A Miniaturized and Highly Sensitive Microwave Sensor Based on CSRR for Characterization of Liquid Materials

Abstract

1. Introduction

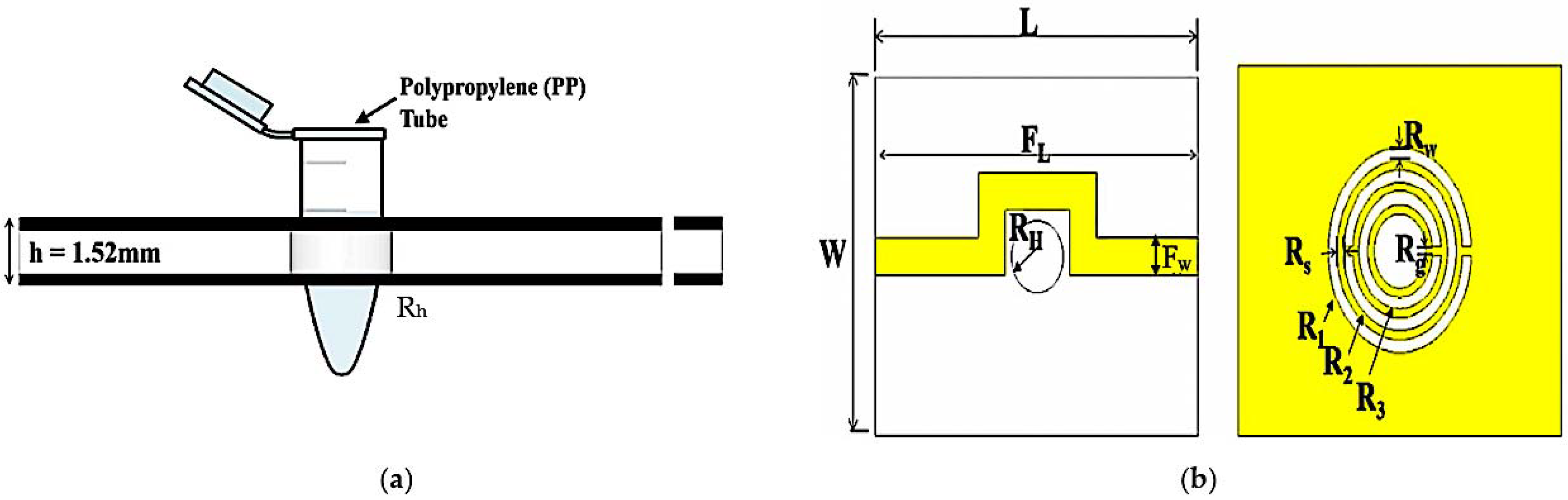

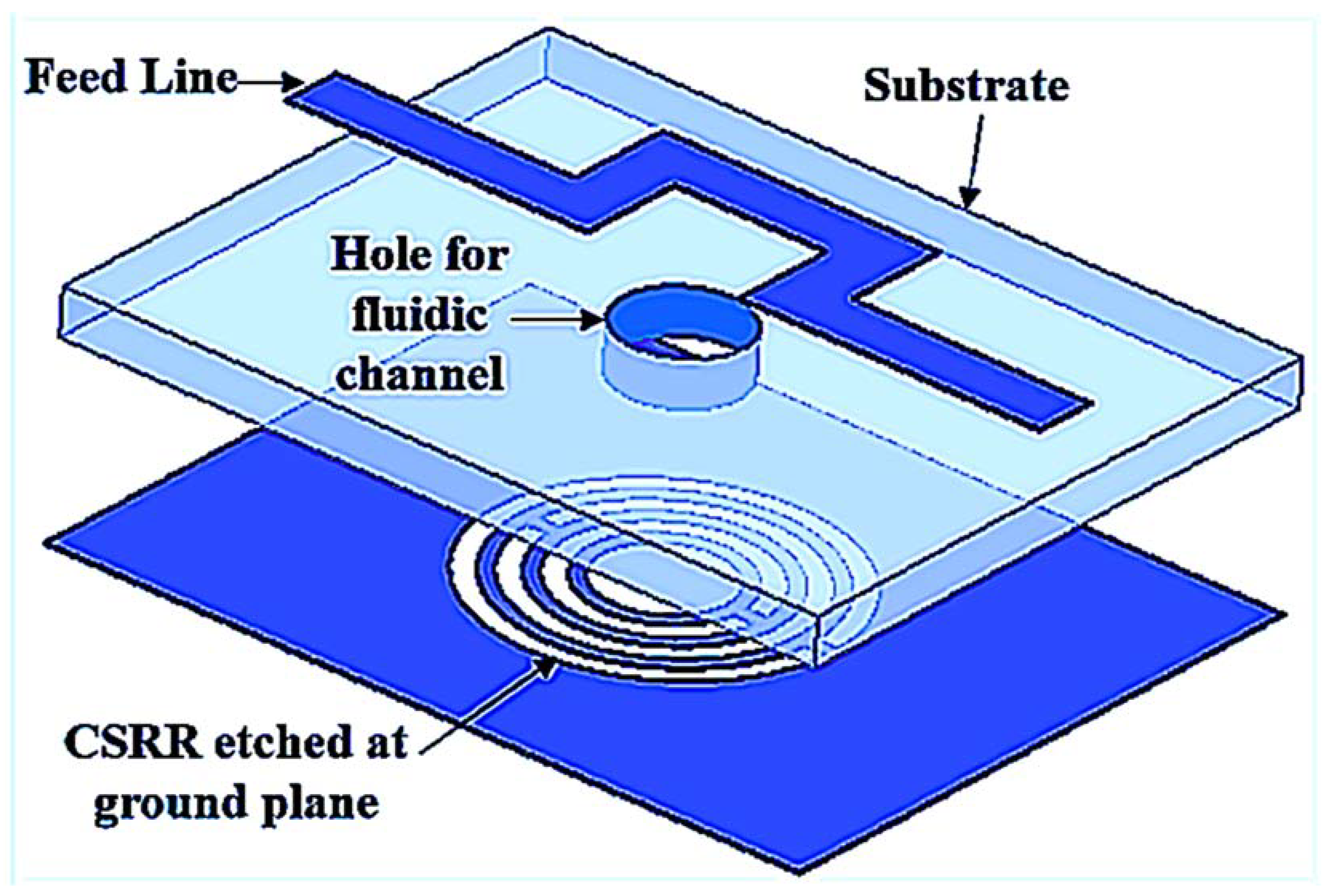

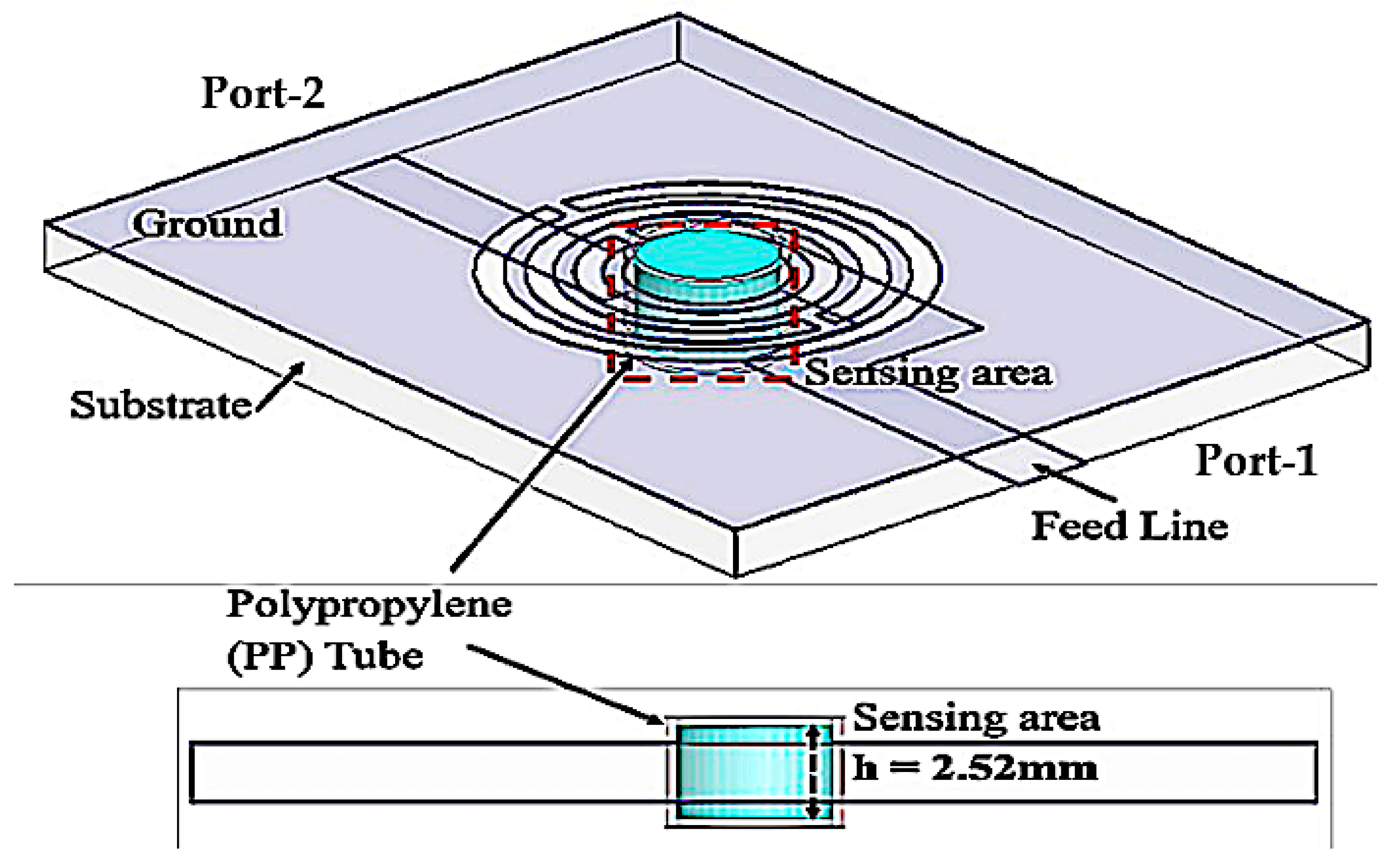

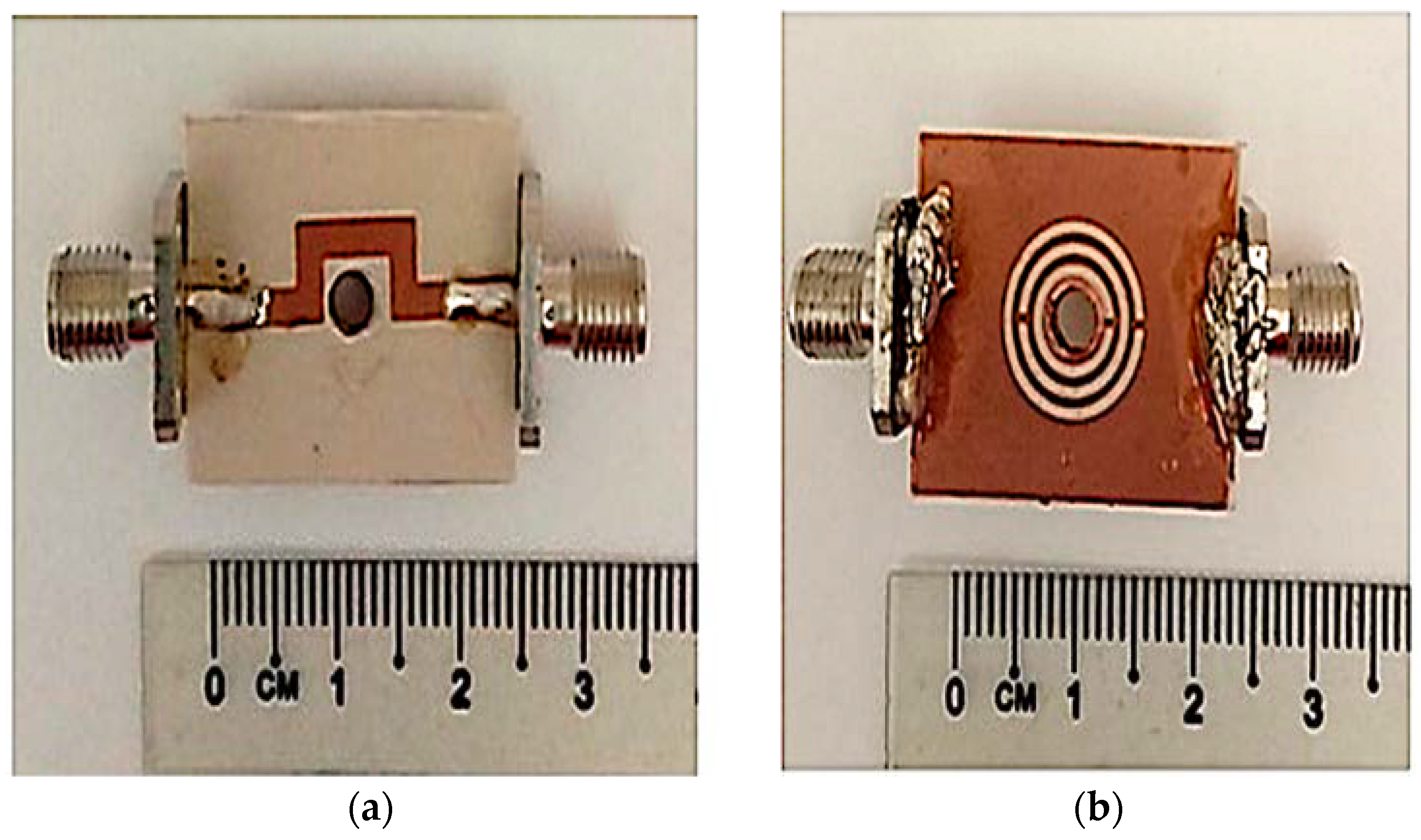

2. Sensor Configuration and Liquid MUTs Validation

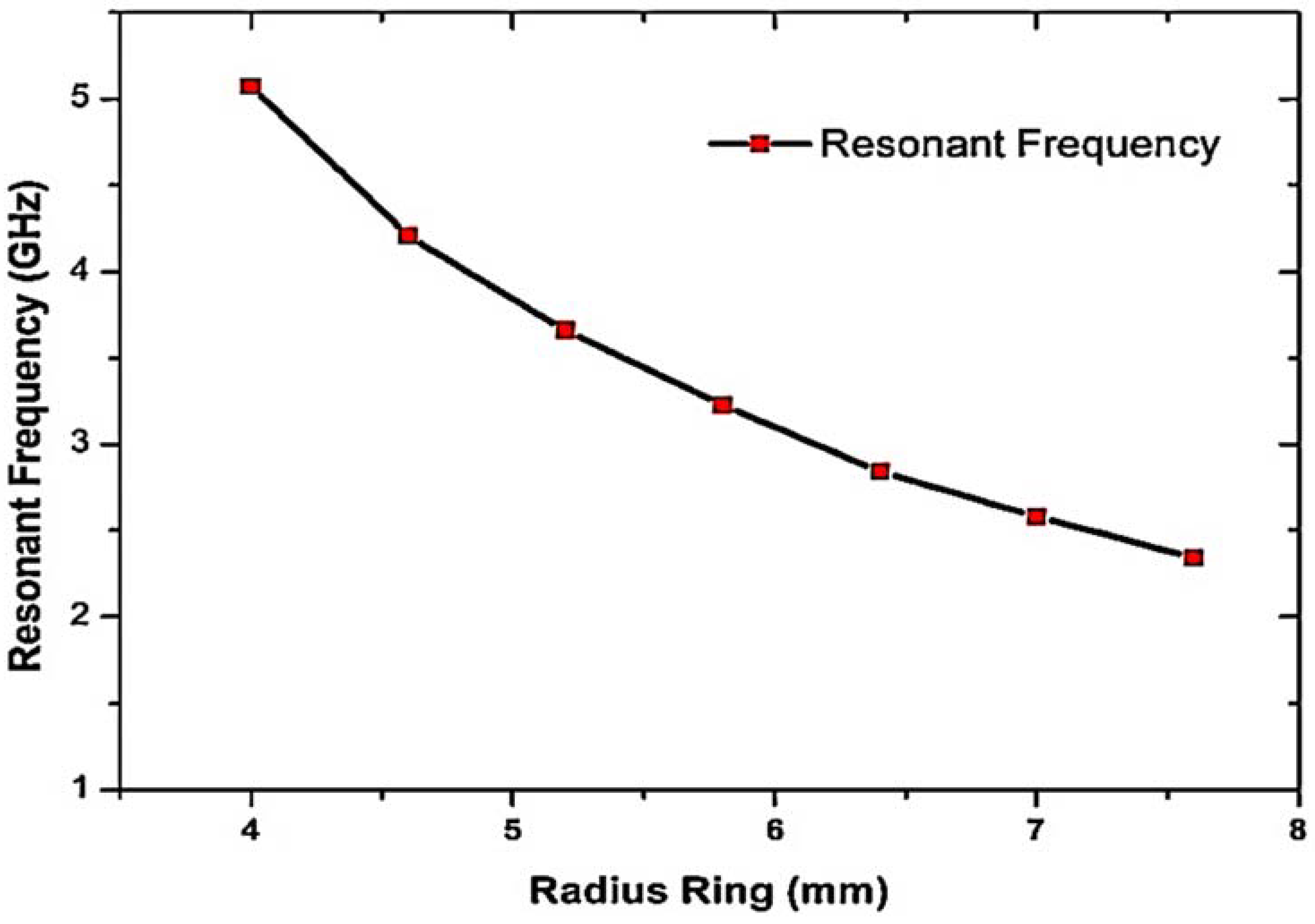

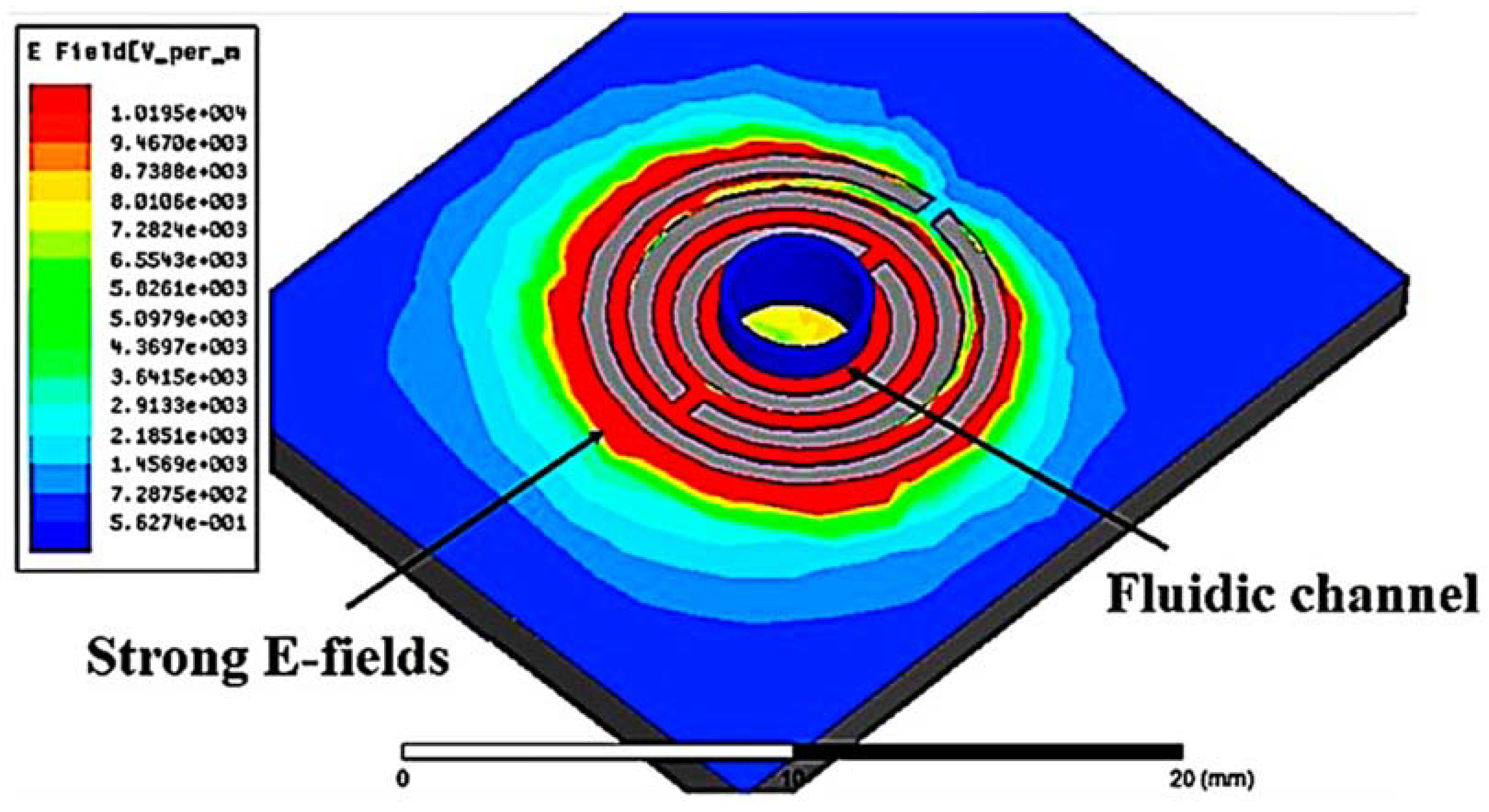

2.1. Sensor Configuration

2.2. Liquid Media under Tests (MUTs)

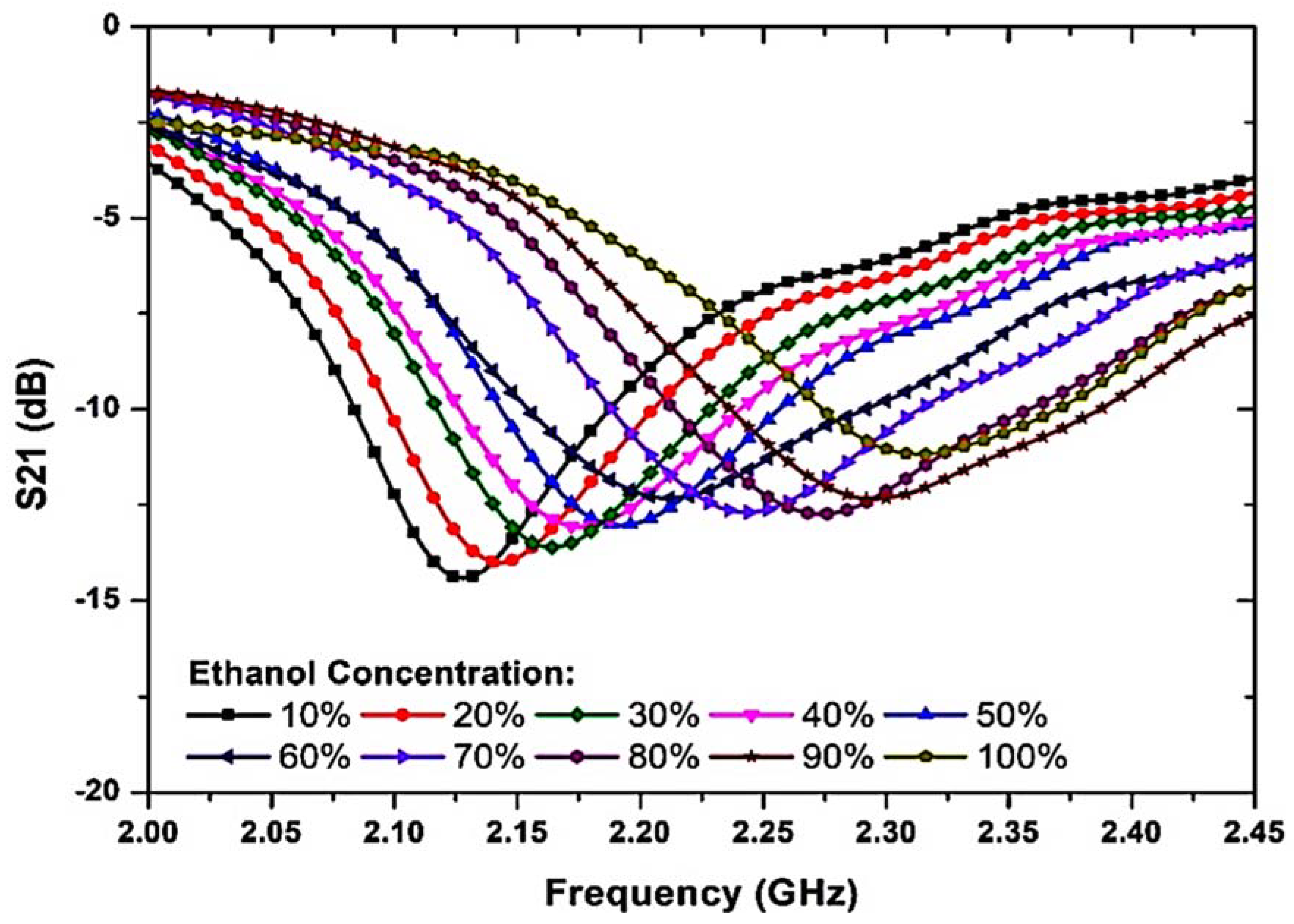

2.3. Ethanol Concentration

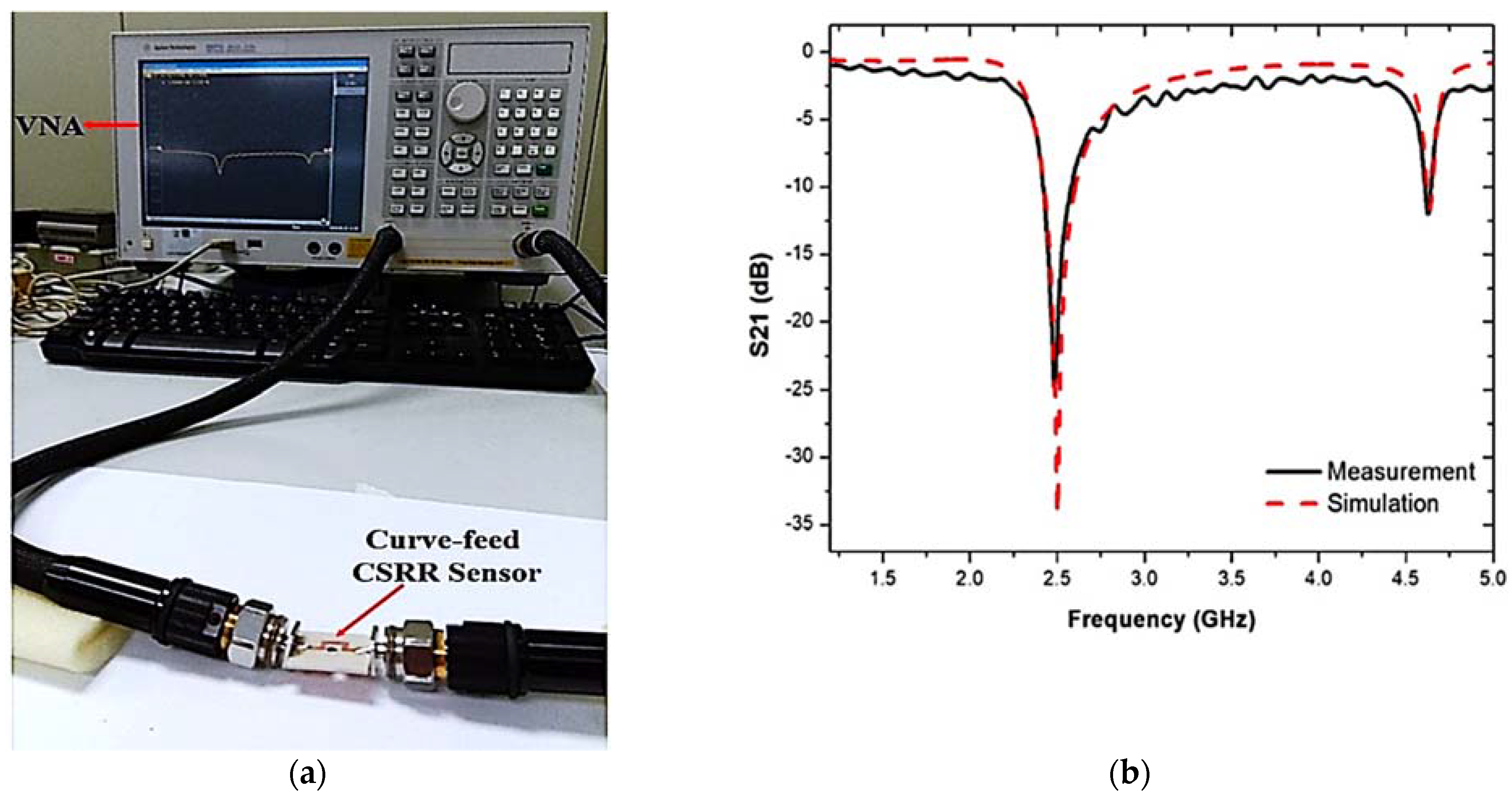

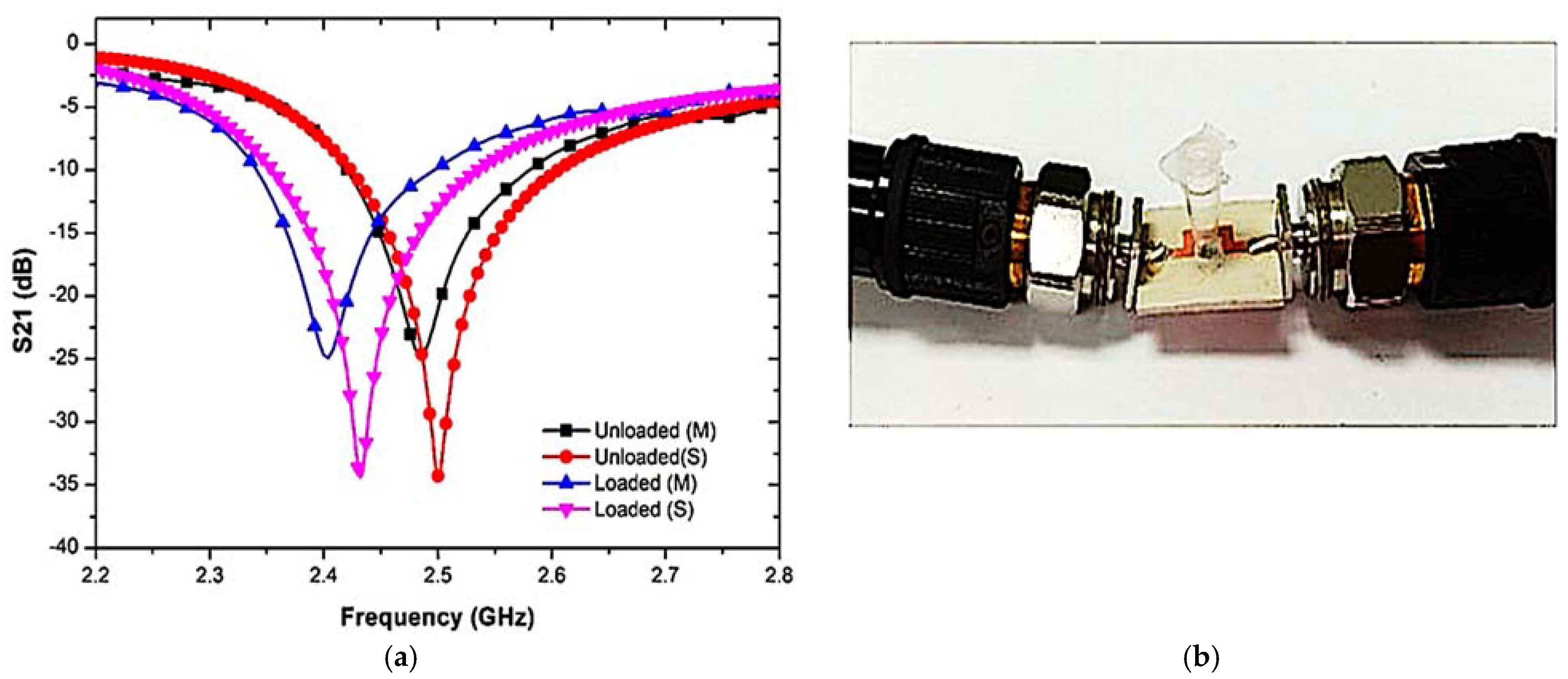

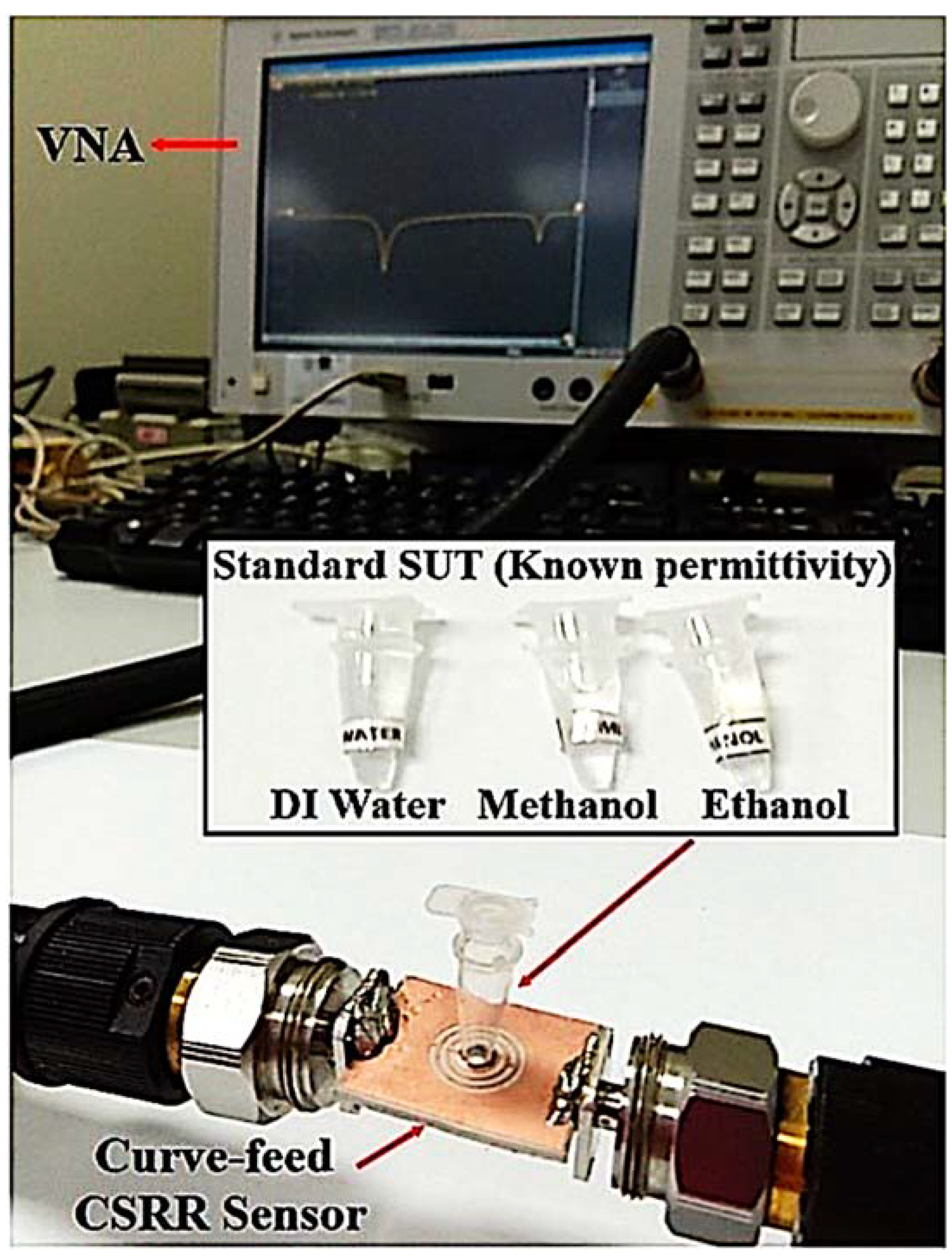

3. Fabrication and Measurement

4. Proposed Sensor Data Analysis

4.1. Liquid MUTs’ Measurement and Validations

4.2. Sensor Sensitivity Calculation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lisovsky, V.V. Automatic control of moisture in agricultural products by methods of microwave aqua-metry. Meas. Sci. Technol. 2007, 18, 1016. [Google Scholar] [CrossRef]

- Jónasson, S.Þ.; Jensen, B.S.; Johansen, T.K. Study of split-ring resonators for use on a phar-maceutical drug capsule for microwave activated drug release. In Proceedings of the 2012 42nd European Microwave Conference, Amsterdam, The Netherlands, 29 October 2012–1 November 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Al-Gburi, A.J.A.; Rahman, N.A.; Zakaria, Z.; Palandoken, M. Detection of Semi-Solid Materials Utilizing Triple-Rings CSRR Microwave Sensor. Sensors 2023, 23, 3058. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Ali, L.; Meng, F.-Y.; Adhikari, K.K.; Zhou, Z.L.; Wei, Y.C.; Zou, D.Q.; Yu, H. High-Accuracy Complex Permittivity Characterization of Solid Materials Using Parallel Interdigital Capacitor- Based Planar Microwave Sensor. IEEE Sens. J. 2021, 21, 6083–6093. [Google Scholar] [CrossRef]

