Microstructure and Mechanical Properties of AlCoCrFeNi High-Entropy Alloy-Reinforced Ti-6Al-4V Composites

Highlights

- An interdiffusion (ID) layer forms among HEA reinforcements and the Ti-6Al-4V metal matrix.

- Coherent metallurgical bonding exists among the reinforcements and matrix.

- The micro-mechanical properties of the ID layer are inferior to that of the reinforcements and matrix.

Abstract

1. Introduction

2. Experimental

2.1. HEA Particle Reinforced MMC Fabrication

2.2. Specimen Preparation for Microscopy

2.3. Micro-Pillar Fabrication and Compression in SEM

3. Results and Discussion

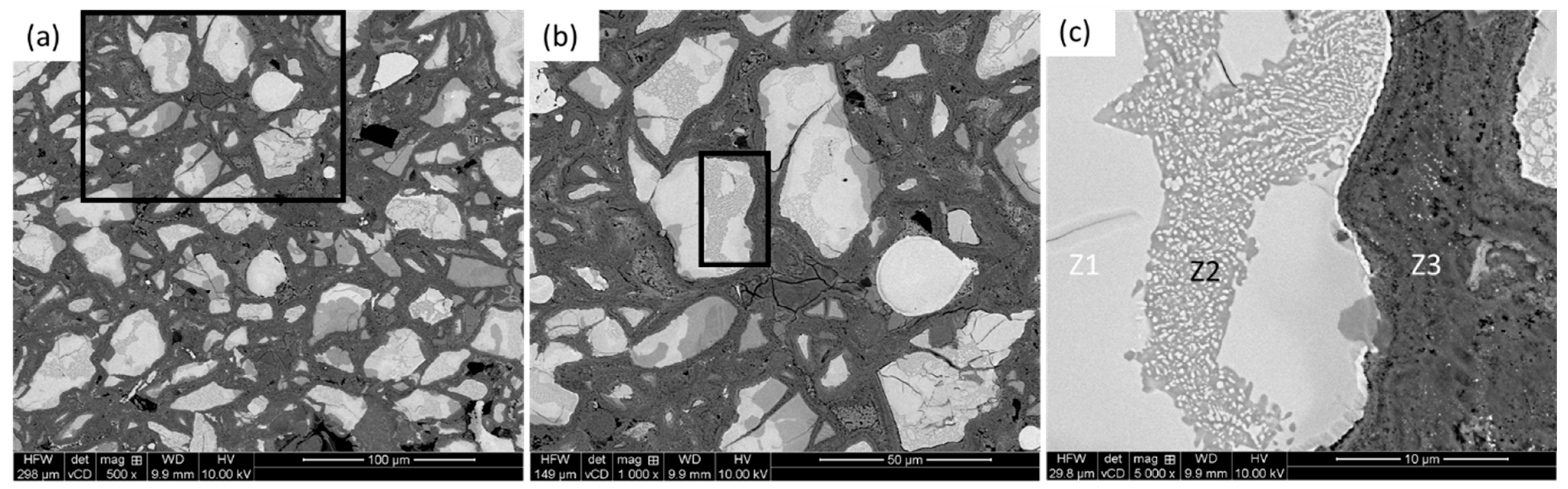

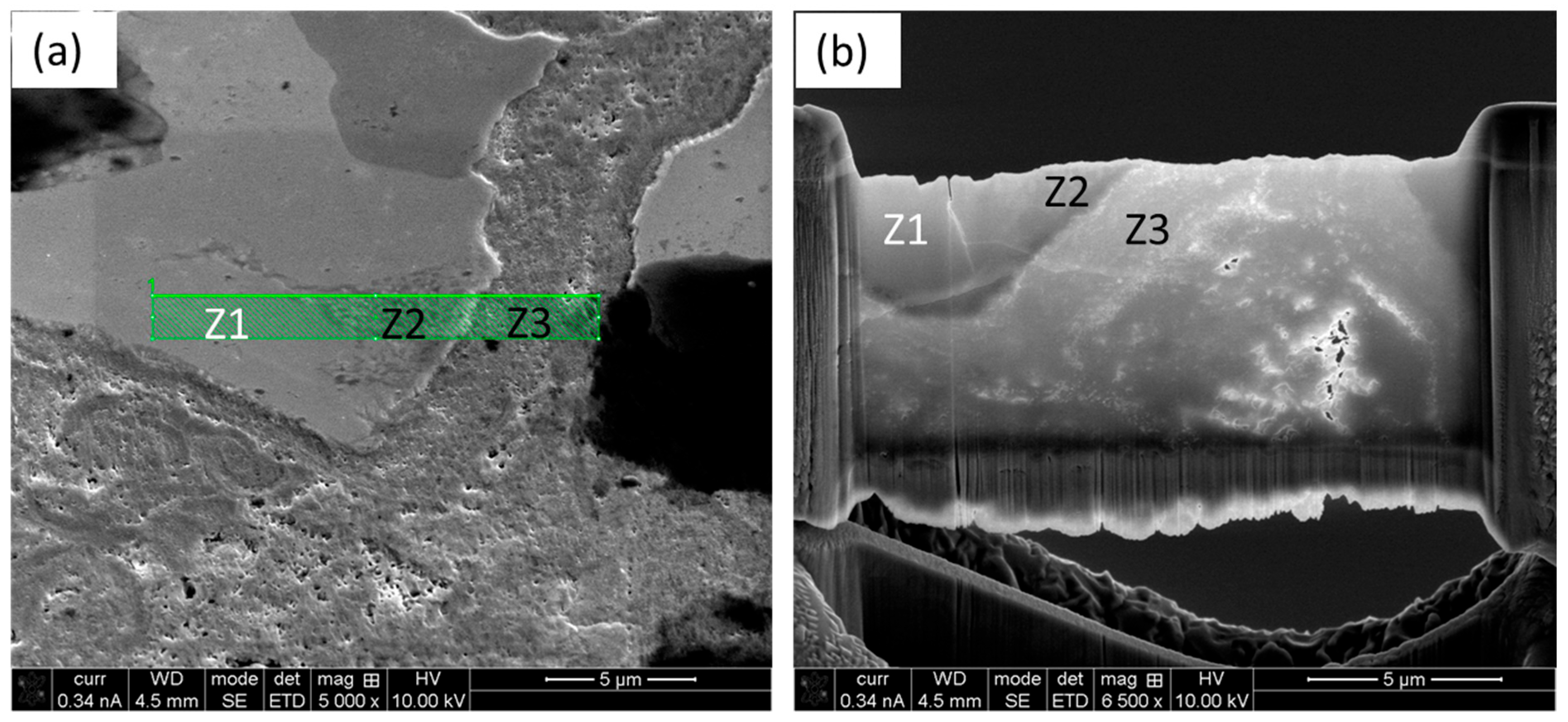

