Bio-Inspired Curved-Elliptical Lattice Structures for Enhanced Mechanical Performance and Deformation Stability

Abstract

:1. Introduction

2. Methods

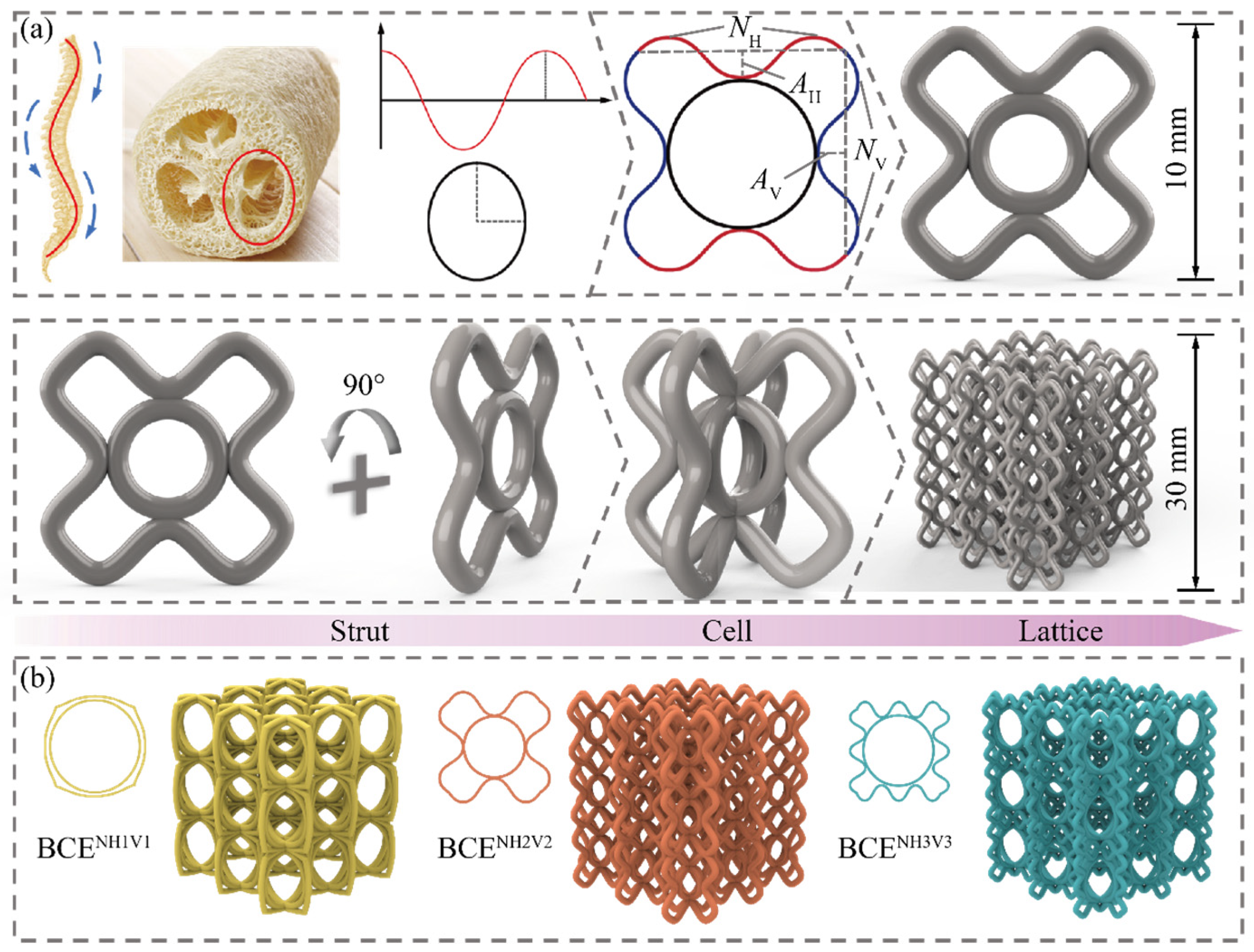

2.1. Design Strategy for BCE Lattice Structures

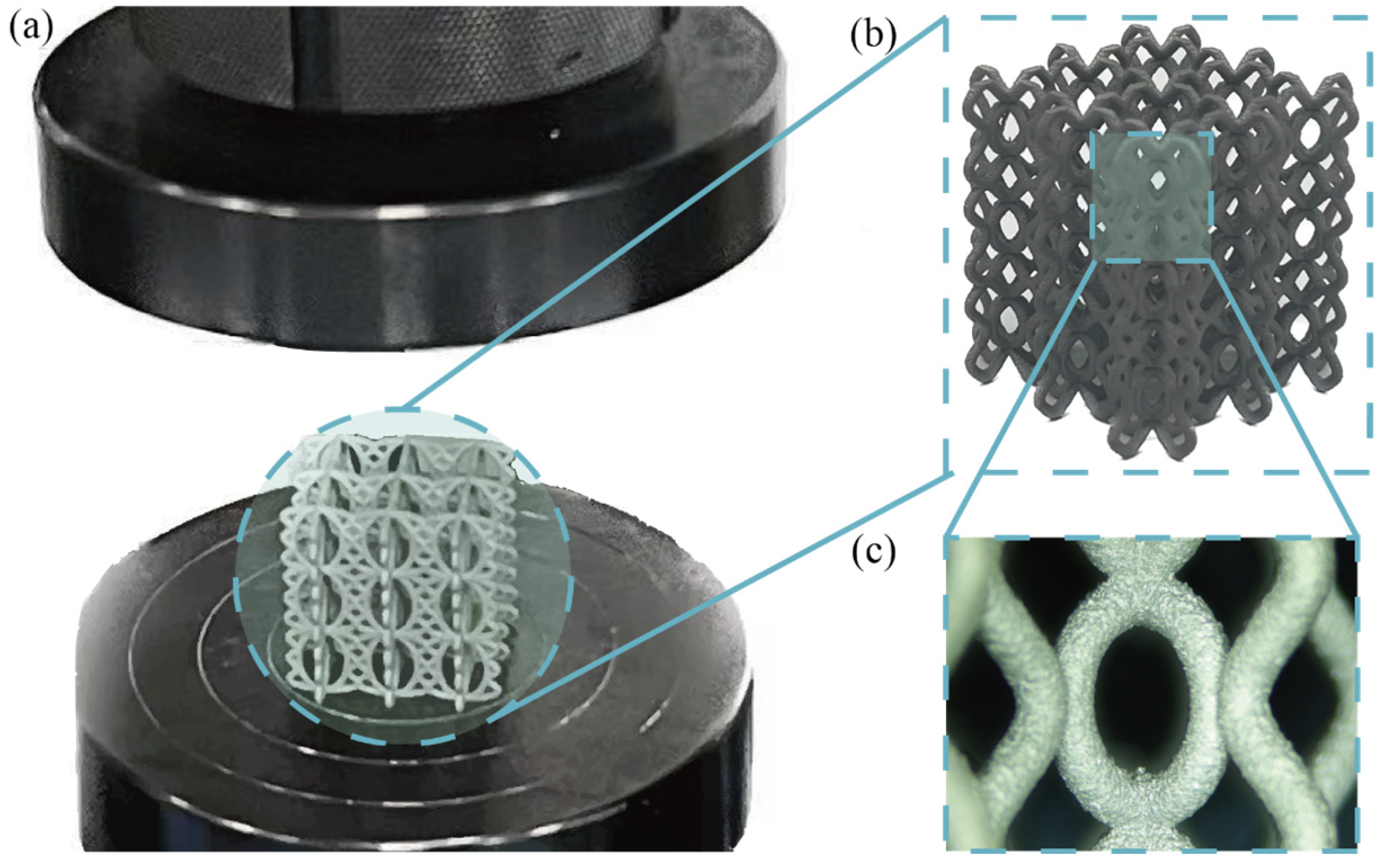

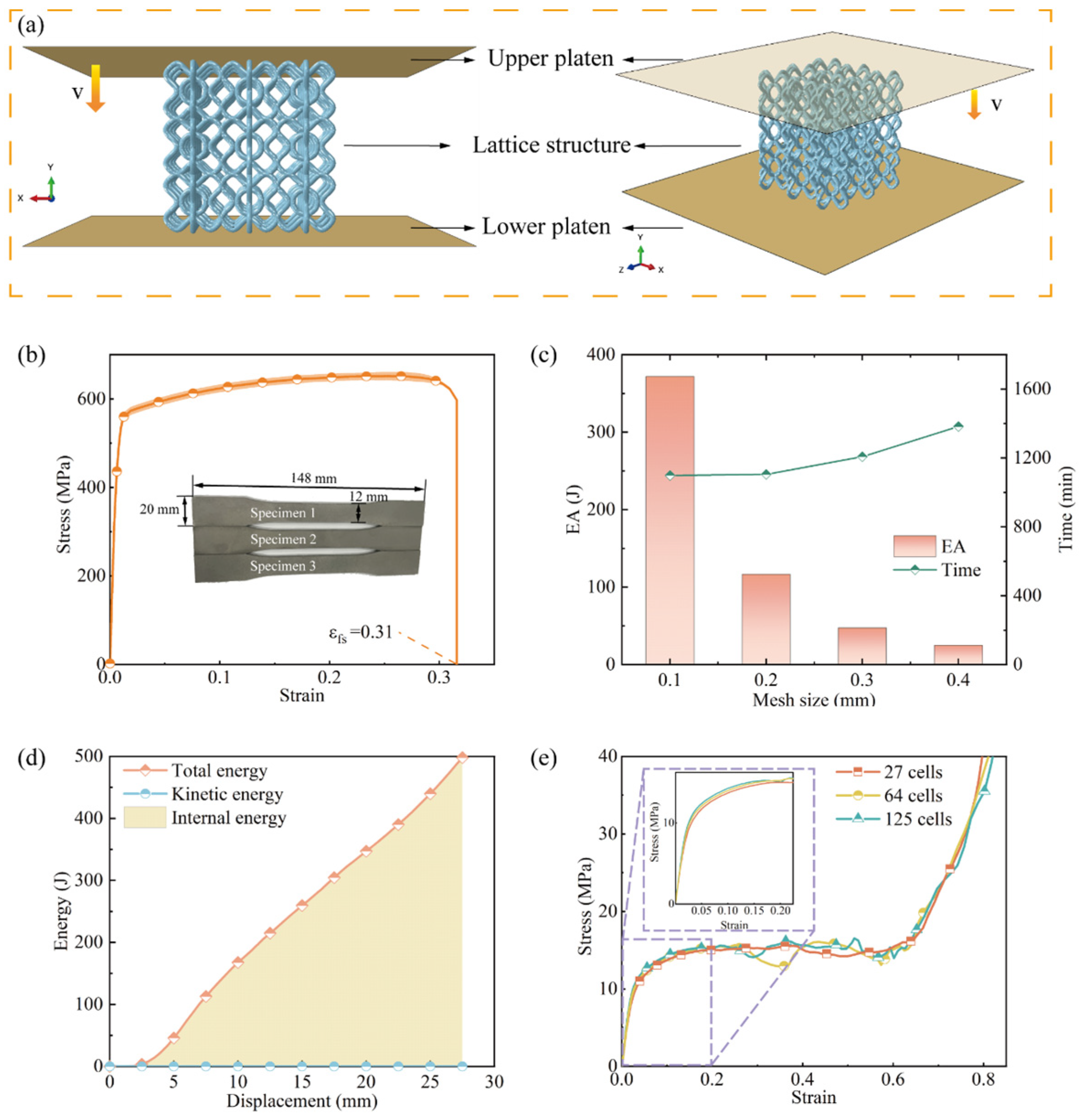