- Xiang, Y.; Huang, J.; Fu, L.; Chen, Y.; Gu, W.; Wu, Y. A Folded Substrate Integrated Waveguide Re-Entrant Cavity for Full Characterization of Magneto-Dielectric Powder Materials. IEEE Sens. J. 2021, 21, 10657–10666. [Google Scholar] [CrossRef]

- Al-Gburi, A.J.A.; Zakaria, Z.; Rahman, N.A.; Alam, S.; Said, M.A.M. A Compact and Low-Profile Curve-Feed Complementary Split-Ring Resonator Microwave Sensor for Solid Material Detection. Micromachines 2023, 14, 384. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Meng, Z.; Soutis, C.; Wang, P.; Gibson, A. Detection and analysis of metallic contaminants in dry foods using a microwave resonator sensor. Food Control 2022, 133, 108634. [Google Scholar] [CrossRef]

- Bobowski, J.S.; Clements, A.P. Permittivity and Conductivity Measured Using a Novel Toroidal Split-Ring Resonator. IEEE Trans. Microw. Theory Tech. 2017, 65, 2132–2138. [Google Scholar] [CrossRef]

- Yeh, C.-H.; Yang, C.-H. Material characterization for Zircaloy claddings in elevated temperatures using a laser ultrasound technique. In Proceedings of the 2012 IEEE International Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012; pp. 265–268. [Google Scholar] [CrossRef]

- Allouti, N.; Chausse, P.; Aumont, C.; Isselé, H.; Vignoud, L.; Rochat, N.; Poulain, C.; Gasiglia, M.; Sourd, C.; Argoud, M.; et al. Photo-dielectric polymers material characterizations for 3D packaging applications. In Proceedings of the 2013 IEEE 15th Electronics Packaging Technology Conference (EPTC 2013), Singapore, 11–13 December 2013; pp. 27–32. [Google Scholar] [CrossRef]

- Gao, R.; Yu, W.; Deng, H.; Ku, H.S.; Li, Z.; Wang, M.; Miao, X.; Lin, Y.; Deng, C. Epitaxial titanium nitride microwave resonators: Structural, chemical, electrical, and microwave properties. Phys. Rev. Mater. 2022, 6, 036202. [Google Scholar] [CrossRef]

