Seismic Performance of Beam–Column Joints in Seawater Sand Concrete Reinforced with Steel-FRP Composite Bars

Abstract

1. Introduction

2. Experimental Programs

2.1. Seawater Sea–Sand Concrete

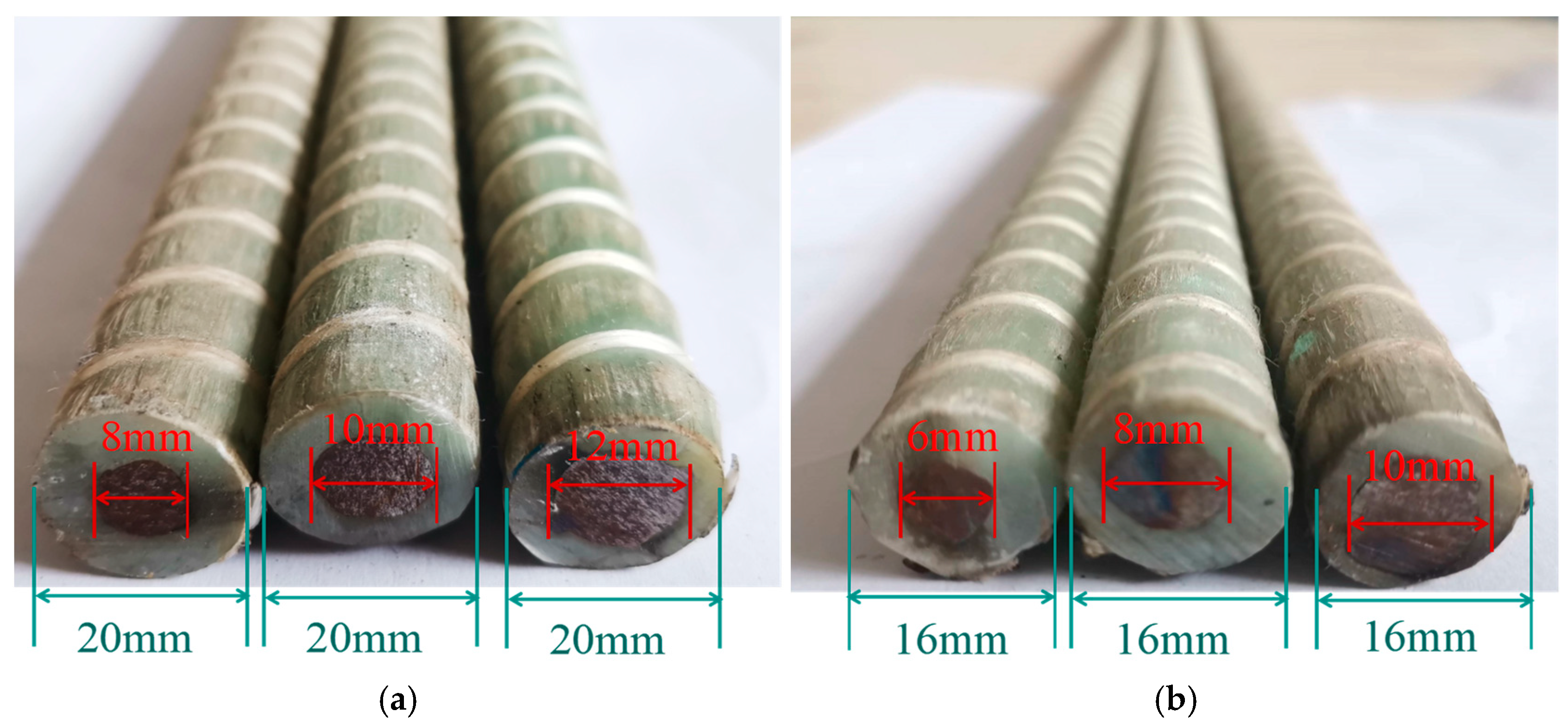

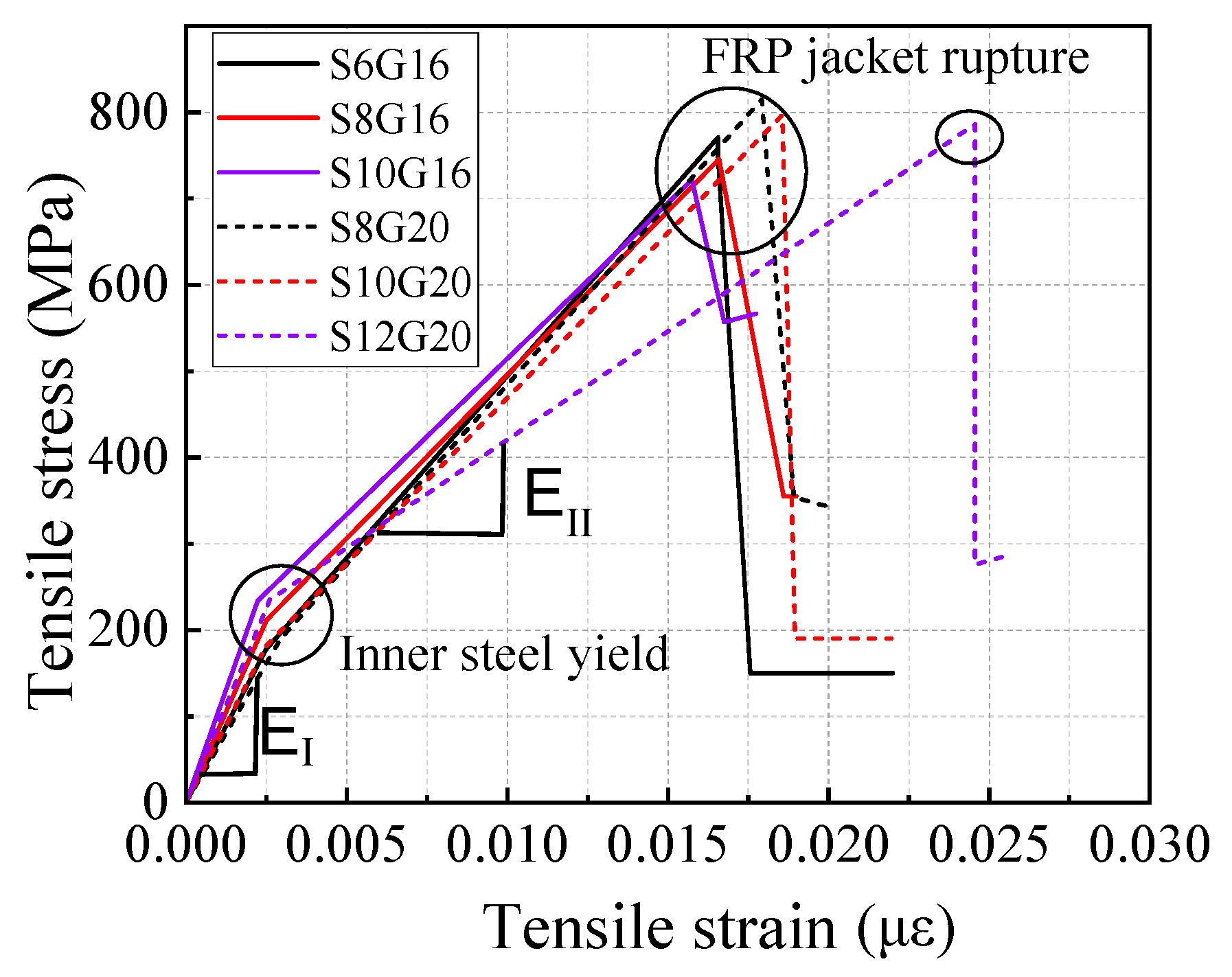

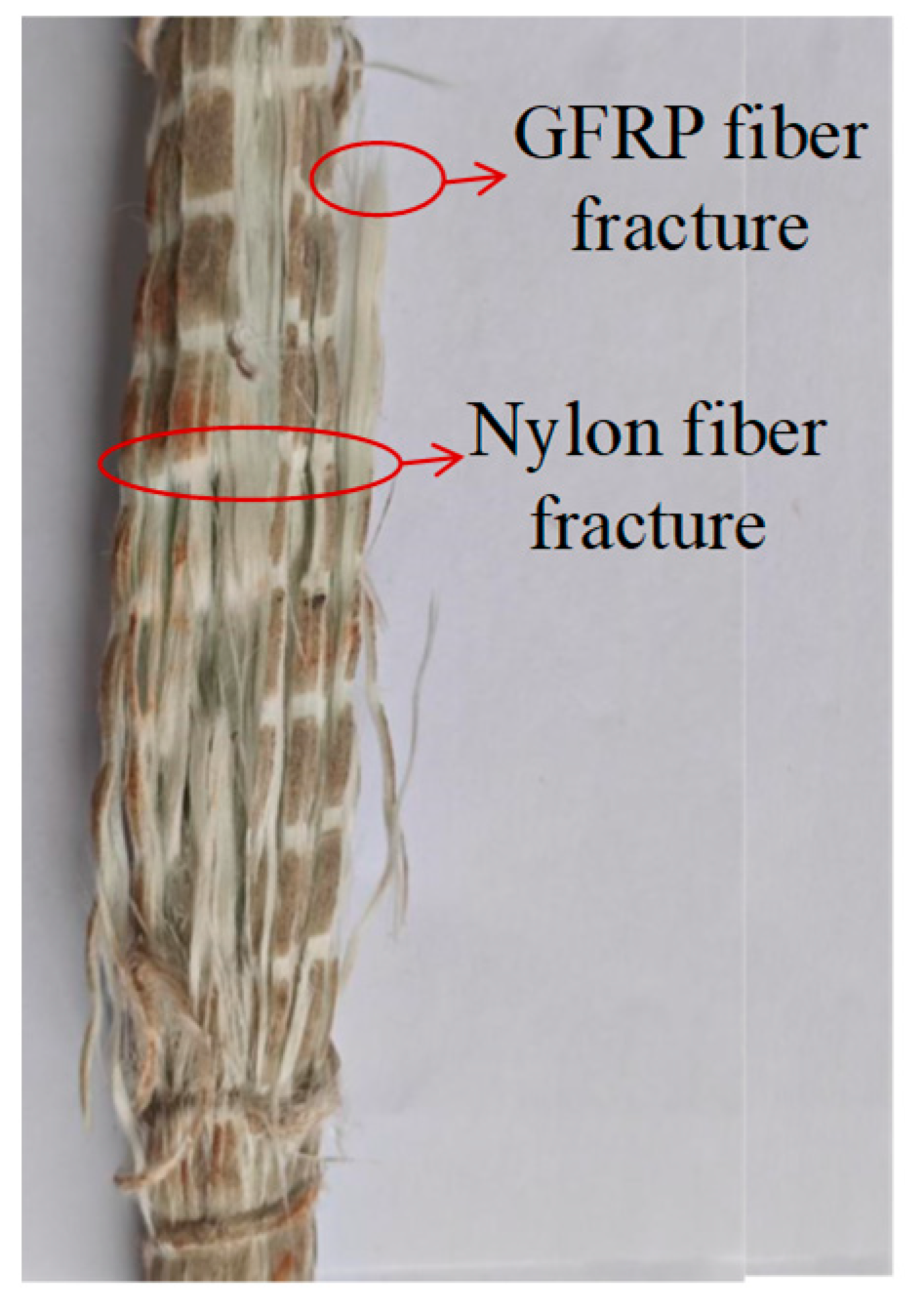

2.2. Mechanical Properties of SFCBs

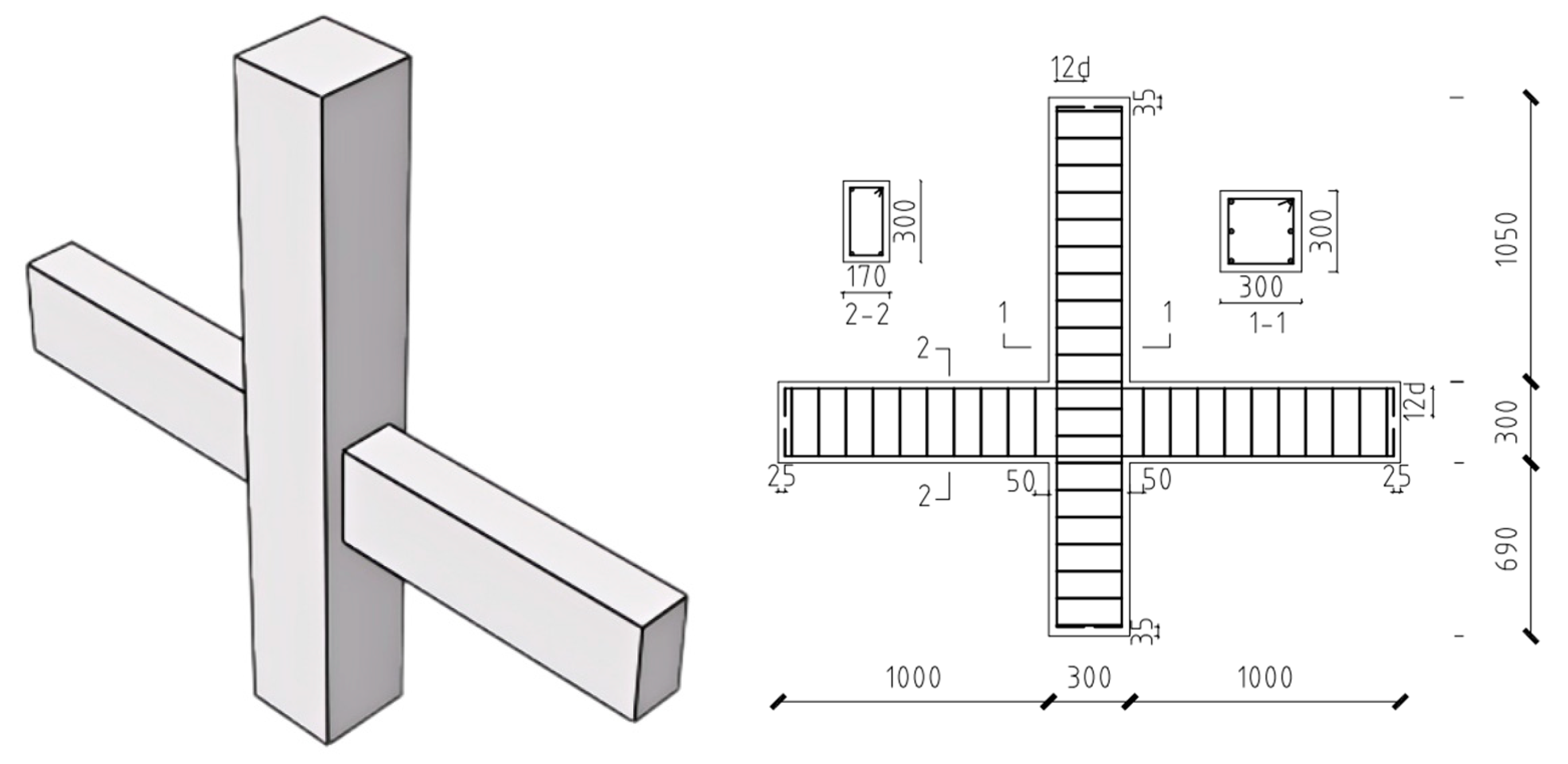

