Synthesis and Evaluation of Engineering Properties of Polymer-Coated Glass Beads

Abstract

1. Introduction

2. Experimental Program

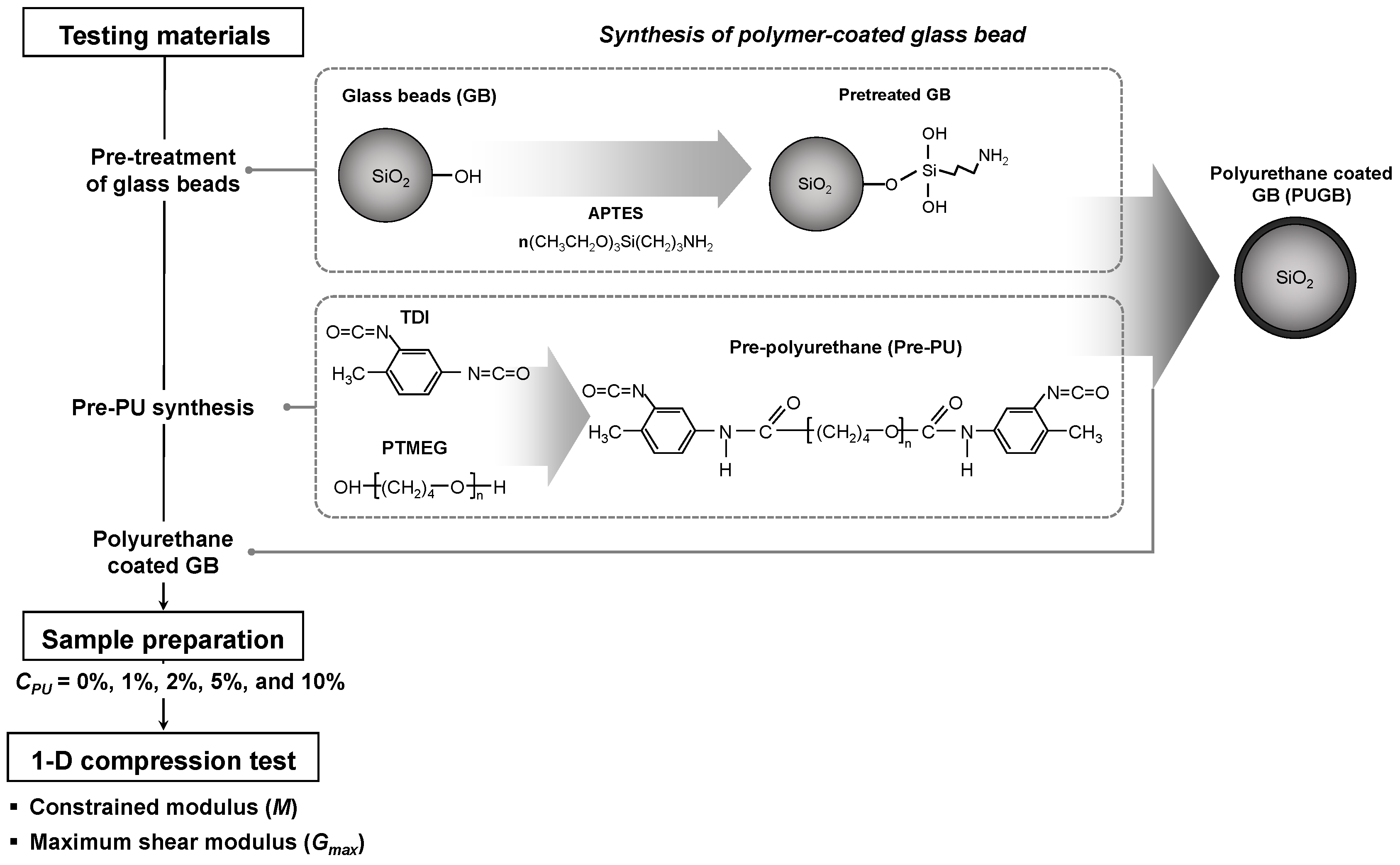

2.1. Testing Materials

2.2. Synthesis of Polyurethane-Coated Glass Bead (PUGB)

2.3. Sample Preparation and Experimental Procedure

3. Experimental Results

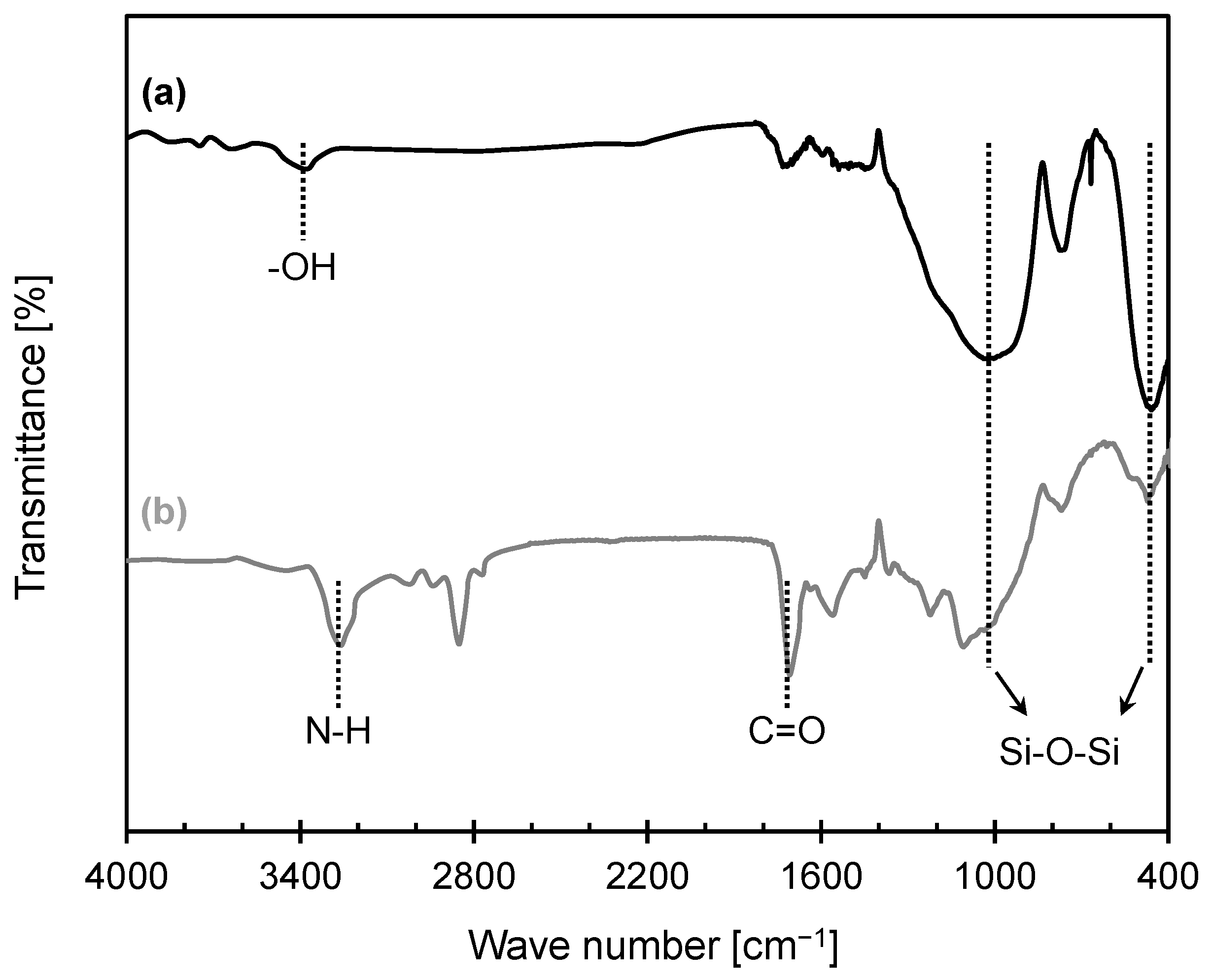

3.1. Analysis of Chemical Structure

3.2. Microstructure Observation

3.3. Variation of Extreme Void Ratios

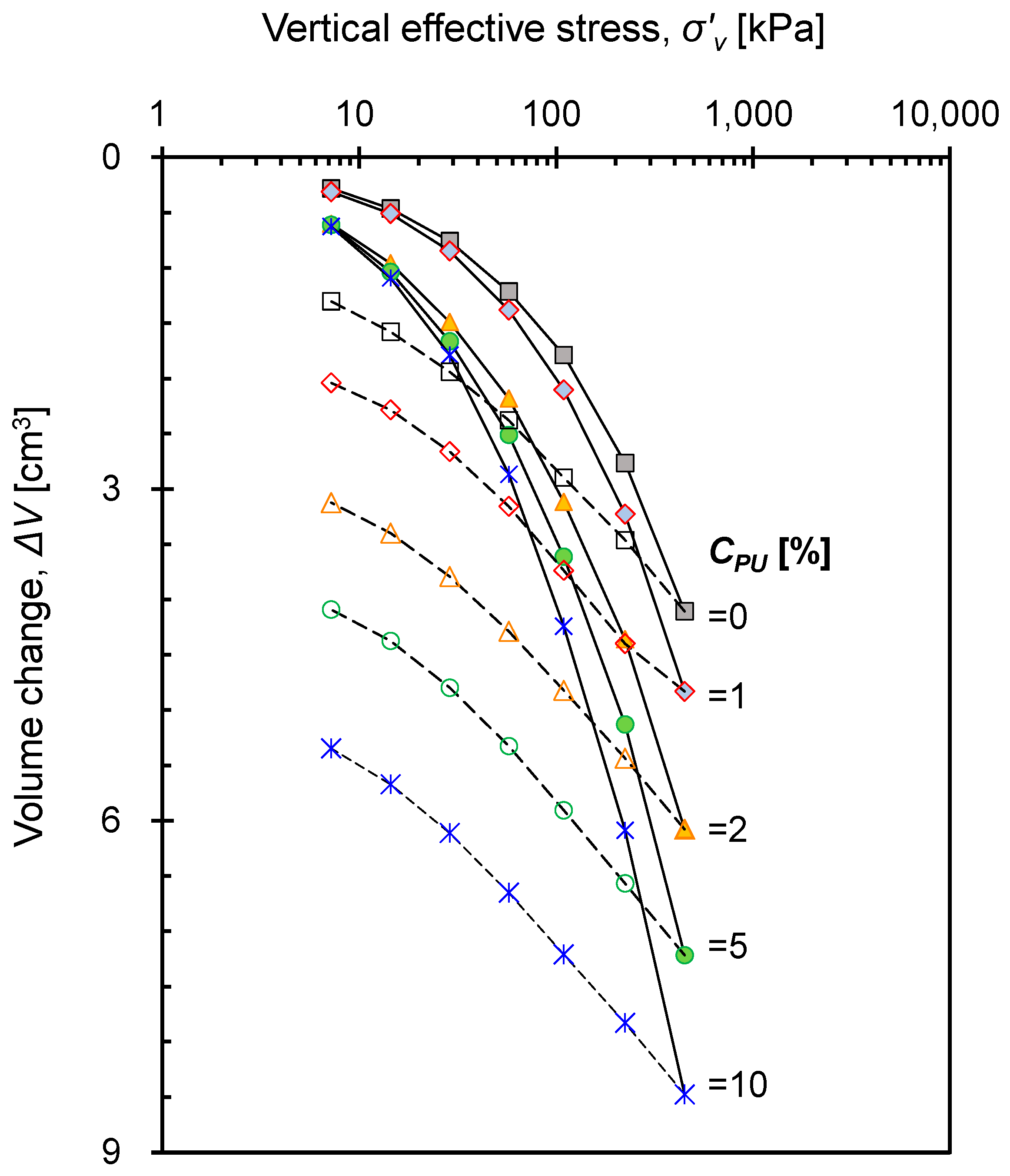

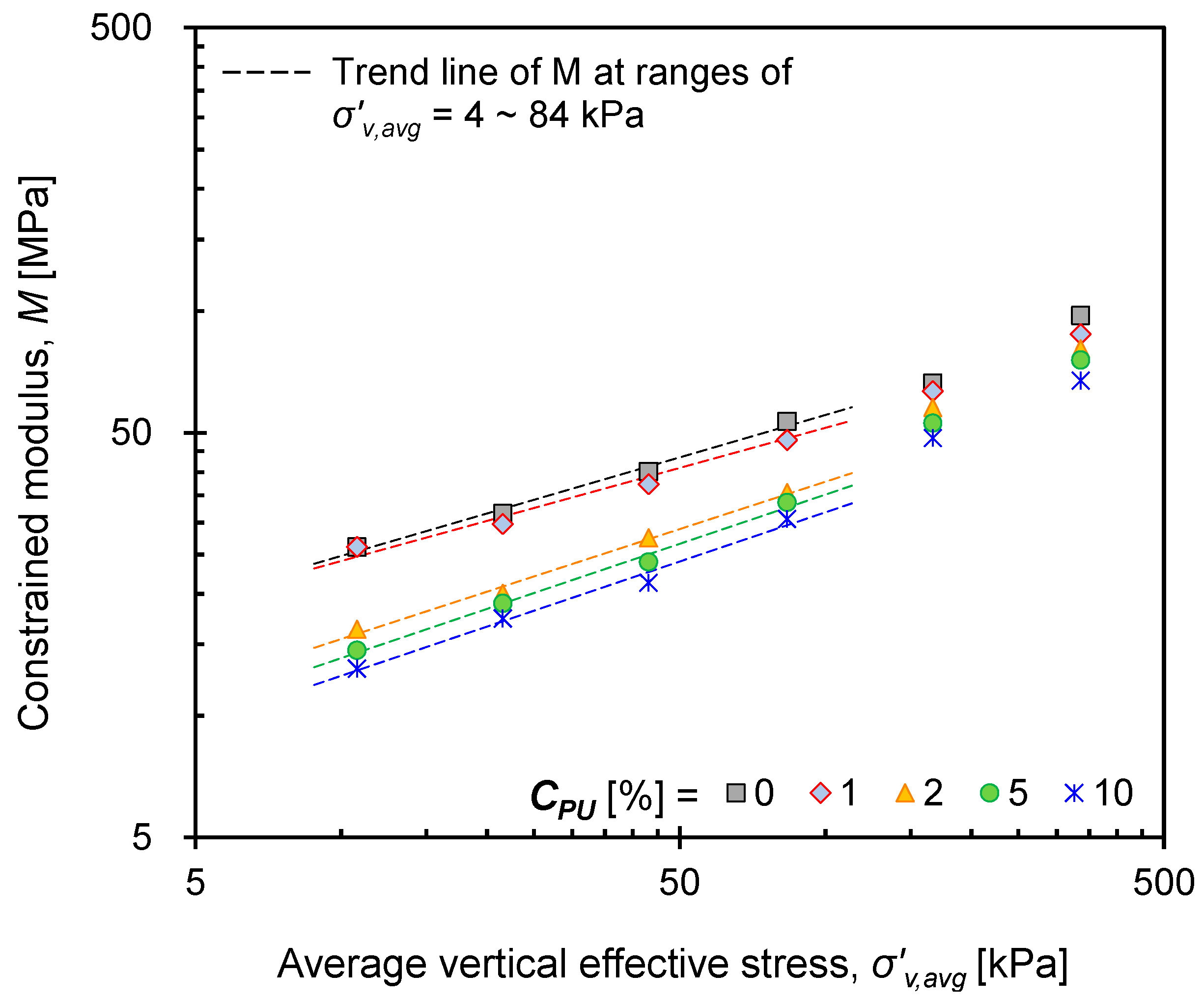

3.4. Vertical Compressibility at Zero-Lateral Strain

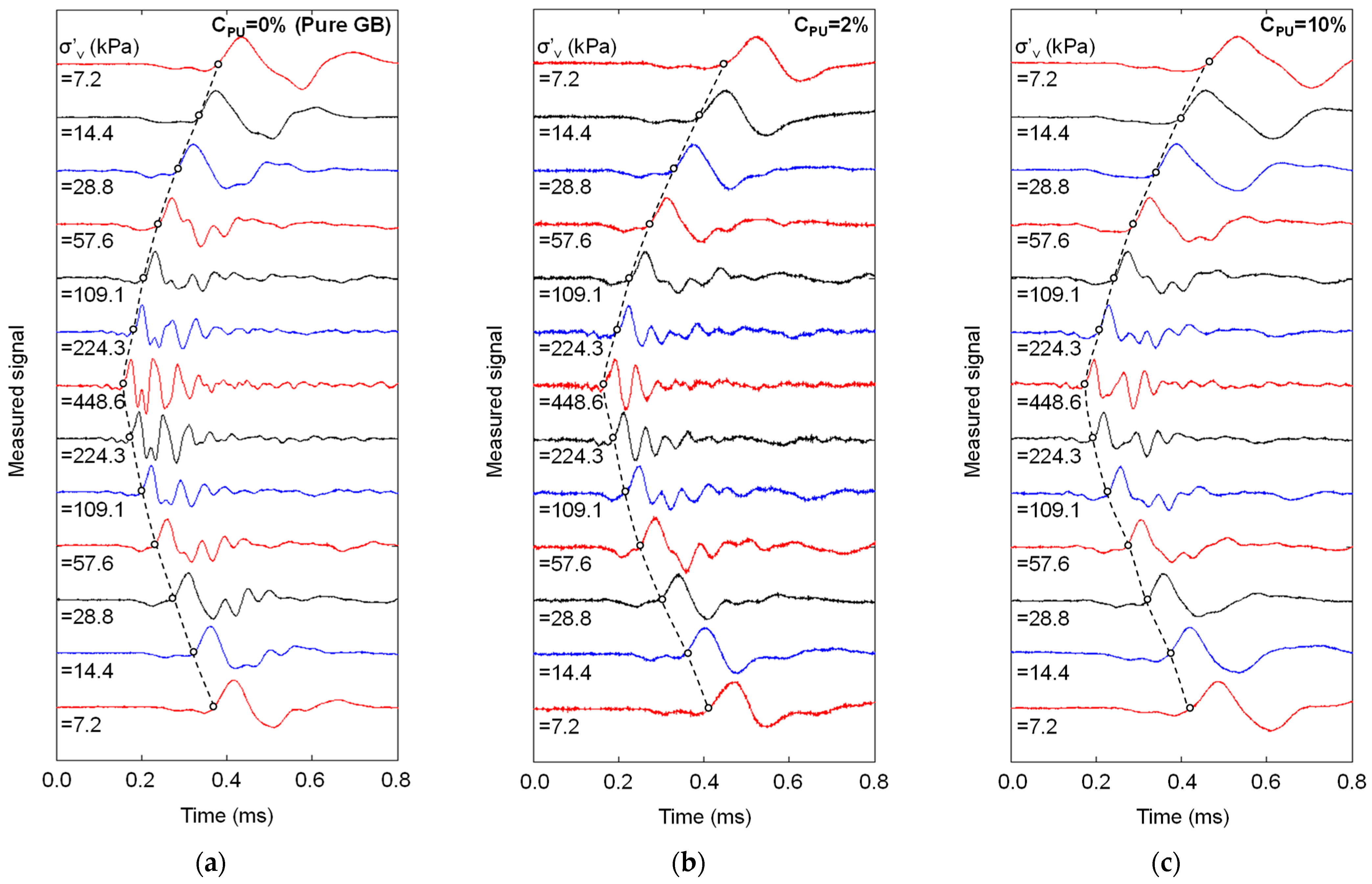

3.5. Shear Wave Velocity Vs

4. Discussion

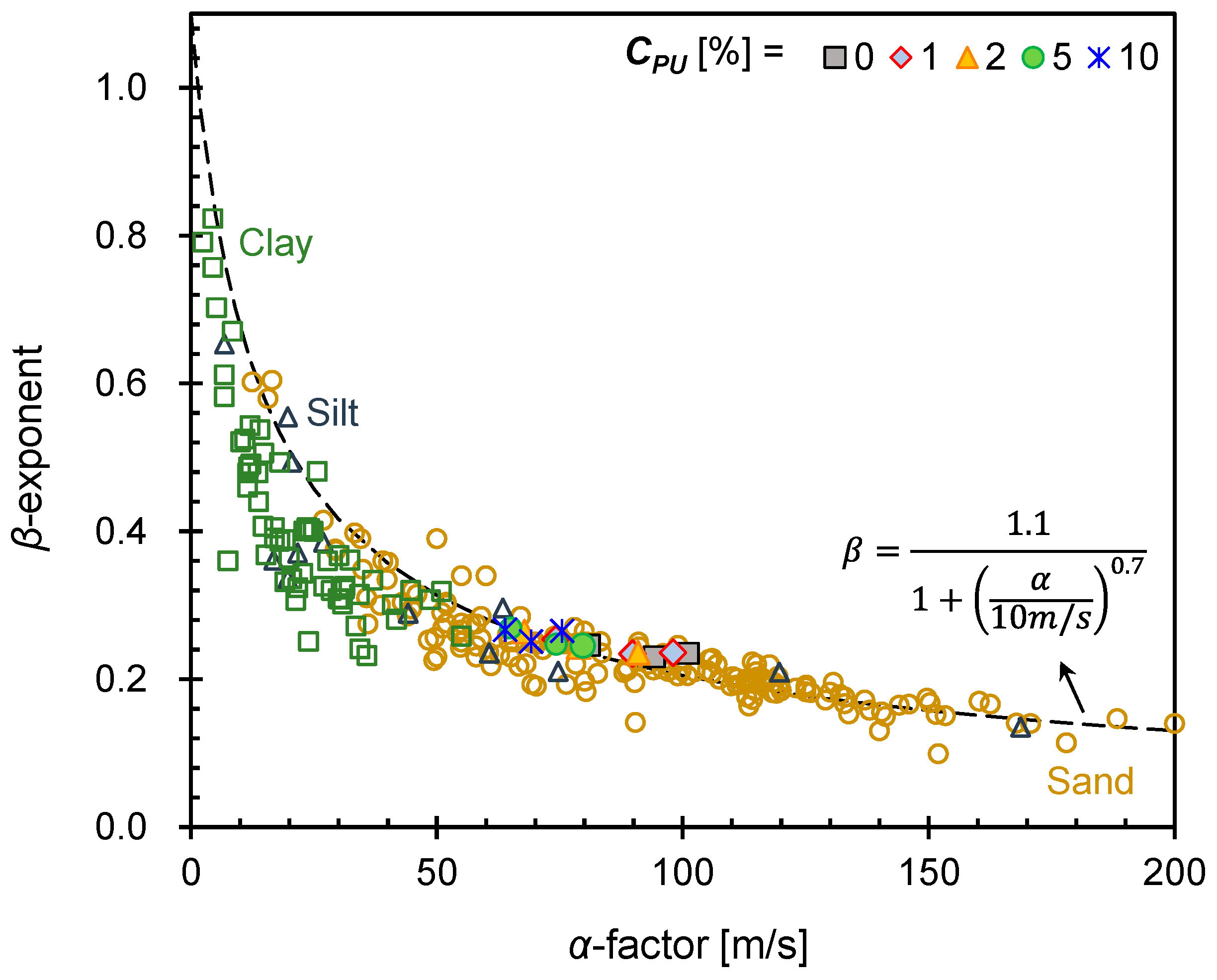

4.1. Relationship between α and β

