Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations

Abstract

1. Introduction

2. Prevailing Trend in the Application of NDT Methods to Composite Materials

2.1. Ultrasonic-Based Testing Methods Testing

2.1.1. Ultrasonic Testing (UT)

2.1.2. Ultrasonic Phased Array Ultrasonic Testing (PAUT)

2.2. Electromagnetic-Based Testing Methods

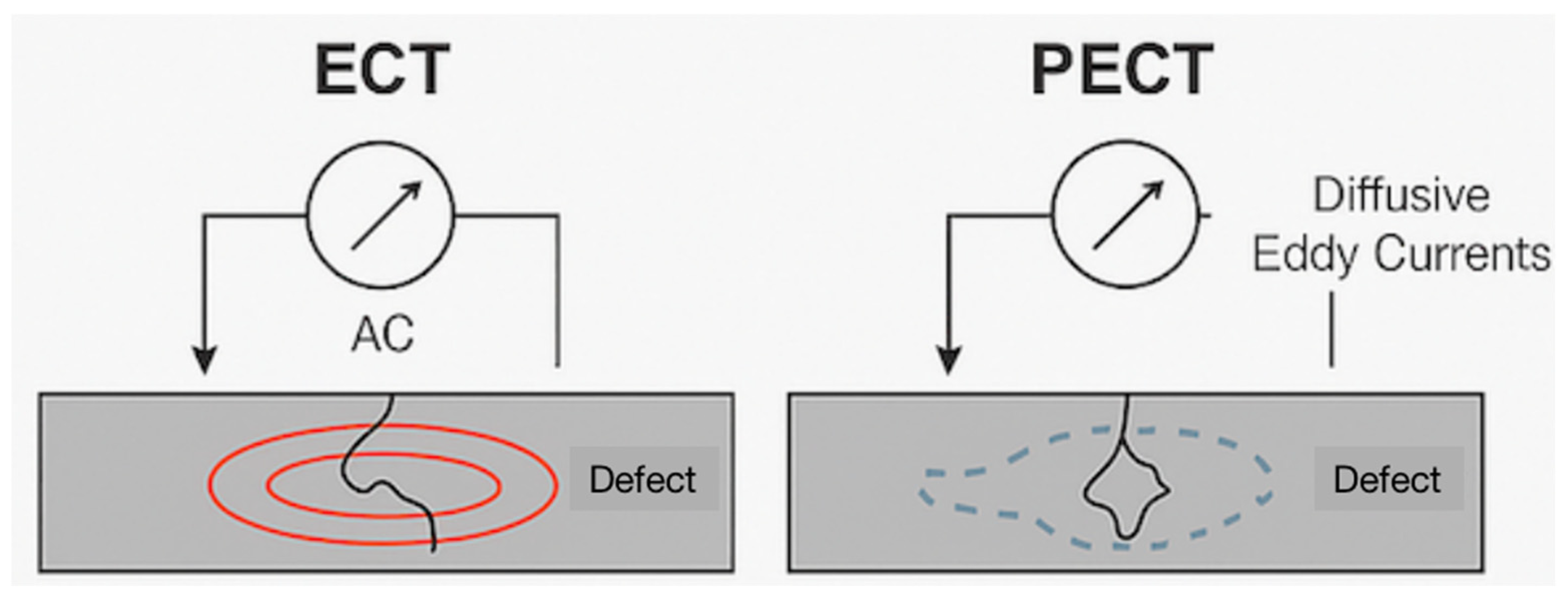

2.2.1. Eddy Current Testing (ECT)

2.2.2. Pulse Eddy Current Testing (PECT)

2.3. Acoustic Emission (AET)

2.4. Thermography (TR) and Infrared Thermography (IRT)

2.5. Microwave (MW)

2.6. Radiographic-Based Testing Methods

2.6.1. Radiography Testing (RT)

2.6.2. Digital Radiography Testing (DRT)

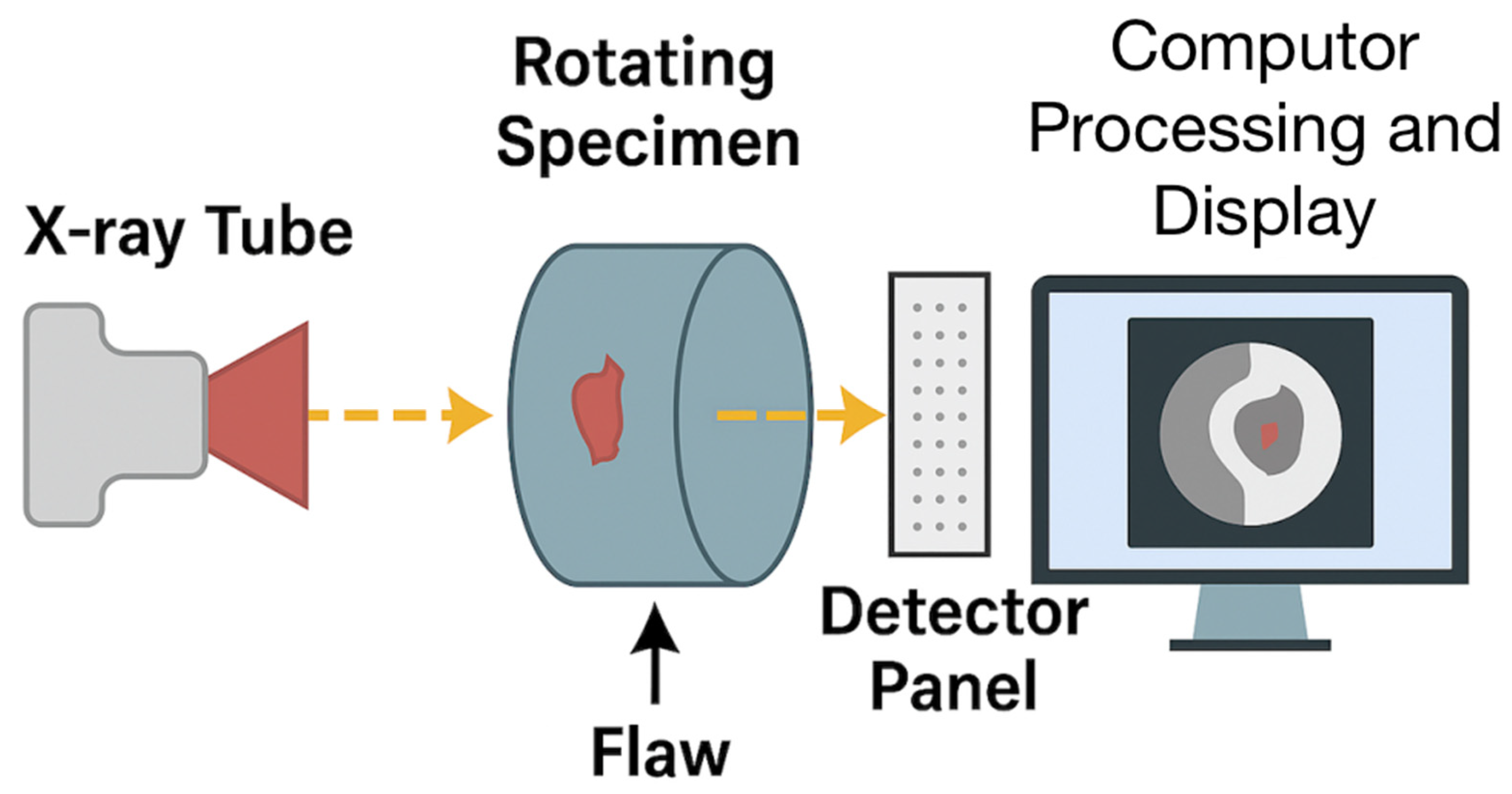

2.6.3. X-Ray Tomography (XCT)

2.7. Comparative Classification of NDT Techniques

3. Literature Review Summary and Key Findings

3.1. Dominance of Ultrasonic and Thermographic Methods

3.2. Emerging but Underutilized Methods

3.3. Summary of Reported Frequency and Key Insights

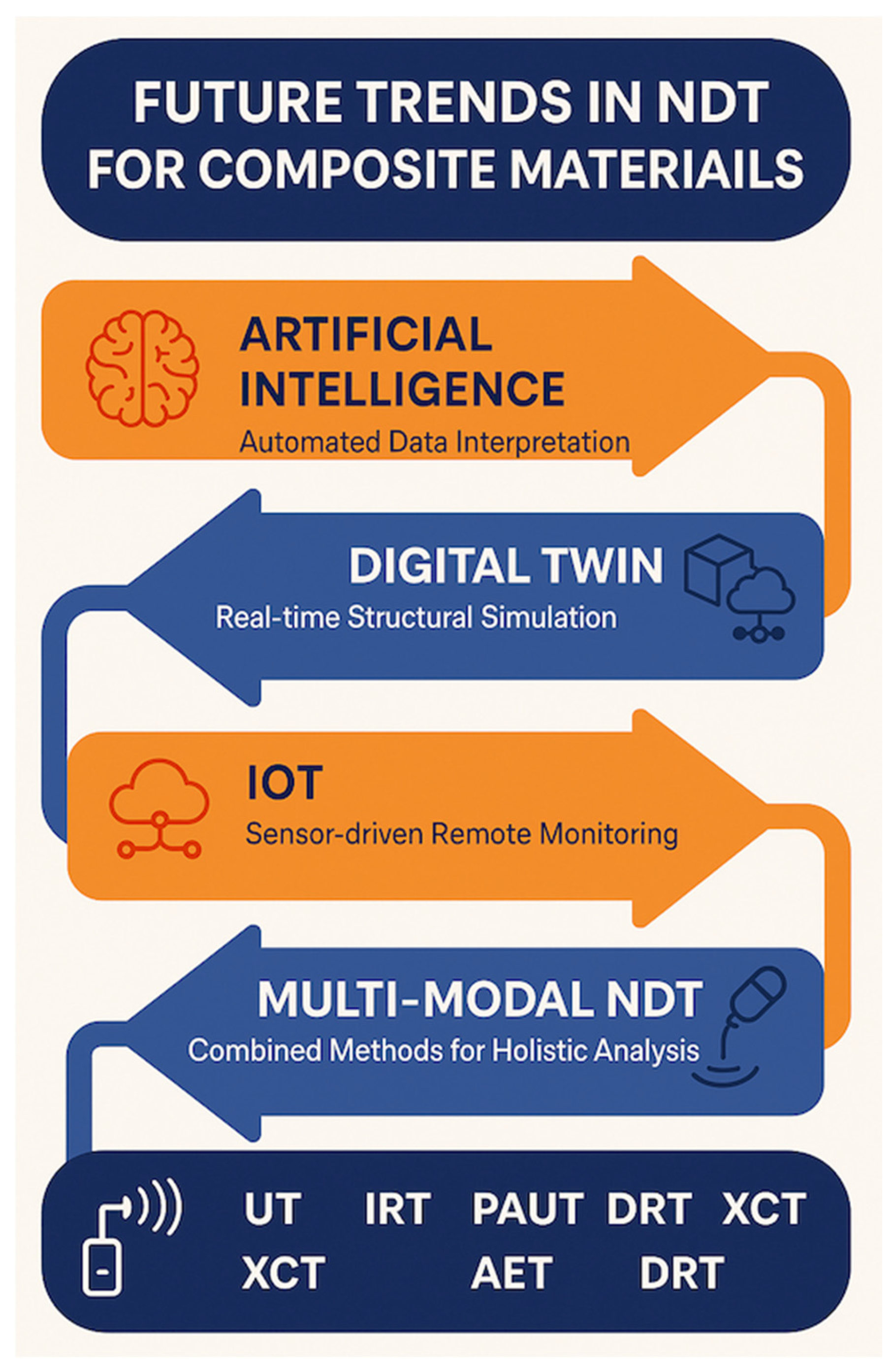

4. Perspective on Future Trends and Potential Applications

4.1. Adoption of Multimodal and Hybrid NDT Systems

4.2. Digital Twin and Industry 4.0 Integration

4.3. Embedded and Wireless Structural Health Monitoring

4.4. Artificial Intelligence and Automated Defect Interpretation

4.5. Environmentally Friendly and Operator-Safe Techniques

4.6. Standardization and Industrial Certification

5. Conclusions

- No single NDT method is universally sufficient for all composite material challenges.

- Multimodal and hybrid NDT approaches offer the most comprehensive defect-detection capability.

- The integration of NDT with Industry 4.0 technologies, such as digital twins and real-time SHM, represents the next frontier.

- AI and ML have shown significant potential for automating defect recognition and improving data analysis reliability.

- Environmentally friendly and operator-safe alternatives such as MW and ECT should be further explored and promoted.

- A major gap exists in the standardization and certification of advanced NDT methods, which require collaborative efforts among industry, academia, and regulatory bodies.

Future Outlook

- Advancing hybrid inspection systems that combine the strengths of multiple methods.

- Developing AI-powered analytics for real-time defect interpretation.

- Promoting sustainable and safe inspection methods.

- Establishing internationally recognized standards and certification protocols to ensure consistency and industry-wide adoption.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saghir, F.; Gohari, S.; Mozafari, F.; Moslemi, N.; Burvill, C.; Smith, A.; Lucas, S. Mechanical Characterization of Particulated FRP Composite Pipes: A Comprehensive Experimental Study. Polym. Test. 2021, 93, 107001. [Google Scholar] [CrossRef]

- Ur Rahman, M.S.; Haryono, A.; Abou-Khousa, M.A. Microwave Non-Destructive Evaluation of Glass Reinforced Epoxy and High Density Polyethylene Pipes. J. Nondestruct. Eval. 2020, 39, 26. [Google Scholar] [CrossRef]

- Towsyfyan, H.; BiguriI, A.; Boardman, R.; Blumensath, T. Successes and Challenges in Non-Destructive Testing of Aircraft Composite Structures. Chin. J. Aeronaut. 2020, 33, 771–791. [Google Scholar] [CrossRef]

- Gandhi, N.; Rose, R.; Croxford, A.J.; Ward, C. Understanding System Complexity in the Non-Destructive Testing of Advanced Composite Products. J. Manuf. Mater. Process. 2022, 6, 71. [Google Scholar] [CrossRef]

- Gholizadeh, S. A Review of Non-Destructive Testing Methods of Composite Materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Herrmann, H.; Schwarz, M.; Summa, J.; Grossmann, F. Non-Destructive Testing for Evaluation of Defects and Interfaces in Metal-Carbon Fiber Reinforced. Int. J. Mater. Metall. Eng. 2017, 11, 546–552. [Google Scholar]

- Sathawane, A.A.; Singh, D. Study on Non-Destructive Testing for Structural Analysis. Int. J. Technol. Res. Eng. 2021, 8, 6–11. [Google Scholar]

- Elkolali, M.; Nogueira, L.P.; Rønning, P.O.; Alcocer, A. Void Content Determination of Carbon Fiber Reinforced Polymers: A Comparison between Destructive and Non-Destructive Methods. Polymers 2022, 14, 1212. [Google Scholar] [CrossRef]

- Ferreira, C.G.; Lopes, R.T.; dos Santos, T.M.P.; Oliveira, D.F.; Martins, F.D.F.; Pereira, G.R. Non-Destructive Inspection of Laminated Pipe Joints in Polymeric Composite Material Reinforced by Fiberglass. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 954, 161154. [Google Scholar] [CrossRef]

