Microwave Soldering of Low-Resistance Conductive Joints—Technical and Economic Aspects

Abstract

1. Introduction

2. Materials and Methods

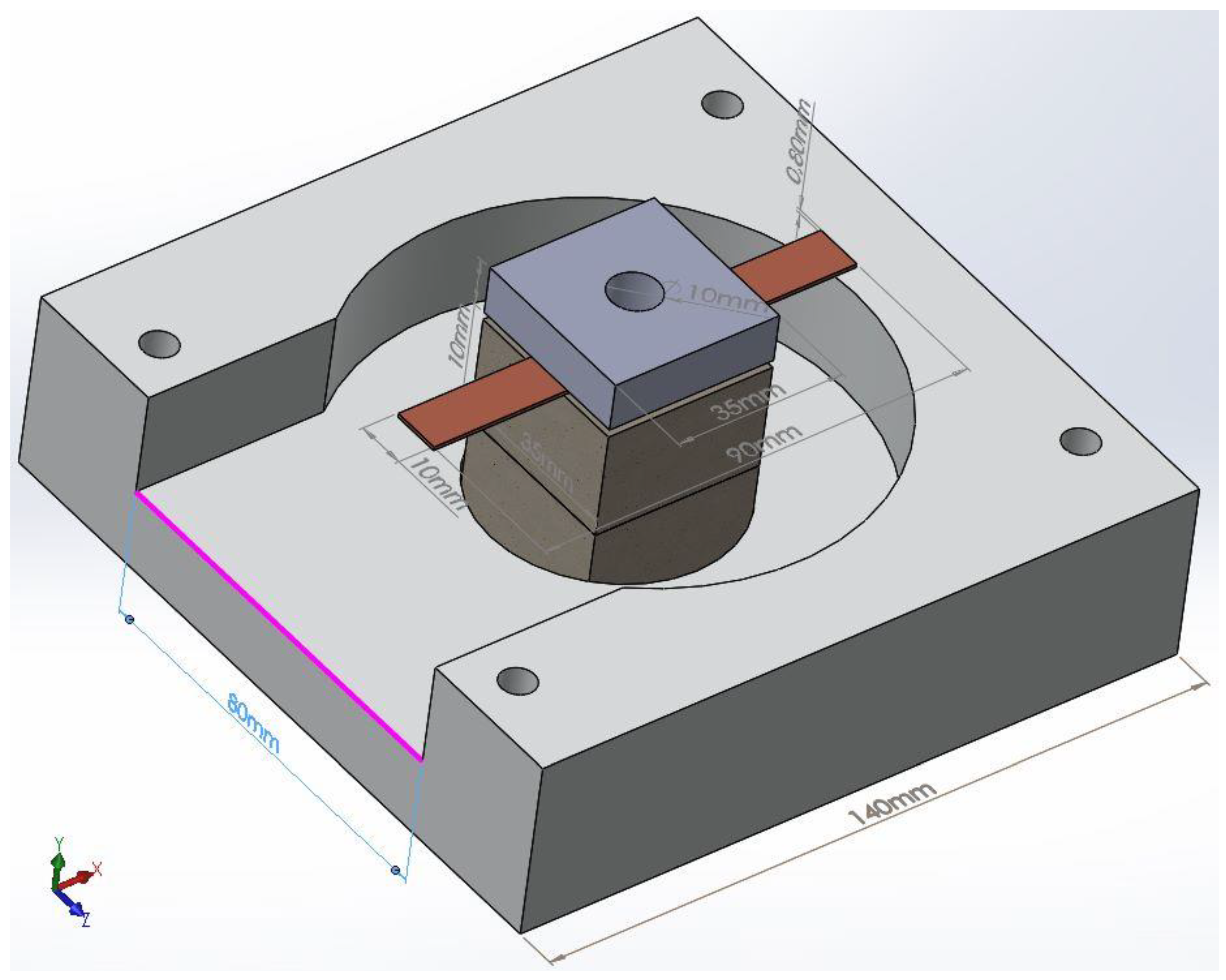

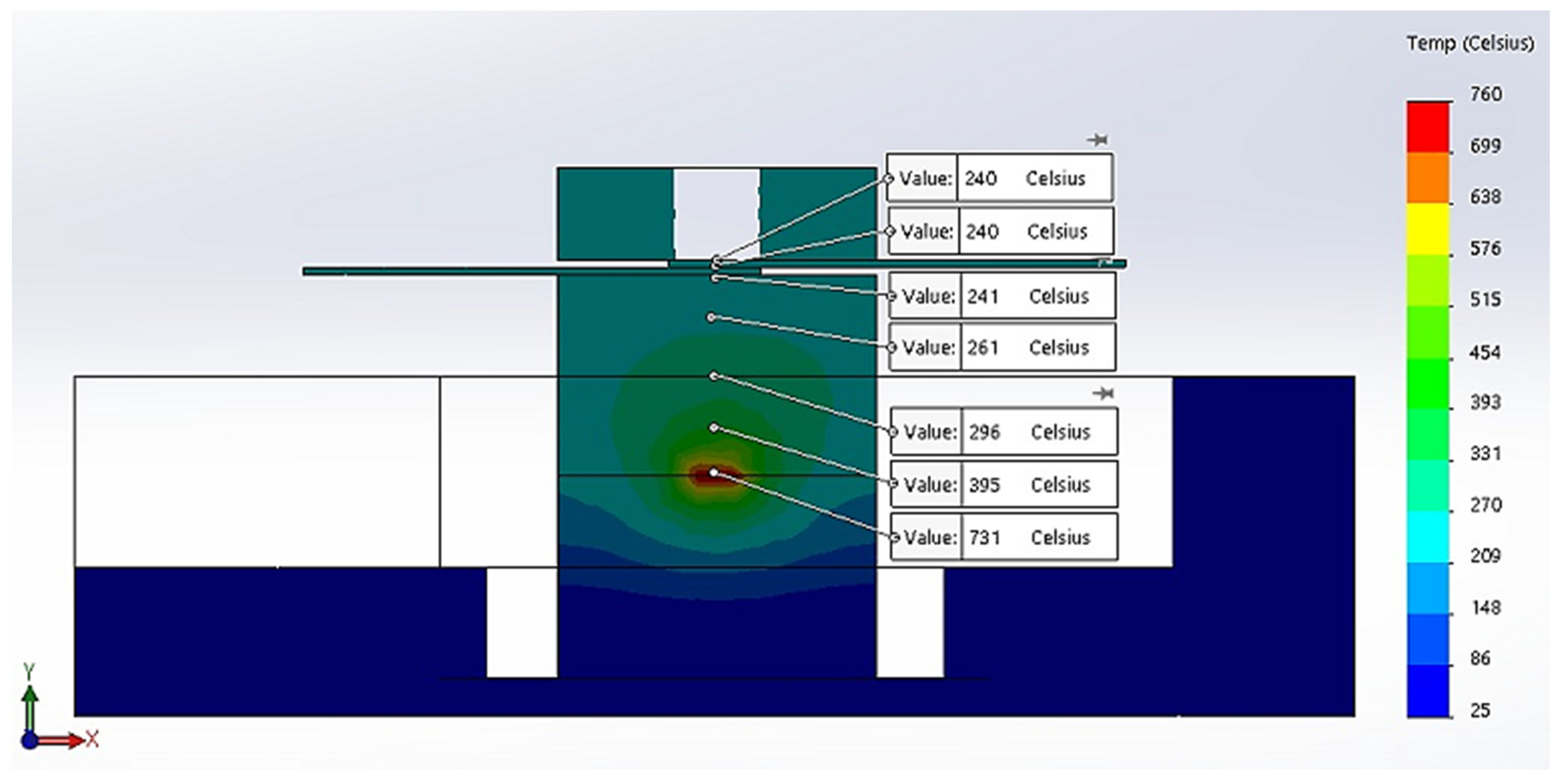

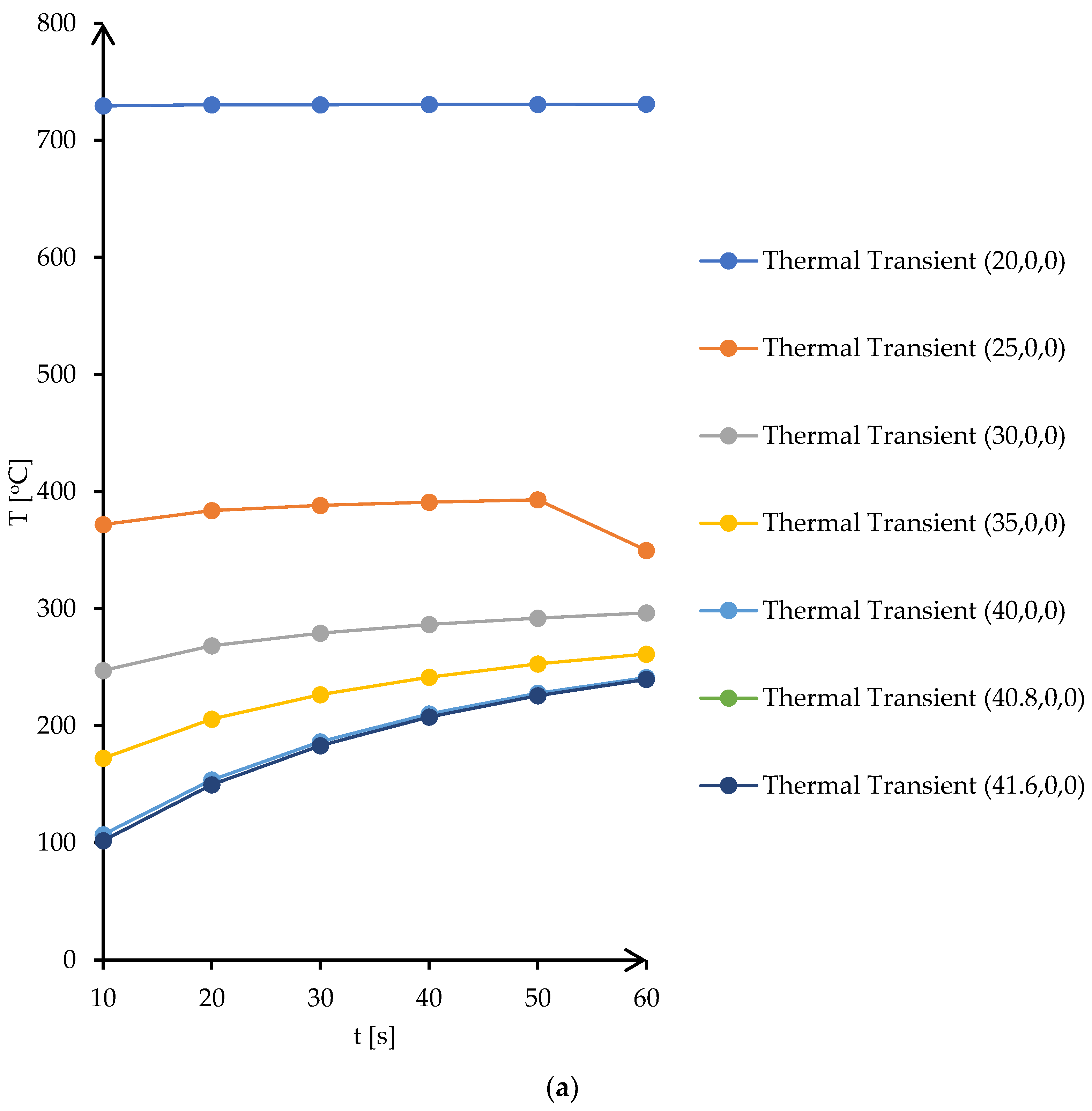

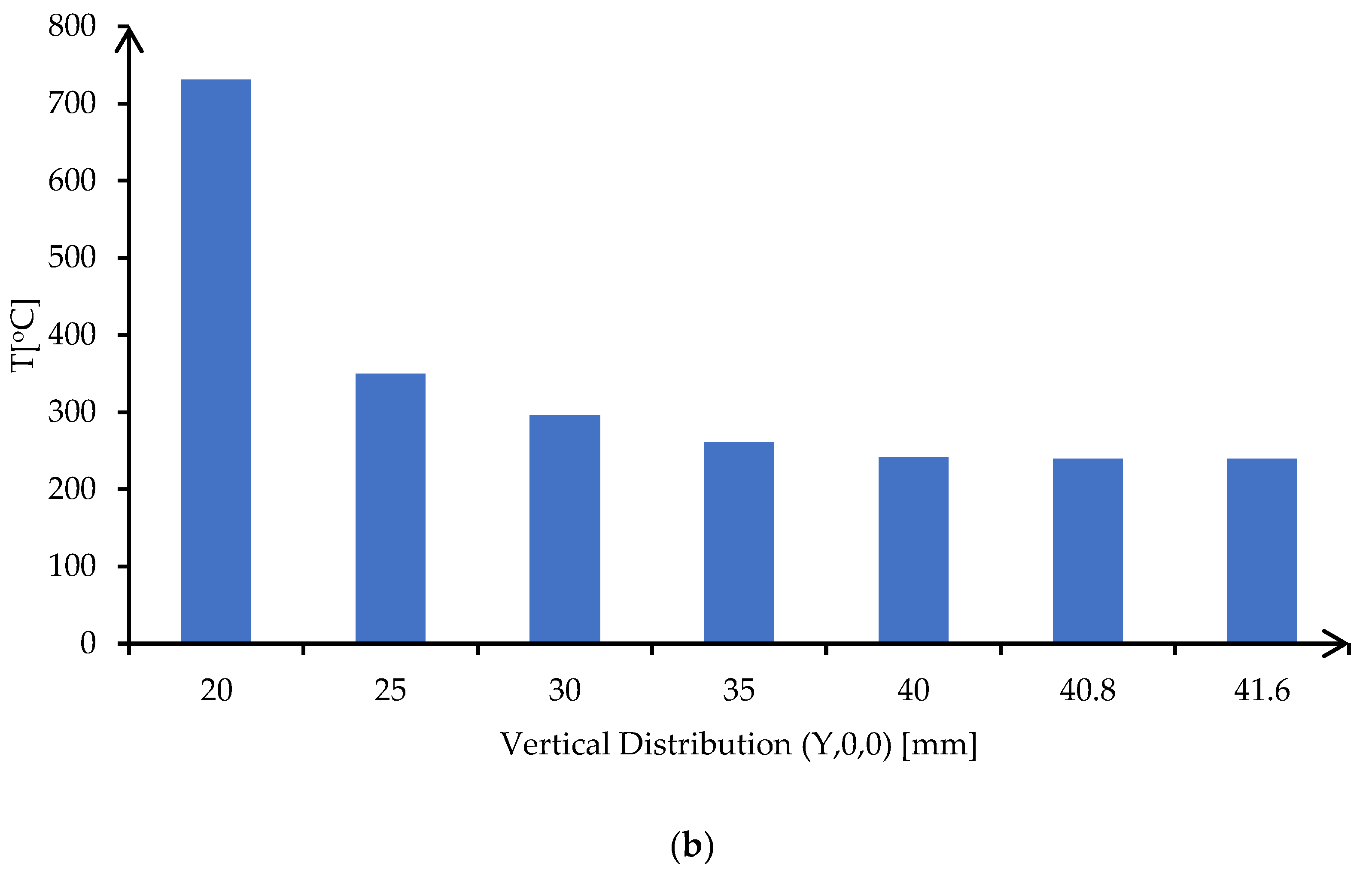

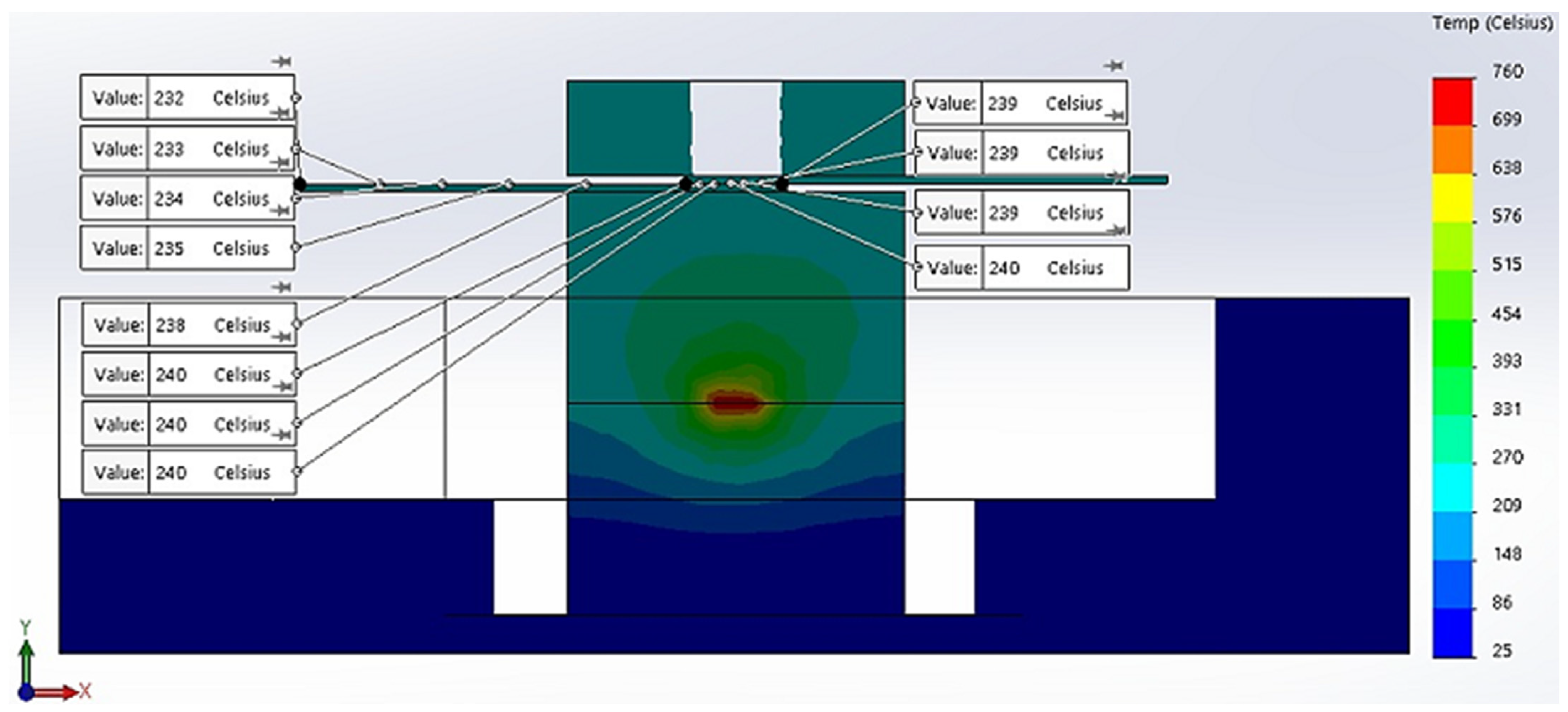

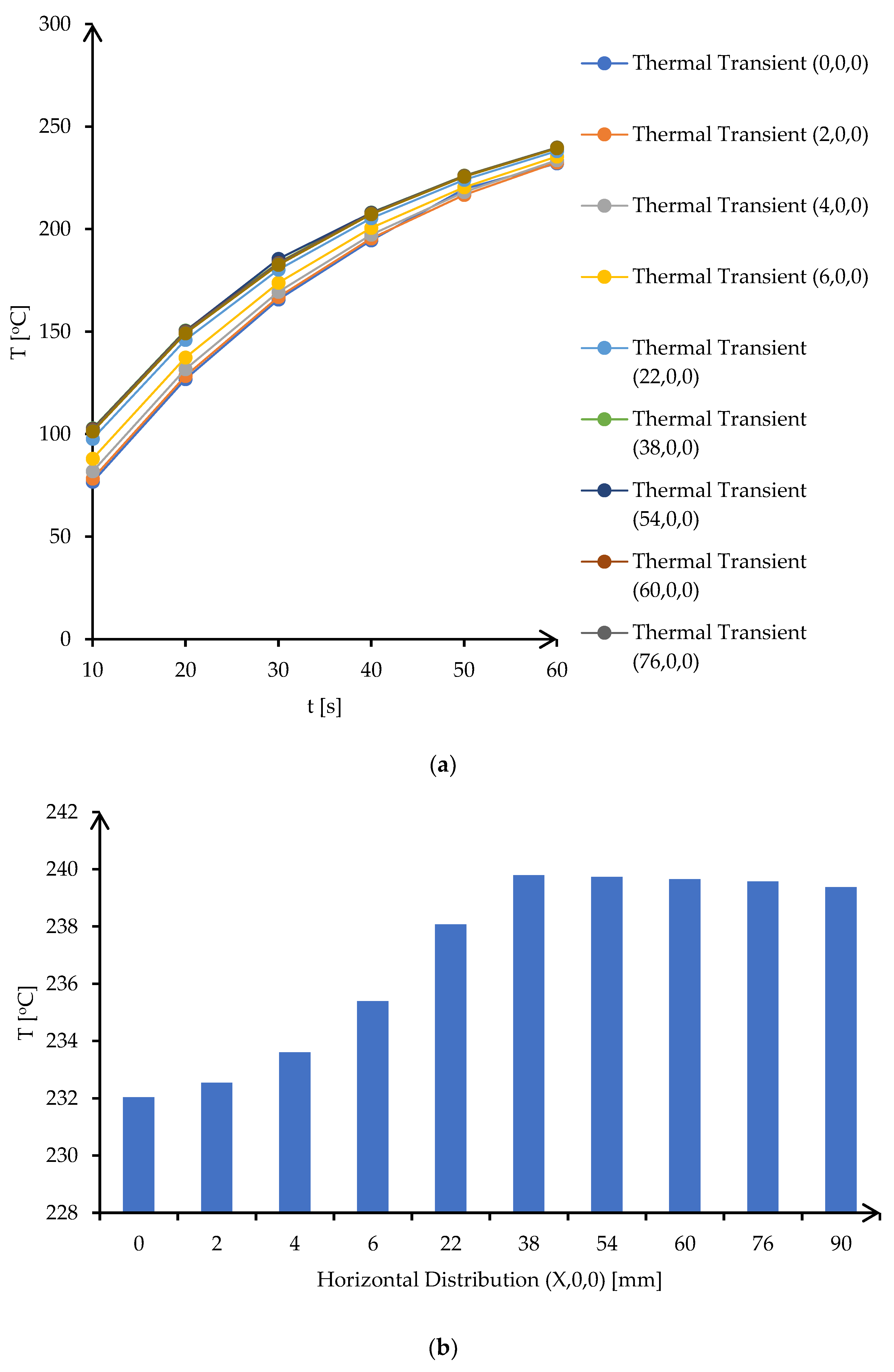

2.1. Simulation of the Thermal Field for Indirect Microwave Soldering

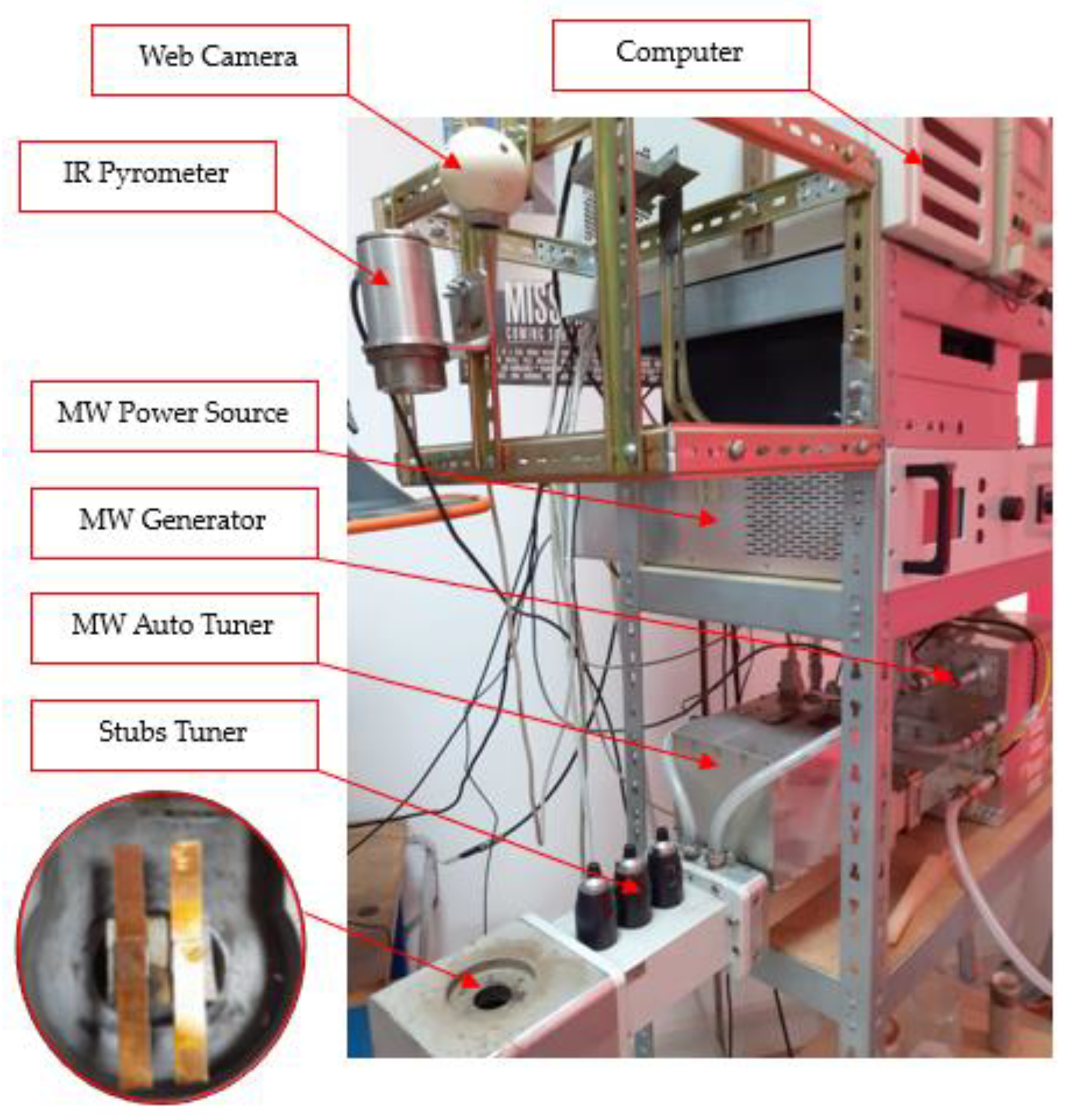

