Plant Waste-Based Bioadditive as an Antioxidant Agent and Rheological Modifier of Bitumen

Abstract

1. Introduction

1.1. Assumptions

1.2. Olive Leaf Residues

1.3. Biomass Antioxidant

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Sample Preparations

2.3. Experimental Techniques

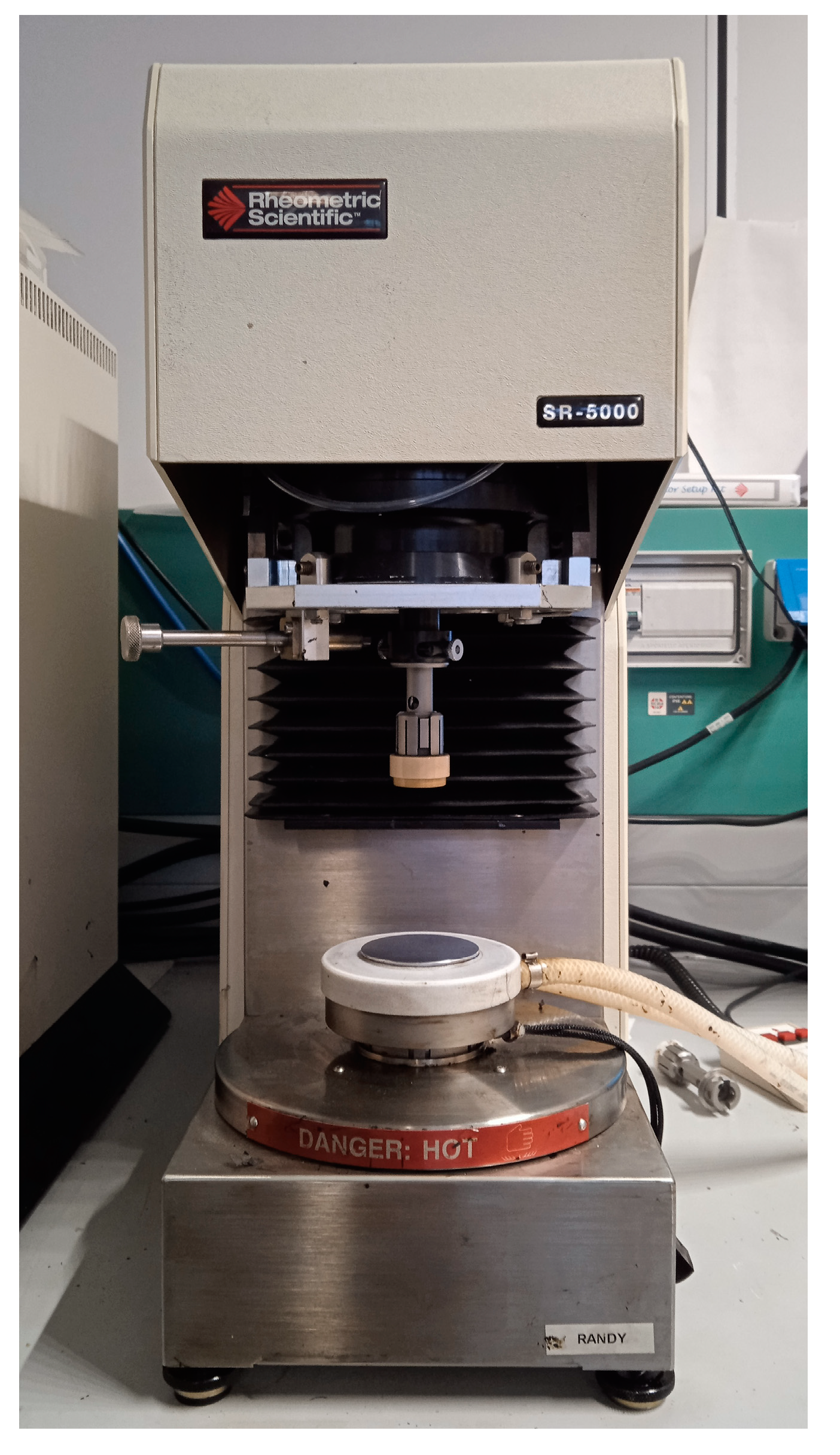

2.3.1. Rheological Characterization

2.3.2. Total Phenol Content

2.3.3. Total Chlorophyll Content

2.3.4. Lignin, Cellulose and Hemicellulose Content