3.1. Microstructural Investigation by Scanning Electron Microscopy (SEM)

3.2. Microstructural Investigation by Transmission Electron Microscopy (TEM)

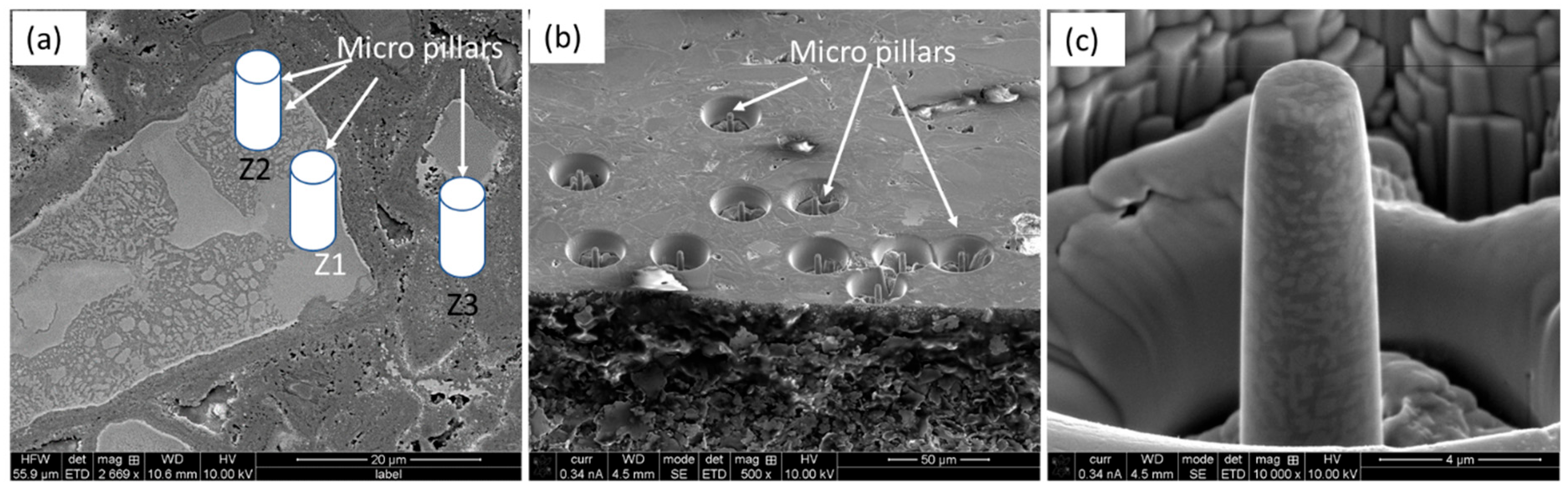

3.3. Mechanical Properties Investigation by Micro-Pillar Compression

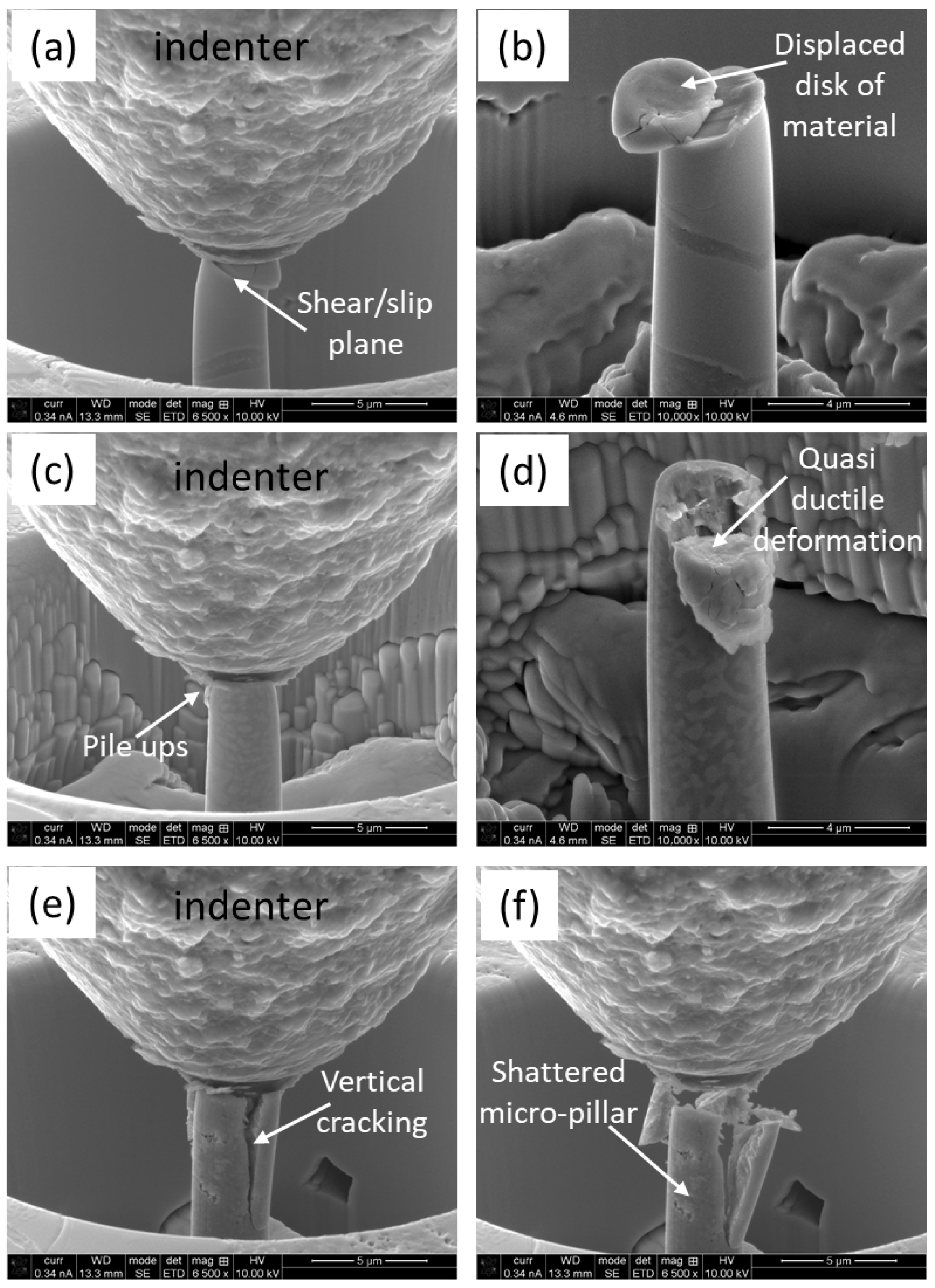

3.4. Deformation of Micro-Pillars During Compression

4. Deformation and Strengthen Mechanism

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Mattern, A.; Huchler, B.; Staudenecker, D.; Oberacker, R.; Nagel, A.; Hoffmann, M. Preparation of interpenetrating ceramic–metal composites. J. Eur. Ceram. Soc. 2004, 24, 3399–3408. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, G. Surface modification of Ti6Al4V alloy via advanced coatings: Mechanical, tribological, corrosion, wetting, and biocompatibility studies. J. Alloys Compd. 2024, 989, 174418. [Google Scholar] [CrossRef]

- Kaczmar, J.; Pietrzak, K.; Włosiński, W. The production and application of metal matrix composite materials. J. Mater. Process. Technol. 2000, 106, 58–67. [Google Scholar] [CrossRef]

- Salur, E.; Acarer, M.; Şavkliyildiz, İ. Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Mater. Today Commun. 2021, 27, 102202. [Google Scholar] [CrossRef]

- Le, J.; Han, Y.; Qiu, P.; Huang, G.; Mao, J.; Lu, W. The impact of matrix texture and whisker orientation on property anisotropy in titanium matrix composites: Experimental and computational evaluation. Compos. Part B Eng. 2021, 212, 108682. [Google Scholar] [CrossRef]

- Pandey, A.B.; Kendig, K.L.; Watson, T.J. Affordable Metal-Matrix Composites for High Performance Applications II; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Hu, Q.; Zhao, H.; Li, F. Microstructures and properties of SiC particles reinforced aluminum-matrix composites fabricated by vacuum-assisted high pressure die casting. Mater. Sci. Eng. A 2017, 680, 270–277. [Google Scholar] [CrossRef]

- Hibi, Y.; Murakami, T.; Miyake, K.; Sasaki, S. Influence of Microstructure on the Wear Behavior of SiC-Reinforced Titanium-Matrix Composites Lubricated by Water and by Ethanol. J. Am. Ceram. Soc. 2008, 91, 508–513. [Google Scholar] [CrossRef]