2.2. Experimental Tests and Numerical Modeling

2.3. Compression Performance Metrics

3. Results and Discussion

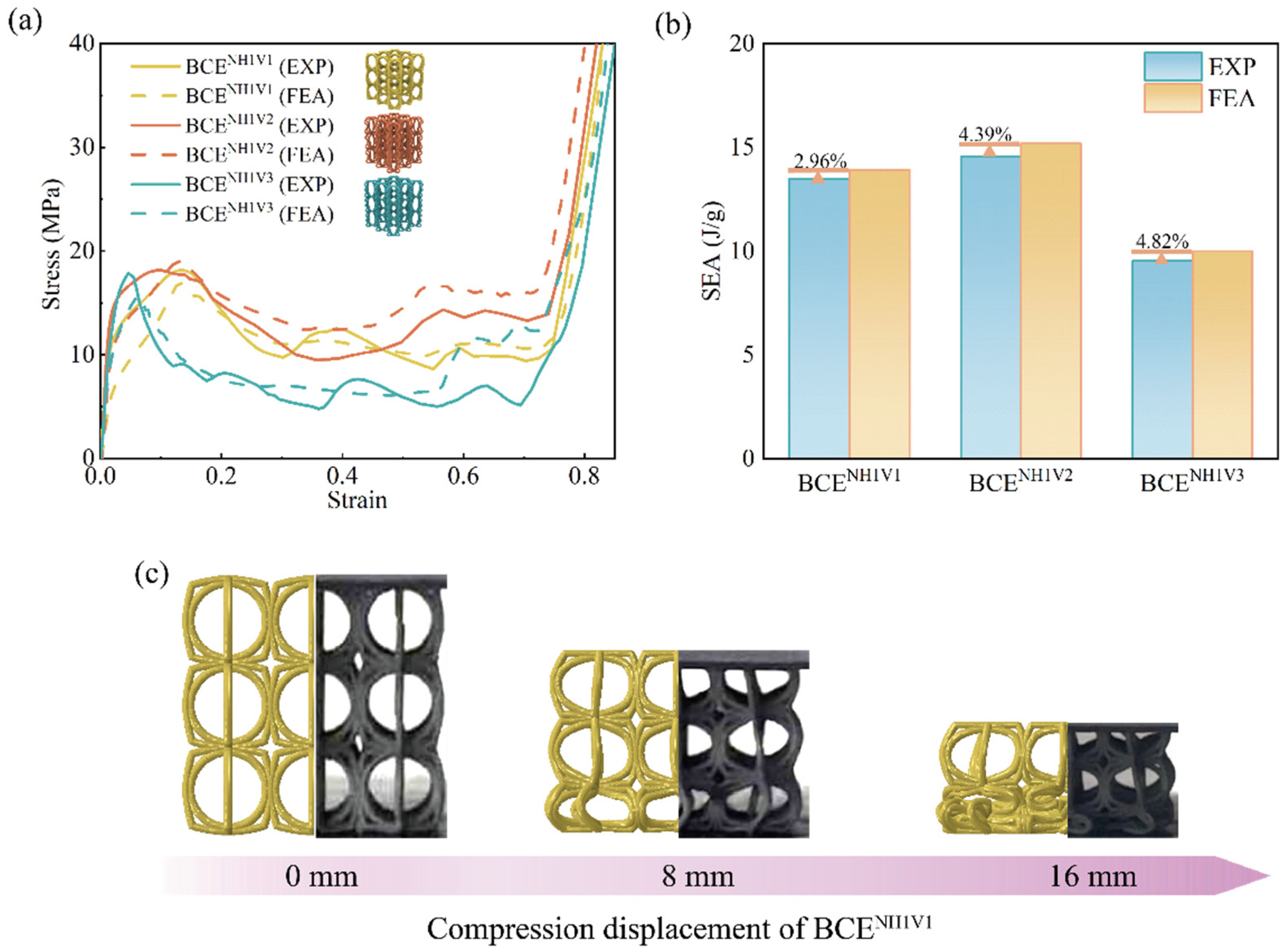

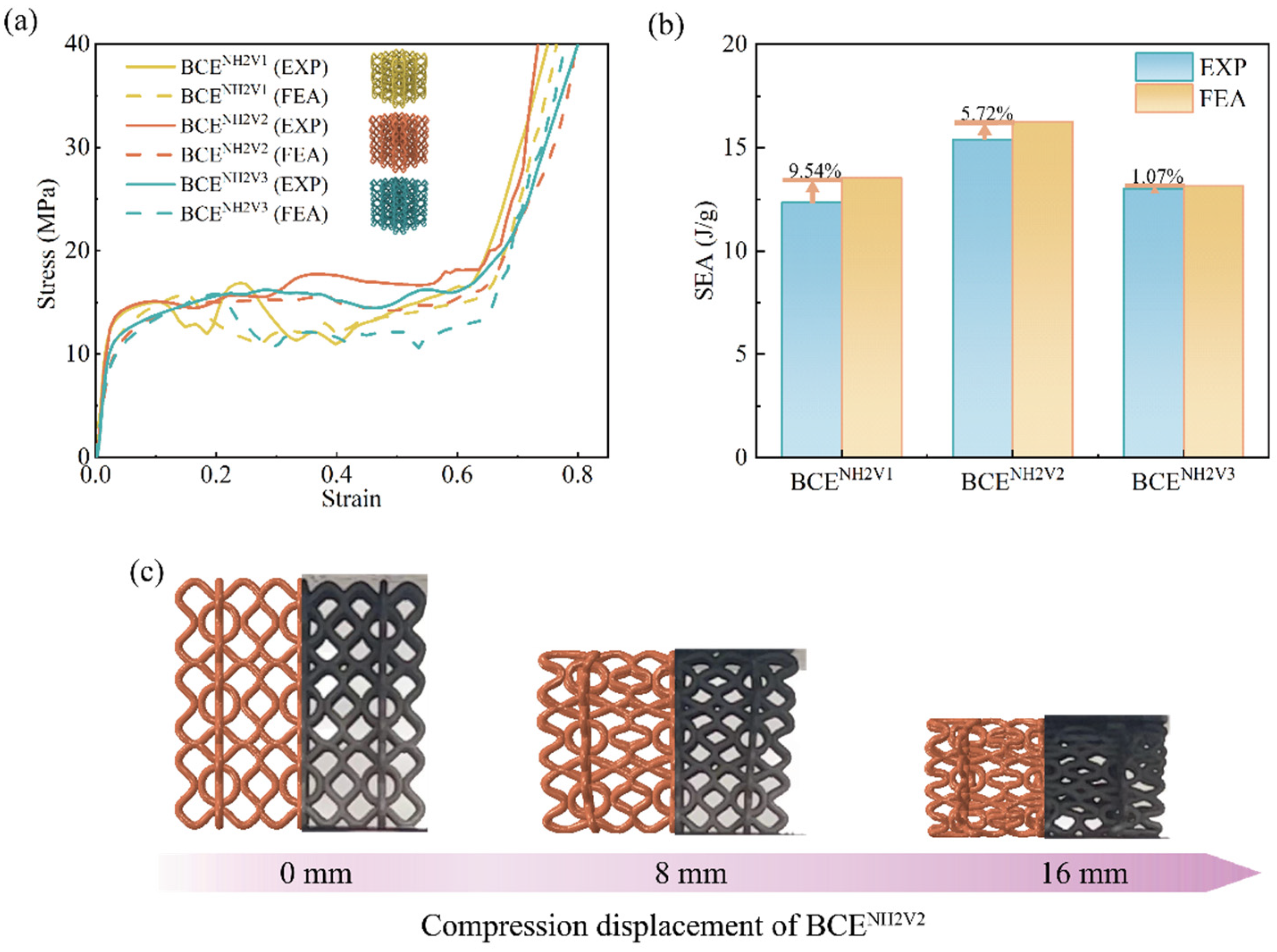

3.1. Comparison between Experiments and FE Simulations

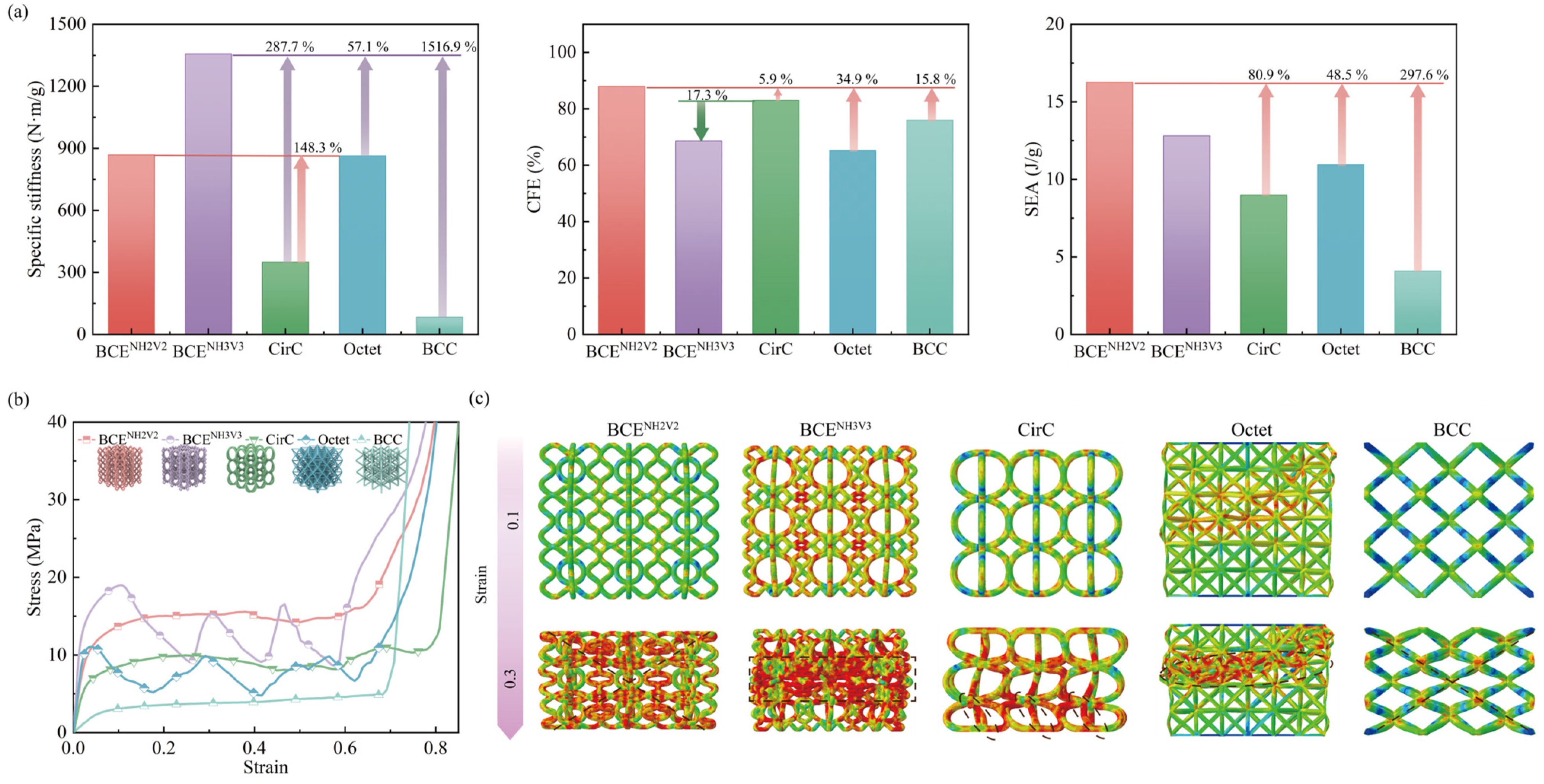

