Enhanced Induction Heating and Self-Healing Properties of Steel Slag Powder Based Asphalt and Asphalt Mixture under Microwave Irradiation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experimental Methods

2.2.1. Preparation of Asphalt Mortars

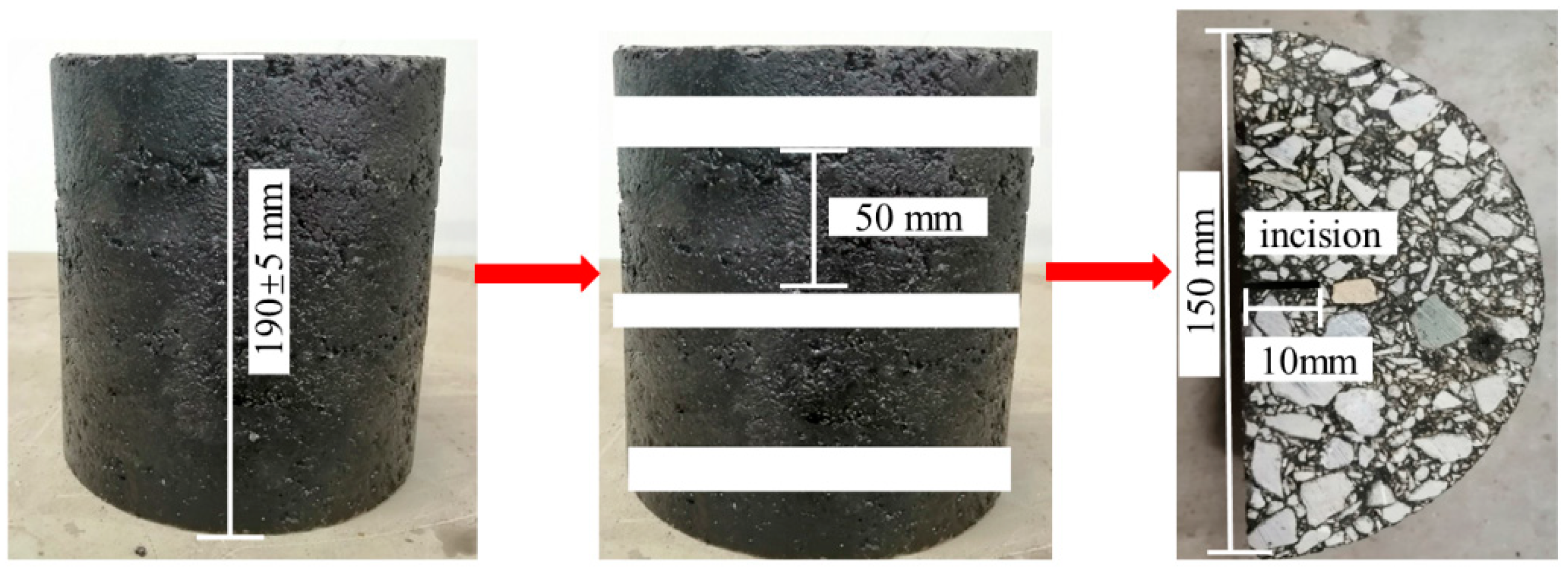

2.2.2. Preparation of Asphalt Mixture Specimen

2.2.3. Microwave Heating of Asphalt Mortar and Mixture