- Basak, A.; Matteazzi, P.; Vardavoulias, M.; Celis, J.-P. Corrosion–wear behaviour of thermal sprayed nanostructured FeCu/WC–Co coatings. Wear 2006, 261, 1042–1050. [Google Scholar] [CrossRef]

- Basak, A.K.; Celis, J.-P.; Vardavoulias, M.; Matteazzi, P. Effect of nanostructuring and Al alloying on friction and wear behaviour of thermal sprayed WC–Co coatings. Surf. Coat. Technol. 2012, 206, 3508–3516. [Google Scholar] [CrossRef]

- Hong, S.-J.; Kim, H.-M.; Huh, D.; Suryanarayana, C.; Chun, B.S. Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater. Sci. Eng. A 2003, 347, 198–204. [Google Scholar] [CrossRef]

- Chen, J.; Niu, P.; Wei, T.; Hao, L.; Liu, Y.; Wang, X.; Peng, Y. Fabrication and mechanical properties of AlCoNiCrFe high-entropy alloy particle reinforced Cu matrix composites. J. Alloys Compd. 2015, 649, 630–634. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Lu, T.; He, T.; Li, Z.; Chen, H.; Han, X.; Fu, Z.; Chen, W. Microstructure, mechanical properties and machinability of particulate reinforced Al matrix composites: A comparative study between SiC particles and high-entropy alloy particles. J. Mater. Res. Technol. 2020, 9, 13646–13660. [Google Scholar] [CrossRef]

- Yuan, Z.; Liu, H.; Ma, Z.; Ma, X.; Wang, K.; Zhang, X. Microstructure and properties of high entropy alloy reinforced titanium matrix composites. Mater. Charact. 2022, 187, 111856. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Wang, C.-W.; Tsai, C.-W.; Shen, W.-J.; Yeh, J.-W.; Gan, J.-Y.; Wu, W.-W. Thermal stability and performance of NbSiTaTiZr high-entropy alloy barrier for copper metallization. J. Electrochem. Soc. 2011, 158, H1161. [Google Scholar] [CrossRef]

- Ming, K.; Bi, X.; Wang, J. Precipitation strengthening of ductile Cr15Fe20Co35Ni20Mo10 alloys. Scr. Mater. 2017, 137, 88–93. [Google Scholar] [CrossRef]

- Mileiko, S.; Firstov, S.; Novokhatskaya, N.; Gorban, V.; Krapivka, N. Oxide-fibre/high-entropy-alloy-matrix composites. Compos. Part A Appl. Sci. Manuf. 2015, 76, 131–134. [Google Scholar] [CrossRef]

- Wu, H.; Han, Y.; Huang, G.; Zong, N.; Mao, J.; Shi, H.; Lu, W. Configuration of new fiber-like structure driven high matching of strength-ductility in TiB reinforced titanium matrix composites. Compos. Part B Eng. 2022, 231, 109564. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, L.; Lu, J.; Huo, W.; Du, Y.; Zhang, W.; Zhang, Y. Microstructure and mechanical properties of SiC nanowires reinforced titanium matrix composites. J. Alloys Compd. 2020, 819, 152953. [Google Scholar] [CrossRef]

- Pandey, V.; Seetharam, R.; Chelladurai, H. A comprehensive review: Discussed the effect of high-entropy alloys as reinforcement on metal matrix composite properties, fabrication techniques, and applications. J. Alloys Compd. 2024, 1002, 175095. [Google Scholar] [CrossRef]

- Ahmady, A.R.; Ekhlasi, A.; Nouri, A.; Nazarpak, M.H.; Gong, P.; Solouk, A. High entropy alloy coatings for biomedical applications: A review. Smart Mater. Manuf. 2023, 1, 100009. [Google Scholar]

