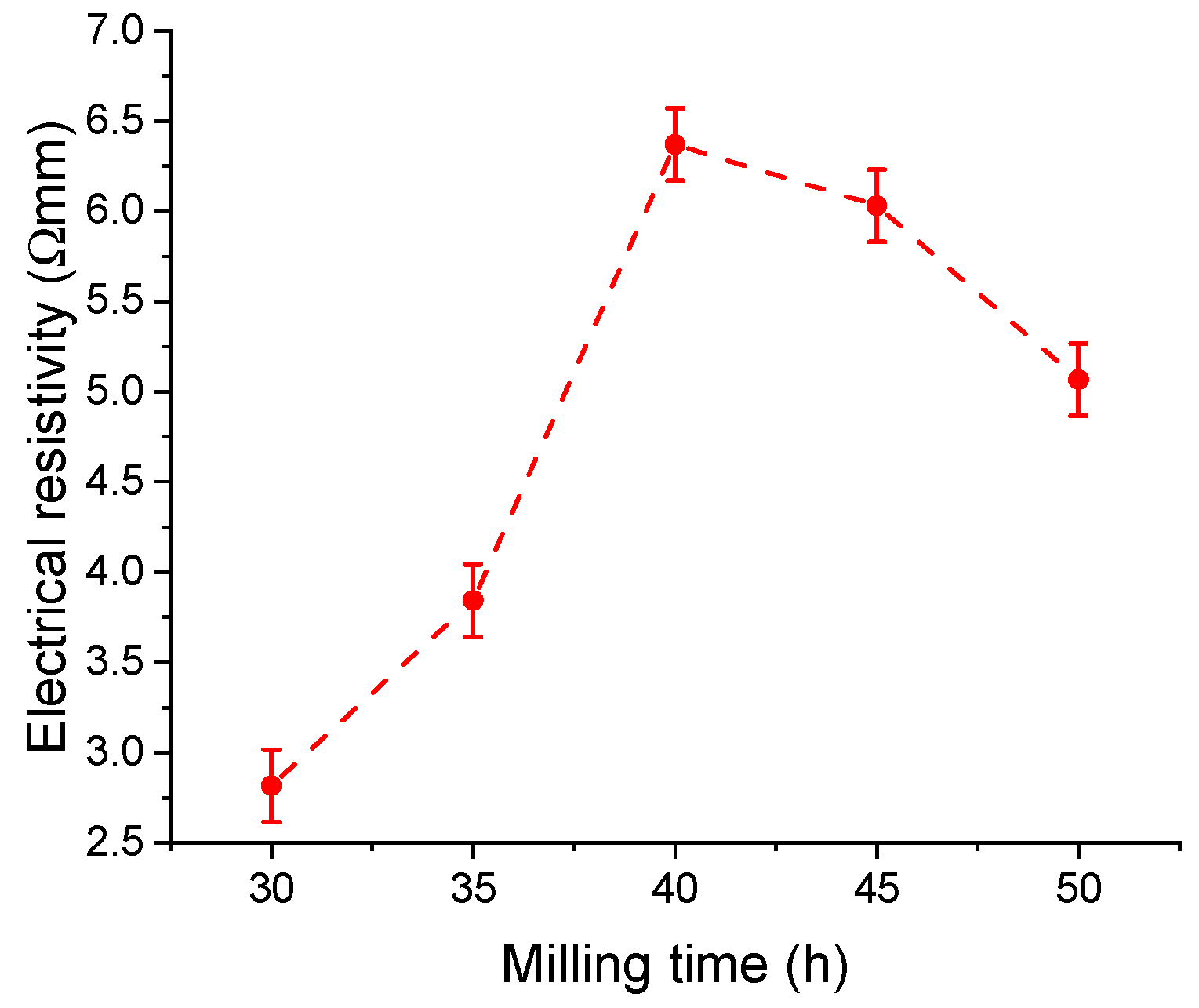

High Milling Time Influence on the Phase Stability and Electrical Properties of Fe50Mn35Sn15 Heusler Alloy Obtained by Mechanical Alloying