2.2.4. Healing Temperature of Asphalt Mortar

2.2.5. Healing Properties of Asphalt Mixture

2.2.6. Self-Healing Factors of Asphalt Mixture

3. Results and Discussion

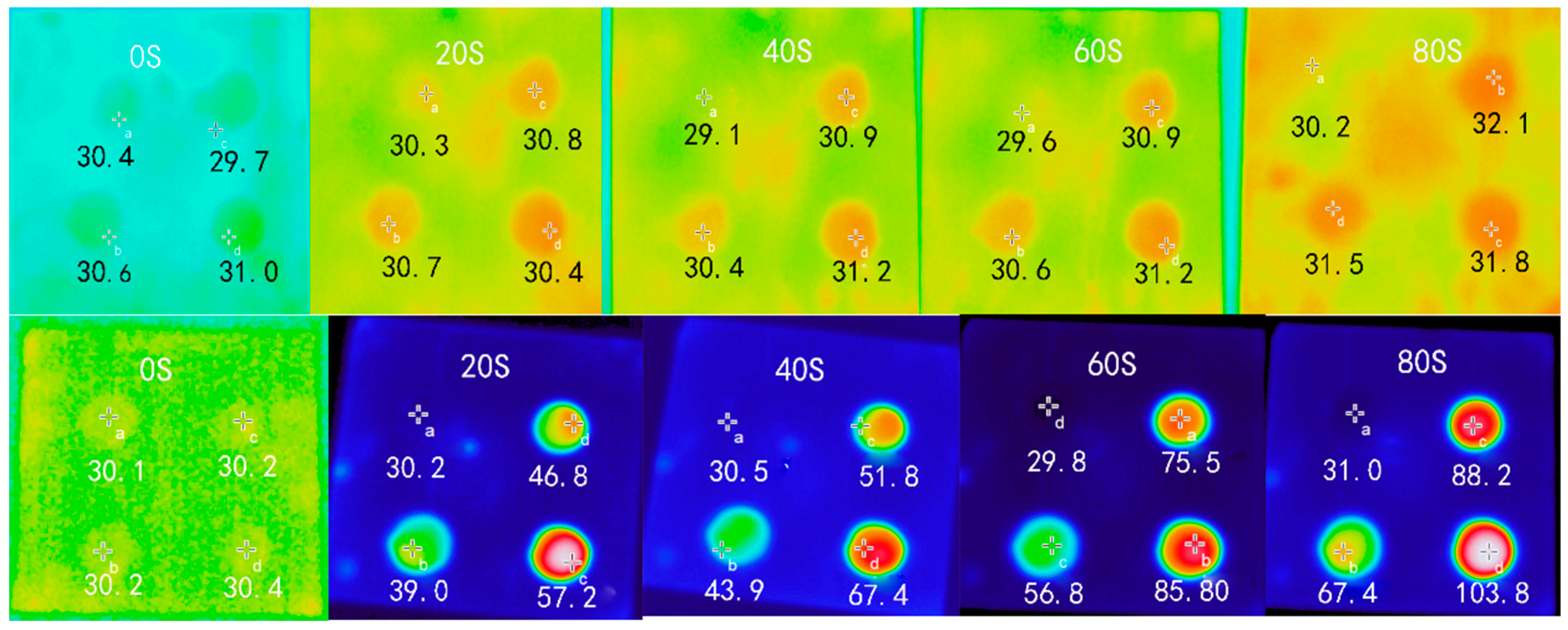

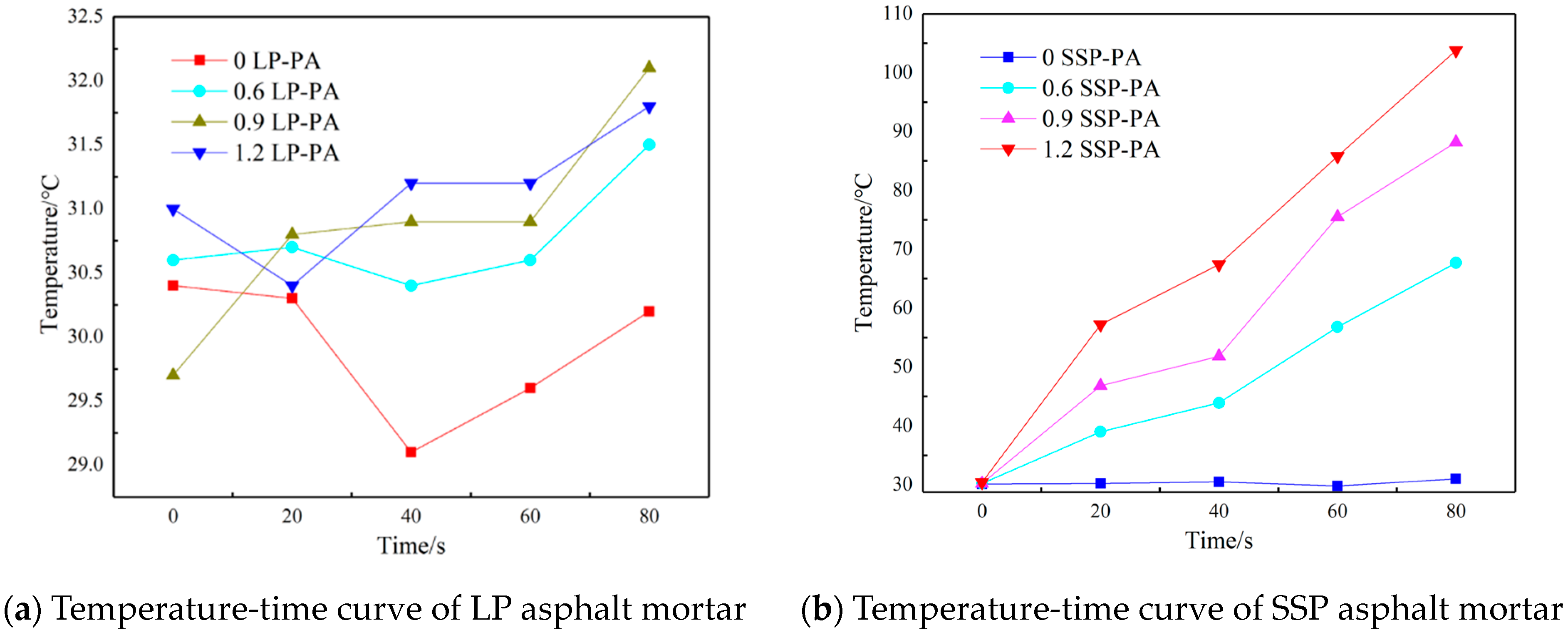

3.1. Microwave Heating Properties of Asphalt Mortar

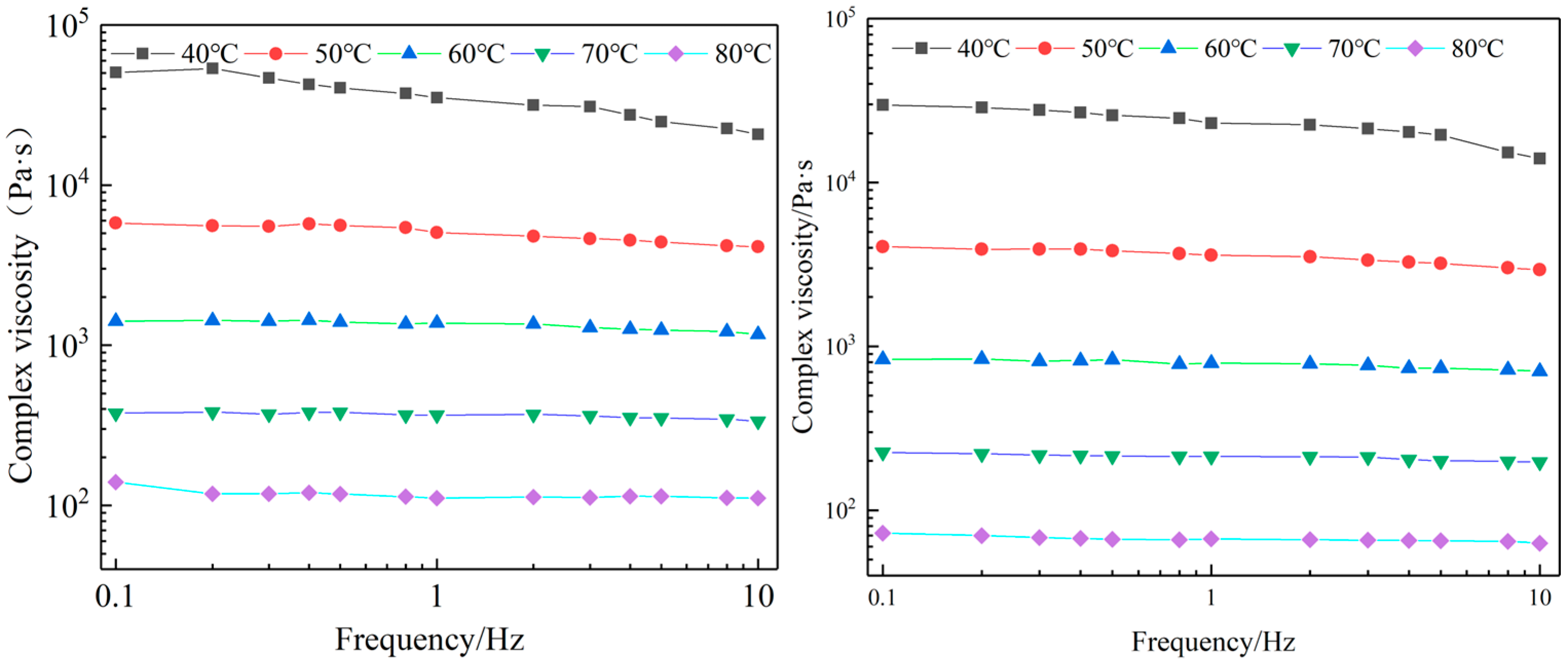