3.2. Comparison between BCE Lattices and Traditional Lattice Structures

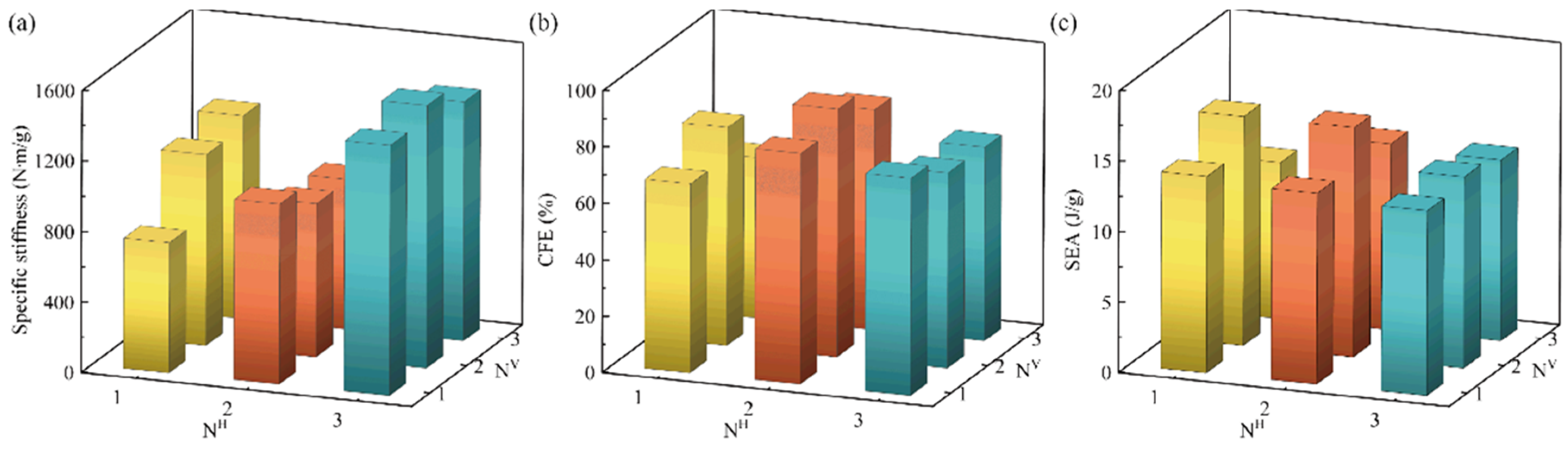

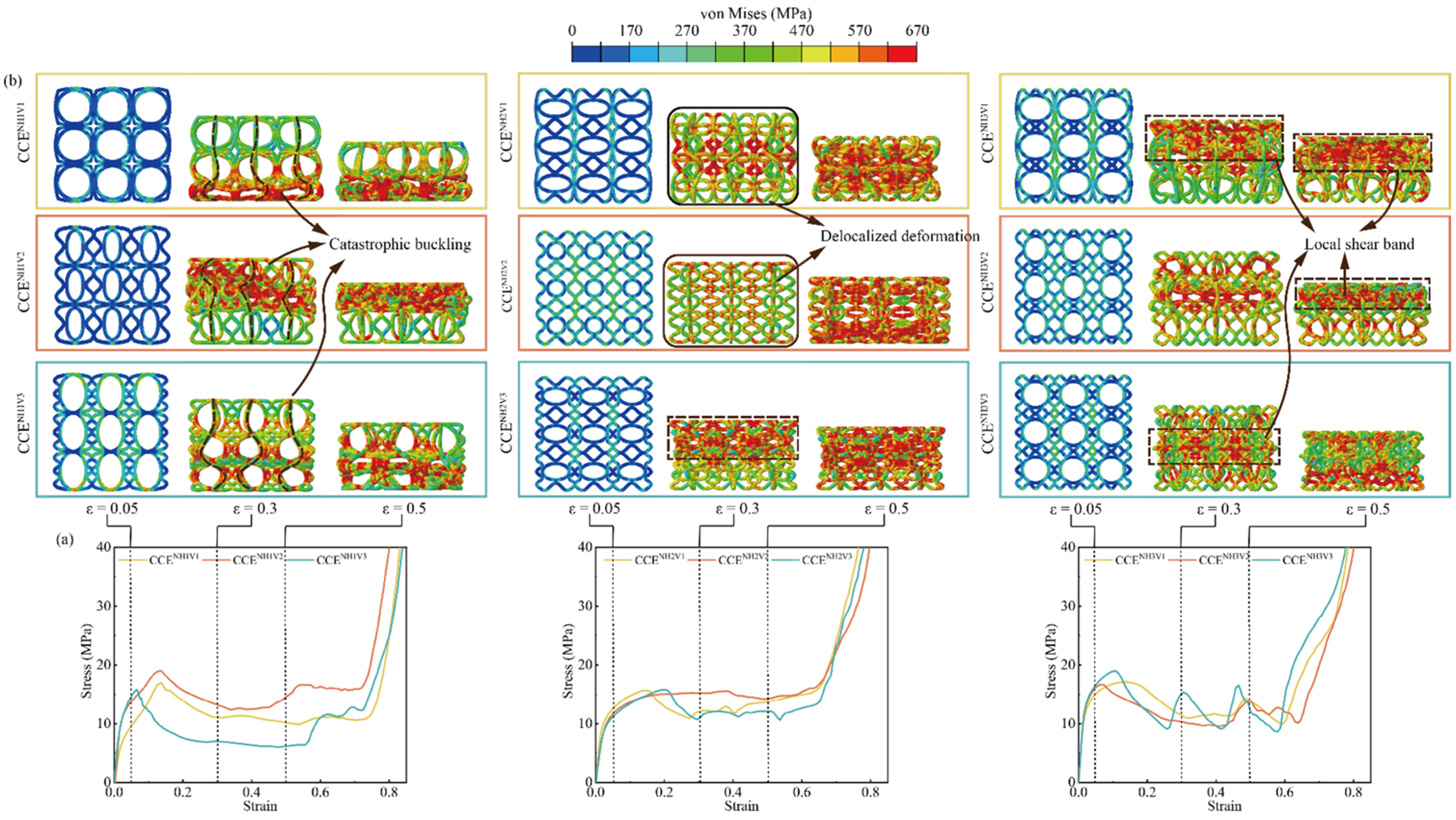

3.3. Parametric Study for BCE Structures

3.3.1. Effect of the Number of Strut Waviness N

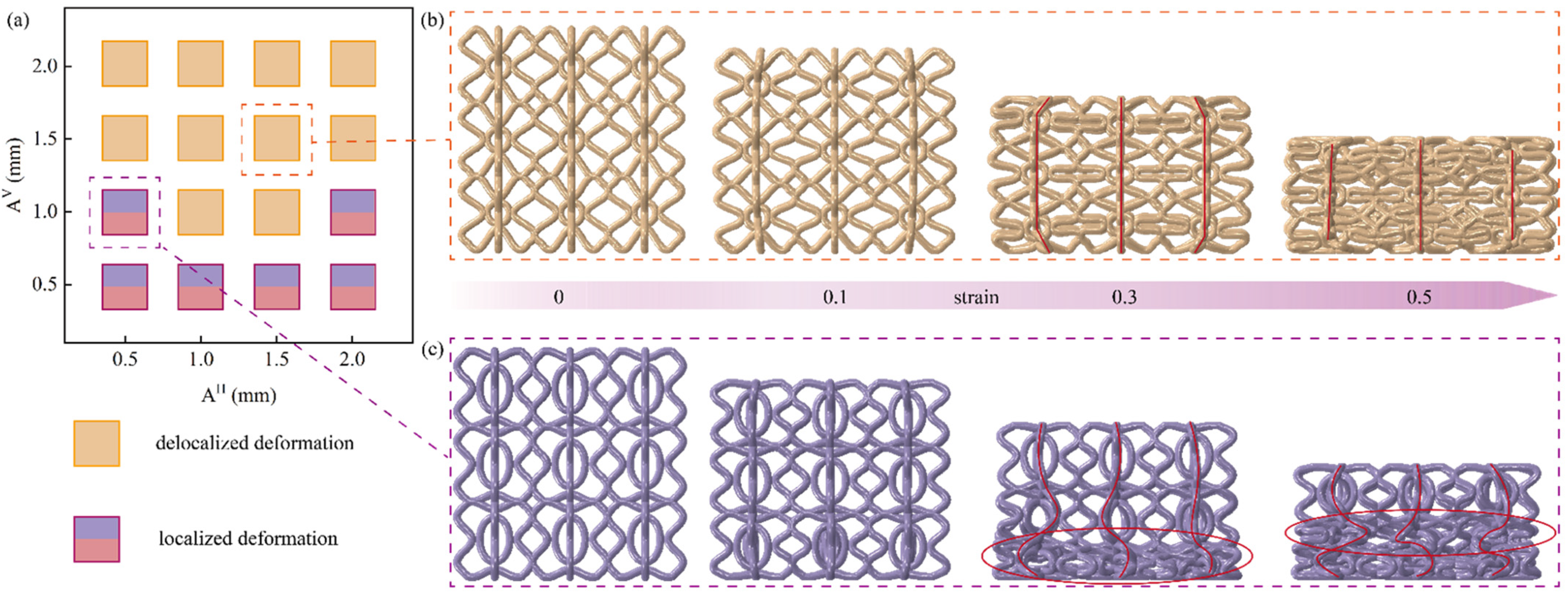

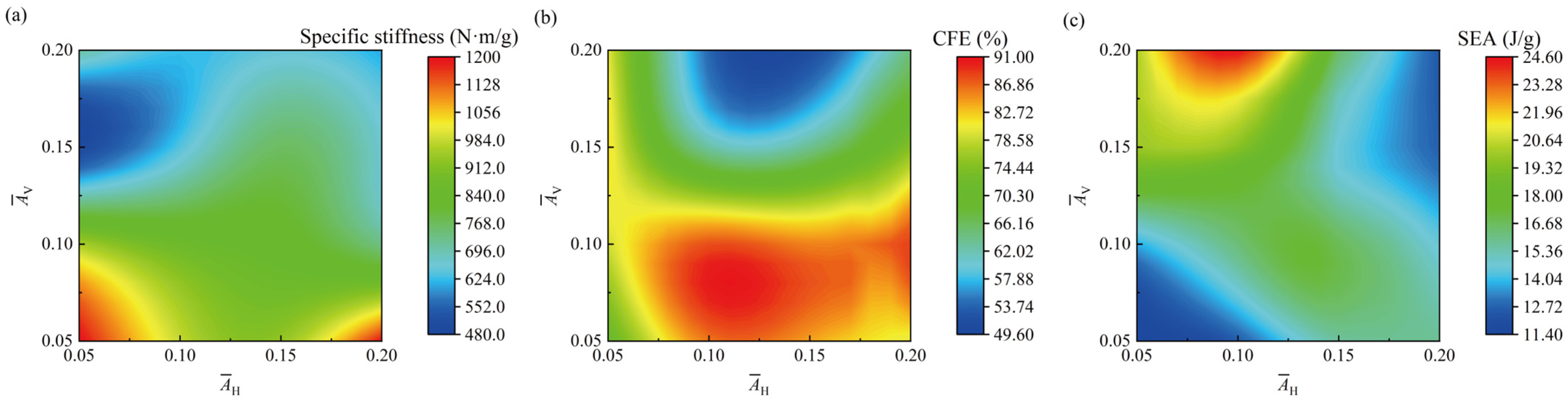

3.3.2. Effect of the Amplitude of the Strut Waviness A

4. Conclusions

- (1)

- The proposed BCE structures with different geometric parameters exhibit different deformation modes. By adjusting the number and amplitude of the strut waviness, a stable delocalized deformation mode can be achieved, avoiding catastrophic collapse during compression. The CFE of BCE is higher than that of Octet, CirC, and BCC, with improvements of 34.9%, 5.9%, and 15.8%, respectively.

- (2)

- The proposed BCE structures exhibit high compression performance in terms of SEA and specific stiffness. The SEA of BCE is higher compared to Octet, CirC, and BCC, with increases of 48.5%, 80.9%, and 297.6%, respectively. Similarly, the specific stiffness is improved by 57.1%, 287.7%, and 1516.9%, respectively. Notably, the BCE structure can achieve simultaneous enhancements of SEA and specific stiffness at appropriate geometric parameters.