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Graf, T.; Felser, C.; Parkin, S.S. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Kawasaki, J.K.; Chatterjee, S.; Canfield, P.C.; Editors, G. Full and half-Heusler compounds. MRS Bull. 2022, 47, 555–558. [Google Scholar] [CrossRef]

- Hirohata, A.; Lloyd, D.C. Heusler alloys for metal spintronics. MRS Bull. 2022, 47, 593–599. [Google Scholar] [CrossRef]

- Galanakis, I. (Ed.) Half-Metallic Alloys Fundamentals and Applications, 2006th ed.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Felser, C.; Hirohata, A. Heusler Alloys: Properties, Growth, Applications; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Felser, C.; Fecher, G.H. Spintronics: From Materials to Devices; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Jiang, S.; Yang, K. Review of high-throughput computational design of Heusler alloys. J. Alloys Compd. 2021, 867, 158854. [Google Scholar] [CrossRef]

- Smith, R.; Gercsi, Z.; Zhang, R.; Siewierska, K.; Rode, K.; Coey, J. Effects of disorder on the magnetic properties of the Heusler alloy V2FeAl. Acta Mater. 2024, 267, 119733. [Google Scholar] [CrossRef]

- Ahn, K. Ni-Mn based conventional full Heusler alloys, all-d-metal full Heusler alloys, and their promising functional properties to solid state cooling by magnetocaloric effect. J. Alloys Compd. 2024, 978, 173378. [Google Scholar] [CrossRef]

- Idrissi, S.; Ziti, S.; Labrim, H.; Bahmad, L. Half-Metallicity and Magnetism in the Full Heusler Alloy Fe2MnSn with L21 and XA Stability Ordering Phases. J. Low Temp. Phys. 2021, 202, 343–359. [Google Scholar] [CrossRef]

- Bachagha, T.; Suñol, J.-J. All-d-Metal Heusler Alloys: A Review. Metals 2023, 13, 111. [Google Scholar] [CrossRef]

- Hirohata, A.; Kikuchi, M.; Tezuka, N.; Inomata, K.; Claydon, J.; Xu, Y.; Vanderlaan, G.; van der Laan, G. Heusler alloy/semiconductor hybrid structures. Curr. Opin. Solid State Mater. Sci. 2006, 10, 93–107. [Google Scholar] [CrossRef]

- Kratochvílová, M.; Klicpera, M.; Malý, F.; Valenta, J.; Veis, M.; Colman, R.; Heczko, O. Systematic experimental search for Fe2YZ Heusler compounds predicted by ab-initio calculation. Intermetallics 2021, 131, 107073. [Google Scholar] [CrossRef]

- Wuttig, M.; Liu, L.; Tsuchiya, K.; James, R.D. Occurrence of ferromagnetic shape memory alloys (invited). J. Appl. Phys. 2000, 87, 4707–4711. [Google Scholar] [CrossRef]

- Hinterleitner, B.; Fuchs, P.; Rehak, J.; Garmroudi, F.; Parzer, M.; Waas, M.; Svagera, R.; Steiner, S.; Kishimoto, M.; Moser, R.; et al. Stoichiometric and off-stoichiometric full Heusler Fe2V1−xWxAl thermoelectric systems. Phys. Rev. B 2020, 102, 075117. [Google Scholar] [CrossRef]

- Boyraz, C.; Guler, A.; Aksu, P.; Arda, L. The concentration effects on structural and magnetic properties of Fe2V1−xMnxGe Heusler alloys. SN Appl. Sci. 2022, 4, 201. [Google Scholar] [CrossRef]

- Jain, V.K.; Lakshmi, N.; Jain, R. Stability of half-metallic behavior with lattice variation for Fe2MnZ (Z = Si, Ge, Sn) Heusler alloy. AIP Conf. Proc. 2018, 1953, 110007. [Google Scholar] [CrossRef]

