Experimental Investigation on the Fracture Behavior of PET-Modified Engineered High-Ductility Concrete: Effects of PET Powder and Precursor Composition

Abstract

1. Introduction

2. Materials and Methods

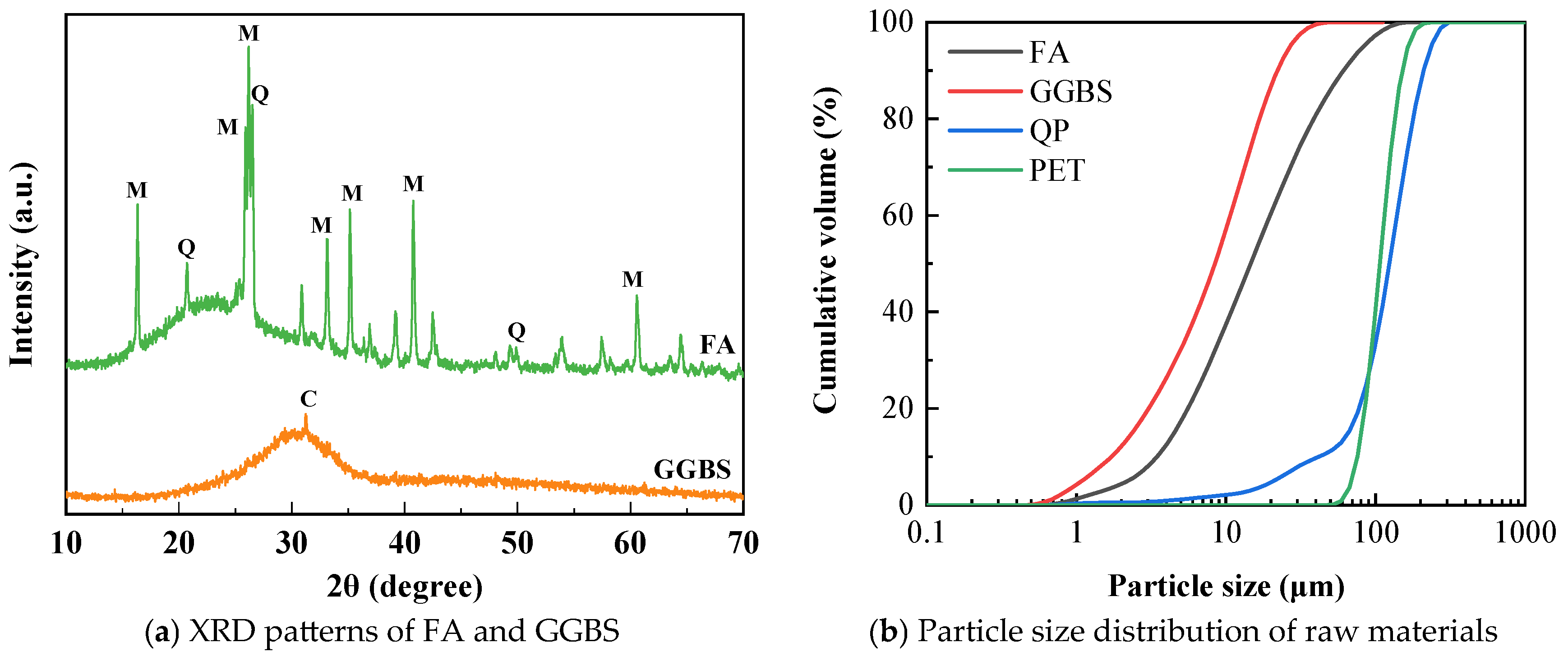

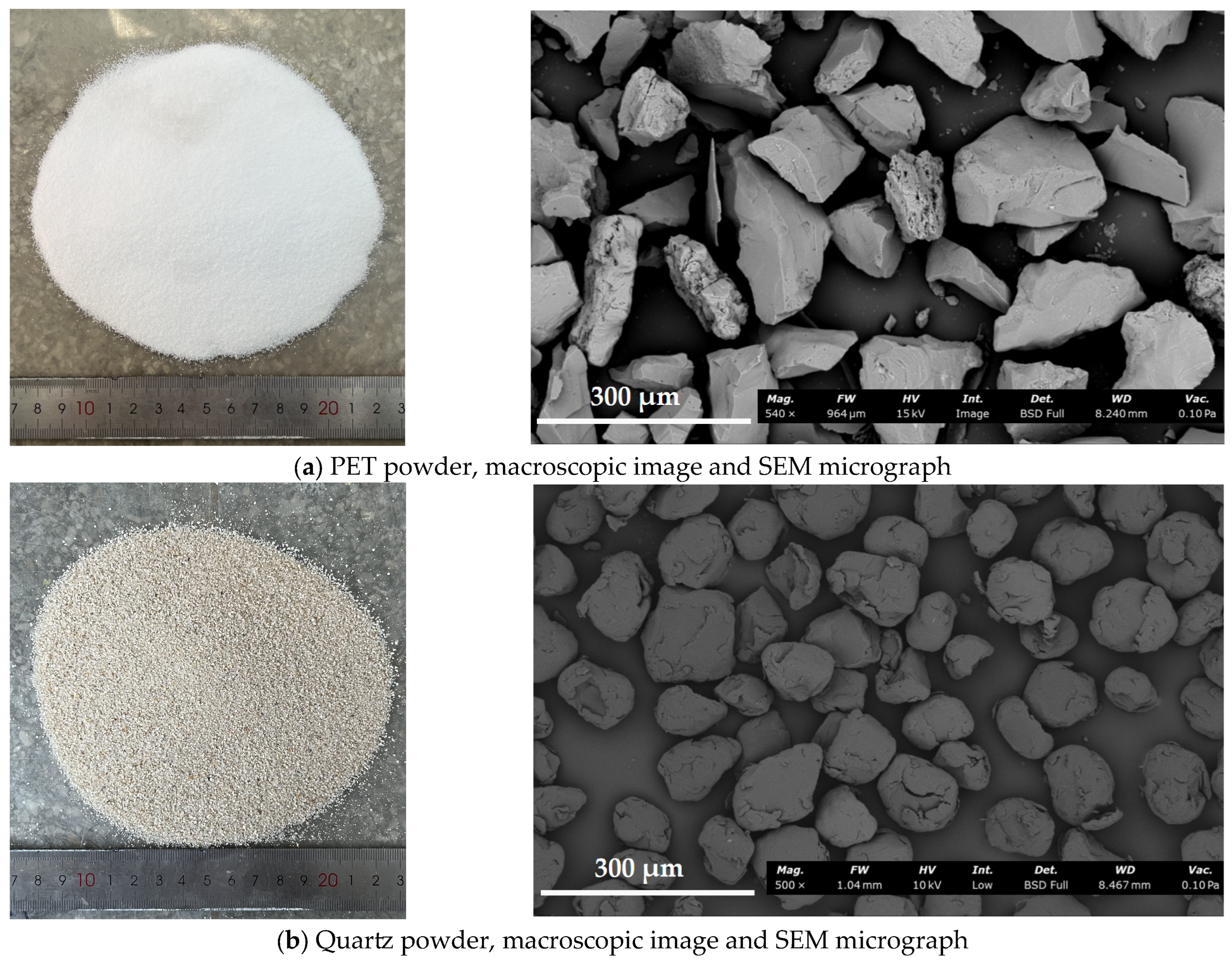

2.1. Materials

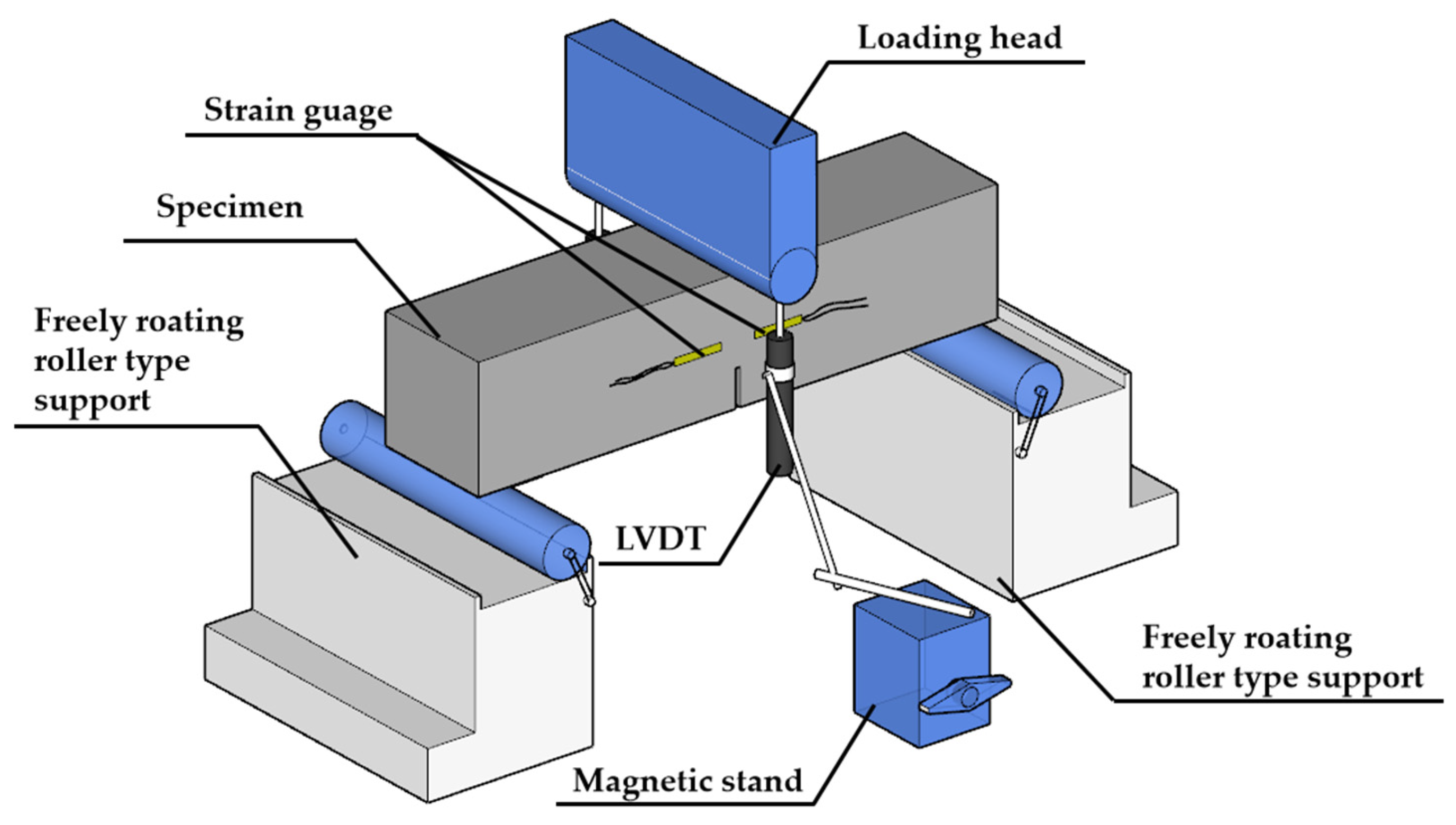

2.2. Testing Setup

2.2.1. Fracture Test

2.2.2. SEM Analysis

3. Results and Discussion

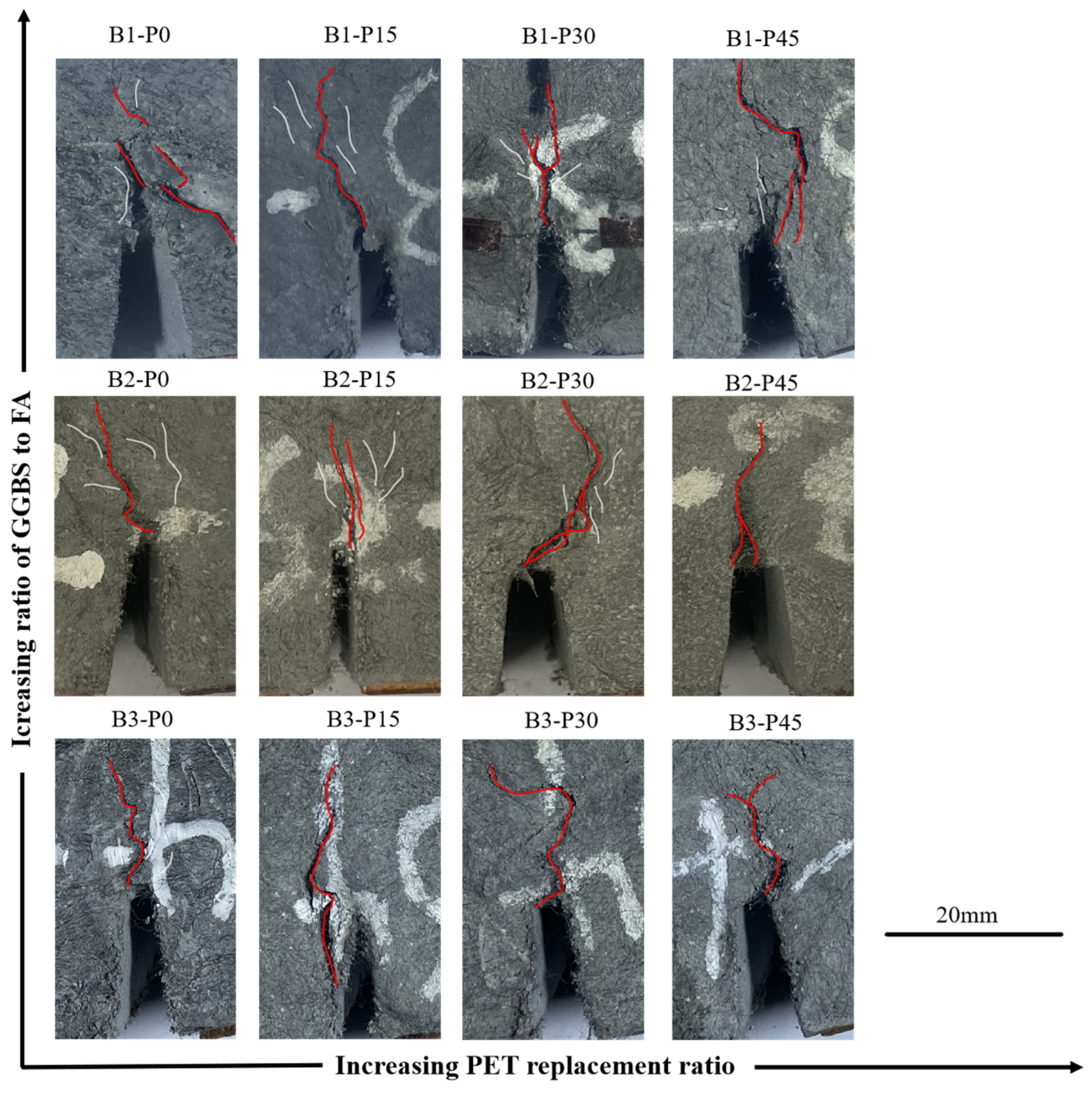

3.1. Failure Mode

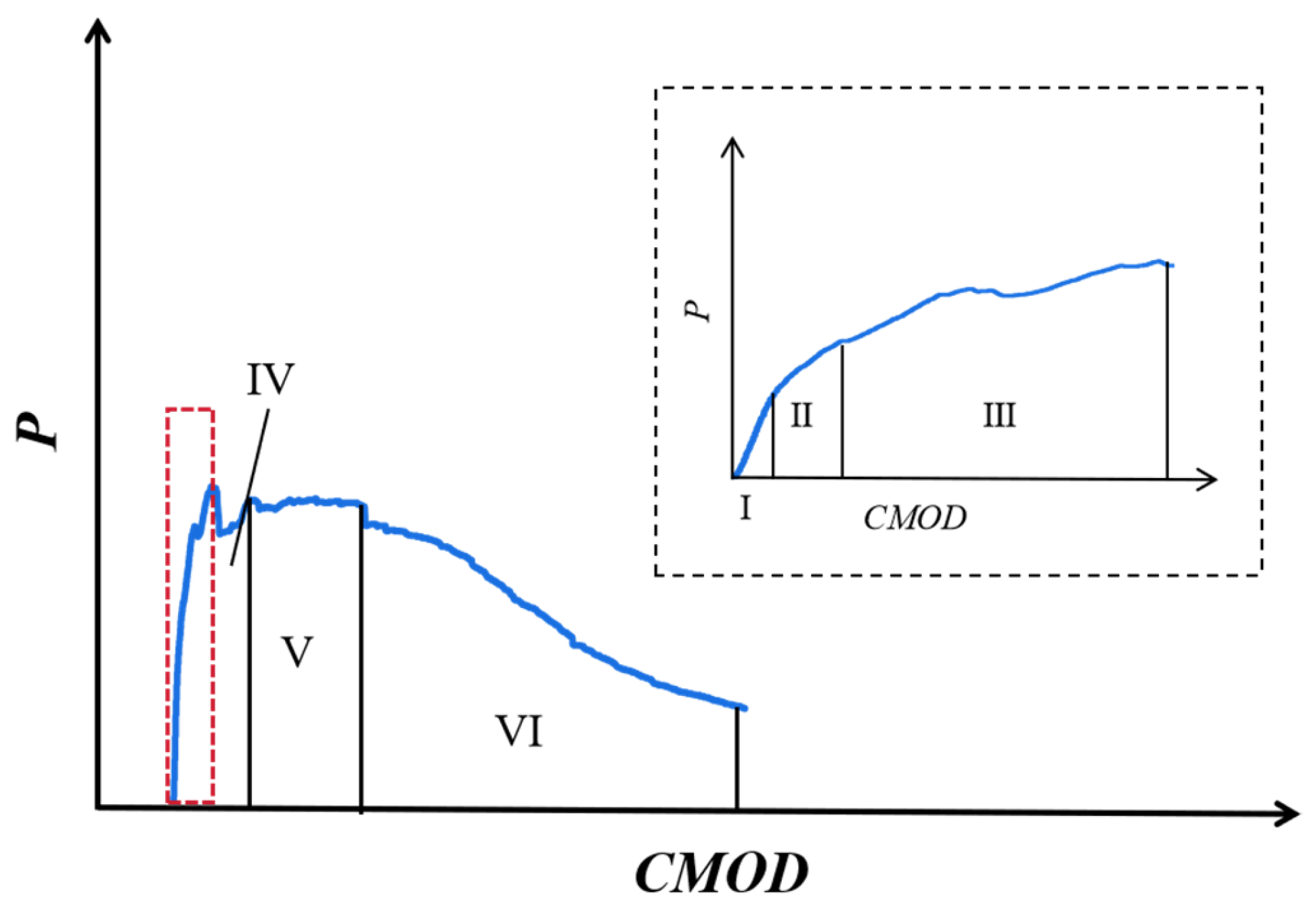

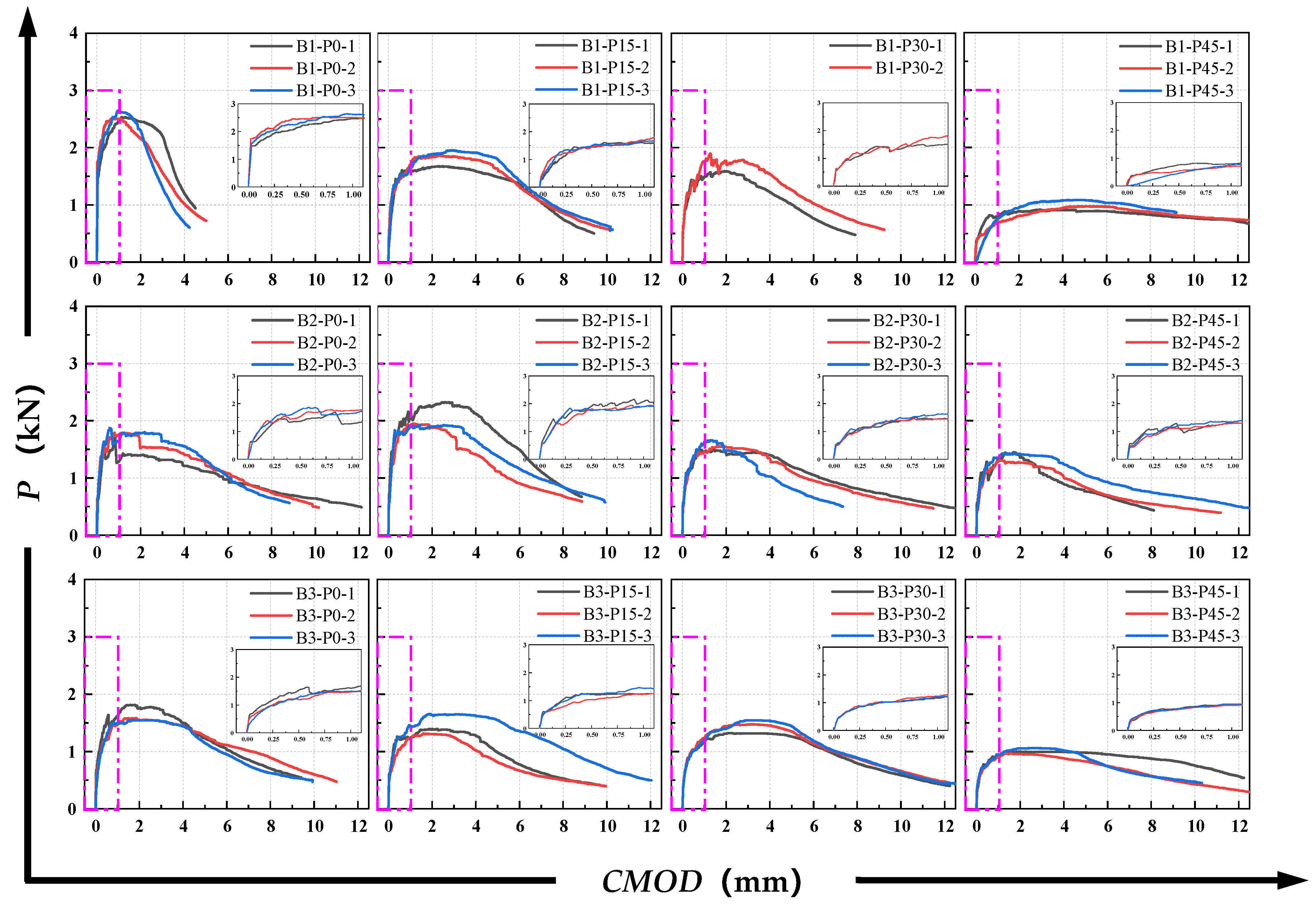

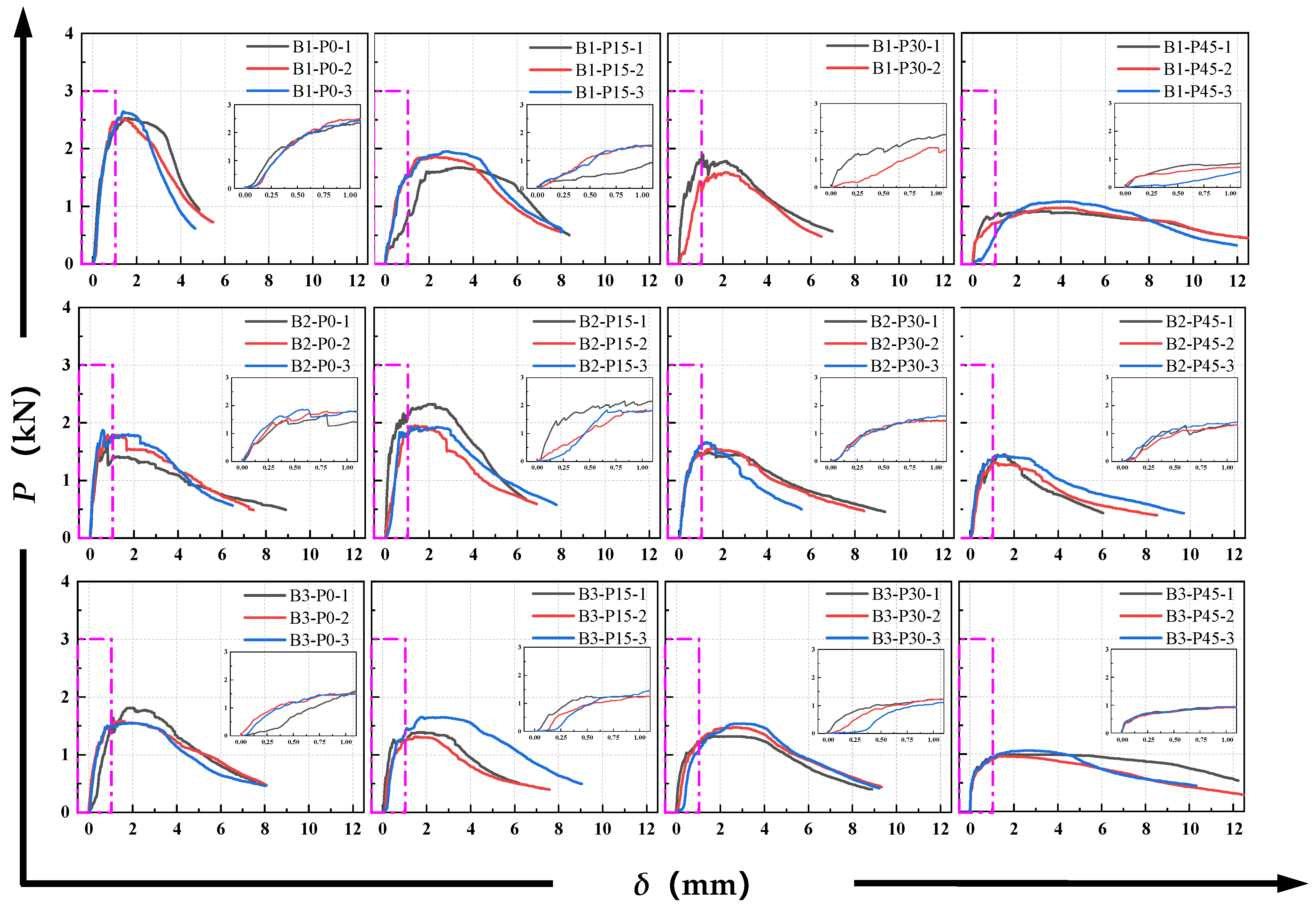

3.2. P-δ Curves and P-CMOD Curves

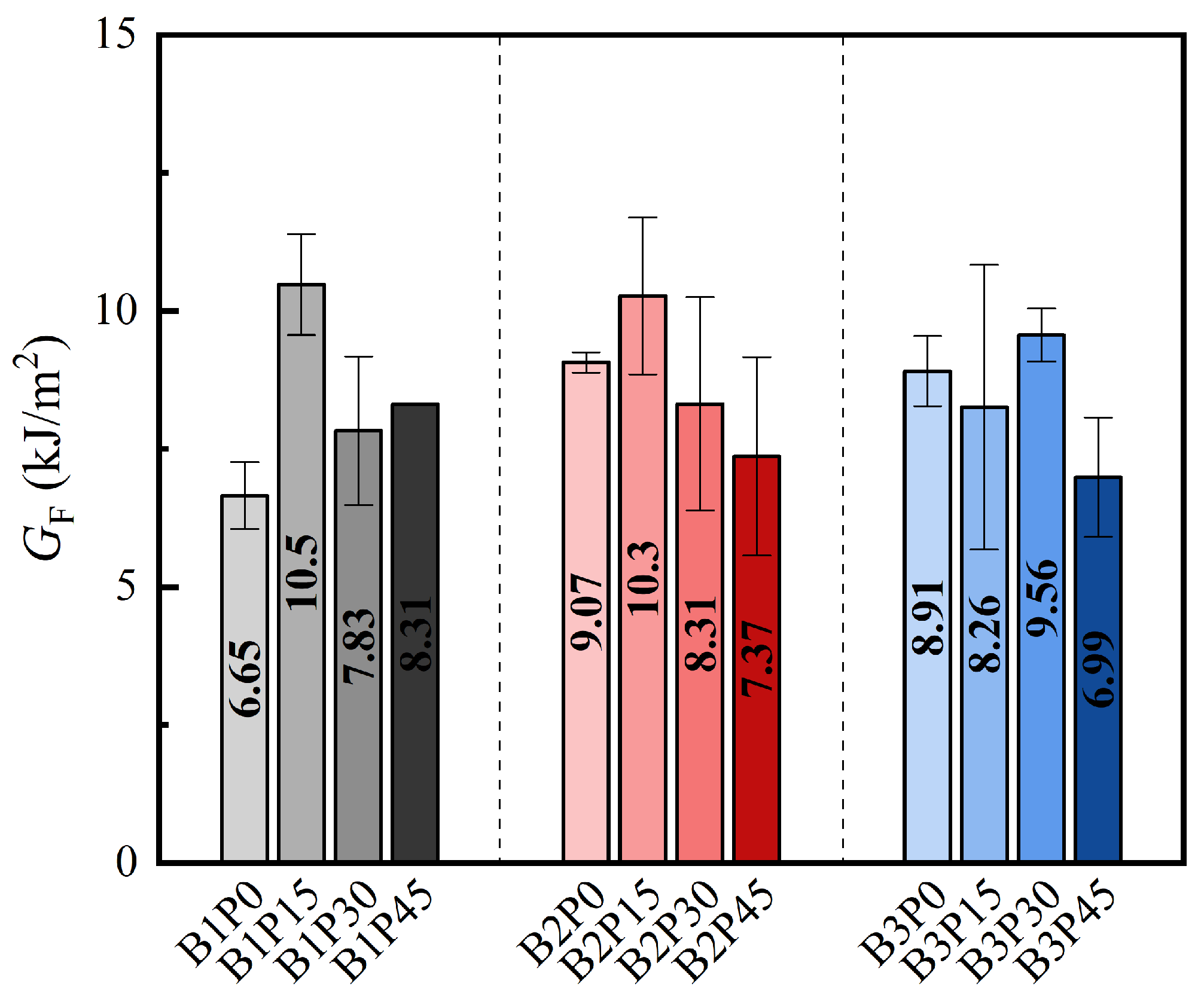

3.3. Mode I Fracture Energy

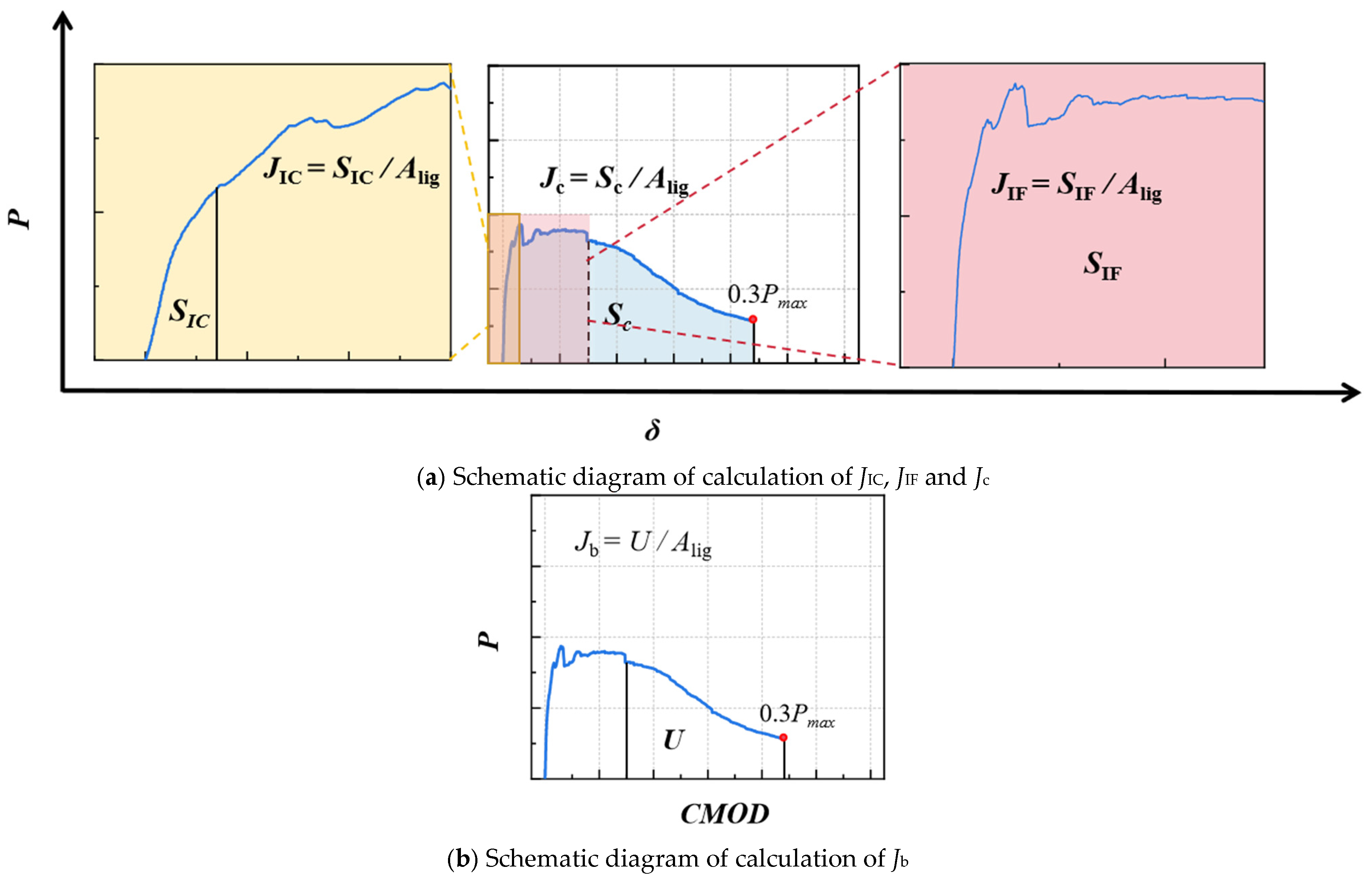

3.4. Fracture Energy Based on J Integral Method

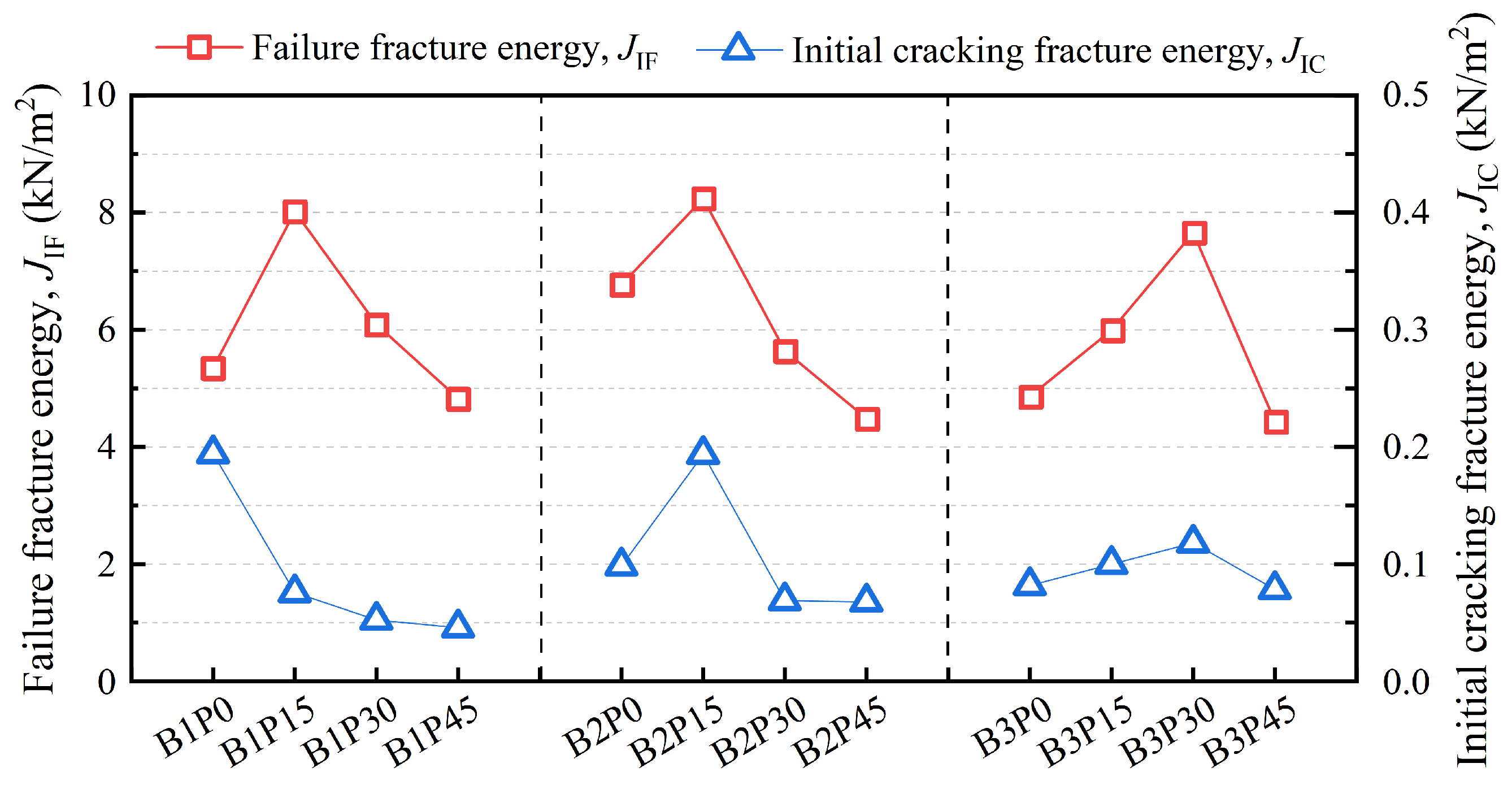

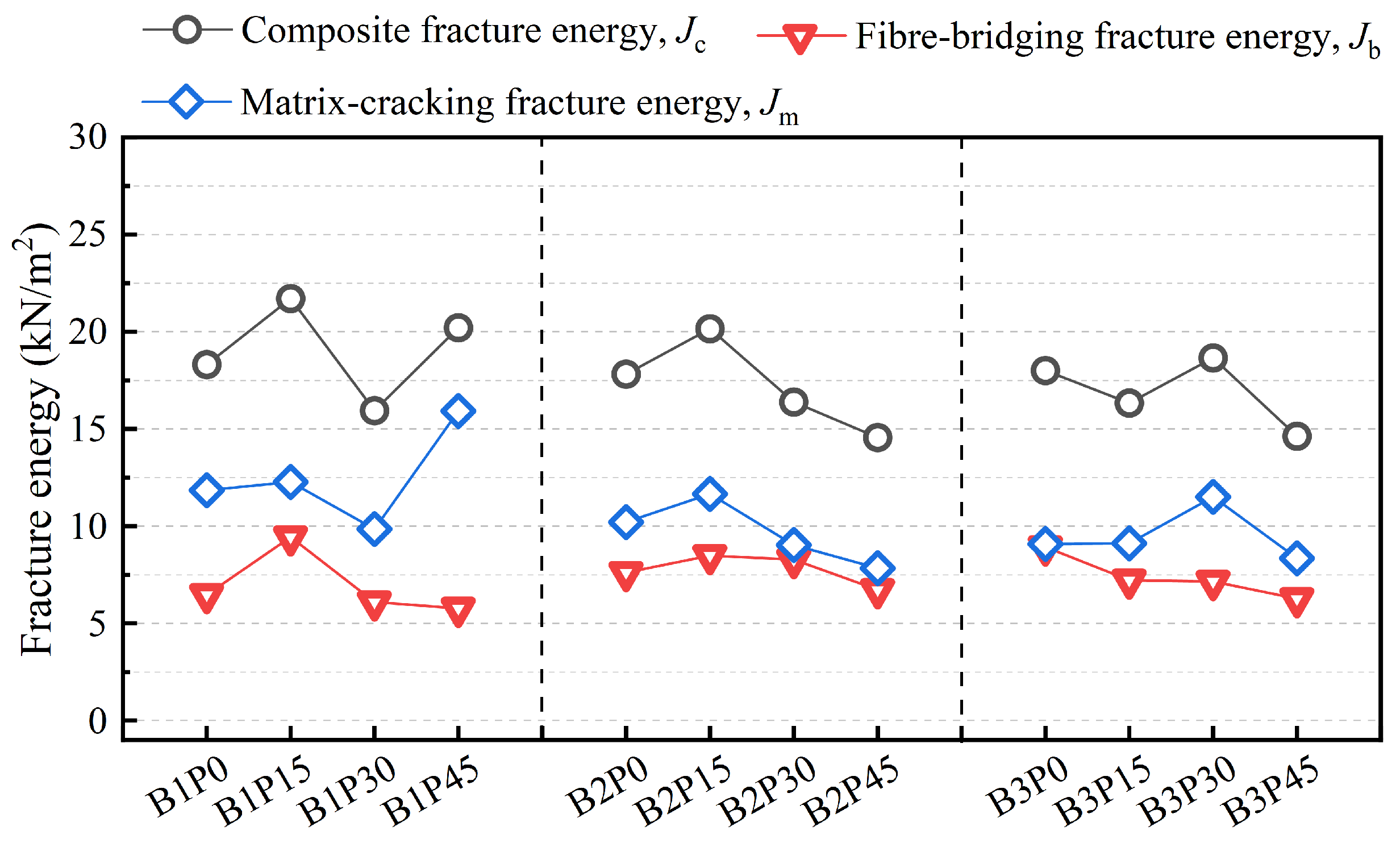

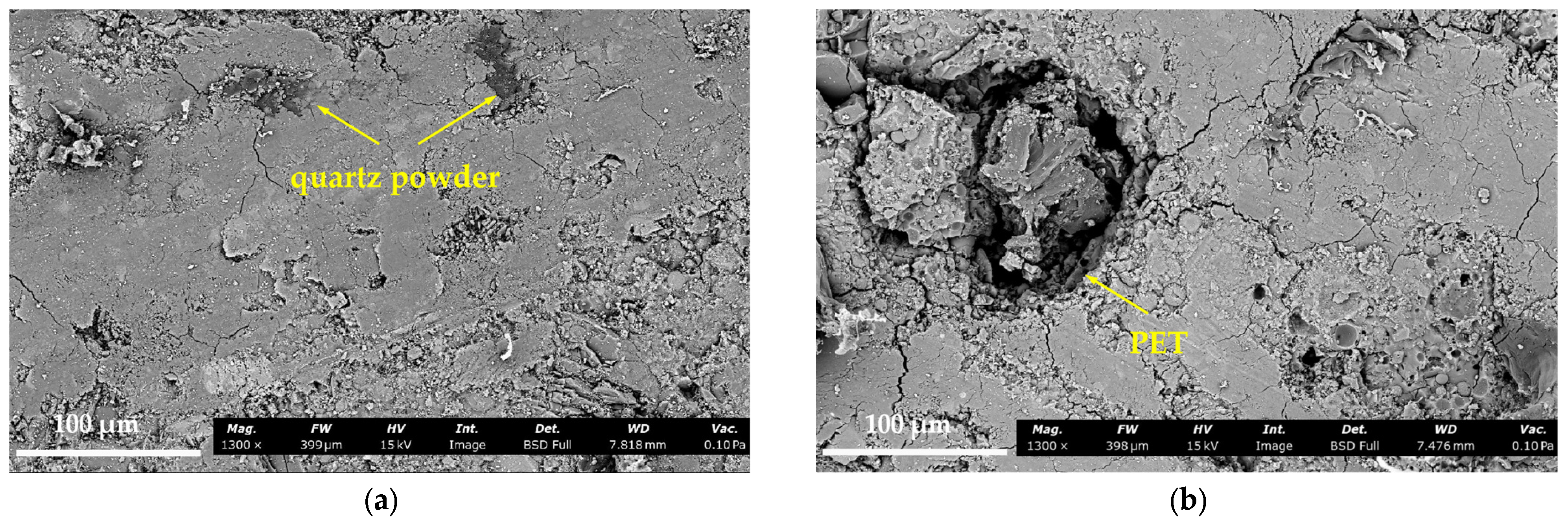

3.5. The Analysis of Microstructure

4. Conclusions

- (1)

- All P-EHDC specimens in this study exhibited “ductile fracture” behavior, with the final failure mode characterized by a main crack accompanied by some microcracks. The increase in PET powder replacement ratio led to a more tortuous path for the main crack but also reduced the initiation of surrounding microcracks to some extent. PET replacement altered the matrix properties, and the tortuous main crack path suggests unevenly distributed defects in the matrix. This should not be regarded as a negative outcome, as the tortuous crack path of the matrix suggests greater fracture energy absorption.