- (3)

- The number N and the amplitude A of the strut waviness are important parameters affecting the compression performance of BCE structures. From the parametric analysis, the deformation mode of BCE structures is most sensitive to the waviness amplitude of the vertical struts and the waviness number of the horizontal struts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, H.; Zhang, W.; Zhu, L.; Meng, F.; Liu, J.; Wen, G. Review on lattice structures for energy absorption properties. Compos. Struct. 2023, 304, 116397. [Google Scholar] [CrossRef]

- Mao, A.; Zhao, N.; Liang, Y.; Bai, H. Mechanically Efficient Cellular Materials Inspired by Cuttlebone. Adv. Mater. 2021, 33, 2007348. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Zhou, J.; Liang, H.; Jiang, Z.; Wu, L. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review. Prog. Mater. Sci. 2018, 94, 114–173. [Google Scholar] [CrossRef]

- Chen, X.; Ji, Q.; Martinez, J.A.I.; Tan, H.; Ulliac, G.; Laude, V.; Kadic, M. Closed tubular mechanical metamaterial as lightweight structure and absorber. J. Mech. Phys. Solids 2022, 167, 104957. [Google Scholar] [CrossRef]

- Li, M.; Zhao, N.; Wang, M.; Dai, X.; Bai, H. Conch-Shell-Inspired Tough Ceramic. Adv. Funct. Mater. 2022, 32, 2205309. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, S.; Zhang, Q.; Li, J.; Yu, C.; Zhang, C. A novel monoclinic auxetic metamaterial with tunable mechanical properties. Int. J. Mech. Sci. 2022, 236, 107750. [Google Scholar] [CrossRef]

- Andrew, J.J.; Verma, P.; Kumar, S. Impact behavior of nanoengineered, 3D printed plate-lattices. Mater. Des. 2021, 202, 109516. [Google Scholar] [CrossRef]

- Spadoni, A.; Ruzzene, M. Numerical and experimental analysis of the static compliance of chiral truss-core airfoils. J. Mech. Mater. Struct. 2007, 2, 965–981. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Zhao, W.; Zou, S.; Zhou, G.; Wang, Y. Structure design and multi-objective optimization of a novel crash box based on biomimetic structure. Int. J. Mech. Sci. 2018, 138, 489–501. [Google Scholar] [CrossRef]

- Yin, S.; Chen, H.; Wu, Y.; Li, Y.; Xu, J. Introducing composite lattice core sandwich structure as an alternative proposal for engine hood. Compos. Struct. 2018, 201, 131–140. [Google Scholar] [CrossRef]

- Feng, J.; Liu, B.; Lin, Z.; Fu, J. Isotropic octet-truss lattice structure design and anisotropy control strategies for implant application. Mater. Des. 2021, 203, 109595. [Google Scholar] [CrossRef]

- Acanfora, V.; Corvino, C.; Saputo, S.; Sellitto, A.; Riccio, A. Application of an Additive Manufactured Hybrid Metal/Composite Shock Absorber Panel to a Military Seat Ejection System. Appl. Sci. 2021, 11, 6473. [Google Scholar] [CrossRef]

- Khosroshahi, S.F.; Tsampas, S.A.; Galvanetto, U. Feasibility study on the use of a hierarchical lattice architecture for helmet liners. Mater. Today Commun. 2018, 14, 312–323. [Google Scholar] [CrossRef]

- Acanfora, V.; Castaldo, R.; Riccio, A. On the Effects of Core Microstructure on Energy Absorbing Capabilities of Sandwich Panels Intended for Additive Manufacturing. Materials 2022, 15, 1291. [Google Scholar] [CrossRef]

- Acanfora, V.; Saputo, S.; Russo, A.; Riccio, A. A feasibility study on additive manufactured hybrid metal/composite shock absorbers. Compos. Struct. 2021, 268, 113958. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Mohr, D. Elastically-isotropic truss lattice materials of reduced plastic anisotropy. Int. J. Solids Struct. 2018, 138, 24–39. [Google Scholar] [CrossRef]

- Li, C.; Shen, H.-S.; Wang, H. Postbuckling behavior of sandwich plates with functionally graded auxetic 3D lattice core. Compos. Struct. 2020, 237, 111894. [Google Scholar] [CrossRef]

- Berger, J.B.; Wadley, H.N.G.; McMeeking, R.M. Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature 2017, 543, 533–537. [Google Scholar] [CrossRef]

- Li, L.; Guo, Z.; Yang, F.; Li, P.; Zhao, M.; Zhong, Z. Additively manufactured acoustic-mechanical multifunctional hybrid lattice structures. Int. J. Mech. Sci. 2024, 269, 109071. [Google Scholar] [CrossRef]

- Jiang, H.; Coomes, A.; Zhang, Z.; Ziegler, H.; Chen, Y. Tailoring 3D printed graded architected polymer foams for enhanced energy absorption. Compos. Part B Eng. 2021, 224, 109183. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, X.; Chen, Z.; Jiang, Y.; Cao, X.; Fang, S.; Zhao, T.; Li, Y.; Fang, D. Numerical and experimental studies on compressive behavior of Gyroid lattice cylindrical shells. Mater. Des. 2020, 186, 108340. [Google Scholar] [CrossRef]

- San, H.N.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar]

- Ren, L.; Wang, Z.; Ren, L.; Han, Z.; Liu, Q.; Song, Z. Graded biological materials and additive manufacturing technologies for producing bioinspired graded materials: An overview. Compos. Part B Eng. 2022, 242, 110086. [Google Scholar] [CrossRef]

- Meza, L.R.; Zelhofer, A.J.; Clarke, N.; Mateos, A.J.; Kochmann, D.M.; Greer, J.R. Resilient 3D hierarchical architected metamaterials. Proc. Natl. Acad. Sci. USA 2015, 112, 11502–11507. [Google Scholar] [CrossRef] [PubMed]

- Plessis, A.D.; Broeckhoven, C.; Yadroitsev, I.; Yadroitsava, I.; le Roux, S.G. Analyzing nature’s protective design: The glyptodont body armor. J. Mech. Behav. Biomed. Mater. 2018, 82, 218–223. [Google Scholar] [CrossRef]

- Han, S.C.; Kang, D.S.; Kang, K. Two nature-mimicking auxetic materials with potential for high energy absorption. Mater. Today 2019, 26, 30–39. [Google Scholar] [CrossRef]

- Fernandes, M.C.; Aizenberg, J.; Weaver, J.C.; Bertoldi, K. Mechanically robust lattices inspired by deep-sea glass sponges. Nat. Mater. 2021, 20, 237–241. [Google Scholar] [CrossRef]