2.3. SFCB Reinforced Concrete Beam–Column Joints Tested

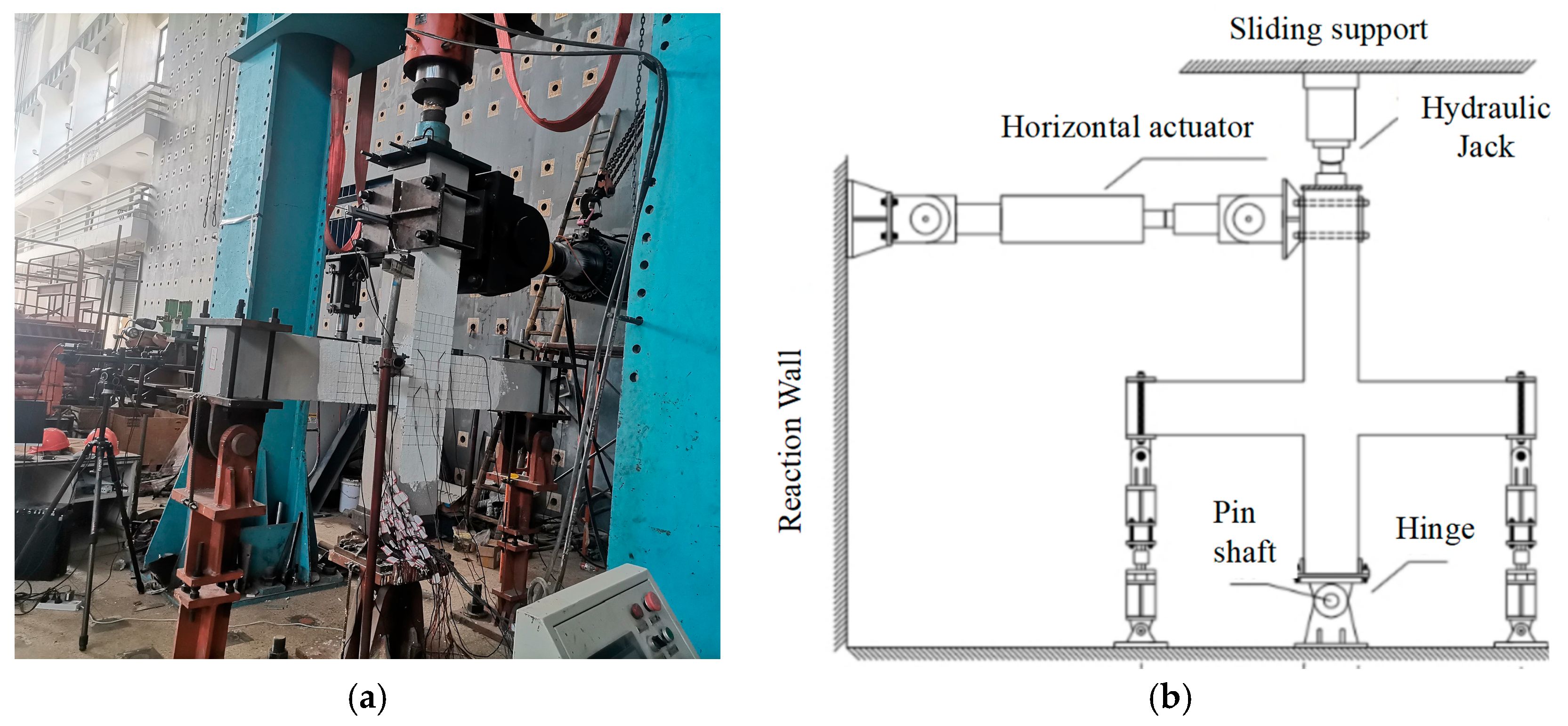

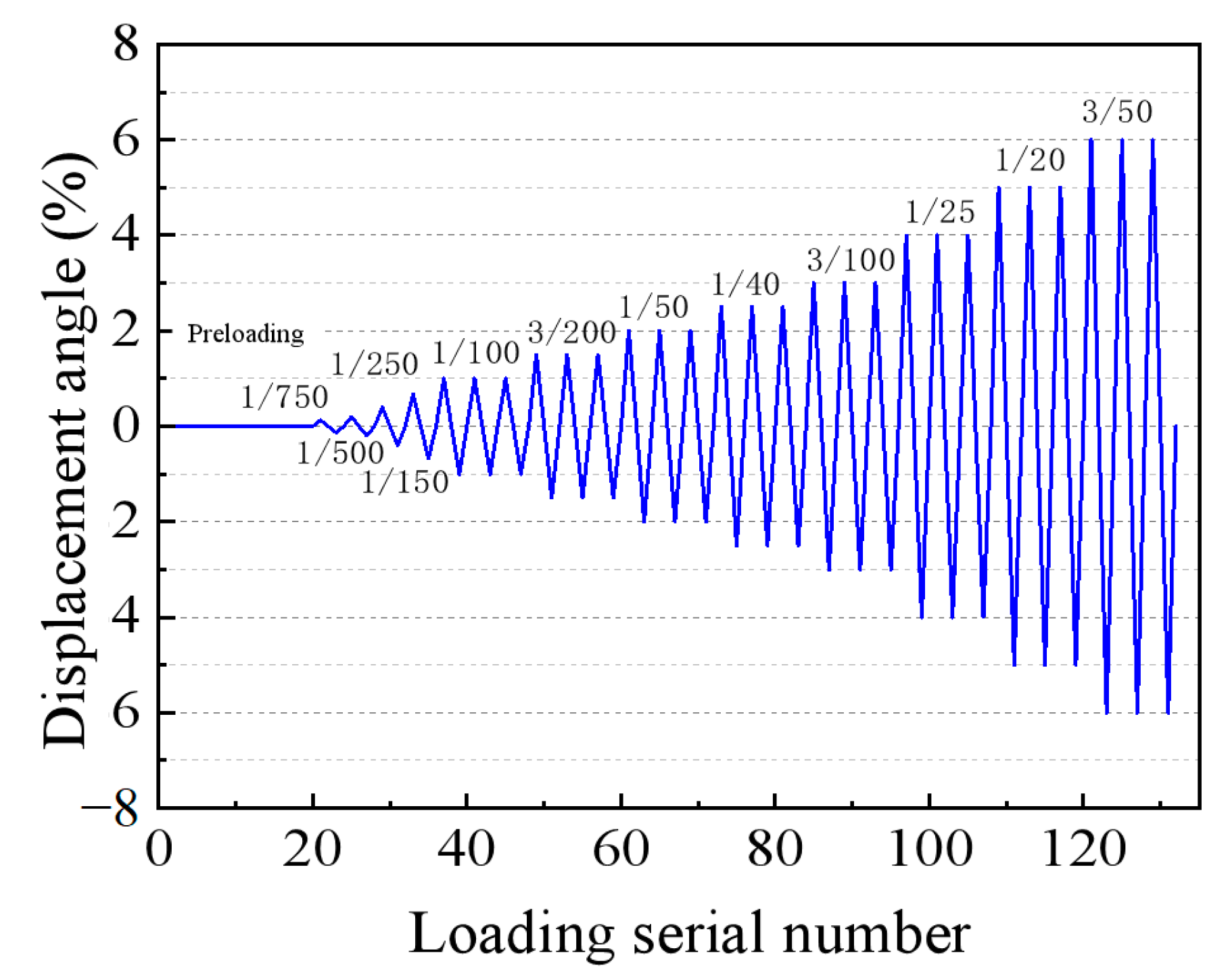

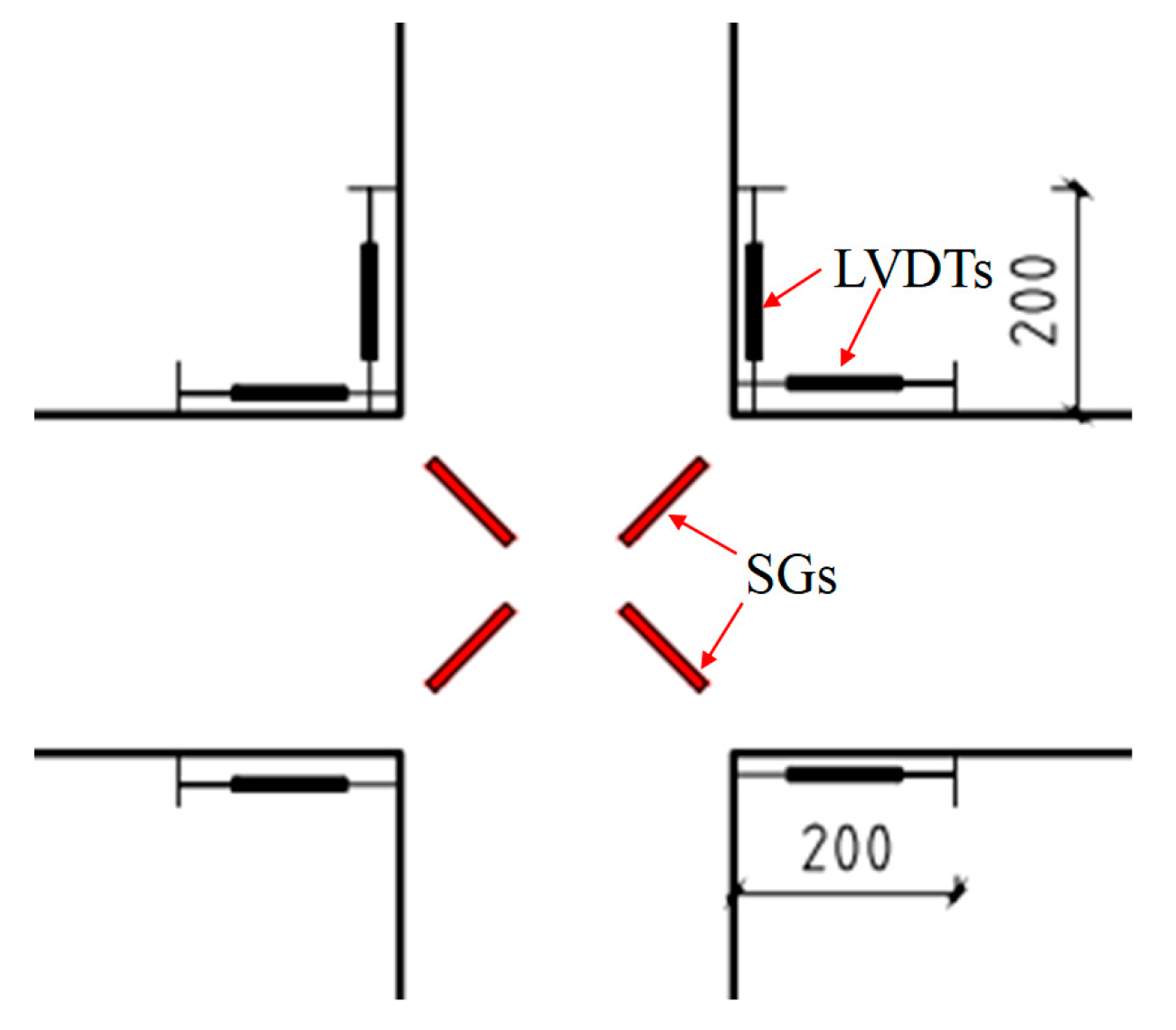

2.4. Loading and Measurement Programs

3. Results and Discussion

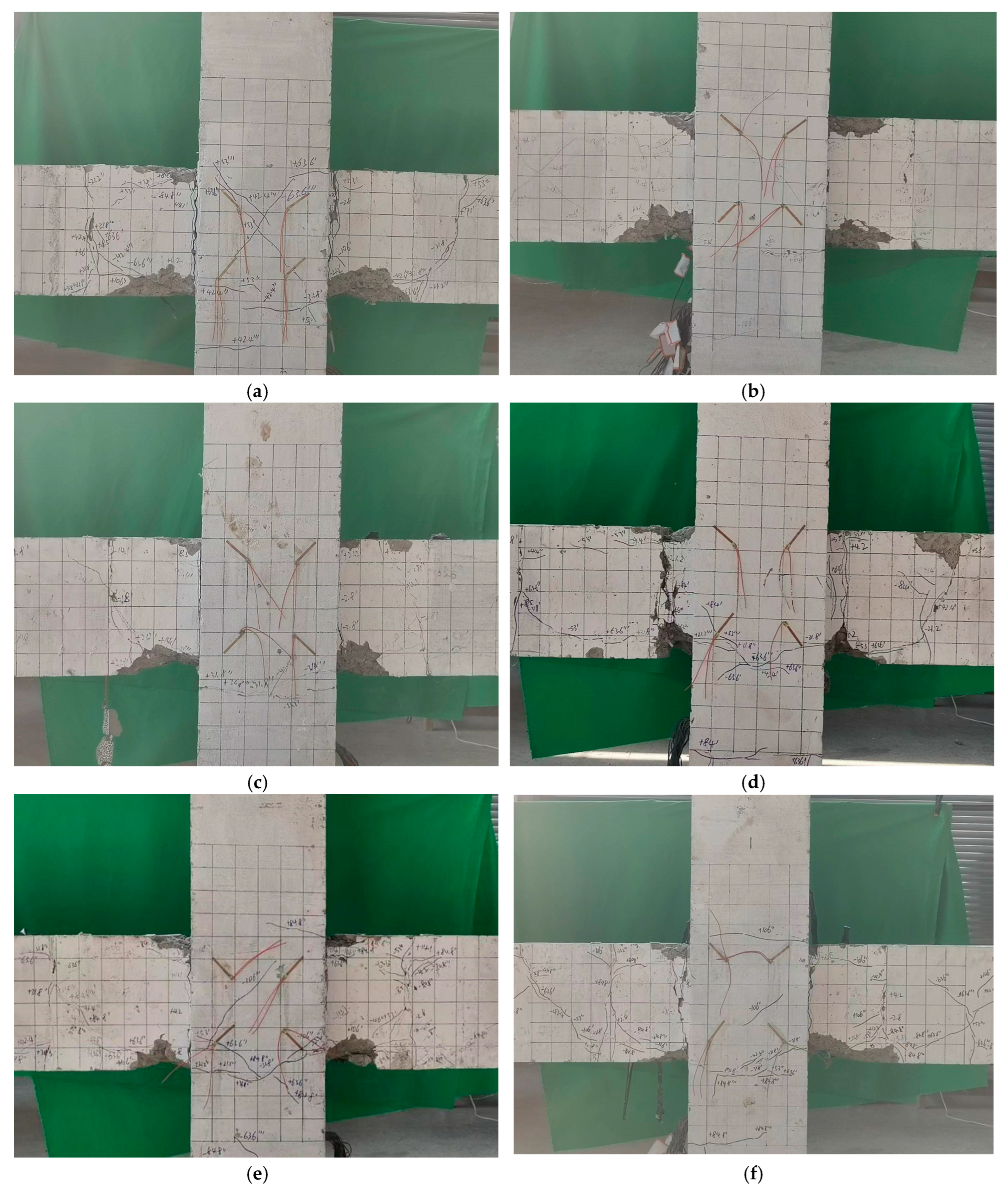

3.1. Failure Modes

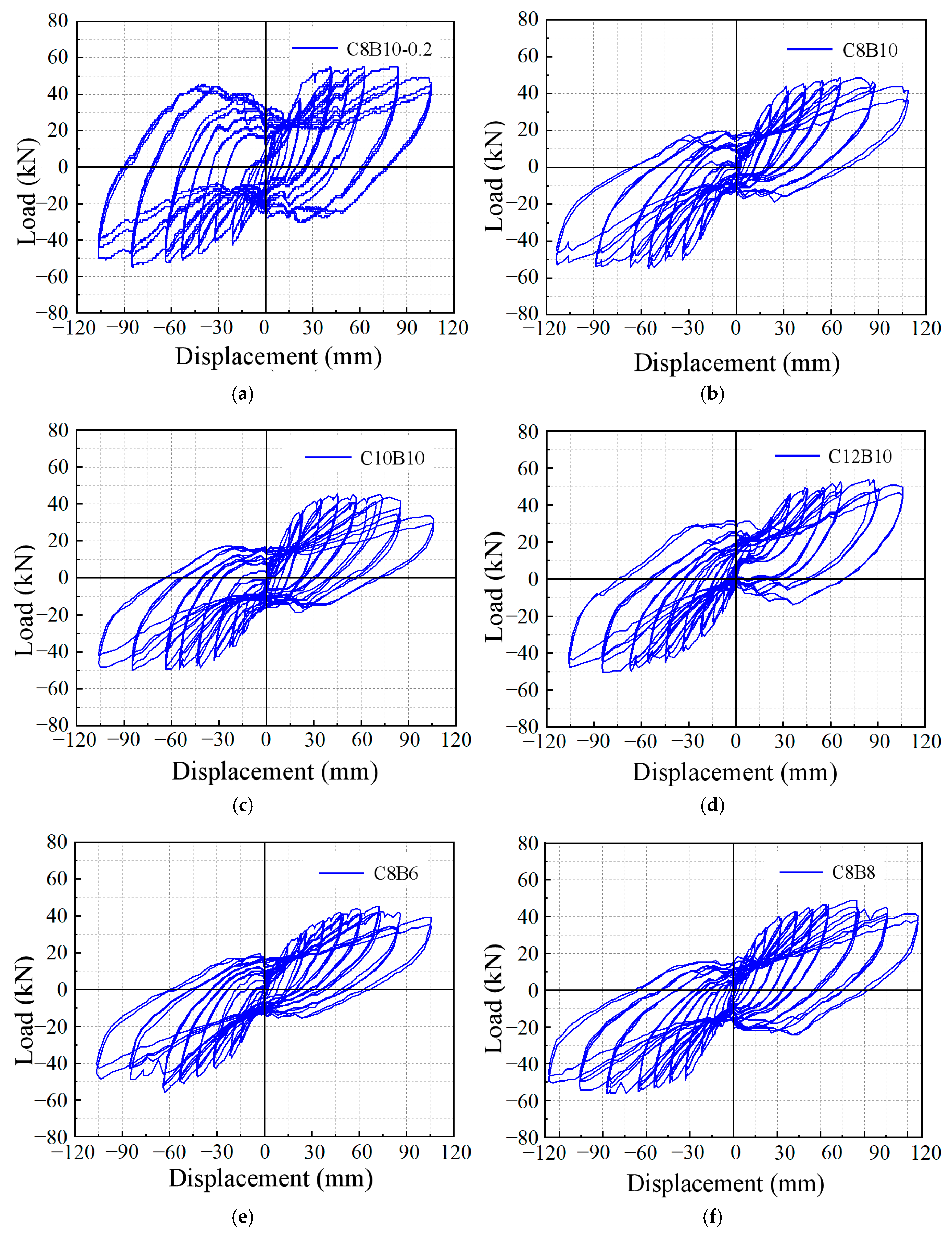