- Jang, C.; Park, J.-K.; Yun, G.-H.; Choi, H.H.; Lee, H.-J.; Yook, J.-G. Radio-Frequency/Microwave Gas Sensors Using Conducting Polymer. Materials 2020, 13, 2859. [Google Scholar] [CrossRef]

- Chernousov, Y.D.; Ivannikov, V.I.; Shebolaev, I.V.; Bolotov, V.A.; Tanashev, Y.Y.; Parmon, V.N. Characteristics of a chemical reactor that is a loaded microwave resonator. J. Commun. Technol. Electron. 2009, 54, 231–233. [Google Scholar] [CrossRef]

- Lodi, M.B.; Curreli, N.; Melis, A.; Garau, E.; Fanari, F.; Fedeli, A.; Randazzo, A.; Mazzarella, G.; Fanti, A. Microwave Characterization and Modeling of the Carasau Bread Doughs During Leavening. IEEE Access 2021, 9, 159833–159847. [Google Scholar] [CrossRef]

- Eremenko, Z.E.; Ganapolskii, E.M.; Vasilchenko, V.V. Exact-calculated resonator method for permittivity measurement of high loss liquids at millimetre wavelength. Meas. Sci. Technol. 2005, 16, 1619–1627. [Google Scholar] [CrossRef]

- Morales-Lovera, H.N.; Olvera-Cervantes, J.L.; Perez-Ramos, A.E.; Corona-Chavez, A.; Saavedra, C.E. Microstrip sensor and methodology for the determination of complex anisotropic per-mittivity using perturbation techniques. Sci. Rep. 2022, 12, 2205. [Google Scholar] [CrossRef] [PubMed]

- Cordoba-Erazo, M.F.; Weller, T.M. Low-cost non-contact microwave probe design for insulating materials characterization. In Proceedings of the 78th ARFTG Microwave Measurement Conference, Tempe, AZ, USA, 1–2 December 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Morozov, O.G.; Nasybullin, A.R.; Danilaev, M.P.; Farkhutdinov, R.V. Sensor applications of Bragg microwave structures realized in coaxial waveguide. In Proceedings of the 2015 International Conference on Antenna Theory and Techniques (ICATT), Kharkiv, Ukraine, 21–24 April 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, J.; Zhang, J.; Li, E.; Li, Y. Measurement of optical signal by Microwave Coaxial resonator. In Proceedings of the 2021 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Chongqing, China, 15–17 November 2021; pp. 130–132. [Google Scholar] [CrossRef]