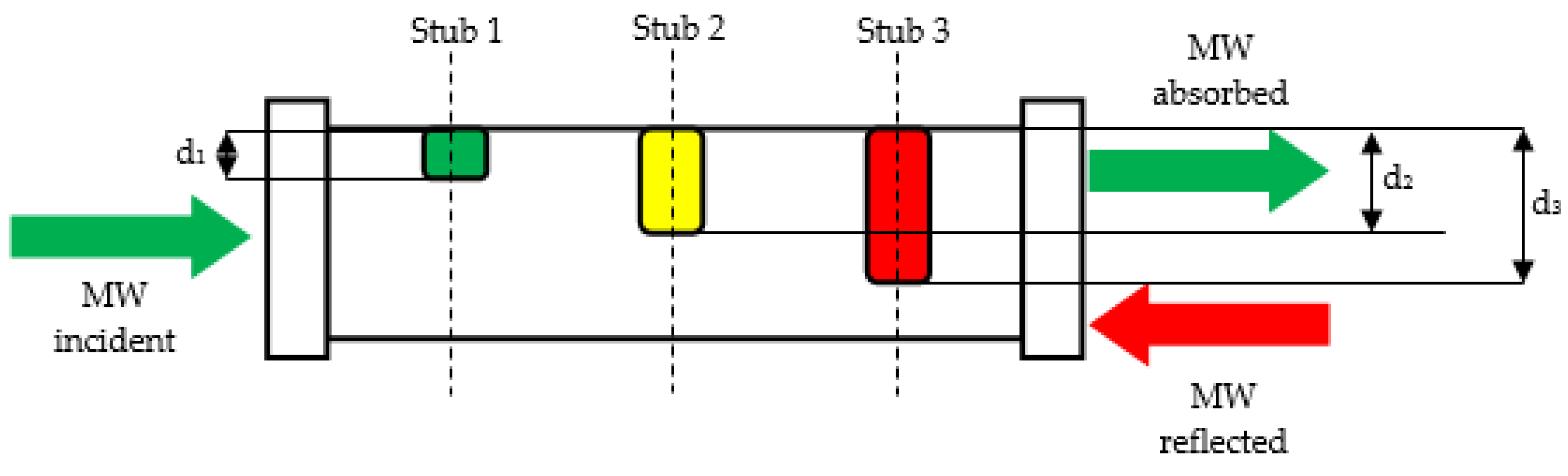

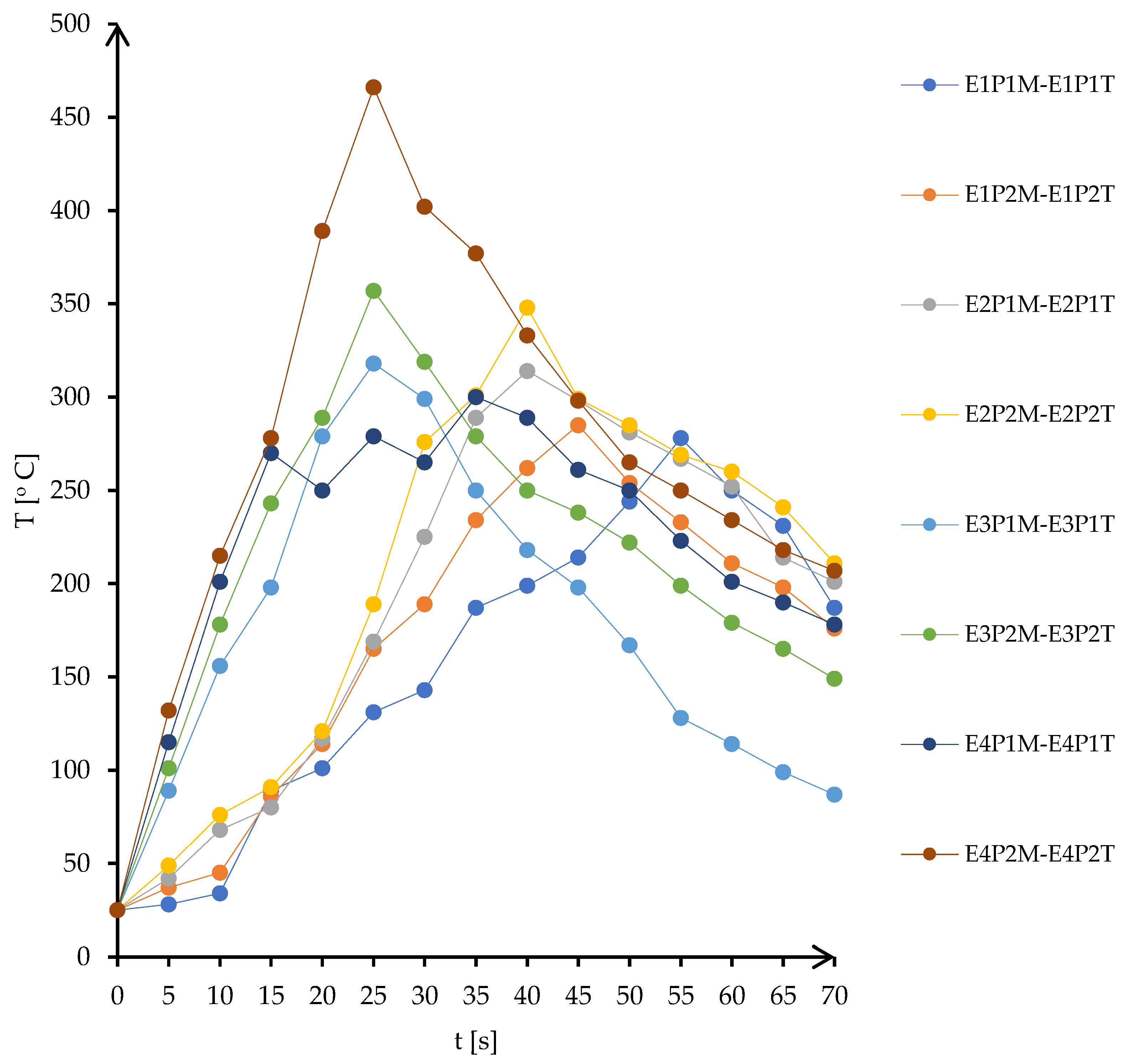

2.2. Indirect Microwave Soldering of Copper Plates

3. Results and Discussions

3.1. Electrical Resistance of Soldered Copper Plates

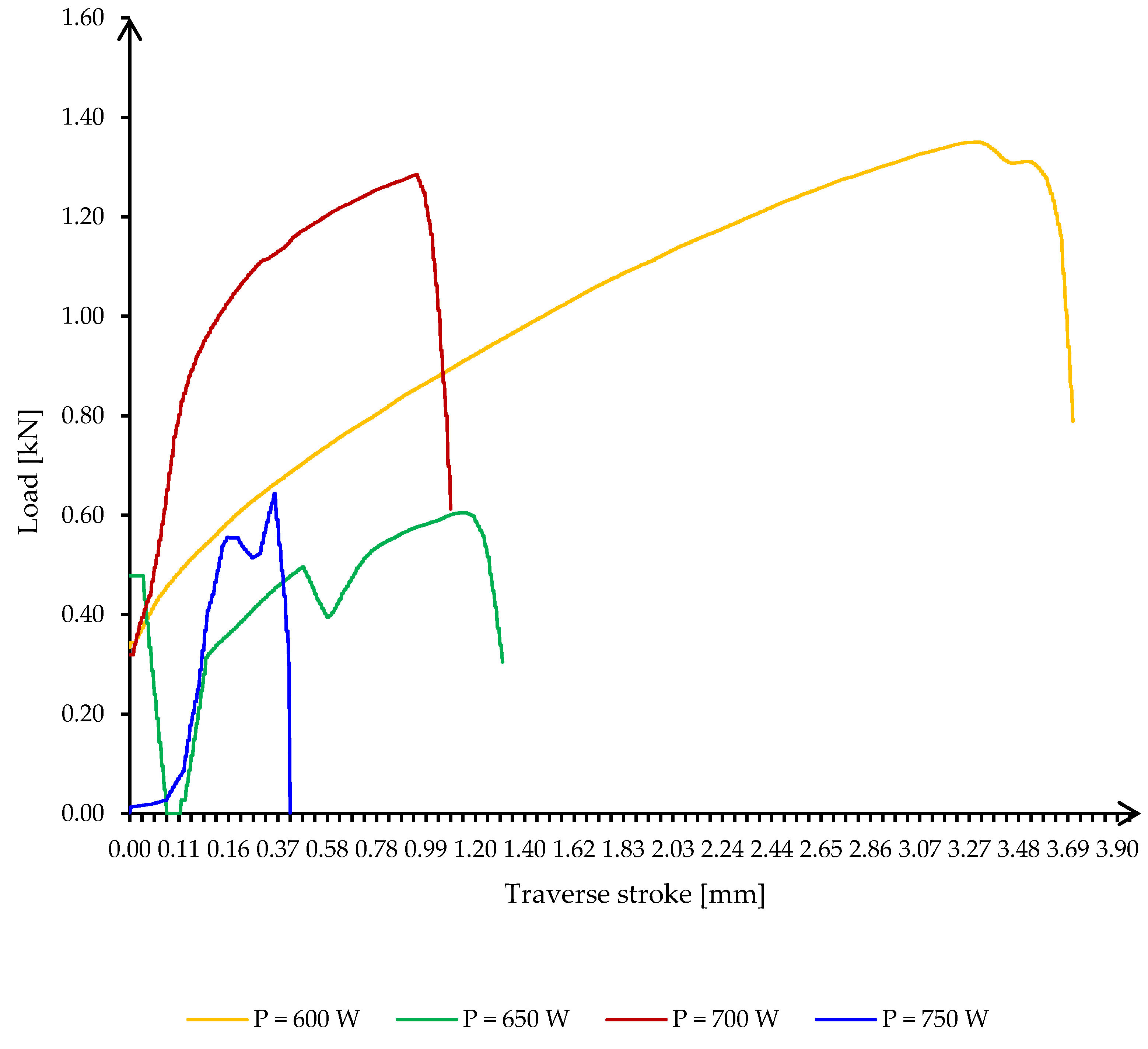

3.2. Evaluation of Tensile and Shear Characteristics of the Soldered Joints

- The general behavior during the mechanical tensile test of the two sets of samples is similar, an aspect confirmed by the appearances of the eight graphs (P1—4 graphs and P2—4 graphs).

