Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

- (1)

- Raw material treatment: Place the stone waste raw materials in a 105 °C oven drying for more than 24 h to ensure constant quality until its moisture content is not greater than 0.2%.

- (2)

- Specimen preparation: Specimen preparation according to Highway Engineering Inorganic Binding Material Stabilization Material Test procedures (JTG E51-2009) [32]. Specimen molds were used with a diameter of 50 mm and a height of 100 mm.

- (3)

- Standard maintenance: According to the requirements of ‘Test Procedure for Inorganic Binding Material Stabilization in (Highway Engineering (JTG E51-2009)) [32], the standard curing is carried out in a standard curing room with a temperature of 20 °C ± 2 °C and a relative humidity of more than 95%.

- (1)

- Drying stage: The specimen is loaded onto a tray and put into a drying oven with a set temperature of 50 °C for 24 h. After drying, the specimen is taken out and the mass, height, and diameter of the specimen are measured with a balance and vernier calipers. The main purpose of this stage is to remove the moisture of the specimen in preparation for the next stage of hydroponics.

- (2)

- Hydroculture stage: The specimen is immersed in distilled water at a water temperature of 20 °C, and transferred to the standard conservation box (20 °C, 98% relative humidity) for a duration of 24 h. At this time, the specimen is defined as the specimen undergoes the first level of dry–wet cycling test.

- (3)

- Repeat dry–wet cycles: Repeat (1) and (2); when the number of dry–wet cycling levels reaches 1, 3, 6, 9, and 12, select the specimen (parallel samples to take 3) for the unconfined compressive strength test, and the differences in strength shall not exceed 10%. Retain the damaged internal specimen for MIP and SEM microscopic test.

- (1)

- Freezing phase: We wrapped the specimen with cling film and put it into a tray, and then put the tray into a freeze–thaw cycling chamber with a set temperature of −20 °C for freezing. After 24 h, the specimen was removed and prepared for the hot thawing stage.

- (2)

- Hot thawing stage: The specimen was moved to the conservation box with standard conservation, relative humidity 98%, and temperature 20 °C, 24 h after the specimen for the determination of mass, height, and diameter. At this time, the specimen is defined as the specimen undergoes a level of freeze–thaw cycle test.

- (3)

- Repeat freeze–thaw cycle: Repeat (1) and (2), when the number of freeze–thaw cycle levels reaches 1, 3, 6, 9, and 12, select the specimen (parallel samples to take 3) to carry out the unconfined compressive strength test, and the differences in strength shall not exceed 10%. Retain the damaged internal specimen, to be reserved for the MIP and SEM microscopic test.