2.3.5. Light Microscopy

3. Results and Discussion

3.1. Total Phenol and Chlorophyll Content

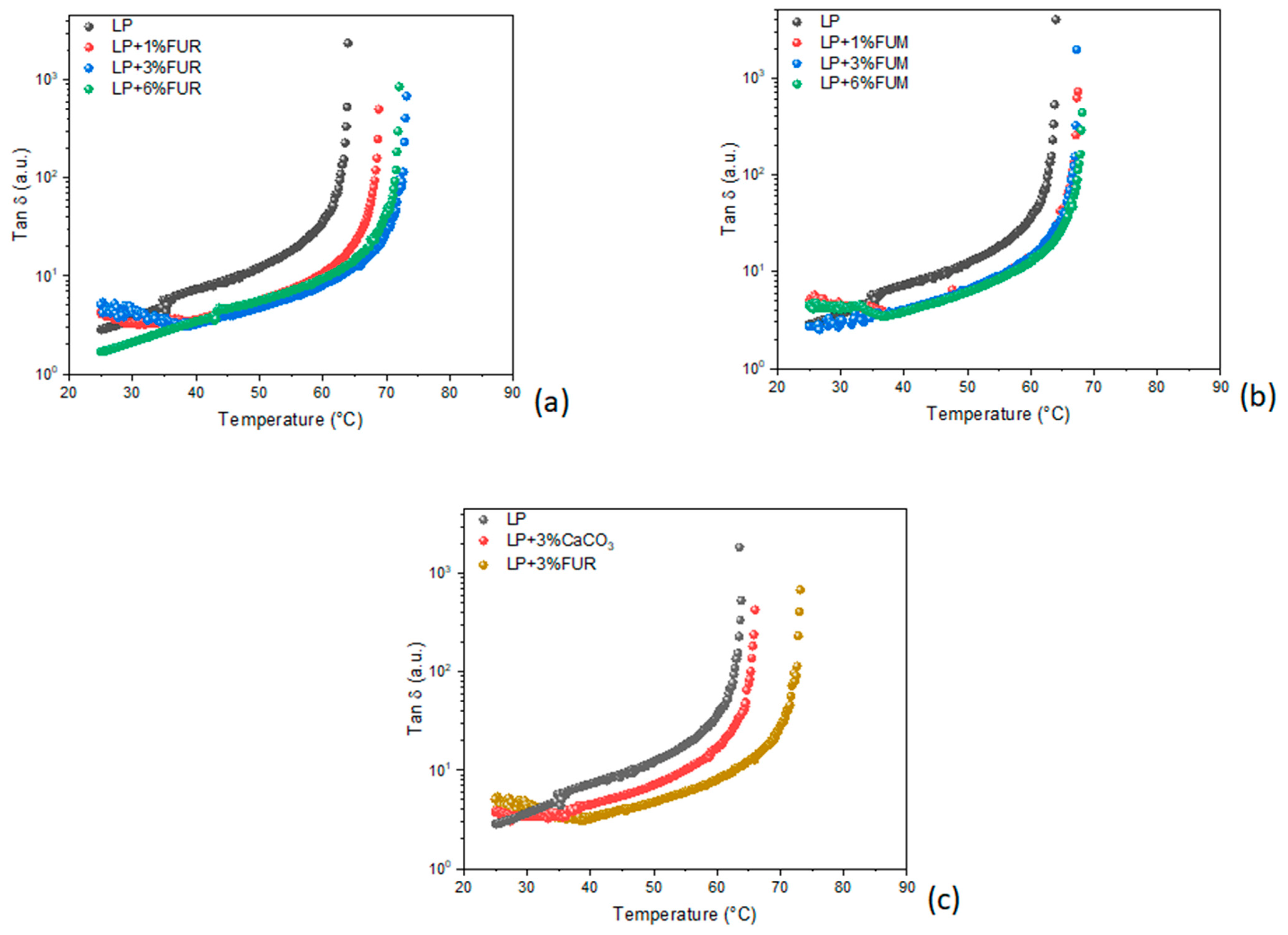

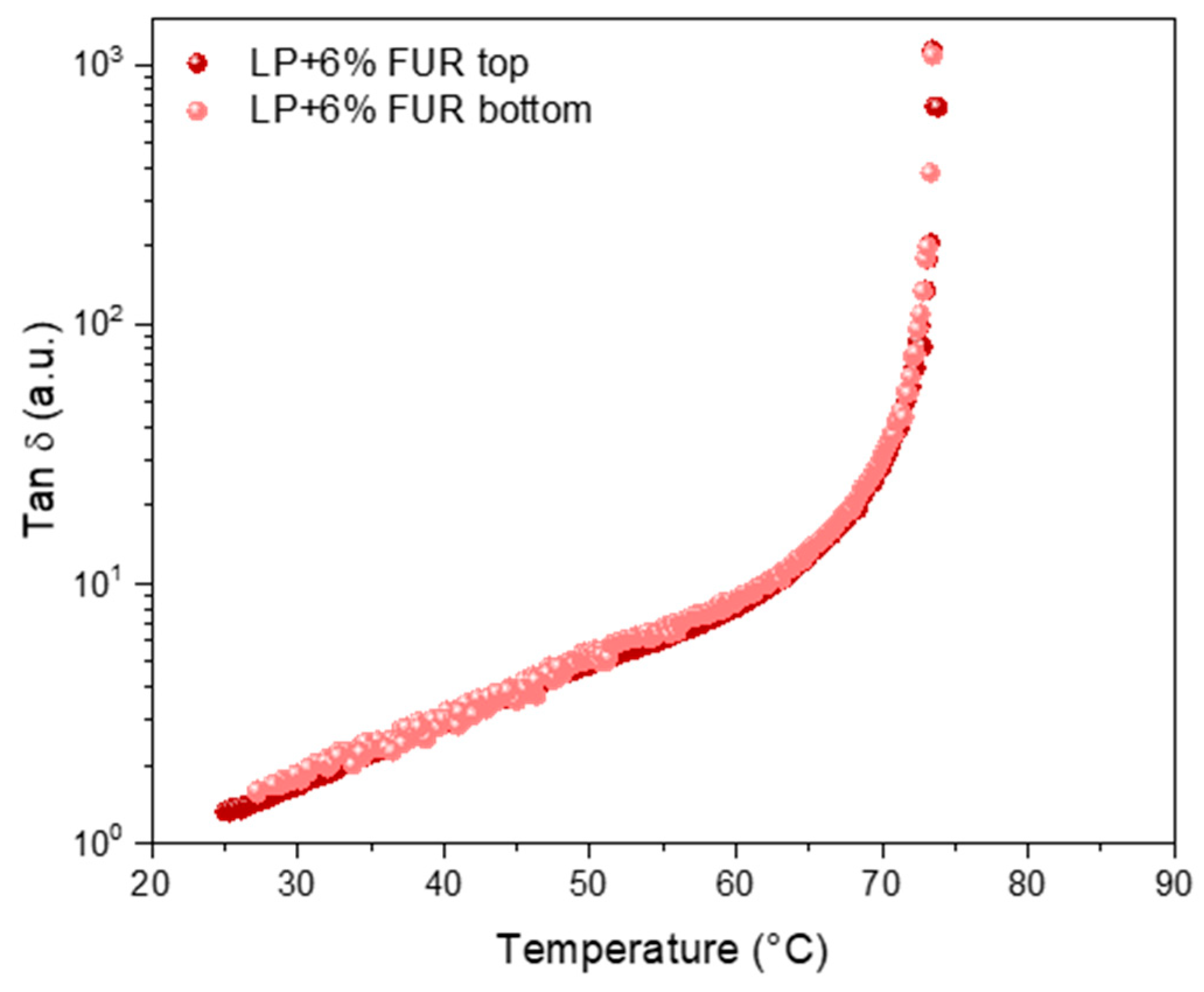

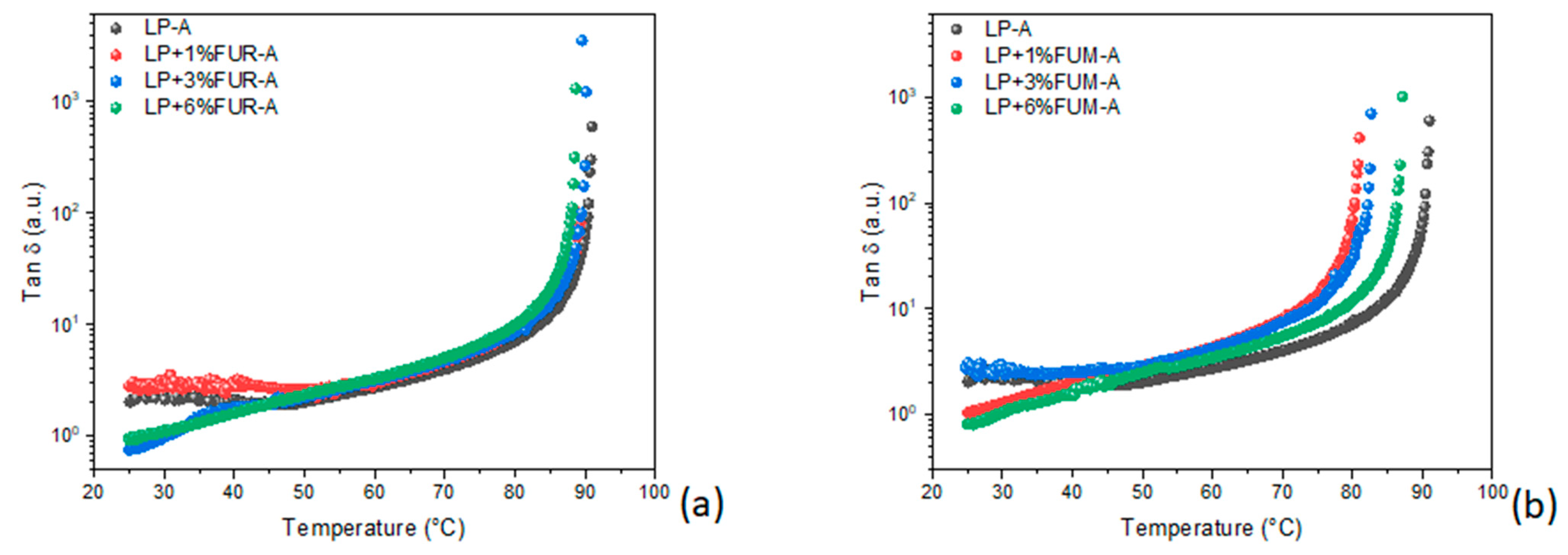

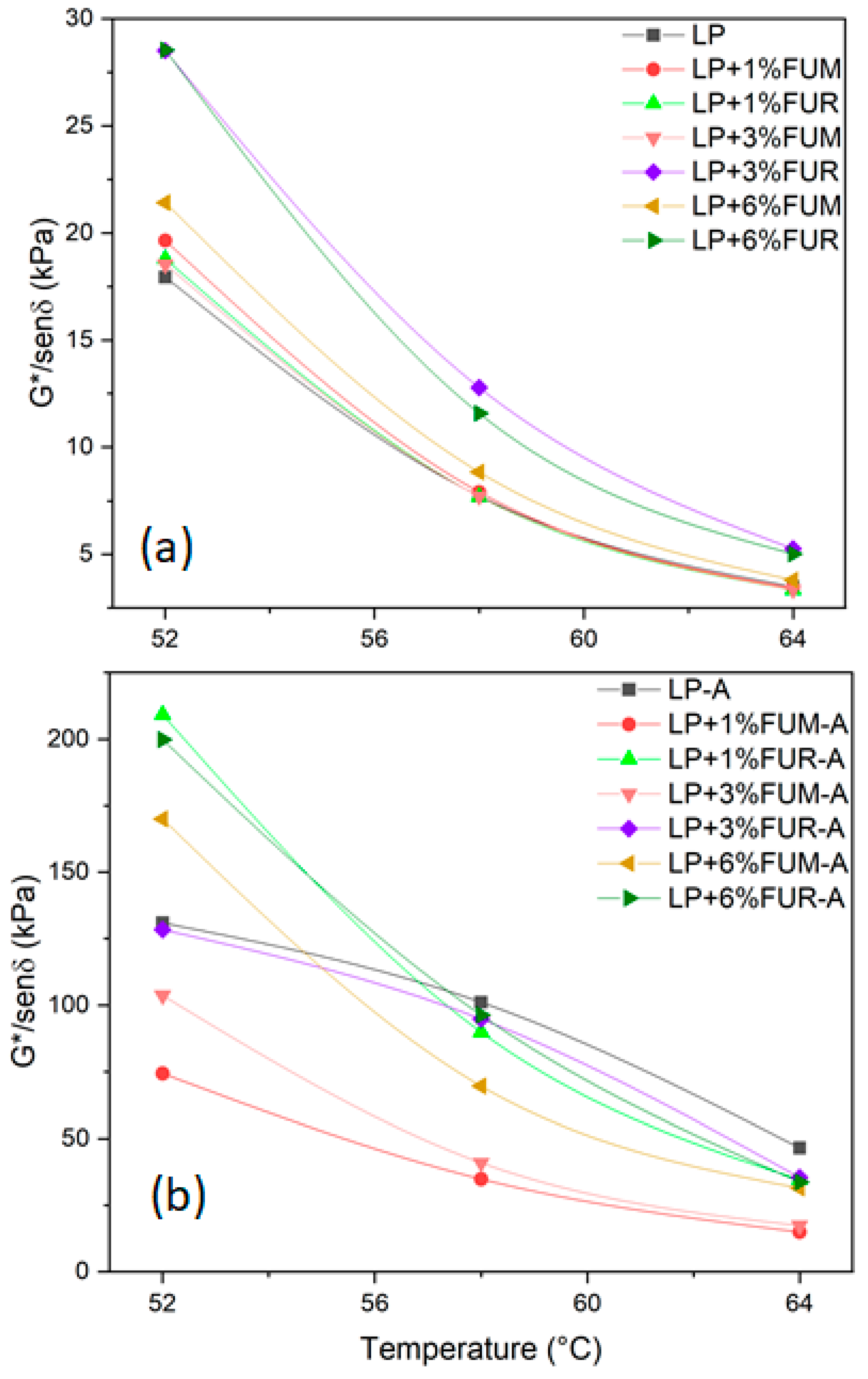

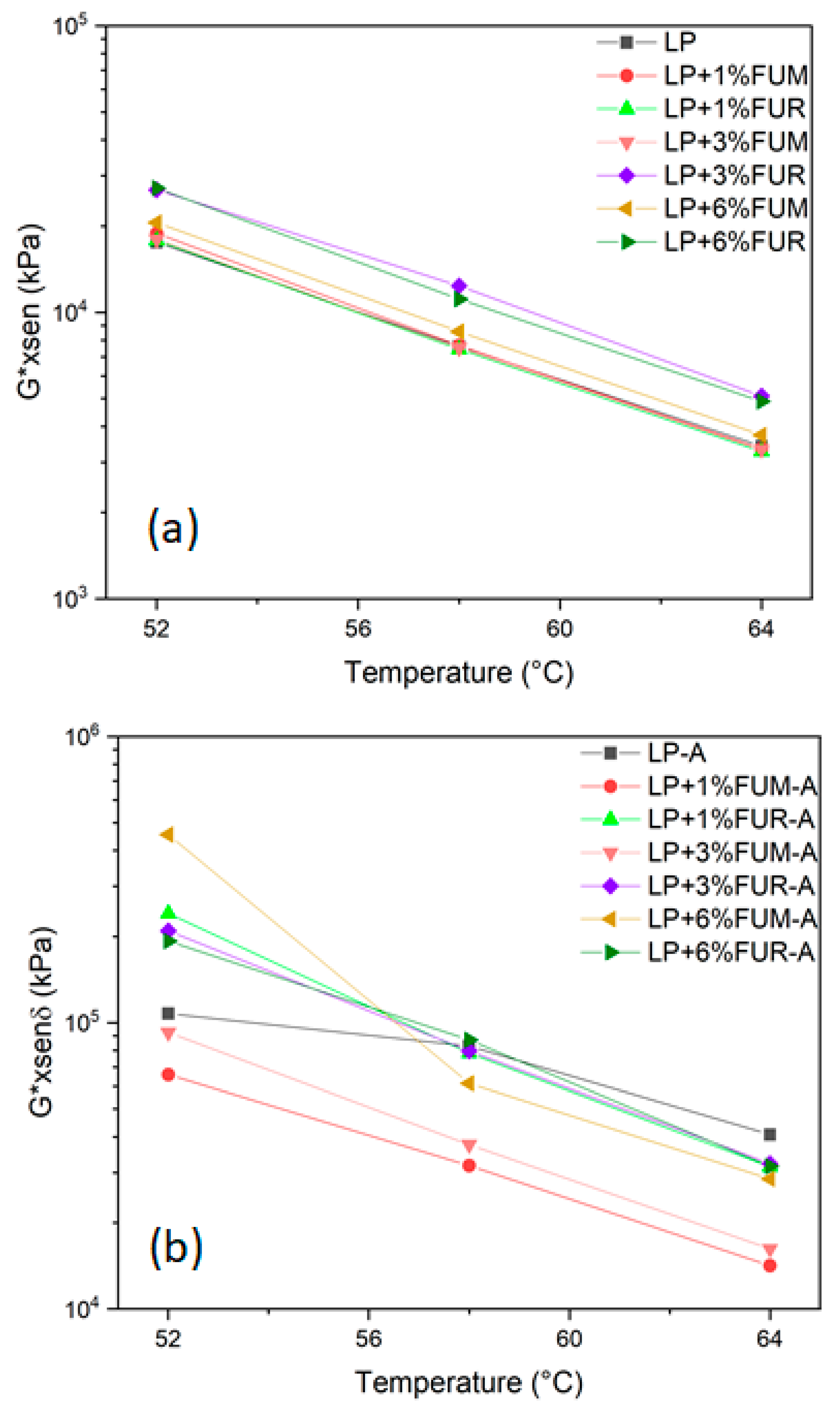

3.2. Rheology and Melting Range

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hosseinnezhad, S.; Zadshir, M.; Yu, X.; Yin, H.; Sharma, B.K.; Fini, E. Differential