- Kratochvílová, M.; Král, D.; Dušek, M.; Valenta, J.; Colman, R.; Heczko, O.; Veis, M. Fe2MnSn—Experimental quest for predicted Heusler alloy. J. Magn. Magn. Mater. 2020, 501, 166426. [Google Scholar] [CrossRef]

- Keshavarz, S.; Naghibolashrafi, N.; Jamer, M.; Vinson, K.; Mazumdar, D.; Dennis, C.; Ratcliff, W.; Borchers, J.; Gupta, A.; LeClair, P. Fe2MnGe: A hexagonal Heusler analogue. J. Alloys Compd. 2019, 771, 793–802. [Google Scholar] [CrossRef]

- Aryal, A.; Dubenko, I.; Zamora, J.; Llamazares, J.S.; Sánchez-Valdés, C.; Mazumdar, D.; Talapatra, S.; Stadler, S.; Ali, N. Synthesis, structural, and magnetic properties of Heusler-type Mn2−xFe1+xGe (0.0 ≤ x ≤ 1.0) alloys. J. Magn. Magn. Mater. 2021, 538, 168307. [Google Scholar] [CrossRef]

- Yin, M.; Nash, P.; Chen, S. Enthalpies of formation of selected Fe2YZ Heusler compounds. Intermetallics 2015, 57, 34–40. [Google Scholar] [CrossRef]

- Nishino, Y.; Kato, H.; Kato, M.; Mizutani, U. Effect of off-stoichiometry on the transport properties of the Heusler-type Fe2VAl compound. Phys. Rev. B 2001, 63, 233303. [Google Scholar] [CrossRef]

- Jain, V.K.; Lakshmi, N.; Jain, V.; K, S.A.; Venugopalan, K. High energy ball milling study of Fe2MnSn Heusler alloy. AIP Conf. Proc. 2015, 1665, 130032. [Google Scholar] [CrossRef]

- Popa, F.; Chicinaş, H.F.; Marinca, T.F.; Chicinaş, I. Influence of mechanical alloying and heat treatment processing on the Ni2MnSn Heusler alloy structure. J. Alloys Compd. 2017, 716, 137–143. [Google Scholar] [CrossRef]

- Popa, F.; Cebotari, V.; Marinca, T.F.; Isnard, O.; Chicinaș, I. Crystallographic and magnetic analysis of ordered-disordered Ni51Mn34Sn15 Heusler alloy obtained by mechanical alloying and annealing. J. Alloys Compd. 2023, 964, 171275. [Google Scholar] [CrossRef]

- Popa, F.; Marinca, T.F.; Chicinaş, H.F.; Isnard, O.; Chicinaş, I. Ni-Mn-Sn Heusler: Milling and annealing effect on structural and magnetic properties. J. Phys. Conf. Ser. 2017, 903, 012045. [Google Scholar] [CrossRef]

- Zhang, L.; Brück, E.; Tegus, O.; Buschow, K.; de Boer, F. The crystallization of amorphous Fe2MnGe powder prepared by ball milling. J. Alloys Compd. 2003, 352, 99–102. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovičová, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Criado, J.M.; Delogu, F.; Dutková, E.; Gaffet, E.; Gotor, F.J.; et al. Hallmarks of mechanochemistry: From nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef] [PubMed]

- Suryanarayana, C. Mechanical Alloying: A Novel Technique to Synthesize Advanced Materials. Research 2019, 2019, 4219812. [Google Scholar] [CrossRef] [PubMed]

- Gaffet, E.; Le Caër, G. Mechanical Processing for Nanomaterials. In Encyclopedia of Nanoscience and Nanotechnology; American Scientific Publishers: Stevenson Ranch, CA, USA, 2004. [Google Scholar]

- Suryanarayana, C. Mechanical alloying: A critical review. Mater. Res. Lett. 2022, 10, 619–647. [Google Scholar] [CrossRef]

- Neikov, O.D. Mechanical Alloying, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Will, G. Powder Diffraction: The Rietveld Method and the Two-Stage Method; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Rietveld, H.M. The Rietveld method. Phys. Scr. 2014, 89, 098002. [Google Scholar] [CrossRef]