- Chen, J.; Yu, Z.; Jin, H. Nondestructive Testing and Evaluation Techniques of Defects in Fiber-Reinforced Polymer Composites: A Review. Front. Mater. 2022, 9, 986645. [Google Scholar] [CrossRef]

- De Almeida, P.D.; Pereira, G.R. Phased Array Inspection of Glass Fiber Reinforced Polymers Pipeline Joints. J. Mater. Res. Technol. 2019, 8, 4736–4740. [Google Scholar] [CrossRef]

- Quinn, J.A.; Davidson, J.R.; Bajpai, A.; Ó Brádaigh, C.M.; McCarthy, E.D. Advanced Ultrasonic Inspection of Thick-Section Composite Structures for In-Field Asset Maintenance. Polymers 2023, 15, 3175. [Google Scholar] [CrossRef] [PubMed]

- Zhongbing, L.U.O.; Song, Z.; Hengkui, Q.; Huanqing, C.A.O.; Huimin, S.U.; Li, L.I.N. Modelling and Wave Propagation Behavior of Phased Array Ultrasonic Testing on Carbon Fiber. Acta Mater. Compos. Sin. 2020, 35, 2829–2838. [Google Scholar]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A Comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Chaki, S.; Krawczak, P. Non-Destructive Health Monitoring of Structural Polymer Composites: Trends and Perspectives in the Digital Era. Materials 2022, 15, 7838. [Google Scholar] [CrossRef]

- Torbali, M.E.; Zolotas, A.; Avdelidis, N.P. A State-of-the-Art Review of Non-Destructive Testing Image Fusion and Critical Insights on the Inspection of Aerospace Composites towards Sustainable Maintenance Repair Operations. Appl. Sci. 2023, 13, 2732. [Google Scholar] [CrossRef]

- Li, Z.; Meng, Z. A Review of the Radio Frequency Non-Destructive Testing for Carbon-Fibre Composites. Meas. Sci. Rev. 2016, 16, 68–76. [Google Scholar] [CrossRef]

- Suhasini, M.U.; Reddy, K.A. A Comprehensive Study on Defects Parameters of Ferrous and Composite Materials Using Non Destructive Testing Methods. Int. J. Res. Trends Innov. 2017, 2, 108–111. [Google Scholar]

- Zhang, X.; Cheng, L.; Liu, Y.; Tao, B.; Wang, J.; Liao, R. A Review of Non-Destructive Methods for the Detection Tiny Defects within Organic Insulating Materials. Front. Mater. 2022, 9, 995516. [Google Scholar] [CrossRef]

- Mohseni, E.; Javadi, Y.; Sweeney, N.E.; Lines, D.; MacLeod, C.N.; Vithanage, R.K.W.; Qiu, Z.; Vasilev, M.; Mineo, C.; Lukacs, P.; et al. Model-Assisted Ultrasonic Calibration Using Intentionally Embedded Defects for in-Process Weld Inspection. Mater. Des. 2021, 198, 109330. [Google Scholar] [CrossRef]

- Boukani, H.H. Evaluation of the Reliability of Nondestructive Ultrasonic Inspection Methods for the Detection and the Characterization of Defects in Hydroelectric Turbine Welded Joints. Ph.D. Thesis, Université du Québec, Quebec, QC, Canada, 2018. [Google Scholar]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Experimental Study on the Efficacy of Ultrasound in In-Situ Detection of Corrosion in Palm Oil Refining Equipment. J. Teknol. 2024, 86, 151–159. [Google Scholar] [CrossRef]

- Jiao, J.; Fan, Z.; Zhong, F.; He, C.; Wu, B. Application of Ultrasonic Methods for Early Detection of Intergranular Corrosion in Austenitic Stainless Steel. Res. Nondestruct. Eval. 2016, 27, 193–203. [Google Scholar] [CrossRef]

- Jadav, C.; Patel, S. Ultrasonic Testing for Determination Internal Flaws and Discontinuities in Metal Casting: A Review. Nat. Volatiles Essent. Oils 2021, 8, 4899–4918. [Google Scholar]

- Tai, J.L.; Sultan, M.T.H.; Tarasiuk, W.; Napiórkowski, J.; Łukaszewicz, A.; Shahar, F.S. Ultrasonic Velocity and Attenuation of Low-Carbon Steel at High Temperatures. Materials 2023, 16, 5123. [Google Scholar] [CrossRef]

- Alobaidi, W.M.; Alkuam, E.A.; Al-Rizzo, H.M.; Sandgren, E. Applications of Ultrasonic Techniques in Oil and Gas Pipeline Industries: A Review. Am. J. Oper. Res. 2015, 05, 274–287. [Google Scholar] [CrossRef]

- Suchato, N.; Sharples, S.; Light, R.; Kalashnikov, A. Experimental Setup of Continuous Ultrasonic Monitoring for Corrosion Assessment. In Proceedings of the 2017 IEEE International Ultrasonics Symposium (IUS), Washington, DC, USA, 6–9 September 2017; pp. 2–5. [Google Scholar] [CrossRef]

- Carboni, M.; Cantini, S. Advanced Ultrasonic “Probability of Detection” Curves for Designing in-Service Inspection Intervals. Int. J. Fatigue 2016, 86, 77–87. [Google Scholar] [CrossRef]

- Markert, M.; Brodscholl, R.; Katzmann, J. Development of an Ultrasonic Testing Method for Continuous Measurements on Concrete with Different Moisture Levels Under Compressive Fatigue Loading. Otto-Graf-J. Vol. 2020, 19, 131–146. [Google Scholar]