- Karthik, G.; Panikar, S.; Ram, G.J.; Kottada, R.S. Additive manufacturing of an aluminum matrix composite reinforced with nanocrystalline high-entropy alloy particles. Mater. Sci. Eng. A 2017, 679, 193–203. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Wang, F.; Meng, X.; Wan, L.; Dong, Z.; Huang, Y. Friction stir processing of high-entropy alloy reinforced aluminum matrix composites for mechanical properties enhancement. Mater. Sci. Eng. A 2020, 792, 139755. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Li, Z.; Wang, X.; Fan, X.; Liu, J. Formation of transition layer and its effect on mechanical properties of AlCoCrFeNi high-entropy alloy/Al composites. J. Alloys Compd. 2019, 780, 558–564. [Google Scholar] [CrossRef]

- Yuan, Z.; Tian, W.; Li, F.; Fu, Q.; Hu, Y.; Wang, X. Microstructure and properties of high-entropy alloy reinforced aluminum matrix composites by spark plasma sintering. J. Alloys Compd. 2019, 806, 901–908. [Google Scholar] [CrossRef]

- Li, G.; Wen, H.; Wang, H.; Ren, W.; Yan, Y.; Chen, J.; Wang, C.; Zhao, Y. Microstructural characteristics and mechanical behavior of microwave-assisted sintered ferromagnetic FeCoNi1.5CrCu HEAp/Al matrix composites. J. Alloys Compd. 2021, 861, 158439. [Google Scholar]

- Xiong, Y.; Zhang, F.; Huang, Y.; Shang, C.; Wan, Q. Multiple strengthening via high-entropy alloy particle addition in titanium matrix composites fabricated by spark plasma sintering. Mater. Sci. Eng. A 2022, 859, 144235. [Google Scholar] [CrossRef]

- Wang, Z.-w.; Yuan, Y.-b.; Zheng, R.-x.; Ameyama, K. Microstructures and mechanical properties of extruded 2024 aluminum alloy reinforced by FeNiCrCoAl3 particles. Trans. Nonferrous Met. Soc. China 2014, 24, 2366–2373. [Google Scholar] [CrossRef]

- Satyanarayanaraju, C.V.; Dixit, R.; Miryalkar, P.; Karunanidhi, S.; AshokKumar, A.; NagaLakshmi, J.; Ramakrishna, U.; Mounika, R.; Saipavan, P. Effect of heat treatment on microstructure and properties of high entropy alloy reinforced titanium metal matrix composites. Mater. Today Proc. 2019, 18, 2409–2414. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, B.; Liu, Y.; Fang, Q.; Guo, W.; Yang, H. Effects of annealing on microstructure and mechanical properties of metastable powder metallurgy CoCrFeNiMo0.2 high entropy alloy. Entropy 2019, 21, 448. [Google Scholar] [CrossRef]

- Qiang, F.; Xin, S.; Guo, P.; Hou, H.; Wang, J.; Hou, W. Formation mechanism of interdiffusion layer and mechanical properties of Al0.6CoCrFeNi high-entropy alloy/Ti composites. J. Alloys Compd. 2023, 943, 169151. [Google Scholar] [CrossRef]

- Mandapalli, M.; Akhil, U.; Radhika, N.; Rajeshkumar, L. Comprehensive investigation of microwave sintered AlCoCrFeNi/Ti-6Al-4V composite: Microstructural insights, mechanical properties, and tribological performance. Alex. Eng. J. 2024, 104, 246–260. [Google Scholar] [CrossRef]

- Basak, A.K.; Kurdi, A.; Radhika, N.; Arputharaj, J.; Prakash, C.; Pramanik, A.; Shankar, S. Compressive mechanical properties of thermal sprayed AlCoCrFeNi high entropy alloy coating. J. Alloys Compd. 2024, 1003, 175721. [Google Scholar] [CrossRef]

- Kurdi, A.; Basak, A. Deformation of electrodeposited gradient Co/Sn multilayered coatings under micro-pillar compression. Eng. Fract. Mech. 2018, 204, 138–146. [Google Scholar] [CrossRef]