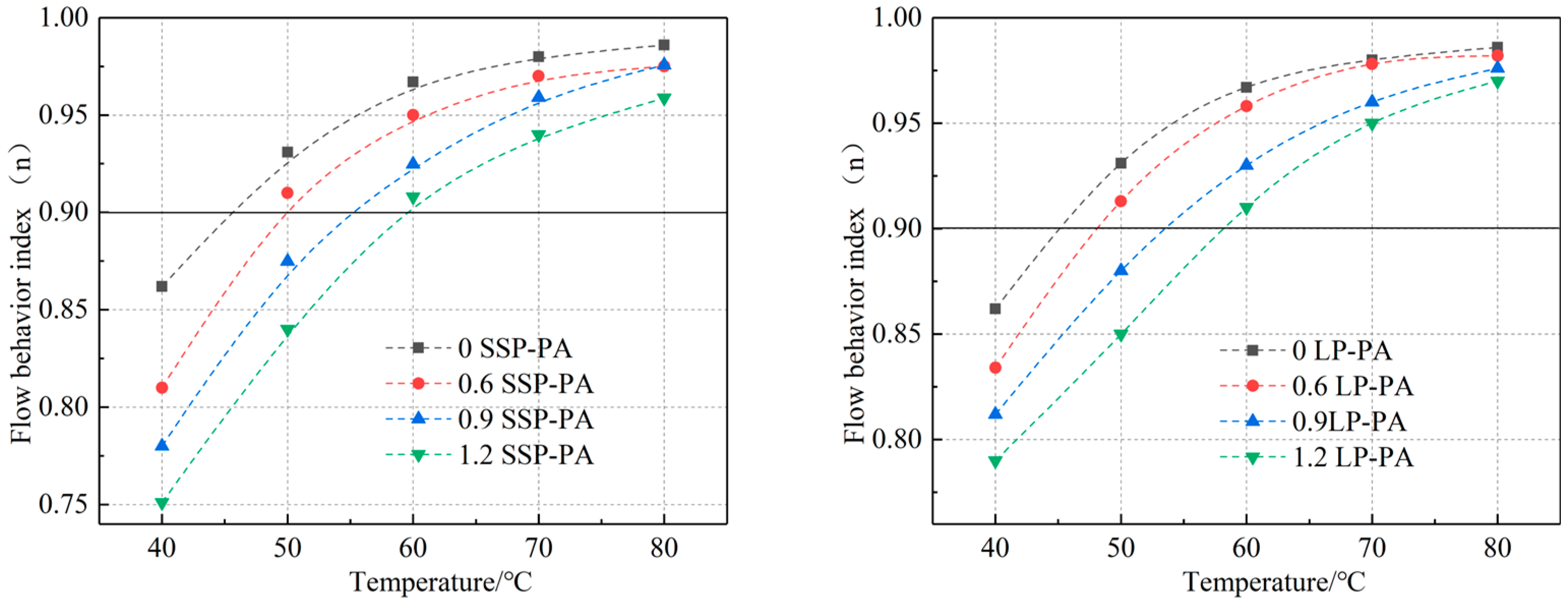

3.2. Research on the Optimum Healing Temperature of Asphalt Mortar

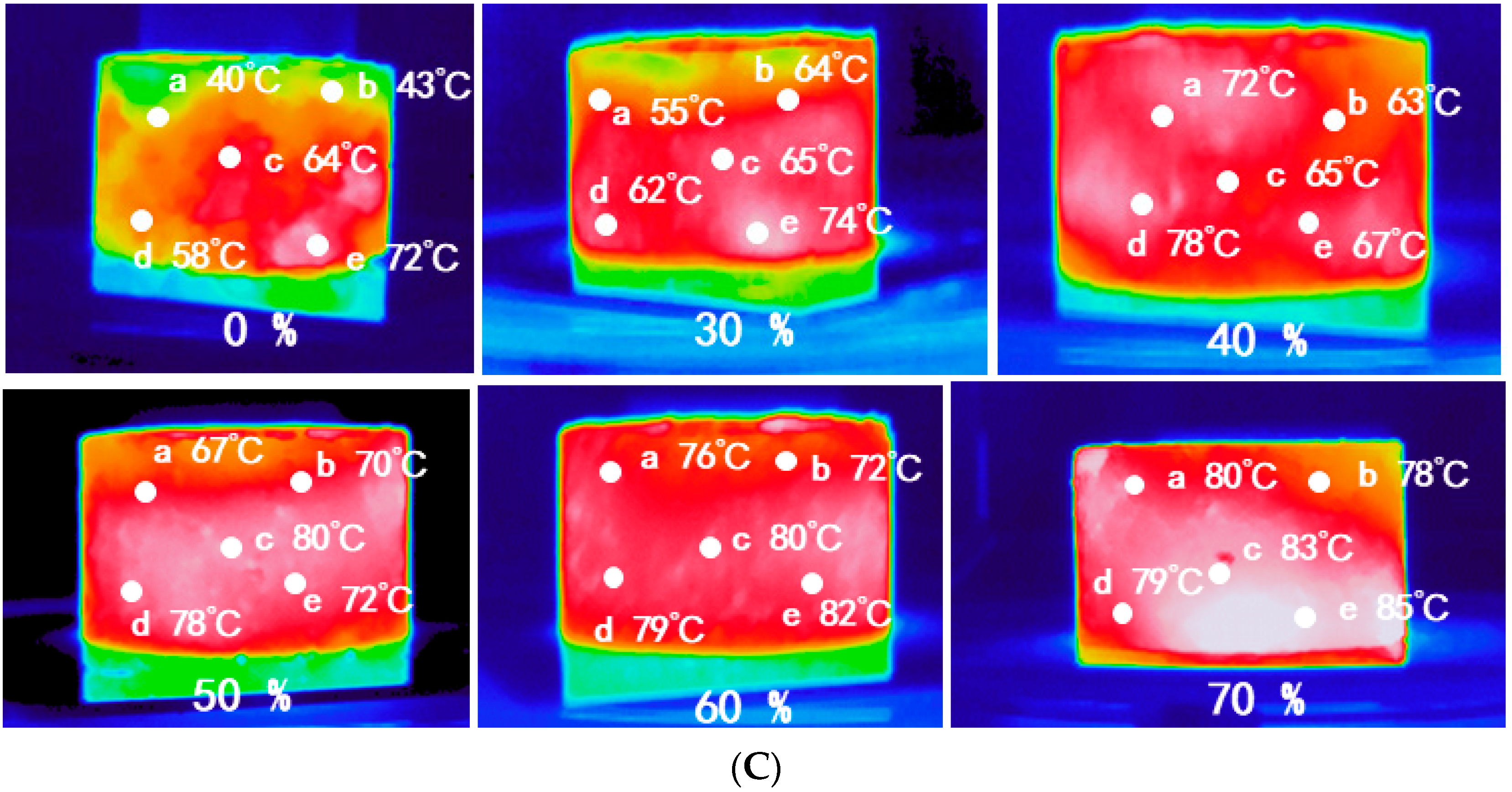

3.3. Microwave Heating Characteristics of Asphalt Mixture

3.4. Effect of SSP Substitution on Self-Healing Properties of Asphalt Mixture

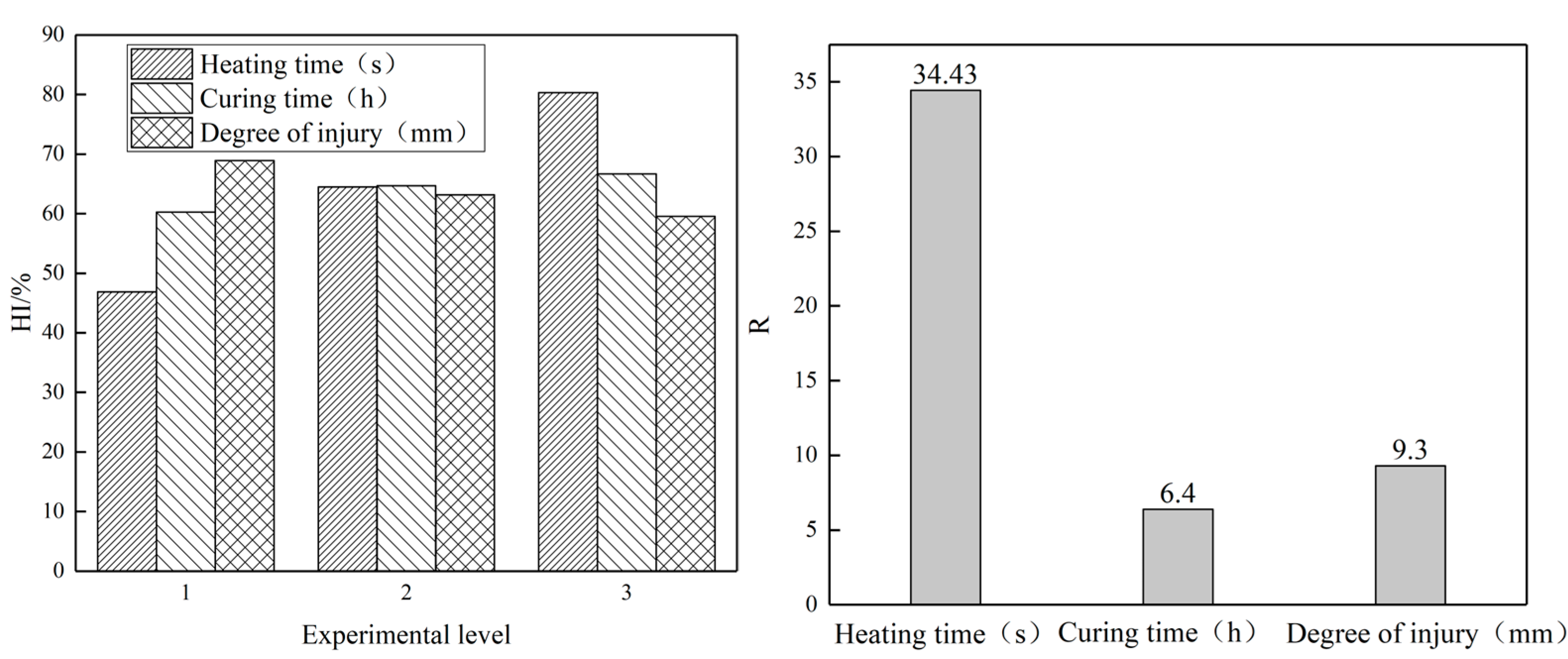

3.5. Analysis of Influencing Factors of Asphalt Mixture Self-Healing under Microwave Radiation

3.5.1. Routine Influencing Factor Analysis

3.5.2. Influence of Multiple Mechanical Fatigue Damages on the Self-Healing Characteristics of Asphalt Mixture

4. Conclusions

- The heating rate of SSP asphalt mortar is noticeably higher than that of LP asphalt mortar under microwave radiation. There are metal oxides with high electromagnetic parameters, such as Fe2O3 and CaO in SSP, but the main component of LP is CaCO3. The ability of metal oxide to absorb and lose electromagnetic waves is greater than that of CaCO3. In addition, the surface structure of SSP is rough and porous. Electromagnetic waves will be reflected and refracted inside SSP many times, and the microwave energy consumed will be converted into heat.