3. Results and Discussion

3.1. Changes in Apparent Characteristics

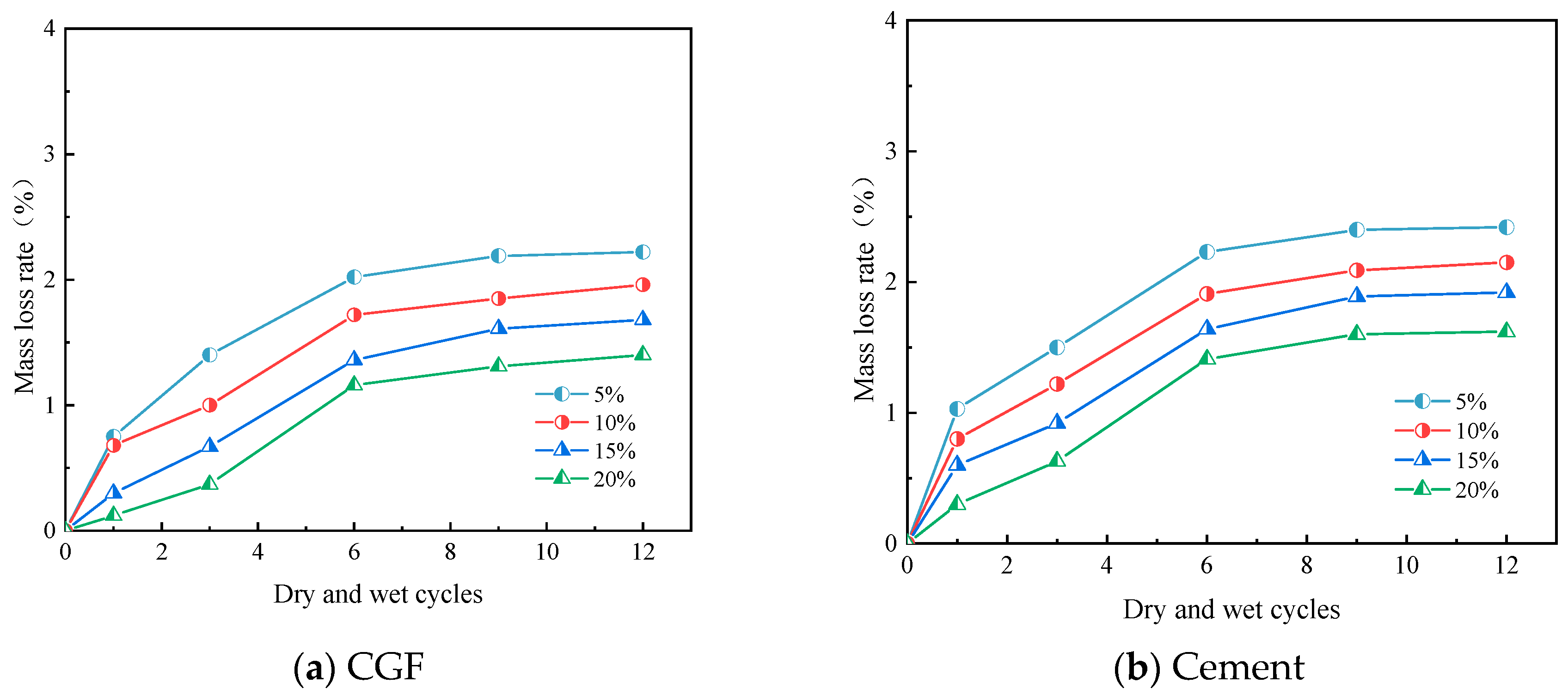

3.2. Mass Loss

3.3. Strength Change

3.4. Microstructure Analysis and Deterioration Mechanism

- (1)

- Analysis of MIP test

- (2)

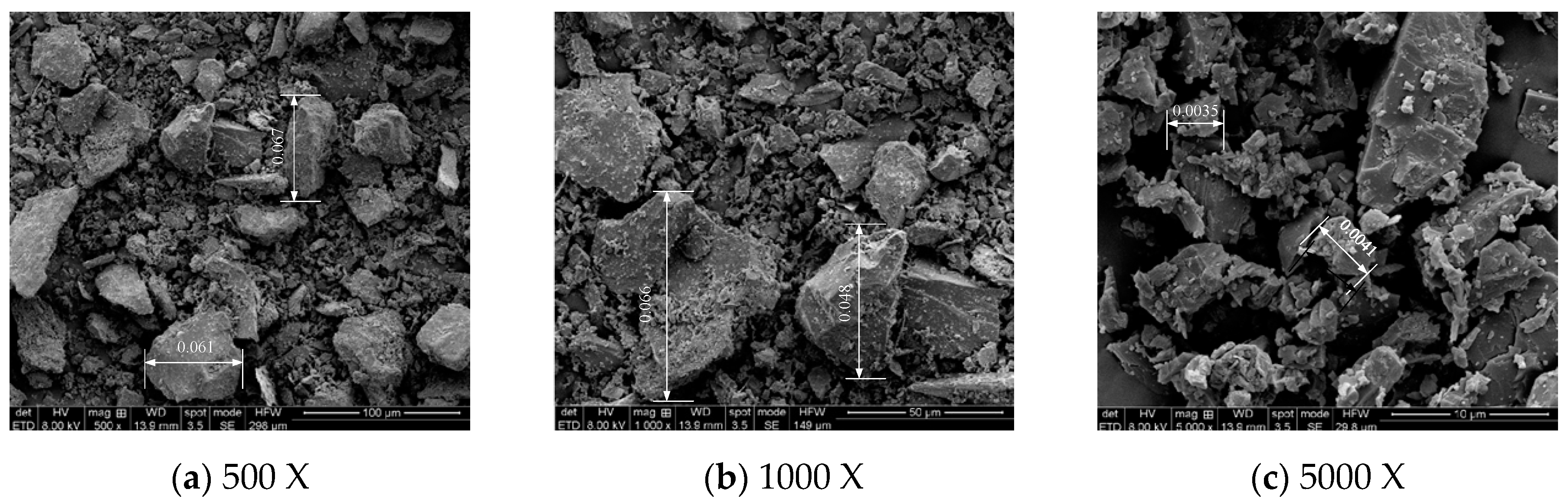

- Analysis of SEM test

4. Conclusions

- (1)

- Through the apparent state of the specimen, it can be observed that the stone waste base material under the conditions of a dry–wet cycle and freeze–thaw cycle has undergone repeated uplift and contraction and the mutual dissolution of pore water, resulting in the damage phenomena of the coarsening of pore space, increasing of fissure, and hydrolysis of cement, which led to the decrease in the quality of the specimen and the decrease in the macroscopic strength. And, with the increase in the number of cycles, there is no obvious crack on the surface of the CGF waste stone road base material specimen, and the surface damage area of the cement stone waste base material specimen gradually increases.