- Kurdi, A.; Basak, A. Micro-mechanical behaviour of selective laser melted Ti6Al4V under compression. Mater. Sci. Eng. A 2021, 826, 141975. [Google Scholar] [CrossRef]

- Kurdi, A.; Zaman, A.; Alsolami, A.; Alshabouna, F.; Degnah, A.; Alfihed, S.; Alnaser, H.; Tabbakh, T. Effect of manufacturing route on microstructure and micromechanical properties of AlCoCrFeNi high entropy alloy. J. Alloys Compd. 2025, 1010, 177477. [Google Scholar] [CrossRef]

- Nandihalli, N.; Gregory, D.H.; Mori, T. Energy-saving pathways for thermoelectric nanomaterial synthesis: Hydrothermal/solvothermal, microwave-assisted, solution-based, and powder processing. Adv. Sci. 2022, 9, 2106052. [Google Scholar] [CrossRef]

- Shukla, A.; Mondal, A.; Upadhyaya, A. Numerical modeling of microwave heating. Sci. Sinter. 2010, 42, 99–124. [Google Scholar] [CrossRef]

- Wang, J.; Stanford, N. Investigation of precipitate hardening of slip and twinning in Mg5% Zn by micropillar compression. Acta Mater. 2015, 100, 53–63. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Lei, S.; Niu, J.; Sun, J. Transition from homogeneous-like to shear-band deformation in nanolayered crystalline Cu/amorphous Cu–Zr micropillars: Intrinsic vs. extrinsic size effect. Acta Mater. 2012, 60, 7183–7196. [Google Scholar] [CrossRef]

- Kurdi, A.; Alshihri, S.; Tabbakh, T.; Darwish, N.B.; Saedon, J.B.; Basak, A.K. Compressive strength and deformation behavior of the hybrid S phase layer under micro-pillar compression. Mater. Sci. Eng. A 2022, 861, 144380. [Google Scholar] [CrossRef]

- Tabbakh, T.; Alshihri, S.; Basak, A.; Kurdi, A. Strength of a 3D printed Al 7068 alloy under micro-pillar compression. Met. Mater. Int. 2022, 28, 2706–2718. [Google Scholar] [CrossRef]

- Kiener, D.; Motz, C.; Dehm, G. Micro-compression testing: A critical discussion of experimental constraints. Mater. Sci. Eng. A 2009, 505, 79–87. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.; Hoagland, R. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Girault, B.; Schneider, A.S.; Frick, C.P.; Arzt, E. Strength effects in micropillars of a dispersion strengthened superalloy. Adv. Eng. Mater. 2010, 12, 385–388. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, F.; Chen, S.; Cao, W. Computational thermodynamics aided high-entropy alloy design. JOM 2012, 64, 839–845. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Yi, H.; Qi, W.; Peng, Q. Effect of molybdenum additives on corrosion behavior of (CoCrFeNi)100−xMox high-entropy alloys. Entropy 2018, 20, 908. [Google Scholar] [CrossRef]

- Cao, G.; Gao, M.; Ma, M.; Chen, C.; Guo, M.; Zhang, B.; Hu, J. Chemical regulation of smart coating under high temperature marine environment: An in-situ bonding reorganization process. Chem. Eng. J. 2025, 516, 164159. [Google Scholar] [CrossRef]

- Kang, L.; Yang, C. A review on high-strength titanium alloys: Microstructure, strengthening, and properties. Adv. Eng. Mater. 2019, 21, 1801359. [Google Scholar] [CrossRef]