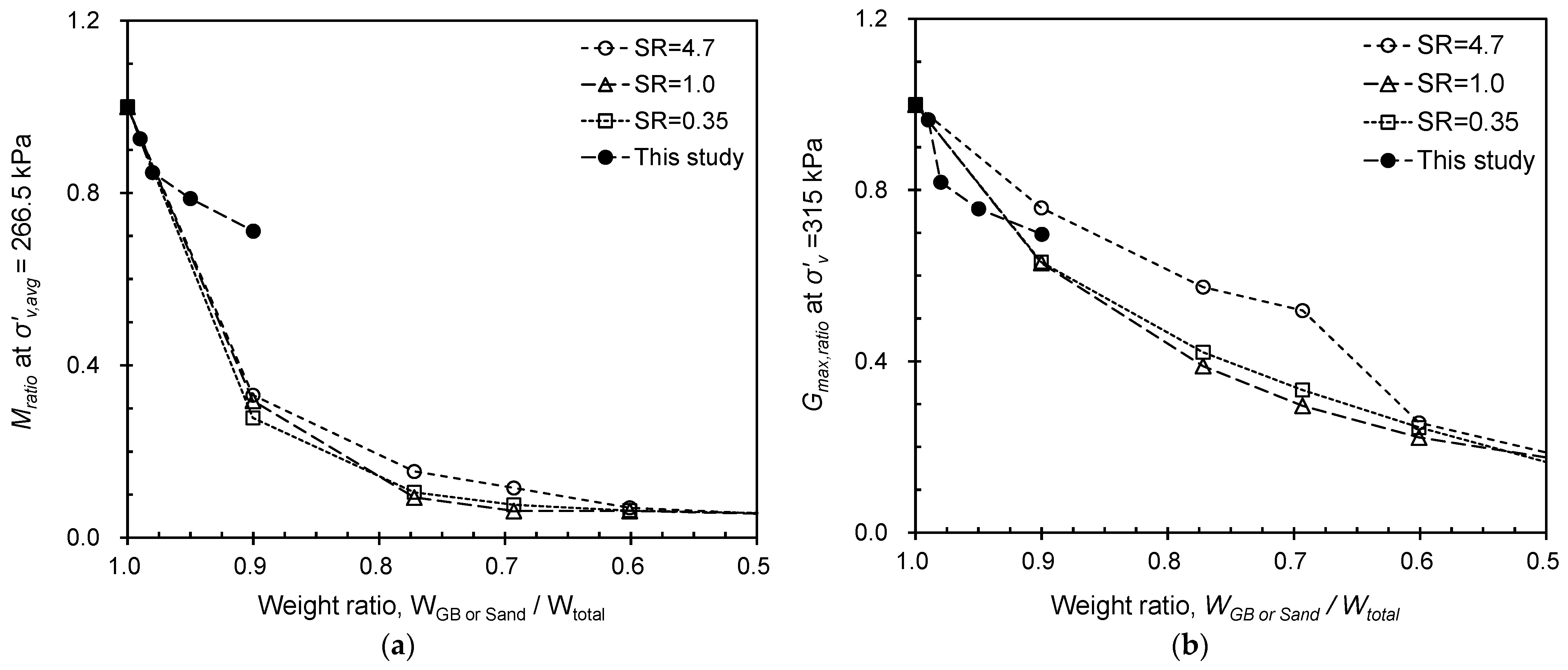

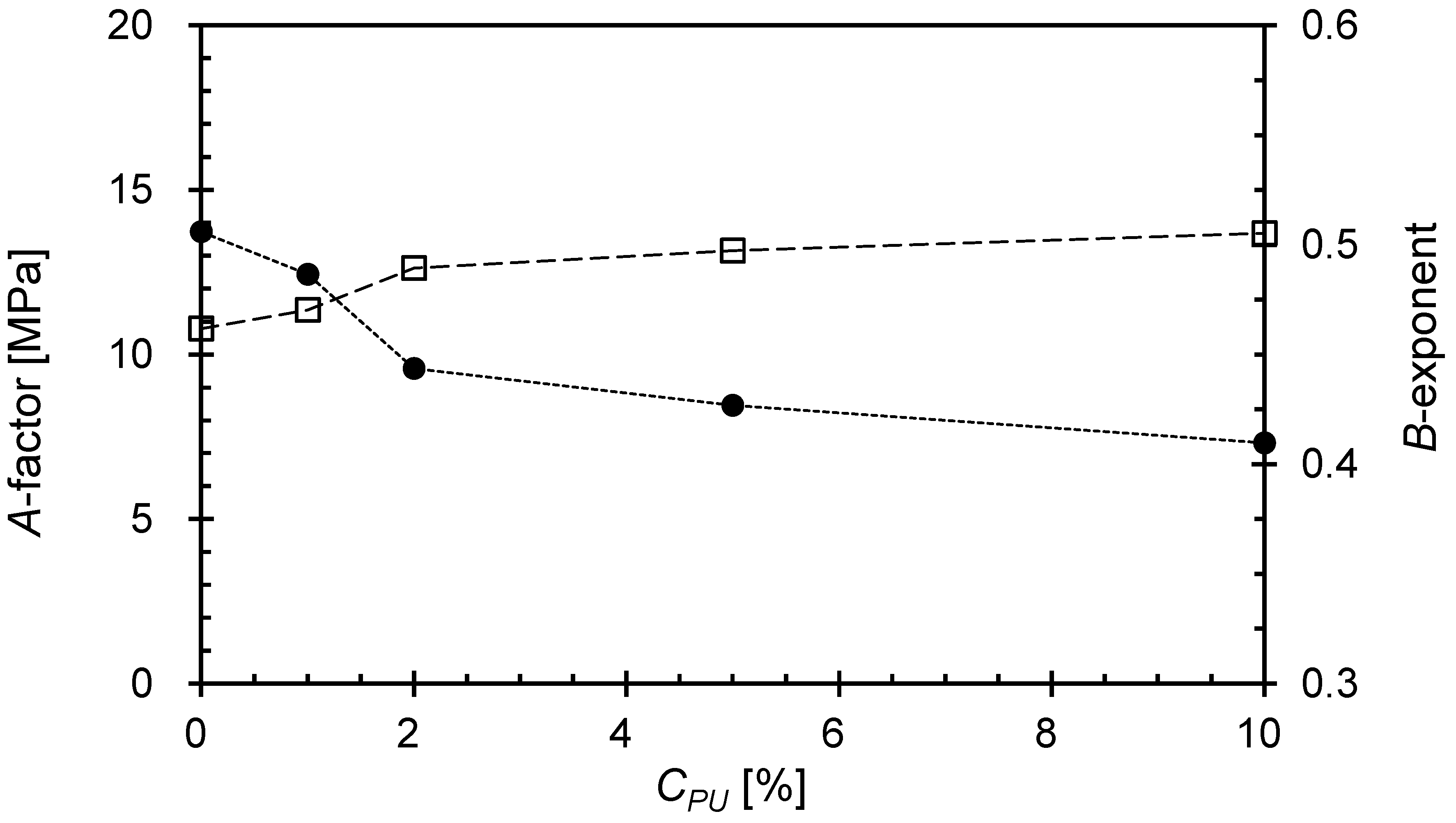

4.2. Variation and Transition Behavior of M and Gmax with CPU

4.3. Potential Use of Surface-Modified Materials as Geotechnical Materials

5. Conclusions

- (1)

- Polymer coating on the GB surface reduced the surface roughness, increasing the contact area of the particles as the CPU increased. The intrinsic adhesion of the polymer increased the maximum void ratio of PUGB-GB mixtures. However, the minimum void ratios of the mixtures showed negligible changes with CPU because the adhesion could not withstand the stress applied during the vibration table test.

- (2)

- Lower constrained modulus (M) was observed for the PUGB-GB mixture with higher CPU as the vertical deformation increased due to an increase in the initial void ratio of the mixture and a decrease in surface roughness.