- Sharma, D.; Hiremath, S.S. Bio-inspired repeatable lattice structures for energy absorption: Experimental and finite element study. Compos. Struct. 2022, 283, 115102. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, L.; Ballard, J.; Usta, F.; Chen, Y. Unveiling the mechanics of deep-sea sponge-inspired tubular metamaterials: Exploring bending, radial, and axial mechanical behavior. Thin-Walled Struct. 2024, 196, 111476. [Google Scholar] [CrossRef]

- Wang, P.; Yang, F.; Zheng, B.; Li, P.; Wang, R.; Li, Y.; Fan, H.; Li, X. Breaking the Tradeoffs between Different Mechanical Properties in Bioinspired Hierarchical Lattice Metamaterials. Adv. Funct. Mater. 2023, 33, 2305978. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papapacharalampopoulos, A. On the impact of additive manufacturing processes complexity on modelling. Appl. Sci. 2021, 11, 7743. [Google Scholar] [CrossRef]

- Yang, Y.; Song, X.; Li, X.; Chen, Z.; Zhou, C.; Zhou, Q.; Chen, Y. Recent progress in biomimetic additive manufacturing technology: From materials to functional structures. Adv. Mater. 2018, 30, 1706539. [Google Scholar] [CrossRef]

- Alomar, Z.; Concli, F. Compressive behavior assessment of a newly developed circular cell-based lattice structure. Mater. Des. 2021, 205, 109716. [Google Scholar] [CrossRef]

- Li, D.; Qin, R.; Xu, J.; Zhou, J.; Chen, B. Improving Mechanical Properties and Energy Absorption of Additive Manufacturing Lattice Structure by Struts’ Node Strengthening. Acta Mech. Solida Sin. 2022, 35, 1004–1020. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Wang, W. Compression and Deformation Behaviors of Hierarchical Circular-Cell Lattice Structure with Enhanced Mechanical Properties and Energy Absorption Capacity. Aerospace 2022, 9, 786. [Google Scholar] [CrossRef]

- Zhu, G.; Wen, D.; Wei, L.; Wang, Z.; Zhao, X. Mechanical performances of novel cosine function cell-based metallic lattice structures under quasi-static compressive loading. Compos. Struct. 2023, 314, 116962. [Google Scholar] [CrossRef]

- Bauer, J.; Kraus, J.A.; Crook, C.; Rimoli, J.J.; Valdevit, L. Tensegrity Metamaterials: Toward Failure-Resistant Engineering Systems through Delocalized Deformation. Adv. Mater. 2021, 33, 2005647. [Google Scholar] [CrossRef]

- Ouyang, J.; Qian, L.; Sun, P. Retrospect and Prospect on Researches of Spine Biomechanics. J. Med. Biomech. 2021, 36, 169–176. [Google Scholar]

- An, X.; Fan, H. Hybrid design and energy absorption of luffa-sponge-like hierarchical cellular structures. Mater. Des. 2016, 106, 247–257. [Google Scholar] [CrossRef]

- Li, Z.; Yao, S.; Ma, W.; Xu, P.; Che, Q. Energy-absorption characteristics of a circumferentially corrugated square tube with a cosine profile. Thin-Walled Struct. 2019, 135, 385–399. [Google Scholar] [CrossRef]

| Technical Specifications | SLM |

|---|---|

| Build envelope (L × W × H) | 280 × 280 × 365 |

| Variable layer thickness/μm | 20–90 |

| Real build rate/cm3·h−1 | Up to 113 |

| Beam focus diameter/μm | 80–115 |

| Average inert gas consumption in process/L·min−1 | 13(Argon) |

| Compressed air requirement/bar | ISO 8573-1:2010 [1:4:1] 7 |

| Machine dimensions (L × W × H)/mm | 4150 × 1200 × 2525 |

| Specific Stiffness (N∙m/g) | CFE (%) | SEA (J/g) | |

|---|---|---|---|

| BCENH2V2 | 868.8 | 87.9 | 16.3 |

| BCENH3V3 | 1356.6 | 68.6 | 12.8 |

| CirC | 349.9 | 82.9 | 8.9 |

| Octet | 863.8 | 65.2 | 10.9 |

| BCC | 83.9 | 75.9 | 4.1 |

| Specific Stiffness (N∙m/g) | CFE (%) | SEA (J/g) | |

|---|---|---|---|

| BCENH1V1 | 741.4 | 67.1 | 13.9 |

| BCENH1V2 | 1082.9 | 77.3 | 16.3 |

| BCENH1V3 | 1149.9 | 56.6 | 11.0 |

| BCENH2V1 | 1021.9 | 81.8 | 13.5 |

| BCENH2V2 | 868.8 | 87.9 | 16.3 |

| BCENH2V3 | 848.2 | 78.0 | 13.2 |

| BCENH3V1 | 1418.8 | 77.1 | 13.1 |

| BCENH3V2 | 1491.8 | 69.2 | 13.6 |

| BCENH3V3 | 1356.6 | 68.6 | 12.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Yang, F.; Li, L.; Wu, J. Bio-Inspired Curved-Elliptical Lattice Structures for Enhanced Mechanical Performance and Deformation Stability. Materials 2024, 17, 4191. https://doi.org/10.3390/ma17174191

Guo Z, Yang F, Li L, Wu J. Bio-Inspired Curved-Elliptical Lattice Structures for Enhanced Mechanical Performance and Deformation Stability. Materials. 2024; 17(17):4191. https://doi.org/10.3390/ma17174191

Chicago/Turabian StyleGuo, Zhengmiao, Fan Yang, Lingbo Li, and Jiacheng Wu. 2024. "Bio-Inspired Curved-Elliptical Lattice Structures for Enhanced Mechanical Performance and Deformation Stability" Materials 17, no. 17: 4191. https://doi.org/10.3390/ma17174191

APA StyleGuo, Z., Yang, F., Li, L., & Wu, J. (2024). Bio-Inspired Curved-Elliptical Lattice Structures for Enhanced Mechanical Performance and Deformation Stability. Materials, 17(17), 4191. https://doi.org/10.3390/ma17174191