3.2. Hysteresis Curves

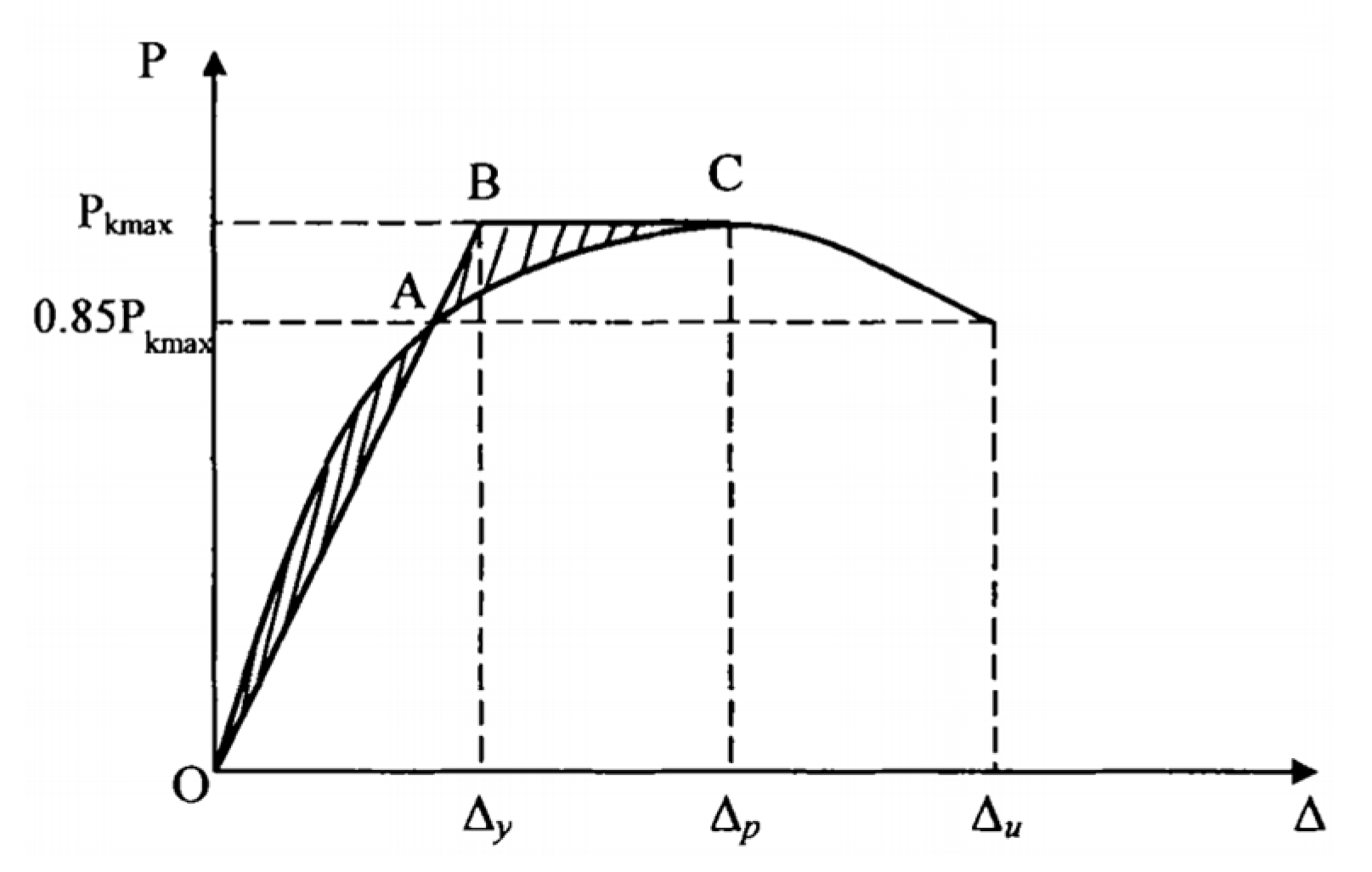

3.3. Skeleton Curves

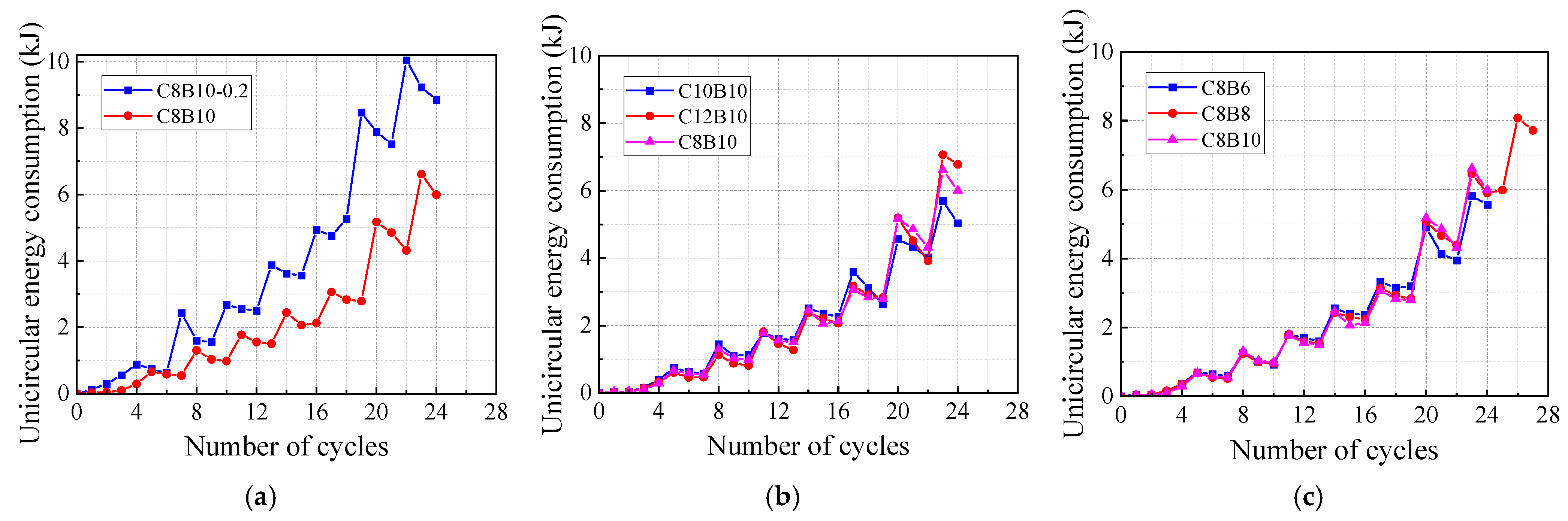

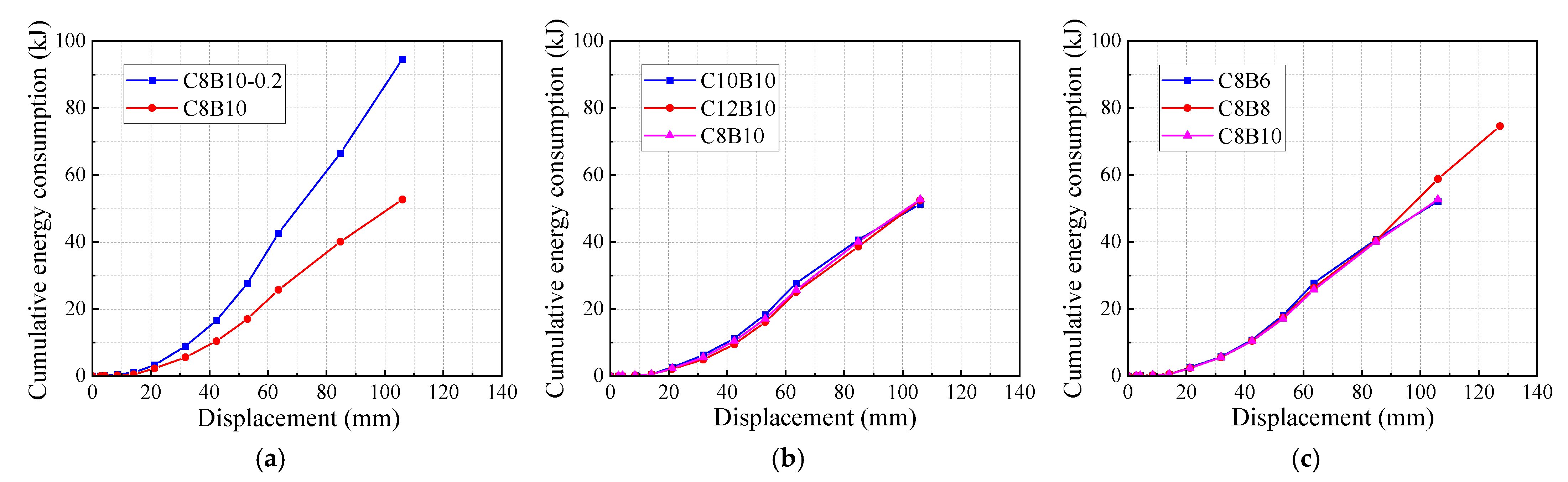

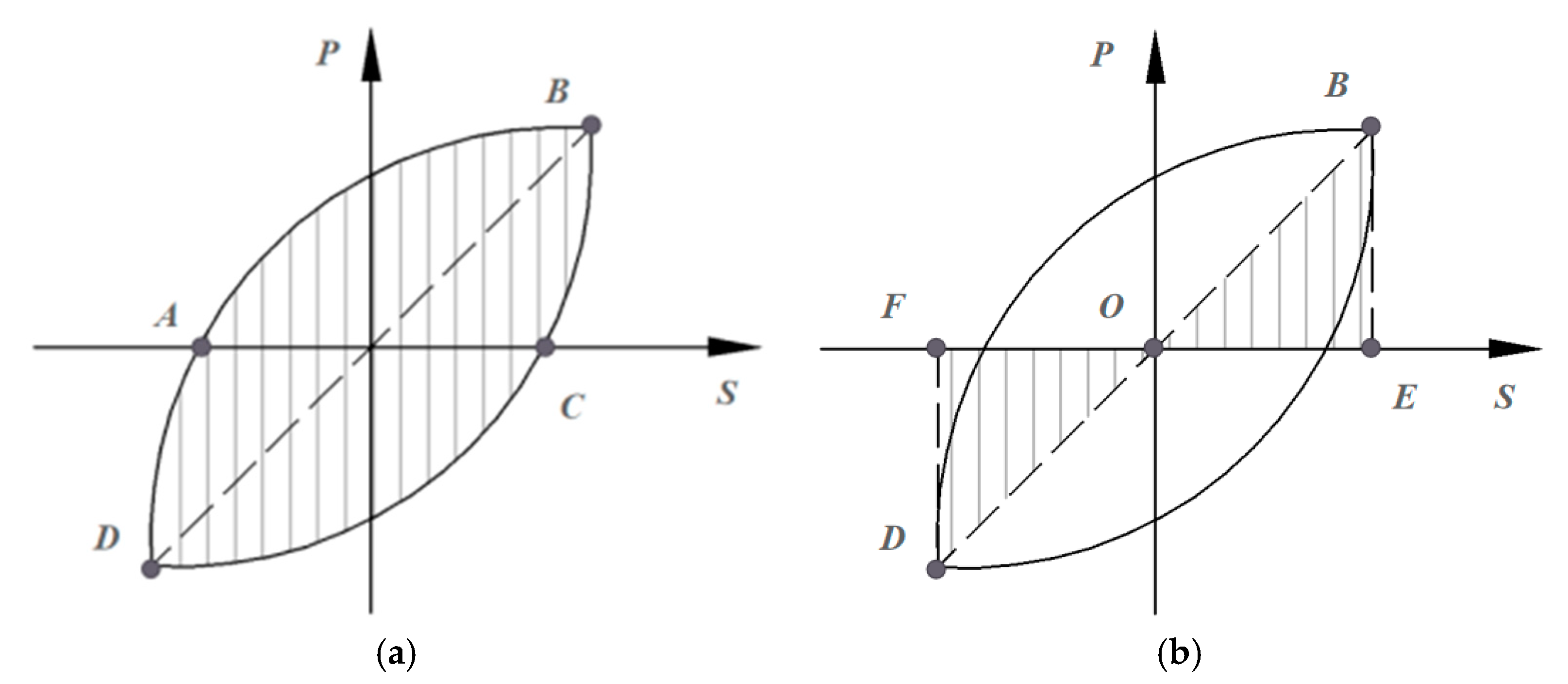

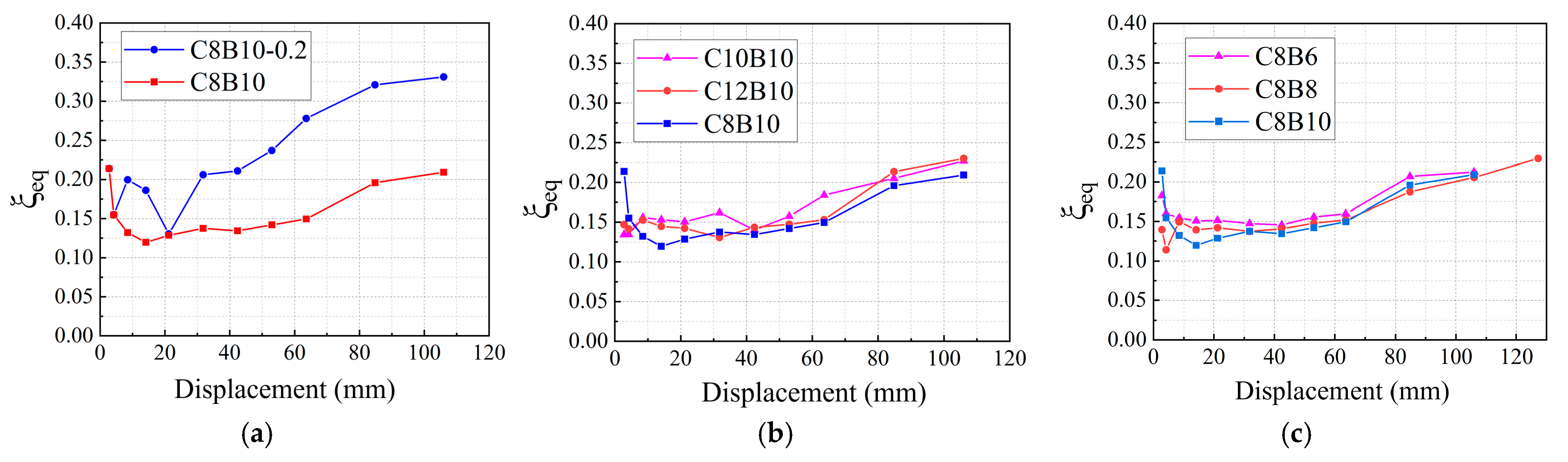

3.4. Energy Consumption

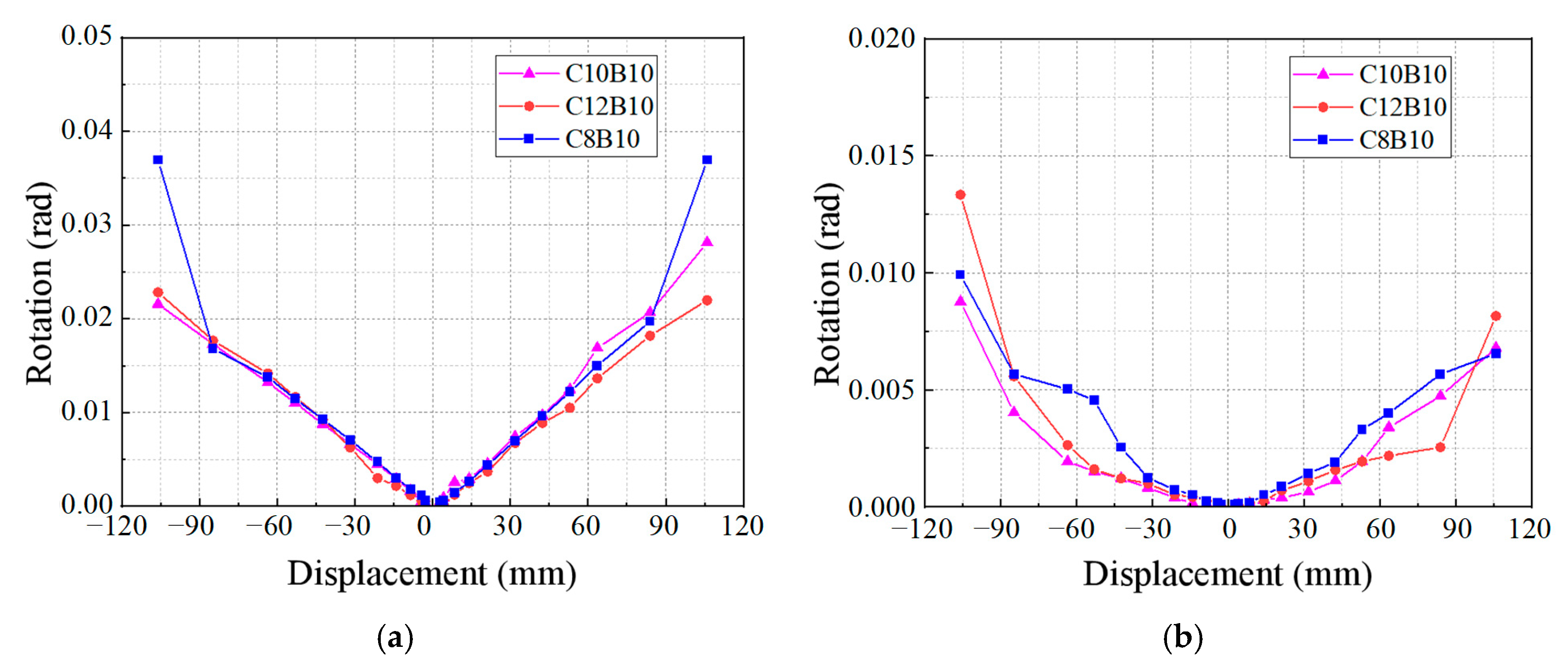

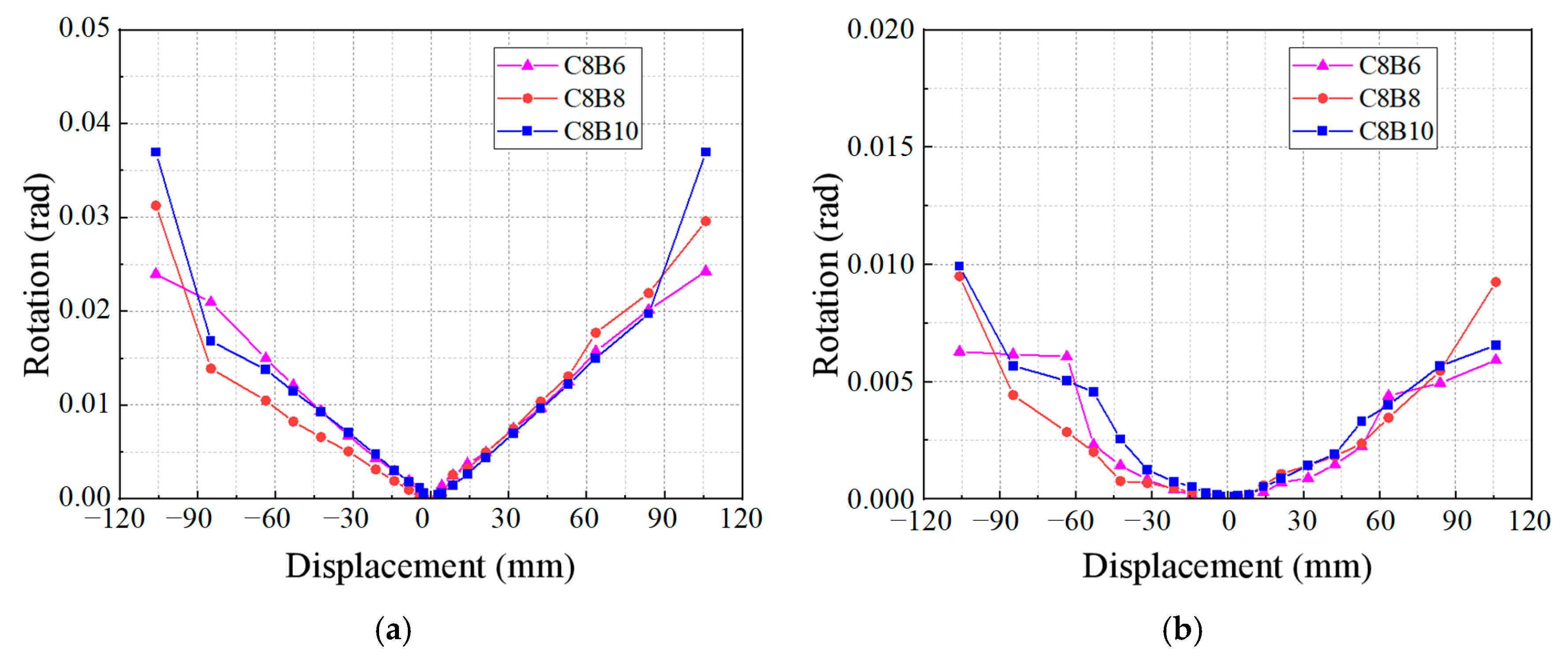

3.5. Fixed-End Rotations of Column and Beam