- (2)

- Compared to the precursor ratio, the PET powder replacement ratio has a more significant effect on Mode I fracture energy (GF). The presence of PET powder promotes cracking in the material, leading to the formation of more fine microcracks around the main crack. The reduction in matrix strength has the same effect, this is also the reason why the main crack path propagates more tortuously.

- (3)

- The hydrophobic PET powder weakens the overall density of the matrix, promoting material cracking. While PET powder itself has a certain bridging effect, excessive usage can still weaken the fiber-matrix bridging. The proportion of GGBS in the precursor affects the matrix strength—higher matrix strength tends to anchor fibers, leading to fiber breakage, while lower matrix strength allows more fibers to pull out and absorb fracture energy. In the B1 series, with a high GGBS proportion, replacing 15 vol% of quartz powder with PET powder lowers the crack initiation fracture energy (JIC). However, the PET powder’s bridging effect and reduced fracture toughness create more microcracks, which increases the fracture energy at failure (JIF). Despite the relatively low replacement ratio, the matrix’s crack initiation threshold does not significantly decrease, but it allows more fibers to pull out and absorb fracture energy during the crack instability phase. Therefore, compared to B1P0, B1P15 shows a 45.7% increase in Jb and a 4.24% increase in Jm.

- (4)

- Based on the findings of this study, it is recommended to use a higher matrix strength with no more than 45 vol% PET powder as a replacement for quartz powder to prepare P-EHDC. This approach can improve the ductile fracture behavior and fracture energy of the material while enhancing the recycling of waste PET powder and promoting the green and low-carbon development of high-performance new materials. Admittedly, the study did not fully integrate the surface crack propagation process of the specimens with the J-integral-based fracture analysis. Future research could employ high-resolution imaging techniques to capture the detailed evolution of surface cracks, enabling correlation with fracture energy parameters derived from the J-integral method. This approach may contribute to the development of a more suitable framework for analyzing and evaluating the fracture behavior of high-ductility materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Li, Q.; Liu, F.; Wang, J.; Xu, S. Shear bond assessment of UHTCC repair using push-out test. Constr. Build. Mater. 2018, 164, 206–216. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.; Leung, C.K.Y.; Lin, X.; Lam, J.Y.K.; Sham, I.M.L.; Shih, K. Matrix design for waterproof Engineered Cementitious Composites (ECCs). Constr. Build. Mater. 2017, 139, 438–446. [Google Scholar] [CrossRef]