- (2)

- Under the condition of six times of dry–wet cycles, the unconfined compressive strength of the stone waste base material changes greatly, and with the increase in the number of cycles, the rate of decrease in the unconfined compressive strength of the specimen gradually decreases.

- (3)

- The CGF stone waste road base material and cement stone waste road base material damage deterioration degree increase are larger at the beginning of the dry–wet cycle, and with the increase in the number of dry–wet cycle, the growth rate is gradually reduced. The CGF stone waste road base material’s resistance to dry–wet cycle ability is better than the cement stone waste road base material.

- (4)

- After the MIP test pressure reaches 4.01 kPa, mercury rapidly enters into the pores of the stone waste road base material, and the CGF is the main peak of the stone waste road base material which gradually moves to the right with the increase in the number of dry–wet and freeze–thaw cycles, indicating that the stone waste road base material is more prone to deterioration reactions during freeze–thaw cycles. The slope of the fitted curve (lnV–lnS) increases with the number of dry–wet and freeze–thaw cycles, which suggests that the development of porosity is a function of the number of cycles for the practical application of stone wastes.

- (5)

- The results of the SEM tests showed that after six dry–wet cycles, the CGF stone waste road base material and the cement stone waste road base material showed internal cracking and similar deterioration, with the degree of deterioration increasing with the number of dry–wet cycles and the degree of cracking intensifying, which is consistent with the strength results and the results of the MIP tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Torres, A.; Brandt, J.; Lear, K.; Liu, J. A looming tragedy of the sand commons. Science 2017, 357, 970–971. [Google Scholar] [CrossRef]

- Entwisle, D.C.; Hobbs, P.R.N.; Jones, L.D.; Gunn, D.; Raines, M.G. The Relationships between Effective Porosity, Uniaxial Compressive Strength and Sonic Velocity of Intact Borrowdale Volcanic Group Core Samples from Sellafield. Geotech. Geol. Eng. 2005, 23, 793–809. [Google Scholar] [CrossRef]

- Thakur, A.K.; Pappu, A.; Thakur, V.K. Resource efficiency impact on marble waste recycling towards sustainable green construction materials. Curr. Opin. Green Sustain. Chem. 2018, 13, 91–101. [Google Scholar] [CrossRef]

- Prakash, B.; Saravanan, T.J.; Kabeer, K.I.S.A.; Bisht, K. Exploring the potential of waste marble powder as a sustainable substitute to cement in cement-based composites: A review. Constr. Build. Mater. 2023, 401, 32887. [Google Scholar] [CrossRef]

- Li, H.; Huang, F.; Cheng, G.; Xie, Y.; Tan, Y.; Li, L.; Yi, Z. Effect of granite dust on mechanical and some durability properties of manufactured sand concrete. Constr. Build. Mater. 2016, 109, 41–46. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Han, J.; Lin, G.; Qian, D.; Liu, Z.; He, Y. Environmental and economical friendly ultra-high performance-concrete incorporating appropriate quarry-stone powders. J. Clean. Prod. 2020, 260, 121112. [Google Scholar] [CrossRef]

- Wu, Y.L.; Yang, J.J. Soil Stabilizer–Materials·Mechanism Applications; Chemical Industry Press: Beijing, China, 2022. [Google Scholar]

- Arel, H.Ş. Recyclability of waste marble in concrete production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Joudi-Bahri, I.; Lecomte, A.; Ouezdou, M.B.; Achour, T. Use of limestone sands and fillers in concrete without superplasticizer. Cem. Concr. Compos. 2012, 34, 771–780. [Google Scholar] [CrossRef]

- Ren, Q.; Xie, M.; Zhu, X.; Zhang, Y.; Jiang, Z. Role of limestone powder in early-age cement paste considering fineness effects. J. Mater. Civ. Eng. 2020, 32, 04020289. [Google Scholar] [CrossRef]

- Munir, M.J.; Kazmi, S.M.S.; Wu, Y. Efficiency of waste marble powder in controlling alkali–silica reaction of concrete: A sustainable approach. Constr. Build. Mater. 2017, 154, 590–599. [Google Scholar] [CrossRef]