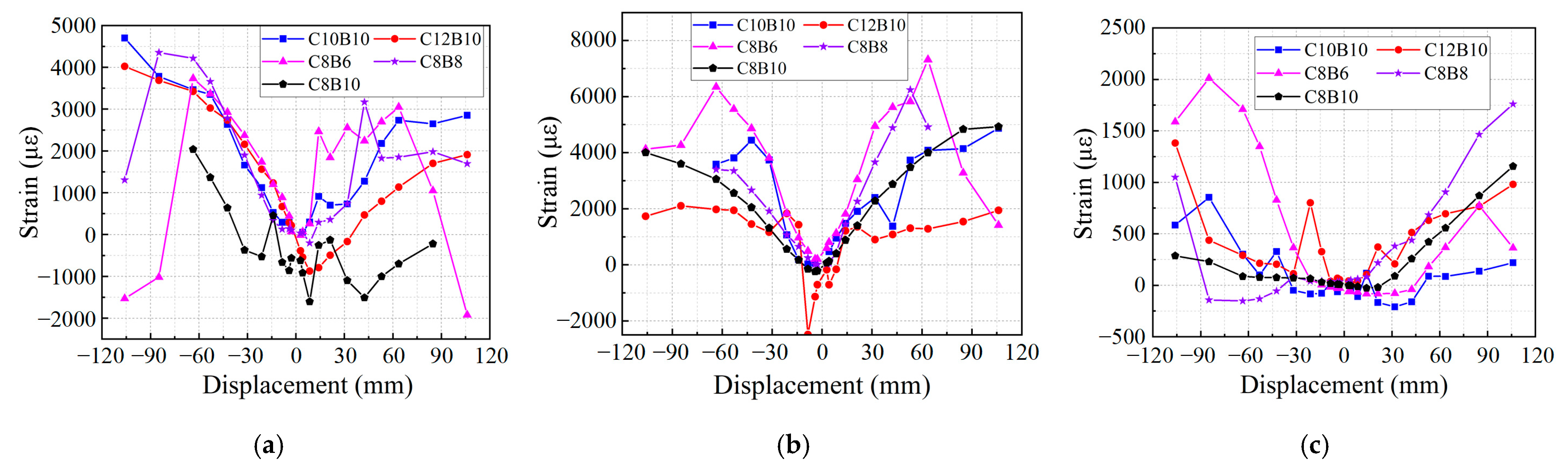

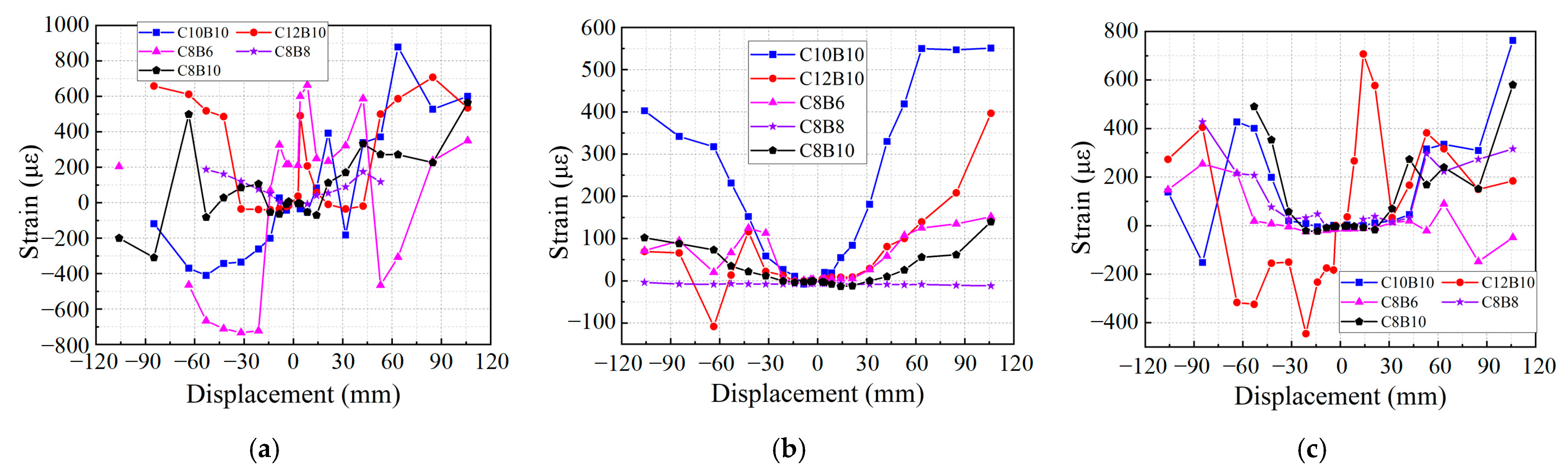

3.6. SFCB Strains

4. Conclusions

- (1)

- All specimens showed beam end bending failure, in line with the design principle of ‘strong column and weak beam’. The longitudinal reinforcement of the column section did not reach yield strain, and the stirrup strain in the core area was low (<800 µε), indicating no significant shear failure occurred in the core area of the joint. Additionally, the combination of SFCBs and seawater sand concrete exhibits excellent bonding properties and crack resistance in a corrosive environment, with no sliding failure of the FRP bars.

- (2)

- Increasing the axial compression ratio (e.g., from 0.1 to 0.2) significantly enhances the shear and bond strength of the joints, effectively inhibiting crack propagation and slip, but also accelerating bearing capacity degradation. At the same displacement angle, the energy consumption of the specimen with an axial compression ratio of 0.2 (e.g., C8B10-0.2) is 52% higher than that of the specimen with 0.1, and the cumulative energy consumption is 80% higher.