- Deng, M.; Ma, F.; Ye, W.; Li, F. Flexural behavior of reinforced concrete beams strengthened by HDC and RPC. Constr. Build. Mater. 2018, 188, 995–1006. [Google Scholar] [CrossRef]

- Redon, C.; Li Victor, C.; Wu, C.; Hoshiro, H.; Saito, T.; Ogawa, A. Measuring and Modifying Interface Properties of PVA Fibers in ECC Matrix. J. Mater. Civ. Eng. 2001, 13, 399–406. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, K.-Q.; Yu, J.-t.; Xu, S.-l. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study. Constr. Build. Mater. 2018, 177, 102–115. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhong, Q.; Xing, F.; Sui, L.; Huang, Z.; Guo, M. Influence of cyclic loading on the tensile fracture characteristics of ultra-high performance engineered cementitious composites. Constr. Build. Mater. 2020, 240, 117937. [Google Scholar] [CrossRef]

- Ouyang, J.; Guo, R.; Wang, X.-Y.; Fu, C.; Wan, F.; Pan, T. Effects of interface agent and cooling methods on the interfacial bonding performance of engineered cementitious composites (ECC) and existing concrete exposed to high temperature. Constr. Build. Mater. 2023, 376, 131054. [Google Scholar] [CrossRef]

- Jiang, B.; Qian, Z.; Gu, D.; Pan, J. Repair concrete structures with high-early-strength engineered cementitious composites (HES-ECC): Material design and interfacial behavior. J. Build. Eng. 2023, 68, 106060. [Google Scholar] [CrossRef]