- Kirgiz, M.S. Use of ultrafine marble and brick particles as raw materials in cement manufacturing. Mater. Struct. 2015, 48, 2929–2941. [Google Scholar] [CrossRef]

- Wu, Y.L.; Yang, J.J.; Chang, R.Q. The design of ternary all-solid-waste binder for solidified soil and the mechanical properties, mechanism and environmental benefits of CGF solidified soil. J. Clean. Prod. 2023, 429, 139439. [Google Scholar] [CrossRef]

- Wang, F.; Meng, F.; Feng, T.; Wang, Y.; Jiang, J.; Shi, J. Effect of stone powder content on the mechanical properties and microstructure of tunnel slag aggregate-based concrete. Constr. Build. Mater. 2023, 388, 131692. [Google Scholar] [CrossRef]

- Zheng, S.; Liang, J.; Hu, Y.; Wei, D.; Lan, Y.; Du, H.; Rong, H. An experimental study on compressive properties of concrete with manufactured sand using different stone powder content. Ferroelectrics 2021, 579, 189–198. [Google Scholar] [CrossRef]

- Campos, H.F.; Klein, N.S.; Marques Filho, J.; Bianchini, M. Low-cement high-strength concrete with partial replacement of Portland cement with stone powder and silica fume designed by particle packing optimization. J. Clean. Prod. 2020, 261, 121228. [Google Scholar] [CrossRef]

- Chen, R.; Jiao, Y.; Xiao, M.; Yang, H.; Wang, C. Effect of Composition Characteristics on Mechanical Properties of UHPMC Based on Response Surface Methodology and Acoustic Emission Monitoring. Materials 2024, 17, 2714. [Google Scholar] [CrossRef]

- Shen, W.; Wu, J.; Du, X.; Li, Z.; Wu, D.; Sun, J.; Wang, Z.; Huo, X.; Zhao, D. Cleaner production of high-quality manufactured sand and ecological utilization of recycled stone powder in concrete. J. Clean. Prod. 2022, 375, 134146. [Google Scholar] [CrossRef]

- Bakis, A. Increasing the Durability and Freeze-Thaw Strength of Concrete Paving Stones Produced from Ahlat Stone Powder and Marble Powder by Special Curing Method. Adv. Mater. Sci. Eng. 2019, 2019, 3593710. [Google Scholar] [CrossRef]

- Chen, J. Experimental analysis of influence factors on pavement concrete performance: Different content of stone powder in manufactured sand. Mater. Des. Process. Commun. 2021, 3, e213. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China. Annual Report on Prevention and Control of Solid Waste Pollution in Large and Medium-sized Cities of China in 2022. 2022. Available online: https://www.mee.gov.cn/hjzl/sthjzk/sthjtjnb/202312/t20231229_1060181.shtml (accessed on 29 December 2023).

- Ministry of Ecology and Environment, People’s Republic of China. Annual Report on China’s Ecological and Environmental Statistics 2021. 2023. Available online: https://www.mee.gov.cn/hjzl/sthjzk/sthjtjnb/202301/t20230118_1013682.shtml (accessed on 18 January 2023).

- Wu, Y.L.; Yang, J.J.; Chang, R.Q.; Li, S.; Kou, H. Strength, leaching characteristics and microstructure of CGF+P all-solid-waste binder solidification/stabilization Cu(II) contaminated soil. Constr. Build. Mater. 2024, 411, 134431. [Google Scholar] [CrossRef]

- Qiu, X.Y.; Yang, J.J.; Wu, Y.L.; Yan, L.; Liu, Q. Effect of fiber content on mechanical properties of fiber-reinforced CGF All-Solid-Waste binder-solidified soil. Materials 2024, 17, 388. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, J.J.; Wu, Y.L.; Wang, Z.M.; Qiu, X.; Yan, L. Physical and mechanical properties of All-Solid-Waste-Based binder-modified abandoned marine soft soil. J. Mar. Sci. Eng. 2024, 12, 393. [Google Scholar] [CrossRef]

- Gi, W.; Monamed, A.; Khalid, N.H.; Nor, H.M.; Hainin, M.R.; Jaya, R.P.; Sani, W.N.H.M.; Ismail, C.R.; Aziz, M.M.A. Recycled concrete aggregate as a road base material. Mater. Sci. Eng. 2019, 12, 1–11. [Google Scholar]