- Luiz, T.; Oliveira, L.; Hadded, M.; Mimouni, S.; Schaan, R.B. The Role of Non-Destructive Testing of Composite Materials for Aerospace Applications. NDT 2025, 3, 3. [Google Scholar] [CrossRef]

- Zarei, A.; Pilla, S. Laser Ultrasonics for Nondestructive Testing of Composite Materials and Structures: A Review. Ultrasonics 2024, 136, 107163. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Comparative Analysis of Ultrasonic Inspection Techniques for Corrosion Monitoring in Petrochemical Plants Using Analytic Hierarchy Process (AHP). Pertanika J. Sci. Technol. 2025, 33, 1439–1457. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, S.; Lee, T.L.; Fancey, K.S.; Mi, J. Non-Destructive Testing and Evaluation of Composite Materials/Structures: A State-of-the-Art Review. Adv. Mech. Eng. 2020, 12, 1–28. [Google Scholar] [CrossRef]

- Small, S.W.; Wilson, H.M. Ultrasonic Testing of Carbon Fiber Bicycles. In Proceedings of the International Ultrasonic Testing Online Conference (UT-Online 2021), Online, 1–30 November 2021. [Google Scholar]

- Hassen, A.A.; Vaidya, U.K.; Clarkson, G.E. Innovative Nondestructive Ultrasonic Testing and Analysis for FRP Piping. In Proceedings of the CAMX 2015—Composites and Advanced Materials Expo, Dallas, TX, USA, 26–29 October 2015; pp. 914–921. [Google Scholar]

- Matalgah, K.; Ravindranath, P.K.; Pulipati, D.; Fleck, T.J. Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing. Polymers 2023, 15, 4691. [Google Scholar] [CrossRef] [PubMed]

- Ellison, A.; Kim, H. Shadowed Delamination Area Estimation in Ultrasonic C-Scans of Impacted Composites Validated by X-Ray CT. J. Compos. Mater. 2020, 54, 549–561. [Google Scholar] [CrossRef]

- Ma, M.; Cao, H.; Jiang, M.; Sun, L.; Zhang, L.; Zhang, F.; Sui, Q.; Tian, A.; Liang, J.; Jia, L. High Precision Detection Method for Delamination Defects in Carbon Fiber Composite Laminates Based on Ultrasonic Technique and Signal Correlation Algorithm. Materials 2020, 13, 3840. [Google Scholar] [CrossRef]

- Jasiūnienė, E.; Mažeika, L.; Samaitis, V.; Cicėnas, V.; Mattsson, D. Ultrasonic Non-Destructive Testing of Complex Titanium/Carbon Fibre Composite Joints. Ultrasonics 2019, 95, 13–21. [Google Scholar] [CrossRef]

- Ibrahim, M.E. Ultrasonic Inspection of Hybrid Polymer Matrix Composites. Compos. Sci. Technol. 2021, 208, 5–13. [Google Scholar] [CrossRef]

- Rizwan, M.K.; Laureti, S.; Mooshofer, H.; Goldammer, M.; Ricci, M. Ultrasonic Imaging of Thick Carbon Fiber Reinforced Polymers through Pulse-Compression-Based Phased Array. Appl. Sci. 2021, 11, 1508. [Google Scholar] [CrossRef]

- Kappatos, V.; Asfis, G.; Salonitis, K.; Tzitzilonis, V.; Avdelidis, N.P.; Cheilakou, E.; Theodorakeas, P. Theoretical Assessment of Different Ultrasonic Configurations for Delamination Defects Detection in Composite Components. Procedia CIRP 2017, 59, 29–34. [Google Scholar] [CrossRef]

- Seo, D.W.; Jung, K.S.; Kim, Y.S.; Kim, H.J.; Na, W.S. Development of a New Temporary Attachment Technique for Detecting Debonding of a Composite Structure Using Impedance Based Non-Destructive Testing Method. Appl. Sci. 2021, 11, 10763. [Google Scholar] [CrossRef]

- Teng, L.; Zhou, Z. A Novel Non-Destructive Testing Method for Turbine Disks Using Dual Array Ultrasonic Transducer. Sci. Rep. 2022, 12, 9427. [Google Scholar] [CrossRef]

- Evans, E.E.; Brooks, R.A.; Liu, J.; Hall, Z.E.C.; Liu, H.; Lowe, T.J.E.; Withers, P.J.; Kinloch, A.J.; Dear, J.P. Comparison of X-Ray Computed Tomography and Ultrasonic C-Scan Techniques and Numerical Modelling of Impact Damage in a CFRP Composite Laminate. Appl. Compos. Mater. 2024, 31, 249–264. [Google Scholar] [CrossRef]

- Amif, M.A.; Jack, D.A. High-Resolution Ultrasound to Quantify Sub-Surface Wrinkles in a Woven CFRP Laminate. Materials 2024, 17, 2002. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.J.; Santos, J.B.; Reis, P.; Amaro, A. Ultrasonic C-Scan Techniques for Damage Evaluation of Carbon Fiber Reinforced Polymers Submitted to Low Energy Impacts. Proc. Meet. Acoust. 2019, 38, 030002. [Google Scholar] [CrossRef]

- Wang, B.; He, P.; Kang, Y.; Jia, J.; Liu, X.; Li, N. Ultrasonic Testing of Carbon Fiber-Reinforced Polymer Composites. J. Sens. 2022, 2022, 5462237. [Google Scholar] [CrossRef]

- Wronkowicz-Katunin, A.; Mihaylov, G.; Dragan, K.; Timofiejczuk, A. Uncertainty Estimation for Ultrasonic Inspection of Composite Aerial Structures. J. Nondestruct. Eval. 2019, 38, 82. [Google Scholar] [CrossRef]

- Lim, J.S.; Park, T.S.; Choi, Y.M.; Park, I.K. Improvement in Accuracy of a Multi-Joint Robotic Ultrasonic Inspection System for the Integrity of Composite Structures. Appl. Sci. 2020, 10, 6967. [Google Scholar] [CrossRef]

- Bardis, K.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Maldague, X.P.V.; Fernandes, H. Advanced Diagnostics of Aircraft Structures Using Automated Non-Invasive Imaging Techniques: A Comprehensive Review. Appl. Sci. 2025, 15, 3584. [Google Scholar] [CrossRef]

- Lopez-Hawa, H.; Vanpelt, A.; Emmanuel, S.; Yihun, Y. Automated Scanning Techniques Using UR5. J. Robot. 2019, 2019, 5304267. [Google Scholar] [CrossRef]

- Tunukovic, V.; McKnight, S.; Hifi, A.; Mohseni, E.; Pierce, S.G.; Vithanage, R.K.W.; Dobie, G.; MacLeod, C.N.; Cochran, S.; O’Hare, T. Human-Machine Collaborative Automation Strategies for Ultrasonic Phased Array Data Analysis of Carbon Fibre Reinforced Plastics. NDT E Int. 2025, 154, 103392. [Google Scholar] [CrossRef]

- Tai, J.L.; Grzejda, R.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Tarasiuk, W.; Rychlik, A. Experimental Investigation on the Corrosion Detectability of A36 Low Carbon Steel by the Method of Phased Array Corrosion Mapping. Materials 2023, 16, 5297. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Processing Plants Damage Mechanisms and On-Stream Inspection Using Phased Array Corrosion Mapping—A Systematic Review. Pertanika J. Sci. Technol. 2024, 32, 1665–1685. [Google Scholar] [CrossRef]

- Antin, K.N.; Machado, M.A.; Santos, T.G.; Vilaça, P. Evaluation of Different Non-Destructive Testing Methods to Detect Imperfections in Unidirectional Carbon Fiber Composite Ropes. J. Nondestruct. Eval. 2019, 38, 23. [Google Scholar] [CrossRef]

- Camineroa, M.A.; García-Morenoa, I.; Rodrígueza, G.P.; Chacónb, J.M. Internal Damage Evaluation of Composite Structures Using Phased Array Ultrasonic Technique: Impact Damage Assessment in CFRP and 3D Printed Reinforced Composites. Compos. B Eng. 2018, 165, 131–142. [Google Scholar] [CrossRef]

- Mohd Tahir, M.F.; Echtermeyer, A.T. Phased Array Ultrasonic Testing on Thick Glass Fiber Reinforced Thermoplastic Composite Pipe Implementing the Classical Time-Corrected Gain Method. J. Nondestruct. Eval. 2024, 43, 74. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S.; Łukaszewicz, A.; Oksiuta, Z.; Grzejda, R. Ultrasound Corrosion Mapping on Hot Stainless Steel Surfaces. Metals 2024, 14, 1425. [Google Scholar] [CrossRef]

- Abdelli, D.E.; Nguyen, T.T.; Clenet, S.; Cheriet, A. Stochastic Metamodel for Probability of Detection Estimation of Eddy-Current Testing Problem in Random Geometric. IEEE Trans. Magn. 2019, 55, 6200604. [Google Scholar] [CrossRef]

- Apostol, E.S.; Nedelcu, A.; Daniel, D.V.; Chiriţǎ, I.; Tǎnase, N. Mathematical Modeling of Eddy Current Non-Destructive Testing. In Proceedings of the 2017 10th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 March 2017; pp. 469–474. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Oksiuta, Z.; Krishnamoorthy, R.R. Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review. Appl. Sci. 2024, 14, 6707. [Google Scholar] [CrossRef]

- Farag, H.E.; Toyserkani, E.; Khamesee, M.B. Non-Destructive Testing Using Eddy Current Sensors for Defect Detection in Additively Manufactured Titanium and Stainless-Steel Parts. Sensors 2022, 22, 5440. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J.; Liu, S.; Ma, M.; Fang, H.; Cheng, J.; Zhang, D. Non-Destructive Testing of Carbon Fibre Reinforced Plastics (CFRP) Using a Dual Transmitter-Receiver Differential Eddy Current Test Probe. Sensors 2022, 22, 6761. [Google Scholar] [CrossRef]

- Abdalla, A.N.; Ali, K.; Paw, J.K.S.; Rifai, D.; Faraj, M.A. A Novel Eddy Current Testing Error Compensation Technique Based on Mamdani-Type Fuzzy Coupled Differential and Absolute Probes. Sensors 2018, 18, 2108. [Google Scholar] [CrossRef]

- Hachi, D.; Benhadda, N.; Helifa, B.; Lefkaier, I.K.; Abdelhadi, B. Composite Material Characterization Using Eddy Current by 3D FEM Associated with Iterative Technique. Adv. Electromagn. 2019, 8, 8–15. [Google Scholar] [CrossRef]