- Hou, M.; Zhang, D.; Li, V.C. Crack width control and mechanical properties of low carbon engineered cementitious composites (ECC). Constr. Build. Mater. 2022, 348, 128692. [Google Scholar] [CrossRef]

- Luo, J.; Wu, G.; Zhao, G.; Ma, Y.; Fang, Z.; Fang, S. Experimental and numerical analysis on shear performance of single embedded nut bolted shear connectors in prefabricated steel-UHPC composite structures under cyclic loading. Structures 2025, 73, 108446. [Google Scholar] [CrossRef]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part I: Utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef]

- Chen, G.; Zhuo, K.-X.; Luo, R.-H.; Lai, H.-M.; Cai, Y.-J.; Xie, B.-X.; Lin, J.-X. Fracture behavior of environmentally friendly high-strength concrete using recycled rubber powder and steel fibers: Experiment and modeling. Case Stud. Constr. Mater. 2024, 21, e03501. [Google Scholar] [CrossRef]

- Xiong, Z.; He, S.H.; Kwan, A.K.H.; Li, L.G.; Zeng, Y. Compressive behaviour of seawater sea-sand concrete containing glass fibres and expansive agents. Constr. Build. Mater. 2021, 292, 123309. [Google Scholar] [CrossRef]

- Cardinale, T.; D’Amato, M.; Sulla, R.; Cardinale, N. Mechanical and Physical Characterization of Papercrete as New Eco-Friendly Construction Material. Appl. Sci. 2021, 11, 1011. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.-G.; Shi, C.-J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Constr. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef]