- (3)

- An increase in the longitudinal SFCB fiber volume ratio (e.g., from 64% to 84%) improves joint stiffness, fracture distribution uniformity, and ductility. The C12B10 specimen, with the highest fiber volume ratio, exhibited the highest bearing capacity (50 kN), 16.7% and 8% higher than C8B10 and C10B10, respectively.

- (4)

- The longitudinal SFCB fiber volume ratio significantly affects the seismic performance of the beam. The specimen with a medium fiber volume ratio (75%) (e.g., C8B8) demonstrated the best performance, with cumulative energy consumption 43% and 41.6% higher than C8B6 and C8B10, respectively. Its cracks were finer, and the concrete integrity was better. A low volume ratio (e.g., 60.9%) resulted in significant cracking of the concrete and a decrease in bearing capacity, while a high volume ratio (e.g., 86%) may reduce energy dissipation efficiency due to stiffness imbalance.

- (5)

- The stable secondary stiffness of SFCBs provides continuous bearing capacity during the joint plastic stage, delays stiffness degradation, and improves the equivalent viscous damping coefficient of the specimen. For instance, C8B8 still maintains high energy dissipation capacity after failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rentier, E.S.; Cammeraat, L.H. The environmental impacts of river sand mining. Sci. Total Environ. 2022, 838, 155877. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.C.; Cai, Y.J.; Xie, Z.H.; Xiao, S.H.; Zhuo, K.X.; Cai, P.D.; Lin, J.X. Experimental investigation of GFRP bar bonding in geopolymer concrete using hinged beam tests. Eng. Struct. 2025, 322, 119036. [Google Scholar] [CrossRef]

- Su, J.Y.; Chen, G.; Pan, H.S.; Lin, J.X.; Zhang, J.; Zhuo, K.X.; Chen, Z.B.; Guo, Y.C. Rubber modified high strength-high ductility concrete: Effect of rubber replacement ratio and fiber length. Constr. Build. Mater. 2023, 404, 133243. [Google Scholar] [CrossRef]

- Liu, X.H.; Chen, Z.X.; Yu, Z.C.; Chen, P.; Zhang, Y.Z. A review on ultra-high performance seawater sea sand concrete: Hydration, microstructure and properties. Constr. Build. Mater. 2024, 438, 136945. [Google Scholar] [CrossRef]

- Zhang, W.; Ding, D.W.; Sun, J.X.; Guo, F.; Feng, H.B.; Ma, H.Y.; Hong, S.X.; Dong, B.Q.; Hou, D.S. Novel insights on the setting process, hardened properties, and durability of sustainable ultra-high-performance seawater sea sand concrete. Constr. Build. Mater. 2024, 447, 138092. [Google Scholar] [CrossRef]

- Hu, X.; Bai, T.; Zhao, Y.; Ren, Q.; Chen, Y.; Li, H.; Shi, C. Interface mechanical properties of CFRP-seawater sea sand concrete under simulated seawater immersion. J. Build. Eng. 2024, 97, 110768. [Google Scholar] [CrossRef]

- Mashayekhi, A.; Hassanli, R.; Zhuge, Y.; Ma, X.; Chow, C.W.K.; Bazli, M.; Manalo, A. Structural behaviour of small GFRP-reinforced seawater sea-sand fiber reinforced concrete culverts. Structures 2024, 69, 107492. [Google Scholar] [CrossRef]

- News, S.L.C. Corrosion News. Mater. Corros. 2020, 71, 1407–1414. [Google Scholar] [CrossRef][Green Version]

- Cristoforetti, A.; Rossi, S.; Deflorian, F.; Fedel, M. Recent progress in understanding filiform corrosion on organic coated steel: A comprehensive review. Prog. Org. Coat. 2024, 192, 108469. [Google Scholar] [CrossRef]

- Dong, S.C.; Zhou, P.; Ning, Z.; Wu, X.; Li, C.G.; Xian, G.J. Durability of carbon- and glass-fiber reinforced thermoplastic polymer composites: A literature review. J. Build. Eng. 2024, 98, 111055. [Google Scholar] [CrossRef]

- Karim, H.; Sheikh, M.N.; Hadi, M.N.S. Longitudinal Reinforcement Limits for Fiber-Reinforced Polymer Reinforced Concrete Members. ACI Struct. J. 2017, 114, 687–696. [Google Scholar] [CrossRef]

- Xiao, S.H.; Cai, Y.C.; Xie, Z.H.; Guo, Y.C.; Zheng, Y.; Lin, J.X. Bond durability between steel-FRP composite bars and concrete under seawater corrosion environments. Constr. Build. Mater. 2024, 419, 135456. [Google Scholar] [CrossRef]

- Cai, Y.J.; Xiao, S.H.; Chen, Y.W.; Huang, Z.R.; Lin, J.X.; Guo, Y.C.; Peng, Y.Q.; Xie, Z.H. Tensile behavior and durability prediction of GFRP-steel composite bars under chloride environments. J. Mater. Res. Technol. 2023, 23, 5746–5759. [Google Scholar] [CrossRef]

- Guo, Y.C.; Xiao, S.H.; Zeng, J.J.; Su, J.Y.; Li, T.Z.; Xie, Z.H. Behavior of concrete-filled FRP tube columns internally reinforced with FRP-steel composite bars under axial compression. Constr. Build. Mater. 2022, 315, 125714. [Google Scholar] [CrossRef]

- Cai, Y.C.; Xie, Z.H.; Xiao, S.H.; Huang, Z.R.; Lin, J.X.; Guo, Y.C.; Zhuo, K.X.; Huang, P.Y. An investigation of fatigue behavior and residual strength model of steel-GFRP composite bar. Compos. Struct. 2024, 327, 117685. [Google Scholar] [CrossRef]

- Xiao, S.H.; Cai, Y.J.; Xie, Z.H.; Zheng, Y.; Lin, J.X.; Guo, Y.C. Effects of marine environment and fatigue pre-damage on the residual tensile properties of SFCBs. Constr. Build. Mater. 2024, 449, 138273. [Google Scholar] [CrossRef]

- Zhao, D.B.; Pan, J.; Zhou, Y.W.; Sui, L.L.; Ye, Z.H. New types of steel-FRP composite bar with round steel bar inner core: Mechanical properties and bonding performances in concrete. Constr. Build. Mater. 2020, 242, 118062. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Wu, G.; Zhao, X.L.; Zhu, H.; Lian, J.L. Bond durability of steel-FRP composite bars embedded in seawater sea-sand concrete under constant bending and shearing stress. Constr. Build. Mater. 2018, 192, 808–817. [Google Scholar] [CrossRef]

- Dong, Z.Q.; Wu, G.; Xu, Y.Q. Experimental study on the bond durability between steel-FRP composite bars (SFCBs) and sea sand concrete in ocean environment. Constr. Build. Mater. 2016, 115, 277–284. [Google Scholar] [CrossRef]

- Han, S.W.; Zhou, A.; Fan, C.; Xiao, G.; Ou, J.P. Seawater sea-sand concrete columns using durable and ductile steel-FRP composite bars and FRP ties: A promising hybrid scheme for marine engineering. Eng. Struct. 2023, 294, 116731. [Google Scholar] [CrossRef]

- Xiao, S.H.; Lin, J.X.; Li, L.J.; Guo, Y.C.; Zeng, J.J.; Xie, Z.H.; Wei, F.F.; Li, M. Experimental study on flexural behavior of concrete beam reinforced with GFRP and steel-fiber composite bars. J. Build. Eng. 2021, 43, 103087. [Google Scholar] [CrossRef]

- Ge, W.J.; Chen, K.B.; Guan, Z.W.; Ashour, A.; Lu, W.G.; Cao, D.F. Eccentric compression behaviour of concrete columns reinforced with steel-FRP composite bars. Eng. Struct. 2021, 238, 112240. [Google Scholar] [CrossRef]

- Han, S.W.; Fan, C.; Zhou, A.; Ou, J.P. Shear behavior of concrete beams reinforced with corrosion-resistant and ductile longitudinal steel-FRP composite bars and FRP stirrups. Eng. Struct. 2023, 278, 115520. [Google Scholar] [CrossRef]

- Han, S.W.; Fan, C.; Zhou, A.; Ou, J.P. Simplified implementation of equivalent and ductile performance for steel-FRP composite bars reinforced seawater sea-sand concrete beams: Equal-stiffness design method. Eng. Struct. 2022, 266, 114590. [Google Scholar] [CrossRef]

- Ding, L.N.; Lei, M.K.; Wang, X.; Shi, Y.W.; Zhu, Z.G.; Yu, P.C.; Wu, Z.S. Durability of concrete members reinforced with steel-FRP composite bars under dry-wet cycles of seawater. Structures 2021, 33, 2273–2283. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Sun, Y.L.; Zheng, Y.; Iwashita, K.; Zhang, J.; Wu, G. Experimental study on precast concrete columns reinforced with bundled SFCBs under horizontal cyclic loading. J. Build. Eng. 2023, 74, 106882. [Google Scholar] [CrossRef]

- Su, C.; Wang, X.; Ding, L.N.; Chen, Z.Y.; Liu, S.; Wu, Z.S. Experimental study on the seismic behavior of seawater sea sand concrete beams reinforced with steel-FRP composite bars. Eng. Struct. 2021, 248, 113269. [Google Scholar] [CrossRef]

- Su, C.; Wang, X.; Ding, L.N.; Wu, Z.S. Seismic degradation behavior of steel-FRP composite bar reinforced concrete beams in marine environment based on experimental and numerical investigation. Compos. Struct. 2023, 313, 116949. [Google Scholar] [CrossRef]

- Niroomandi, A.; Maheri, A.; Maheri, M.R.; Mahini, S.S. Seismic performance of ordinary RC frames retrofitted at joints by FRP sheets. Eng. Struct. 2010, 32, 2326–2336. [Google Scholar] [CrossRef]

- Sadeghi-Movahhed, A.; De Domenico, D.; Majdi, A. Structural flexibility impact on pounding severity and seismic performance of adjacent isolated buildings. Soil Dyn. Earthq. Eng. 2024, 181, 108667. [Google Scholar] [CrossRef]