- P1 samples show significantly lower maximum forces before breaking than P2 samples.

- The only noticeable difference is that in the case of the samples made with the power of 750 W where a P1 sample reaches the maximum force faster, but yields much more slowly, compared to a P2 sample which cracks suddenly, and the force drops to zero in 0.2 s.

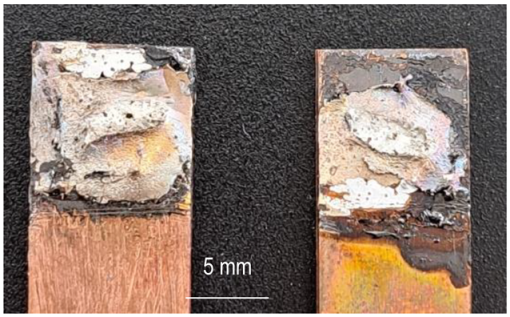

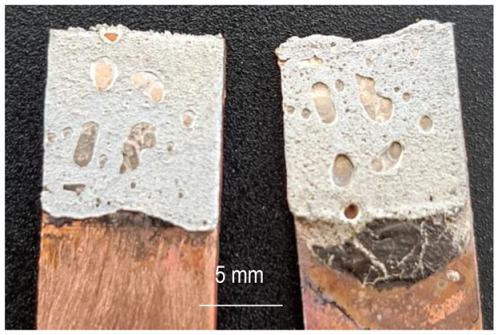

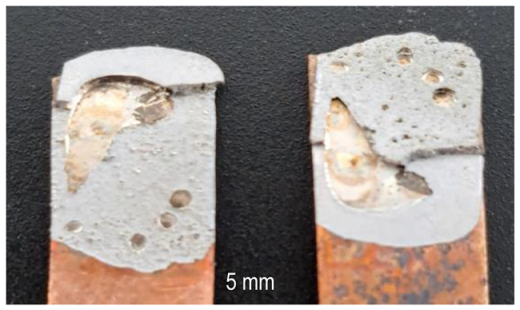

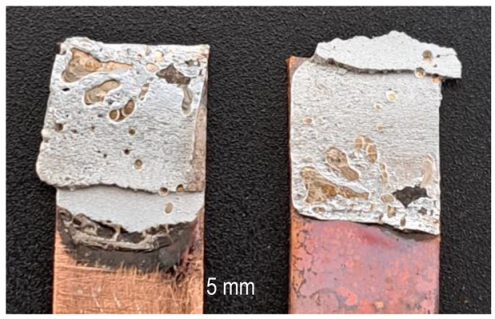

