo, W.; Xu, F. Mechanical behaviour and permeability of expansive soils mixed with scrap tire rubbers subjected to freeze-thaw cycles. Cold Reg. Sci. Technol. 2022, 199, 103580. [Google Scholar] [CrossRef]

| Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Specific Gravity |

|---|---|---|---|

| 42.80 | 24.06 | 18.74 | 2.69 |

| Component | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | K2O | TiO2 | Na2O | P2O5 | SrO | Rb2O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass (%) | 52.96 | 18.75 | 11.80 | 7.36 | 3.86 | 3.42 | 0.79 | 0.40 | 0.21 | 0.05 | 0.01 |

| Group | Rubber Content (%) | Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|---|

| CR0 | 0 | 24.42 | 1.59 |

| CRA2.5 | 2.5 | 23.45 | 1.55 |

| CRA5 | 5 | 23.06 | 1.51 |

| CRA7.5 | 7.5 | 22.72 | 1.5 |

| CRA10 | 10 | 21.00 | 1.48 |

| CRB2.5 | 2.5 | 22.90 | 1.56 |

| CRB5 | 5 | 22.28 | 1.48 |

| CRB7.5 | 7.5 | 21.17 | 1.45 |

| CRB10 | 10 | 20.33 | 1.42 |

| CRC2.5 | 2.5 | 22.74 | 1.55 |

| CRC5 | 5 | 22.71 | 1.55 |

| CRC7.5 | 7.5 | 22.09 | 1.53 |

| CRC10 | 10 | 21.09 | 1.49 |

| Group | Rubber Content (%) | CaCO3 Content (%) | CaCO3 Conversion Rate (%) |

|---|---|---|---|

| CR0 | 0 | 0.69 | 70.31 |

| CRA2.5 | 2.5 | 0.649 | 68.33 |

| CRA5 | 5 | 0.638 | 68.09 |

| CRA7.5 | 7.5 | 0.56 | 60.49 |

| CRA10 | 10 | 0.5 | 57.61 |

| CRB2.5 | 2.5 | 0.61 | 65.47 |

| CRB5 | 5 | 0.592 | 64.98 |

| CRB7.5 | 7.5 | 0.52 | 59.52 |

| CRB10 | 10 | 0.48 | 56.82 |

| CRC2.5 | 2.5 | 0.601 | 64.87 |

| CRC5 | 5 | 0.59 | 63.75 |

| CRC7.5 | 7.5 | 0.53 | 58.58 |

| CRC10 | 10 | 0.49 | 56.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Li, M.; Zeng, C.; Shu, H.; Xi, L.; Tao, Y.; Lu, X. Effect of Rubber Particle Size and Content on the Mechanical Properties of Rubber–Clay Mixtures Solidified by EICP. Materials 2025, 18, 3429. https://doi.org/10.3390/ma18153429

Ma Q, Li M, Zeng C, Shu H, Xi L, Tao Y, Lu X. Effect of Rubber Particle Size and Content on the Mechanical Properties of Rubber–Clay Mixtures Solidified by EICP. Materials. 2025; 18(15):3429. https://doi.org/10.3390/ma18153429

Chicago/Turabian StyleMa, Qiang, Meng Li, Chen Zeng, Hang Shu, Lei Xi, Yue Tao, and Xuesong Lu. 2025. "Effect of Rubber Particle Size and Content on the Mechanical Properties of Rubber–Clay Mixtures Solidified by EICP" Materials 18, no. 15: 3429. https://doi.org/10.3390/ma18153429

APA StyleMa, Q., Li, M., Zeng, C., Shu, H., Xi, L., Tao, Y., & Lu, X. (2025). Effect of Rubber Particle Size and Content on the Mechanical Properties of Rubber–Clay Mixtures Solidified by EICP. Materials, 18(15), 3429. https://doi.org/10.3390/ma18153429