- Mondal, D.; Tiwari, N.K.; Akhtar, M.J. Microwave Assisted Non-Invasive Microfluidic Biosensor for Monitoring Glucose Concentration. In Proceedings of the 2018 IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Kulkarni, S.; Joshi, M.S. Design and Analysis of Shielded Vertically Stacked Ring Resonator as Complex Permittivity Sensor for Petroleum Oils. IEEE Trans. Microw. Theory Tech. 2015, 63, 2411–2417. [Google Scholar] [CrossRef]

- Hamzah, H.; Abduljabar, A.; Lees, J.; Porch, A. A Compact Microwave Microfluidic Sensor Using a Re-Entrant Cavity. Sensors 2018, 18, 910. [Google Scholar] [CrossRef]

- Ye, W.; Zhao, W.-S.; Wang, J.; Wang, D.-W.; Wang, G. A Split-Ring Resonator-Based Planar Microwave Sensor for Microfluidic Applications. In Proceedings of the 2022 IEEE MTT-S International Microwave Biomedical Conference (IMBioC), Suzhou, China, 16–18 May 2022; pp. 34–36. [Google Scholar] [CrossRef]

- Mukherjee, S.; Shi, X.; Udpa, L.; Udpa, S.; Deng, Y.; Chahal, P. Design of a Split-Ring Resonator Sensor for Near-Field Microwave Imaging. IEEE Sens. J. 2018, 18, 7066–7076. [Google Scholar] [CrossRef]

- Khan, M.S.; Varshney, G.; Giri, P. Altering the Multimodal Resonance in Ultrathin Silicon Ring for Tunable THz Biosensing. IEEE Trans. NanoBioscience 2021, 20, 488–496. [Google Scholar] [CrossRef]

- Pan, Y.M.; Zheng, S.Y. A Low-Profile Stacked Dielectric Resonator Antenna with High-Gain and Wide Bandwidth. IEEE Antennas Wirel. Propag. Lett. 2015, 1225, 68–71. [Google Scholar] [CrossRef]

- Kundal, S.; Khandelwal, A. Highly sensitive ring resonator based refractive index sensor for label free biosensing applications. In Proceedings of the 2022 International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD), Turin, Italy, 12–16 September 2022; pp. 157–158. [Google Scholar] [CrossRef]