- Chen, G.; Liu, L.-Y.; Li, J.-F.; Lin, J.-X.; Guo, Y.-C. In-situ tensile behavior of hybrid PE/PP fibers reinforced strain-hardening alkali-activated composites (H-SHAAC) subjected to different temperatures. J. Build. Eng. 2024, 98, 111332. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-p.; Chen, Y.-w.; Lin, J.-X.; Lao, W.-j.; Guo, Y.-c.; Chen, Z.-b.; Lan, X.-w. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Deepa Raj, S. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Mohd Tahir, M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Pan, H.; Xie, Z.; Chen, G.; Su, J.; Zhuo, K.; Chen, Z.; Lin, J.; Feng, C.; Guo, Y. Dynamic compressive behavior of high-strength engineered geopolymer composites. J. Build. Eng. 2023, 80, 108036. [Google Scholar] [CrossRef]

- Chen, Z.; Pan, H.; Zhuo, K.; Su, J.; Xie, B.; Lin, J.; Guo, Y. Dynamic compressive behavior of environmentally friendly high-strength concrete: Experimental investigation and modelling. Constr. Build. Mater. 2024, 427, 136259. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. Micromechanics-based investigation of a sustainable ambient temperature cured one-part strain hardening geopolymer composite. Constr. Build. Mater. 2017, 131, 552–563. [Google Scholar] [CrossRef]