- Yi, Q.; Tian, G.Y.; Malekmohammadi, H.; Zhu, J.; Laureti, S.; Ricci, M. New Features for Delamination Depth Evaluation in Carbon Fiber Reinforced Plastic Materials Using Eddy Current Pulse-Compression Thermography. NDT E Int. 2019, 102, 264–273. [Google Scholar] [CrossRef]

- Pelkner, M.; Casperson, R.; Pohl, R.; Munzke, D.; Becker, B. Eddy Current Testing of Composite Pressure Vessels. Int. J. Appl. Electromagn. Mech. 2019, 59, 1221–1226. [Google Scholar] [CrossRef]

- Zheng, X.; Huang, J.; Luo, N. Enhanced Nondestructive Testing Using Pulsed Eddy Current and Electromagnetic Ultrasonic Techniques. Appl. Sci. 2024, 14, 6488. [Google Scholar] [CrossRef]

- Zhang, K.; He, Y.; Dong, Z. Pulsed Eddy Current Nondestructive Testing for Defect Evaluation and Imaging of Automotive Lightweight Alloy Materials. J. Sens. 2018, 2018, 1639387. [Google Scholar] [CrossRef]

- Tytko, G.; Yin, W.; Luo, Y.; Adamczyk-Habrajska, M. Eddy Current Testing of Conductive Tubes With the Employment of the I-Core Sensor. IEEE Access 2024, 12, 25525–25535. [Google Scholar] [CrossRef]

- Ma, M.; Liu, S.; Zhang, R.; Zhang, Q.; Wu, Y.; Chen, B. Non-Destructive Testing of Carbon Fiber-Reinforced Plastics (CFRPs) Using a Resonant Eddy Current Sensor. Sensors 2024, 24, 3449. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, L.; Peng, Y.; Zhang, Q.; Gao, M.; Fu, Y. Principle Analysis of Soil Electrical Conductivity Test Based on Pulsed Eddy Current. IOP Conf. Ser. Earth Environ. Sci. 2019, 242, 042018. [Google Scholar] [CrossRef]

- Romhány, G.; Czigány, T.; Karger-Kocsis, J. Failure Assessment and Evaluation of Damage Development and Crack Growth in Polymer Composites Via Localization of Acoustic Emission Events: A Review. Polym. Rev. 2017, 57, 397–439. [Google Scholar] [CrossRef]

- Kourkoulis, S.K.; Loukidis, A.; Pasiou, E.D.; Stavrakas, I.; Triantis, D. Response of Fiber Reinforced Concrete While Entering into the Critical Stage: An Attempt to Detect Pre-Failure Indicators in Terms of Non-Extensive Statistical Mechanics. Theor. Appl. Fract. Mech. 2023, 123, 103690. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Siemiątkowski, Z.; Skorulski, G.; Shahar, F.S. Preventing Catastrophic Failures: A Review of Applying Acoustic Emission Testing in Multi-Bolted Flanges. Metals 2025, 15, 438. [Google Scholar] [CrossRef]

- Samborski, S.; Korzec, I. Application of the Acoustic Emission Technique for Damage Identification in the Fiber Reinforced Polymer Composites. Adv. Sci. Technol. Res. J. 2023, 17, 210–221. [Google Scholar] [CrossRef]

- Joseph, R.; Giurgiutiu, V. Non-Crack-Growth Acoustic Emission Observed in Controlled-Stress-Intensity-Factor High-Cycle-Fatigue Tests. Actuators 2023, 12, 93. [Google Scholar] [CrossRef]

- Ding, L.; Zhao, Y.; Pan, Y.; Fan, Y. Investigation on Acoustic Emission Characteristics of Fault Stick-Slip under Different Lateral Pressures. Sci. Rep. 2024, 14, 6718. [Google Scholar] [CrossRef]

- Zhou, Q.; Wen, B. Fatigue Damage Assessment Using Adaptive Acoustic Emission Waveform Analysis. Results Eng. 2025, 27, 105713. [Google Scholar] [CrossRef]

- Jung, D.; Yu, W.R.; Ahn, H.; Na, W. New B-Value Parameter for Quantitatively Monitoring the Structural Health of Carbon Fiber-Reinforced Composites. Mech. Syst. Signal Process 2022, 165, 108328. [Google Scholar] [CrossRef]

- Triantis, D.; Pasiou, E.D.; Stavrakas, I.; Kourkoulis, S.K. Revealing the Proximity of Concrete Specimens to Their Critical Damage Level by Exploring the Cumulative Counts of the Acoustic Emissions in the Natural Time Domain. Materials 2024, 17, 1017. [Google Scholar] [CrossRef]

- Brunner, A.J. Identification of Damage Mechanisms in Fiber-Reinforced Polymer-Matrix Composites with Acoustic Emission and the Challenge of Assessing Structural Integrity and Service-Life. Constr. Build. Mater. 2018, 173, 629–637. [Google Scholar] [CrossRef]

- Šofer, M.; Cienciala, J.; Fusek, M.; Pavlicek, P.; Moravec, R. Damage Analysis of Composite CFRP Tubes Using Acoustic Emission Monitoring and Pattern Recognition Approach. Materials 2021, 14, 786. [Google Scholar] [CrossRef]

- Guo, F.; Li, W.; Jiang, P.; Chen, F.; Liu, Y. Deep Learning Approach for Damage Classification Based on Acoustic Emission Data in Composite Materials. Materials 2022, 15, 4270. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Application of Different Acoustic Emission Descriptors in Damage Assessment of Fiber Reinforced Plastics: A Comprehensive Review. Eng. Fract. Mech. 2020, 235, 107083. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A Review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef] [PubMed]

- Hamam, Z.; Godin, N.; Fusco, C.; Doitrand, A.; Monnier, T. Acoustic Emission Signal Due to Fiber Break and Fiber Matrix Debonding in Model Composite: A Computational Study. Appl. Sci. 2021, 11, 8406. [Google Scholar] [CrossRef]

- Oliveira, T.L.L.; Bortoluzzi, D.B.; Barbosa, L.C.M.; Ancelotti, A.C. Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP. NDT 2024, 2, 32–52. [Google Scholar] [CrossRef]

- Kersemans, M.; Verboven, E.; Segers, J.; Hedayatrasa, S.; van Paepegem, W. Non-Destructive Testing of Composites by Ultrasound, Local Defect Resonance and Thermography. Proc. West. Mark. Ed. Assoc. Conf. 2018, 2, 554. [Google Scholar] [CrossRef]

- Kim, J. Non-Destructive Characterization of Railway Materials and Components with Infrared Thermography Technique. Materials 2019, 12, 4077. [Google Scholar] [CrossRef]

- Zhang, H.; Avdelidis, N.P.; Osman, A.; Ibarra-Castanedo, C.; Sfarra, S.; Fernandes, H.; Matikas, T.E.; Maldague, X.P.V. Enhanced Infrared Image Processing for Impacted Carbon/Glass Fiber-Reinforced Composite Evaluation. Sensors 2018, 18, 45. [Google Scholar] [CrossRef]

- Fang, Q.; Maldague, X. A Method of Defect Depth Estimation for Simulated Infrared Thermography Data with Deep Learning. Appl. Sci. 2020, 10, 6819. [Google Scholar] [CrossRef]

- Švantner, M.; Muzika, L.; Moskovchenko, A.; Pereira, C.M.C.; Das, S. Repeatability Study of Flash-Pulse Thermographic Inspection of CFRP Samples. Eng. Proc. 2021, 8, 1. [Google Scholar] [CrossRef]

- Chang, H.L.; Ren, H.T.; Wang, G.; Yang, M.; Zhu, X.Y. Infrared Defect Recognition Technology for Composite Materials. Front. Phys. 2023, 11, 1203762. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and Application of Infrared Thermography Non-Destructive Testing Techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Huai, W.; Wang, S.; Ren, L. A Real-Time Infrared Imaging Simulation Method with Physical Effects Modeling of Infrared Sensors. Infrared Phys. Technol. 2016, 78, 45–57. [Google Scholar] [CrossRef]

- Swiderski, W. CFRP Non-Destructive Testing Using IR Thermography Methods. Proc. West. Mark. Ed. Assoc. Conf. 2019, 27, 30. [Google Scholar] [CrossRef]

- Notebaert, A.; Quinten, J.; Moonens, M.; Olmez, V.; Barros, C.; Cunha, S.S.; Demarbaix, A. Numerical Modelling of the Heat Source and the Thermal Response of an Additively Manufactured Composite during an Active Thermographic Inspection. Materials 2024, 17, 13. [Google Scholar] [CrossRef]

- D’accardi, E.; Palumbo, D.; Galietti, U. A Comparison among Different Ways to Investigate Composite Materials with Lock-in Thermography: The Multi-frequency Approach. Materials 2021, 14, 2525. [Google Scholar] [CrossRef]

- Junyan, L.; Yang, L.; Fei, W.; Yang, W. Study on Probability of Detection (POD) Determination Using Lock-in Thermography for Nondestructive Inspection (NDI) of CFRP Composite Materials. Infrared Phys. Technol. 2015, 71, 448–456. [Google Scholar] [CrossRef]

- Boccardi, S.; Boffa, N.D.; Carlomagno, G.M.; Del Core, G.; Meola, C.; Monaco, E.; Russo, P.; Simeoli, G. Lock-in Thermography and Ultrasonic Testing of Impacted Basalt Fibers Reinforced Thermoplastic Matrix Composites. Appl. Sci. 2019, 9, 3025. [Google Scholar] [CrossRef]

- Peeters, J.; Ibarra-Castanedo, C.; Khodayar, F.; Mokhtari, Y.; Sfarra, S.; Zhang, H.; Maldague, X.; Dirckx, J.J.J.; Steenackers, G. Optimised Dynamic Line Scan Thermographic Detection of CFRP Inserts Using FE Updating and POD Analysis. NDT E Int. 2018, 93, 141–149. [Google Scholar] [CrossRef]

- Duan, Y.; Zhang, H.; Maldague, X.P.V.; Ibarra-Castanedo, C.; Servais, P.; Genest, M.; Sfarra, S.; Meng, J. Reliability Assessment of Pulsed Thermography and Ultrasonic Testing for Impact Damage of CFRP Panels. NDT E Int. 2019, 102, 77–83. [Google Scholar] [CrossRef]

- Dayal, V.; Benedict, Z.G.; Bhatnagar, N.; Harper, A.G. Development of Composite Calibration Standard for Quantitative NDE by Ultrasound and Thermography. AIP Conf. Proc. 2018, 1949, 060006. [Google Scholar] [CrossRef]