effects of ultraviolet radiation and oxidative aging on bio-modified binders. Fuel 2019, 251, 45–56. [Google Scholar] [CrossRef]

- Habal, A.; Singh, D. Influence of Recycled Asphalt Pavement on Interfacial Energy and Bond Strength of Asphalt Binder for Different Types of Aggregates. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 154–166. [Google Scholar] [CrossRef]

- Fallah, F.; Khabaz, F.; Kim, Y.-R.; Kommidi, S.R.; Haghshenas, H.F. Molecular dynamics modeling and simulation of bituminous binder chemical aging due to variation of oxidation level and saturate-aromaticresin-asphaltene fraction. Fuel 2019, 237, 71–80. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Rea, R.; Reinke, G.; Zaumanis, M.; Fini, E. Relationship between colloidal index and chemo-rheological properties of asphalt binders modified by various recycling agents. Constr. Build. Mater. 2022, 318, 126161. [Google Scholar] [CrossRef]

- Espeso, J.; Isaza, A.; Lee, J.Y.; Sörensen, P.M.; Jurado, P.; Avena-Bustillos, R.d.J.; Olaizola, M.; Arboleya, J.C. Olive Leaf Waste Management. Front. Sustain. Food Syst. 2021, 5, 660582. [Google Scholar] [CrossRef]

- Khemakhem, I.; Ahmad-Qasem, M.H.; Catalán, E.B.; Micol, V.; García-Pérez, J.V.; Ayadi, M.A.; Bouaziz, M. Kinetic improvement of olive leaves’ bioactive compounds extraction by using power ultrasound in a wide temperature range. Ultrason. Sonochem. 2017, 34, 466–473. [Google Scholar] [CrossRef] [PubMed]