- Yang, K.-H.; Song, J.-K.; Song, K.-I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Bamigboye, G.; Tarverdi, K.; Adigun, D.; Daniel, B.; Okorie, U.; Adediran, J. An appraisal of the mechanical, microstructural, and thermal characteristics of concrete containing waste PET as coarse aggregate. Clean. Waste Syst. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Ngene, B.U.; Ademola, D.; Jolayemi, J.K. Experimental Study on the Use of Waste Polyethylene Terephthalate (PET) and River Sand in Roof Tile Production. J. Phys. Conf. Ser. 2019, 1378, 042105. [Google Scholar] [CrossRef]

- Alqahtani, F.; Ghataora, G.; Iqbal, K.; Dirar, S.; Azzedine, K.; Mansour, A.-O. Lightweight Concrete Containing Recycled Plastic Aggregates. In Proceedings of the 2015 International Conference on Electromechanical Control Technology and Transportation, Zhuhai, China, 31 October—1 November 2015. [Google Scholar]

- Alqahtani, F.K.; Sherif, M.A.; Ghanem, A.M. Green lightweight concrete utilizing sustainable processed recycled plastic aggregates: Technical, economic and environmental assessment. Constr. Build. Mater. 2023, 393, 132027. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S. Novel lightweight concrete containing manufactured plastic aggregate. Constr. Build. Mater. 2017, 148, 386–397. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Khan, S.U.; Ayub, T. PET Fiber–Reinforced Engineered Geopolymer and Cementitious Composites. J. Mater. Civ. Eng. 2022, 34, 06021010. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Almeshal, I.; Magbool, H.M.; Alabduljabbar, H.; Alyousef, R. Performance of sustainable concrete containing different types of recycled plastic. J. Clean. Prod. 2021, 328, 129517. [Google Scholar] [CrossRef]

- Olofinnade, O.; Chandra, S.; Chakraborty, P. Recycling of high impact polystyrene and low-density polyethylene plastic wastes in lightweight based concrete for sustainable construction. Mater. Today Proc. 2021, 38, 2151–2156. [Google Scholar] [CrossRef]

- Chithambar Ganesh, A.; Deepak, N.; Deepak, V.; Ajay, S.; Pandian, A.; Karthik. Utilization of PET bottles and plastic granules in geopolymer concrete. Mater. Today Proc. 2021, 42, 444–449. [Google Scholar] [CrossRef]

- Gao, S.; Qi, L.; Zhu, Y.; Wang, W. Effect of notch depth ratio on mode I and mixed mode I-II fracture properties of engineered cementitious composites (ECC). Int. J. Solids Struct. 2022, 236–237, 111363. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, P.; Jia, X.; Li, Z.; Pan, J.; Zhou, J. Crack development and fracture performance of Recycled Powder Engineered Cementitious Composites (ECC): Experimental investigation. Constr. Build. Mater. 2024, 429, 136388. [Google Scholar] [CrossRef]

- Su, J.-Y.; Luo, R.-H.; Chen, Z.-B.; Lin, J.-X.; Huang, P.-Y.; Guo, Y.-C. Experimental study on the fracture performance of rubberized high strength-high ductility concrete with J-integral method. Constr. Build. Mater. 2024, 421, 135668. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H.W. A simplified method for determining double-K fracture parameters for three-point bending tests. Int. J. Fract. 2000, 104, 181–209. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H.W. Determination of double-K criterion for crack propagation in quasi-brittle fracture, Part II: Analytical evaluating and practical measuring methods for three-point bending notched beams. Int. J. Fract. 1999, 98, 151–177. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H.W. Determination of double-Determination of double-K criterion for crack propagation in quasi-brittle fracture Part I: Experimental investigation of crack propagation. Int. J. Fract. 1999, 98, 111–149. [Google Scholar] [CrossRef]

- Xu, S.; Lyu, Y.; Xu, S.; Li, Q. Enhancing the initial cracking fracture toughness of steel-polyvinyl alcohol hybrid fibers ultra high toughness cementitious composites by incorporating multi-walled carbon nanotubes. Constr. Build. Mater. 2019, 195, 269–282. [Google Scholar] [CrossRef]

- Chen, Z.-B.; Su, J.-Y.; Luo, R.-H.; Lin, J.-X.; Chen, X.-F.; Huang, P.-Y.; Guo, Y.-C. Experimental investigation on fracture behavior of rubberized engineered cementitious composites under thermo-mechanical loadings. Eng. Fract. Mech. 2025, 315, 110838. [Google Scholar] [CrossRef]

- Liu, W.; Xu, S.; Li, Q. Experimental study on fracture performance of ultra-high toughness cementitious composites with J-integral. Eng. Fract. Mech. 2012, 96, 656–666. [Google Scholar] [CrossRef]

- Peng, Y.-Q.; Zheng, D.-P.; Pan, H.-S.; Yang, J.-L.; Lin, J.-X.; Lai, H.-M.; Wu, P.-Z.; Zhu, H.-Y. Strain hardening geopolymer composites with hybrid POM and UHMWPE fibers: Analysis of static mechanical properties, economic benefits, and environmental impact. J. Build. Eng. 2023, 76, 107315. [Google Scholar] [CrossRef]

- Sanyin, Z.; Qijun, Y.; Fei, Q.; Jiaqi, H.; Suhong, Y.; Ziyun, W.; Guobang, G. Setting and strength characteristics of alkali-activated carbonatite cementitious materials with ground slag replacement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2006, 21, 125–128. [Google Scholar] [CrossRef]

- Swathi, B.; Vidjeapriya, R. Influence of precursor materials and molar ratios on normal, high, and ultra-high performance geopolymer concrete—A state of art review. Constr. Build. Mater. 2023, 392, 132006. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Qiu, G.H.; Kodur, V.; Yuan, Z.S. Spalling behavior of metakaolin-fly ash based geopolymer concrete under elevated temperature exposure. Cem. Concr. Compos. 2020, 106, 103483. [Google Scholar] [CrossRef]

- JCI-S-001-2003; Method of Test for Fracture Energy of Concrete by Use of Notched Beam, Materials and Structures. JCI Standard: Tokyo, Japan, 2003.

- Su, J.-Y.; Chen, G.; Pan, H.-S.; Lin, J.-X.; Zhang, J.; Zhuo, K.-X.; Chen, Z.-B.; Guo, Y.-C. Rubber modified high strength-high ductility concrete: Effect of rubber replacement ratio and fiber length. Constr. Build. Mater. 2023, 404, 133243. [Google Scholar] [CrossRef]

- Lin, J.-X.; Luo, R.-H.; Su, J.-Y.; Guo, Y.-C.; Chen, W.-S. Coarse synthetic fibers (PP and POM) as a replacement to steel fibers in UHPC: Tensile behavior, environmental and economic assessment. Constr. Build. Mater. 2024, 412, 134654. [Google Scholar] [CrossRef]

- Lin, J.-X.; Chen, G.; Pan, H.-S.; Wang, Y.-C.; Guo, Y.-C.; Jiang, Z.-X. Analysis of stress-strain behavior in engineered geopolymer composites reinforced with hybrid PE-PP fibers: A focus on cracking characteristics. Compos. Struct. 2023, 323, 117437. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Keck, S.; Fulland, M. Effect of fibre volume fraction and fibre direction on crack paths in flax fibre-reinforced composites. Eng. Fract. Mech. 2016, 167, 201–209. [Google Scholar] [CrossRef]

- Heald, P.T.; Spink, G.M.; Worthington, P.J. Post yield fracture mechanics. Mater. Sci. Eng. 1972, 10, 129–138. [Google Scholar] [CrossRef]

- Carpinteri, A.; Fortese, G.; Ronchei, C.; Scorza, D.; Vantadori, S. Mode I fracture toughness of fibre reinforced concrete. Theor. Appl. Fract. Mech. 2017, 91, 66–75. [Google Scholar] [CrossRef]