- Laureti, S.; Khalid Rizwan, M.; Malekmohammadi, H.; Burrascano, P.; Natali, M.; Torre, L.; Rallini, M.; Puri, I.; Hutchins, D.; Ricci, M. Delamination Detection in Polymeric Ablative Materials Using Pulse-Compression Thermography and Air-Coupled Ultrasound. Sensors 2019, 19, 2198. [Google Scholar] [CrossRef] [PubMed]

- Summa, J.; Herrmann, H.G. Using Quantitative Passive Thermography and Modified Paris-Law for Probabilistic Calculation of the Fatigue Damage Development in a Cfrp-Aluminum Hybrid Joint. Polymers 2021, 13, 349. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.; Wang, X.; Hu, J.; Wang, Y.; Li, X.; Yang, D.; Mostacci, M.; Sfarra, S.; Maldague, X.; Jiang, Q.; et al. Simulation-Aided Infrared Thermography with Decomposition-Based Noise Reduction for Detecting Defects in Ancient Polyptychs. Herit. Sci. 2023, 11, 223. [Google Scholar] [CrossRef]

- Kim, H.J.; Shrestha, R.; Pradhan, S.S.; Gurung, P.; Bhattarai, P.; Lamichhane, N.; Kim, C.S.; Shrestha, R. Modelling and Simulation for Defect Detection in Hydroelectric Penstock Using Infrared Thermography. Therm. Sci. Eng. 2023, 6, 2494. [Google Scholar] [CrossRef]

- Wei, Z.; Fernandes, H.; Herrmann, H.G.; Tarpani, J.R.; Osman, A. A Deep Learning Method for the Impact Damage Segmentation of Curve-Shaped Cfrp Specimens Inspected by Infrared Thermography. Sensors 2021, 21, 395. [Google Scholar] [CrossRef]

- Liu, K.; Ma, Z.; Liu, Y.; Yang, J.; Yao, Y. Enhanced Defect Detection in Carbon Fiber Reinforced Polymer Composites via Generative Kernel Principal Component Thermography. Polymers 2021, 13, 825. [Google Scholar] [CrossRef]

- Pirinu, A.; Saponaro, A.; Nobile, R.; Panella, F.W. Low-Velocity Impact Damage Quantification on Sandwich Panels by Thermographic and Ultrasonic Procedures. Exp. Tech. 2024, 48, 299–322. [Google Scholar] [CrossRef]

- Boni, L.; Fanteria, D.; Lazzeri, L.; Panettieri, E.; Mariani, U.; Rigamonti, M. Influence of Environment Conditioning on the Interlaminar Fracture Toughness of a Graphite/Epoxy Unidirectional Material. Compos. B Eng. 2018, 153, 97–107. [Google Scholar] [CrossRef]

- Pitarresi, G.; Scalici, T.; Catalanotti, G. Infrared Thermography Assisted Evaluation of Static and Fatigue Mode II Fracture Toughness in FRP Composites. Compos. Struct. 2019, 226, 111220. [Google Scholar] [CrossRef]

- Bang, H.T.; Park, S.; Jeon, H. Defect Identification in Composite Materials via Thermography and Deep Learning Techniques. Compos. Struct. 2020, 246, 112405. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. Evaluation of Interlaminar Delaminations in Titanium-Graphite Fibre Metal Laminates by Infrared NDT Techniques. NDT E Int. 2018, 98, 134–146. [Google Scholar] [CrossRef]

- Pušnik, I.; Geršak, G. Evaluation of the Size-of-Source Effect in Thermal Imaging Cameras. Sensors 2021, 21, 607. [Google Scholar] [CrossRef] [PubMed]

- Deane, S.; Nicolas, P.A.; Clemente, I.-C.; Alex, A.W.; Stephen, W.; Argyrios, Z.; Xavier, P.V.M.; Mohammad, A.; Shashank, P.; Marc, G.; et al. Development of a Thermal Excitation Source Used in an Active Thermographic UAV Platform. Quant. Infrared Thermogr. J. 2023, 20, 198–229. [Google Scholar] [CrossRef]

- Naik, M.; Hegde, G.; Giri, L.I. A Novel Method Based on Thermal Imaging and FEA Simulation for Depth Prediction of Internal Defects in Concrete Slabs. J. Build. Eng. 2024, 95, 110228. [Google Scholar] [CrossRef]

- Li, X.; Tao, N.; Feng, L.; Sun, J.G. Thickness Measurement Research Using Transmission Step-Heating Thermography. NDT E Int. 2022, 126, 102590. [Google Scholar] [CrossRef]

- Wei, Z.; Osman, A.; Valeske, B.; Maldague, X. Pulsed Thermography Dataset for Training Deep Learning Models. Appl. Sci. 2023, 13, 2901. [Google Scholar] [CrossRef]

- Liu, K.; Yu, Q.; Liu, Y.; Yang, J.; Yao, Y. Convolutional Graph Thermography for Subsurface Defect Detection in Polymer Composites. IEEE Trans. Instrum. Meas. 2022, 71, 4506411. [Google Scholar] [CrossRef]

- Tu, Y.; Mei, H.; Liu, L.; Sun, R.; Guo, C.; Shen, Z.; Wang, L. Distance Effect in Transient Thermography for Internal Defects Detection in Composites. IEEE Trans. Instrum. Meas. 2022, 71, 3525712. [Google Scholar] [CrossRef]

- Unnikrishnakurup, S.; Kidangan, R.T.; Krishnamurthy, C.V.; Balasubramaniam, K.; Ngo, A. Assessment of Fiber Orientation and Order in Carbon Fiber Reinforced Polymer Composites Using Induction Thermography and Radon Transform Analysis. Compos. B Eng. 2025, 296, 112224. [Google Scholar] [CrossRef]

- Kidangan, R.T.; Unnikrishnakurup, S.; Krishnamurthy, C.V.; Balasubramaniam, K. Induction Thermography for Unidirectional CFRP Composites: A Novel Inspection Approach through Global Current Path Integration. Compos. Struct. 2024, 327, 117678. [Google Scholar] [CrossRef]

- Ratsakou, A.; Reboud, C.; Skarlatos, A.; Lesselier, D. Fast Simulation Approach Dedicated to Infrared Thermographic Inspection of Delaminated Planar Pieces. AIP Conf. Proc. 2019, 2102, 120004. [Google Scholar] [CrossRef]

- Lee, D.; Park, J. Development of Solar-Panel Monitoring Method Using Unmanned Aerial Vehicle and Thermal Infrared Sensor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 611, 012085. [Google Scholar] [CrossRef]

- Wen, B.; Zhou, Z.; Zeng, B.; Yang, C.; Fang, D.; Xu, Q.; Shao, Y.; Wan, C. Pulse-Heating Infrared Thermography Inspection of Bonding Defects on Carbon Fiber Reinforced Polymer Composites. Sci. Prog. 2020, 103, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Loganathan, T.M.; Sultan, M.T.H.; Muhammad Amir, S.M.; Jamil, J.; Yusof, M.R.; Md Shah, A.U. Infrared Thermographic and Ultrasonic Inspection of Randomly-Oriented Short-Natural Fiber-Reinforced Polymeric Composites. Front. Mater. 2021, 7, 604459. [Google Scholar] [CrossRef]

- Guo, J.; Xue, H.; Chen, Y.; Li, X.; Chen, Y.; Zhang, X.; An, Y.; Zhang, H.; Yang, Y.; Cai, L.; et al. Infrared Thermography-Based Radiomics for Early Detection of Metabolic Syndrome. Sci. Rep. 2025, 15, 13984. [Google Scholar] [CrossRef]

- Pathak, P.; Gururaja, S.; Kumar, V.; Nuttall, D.; Mahmoudi, A.; Khonsari, M.M.; Vaidya, U. Examining Infrared Thermography Based Approaches to Rapid Fatigue Characterization of Additively Manufactured Compression Molded Short Fiber Thermoplastic Composites. Compos. Struct. 2025, 351, 118610. [Google Scholar] [CrossRef]

- Balakrishnan, G.K.; Yaw, C.T.; Koh, S.P.; Abedin, T.; Raj, A.A.; Tiong, S.K.; Chen, C.P. A Review of Infrared Thermography for Condition-Based Monitoring in Electrical Energy: Applications and Recommendations. Energies 2022, 15, 6000. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Chulkov, A.O.; Smotrova, S.A.; Smotrov, A.V.; Scherbakov, V.N.; Storozhenko, V.A. Infrared Thermographic Analysis of Thermal Property Variations in Composites Subjected to Impact Damage, Thermal Cycling and Moisture Saturation. Compos. Struct. 2022, 296, 115927. [Google Scholar] [CrossRef]

- Shrestha, P.; Avci, O.; Rifai, S.; Abla, F.; Seek, M.; Barth, K.; Halabe, U. A Review of Infrared Thermography Applications for Civil Infrastructure. SDHM Struct. Durab. Health Monit. 2025, 19, 193–231. [Google Scholar] [CrossRef]

- Tonga, D.A.; Akbar, M.F.; Shrifan, N.H.M.M.; Jawad, G.N.; Ghazali, N.A.; Packeer Mohamed, M.F.; Al-Gburi, A.J.A.; Ab Wahab, M.N. Nondestructive Evaluation of Fiber-Reinforced Polymer Using Microwave Techniques: A Review. Coatings 2023, 13, 590. [Google Scholar] [CrossRef]

- Li, Z.; Haigh, A.; Soutis, C.; Gibson, A. Principles and Applications of Microwave Testing for Woven and Non-Woven Carbon Fibre-Reinforced Polymer Composites: A Topical Review. Appl. Compos. Mater. 2018, 25, 965–982. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. The Use of Free-Space Microwave Non-Destructive Techniques: Simulation of Damage Detection in Carbon Fibre Reinforced Composites. In Proceedings of the 11th Symposium on NDT in Aerospace, Saclay, France, 13–15 November 2019; pp. 1–10. [Google Scholar]

- Carrigan, T.D.; Forrest, B.E.; Andem, H.N.; Gui, K.; Johnson, L.; Hibbert, J.E.; Lennox, B.; Sloan, R. Nondestructive Testing of Nonmetallic Pipelines Using Microwave Reflectometry on an In-Line Inspection Robot. IEEE Trans. Instrum. Meas. 2018, 68, 586–594. [Google Scholar] [CrossRef]