- The complex viscosity of SSP and LP asphalt mortar decreased with the increase in frequency, but when the test temperature was higher, the asphalt mortar approached or became a Newtonian fluid, and the viscosity remained unchanged with frequency. The flow behavior index n of the two asphalt mortars was proportional to the temperature but decreased with the increase in the filler–bitumen ratio. The temperature corresponding to n = 0.9 was selected as the most optimum healing temperature of the mortar and results showed that the optimum healing temperature of the two asphalt mortars was between 50 °C and 60 °C.

- Under microwave radiation, the temperature distribution of the aggregate and ordinary asphalt mixture was uneven, and there was a phenomenon of temperature concentration, but the overall temperature of the asphalt mixture containing SSP increased with the increase in the SSP replacement amount, and the temperature difference decreased. From the perspective of the healing effect, the healing indexes of asphalt mixtures with 30%, 40%, 50%, 60%, and 70% steel slag replacements increased by 8.7%, 17.3%, 22.1%, 26.9%, and 27.7%, respectively, compared with ordinary asphalt mixtures, and the growth trend gradually slowed down.

- The order of influencing factors on the microwave-induced self-healing behavior of the asphalt mixture was healing temperature > damage degree > healing time. The SSP asphalt mixture has a great advantage in terms of healing ability, and the healing index can still be maintained at more than 50% after repeated mechanical damage. In road maintenance work, the maintenance time should be controlled, and the detection of road crack damage should be carried out every year. For pavement with micro-cracks, pre-maintenance should be carried out in time to extend the service life of the pavement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Ji, X.P.; Fang, X.Z.; Hu, Y.L.; Hua, W.L.; Zhang, Z.M.; Shao, D.Y. Self-healing performance and prediction model of microcapsule asphalt. Constr. Build. Mater. 2022, 330, 127085. [Google Scholar] [CrossRef]

- Wang, X.A.; Guo, G.J.; Zou, F.B.; Zhao, H.; Li, Y. Enhancing self-healing properties of microcrack on aged asphalt incorporating with microcapsules encapsulating rejuvenator. Constr. Build. Mater. 2022, 344, 128123. [Google Scholar] [CrossRef]

- Wan, P.; Liu, Q.; Wu, S.; Zou, Y.; Zhao, F.; Wang, H.; Niu, Y.; Ye, Q. Dual responsive self-healing system based on calcium alginate/Fe3O4 capsules for asphalt mixtures. Constr. Build. Mater. 2022, 360, 129585. [Google Scholar] [CrossRef]

- Wang, H.M.; Yuan, M.; Wu, J.; Wan, P.; Liu, Q. Self-Healing Properties of Asphalt Concrete with Calcium Alginate Capsules Containing Different Healing Agents. Materials 2022, 15, 5555. [Google Scholar] [CrossRef]

- Ul Abadeen, A.Z.; Hussain, A.; Kumar, V.S.; Murali, G.; Vatin, N.I.; Riaz, H. Comprehensive Self-Healing Evaluation of Asphalt Concrete Containing Encapsulated Rejuvenator. Materials 2022, 15, 3672. [Google Scholar] [CrossRef] [PubMed]

- Behnia, B.; Reis, H. Self-healing of thermal cracks in asphal pavements. Constr. Build. Mater. 2019, 218, 316–322. [Google Scholar] [CrossRef]

- He, L.; Zhao, L.; Ling, T.-q.; Ma, Y.; Liu, Q.-t. Study on crack induction heat self-healing performance of dense asphalt mixture. China J. Highw. 2017, 30, 17–24. [Google Scholar]

- Gómez-Meijide, B.; Ajam, H.; Lastra-González, P.; Garcia, A. Effect of air voids content on asphalt self-healing via induction and infrared heating. Constr. Build. Mater. 2016, 126, 957–966. [Google Scholar] [CrossRef]

- Mirzamojeni, M.; Aghayan, I.; Behzadian, R. Evaluation of field aging effect on self-healing capability of asphalt mixtures. Constr. Build. Mater. 2023, 369, 12. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.P.; Xie, J.; Amirkhanian, S.; Liu, Q.; Zhang, J.; Xiao, Y.; Zhao, Z.; Xu, H.; Li, N.; et al. Enhanced induction heating and self-healing performance of recycled asphalt mixtures by incorporating steel slag. J. Clean. Prod. 2022, 366, 132999. [Google Scholar] [CrossRef]

- Hu, C.H.; Li, P.F.; Zhu, Y.L.; Zhao, Q.; Zhang, H. Experimental study on microwave absorption properties of HMA containing copper slag. Constr. Build. Mater. 2022, 341, 127850. [Google Scholar] [CrossRef]

- Wang, R.R.; Xiong, Y.C.; Ma, X.P.; Guo, Y.; Yue, M.; Yue, J. Investigating the differences between steel slag and natural limestone in asphalt mixes in terms of microscopic mechanism, fatigue behavior and microwave-induced healing performance. Constr. Build. Mater. 2022, 328, 127107. [Google Scholar] [CrossRef]