3.3. Macrographic Examination

3.4. Economical Sustainability of the Microwave Soldering Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, C.-M.; Lin, C.-M. Solder joint reliability of fine-pitch copper pillar bump by wave soldering. J. Electron. Packag. 2015, 137, 031010. [Google Scholar]

- Palcut, M.; Sopousek, J.; Trnková, L.; Hodulova, E.; Szewczyková, B.; Ozvold, M.; Turna, M.; Janovec, J. Thermal analysis of selected tin-based lead-free solder alloys. Kov. Mater. 2009, 47, 43–50. [Google Scholar]

- Liao, B.; Hong, W.; Weiping, X.; Yu, C.; Xingpeng, G. Recent advances in method of suppressing dendrite formation of tin-based solder alloys. J. Mater. Sci. Mater. Electron. 2020, 31, 13001–13010. [Google Scholar] [CrossRef]

- Sandeep, M.; Elviz, G.; Osterman, M.; Pecht, M. High lead solder (over 85%) solder in the electronics industry: RoHS exemptions and alternatives. J. Mater. Sci. Mater. Electron. 2015, 26, 4021–4030. [Google Scholar]

- Asyraf, A.; Siti, R.A.I. A review: Effect of copper percentage solder alloy after laser soldering. Solder. Surf. Mt. Technol. 2022; ahead of print. [Google Scholar]

- Savu, S.V.; Savu, I.D.; Benga, G.C.; Ciupitu, I. Improving functionality of Ti6Al4V by laser technology surfacing. Optoelectron. Adv. Mater.–Rapid Commun. 2016, 10, 752–760. [Google Scholar]

- Li, W.; Ding, Z.; Xue, H.; Guo, W.; Chen, C.; Jia, Y.; Wan, Z. Interfacial bonding mechanisms in ultrasonic-assisted soldered Si/Cu joint using Sn-3.5Ag-4Al solder. Mater. Charact. 2023, 199, 112833. [Google Scholar] [CrossRef]