- Bari, R.T.B.; Haque, E.; Rahman, T.; Faruque, O. Improved Design of a Ring Resonator Based Notch Filter with High Quality Factor and Sensitivity. In Proceedings of the 2022 IEEE IAS Global Conference on Emerging Technologies (GlobConET), Arad, Romania, 20–22 May 2022; pp. 406–410. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Daneshmand, M.; Iyer, A.K. Strongly Enhanced Sensitivity in Planar Microwave Sensors Based on Metamaterial Coupling. IEEE Trans. Microw. Theory Tech. 2018, 66, 1843–1855. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Katchinskiy, N.; Elezzabi, A.Y.; Light, P.E.; Daneshmand, M. Noninvasive Glucose Sensing in Aqueous Solutions Using an Active Split-Ring Resonator. IEEE Sens. J. 2021, 21, 18742–18755. [Google Scholar] [CrossRef]

- Chudpooti, N.; Silavwe, E.; Akkaraekthalin, P.; Robertson, I.D.; Somjit, N. Nano-Fluidic Millimeter-Wave Lab-on-a-Waveguide Sensor for Liquid-Mixture Characterization. IEEE Sens. J. 2017, 18, 157–164. [Google Scholar] [CrossRef]

- Bahar, A.A.M.; Zakaria, Z.; Ab Rashid, S.R.; Isa, A.A.M.; Alahnomi, R.A. Dielectric analysis of liquid solvents using microwave resonator sensor for high efficiency measurement. Microw. Opt. Technol. Lett. 2017, 59, 367–371. [Google Scholar] [CrossRef]

- Buragohain, A.; Mostako, A.T.T.; Das, G.S. Low-Cost CSRR Based Sensor for Determination of Dielectric Constant of Liquid Samples. IEEE Sens. J. 2021, 21, 27450–27457. [Google Scholar] [CrossRef]

- Stuchly, M.A.; Stuchly, S.S. Coaxial Line Reflection Methods for Measuring Dielectric Properties of Biological Substances at Radio and Microwave Frequencies-A Review. IEEE Trans. Instrum. Meas. 1980, 29, 176–183. [Google Scholar] [CrossRef]

- Gregory, A.; Clarke, R. A review of RF and microwave techniques for dielectric measurements on polar liquids. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 727–743. [Google Scholar] [CrossRef]

- Jha, S.N.; Narsaiah, K.; Basediya, A.L.; Sharma, R.; Jaiswal, P.; Kumar, R.; Bhardwaj, R. Measurement techniques and application of electrical properties for nondestructive quality evaluation of foods—A review. J. Food Sci. Technol. 2011, 48, 387–411. [Google Scholar] [CrossRef] [PubMed]

- Gregory, A.P.; Clarke, R.N. Tables of the Complex Permittivity of Dielectric Reference Liquids at Frequencies up to 5 GHz, NPL Report, MAT 23. 2012. Available online: https://www.researchgate.net/publication/235800733_Tables_of_the_complex_permittivity_of_dielectric_reference_liquids_at_frequencies_up_to_5_GHz (accessed on 8 April 2023).

- Kiani, S.; Rezaei, P.; Fakhr, M. Dual-Frequency Microwave Resonant Sensor to Detect Noninvasive Glucose-Level Changes Through the Fingertip. IEEE Trans. Instrum. Meas. 2021, 70, 6004608. [Google Scholar] [CrossRef]

- Navaei, M.; Rezaei, P.; Kiani, S. Microwave Split Ring Resonator Sensor for Determination of the Fluids Permittivity with Measurement of Human Milk Samples. Radio Sci. 2022, 57, e2022RS007435. [Google Scholar] [CrossRef]

- Munoz-Enano, J.; Velez, P.; Gil, M.; Martin, F. Frequency-Variation Sensors for Permittivity Measurements Based on Dumbbell-Shaped Defect Ground Structures (DB-DGS): Analytical Method and Sensitivity Analysis. IEEE Sens. J. 2022, 22, 9378–9386. [Google Scholar] [CrossRef]

- Wu, W.-J.; Zhao, W.-S.; Wang, D.-W.; Yuan, B.; Wang, G. An active microfluidic sensor based on slow-wave substrate integrated waveguide for measuring complex permittivity of liquids. Sens. Actuators A Phys. 2022, 344, 113699. [Google Scholar] [CrossRef]

- Al-Gburi, A.J.A.; Rahman, N.A.; Zakaria, Z.; Akbar, M.F. Realizing the High Q-Factor of a CSIW Microwave Resonator Based on an MDGS for Semisolid Material Characterization. Micromachines 2023, 14, 922. [Google Scholar] [CrossRef]

- Kiani, S.; Rezaei, P.; Navaei, M. Dual-sensing and dual-frequency microwave SRR sensor for liquid samples per-mittivity detection. Measurement 2020, 160, 107805. [Google Scholar] [CrossRef]

- Su, L.; Munoz-Enano, J.; Velez, P.; Martel, J.; Medina, F.; Martin, F. On the Modeling of Microstrip Lines Loaded with Dumbbell Defect-Ground-Structure (DB-DGS) and Folded DB-DGS Resonators. IEEE Access 2021, 9, 150878–150888. [Google Scholar] [CrossRef]

- Kandwal, A.; Nie, Z.; Igbe, T.; Li, J.; Liu, Y.; Liu, L.W.; Hao, Y. Surface Plasmonic Feature Microwave Sensor with Highly Confined Fields for Aqueous-Glucose and Blood-Glucose Measurements. IEEE Trans. Instrum. Meas. 2021, 70, 8000309. [Google Scholar] [CrossRef]

- Mohammadi, S.; Adhikari, K.K.; Jain, M.C.; Zarifi, M.H. High-Resolution, Sensitivity-Enhanced Active Resonator Sensor Using Substrate-Embedded Channel for Characterizing Low-Concentration Liquid Mixtures. IEEE Trans. Microw. Theory Tech. 2022, 70, 576–586. [Google Scholar] [CrossRef]

- Wiltshire, B.D.; Zarifi, M.H. 3-D Printing Microfluidic Channels with Embedded Planar Microwave Resonators for RFID and Liquid Detection. IEEE Microw. Wirel. Components Lett. 2019, 29, 65–67. [Google Scholar] [CrossRef]

- Zarifi, M.H.; Daneshmand, M. Liquid sensing in aquatic environment using high quality planar microwave resonator. Sens. Actuators B Chem. 2016, 225, 517–521. [Google Scholar] [CrossRef]

- Ansari, M.A.H.; Jha, A.K.; Akhtar, M.J. Design and Application of the CSRR-Based Planar Sensor for Noninvasive Measurement of Complex Permittivity. IEEE Sens. J. 2015, 15, 7181–7189. [Google Scholar] [CrossRef]

- Daniel, R.S.; Pandeeswari, R.; Raghavan, S. Multiband monopole antenna loaded with Complementary Split Ring Resonator and C-shaped slots. AEU Int. J. Electron. Commun. 2017, 75, 8–14. [Google Scholar] [CrossRef]

- Al-Gburi, A.J.A.; Zakaria, Z.; Ibrahim, I.M.; Aswir, R.S.; Alam, S. Solid Characterization Utilizing Planar Microwave Resonator Sensor. Appl. Comput. Electromagn. Soc. 2022, 37, 222–228. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Fontgalland, G.; Roger, L.L.B. Microwave Sensor for Liquid Dielectric Characterization Based on Metamaterial Complementary Split Ring Resonator. IEEE Sens. J. 2018, 18, 9978–9983. [Google Scholar] [CrossRef]

- Van der Eycken, E.V. Practical Microwave Synthesis for Organic Chemists. J. Am. Chem. Soc. 2009, 121, 2828–2829. [Google Scholar]

- Aziz, N.A.A.; Malaysia, U.P.; Hassan, J.; Abbas, Z.; Osman, N.H. Microwave Dielectric Properties of Four Types of Rhizomes from Zingiberaceace Family. J. Phys. Sci. 2017, 28, 15–26. [Google Scholar] [CrossRef]

- Withayachumnankul, W.; Jaruwongrungsee, K.; Tuantranont, A.; Fumeaux, C.; Abbott, D. Metamaterial-Based Microfluidic Sensor for Dielectric Characterization. Sens. Actuators A Phys. 2013, 189, 233–237. [Google Scholar] [CrossRef]

- Benkhaoua, L.; Benhabiles, M.T.; Mouissat, S.; Riabi, M.L. Miniaturized Quasi-Lumped Resonator for Dielectric Characterization of Liquid Mixtures. IEEE Sens. J. 2016, 16, 1603–1610. [Google Scholar] [CrossRef]

- Bakir, M. Electromagnetic-Based Microfluidic Sensor Applications. J. Electrochem. Soc. 2017, 164, B488–B494. [Google Scholar] [CrossRef]

- Jafari, F.S.; Ahmadi-Shokouh, J. Reconfigurable microwave SIW sensor based on PBG structure for high accuracy per-mittivity characterization of industrial liquids. Sens. Actuators A Phys. 2018, 283, 386–395. [Google Scholar] [CrossRef]

- Zhang, X.; Ruan, C.; Haq, T.U.; Chen, K. High-Sensitivity Microwave Sensor for Liquid Characterization Using a Complementary Circular Spiral Resonator. Sensors 2019, 19, 787. [Google Scholar] [CrossRef]

- Armghan, A.; Alanazi, T.M.; Altaf, A.; Haq, T. Characterization of Dielectric Substrates Using Dual Band Microwave Sensor. IEEE Access 2021, 9, 62779–62787. [Google Scholar] [CrossRef]

- Velez, P.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martin, F. Highly-Sensitive Microwave Sensors Based on Open Complementary Split Ring Resonators (OCSRRs) for Dielectric Characterization and Solute Concentration Measurement in Liquids. IEEE Access 2018, 6, 48324–48338. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Huang, Z.; Yu, S.; Yang, X.; Shang, X. A Sensor for Characterisation of Liquid Materials with High Permittivity and High Dielectric Loss. Sensors 2022, 22, 1764. [Google Scholar] [CrossRef] [PubMed]

- Javed, A.; Arif, A.; Zubair, M.; Mehmood, M.Q.; Riaz, K. A Low-Cost Multiple Complementary Split-Ring Resonator-Based Microwave Sensor for Contactless Dielectric Characterization of Liquids. IEEE Sens. J. 2020, 20, 11326–11334. [Google Scholar] [CrossRef]

- Abdulkarim, Y.I.; Deng, L.; Karaaslan, M.; Altıntaş, O.; Awl, H.N.; Muhammadsharif, F.F.; Liao, C.; Unal, E.; Luo, H. Novel Metamaterials-Based Hypersensitized Liquid Sensor Integrating Omega-Shaped Resonator with Microstrip Transmission Line. Sensors 2020, 20, 943. [Google Scholar] [CrossRef] [PubMed]

- Kiani, S.; Rezaei, P.; Navaei, M.; Abrishamian, M.S. Microwave Sensor for Detection of Solid Material Permittivity in Single/Multilayer Samples with High Quality Factor. IEEE Sens. J. 2018, 18, 9971–9977. [Google Scholar] [CrossRef]

- Alhegazi, A.; Zakaria, Z.; Shairi, N.A.; Kamarudin, M.R.; Alahnomi, R.A.; Azize, A.; Wan Haszerila, W.H.; Bahar, A.A.M.; Al-Gburi, A.J.A. Novel Technique of Gap Waveguide Cavity Resonator Sensor with High Resolution for Liquid Detection. Int. J. Antennas Propag. 2022, 22, 2401586. [Google Scholar] [CrossRef]