- Huang, Z.; Gong, L.; Jiang, L.; Chen, Y.F.; Qi, J.; Huang, Y. Study on seismic performance and restoring force model of framed CFST column-composite box beam joints. Structures 2024, 69, 107458. [Google Scholar] [CrossRef]

- Yuen, Y.P.; Kuang, J.S. Nonlinear seismic responses and lateral force transfer mechanisms of RC frames with different infill configurations. Eng. Struct. 2015, 91, 125–140. [Google Scholar] [CrossRef]

- Favvata, M.J.; Izzuddin, B.A.; Karayannis, C.G. Modelling exterior beam–column joints for seismic analysis of RC frame structures. Earthq. Eng. Struct. Dyn. 2008, 37, 1527–1548. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M. Influence of mixture composition on the structural behaviour of reinforced concrete beam-column joints: A review. Structures 2022, 42, 29–52. [Google Scholar] [CrossRef]

- del Rey Castillo, E.; Niroomandi, A.; Triantafillou, T. Seismic Retrofitting of Realistic Beam–Column Joints with Shear Failure Using FRP Sheets and FRP Anchors. J. Compos. Const. 2024, 28, 1–16. [Google Scholar] [CrossRef]

- Attari, N.; Youcef, Y.S.; Amziane, S. Seismic performance of reinforced concrete beam–column joint strengthening by frp sheets. Structures 2019, 20, 353–364. [Google Scholar] [CrossRef]

- Yu, F.; Xu, B.; Wang, J.M.; Fang, Y.; Yang, Y.Z.; Chen, Z.P.; Zhang, Y.F. Influence of joint forms on the seismic behavior of concrete-filled PVC-CFRP tubular column-RC beam joints connected with core steel tubes. Eng. Struct. 2024, 303, 1. [Google Scholar] [CrossRef]

- Shokrzadeh, M.R.; Aziminejad, A.; Moghaddam, A.S. Evaluation of various FRP strengthening configurations for RC beam-column joints. Bridg. Struct. 2024, 20, 71–91. [Google Scholar] [CrossRef]

- Xu, W. Experimental Study on Seismic Performance of Steel-Continuous Fiber Composite Reinforced Concrete Joints. Master’s Thesis, Southeast University, Nanjing, China, 2010. (In Chinese). [Google Scholar]

- ASTM D1141-98; Standard Practice for the Preparation of Substitute Ocean Water. ASTM International: West Conshohocken, PA, USA, 2013.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the PRC; State Administration for Market Regulation: Beijing, China, 2019.

- ASTM C469; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2010.

- GB/T 30022-2013; Test Method for Basic Mechanical Properties of Fiber Reinforced Polymer Bar. Standardization Administration of China: Beijing, China, 2013.

- GB/T 228.1-2010; Metallic Materials-Tensile Testing at Ambient Temperature. State Administration for Market Regulation; Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Lin, G.; Zeng, J.J.; Liang, S.D.; Liao, J.J.; Zhuge, Y. Seismic behavior of novel GFRP bar reinforced concrete beam-column joints internally reinforced with an FRP tube. Eng. Struct. 2022, 273, 115100. [Google Scholar] [CrossRef]

- GB 50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-rural Construction of the People’s Republic of China and the General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2016.

- JGJ/T101-2015; Specifications for Seismic Test of Buildings. China Architecture & Building Press: Beijing, China, 2015.

- Fu, J.P.; Chen, T.; Wang, Z.; Bai, S.L. Effect of axial load ratio on seismic behaviour of interior beam–column joints. In Proceedings of the 2th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

| Cement (kg/m3) | Sand (kg/m3) | Stone (kg/m3) | Fly Ash (kg/m3) | Mineral Powder (kg/m3) | Seawater (kg/m3) | Water Reducer (kg/m3) |

|---|---|---|---|---|---|---|

| 252 | 779 | 1034 | 54 | 54 | 170 | 7.96 |

| Particle Size (mm) | Flakiness and Elongation Index (%) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Fines Content (%) |

|---|---|---|---|---|

| 5~25 | 4 | 2620 | 1510 | 0.40 |

| Component | Concentration (g/L) |

|---|---|

| NaCl | 24.530 |

| MgCl2 | 5.200 |

| Na2SO4 | 4.090 |

| CaCl2 | 1.160 |

| KCl | 0.695 |

| NaHCO3 | 0.201 |

| KBr | 0.101 |

| H3BO3 | 0.027 |

| SrCl2 | 0.025 |

| NaF | 0.003 |

| Specimens | Diameter d (mm) | Anchor Section Length l1 (mm) | Working Section Length l0 (mm) | Overall Length l (mm) |

|---|---|---|---|---|

| SFCB | 16 | 200 | 350 | 750 |

| SFCB | 20 | 300 | 400 | 1000 |

| GFRP | 10 | 150 | 200 | 500 |

| Specimens 1 | Diameter d (mm) | Modulus of Elasticity Es (GPa) | Secondary Rigidity Es′ (GPa) | Yielding Strength fy (MPa) | Ultimate Strength fu (MPa) |

|---|---|---|---|---|---|

| S6 | 6 | 206.21 | / | 559.28 | 759.31 |

| S8 | 8 | 186.86 | / | 525.36 | 714.63 |

| S10 | 10 | 202.33 | / | 523.73 | 649.38 |

| S12 | 12 | 205.72 | / | 518.17 | 622.66 |

| G10 | 10 | 44.75 | / | / | 770.82 |

| S6G16 | 16 | 71.35 | 35.81 | 177.48 | 771.28 |

| S8G16 | 16 | 84.22 | 32.19 | 211.76 | 746.75 |

| S10G16 | 16 | 104.69 | 31.01 | 233.73 | 722.28 |

| S8G20 | 20 | 64.92 | 34.71 | 189.06 | 811.66 |

| S10G20 | 20 | 72.87 | 32.97 | 181.05 | 793.27 |

| S12G20 | 20 | 90.15 | 22.39 | 235.23 | 785.68 |

| Specimens | Column Longitudinal Bar | Beam Longitudinal Bar | Axial Compression Ratio | ||||

|---|---|---|---|---|---|---|---|

| Configuration | RR 1 (%) | FVR 1 (%) | Configuration | RR (%) | FVR (%) | ||

| C8B10 | 6S8G20 | 2.09 | 84 | 4S10G16 | 1.58 | 60.9 | 0.1 |

| C8B10-0.2 | 6S8G20 | 2.09 | 84 | 4S10G16 | 1.58 | 60.9 | 0.2 |

| C10B10 | 6S10G20 | 2.09 | 75 | 4S10G16 | 1.58 | 60.9 | 0.1 |

| C12B10 | 6S12G20 | 2.09 | 64 | 4S10G16 | 1.58 | 60.9 | 0.1 |

| C8B6 | 6S8G20 | 2.09 | 84 | 4S6G16 | 1.58 | 86 | 0.1 |

| C8B8 | 6S8G20 | 2.09 | 84 | 4S8G16 | 1.58 | 75 | 0.1 |

| C8B10 | 6S8G20 | 2.09 | 84 | 4S10G16 | 1.58 | 60.9 | 0.1 |

| C8B10-0.2 | 6S8G20 | 2.09 | 84 | 4S10G16 | 1.58 | 60.9 | 0.2 |

| Specimens | Py (kN) | Δy (mm) | Pm (kN) | Δm (mm) | Pu (kN) | Δu (mm) | DC | Average Value |

|---|---|---|---|---|---|---|---|---|

| C8B10-0.2 | 45.80 | 35.80 | 53.94 | 84.52 | 45.80 | 105.95 | 2.96 | 2.88 |

| −44.13 | −37.92 | −54.70 | −85.09 | −49.82 | −106.2 | 2.80 | ||

| C10B10 | 37.19 | 28.80 | 43.23 | 45.30 | 36.46 | 88.28 | 3.07 | 3.31 |

| −42.36 | −29.90 | −49.23 | −63.70 | −46.21 | −106.10 | 3.55 | ||

| C12B10 | 45.36 | 35.61 | 50.46 | 67.05 | 47.66 | 105.95 | 2.98 | 2.79 |

| −41.00 | −40.64 | −47.81 | −67.25 | −44.68 | −106.05 | 2.61 | ||

| C8B6 | 39.13 | 40.07 | 44.24 | 72.62 | 37.60 | 103.64 | 2.59 | 2.62 |

| −44.13 | −40.14 | −53.48 | −63.88 | −45.71 | −106.28 | 2.65 | ||

| C8B8 | 39.10 | 33.02 | 46.38 | 65.44 | 40.28 | 127.14 | 3.85 | 3.54 |

| −49.81 | −39.49 | −56.06 | −87.26 | −49.51 | −127.26 | 3.22 | ||

| C8B10 | 41.53 | 33.05 | 46.50 | 65.97 | 41.58 | 108.77 | 3.29 | 3.26 |

| −50.11 | −35.17 | −53.78 | −88.64 | −49.94 | −113.54 | 3.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, R.; Zhang, B.; Liang, Z.; Li, X.; Xiao, S. Seismic Performance of Beam–Column Joints in Seawater Sand Concrete Reinforced with Steel-FRP Composite Bars. Materials 2025, 18, 2282. https://doi.org/10.3390/ma18102282

Liang R, Zhang B, Liang Z, Li X, Xiao S. Seismic Performance of Beam–Column Joints in Seawater Sand Concrete Reinforced with Steel-FRP Composite Bars. Materials. 2025; 18(10):2282. https://doi.org/10.3390/ma18102282

Chicago/Turabian StyleLiang, Ruiqing, Botao Zhang, Zhensheng Liang, Xiemi Li, and Shuhua Xiao. 2025. "Seismic Performance of Beam–Column Joints in Seawater Sand Concrete Reinforced with Steel-FRP Composite Bars" Materials 18, no. 10: 2282. https://doi.org/10.3390/ma18102282

APA StyleLiang, R., Zhang, B., Liang, Z., Li, X., & Xiao, S. (2025). Seismic Performance of Beam–Column Joints in Seawater Sand Concrete Reinforced with Steel-FRP Composite Bars. Materials, 18(10), 2282. https://doi.org/10.3390/ma18102282