- Shin, C.M.; Salleh, M.A.A.M.; Halin, D.S.C. Influence of thermal aging on Lead-Free Solder Joints Reliability: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012183. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Lin, H.-K.; Hsu, C.-C.; Chiu, Y.-C. Influence of soldering parameters on microstructure and mechanical properties of copper micro-solder joints. J. Electron. Mater. 2015, 44, 1264–1270. [Google Scholar]

- Metaxas, A.C. Microwave heating. Power Eng. 1991, 5, 237–247. [Google Scholar] [CrossRef]

- Sajjad, T.M.; Mohsen, B. Microwave absorption theory and recent advances in microwave absorbers by polymer-based nanocomposites (carbon, oxides, sulfides, metals and alloys). Inorg. Chem. Commun. 2023, 149, 110407. [Google Scholar]

- Liu, M.; Zhou, D.; Peng, Y.; Tang, Z.; Huang, K.; Hong, T. High-efficiency continuous-flow microwave heating system based on metal-ring resonant structure. Innov. Food Sci. Emerg. Technol. 2023, 85, 103330. [Google Scholar] [CrossRef]

- Jinyao, L.; Wei, T.; Yifan, L.; Baoshan, W.; Xian, J.; Longjiang, D. Achieving enhanced microwave absorption performance based on metal/covalent organic frameworks-derived heterostructures. Compos. Part B Eng. 2022, 245, 110199. [Google Scholar]

- Egorov, S.V.; Eremeev, A.G.; Kholoptsev, V.V.; Plotnikov, I.V.; Rybakov, K.I.; Sorokin, A.A.; Balabanov, S.S.; Rostokina, E.Y. Rapid sintering of barium titanate ceramics using direct susceptor-assisted microwave heating. Materialia 2022, 24, 101513. [Google Scholar] [CrossRef]

- Ozgur, S.C.; Levent, K.; Erhan, A.; Necip, S.C.; Alpagut, K.; Veronesi, P. Susceptor-assisted fast microwave sintering of TiN reinforced SiAlON composites in single mode cavity. Ceram. Int. 2021, 47, 825–835. [Google Scholar]

- Savu, S.V.; Tarnita, D.; Benga, G.C.; Dumitru, I.; Stefan, I.; Craciunoiu, N.; Olei, A.B.; Savu, I.D. Microwave technology using low energy concentrated beam for processing of solid waste materials from Rapana Thomasiana seashells. Energies 2021, 14, 6780. [Google Scholar] [CrossRef]

- You, X.; Zhang, Q.; Yang, J.; Dong, S. Review on 3D-printed graphene-reinforced composites for structural applications. Compos. Part A 2023, 167, 107420. [Google Scholar] [CrossRef]

- Kanti Das, T.; Bhawal, P.; Ganguly, S.; Mondal, S.; Remanan, S.; Ghosh, S.; Das, N. Synthesis of hydroxyapatite nanorods and its use as a nanoreinforcement block for ethylene methacrylate copolymer matrix. Polym. Bull. 2019, 76, 3621–3642. [Google Scholar]

- Menezes, R.R.; Souto, P.M.; Kiminami, R.H.G.A. Microwave fast sintering of ceramic materials. In Sintering of Ceramics—New Emerging Technologies; IntechOpen: Rijeka, Croatia, 2012; pp. 3–26. [Google Scholar]

- Stefan, I.; Savu, S.V.; Ghermec, O.; Nicolicescu, C.; Trotea, M. Research regarding the elaboration of barium hexaferrite from microwave heating. Solid State Phenom. 2012, 188, 369–375. [Google Scholar] [CrossRef]

- Mangra, G.I.; Savu, S.V.; Savu, I.D. Inductive sensor with sintered magnetic core to evaluate the performance of table tennis players. Mater. Sci. Forum 2011, 672, 105–108. [Google Scholar] [CrossRef]

- Jacinto, C.C.; Lacerda, L.A.; Tadeu, A. Coupling the BEM and analytical solutions for the numerical simulation of transient heat conduction in heterogeneous solid medium. Eng. Anal. Bound. Elem. 2021, 124, 110–123. [Google Scholar] [CrossRef]

- Oliveira, A.V.S.; Teixeira, J.; Schick, V.; Gradeck, M.; Denis, S. Using a linear inverse heat conduction model to estimate boundary heat flux with material undergoing phase transformation. Appl. Therm. Eng. 2023, 219 Pt A, 119406. [Google Scholar] [CrossRef]

- Engineering ToolBox. Solids, Liquids and Gases—Thermal Conductivities. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 15 February 2023).

- Engineering ToolBox. Specific Heat of Common Substances. Available online: https://www.engineeringtoolbox.com/specific-heat-capacity-d_391.html (accessed on 15 February 2023).

- Curet, S.; Rouaud, O.; Boilllereaux, L. Heat transfer model for microwave thawing applications. In Proceedings of the 13th Congress of Food Science and Technology, Nantes, France, 17–21 September 2006; pp. 1–6. [Google Scholar]

- Savu, S.V.; Marin, R.C.; David, A.; Olei, A.B.; Dumitru, I.; Tarnita, D.; Maternova, A.; Savu, I.D. Reducing NOx emissions through microwave heating of aftertreatment systems for sustainable transport in the inland waterway sector. Sustainability 2022, 14, 4156. [Google Scholar] [CrossRef]

- Garnault, T.; Bouvard, D.; Chaix, J.-M.; Marinel, S.; Harnois, C. Is direct microwave heating well suited for sintering ceramics? Ceram. Int. 2021, 47, 16716–16729. [Google Scholar] [CrossRef]

- Vriezinga, C.A.; Pedreno-Sanchez, S.; Grasman, J. Thermal Runaway in microwave heating: A mathematical analysis. Appl. Math. Model. 2002, 26, 1029–1038. [Google Scholar] [CrossRef]

- Savu, I.D.; Savu, S.V.; Benga, G.C. Thermal runaway of the BaCO3 + Fe2O3 homogenous mixture and mechanical alloys at the microwave heating. Adv. Mater. Res. 2014, 837, 185–189. [Google Scholar] [CrossRef]

- Wickham, M.; Nottay, J.; Hunt, C. A Review of Mechanical Test Method Standards for Lead-Free Solders; NPL Report MATC(A)69; National Physical Laboratory: Teddington, UK, 2002. [Google Scholar]

- Tada, N.; Tanaka, T.; Uemori, T.; Nakata, T. Evaluation of Thin Copper Wire and Lead-Free Solder Joint Strength by Pullout Tests and Wire Surface Observation. Crystals 2017, 7, 255. [Google Scholar] [CrossRef]

- Tada, N.; Masago, H. Evaluation of Tensile Strength of Copper-Cored Lead-Free Solder Joints in Air, Distilled Water, and NaCl Solution using Testing Device with Permanent Magnets. In Proceedings of the 2014 9th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 22–24 October 2020; pp. 92–95. [Google Scholar]

- Tsurusaki, T.; Ohgai, T. Mechanical Properties of Solder-Jointed Copper Rods with Electrodeposited Sn-Zn Alloy Films. Materials 2020, 13, 1330. [Google Scholar] [CrossRef]

- Visniakov, N.; Novickij, J.; Ščekaturovienė, D.; Petrauskas, A. Quality Analysis of Welded and Soldered Joints of Cu-Nb Microcomposite Wires. Mater. Sci. 2011, 7, 16–19. [Google Scholar] [CrossRef]

- Kolenak, R.; Kostolny, I.; Drapala, J.; Babincova, P.; Gogola, P. Characterization of Soldering Alloy Type Bi-Ag-Ti and the Study of Ultrasonic Soldering of Silicon and Copper. Metals 2021, 11, 624. [Google Scholar] [CrossRef]

- Eurostat. Hourly Compensation of Employees in EU Regions—Products Eurostat News—Eurostat. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/DDN-20190322-1 (accessed on 10 March 2023).