- López-Linares, J.C.; Romero-García, J.M.; Romero, I.; Ruiz, E.; Castro, E. Development of a biorefinery from olive mill leaves: Comparison of different process configurations. Ind. Crops Prod. 2023, 200, 116813. [Google Scholar] [CrossRef]

- Molina-Alcaide, E.; Yáñez-Ruiz, D.R. Potential use of olive by-products in ruminant feeding: A review. Anim. Feed Sci. Technol. 2008, 147, 247–264. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Romero-García, J.M.; López-Linares, J.C.; Ramos, E.R.; Castro, E.; Alzate, C.A.C. Simulation approach through the biorefinery concept of the antioxidants, lignin and ethanol production using olive leaves as raw material. Chem. Eng. Trans. 2018, 70, 925–930. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Niño, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass. State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Salvachúa, D.; Martínez, M.J.; Diaz, L.F.; Zamorano, M. Analysis of the relation between the cellulose, hemicellulose and lignin content and the thermal behavior of residual biomass from olive trees. Waste Manag. 2013, 33, 2245–2249. [Google Scholar] [CrossRef] [PubMed]

- Negro, M.J.; Manzanares, P.; Ruiz, E.; Castro, E.; Ballesteros, M. Chapter 3—The biorefinery concept for the industrial valorization of residues from olive oil industry, In Olive Mill Waste; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 57–78. [Google Scholar] [CrossRef]

- Lama-Muñoz, A.; Del Mar Contreras, M.; Espínola, F.; Moya, M.; de Torres, A.; Romero, I.; Castro, E. Extraction of oleuropein and luteolin-7-O-glucoside from olive leaves: Optimization of technique and operating conditions. Food Chem. 2019, 293, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Medina, E.; Romero, C.; García, P.; Brenes, M. Characterization of bioactive compounds in commercial olive leaf extracts, and olive leaves and their infusions. Food Funct. 2019, 10, 4716–4724. [Google Scholar] [CrossRef] [PubMed]

- Talhaoui, N.; Taamalli, A.; Caravaca, A.M.G.; Fernández-Gutiérrez, A.; Segura Carretero, A. Phenolic compounds in olive leaves: Analytical determination, biotic and abiotic influence, and health benefits. Food Res. Int. 2015, 77, 92–108. [Google Scholar] [CrossRef]

- Bianco, A.; Buiarelli, F.; Cartoni, G.; Coccioli, F.; Muzzalupo, I.; Polidori, A.; Uccella, N. Analysis by HPLC-MS-MS of biophenolics in olives and oils. Anal. Lett. Anal. Lett. 2001, 34, 1033–1051. [Google Scholar] [CrossRef]

- Egner, P.A.; Muñoz, A.; Kensler, T.W. Chemoprevention with chlorophyllin in individuals exposed to dietary aflatoxin. Mutat. Res. 2003, 523–524, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Ferruzzi, M.; Blakeslee, J. Digestion, absorption, and cancer preventative activity of dietary chlorophyll derivatives. Nutr. Res. Nutr. Res. 2007, 27. [Google Scholar] [CrossRef]

- Wanasundara, U.N.; Shahidi, F. Antioxidant and pro-oxidant activity of green tea extracts in marine oils. Food Chem. 1998, 63, 335–342. [Google Scholar] [CrossRef]

- Zhang, Y.; Si, C.; Fan, T.; Zhu, Y.; Li, S.; Ren, S.; Lin, P. Research on the optimal dosage of Bio-Oil/Lignin composite modified asphalt based on rheological and Anti-Aging properties. Constr. Build. Mater. 2023, 389, 131796. [Google Scholar] [CrossRef]

- Pahlavan, F.; Lamanna, A.; Park, K.-B.; Kabir, S.F.; Kim, J.-S.; Fini, E.H. Phenol-rich bio-oils as free-radical scavengers to hinder oxidative aging in asphalt binder. Resour. Conserv. Recycl. 2022, 187, 106601. [Google Scholar] [CrossRef]

- Park, K.-B.; Kim, J.-S.; Pahlavan, F.; Fini, E.H. Biomass Waste to Produce Phenolic Compounds as Antiaging Additives for Asphalt. ACS Sustain. Chem. Eng. 2022, 10, 3892–3908. [Google Scholar] [CrossRef]

- Pahlavan, F.; Gholipour, A.; Zhou, T.; Fini, E.H. Cleaner Asphalt Production by Suppressing Emissions Using Phenolic Compounds. ACS Sustain. Chem. Eng. 2023, 11, 2737–2751. [Google Scholar] [CrossRef]

- Pahlavan, F.; Fini, E.H. Phenolic Compounds to Hinder Sulfur Crystallization in Sulfur-Extended Bitumen. Resour. Conserv. Recycl. 2022, 180, 106184. [Google Scholar] [CrossRef]