- (3)

- The shear wave velocity (Vs) of the mixtures decreased with CPU because coated polymer reduced the contact stiffness between particles.

- (4)

- The critical CPU, at which the PUGB particles start to become involved in the load-carrying skeleton of the mixture, was found to be ~2%. This finding was also confirmed by the A-factor and B-exponent values, which describe the measured state of the maximum shear modulus (Gmax), which are also found to vary significantly at CPU = ~2%.

- (5)

- The stress- and strain- dependent behavior of the PUGB-GB mixture is demonstrated by comparing the evolution of modulus, where the trends of M exhibit changes at certain average stress, while variation trends of Gmax remain constant over the ranges of applied stress.

- (6)

- Comparing the behavior of PUGB-GB mixtures and the rubber-sand mixtures, it can be seen that the introduction of PUGB particles leads to a smaller M reduction with a similar Gmax of the mixture compared to rubber.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Susilorini, R.M.I.R.; Hardjasaputra, H.; Tudjono, S.; Hapsari, G.; Wahyu, S.R.; Hadikusumo, G.; Sucipto, J. The Advantage of Natural Polymer Modified Mortar with Seaweed: Green Construction Material Innovation for Sustainable Concrete. Procedia Eng. 2014, 95, 419–425. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Soliman, A.; Hafeez, G.; Erkmen, E.; Ganesan, R.; Ouf, M.; Hammad, A.; Eicker, U.; Moselhi, O. Innovative construction material technologies for sustainable and resilient civil infrastructure. Mater. Today Proc. 2022, 60, 365–372. [Google Scholar] [CrossRef]