- Gallego, J.; Val, M.; Contreras, V.; Páez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Zhu, X.; Ye, F.; Cai, Y.; Birgisson, B.; Lee, K. Self-healing properties of ferrite-filled open-graded friction course (OGFC) asphalt mixture after moisture damage. J. Clean. Prod. 2019, 232, 518–530. [Google Scholar] [CrossRef]

- Zhu, X.; Ye, F.; Cai, Y.; Birgisson, B.; Yu, Y. Digital image correlation-based investigation of self-healing properties of ferrite-filled open-graded friction course asphalt mixture. Constr. Build. Mater. 2020, 234, 117378. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2017, 159, 164–174. [Google Scholar] [CrossRef]

- Zhu, H.-z.; Yuan, H.; Liu, Y.-f.; Fan, S.P.; Ding, Y.J. SBS modified asphalt mixture macroscopic crack microwave self-healing research. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2020, 39, 84–89. [Google Scholar]

- Zhu, H.-Z.; Yuan, H.; Wei, Q.; Liu, Y.-F.; Fan, S.P. Analysis of influencing factors of asphalt mixture fracture-microwave self-healing. Sci. Technol. Eng. 2020, 20, 4547–4552. [Google Scholar]

- Sun, Y. Study on Self-Healing Characteristics of Asphalt and Asphalt Mixture. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2017. [Google Scholar]

- Wang, F.; Zhu, H.B.; Shu, B.A.; Li, Y.; Gu, D.; Gao, Y.; Chen, A.; Feng, J.; Wu, S.; Liu, Q.; et al. Microwave heating mechanism and self-healing performance of asphalt mixture with basalt and limestone aggregates. Constr. Build. Mater. 2022, 342, 127973. [Google Scholar] [CrossRef]

- Liu, J.N.; Zhang, T.H.; Guo, H.Y.; Wang, Z.; Wang, X. Evaluation of self-healing properties of asphalt mixture containing steel slag under microwave heating, Mechanical, thermal transfer and voids microstructural characteristics. J. Clean. Prod. 2022, 342, 130932. [Google Scholar] [CrossRef]

- Wu, S.; Cui, P.; Xie, J.; Liu, Q.; Pang, L. Research status of steel slag aggregate expansion inhibition method and mixture volume stability. China J. Highw. 2021, 34, 166–179. [Google Scholar]

- Wang, L.; Li, J.; Tao, Y.-x.; Wang, B.H.; Yan, J.T. Shaking table test on seismic performance of geogrid reinforced retaining wall with waste steel slag backfill. China J. Highw. 2021, 34, 35–46. [Google Scholar]

- Lou, B.; Sha, A.; Barbieri, D.M.; Liu, Z.; Zhang, F. Microwave heating properties of steel slag asphalt mixture using a coupled electromagnetic and heat transfer model. Constr. Build. Mater. 2021, 291, 123248. [Google Scholar] [CrossRef]

- Gan, Y.W.; Li, C.M.; Ke, W.; Deng, Q.; Yu, T. Study on pavement performance of steel slag asphalt mixture based on surface treatment. Case Stud. Constr. Mater. 2022, 16, e01131. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Zhou, Y.; Hu, R. Research on microwave heating performance of modified steel slag asphalt mixture. Adv. Mech. Eng. 2021, 13, 1687814021990479. [Google Scholar] [CrossRef]

- Yan, Z.; Zhou, Y. Analysis on the Properties of Modified Steel Slag Asphalt Mixture. J. Phys. Conf. Ser. 2020, 1649, 012034. [Google Scholar]

- Guo, Y.; Wu, H.; Shen, A.; Yang, X.; Cui, T. Study of the long-term water stability of asphalt mixtures containing steel slag aggregate. J. Adhes. Sci. Technol. 2020, 34, 877–902. [Google Scholar] [CrossRef]

- Menozzi, A.; Garcia, A.; Partl, M.N.; Tebaldi, G.; Schuetz, P. Induction healing of fatigue damage in asphalt test samples. Constr. Build. Mater. 2015, 74, 162–168. [Google Scholar] [CrossRef]

- Garcia, A.; Norambuena-Contreras, J.; Bueno, M.; Partl, M.N. Influence of Steel Wool Fibers on the Mechanical, Termal, and Healing Properties of Dense Asphalt Concrete; ASTM International: West Conshohocken, PN, USA, 2014; Volume 42, pp. 1107–1118. [Google Scholar]