- Roisnel, T.; Rodríquez-Carvajal, J. WinPLOTR: A windows tool for powder diffraction pattern analysis. Mater. Sci. Forum 2001, 378–381, 118–123. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys. B Phys. Condens. Matter 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Vives, S.; Gaffet, E.; Meunier, C. X-ray diffraction line profile analysis of iron ball milled powders. Mater. Sci. Eng. A 2004, 366, 229–238. [Google Scholar] [CrossRef]

- Langford, J.I. The use of the Voigt function in determining microstructural properties from diffraction data by means of pattern decomposition. In Proceedings of the International Conference: Accuracy in Powder Diffraction II, Gaithersburg, MD, USA, 26–29 May 1992; pp. 110–126. [Google Scholar]

- Vinesh, A.; Bhargava, H.; Lakshmi, N.; Venugopalan, K. Magnetic anisotropy induced by high energy ball milling of Fe2MnAl. J. Appl. Phys. 2009, 105, 14–17. [Google Scholar] [CrossRef]

- Zuo, B.; Saraswati, N.; Sritharan, T.; Hng, H. Production and annealing of nanocrystalline Fe-Si and Fe-Si-Al alloy powders. Mater. Sci. Eng. A 2004, 371, 210–216. [Google Scholar] [CrossRef]

- Wu, Q.; Li, C.S.; Tang, H.; Yu, X.H.; Cao, K.S.; Yang, J.H. Microstructure evolution during mechanical alloying of face centered cubic Ti3Si nanoparticles. J. Nano Res. 2009, 6, 177–184. [Google Scholar] [CrossRef]

- Prasad, N.K.; Kumar, V. Structure–magnetic properties correlation in mechanically alloyed nanocrystalline Fe–Co–Ni–(Mg–Si)x alloy powders. J. Mater. Sci. Mater. Electron. 2016, 27, 10136–10146. [Google Scholar] [CrossRef]

- Popa, F.; Marinca, T.F.; Sechel, N.A.; Frunzӑ, D.I.; Chicinaș, I. Influence of Long Milling Time on the Electrical Resistivity of Nanocrystalline Ni2MnSn Heusler Alloy Obtained by Mechanosynthesis. Nanomaterials 2024, 14, 1156. [Google Scholar] [CrossRef]

| Milling Time (h) | D10 | D50 | D90 |

|---|---|---|---|

| 30 | 1.57 | 15.55 | 58.03 |

| 40 | 1.59 | 14.39 | 144.49 |

| 50 | 2.10 | 31.59 | 104.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popa, F.; Marinca, T.F.; Sechel, N.A.; Frunză, D.I.; Chicinaș, I. High Milling Time Influence on the Phase Stability and Electrical Properties of Fe50Mn35Sn15 Heusler Alloy Obtained by Mechanical Alloying. Materials 2024, 17, 4355. https://doi.org/10.3390/ma17174355

Popa F, Marinca TF, Sechel NA, Frunză DI, Chicinaș I. High Milling Time Influence on the Phase Stability and Electrical Properties of Fe50Mn35Sn15 Heusler Alloy Obtained by Mechanical Alloying. Materials. 2024; 17(17):4355. https://doi.org/10.3390/ma17174355

Chicago/Turabian StylePopa, Florin, Traian Florin Marinca, Niculina Argentina Sechel, Dan Ioan Frunză, and Ionel Chicinaș. 2024. "High Milling Time Influence on the Phase Stability and Electrical Properties of Fe50Mn35Sn15 Heusler Alloy Obtained by Mechanical Alloying" Materials 17, no. 17: 4355. https://doi.org/10.3390/ma17174355

APA StylePopa, F., Marinca, T. F., Sechel, N. A., Frunză, D. I., & Chicinaș, I. (2024). High Milling Time Influence on the Phase Stability and Electrical Properties of Fe50Mn35Sn15 Heusler Alloy Obtained by Mechanical Alloying. Materials, 17(17), 4355. https://doi.org/10.3390/ma17174355