- Sobkiewicz, P.; Bienkowski, P.; Błazejewski, W. Microwave Non-Destructive Testing for Delamination Detection in Layered Composite Pipelines. Sensors 2021, 21, 4168. [Google Scholar] [CrossRef] [PubMed]

- Shrifan, N.H.M.M.; Jawad, G.N.; Isa, N.A.M.; Akbar, M.F. Microwave Nondestructive Testing for Defect Detection in Composites Based on K-Means Clustering Algorithm. IEEE Access 2021, 9, 4820–4828. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Bai, J.; Al-Sabaawi, A.; Santamaría, J.; Albahri, A.S.; Al-dabbagh, B.S.N.; Fadhel, M.A.; Manoufali, M.; Zhang, J.; Al-Timemy, A.H.; et al. A Survey on Deep Learning Tools Dealing with Data Scarcity: Definitions, Challenges, Solutions, Tips, and Applications. J. Big Data 2023, 10, 46. [Google Scholar] [CrossRef]

- Ashebir, D.A.; Hendlmeier, A.; Dunn, M.; Arablouei, R.; Lomov, S.V.; Di Pietro, A.; Nikzad, M. Detecting Multi-Scale Defects in Material Extrusion Additive Manufacturing of Fiber-Reinforced Thermoplastic Composites: A Review of Challenges and Advanced Non-Destructive Testing Techniques. Polymers 2024, 16, 2986. [Google Scholar] [CrossRef]

- Aal E Ali, R.S.; Meng, J.; Khan, M.E.I.; Jiang, X. Machine Learning Advancements in Organic Synthesis: A Focused Exploration of Artificial Intelligence Applications in Chemistry. Artif. Intell. Chem. 2024, 2, 100049. [Google Scholar] [CrossRef]

- Boaretto, N.; Centeno, T.M. Automated Detection of Welding Defects in Pipelines from Radiographic Images DWDI. NDT E Int. 2016, 115, 60–66. [Google Scholar] [CrossRef]

- Khorshidi, A.; Khosrowpour, B.; Hosseini, S.H. Determination of Defect Depth in Industrial Radiography Imaging Using MCNP Code and SuperMC Software. Nucl. Eng. Technol. 2020, 52, 1597–1601. [Google Scholar] [CrossRef]

- Kengyelics, S.M.; Treadgold, L.A.; Davies, A.G. X-Ray System Simulation Software Tools for Radiology and Radiography Education. Comput. Biol. Med. 2018, 93, 175–183. [Google Scholar] [CrossRef]

- Malarvel, M.; Singh, H. An Autonomous Technique for Weld Defects Detection and Classification Using Multi-Class Support Vector Machine in X-Radiography Image. Optik 2021, 231, 166342. [Google Scholar] [CrossRef]

- Troitskiy, V.A. Quick Industrial X-Ray Testing without Intermediate Data Carriers of Information. NDT Tech. 2017, 15, 1–16. [Google Scholar]

- Wahjudi, A.; Widodo, A.S. A Comprehensive Review on the Non-Destructive Test for Polymer Matrix Composite. J. Rekayasa Mesin 2023, 14, 987–1000. [Google Scholar] [CrossRef]

- Anoshkin, A.N.; Osokin, V.M.; Tretyakov, A.A.; Potrakhov, N.N.; Bessonov, V.B. Application of Operational Radiographic Inspection Method for Flaw Detection of Blade Straightener from Polymeric Composite Materials. J. Phys. Conf. Ser. 2017, 808, 012003. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Bhatt, M.K.; Rai, K.K.; Sori, A.; Singh, S.K.; Ramesh, M.V.L.; Mohan, J.R. Quantitative Assessment of Thermal Liner Delaminations in Large Size Composite Rocket Boosters for Its Repair Using X-Ray Radiography. E-J. Nondestruct. Test. 2015, 20, 6. [Google Scholar]

- Endrizzi, M.; Murat, B.I.S.; Fromme, P.; Olivo, A. Edge-Illumination X-Ray Dark-Field Imaging for Visualising Defects in Composite Structures. Compos. Struct. 2015, 134, 895–899. [Google Scholar] [CrossRef]

- Sharma, R.S.; Vijayakumar, M.N. Recent Developments in Damage Detection of CFRP Composites Using Non-Destructive Techniques—A Review. J. Eng. Res. Rep. 2023, 25, 51–65. [Google Scholar] [CrossRef]

- Li, X.F.; Jie, S.; Lu, S.; Wang, L. Application of On-Line Digital Radiographic Inspection for Pipeline with Insulation. J. Phys. Conf. Ser. 2022, 2366, 012006. [Google Scholar] [CrossRef]

- Kusk, M.W.; Jensen, J.M.; Gram, E.H.; Nielsen, J.; Precht, H. Anode Heel Effect: Does It Impact Image Quality in Digital Radiography? A Systematic Literature Review. Radiography 2021, 27, 976–981. [Google Scholar] [CrossRef]

- Kraai, B. Digital Radiography in Industry: Digital Detector Arrays in Radiographic Testing. NDT Tech. 2016, 15, 1–6. [Google Scholar]

- Kourra, N.; Warnett, J.M.; Attridge, A.; Kiraci, E.; Gupta, A.; Barnes, S.; Williams, M.A. Metrological Study of CFRP Drilled Holes with X-Ray Computed Tomography. Int. J. Adv. Manuf. Technol. 2015, 78, 2025–2035. [Google Scholar] [CrossRef]

- Chipanga, T.; Nemraoui, O.; Ismail, F. Damage Assessment of Low-Velocity Impacted Sandwich Composite Structures Using X-Ray Micro-Computed Tomography. J. Eng. 2024, 2024, 6147948. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Su, S.; Jiang, N. Prediction Models of Mechanical Properties of Jute/PLA Composite Based on X-Ray Computed Tomography. Polymers 2024, 16, 160. [Google Scholar] [CrossRef] [PubMed]

- Tsamos, A.; Evsevleev, S.; Fioresi, R.; Faglioni, F.; Bruno, G. Synthetic Data Generation for Automatic Segmentation of X-Ray Computed Tomography Reconstructions of Complex Microstructures. J. Imaging 2023, 9, 22. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-Ray Computed Tomography of Polymer Composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Tretiak, I.; Smith, R.A. A Parametric Study of Segmentation Thresholds for X-Ray CT Porosity Characterisation in Composite Materials. Compos. Part A Appl. Sci. Manuf. 2019, 123, 10–24. [Google Scholar] [CrossRef]

- Ahn, J.H.; Hwang, H.J.; Chang, S.; Jung, S.N.; Kalow, S.; Keimer, R. X-Ray Computed Tomography Method for Macroscopic Structural Property Evaluation of Active Twist Composite Blades. Aerospace 2021, 8, 370. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Pach, J.; Pyka, D.; Kurzynowski, T.; Jamroziak, K. X-Ray Computed Tomography for the Development of Ballistic Composite. Materials 2020, 13, 5566. [Google Scholar] [CrossRef]

- Xu, X.; Leung, N.; Jargalsaikhan, U.; Bongaers, E.; Sui, T. Observation of Damage Initiation for Trans-Laminar Fracture Using in Situ Fast Synchrotron X-Ray Radiography and Ex Situ X-Ray Computed Tomography. Appl. Compos. Mater. 2024, 31, 765–774. [Google Scholar] [CrossRef]

- Galvez-Hernandez, P.; Smith, R.; Gaska, K.; Mavrogordato, M.; Sinclair, I.; Kratz, J. The Effect of X-Ray Computed Tomography Scan Parameters on Porosity Assessment of Carbon Fibre Reinfored Plastics Laminates. J. Compos. Mater. 2023, 57, 4535–4548. [Google Scholar] [CrossRef]

- Tsamos, A.; Evsevleev, S.; Fioresi, R.; Faglioni, F.; Bruno, G. A Complete Strategy to Achieve High Precision Automatic Segmentation of Challenging Experimental X-Ray Computed Tomography Data Using Low-Resemblance Synthetic Training Data. Adv. Eng. Mater. 2024, 26, 202301030. [Google Scholar] [CrossRef]

- Katunin, A.; Wronkowicz-Katunin, A.; Dragan, K. Impact Damage Evaluation in Composite Structures Based on Fusion of Results of Ultrasonic Testing and X-Ray Computed Tomography. Sensors 2020, 20, 1867. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Guo, W.; Xin, S.; Hu, W.; Yan, H. Characterization of Oxidation Behavior of 3D Needled C/C Composite by Synchrotron Radiation X-Ray Micro-Computed Tomography. J. Ceram. Soc. Jpn. 2022, 130, 219–224. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef]

- Muir, C.; Swaminathan, B.; Fields, K.; Almansour, A.S.; Sevener, K.; Smith, C.; Presby, M.; Kiser, J.D.; Pollock, T.M.; Daly, S. A Machine Learning Framework for Damage Mechanism Identification from Acoustic Emissions in Unidirectional SiC/SiC Composites. NPJ Comput. Mater. 2021, 7, 146. [Google Scholar] [CrossRef]

- Wang, Z.; Chegdani, F.; Yalamarti, N.; Takabi, B.; Tai, B.; El Mansori, M.; Bukkapatnam, S. Acoustic Emission Characterization of Natural Fiber Reinforced Plastic Composite Machining Using a Random Forest Machine Learning Model. J. Manuf. Sci. Eng. Trans. ASME 2020, 142, 031003. [Google Scholar] [CrossRef]

- Siljama, O.; Koskinen, T.; Jessen-Juhler, O.; Virkkunen, I. Automated Flaw Detection in Multi-Channel Phased Array Ultrasonic Data Using Machine Learning. J. Nondestruct. Eval. 2021, 40, 67. [Google Scholar] [CrossRef]

- Zhu, Z.; Lei, Y.; Qi, G.; Chai, Y.; Mazur, N.; An, Y.; Huang, X. A Review of the Application of Deep Learning in Intelligent Fault Diagnosis of Rotating Machinery. Measurement 2023, 206, 112346. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Machine-Learning-Based Methods for Acoustic Emission Testing: A Review. Appl. Sci. 2022, 12, 10476. [Google Scholar] [CrossRef]

- Virkkunen, I.; Koskinen, T.; Jessen-Juhler, O.; Rinta-aho, J. Augmented Ultrasonic Data for Machine Learning. J. Nondestruct. Eval. 2021, 40, 4. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Ben Chaabene, W.; Nehdi, M.L. Machine Learning Algorithms in Civil Structural Health Monitoring: A Systematic Review. Arch. Comput. Methods Eng. 2021, 28, 2621–2643. [Google Scholar] [CrossRef]