- Eurostat. Electricity Prices (Including Taxes) for Household Consumers, First Half 2022. Electricity Price Statistics—Statistics Explained. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20221031-1 (accessed on 10 March 2023).

| Code | Ri (Ω) | Wi (mm) | RiS1 (Ω) | WS1+SAC305 (mm) | RiS2 [Ω] | WS2+SAC305 [mm] |

|---|---|---|---|---|---|---|

| PMW = 600 W | ||||||

| E1P1T | 0.0400 | 0.8 | 0.0200 | 1.68 | 0.0200 | 0.8 |

| E1P1M | 0.0400 | 0.8 | 0.0200 | 1.73 | 0.0200 | 0.8 |

| E1P2T | 0.0400 | 0.8 | 0.0200 | 1.50 | 0.0200 | 1.59 |

| E1P2M | 0.0400 | 0.8 | 0.0200 | 1.71 | 0.0200 | 1.69 |

| PMW = 650 W | ||||||

| E2P1T | 0.0400 | 0.8 | 0.0200 | 1.53 | 0.0200 | 0.8 |

| E2P1M | 0.0400 | 0.8 | 0.0200 | 1.67 | 0.0200 | 0.8 |

| E2P2T | 0.0400 | 0.8 | 0.0200 | 1.51 | 0.0200 | 1.55 |

| E2P2M | 0.0400 | 0.8 | 0.0200 | 1.65 | 0.0200 | 1.65 |

| PMW = 700 W | ||||||

| E3P1T | 0.0400 | 0.8 | 0.0200 | 1.41 | 0.0200 | 0.8 |

| E3P1M | 0.0400 | 0.8 | 0.0200 | 1.40 | 0.0200 | 0.8 |

| E3P2T | 0.0400 | 0.8 | 0.0200 | 1.33 | 0.0200 | 1.34 |

| E3P2M | 0.0400 | 0.8 | 0.0200 | 1.44 | 0.0200 | 1.25 |

| PMW = 750 W | ||||||

| E4P1T | 0.0400 | 0.8 | 0.0200 | 1.45 | 0.0200 | 0.8 |

| E4P1M | 0.0400 | 0.8 | 0.0200 | 1.27 | 0.0200 | 0.8 |

| E4P2T | 0.0400 | 0.8 | 0.0200 | 1.43 | 0.0200 | 1.46 |

| E4P2M | 0.0400 | 0.8 | 0.0200 | 1.47 | 0.0200 | 1.43 |

| Code | Ri (Ω) | Rw (Ω) | Ww (mm) | ε (%) |

|---|---|---|---|---|

| E1P1T | 0.0400 | 0.0398 | 1.89 | 0.5 |

| E1P1M | 0.0400 | 0.0403 | 2.11 | 0.75 |

| E1P2T | 0.0400 | 0.0396 | 1.81 | 1 |

| E1P2M | 0.0400 | 0.0397 | 1.81 | 0.75 |

| E2P1T | 0.0400 | 0.0400 | 2.59 | 0 |

| E2P1M | 0.0400 | 0.0402 | 1.84 | 0.5 |

| E2P2T | 0.0400 | 0.0404 | 2.74 | 1 |

| E2P2M | 0.0400 | 0.0401 | 1.74 | 0.25 |

| E3P1T | 0.0400 | 0.0398 | 1.72 | 0.5 |

| E3P1M | 0.0400 | 0.0400 | 1.64 | 0 |

| E3P2T | 0.0400 | 0.0396 | 2.22 | 1 |

| E3P2M | 0.0400 | 0.0397 | 2.25 | 0.75 |

| E4P1T | 0.0400 | 0.0397 | 1.90 | 0.75 |

| E4P1M | 0.0400 | 0.0397 | 1.86 | 0.75 |

| E4P2T | 0.0400 | 0.0397 | 1.80 | 0.75 |

| E4P2M | 0.0400 | 0.0394 | 3.67 | 1.5 |

| MW Power (W) | One Side Deposited Solder (P1) | Double-Side Deposited Solder (P2) |

|---|---|---|

| 600 |  |  |

| 650 |  |  |

| 700 |  |  |

| 750 |  |  |

| One Side Deposited Solder (P1) | Double-Side Deposited Solder (P2) |

|---|---|

|  |

|  |

| Soldering Process | Energy (EUR) | Personnel (EUR) | Total (EUR) |

|---|---|---|---|

| MS (1 sample) | 0.0010 | 1.9166 | 1.9176 |

| MWS (100 samples) | 0.0026 | 0.3833 | 0.3859 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savu, S.V.; Ghelsingher, C.D.; Stefan, I.; Sîrbu, N.-A.; Tarniță, D.; Simion, D.; Savu, I.D.; Bucșe, I.G.; Țunescu, T. Microwave Soldering of Low-Resistance Conductive Joints—Technical and Economic Aspects. Materials 2023, 16, 3311. https://doi.org/10.3390/ma16093311

Savu SV, Ghelsingher CD, Stefan I, Sîrbu N-A, Tarniță D, Simion D, Savu ID, Bucșe IG, Țunescu T. Microwave Soldering of Low-Resistance Conductive Joints—Technical and Economic Aspects. Materials. 2023; 16(9):3311. https://doi.org/10.3390/ma16093311

Chicago/Turabian StyleSavu, Sorin Vasile, Cristian Daniel Ghelsingher, Iulian Stefan, Nicusor-Alin Sîrbu, Daniela Tarniță, Dalia Simion, Ionel Dănuț Savu, Ionela Gabriela Bucșe, and Traian Țunescu. 2023. "Microwave Soldering of Low-Resistance Conductive Joints—Technical and Economic Aspects" Materials 16, no. 9: 3311. https://doi.org/10.3390/ma16093311

APA StyleSavu, S. V., Ghelsingher, C. D., Stefan, I., Sîrbu, N.-A., Tarniță, D., Simion, D., Savu, I. D., Bucșe, I. G., & Țunescu, T. (2023). Microwave Soldering of Low-Resistance Conductive Joints—Technical and Economic Aspects. Materials, 16(9), 3311. https://doi.org/10.3390/ma16093311