- Basak, A.K.; Radhika, N.; Prakash, C.; Pramanik, A. Investigation on the microstructure and micro-mechanical properties of thermal-sprayed NiCoCrAlY high entropy alloy coating. Designs 2024, 8, 37. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, H.; Dong, P.; Yan, Z.; Wang, W. A study on the formation of multiple intermetallic compounds of friction stir processed high entropy alloy particles reinforced Al matrix composites. Mater. Charact. 2022, 183, 111646. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Liu, J.; Zhang, P.; Wang, Y. Core-shell structure mediated microstructure and mechanical properties of high entropy alloy CoCrFeNi/Al composites. Vacuum 2021, 192, 110454. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Gu, H.; Li, R.; Chen, P.; Kong, C.; Yu, H. Insight of high-entropy alloy particles-reinforced 2219 Al matrix composites via the ultrasonic casting technology. Mater. Charact. 2021, 182, 111548. [Google Scholar] [CrossRef]

- Du, G.; Li, C.; Li, J.; Wu, G.; Huang, Z.; Mao, A.; Ma, M.; Guo, Z.; Chen, Z. Research progress on high entropy oxide ceramics: Principles, preparation, and properties. J. Mater. Res. Technol. 2025, 35, 265–288. [Google Scholar] [CrossRef]

- Noble, N.; Radhika, N.; Sathishkumar, M.; Basak, A. Slurry erosion behaviour of AlCoCrFeNi high entropy alloy coating prepared by atmospheric plasma spraying. Trans. IMF 2024, 102, 161–168. [Google Scholar] [CrossRef]

- Basak, A.; Pramanik, A.; Prakash, C. Deformation and strengthening of SiC reinforced Al-MMCs during in-situ micro-pillar compression. Mater. Sci. Eng. A 2019, 763, 138141. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Wang, Y.; Chen, G. Solid solution alloys of AlCoCrFeNiTix with excellent room-temperature mechanical properties. Appl. Phys. Lett. 2007, 90, 181904. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Yu, Y.; Zhang, Z.; Zhu, S.; Wang, Z. Ti content effect on microstructure and mechanical properties of plasma-cladded CoCrFeMnNiTix high-entropy alloy coatings. Surf. Topogr. Metrol. Prop. 2020, 8, 015004. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Yu, Y.; Zhang, Z.; Zhu, S.; Lou, X.; Wang, Z. Study of high temperature friction and wear performance of (CoCrFeMnNi)85Ti15 high-entropy alloy coating prepared by plasma cladding. Surf. Coat. Technol. 2020, 384, 125337. [Google Scholar] [CrossRef]

| Different Zones in the Composite | Yield Strength (σy), MPa | Ultimate Compressive Strength (σUTS), MPa | Elastic Modulus (E), MPa |

|---|---|---|---|

| HEA particle (Z1) | 2157 ± 107 | 3356 ± 126 | 643 ± 36 |

| Interdiffusion (ID) layer (Z2) | 1573 ± 98 | 1867 ± 103 | 570 ± 34 |

| Matrix (Z3) | 2372 ± 118 | 2661 ± 172 | 721 ± 42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurdi, A.; Basak, A.K.; Radhika, N.; Degnah, A. Microstructure and Mechanical Properties of AlCoCrFeNi High-Entropy Alloy-Reinforced Ti-6Al-4V Composites. Materials 2025, 18, 3179. https://doi.org/10.3390/ma18133179

Kurdi A, Basak AK, Radhika N, Degnah A. Microstructure and Mechanical Properties of AlCoCrFeNi High-Entropy Alloy-Reinforced Ti-6Al-4V Composites. Materials. 2025; 18(13):3179. https://doi.org/10.3390/ma18133179

Chicago/Turabian StyleKurdi, Abdulaziz, Animesh Kumar Basak, Nachimuthu Radhika, and Ahmed Degnah. 2025. "Microstructure and Mechanical Properties of AlCoCrFeNi High-Entropy Alloy-Reinforced Ti-6Al-4V Composites" Materials 18, no. 13: 3179. https://doi.org/10.3390/ma18133179

APA StyleKurdi, A., Basak, A. K., Radhika, N., & Degnah, A. (2025). Microstructure and Mechanical Properties of AlCoCrFeNi High-Entropy Alloy-Reinforced Ti-6Al-4V Composites. Materials, 18(13), 3179. https://doi.org/10.3390/ma18133179