- Yi, Z.; Xueyan, L.; Shisong, R.; Ruxin, J.; Peng, L.; Panos, A.; Sandra, E.; Xuancang, W.; Tom, S. Effect of Bio-oil on Rheology and Chemistry of Organosolv Lignin–Modified Bitumen. J. Mater. Civ. Eng. 2022, 34, 4022009. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Bitumen improvement with bio-oil and natural or organomodified montmorillonite: Structure, rheology, and adhesion of composite asphalt binders. Constr. Build. Mater. 2023, 364, 129919. [Google Scholar] [CrossRef]

- Caputo, P.; Loise, V.; Crispini, A.; Sangiorgi, C.; Scarpelli, F.; Oliviero Rossi, C. The efficiency of bitumen rejuvenator investigated through Powder X-ray Diffraction (PXRD) analysis and T <inf>2</inf> -NMR spectroscopy. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 571, 50–54. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Shaw, M.T.; Airey, G.D. Modelling the linear viscoelastic rheological properties of bituminous binders. Constr. Build. Mater. 2011, 25, 2171–2189. [Google Scholar] [CrossRef]

- Loeber, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in colloid science: A chemical, structural and rheological approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Loise, V.; Caputo, P.; Porto, M.; Teltayev, B.; Angelico, R.; Oliviero Rossi, C. Unravelling the role of a green rejuvenator agent in contrasting the aging effect on bitumen: A dynamics rheology, nuclear magnetic relaxometry and self-diffusion study. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 603, 125182. [Google Scholar] [CrossRef]

- Difonzo, G.; Russo, A.; Trani, A.; Paradiso, V.M.; Ranieri, M.; Pasqualone, A.; Summo, C.; Tamma, G.; Silletti, R.; Caponio, F. Green extracts from Coratina olive cultivar leaves: Antioxidant characterization and biological activity. J. Funct. Foods 2017, 31, 63–70. [Google Scholar] [CrossRef]

- Cifá, D.; Skrt, M.; Pittia, P.; Di Mattia, C.; Poklar Ulrih, N. Enhanced yield of oleuropein from olive leaves using ultrasound-assisted extraction. Food Sci. Nutr. 2018, 6, 1128–1137. [Google Scholar] [CrossRef]

- Muzzalupo, I.; Stefanizzi, F.; Perri, E.; Chiappetta, A.A. Transcript levels of CHL P gene, antioxidants and chlorophylls contents in olive (Olea europaea L.) pericarps: A comparative study on eleven olive cultivars harvested in two ripening stages. Plant Foods Hum. Nutr. 2011, 66, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Lichtenthaler, H.K.B.T.-M. in E. [34] Chlorophylls and carotenoids: Pigments of photosynthetic biomembranes. In Plant Cell Membranes; Academic Press: Cambridge, MA, USA, 1987; Volume 148, pp. 350–382. ISBN 0076-6879. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of Structural Carbohydrates and Lignin in Biomass Laboratory Analytical Procedure (LAP) 2012. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 7 May 2024).

- Loise, V.; Calandra, P.; Abe, A.A.; Porto, M.; Oliviero Rossi, C.; Davoli, M.; Caputo, P. Additives on aged bitumens: What probe to distinguish between rejuvenating and fluxing effects? J. Mol. Liq. 2021, 339, 116742. [Google Scholar] [CrossRef]

- Szerb, E.; Nicotera, I.; Teltayev, B.; Vaiana, R.; Oliviero, C. Highly stable surfactant-crumb rubber-modified bitumen: NMR and rheological investigation. Road Mater. Pavement Des. 2017, 19, 1192–1202. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Zhang, Y.; Lin, P.; Apostolidis, P.; Erkens, S.; Li, M.; Xu, J. Multi-scale characterization of lignin modified bitumen using experimental and molecular dynamics simulation methods. Constr. Build. Mater. 2021, 287, 123058. [Google Scholar] [CrossRef]

- Kalampokis, S.; Papamoschou, M.; Kalama, D.M.; Pappa, C.P.; Manthos, E.; Triantafyllidis, K.S. Investigation of the Characteristic Properties of Lignin-Modified Bitumen. CivilEng 2022, 3, 734–747. [Google Scholar] [CrossRef]

- Akbulut, H. Rheological properties of cellulose fibre modified bitumen. Technology 2011, 14, 59–66. [Google Scholar]

- Tayh, S.; Yousif, R.; Banyhussan, Q. A Comparative Study of Physical Properties Using Various Grades Asphalt Binder with Different Type of Fibers. J. Eng. Res. 2020, 17, 34–40. [Google Scholar] [CrossRef]

- Singh, D.; Kataware, A. V Comparison of different rheological parameters for rutting susceptibility of SBS + WMA modified binders. Innov. Infrastruct. Solut. 2016, 1, 28. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J. Evaluation of Rutting Parameters of Asphalt Binder Based on Rheological Test. Int. J. Eng. Technol. 2014, 6, 30–33. [Google Scholar] [CrossRef][Green Version]

- Radhakrishnan, V.; Ramya Sri, M.; Sudhakar Reddy, K. Evaluation of asphalt binder rutting parameters. Constr. Build. Mater. 2018, 173, 298–307. [Google Scholar] [CrossRef]