- Vincens, E.; Witt, K.J.; Homberg, U. Approaches to determine the constriction size distribution for understanding filtration phenomena in granular materials. Acta Geotech. 2015, 10, 291–303. [Google Scholar] [CrossRef]

- Roy, S.; Bhalla, S.K. Role of geotechnical properties of soil on civil engineering structures. Resour. Environ. 2017, 7, 103–109. [Google Scholar]

- Afrin, H. A review on different types soil stabilization techniques. Int. J. Transp. Eng. Technol. 2017, 3, 19–24. [Google Scholar] [CrossRef]

- Choo, H.; Yoon, B.; Lee, W.; Lee, C. Evaluation of compressibility and small strain stiffness characteristics of sand reinforced with discrete synthetic fibers. Geotext. Geomembr. 2017, 45, 331–338. [Google Scholar] [CrossRef]

- MolaAbasi, H.; Naderi Semsani, S.; Saberian, M.; Khajeh, A.; Li, J.; Harandi, M. Evaluation of the long-term performance of stabilized sandy soil using binary mixtures: A micro- and macro-level approach. J. Clean. Prod. 2020, 267, 122209. [Google Scholar] [CrossRef]

- Choo, H.; Lee, W.; Lee, C. Compressibility and small strain stiffness of kaolin clay mixed with varying amounts of sand. KSCE J. Civ. Eng. 2017, 21, 2152–2161. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Aboulayt, A.; Jaafri, R.; Samouh, H.; Cherki El Idrissi, A.; Roziere, E.; Moussa, R.; Loukili, A. Stability of a new geopolymer grout: Rheological and mechanical performances of metakaolin-fly ash binary mixtures. Constr. Build. Mater. 2018, 181, 420–436. [Google Scholar] [CrossRef]