- Koleva, D.A.; Breugel, K.V.; Wit, J.H. Correlation of microstructure, electrical properties and electrochemical phenomena in reinforced mortar. Breakdown to multiphase interface structures. Part I: Microstructural observations and electrical properties. Mater. Charact. 2008, 59, 290. [Google Scholar] [CrossRef]

- Care, S. Effect of temperature on porosity and on chloride diffusion in cement pastes. Constr. Build. Mater. 2008, 22, 1560. [Google Scholar] [CrossRef]

- Wang, M.; Yang, J.J.; Wu, Y.L.; Lu, Y. Rapid predictive method for the deterioration depth of cement solidified marine soft soil. Soils Found. 2024, 64, 101494. [Google Scholar] [CrossRef]

- Wang, M.; Yang, J.; Wu, Y.; Yan, L. Laboratory Test study on deterioration process of cement soil piles in radial direction in k0 consolidated marine soft soil foundation. Measurement 2024, 237, 115–216. [Google Scholar] [CrossRef]

- JTG/E51-200; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport of The People’s Republic of China: Beijing, China, 2009.

- GB-T50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Jiao, Z.; Wang, Y.; Zheng, W.; Huang, W. Effect of dosage of sodium carbonate on the strength and drying shrinkage of sodium hydroxide based alkali-activated slag paste. Constr. Build. Mater. 2018, 179, 11–24. [Google Scholar] [CrossRef]

- JBT 6842-1993; Scanning Electron Microscope Test Methods. Ministry of Machinery Industry: Beijing, China, 1993.

- GB/T 21650.1-2008; Determination of Pore Size Distribution and Porosity of Solid Materials by Mercuric Pressure and Gas Adsorption Methods, Part 1. China Planning Press: Beijing, China, 2008.

- Kim, J.H.; Choi, S.W.; Lee, K.M.; Choi, Y.C. Influence of internal curing on the pore size distribution of high strength concrete. Constr. Build. Mater. 2018, 192, 50–57. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Y.; Sun, Y.; Ren, J.; Zhao, Z.; Zhang, J. Evaluation of pore size distribution and permeability reduction behavior in pervious concrete. Constr. Build. Mater. 2021, 290, 123228. [Google Scholar] [CrossRef]

| Particle Density (GS) | Plastic Limit (%) | Fine Stone Waste (<0.005 mm) | |||

|---|---|---|---|---|---|

| Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (Ip) | Liquidity Index (IL) | ||

| 2.68 | 15.6 | 39.5 | 18.9 | 20.6 | 1.1 |

| Specimen Number | Type of Binder | Binder Content (%) | Water–Binder Ratio | Curing Time (Days) | Tests | Number of Test Groups |

|---|---|---|---|---|---|---|

| C5 | CGF | 5% | 1 | 28 | Dry–wet cycle Freeze–thaw cycle UCST MIP SEM–EDS | 3 |

| C10 | CGF | 10% | ||||

| C15 | CGF | 15% | ||||

| C20 | CGF | 20% | ||||

| S5 | Cement | 5% | ||||

| S10 | Cement | 10% | ||||

| S15 | Cement | 15% | ||||

| S20 | Cement | 20% |

| Test | Test Instrument Parameters | Test Norms |

|---|---|---|

| Dry–wet cycle | Constant temperature and humidity maintenance box, YH-40B Electrothermal constant temperature blast drying box, DHG-9245A | JTG E51-2009 [32] |

| Freeze–thaw cycle | Freezing and thawing box, ZT-CTH-225L | JTG E51-2009 [32] |

| UCST | Strain-controlled and the rate of vertical displacement was fixed at 1%/min. | GB/T50123-2019 [33] |

| SEM | HITACHI S-4800, secondary electron imaging resolution: 1.0 nm@15 KV, magnification: 20×–800,000×, accelerating voltage: 0.1–30 KV, sample stage: three-axis motor stage, and maximum sample size: Φ100 mm. | JBT 6842-1993 [35] |

| MIP | Micro Active AutoPore V 9600. | GB/T 21650.1-2008 [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yang, J.; Wu, Y. Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles. Materials 2024, 17, 4272. https://doi.org/10.3390/ma17174272

Wang Z, Yang J, Wu Y. Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles. Materials. 2024; 17(17):4272. https://doi.org/10.3390/ma17174272

Chicago/Turabian StyleWang, Zimou, Junjie Yang, and Yalei Wu. 2024. "Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles" Materials 17, no. 17: 4272. https://doi.org/10.3390/ma17174272

APA StyleWang, Z., Yang, J., & Wu, Y. (2024). Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles. Materials, 17(17), 4272. https://doi.org/10.3390/ma17174272