- Salim, R.; Gundla, A.; Zalghout, A.; Underwood, S.; Kaloush, K. Relationship between Asphalt Binder Parameters and Asphalt Mixture Rutting. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 431–446. [Google Scholar] [CrossRef]

| Sample | ID | Sample | ID |

|---|---|---|---|

| Bitumen 50/70 | LP | Bitumen aged by RTFOT, 225 min | LP-A |

| Bitumen 50/70 + 1% FUM | LP + 1% FUM | Bitumen aged by 50/70 + 1% FUM RTFOT, 225 min | LP + 1% FUM-A |

| Bitumen 50/70 + 3% FUM | LP + 3% FUM | Bitumen aged by 50/70 + 3% FUM RTFOT, 225 min | LP + 3% FUM-A |

| Bitumen 50/70 + 6% FUM | LP + 6% FUM | Bitumen aged by 50/70 + 6% FUM RTFOT, 225 min | LP + 6% FUM-A |

| Bitumen 50/70 + 1% FUR | LP + 1% FUR | Bitumen aged by 50/70 + 1% FUR RTFOT, 225 min | LP + 1% FUR-A |

| Bitumen 50/70 + 3% FUR | LP + 3% FUR | Bitumen aged by 50/70 + 3% FUR RTFOT, 225 min | LP + 3% FUR-A |

| Bitumen 50/70 + 6% FUR | LP + 6% FUR | Bitumen aged by 50/70 + 6% FUR RTFOT, 225 min | LP + 6% FUR-A |

| FUM | FUR | |

|---|---|---|

| Phenol Totals | 637.1 ± 8.9 mg/g (Dry Weight) | 544.6 ± 7.7 mg/g (Dry Weight) |

| Hydroxytyrosol | 3.2 ± 0.4 | 2.1 ± 0.7 |

| Tyrosol | 0.3 ±0.1 | 0.1 ± 0.0 |

| 4-Hydroxyphenylacetic acid | 17.6 ± 1.9 | 15.0 ± 1.3 |

| Caffeic acid | 1.1 ± 0.4 | 0.5 ± 0.2 |

| Ferulic acid | 1.7 ± 0.6 | 0.8 ± 0.3 |

| p-Coumaric acid | 1.7 ± 0.5 | 0.8 ± 0.4 |

| Oleuropein | 517.8 ± 6.4 | 450.1 ± 5.5 |

| Verbascoside | 26.6 ± 1.9 | 21.3 ± 1.4 |

| Ligstroside | 17.3 ± 1.1 | 11.4 ± 1.0 |

| Luteolin-7-glucoside | 49.8 ± 2.9 | 42.5 ± 2.6 |

| Chlorophylls (a + b) | 2.11 ± 0.9 | 1.83 ± 0.5 |

| FUM | FUR | |

|---|---|---|

| % (Dry Weight) | % (Dry Weight) | |

| Lignin | 14.3 ± 0.9 | 17.2 ± 0.1 |

| Cellulose | 7.7 ± 1.1 | 6.9 ± 0.5 |

| Hemicellulose | 7.4 ± 1.5 | 6.7 ± 0.3 |

| Glucose | 6.5 ± 1.2 | 6.7 ± 0.5 |

| Sample | Melting Range (±5 °C) |

|---|---|

| LP | 150–160 |

| LP-A | 175–185 |

| LP + 1%FUM-A | 165–170 |

| LP + 1%FUR-A | 170–175 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loise, V.; Abe, A.A.; Porto, M.; Muzzalupo, I.; Madeo, L.; Colella, M.F.; Rossi, C.O.; Caputo, P. Plant Waste-Based Bioadditive as an Antioxidant Agent and Rheological Modifier of Bitumen. Materials 2024, 17, 2303. https://doi.org/10.3390/ma17102303

Loise V, Abe AA, Porto M, Muzzalupo I, Madeo L, Colella MF, Rossi CO, Caputo P. Plant Waste-Based Bioadditive as an Antioxidant Agent and Rheological Modifier of Bitumen. Materials. 2024; 17(10):2303. https://doi.org/10.3390/ma17102303

Chicago/Turabian StyleLoise, Valeria, Abraham A. Abe, Michele Porto, Innocenzo Muzzalupo, Luigi Madeo, Maria Francesca Colella, Cesare Oliviero Rossi, and Paolino Caputo. 2024. "Plant Waste-Based Bioadditive as an Antioxidant Agent and Rheological Modifier of Bitumen" Materials 17, no. 10: 2303. https://doi.org/10.3390/ma17102303

APA StyleLoise, V., Abe, A. A., Porto, M., Muzzalupo, I., Madeo, L., Colella, M. F., Rossi, C. O., & Caputo, P. (2024). Plant Waste-Based Bioadditive as an Antioxidant Agent and Rheological Modifier of Bitumen. Materials, 17(10), 2303. https://doi.org/10.3390/ma17102303