- Tang, J. Study on Thermal Induced Self-Healing Characteristics of Asphalt and Asphalt Mixture. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2017. [Google Scholar]

| Properties | Matrix Asphalt | Requirements |

|---|---|---|

| Softening point (°C) | 52.8 | ≥42 |

| Ductility (15 °C, mm) | >1000 | >1000 |

| Penetration at (25 °C, 0.1 mm) | 67.9 | 60–80 |

| Density (15 °C, g/cm3) | 1.024 | – |

| Properties | LP | SSP | Requirements |

|---|---|---|---|

| Hydrophilic coefficient | 0.70 | 0.66 | <1.00 |

| Density (g/cm3) | 2.68 | 3.39 | ≥2.50 |

| Water absorption (%) | 0.55 | 0.69 | ≤1.00 |

| Properties | Limestone Aggregate | |||

|---|---|---|---|---|

| Aggregate size (mm) | 0–5 | 5–10 | 10–15 | |

| Crush value (%) | / | 20.6 | 21.2 | |

| Los Angeles wear value (%) | 18.6 | 21.8 | 23.4 | |

| Apparent specific gravity (g/cm3) | 2.724 | 2.723 | 2.737 | |

| Flat elongated particles content (%) | >9.5 mm | / | 9.6 | 8.3 |

| <9.5 mm | 11.4 | 9.2 | ||

| Size (mm) | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Gradation range | 100 | 90–100 | 68–85 | 38–68 | 24–50 | 15–38 | 10–28 | 7–20 | 5–15 | 4–8 |

| Target gradation | 100 | 95 | 76.5 | 53 | 37 | 26.5 | 19 | 13.5 | 10 | 6 |

| Experiment Level | Microwave Heating Time (s) | Maintenance Time at Room Temperature (h) | Degree of Injury (mm) |

|---|---|---|---|

| 1 | 120 | 2 | 3 |

| 2 | 150 | 3 | 3.5 |

| 3 | 180 | 4 | 4 |

| CaCO3 | SiO2 | CaO | Fe2O3 | MaO | MgO | Al2O3 | Loss | |

|---|---|---|---|---|---|---|---|---|

| SSP | - | 14.2 | 40.5 | 30.5 | 5.2 | 1.9 | 3.2 | 4.5 |

| LP | 92.1 | 2.0 | - | 0.5 | 2.4 | - | 1.2 | 1.8 |

| LP Asphalt Mortar | Optimum Temperature (°C) | SSP Asphalt Mortar | Optimum Temperature (°C) |

|---|---|---|---|

| filler–bitumen ratio 0 | 45.5 | filler–bitumen ratio 0 | 45.5 |

| filler–bitumen ratio 0.6 | 48.4 | filler–bitumen ratio 0.6 | 49.6 |

| filler–bitumen ratio 0.9 | 53.1 | filler–bitumen ratio 0.9 | 55.3 |

| filler–bitumen ratio 1.2 | 57.2 | filler–bitumen ratio 1.2 | 59.8 |

| Steel Slag Substitution (%) | F0 (KN) | F1 (KN) | HI (%) |

|---|---|---|---|

| 0 | 9.33 | 5.46 | 58.5 |

| 30 | 9.52 | 6.39 | 67.2 |

| 40 | 9.71 | 7.36 | 75.8 |

| 50 | 9.82 | 7.91 | 80.6 |

| 60 | 10.12 | 8.64 | 85.4 |

| 70 | 10.76 | 9.28 | 86.2 |

| Numbering | Heating Time (min) | Maintenance Time at Room Temperature (h) | Degree of Injury (mm) | HI (%) |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 50.1 |

| 2 | 1 | 2 | 2 | 45.2 |

| 3 | 1 | 3 | 3 | 45.3 |

| 4 | 2 | 1 | 2 | 60.1 |

| 5 | 2 | 2 | 3 | 62.8 |

| 6 | 2 | 3 | 1 | 70.5 |

| 7 | 3 | 1 | 3 | 70.6 |

| 8 | 3 | 2 | 1 | 86.1 |

| 9 | 3 | 3 | 2 | 84.2 |

| K1 | 140.60 | 180.80 | 206.70 | |

| K2 | 193.40 | 194.10 | 189.50 | |

| K3 | 240.90 | 200.00 | 178.70 | |

| 1 | 46.87 | 60.27 | 68.90 | |

| 2 | 64.47 | 64.70 | 63.17 | |

| 3 | 80.30 | 66.67 | 59.57 | |

| R | 33.43 | 6.40 | 9.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Sun, M.; Luo, G. Enhanced Induction Heating and Self-Healing Properties of Steel Slag Powder Based Asphalt and Asphalt Mixture under Microwave Irradiation. Materials 2023, 16, 3312. https://doi.org/10.3390/ma16093312

Xu H, Sun M, Luo G. Enhanced Induction Heating and Self-Healing Properties of Steel Slag Powder Based Asphalt and Asphalt Mixture under Microwave Irradiation. Materials. 2023; 16(9):3312. https://doi.org/10.3390/ma16093312

Chicago/Turabian StyleXu, Hao, Mingzhi Sun, and Guobao Luo. 2023. "Enhanced Induction Heating and Self-Healing Properties of Steel Slag Powder Based Asphalt and Asphalt Mixture under Microwave Irradiation" Materials 16, no. 9: 3312. https://doi.org/10.3390/ma16093312

APA StyleXu, H., Sun, M., & Luo, G. (2023). Enhanced Induction Heating and Self-Healing Properties of Steel Slag Powder Based Asphalt and Asphalt Mixture under Microwave Irradiation. Materials, 16(9), 3312. https://doi.org/10.3390/ma16093312