- Mihai, S.; Davis, W.; Hung, D.V.; Trestian, R.; Karamanoglu, M.; Barn, B.; Prasad, R.; Venkataraman, H.; Nguyen, H.X. A Digital Twin Framework for Predictive Maintenance in Industry 4.0. In Proceedings of the International Conference High Performance Computing & Simulation, Online, 22–27 March 2021; pp. 1–8. [Google Scholar]

- Fu, Y.; Zhu, G.; Zhu, M.; Xuan, F. Digital Twin for Integration of Design-Manufacturing-Maintenance: An Overview. Chin. J. Mech. Eng. (Engl. Ed.) 2022, 35, 80. [Google Scholar] [CrossRef]

- Langlotz, P.; Klar, M.; Yi, L.; Hussong, M.; Sousa, F.J.P.; Aurich, J.C. Concept of Hybrid Modeled Digital Twins and Its Application for an Energy Management of Manufacturing Systems. Procedia CIRP 2022, 112, 549–554. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Ahmad, Z.; Kim, J.M. A Scheme with Acoustic Emission Hit Removal for the Remaining Useful Life Prediction of Concrete Structures. Sensors 2021, 21, 7761. [Google Scholar] [CrossRef] [PubMed]

- Kabashkin, I. Digital Twin Framework for Aircraft Lifecycle Management Based on Data-Driven Models. Mathematics 2024, 12, 2979. [Google Scholar] [CrossRef]

- Ming, N.K.; Philip, N.; Sahlan, S. Proactive and Predictive Maintenance Strategies and Application for Instrumentation & Control in Oil & Gas Industry. Int. J. Integr. Eng. 2019, 11, 119–130. [Google Scholar] [CrossRef]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive Maintenance Using Digital Twins: A Systematic Literature Review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Iranshahi, K.; Brun, J.; Arnold, T.; Sergi, T.; Müller, U.C. Digital Twins: Recent Advances and Future Directions in Engineering Fields. Intell. Syst. Appl. 2025, 26, 200516. [Google Scholar] [CrossRef]

- O’Connell, E.; O’Brien, W.; Bhattacharya, M.; Moore, D.; Penica, M. Digital Twins: Enabling Interoperability in Smart Manufacturing Networks. Telecom 2023, 4, 265–278. [Google Scholar] [CrossRef]

- Alves Coelho, J.; Glória, A.; Sebastião, P. Precise Water Leak Detection Using Machine Learning and Real-Time Sensor Data. Internet Things 2020, 1, 474–493. [Google Scholar] [CrossRef]

- Smolnicki, M.; Duda, S.; Stabla, P.; Zielonka, P.; Lesiuk, G. Acoustic Emission with Machine Learning in Fracture of Composites: Preliminary Study. Arch. Civ. Mech. Eng. 2023, 23, 254. [Google Scholar] [CrossRef]

- Muir, C.; Swaminathan, B.; Almansour, A.S.; Sevener, K.; Smith, C.; Presby, M.; Kiser, J.D.; Pollock, T.M.; Daly, S. Damage Mechanism Identification in Composites via Machine Learning and Acoustic Emission. NPJ Comput. Mater. 2021, 7, 95. [Google Scholar] [CrossRef]

- Zhang, T.; Mahdi, M.; Issa, M.; Xu, C.; Ozevin, D. Experimental Study on Monitoring Damage Progression of Basalt-FRP Reinforced Concrete Slabs Using Acoustic Emission and Machine Learning. Sensors 2023, 23, 8356. [Google Scholar] [CrossRef] [PubMed]

- Kozanecki, D.; Wirowski, A.; Kowalczyk, I.; Krason, S.; Rabenda, M.; Domagalski, Ł. The Machine Learning Methods in Non-Destructive Testing of Dynamic Properties of Vacuum Insulated Glazing Type Composite Panels. Materials 2023, 16, 5055. [Google Scholar] [CrossRef]

- Ahn, B.; Kim, J.; Choi, B.; Ahn, B.; Kim, J.; Choi, B. Artificial Intelligence-Based Machine Learning Considering Flow and Temperature of the Pipeline for Leak Early Detection Using Acoustic Emission. Eng. Fract. Mech. 2018, 210, 381–392. [Google Scholar] [CrossRef]

- Saade, M.; Mustapha, S. Assessment of the Structural Conditions in Steel Pipeline under Various Operational Conditions—A Machine Learning Approach. Measurement 2020, 166, 108262. [Google Scholar] [CrossRef]

- Fort, A.; Landi, E.; Mugnaini, M.; Vignoli, V. A Low Complexity Rolling Bearing Diagnosis Technique Based on Machine Learning and Smart Preprocessing. Sensors 2023, 23, 7546. [Google Scholar] [CrossRef]

- Khan, M.A.; Sun, J.; Li, B.; Przybysz, A.; Kosel, J. Magnetic Sensors—A Review and Recent Technologies. Eng. Res. Express 2021, 3, 022005. [Google Scholar] [CrossRef]

- Mandal, D.; Banerjee, S. Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Józwik, J.; Oksiuta, Z.; Shahar, F.S. Advanced Non-Destructive Testing Simulation and Modeling Approaches for Fiber-Reinforced Polymer Pipes: A Review. Materials 2025, 18, 2466. [Google Scholar] [CrossRef]

- Alharam, A.; Almansoori, E.; Elmadeny, W.; Alnoiami, H. Real Time AI-Based Pipeline Inspection Using Drone for Oil and Gas Industries in Bahrain. In Proceedings of the 2020 International Conference on Innovation and Intelligence for Informatics, Computing and Technologies, 3ICT 2020, Sakheer, Bahrain, 20–21 December 2020. [Google Scholar] [CrossRef]

- Nagy, M.; Figura, M.; Valaskova, K.; Lăzăroiu, G. Predictive Maintenance Algorithms, Artificial Intelligence Digital Twin Technologies, and Internet of Robotic Things in Big Data-Driven Industry 4.0 Manufacturing Systems. Mathematics 2025, 13, 981. [Google Scholar] [CrossRef]

- Ali, M.A.H.; Baggash, M.; Rustamov, J.; Abdulghafor, R.; Abdo, N.A.D.N.; Abdo, M.H.G.; Mohammed, T.S.; Hasan, A.A.; Abdo, A.N.; Turaev, S.; et al. An Automatic Visual Inspection of Oil Tanks Exterior Surface Using Unmanned Aerial Vehicle with Image Processing and Cascading Fuzzy Logic Algorithms. Drones 2023, 7, 133. [Google Scholar] [CrossRef]

| Method | Description | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Ultrasonic Testing (UT) | A conventional NDT method using high-frequency sound waves (typically 1–25 MHz) to detect internal flaws. A transducer sends pulses into the material, and reflections are analyzed to identify defects. | - Non-destructive and field-portable - Effective for internal flaw detection (e.g., delamination, voids, inclusions) - Measures thickness and material integrity - Cost-effective and widely available | - Signal attenuation in thick or anisotropic composites - Requires couplant (e.g., water or gel) - Less sensitive to small/tight flaws - Challenging for curved geometries | - FRP pipeline inspection - Aerospace structural panels - Wind turbine blades - Automotive composite parts |

| Phased Array Ultrasonic Testing (PAUT) | An advanced UT technique using multiple piezoelectric elements in a phased array to steer and focus ultrasonic beams. Enables dynamic beam control, sectorial scans, and improved resolution. | - Beam steering for complex geometries - Higher resolution than UT - Faster scanning and imaging - Can detect small, embedded defects | - Higher cost and complexity - Requires skilled operators and calibration - Sensitive to surface conditions - Depth penetration still limited in thick composites | - Thermoplastic composite pipe (TCP) inspection - Detection of fiber breakage and matrix cracks - Aircraft composite skin and rib inspections - Multilayer CFRP delamination detection |

| Method | Description | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Eddy Current Testing (ECT) | ECT uses alternating current to induce eddy currents in a conductive material. Variations in the induced currents—caused by flaws or changes in conductivity—are measured via electromagnetic coupling to detect surface anomalies. | - High sensitivity to small surface and near-surface defects - Fast and non-contact inspection - Suitable for metallic and CFRP materials - Works on complex geometries with appropriate probe selection | - Limited penetration depth (only effective for near-surface flaws) - Sensitive to lift-off and material properties - Less effective for non-conductive or highly anisotropic materials | - Crack detection in metallic pipes - Conductivity evaluation in CFRP panels - Surface corrosion monitoring - Quality control of heat exchanger tubes |

| Pulse Eddy Current Testing (PECT) | PECT uses short, broadband pulses to generate transient eddy currents. The decaying signal response is captured and analyzed in the time domain, allowing the detection of surface and subsurface flaws through coatings or insulation. | - Penetrates coatings and insulation - Effective for subsurface and multilayer defects - Less sensitive to lift-off than ECT - Enables defect depth profiling - Portable and suitable for field use | - Lower spatial resolution than conventional ECT - Signal interpretation can be complex and affected by noise - Requires specialized signal processing and calibration for layered or composite systems | - Corrosion under insulation (CUI) - Thickness loss in storage tanks and pipelines - Inspection of CFRP/GFRP laminates - Structural health monitoring in aerospace/marine |

| Feature | Description | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Real-time damage detection | AET captures elastic waves released from localized failure sources within composite materials during mechanical loading. | - Enables early identification of failure modes - Monitors damage progression in real-time - Applicable for in-service SHM | - Requires continuous monitoring - Interpretation can be affected by background noise | - Aerospace composite panels - Pressure vessels - Structural fatigue testing |

| Signal parameters | Analyzes number of events, energy release, event rate, counts, amplitude, and frequency spectrum. b-value analysis is used to detect critical rupture precursors. | - Provides rich data for understanding damage mechanisms - Enables predictive failure modeling | - Requires advanced signal processing and calibration - Sensor placement critical for localization accuracy | - Fracture initiation studies - Fatigue crack growth monitoring |

| Smart structure integration | Embedded piezoelectric sensors (PZT, PVDF) enable continuous health monitoring from within the composite layers. | - No need for external inspection - Suitable for integration in next-gen SHM systems | - Sensor embedding may affect material integrity - Long-term sensor durability under stress is a concern | - Wind turbine blades - Aerospace composite spars - Marine sandwich panels |

| Type of Thermography | Description | Advantage | Limitation | Real-World Application |

|---|---|---|---|---|

| Active Thermography |

|

|

|

|

| Passive Thermography | • Passive thermography relies on the natural thermal differences in the object, without applying any external heating or excitation. This is commonly used for condition monitoring and predictive maintenance applications. |