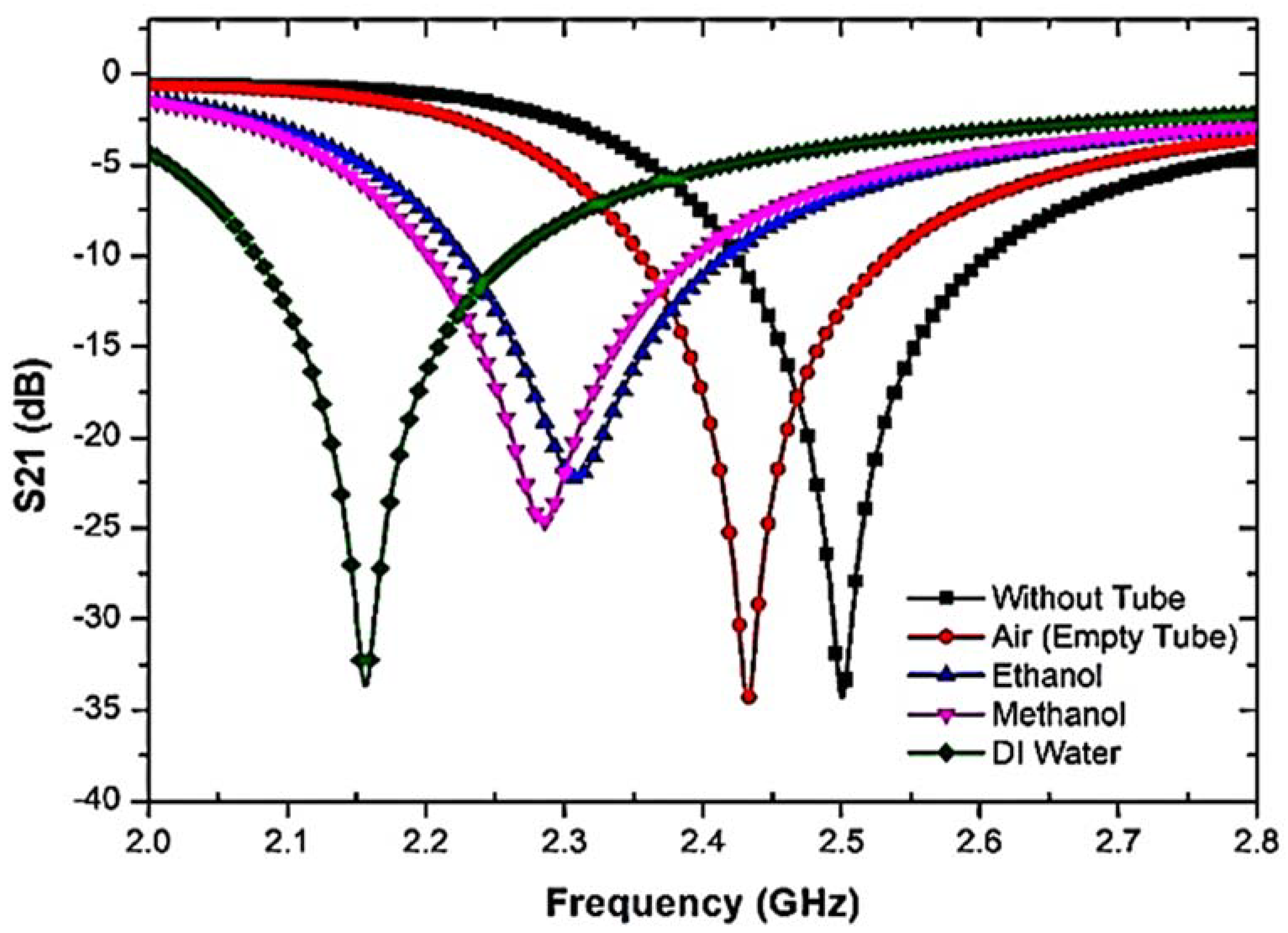

| Liquid MUTs | Frequency (GHz) | S21 (dB) | Frequency Shift (MHz) |

|---|---|---|---|

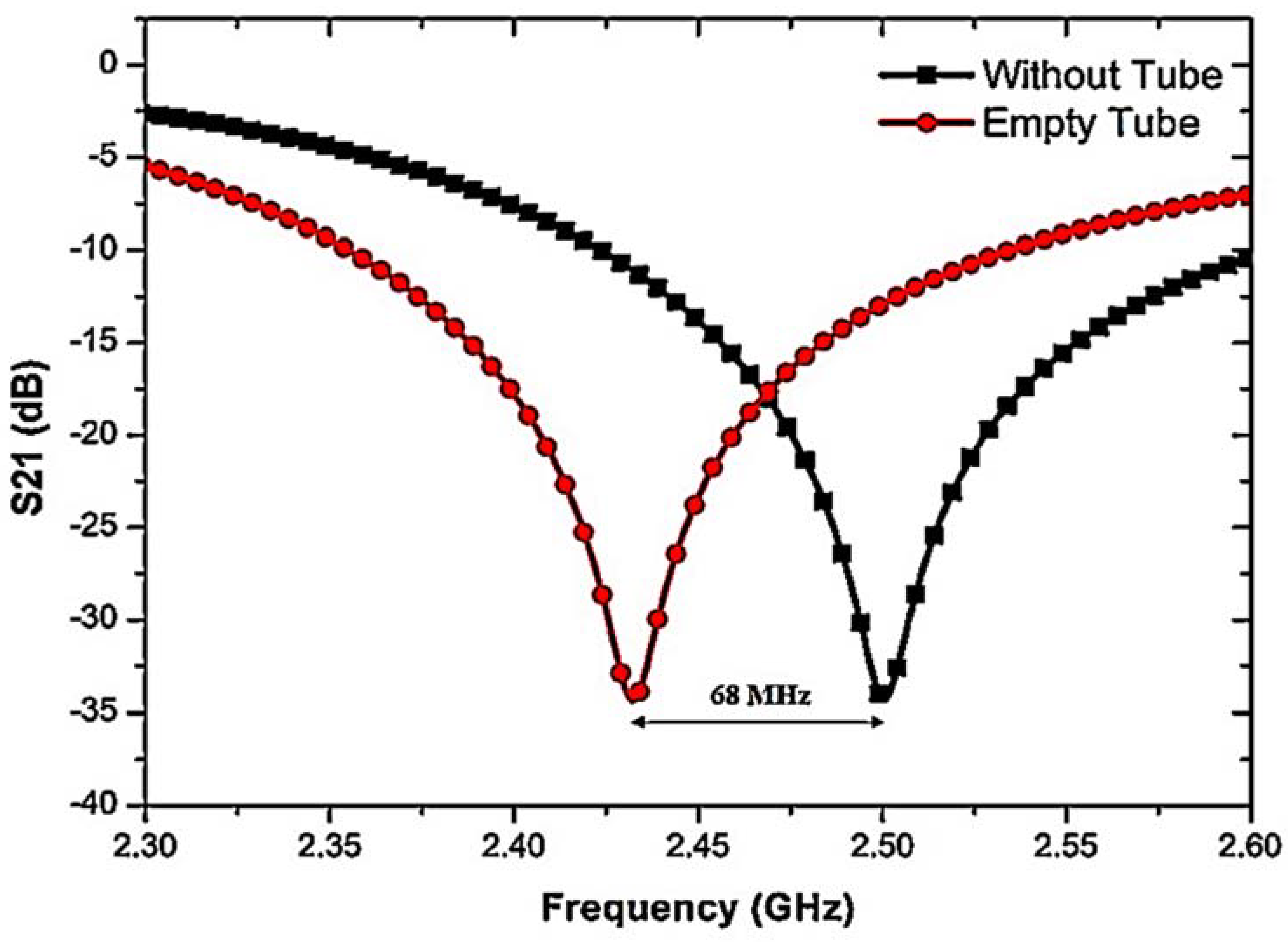

| Without tube | 2.5 | −34.3829 | 0 |

| Air (empty tube) | 2.432 | −34.3829 | 68 |

| Ethanol | 2.32 | −22.2325 | 180 |

| Methanol | 2.29 | −24.6268 | 210 |

| DI Water | 2.16 | −33.6507 | 340 |

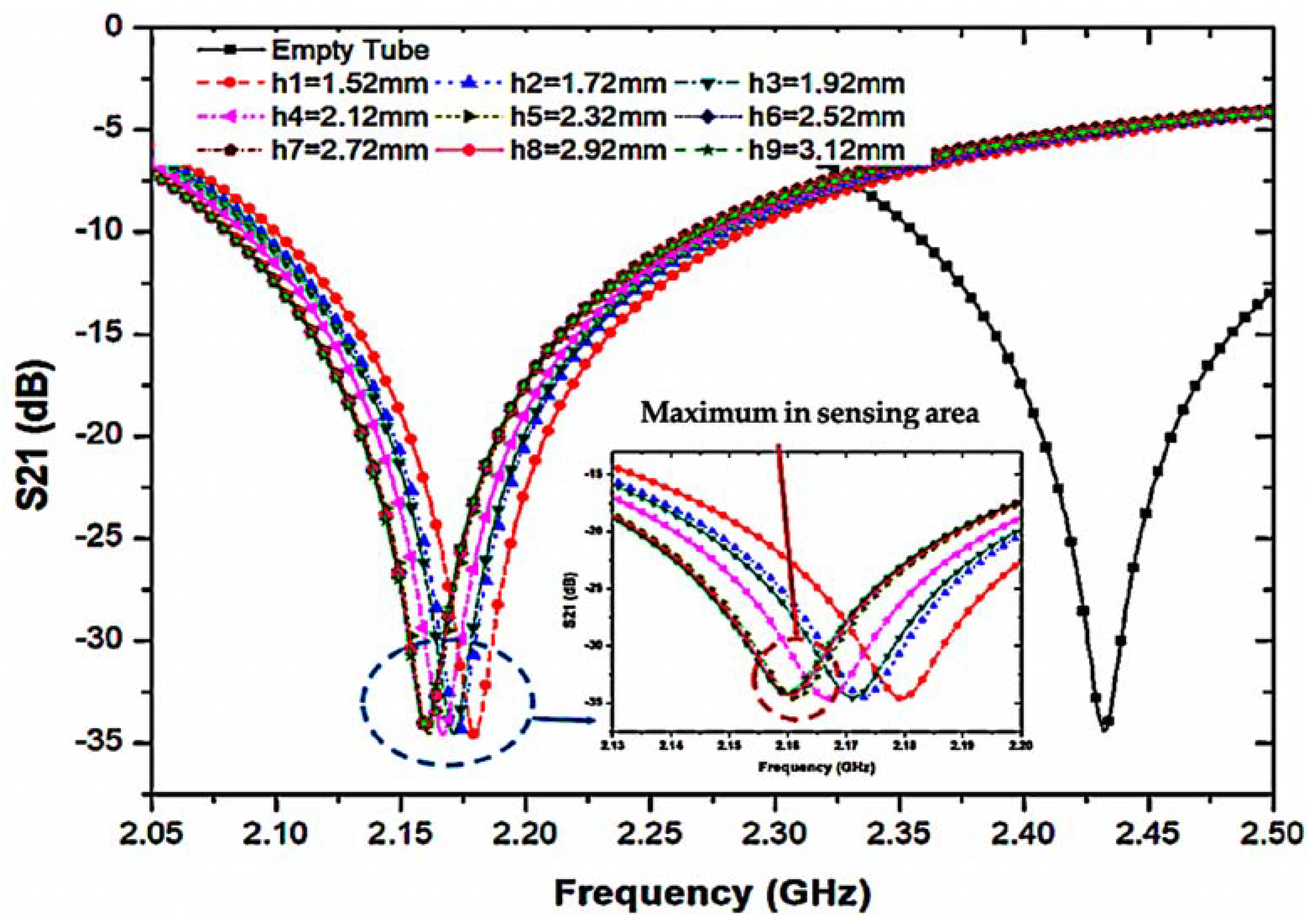

| The Fractional Concentration of Ethanol-Water (C2H8O2) (%) | Resonance Frequency Shifted (GHz) | Insertion Loss Shifted (dB) |