- Garga, V.K.; O’Shaughnessy, V. Tire-reinforced earthfill. Part 1: Construction of a test fill, performance, and retaining wall design. Can. Geotech. J. 2000, 37, 75–96. [Google Scholar] [CrossRef]

- Bosscher, P.J.; Edil, T.B.; Kuraoka, S. Design of highway embankments using tire chips. J. Geotech. Geoenvironmental Eng. 1997, 123, 295–304. [Google Scholar] [CrossRef]

- Poh, P.S.; Broms, B.B. Slope stabilization using old rubber tires and geotextiles. J. Perform. Constr. Facil. 1995, 9, 76–79. [Google Scholar] [CrossRef]

- Zornberg, J.G.; Christopher, B.R.; LaRocque, C.J. Applications of tire bales in transportation projects. In Recycled Materials in Geotechnics; ASCE: Reston, VA, USA, 2005; pp. 42–60. [Google Scholar]

- Masad, E.; Taha, R.; Ho, C.; Papagiannakis, T. Engineering properties of tire/soil mixtures as a lightweight fill material. Geotech. Test. J. 1996, 19, 297–304. [Google Scholar]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Q.; Shi, W.; Lv, J.; Lu, Z.; Ling, X. Advances in Properties of Rubber Reinforced Soil. Adv. Civ. Eng. 2020, 2020, 6629757. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, J.; Chen, X.; Wang, X.; Jia, Y. Experimental investigation on static and dynamic characteristics of granulated rubber-sand mixtures as a new railway subgrade filler. Constr. Build. Mater. 2021, 273, 121955. [Google Scholar] [CrossRef]

- Madhusudhan, B.R.; Boominathan, A.; Banerjee, S. Factors Affecting Strength and Stiffness of Dry Sand-Rubber Tire Shred Mixtures. Geotech. Geol. Eng. 2019, 37, 2763–2780. [Google Scholar] [CrossRef]

- Feng, Z.-Y.; Sutter, K.G. Dynamic properties of granulated rubber/sand mixtures. Geotech. Test. J. 2000, 23, 338–344. [Google Scholar]

- Senetakis, K.; Anastasiadis, A.; Pitilakis, K.; Souli, A.; Edil, T.; Dean, S. Dynamic behavior of sand/rubber mixtures. Part II: Effect of rubber content on G/Go-c-DT curves and volumetric threshold strain. J. ASTM Int. 2012, 9, 103711–1037112. [Google Scholar] [CrossRef]

- Li, B.; Huang, M.; Zeng, X. Dynamic Behavior and Liquefaction Analysis of Recycled-Rubber Sand Mixtures. J. Mater. Civ. Eng. 2016, 28, 04016122. [Google Scholar] [CrossRef]

- Madhusudhan, B.R.; Boominathan, A.; Banerjee, S. Static and Large-Strain Dynamic Properties of Sand–Rubber Tire Shred Mixtures. J. Mater. Civ. Eng 2017, 29, 04017165. [Google Scholar] [CrossRef]

- Rios, S.; Kowalska, M.; Viana da Fonseca, A. Cyclic and Dynamic Behavior of Sand–Rubber and Clay–Rubber Mixtures. Geotech. Geol. Eng. 2021, 39, 3449–3467. [Google Scholar] [CrossRef]

- Chen, L.; Wang, X.; Jia, Z.; Luo, Y.; Jia, D. Use of precipitated silica with silanol groups as an inorganic chain extender in polyurethane. Mater. Des. 2015, 87, 324–330. [Google Scholar] [CrossRef]

- Arslan, G.; Özmen, M.; Gündüz, B.; Zhang, X.; Ersöz, M. Surface modification of glass beads with an aminosilane monolayer. Turk. J. Chem. 2006, 30, 203–210. [Google Scholar]

- Lee, J.-S.; Santamarina, J.C. Bender elements: Performance and signal interpretation. J. Geotech. Geoenvironmental Eng. 2005, 131, 1063–1070. [Google Scholar] [CrossRef]

- Ozmen, M.; Can, K.; Akin, I.; Arslan, G.; Tor, A.; Cengeloglu, Y.; Ersoz, M. Surface modification of glass beads with glutaraldehyde: Characterization and their adsorption property for metal ions. J. Hazard. Mater. 2009, 171, 594–600. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.-K.; Peng, S.-L.; Chu, I.M.; Ni, S.-C. Effects of heat treatment on the properties of poly(methyl methacrylate)/silica hybrid materials prepared by sol–gel process. Polymer 2001, 42, 4189–4196. [Google Scholar] [CrossRef]

- Zappone, B.; Rosenberg, K.J.; Israelachvili, J. Role of nanometer roughness on the adhesion and friction of a rough polymer surface and a molecularly smooth mica surface. Tribol. Lett. 2007, 26, 191–201. [Google Scholar] [CrossRef]

- Liu, D.; Sandeep, C.S.; Senetakis, K.; Nardelli, V.; Lourenço, S.D.N. Micromechanical behaviour of a polymer-coated sand. Powder Technol. 2019, 347, 76–84. [Google Scholar] [CrossRef]

- Yu, M.; Ji, A.-H.; Dai, Z.-D. Effect of microscale contact state of polyurethane surface on adhesion and friction. J. Bionic Eng. 2006, 3, 87–91. [Google Scholar] [CrossRef]

- Lambe, T.W.; Whitman, R.V. Soil Mechanics, Series in Soil Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1969. [Google Scholar]

- Lee, C.; Lee, J.S.; Lee, W.; Cho, T.H. Experiment setup for shear wave and electrical resistance measurements in an oedometer. Geotech. Test. J. 2008, 31, 8. [Google Scholar]