|

|

|

| Transient Thermography | • Transient thermography involves monitoring the surface temperature of an object as it cools down after a brief heating pulse. Defects are detected by analyzing the cooling patterns. |

|

|

|

| Infrared Thermography (IRT) | • IRT is the most common type of thermography, which uses infrared cameras to capture the thermal patterns on the surface of an object. |

|

|

|

| Feature | Description | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Microwave Testing (MW) | MW-based NDT uses electromagnetic radiation in the 300 MHz to 300 GHz range to inspect dielectric or conductive materials. It measures reflected and transmitted waves to detect anomalies caused by defects or inhomogeneities. | - Non-contact and non-invasive - Environmentally safe (non-ionizing) - High penetration depth - Suitable for coated or multilayer composites - Supports advanced signal interpretation (e.g., S-parameters, AI integration) | - Requires complex antenna and probe design - Sensitive to surface roughness or coating interference - Lower spatial resolution compared to UT or XCT - Interpretation requires specialized signal processing | - Detection of delamination or moisture ingress in CFRP - Inspection of honeycomb sandwich structures - Nonmetallic pipeline defect detection - Aerospace and wind energy composite panels |

| X-Ray | Gamma-Ray |

|---|---|

| X-rays are produced by the interaction of high-energy electrons with a metal target, typically made of tungsten or copper, within an X-ray tube. | Gamma rays are emitted from the nucleus of radioactive isotopes, such as Iridium-192 or Cobalt-60, during the radioactive decay process. |

| The energy of X-rays can be controlled by adjusting the voltage and current applied to the X-ray tube. | The energy of gamma rays is determined by the specific radioactive isotope and cannot be easily adjusted. |

| X-rays have a wavelength range of approximately 0.01 to 10 nanometers, which is longer than the wavelength of gamma rays. | Gamma rays have a shorter wavelength and higher frequency than X-rays, typically ranging from 0.01 to 0.1 nanometers. |

| X-ray sources can be turned on and off, allowing for controlled exposure and better regulation of the radiation dose. | Gamma ray sources are continuously emitting radiation and cannot be turned off, requiring more stringent safety measures. |

| Method | Description | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Radiographic Testing (RT) | RT uses X-rays or gamma rays to generate 2D images of internal features based on differential absorption in materials. Film or digital sensors capture the transmitted radiation to detect voids, inclusions, and delamination. | - Effective for identifying internal defects - Can inspect complex geometries - Compatible with both metallic and composite structures - Provides permanent image records | - Involves ionizing radiation (safety risk) - Limited depth penetration in thick composites - Image interpretation requires experience - Defect orientation affects visibility | - Aerospace component inspection - Thermal liner delamination in rocket boosters - Defect mapping in polymeric composites |

| Digital Radiographic Testing (DRT) | DRT is an advanced form of RT that replaces film with digital detectors, enabling real-time image acquisition, enhancement, and analysis with higher sensitivity and resolution. | - High-resolution imaging - Real-time inspection and faster processing - Enhanced image contrast and defect visibility - Reduces need for retakes | - Higher equipment cost- Requires digital image processing expertise - Image artifacts (e.g., anode heel effect) - Limited detector size for large components | - Insulated pipeline inspection - Weld quality assessment in CFRP and GFRP structures - Field inspection of infrastructure composites |

| X-ray Computed Tomography (XCT) | XCT reconstructs 3D internal structures from multiple 2D X-ray projections. It enables the precise visualization and measurement of internal defects like porosity, delamination, and fiber misalignment in composites. | - High-resolution 3D imaging - Enables quantification of fiber orientation, void volume, and porosity - Non-destructive and repeatable - Supports modeling and machine learning | - Long scan and processing times - Expensive hardware and high data storage needs - Limited sample size due to machine constraints - Requires advanced image segmentation skills | - Ballistic panel microstructure analysis - Drilled-hole quality inspection - Damage tracking in aerospace sandwich panels - Dataset generation for AI training |

| NDT Method | Operating Frequency | Coupling Requirement | Detectable Defects | Typical Defect Size Range | Applications |

|---|---|---|---|---|---|

| Ultrasonic Testing (UT) | 0.5–15 MHz | Contact (gel) | Delamination, cracks, voids | 0.1–1 mm | Composite panels, bonded joints |

| Phased Array Ultrasonic Testing (PAUT) | 1–10 MHz | Contact (gel), automated scan | Delamination, cracks, porosity | 0.1 mm or less | Aerospace laminates, CFRP |

| Eddy Current Testing (ECT) | 100 kHz–10 MHz | Non-contact (lift-off sensitive) | Surface cracks, corrosion | 0.1–1 mm | Conductive surface inspections |

| Pulsed Eddy Current Testing (PECT) | 10 Hz–1 kHz (time–domain) | Non-contact (lift-off tolerant) | Subsurface corrosion, cracks | 1–5 mm subsurface | CUI detection, corrosion mapping |

| Acoustic Emission Testing (AET) | 100 kHz–1 MHz | Passive, no coupling | Crack initiation, delamination | Micron to mm (based on signal) | SHM, real-time monitoring |

| Infrared Thermography (IRT) | 0.1–100 Hz (thermal) | Non-contact (IR camera) | Disbonding, surface defects | 1–5 mm (thermal gradient) | Impact damage, debonding |

| Microwave Testing (MWT) | 300 MHz–300 GHz | Non-contact (free-space/waveguide) | Delamination, internal voids | 1–3 mm (CFRP) | CFRP, GRE, HDPE inspection |

| Radiographic Testing (RT) | Up to 1018 Hz (X-ray/gamma) | Non-contact (radiation exposure) | Voids, inclusions, delamination | 50 µm–mm | Aerospace structures, composites |

| Digital Radiography Testing (DRT) | Up to 1018 Hz (X-ray) | Non-contact (digital detector) | Voids, inclusions, weld flaws | 50 µm–mm | In-field CFRP/GFRP inspection |

| X-ray Computed Tomography (XCT) | Multiple projections (X-ray) | Non-contact, enclosed system | Porosity, fiber misalignment | <10 µm | 3D microstructure analysis |

| NDE Technique | Key Findings | Frequency of Use |

|---|---|---|

| Ultrasonic Testing (UT) | UT is widely used for its ability to detect internal defects such as delaminations, disbonds, and porosity. However, its effectiveness is limited by the anisotropic nature of composite materials, requiring advanced signal processing techniques. | 45% of the reviewed articles utilized UT |

| Phased Array Ultrasonic Testing (PAUT) | PAUT overcomes some limitations of conventional UT by providing better defect detection and flexibility in complex composite structures. However, it requires specialized equipment and training. | 20% of the reviewed articles employed PAUT. |

| Eddy Current Testing (ECT) | ECT is effective for detecting surface and subsurface defects but faces challenges in interpreting signals due to the complexity of composite materials. | 15% of the reviewed articles discussed ECT. |

| Acoustic Emission (AET) | AET is valuable for real-time damage detection but is limited by environmental factors and the difficulty in localizing defect sources. | 10% of the reviewed articles focused on AET. |

| Thermography (IRT) | IRT is a non-contact method suitable for various applications but is influenced by environmental factors and may not easily detect subsurface defects. | 25% of the reviewed articles utilized IRT. |

| Microwave (MW) | MW offers high penetration depth and is environmentally safe but requires complex probe designs and advanced interpretation techniques. | 5% of the reviewed articles discussed MW. |

| Radiography Testing (RT) | RT is effective in identifying a wide range of internal defects but carries potential health risks due to ionizing radiation. | 20% of the reviewed articles employed RT. |

| Digital Radiography Testing (DRT) | DRT offers high sensitivity and resolution but is more expensive and requires specialized training. | 15% of the reviewed articles utilized DRT. |

| X-Ray Tomography (XCT) | XCT provides unparalleled insight into the internal features of complex materials but is limited by data processing requirements and sample size restrictions. | 10% of the reviewed articles discussed XCT. |

| NDE Technique | Advantages | Limitations |

|---|---|---|

| Ultrasonic Testing (UT) | Cost-effective, effective for metal parts and assemblies, can detect internal defects. | Limited by anisotropic structure, high attenuation, and low signal-to-noise ratio of composites. |

| Phased Array Ultrasonic Testing (PAUT) | Overcome limitations of UT, capable of focusing and steer ultrasonic signals. | Requires specialized equipment and training. |

| Eddy Current Testing (ECT) | Quick and accurate inspection, can detect surface and subsurface defects. | Complexity of composite materials can pose challenges in the interpretation of ECT signals. |

| Acoustic Emission (AET) | Effective in detecting and identifying different damage mechanisms in real-time. | Limited by environmental factors and difficulty in accurately localizing the source of AET events in complex composite structures. |

| Thermography (IRT) | Non-contact, can provide a wide range of applications. | Effectiveness can be influenced by environmental factors, and subsurface defects may not be easily detected. |

| Microwave (MW) | High penetration depth, non-invasive, environmentally safe. | Complexity of probe design, interpretation of results can be challenging. |

| Radiography Testing (RT) | Can identify a wide range of internal defects within composite structures. | Use of ionizing radiation carries potential health risks and must be carefully managed. |

| Digital Radiography Testing (DRT) | High sensitivity and resolution, improved image quality, faster inspection times. | More expensive than traditional film-based radiography, specialized training may be required. |

| X-Ray Tomography (XCT) | Provides unparalleled insight into the internal features of complex materials, multi-scale analysis. | Data processing requirements, sample size restrictions, acquisition time can be limiting factors. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Józwik, J.; Oksiuta, Z.; Shahar, F.S. Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations. Materials 2025, 18, 3146. https://doi.org/10.3390/ma18133146

Tai JL, Sultan MTH, Łukaszewicz A, Józwik J, Oksiuta Z, Shahar FS. Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations. Materials. 2025; 18(13):3146. https://doi.org/10.3390/ma18133146

Chicago/Turabian StyleTai, Jan Lean, Mohamed Thariq Hameed Sultan, Andrzej Łukaszewicz, Jerzy Józwik, Zbigniew Oksiuta, and Farah Syazwani Shahar. 2025. "Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations" Materials 18, no. 13: 3146. https://doi.org/10.3390/ma18133146

APA StyleTai, J. L., Sultan, M. T. H., Łukaszewicz, A., Józwik, J., Oksiuta, Z., & Shahar, F. S. (2025). Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations. Materials, 18(13), 3146. https://doi.org/10.3390/ma18133146