|---|---|---|

| 10 | 2.128 | −14.414 |

| 20 | 2.144 | −12.344 |

| 30 | 2.164 | −12.737 |

| 40 | 2.176 | −13.083 |

| 50 | 2.192 | −13.036 |

| 60 | 2.212 | −12.326 |

| 70 | 2.244 | −12.698 |

| 80 | 2.272 | −12.737 |

| 90 | 2.296 | −12.344 |

| 100 | 2.312 | −11.172 |

| MUT | Q-Factor | Simulation | Measurement | ||

|---|---|---|---|---|---|

| Frequency (GHz) | S21(dB) | Frequency (GHz) | S21(dB) | ||

| Unloaded | 530 | 2.5 | −34.281 | 2.484 | −24.799 |

| Loaded | 230 | 2.432 | −34.383 | 2.404 | −24.901 |

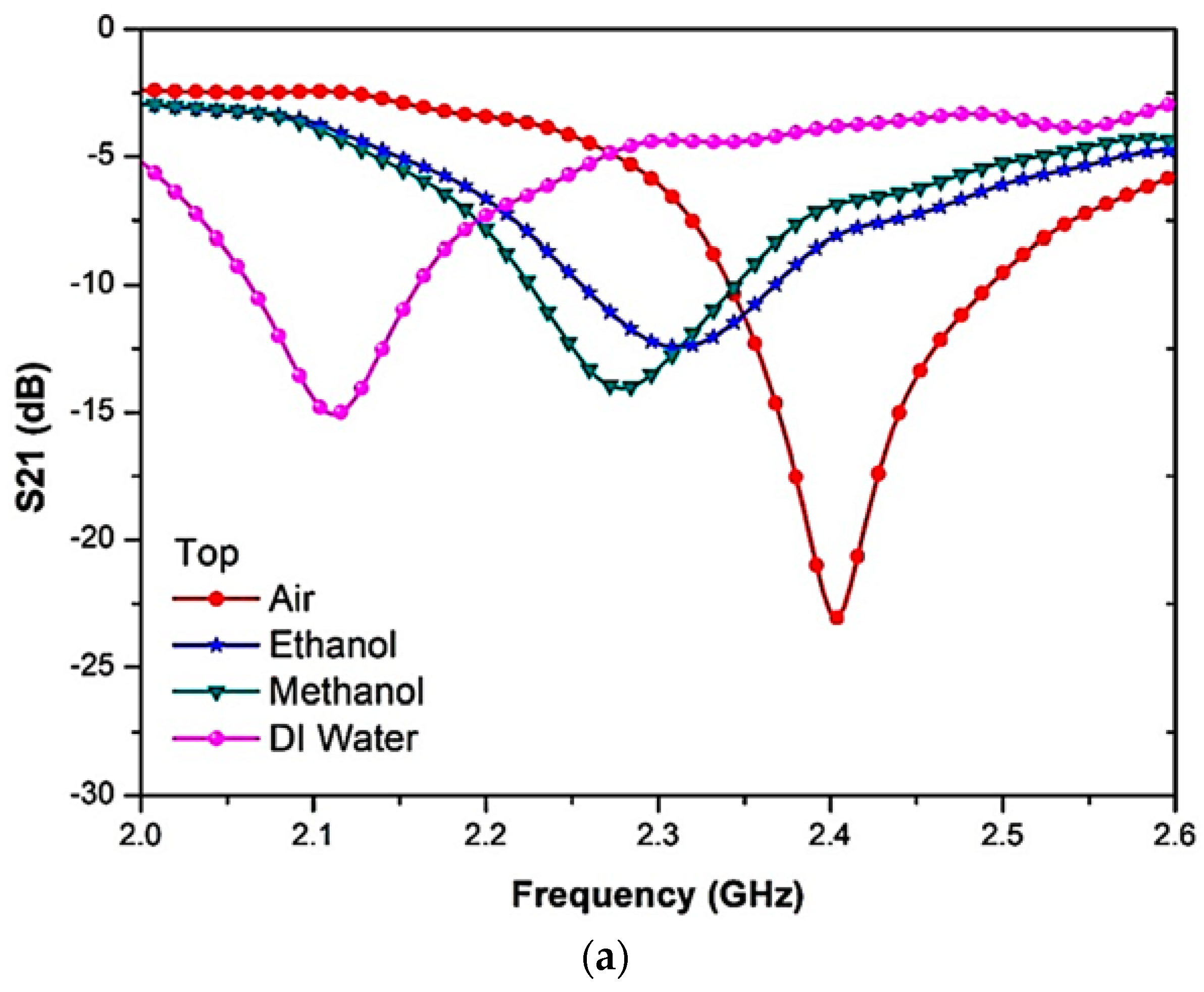

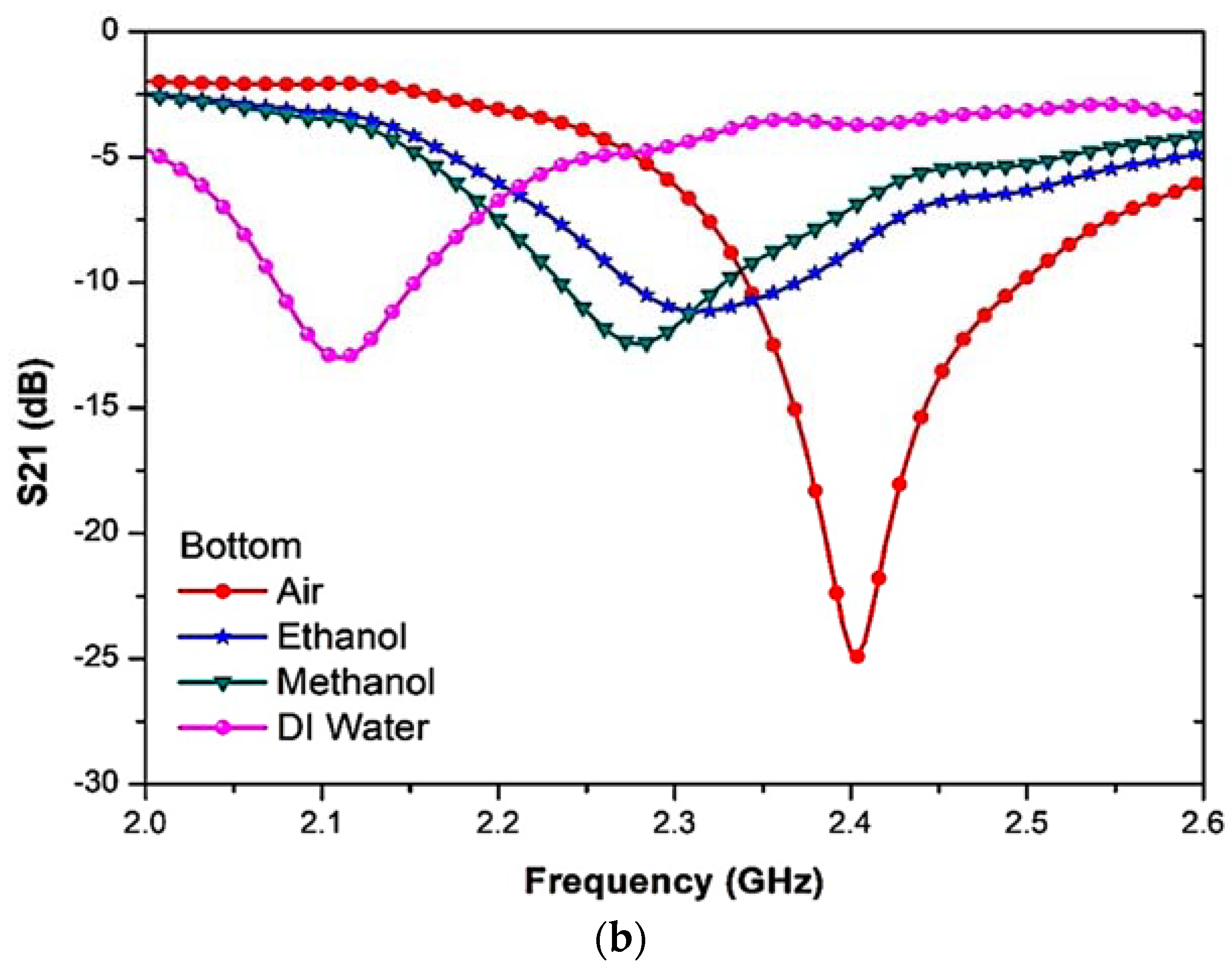

| MUTs | Top | Bottom | ||

|---|---|---|---|---|

| Frequency (GHz) | S21 (dB) | Frequency (GHz) | S21 (dB) | |

| Air (Empty tube) | 2.404 | −24.9078 | 2.404 | −23.0683 |

| Ethanol | 2.312 | −11.1717 | 2.312 | −12.4376 |

| Methanol | 2.28 | −12.4446 | 2.28 | −14.0498 |

| DI water | 2.112 | −13.0072 | 2.112 | −15.0731 |

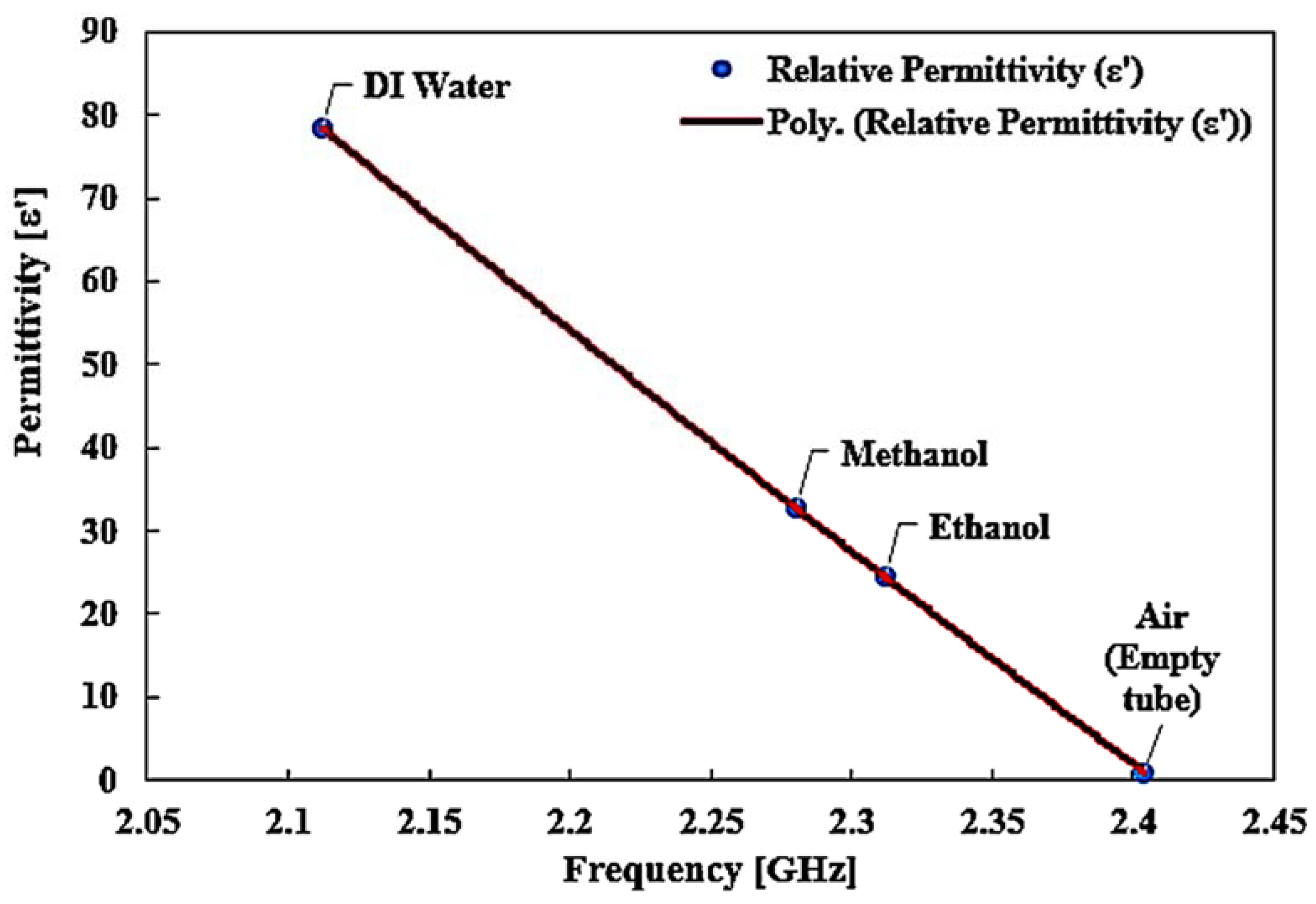

| MUTs | Relative Permittivity (εr) | Simulation | Measurement | ||

|---|---|---|---|---|---|

| Frequency (GHz) | S21 (dB) | Frequency (GHz) | S21 (dB) | ||

| Air (Empty tube) | 1.0006 | 2.432 | −34.38 | 2.404 | −24.90 |

| Ethanol | 24.5 | 2.32 | −22.23 | 2.312 | −11.17 |

| Methanol | 32.7 | 2.29 | −24.62 | 2.28 | −12.44 |

| DI water | 78.4 | 2.16 | −33.65 | 2.112 | −13.01 |

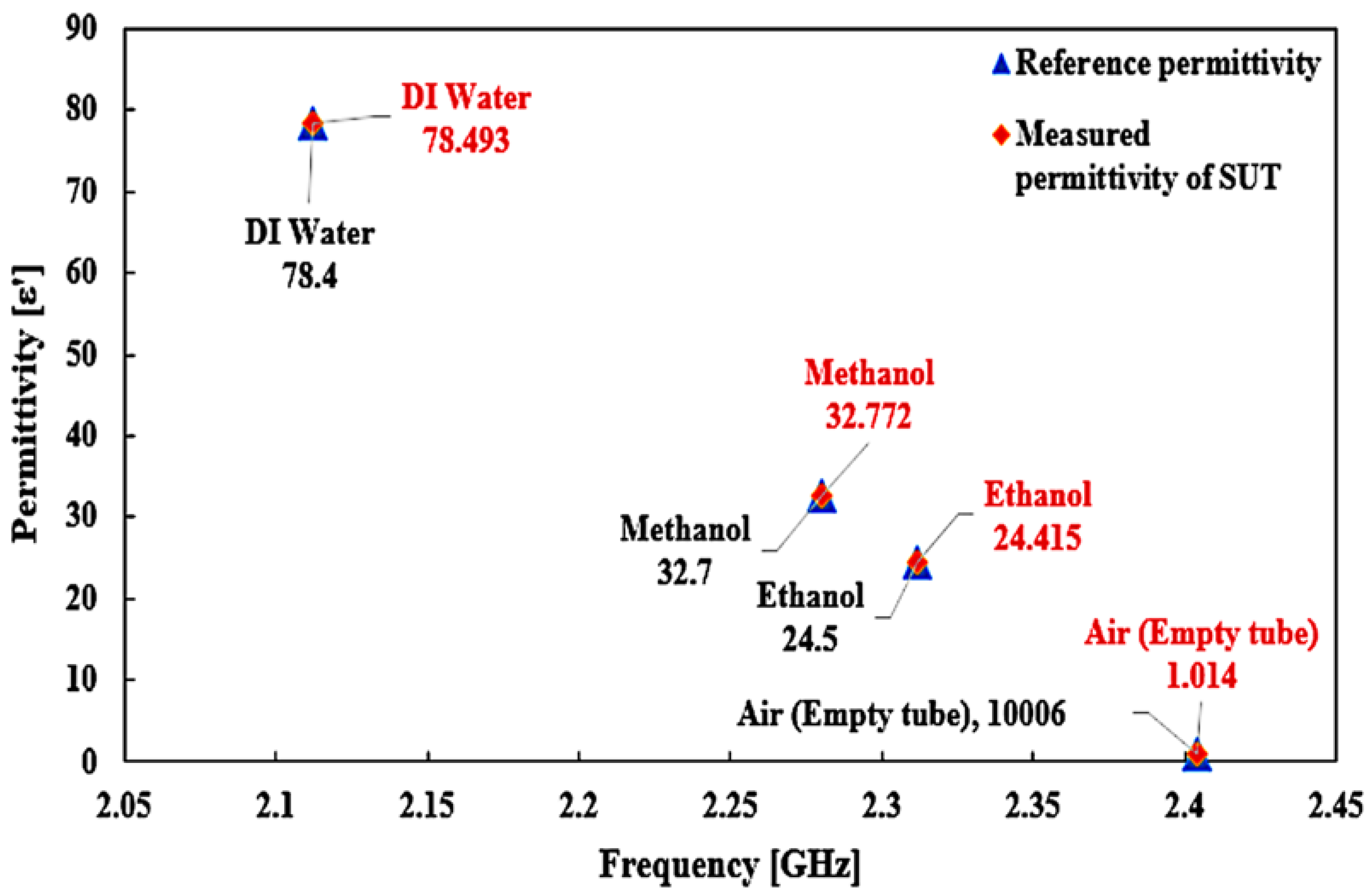

| MUT | Frequency (GHz) | Reference Real Permittivity | Real Permittivity (ε′) | Error (%) |

|---|---|---|---|---|

| Air | 2.404 | 1.0006 | 1.014 | 1.339 |

| Ethanol | 2.312 | 24.5 | 24.415 | 0.347 |

| Methanol | 2.28 | 32.7 | 32.772 | 0.22 |

| Water | 2.112 | 78.4 | 78.493 | 0.119 |

| Average Error | 0.28% | |||

| MUTs | Frequency (GHz) | ∆𝑓 (MHz) | ∆𝑓 | ∆εr | Sensitivity (MHz)/εr |

|---|---|---|---|---|---|

| Air (Empty tube) | 2.404 | 80 | 1.0006 | 0 | 0 |

| Ethanol | 2.312 | 172 | 24.5 | 23.494 | 7.321 |

| Methanol | 2.28 | 204 | 32.7 | 31.694 | 6.437 |

| DI Water | 2.112 | 372 | 78.4 | 77.394 | 4.807 |

| # | References | Sensors Sizes (mm) | Used Techniques | MUTs Samples | Frequency Band (GHz) | Q-Factor | Sensitivity (S, (MHz)/εr)) |

|---|---|---|---|---|---|---|---|

| 1 | [27] | 80 × 40 × 0.8 | Metamaterial coupling | Ethanol and Methanol | 2.5 | Not reported | 0.27 |

| 2 | [30] | 80 × 25 × 0.8 | Loss-compensated SRR | Glucose | 1.156 | 190 | Not reported |