- Lee, C.; Truong, Q.H.; Lee, W.; Lee, J.-S. Characteristics of Rubber-Sand Particle Mixtures according to Size Ratio. J. Mater. Civ. Eng. 2010, 22, 323–331. [Google Scholar] [CrossRef]

- Knox, D.P.; Stokoe, K.H.; Kopperman, S.E. Effect of State of Stress on Velocity of Low-Amplitude Shear Waves Propagating along Princiapl Stress Directions in Dry Sand; University of Texas: Austin, TX, USA, 1982. [Google Scholar]

- Roesler, S.K. Anisotropic shear modulus due to stress anisotropy. J. Geotec. Eng. Div. 1979, 105, 871–880. [Google Scholar] [CrossRef]

- Yu, P.; Richart, F., Jr. Stress ratio effects on shear modulus of dry sands. J. Geotech. Eng. 1984, 110, 331–345. [Google Scholar] [CrossRef]

- Santamarina, J.; Cascante, G. Stress anisotropy and wave propagation: A micromechanical view. Can. Geotech. J. 1996, 33, 770–782. [Google Scholar] [CrossRef]

- Santamarina, J.C.; Klein, K.A.; Fam, M.A. Soils and Waves; J. Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Ramirez, M.S.; Park, J.; Terzariol, M.; Jiang, J.; Santamarina, J.C. Shallow Seafloor Sediments: Density and Shear Wave Velocity. J. Geotech. Geoenvironmental Eng. 2023, 149, 04023022. [Google Scholar] [CrossRef]

- Cha, M.; Santamarina, J.C.; Kim, H.-S.; Cho, G.-C. Small-strain stiffness, shear-wave velocity, and soil compressibility. J. Geotech. Geoenvironmental Eng. 2014, 140, 06014011. [Google Scholar] [CrossRef]

- Ku, T.; Mayne, P.; Gutierrez, B. Hierarchy of V s modes and stress-dependency in geomaterials. In Deformation Characteristics of Geomaterials; IOS Press: Amsterdam, The Netherlands, 2011; pp. 533–540. [Google Scholar]

- Ku, T. Geostatic Stress State Evaluation by Directional Shear Wave Velocities, with Application towards Geocharacterization at Aiken, SC; Georgia Institute of Technology: Atlanta, GA, USA, 2012. [Google Scholar]

- Ku, T.; Subramanian, S.; Moon, S.-W.; Jung, J. Stress Dependency of Shear-Wave Velocity Measurements in Soils. J. Geotech. Geoenvironmental Eng. 2017, 143, 04016092. [Google Scholar] [CrossRef]

- Park, J.; Santamarina, J.C. Revised Soil Classification System for Coarse-Fine Mixtures. J. Geotech. Geoenvironmental Eng. 2017, 143, 04017039. [Google Scholar] [CrossRef]

- Lee, J.; Dodds, J.; Santamarina, J.C. Behavior of Rigid-Soft Particle Mixtures. J. Mater. Civ. Eng 2007, 19, 179–184. [Google Scholar] [CrossRef]

- Choo, H.; Burns, S. Effect of overconsolidation ratio on dynamic properties of binary mixtures of silica particles. Soil Dyn. Earthq. Eng. 2014, 60, 44–50. [Google Scholar] [CrossRef]

- Anastasiadis, A.; Senetakis, K.; Pitilakis, K. Small-strain shear modulus and damping ratio of sand-rubber and gravel-rubber mixtures. Geotech. Geol. Eng. 2012, 30, 363–382. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, W.J.; Liu, Q.; Zhao, K.; Chen, G. Dynamic shear modulus and damping ratio of rubber-sand mixtures with a wide range of rubber content. Mater. Today Commun. 2021, 27, 102341. [Google Scholar] [CrossRef]

- Zhong, X.; Zeng, X.; Rose, J. Shear modulus and damping ratio of rubber-modified asphalt mixes and unsaturated subgrade soils. J. Mater. Civ. Eng. 2002, 14, 496–502. [Google Scholar] [CrossRef]

- Neaz Sheikh, M.; Mashiri, M.; Vinod, J.; Tsang, H.-H. Shear and compressibility behavior of sand–tire crumb mixtures. J. Mater. Civ. Eng. 2013, 25, 1366–1374. [Google Scholar] [CrossRef]

| Material | Glass Bead (GB) | Device/Technique | |

|---|---|---|---|

| Specific gravity, GS | 2.48 | Pycnometer (ASTM D845) | |

| Median particle size D50 [mm] | 0.51 | Sieve (ASTM D6913) | |

| Coefficient of uniformity, Cu | 1.22 | - | |

| Coefficient of curvature, Cc | 0.97 | - | |

| Extreme void ratio | Minimum void ratio, emin | 0.55 | Vibratory Table (ASTM D4253) |

| Maximum void ratio, emax | 0.69 | Funnel (ASTM D4254) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, B.; Choo, H.; Lee, C. Synthesis and Evaluation of Engineering Properties of Polymer-Coated Glass Beads. Materials 2023, 16, 4476. https://doi.org/10.3390/ma16124476

Yoon B, Choo H, Lee C. Synthesis and Evaluation of Engineering Properties of Polymer-Coated Glass Beads. Materials. 2023; 16(12):4476. https://doi.org/10.3390/ma16124476

Chicago/Turabian StyleYoon, Boyoung, Hyunwook Choo, and Changho Lee. 2023. "Synthesis and Evaluation of Engineering Properties of Polymer-Coated Glass Beads" Materials 16, no. 12: 4476. https://doi.org/10.3390/ma16124476

APA StyleYoon, B., Choo, H., & Lee, C. (2023). Synthesis and Evaluation of Engineering Properties of Polymer-Coated Glass Beads. Materials, 16(12), 4476. https://doi.org/10.3390/ma16124476