- Hou, M.; Xu, K.; Monteiro, P.J.M.; Li, V.C. Rubber particle bridging effect on crack width control of low carbon Engineered Cementitious Composites (ECC). Cem. Concr. Compos. 2023, 140, 105106. [Google Scholar] [CrossRef]

| Property Parameters | CaO | SiO2 | Al2O3 | SO3 | Fe2O3 | MgO | TiO2 | Other | Loss on Ignition (%) | Compressive Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt% | |||||||||||

| GGBS | 34.0 | 34.5 | 17.7 | 1.64 | 1.03 | 6.01 | / | 5.12 | 0.840 | / | / |

| FA | 4.01 | 54.8 | 31.2 | 2.20 | 4.16 | 1.01 | 1.13 | 2.37 | 4.60 | / | / |

| QP | 0.09 | 89.2 | 5.97 | 0.23 | 0.67 | 0.09 | 0.20 | 0.65 | / | / | / |

| PET | / | / | / | / | / | / | / | / | / | 130 | 1.10 |

| Fiber Type | Length (mm) | Diameter (um) | Strength (MPa) | Aspect Ratio (L/d) | Density (g/cm3) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| PE | 12.0 (Mean value) | 20.0 | 2500 | 600 | 0.970 | 120 | 3.70 |

| Cementitious Material ID | Mix ID | Mix Design (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| GGBS | FA | QP | Alkaline Solution | Water | Retarder | PET | PE | ||

| B1 | B1-P0 | 491 | 736 | 245 | 491 | 73.6 | 12.3 | 0.00 | 19.4 |

| B1-P15 | 491 | 736 | 209 | 491 | 73.6 | 12.3 | 23.3 | 19.4 | |

| B1-P30 | 491 | 736 | 172 | 491 | 73.6 | 12.3 | 46.7 | 19.4 | |

| B1-P45 | 491 | 736 | 135 | 491 | 73.6 | 12.3 | 70.0 | 19.4 | |

| B2 | B2-P0 | 364 | 850 | 243 | 486 | 72.8 | 12.1 | 0.00 | 19.4 |

| B2-P15 | 364 | 850 | 206 | 486 | 72.8 | 12.1 | 23.1 | 19.4 | |

| B2-P30 | 364 | 850 | 170 | 486 | 72.8 | 12.1 | 46.2 | 19.4 | |

| B2-P45 | 364 | 850 | 134 | 486 | 72.8 | 12.1 | 69.3 | 19.4 | |

| B3 | B2-P0 | 239 | 956 | 239 | 478 | 71.7 | 12.0 | 0.00 | 19.4 |

| B2-P15 | 239 | 956 | 203 | 478 | 71.7 | 12.0 | 22.7 | 19.4 | |

| B2-P30 | 239 | 956 | 167 | 478 | 71.7 | 12.0 | 45.5 | 19.4 | |

| B2-P45 | 239 | 956 | 132 | 478 | 71.7 | 12.0 | 68.2 | 19.4 | |

| Mix IDs | Pini | Pmax | m1 | CMOD0 | W0 | W1 | GF |

|---|---|---|---|---|---|---|---|

| (kN) | (kN) | (kg) | (mm) | (kN·mm) | (kN·mm) | (kJ·m−2) | |

| B1-P0 | 0.705 (0.022) | 2.56 (0.025) | 0.521 (0.001) | 4.58 (0.39) | 8.48 (0.77) | 0.0244 (0.0022) | 6.55 (0.61) |

| B1-P15 | 0.773 (0.015) | 1.83 (0.171) | 0.509 (0.001) | 10.2 (0.5) | 13.4 (1.2) | 0.0376 (0.0033) | 10.5 (0.9) |

| B1-P30 | 0.605 (0.025) | 1.59 (0.60) | 0.489 (0.007) | 8.53 (0.91) | 9.99 (1.72) | 0.0270 (0.0046) | 7.83 (1.35) |

| B1-P45 | 0.372 (0.025) | 1.29 (0.77) | 0.482 (0.003) | 13.2 (0.1) | 10.6 (0.0) | 0.0282 (0.0000) | 8.31 (0.00) |

| B2-P0 | 0.873 (0.101) | 1.79 (0.02) | 0.494 (0.006) | 10.2 (1.6) | 11.6 (0.23) | 0.0316 (0.0006) | 9.07 (0.18) |

| B2-P15 | 0.804 (0.110) | 2.07 (0.33) | 0.488 (0.001) | 9.13 (0.67) | 13.1 (1.8) | 0.0353 (0.0049) | 10.3 (1.4) |

| B2-P30 | 1.04 (0.09) | 1.58 (0.06) | 0.463 (0.002) | 10.5 (2.8) | 10.6 (2.5) | 0.0271 (0.0063) | 8.31 (1.93) |

| B2-P45 | 0.642 (0.044) | 1.40 (0.14) | 0.458 (0.002) | 10.7 (2.5) | 9.40 (2.30) | 0.0238 (0.0058) | 7.37 (1.80) |

| B3-P0 | 0.642 (0.044) | 1.65 (0.83) | 0.462 (0.004) | 10.1 (0.8) | 11.4 (0.8) | 0.0291 (0.0021) | 8.91 (0.63) |

| B3-P15 | 0.923 (0.031) | 1.45 (0.50) | 0.450 (0.011) | 10.5 (1.3) | 10.5 (3.3) | 0.0261 (0.0082) | 8.27 (2.58) |

| B3-P30 | 0.988 (0.022) | 1.45 (0.30) | 0.433 (0.003) | 12.0 (0.3) | 12.2 (0.6) | 0.0292 (0.0015) | 9.56 (0.48) |

| B3-P45 | 0.733 (0.009) | 1.01 (0.19) | 0.427 (0.002) | 11.7 (1.2) | 8.91 (1.38) | 0.0210 (0.0032) | 6.99 (1.08) |

| Mix IDs | JIC (kJ/m2) | JIF (kJ/m2) | Jc (kJ/m2) | Jb (kJ/m2) | Jm (kJ/m2) |

|---|---|---|---|---|---|

| B1-P0 | 0.194 (0.041) | 5.35 (0.99) | 18.3 (1.6) | 6.48 (0.68) | 11.8 (0.9) |

| B1-P15 | 0.0757 (0.0455) | 8.02 (1.19) | 21.7 (1.1) | 9.44 (0.99) | 12.3 (0.9) |

| B1-P30 | 0.0524 (0.0031) | 6.09 (1.22) | 15.9 (2.5) | 6.10 (1.61) | 9.85 (0.88) |

| B1-P45 | 0.0456 (0.0209) | 4.83 (0.088) | 20.2 (1.6) | 5.77 (0.15) | 15.9 (2.4) |

| B2-P0 | 0.0985 (0.0476) | 6.77 (1.88) | 17.8 (0.6) | 7.61 (1.40) | 10.2 (0.9) |

| B2-P15 | 0.194 (0.068) | 8.24 (2.32) | 20.2 (2.3) | 8.49 (0.69) | 11.7 (2.0) |

| B2-P30 | 0.0689 (0.0217) | 5.64 (1.63) | 16.4 (3.7) | 8.29 (0.15) | 9.04 (2.14) |

| B2-P45 | 0.0677 (0.0107) | 4.48 (0.82) | 14.6 (3.6) | 6.73 (1.43) | 7.84 (2.21) |

| B3-P0 | 0.0816 (0.0180) | 4.86 (1.32) | 18.0 (0.8) | 8.93 (1.15) | 9.08 (1.09) |

| B3-P15 | 0.100 (0.034) | 5.99 (1.81) | 16.3 (4.8) | 7.23 (2.11) | 9.11 (2.11) |

| B3-P30 | 0.118 (0.022) | 7.65 (0.18) | 18.7 (1.0) | 7.16 (0.80) | 11.5 (0.3) |

| B3-P45 | 0.0783 (0.0301) | 4.44 (1.16) | 14.6 (2.2) | 6.27 (0.48) | 8.35 (2.43) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, F.; Luo, S.; Sun, J.; Zhang, C.; Xu, L.; Zhang, L.; Qing, F.; Zeng, J.; Luo, R.; Guo, Y. Experimental Investigation on the Fracture Behavior of PET-Modified Engineered High-Ductility Concrete: Effects of PET Powder and Precursor Composition. Materials 2025, 18, 2132. https://doi.org/10.3390/ma18092132

Meng F, Luo S, Sun J, Zhang C, Xu L, Zhang L, Qing F, Zeng J, Luo R, Guo Y. Experimental Investigation on the Fracture Behavior of PET-Modified Engineered High-Ductility Concrete: Effects of PET Powder and Precursor Composition. Materials. 2025; 18(9):2132. https://doi.org/10.3390/ma18092132

Chicago/Turabian StyleMeng, Fei, Shen Luo, Jingxian Sun, Cheng Zhang, Leilei Xu, Liqun Zhang, Fumin Qing, Junfeng Zeng, Ruihao Luo, and Yongchang Guo. 2025. "Experimental Investigation on the Fracture Behavior of PET-Modified Engineered High-Ductility Concrete: Effects of PET Powder and Precursor Composition" Materials 18, no. 9: 2132. https://doi.org/10.3390/ma18092132

APA StyleMeng, F., Luo, S., Sun, J., Zhang, C., Xu, L., Zhang, L., Qing, F., Zeng, J., Luo, R., & Guo, Y. (2025). Experimental Investigation on the Fracture Behavior of PET-Modified Engineered High-Ductility Concrete: Effects of PET Powder and Precursor Composition. Materials, 18(9), 2132. https://doi.org/10.3390/ma18092132