| 3 | [31] | 26 × 30 × 26.5 | Waveguide with loop slot | Ethanol and DI water | 91 | Not reported | Not reported |

| 4 | [32] | 112.96 × 49.16 × 3.175 | Multiple split-ring resonator | Ethanol, Methanol and Air | 2.1 | 525 | Not reported |

| 5 | [59] | 25 × 30 × 1.54 | CCSR | Ethanol, Methanol and Milk | 2.4 | Not reported | Not reported |

| 6 | [60] | 30 × 25 × 1.6 | CSSRRs | AIR, HDPE and PVC | 5.35 and 7.99 | 267.5 | 0.04 |

| 7 | [61] | 46 × 46 × 1.6 | OCSRRs | Ethanol, Methanol and DI water | 0.9 | Not reported | 4.3 |

| 8 | [62] | 28 × 20 × 0.75 | CSRR | Ethanol and Water | 2.85 and 2.96 | 145 | 3.0 |

| 9 | [63] | 35 × 25 × 1.6 | SRR | Ethanol, Methanol and DI water | 2.45 | 31 | 0.214 |

| 10 | [64] | 40× 20 × 1.6 | OSRR | Ethanol, Methanol, DI water | 2.5-3.5 | Not reported | Not reported |

| 11 | [65] | 30× 13 × 0.508 | MML | Solid | 5.65 | 217 | 3.25 |

| 12 | [66] | 38 ×35.4×15.73 | GWCR | Ethanol, Methanol and Air | 5.96 | 66.8 | 0.156 |

| This work | 25 × 20 × 1.52 | TR CSRR | Sample (without tube), Air (empty tube), Ethanol, Methanol, DI Water | 2.5 | 520 | 7.321 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Gburi, A.J.A.; Zakaria, Z.; Rahman, N.A.; A. Althuwayb, A.; Ibrahim, I.M.; Saeidi, T.; Dayo, Z.A.; Ahmad, S. A Miniaturized and Highly Sensitive Microwave Sensor Based on CSRR for Characterization of Liquid Materials. Materials 2023, 16, 3416. https://doi.org/10.3390/ma16093416

Al-Gburi AJA, Zakaria Z, Rahman NA, A. Althuwayb A, Ibrahim IM, Saeidi T, Dayo ZA, Ahmad S. A Miniaturized and Highly Sensitive Microwave Sensor Based on CSRR for Characterization of Liquid Materials. Materials. 2023; 16(9):3416. https://doi.org/10.3390/ma16093416

Chicago/Turabian StyleAl-Gburi, Ahmed Jamal Abdullah, Zahriladha Zakaria, Norhanani Abd Rahman, Ayman A. Althuwayb, Imran Mohd Ibrahim, Tale Saeidi, Zaheer Ahmed Dayo, and Sarosh Ahmad. 2023. "A Miniaturized and Highly Sensitive Microwave Sensor Based on CSRR for Characterization of Liquid Materials" Materials 16, no. 9: 3416. https://doi.org/10.3390/ma16093416

APA StyleAl-Gburi, A. J. A., Zakaria, Z., Rahman, N. A., A. Althuwayb, A., Ibrahim, I. M., Saeidi, T., Dayo, Z. A., & Ahmad, S. (2023). A Miniaturized and Highly Sensitive Microwave Sensor Based on CSRR for Characterization of Liquid Materials. Materials, 16(9), 3416. https://doi.org/10.3390/ma16093416