Piezoelectric and Dielectric Properties in Bi0.5(Na,K)0.5TiO3-x Ag2O Lead-Free Piezoceramics

(This article belongs to the Section Electronic Materials)

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

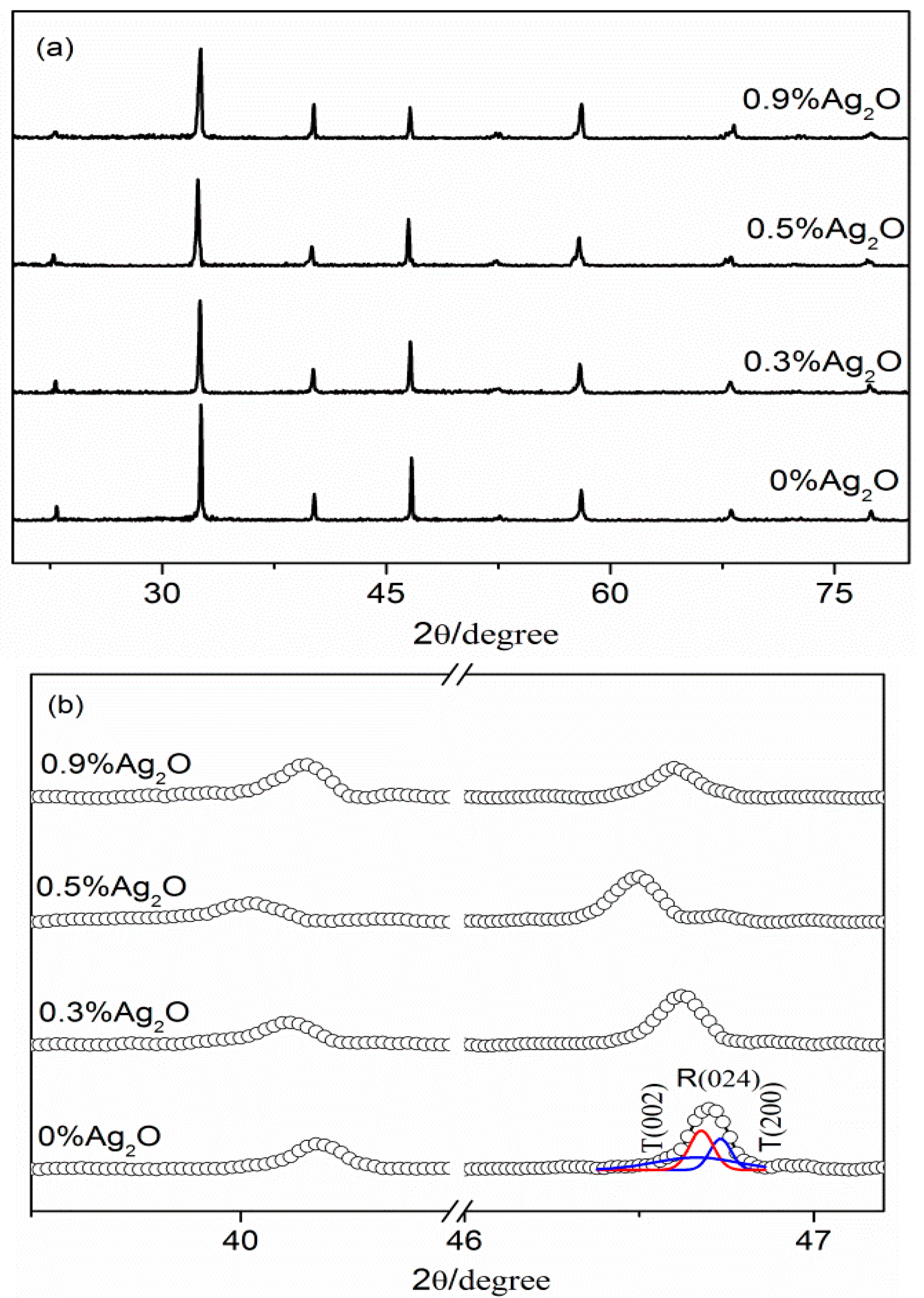

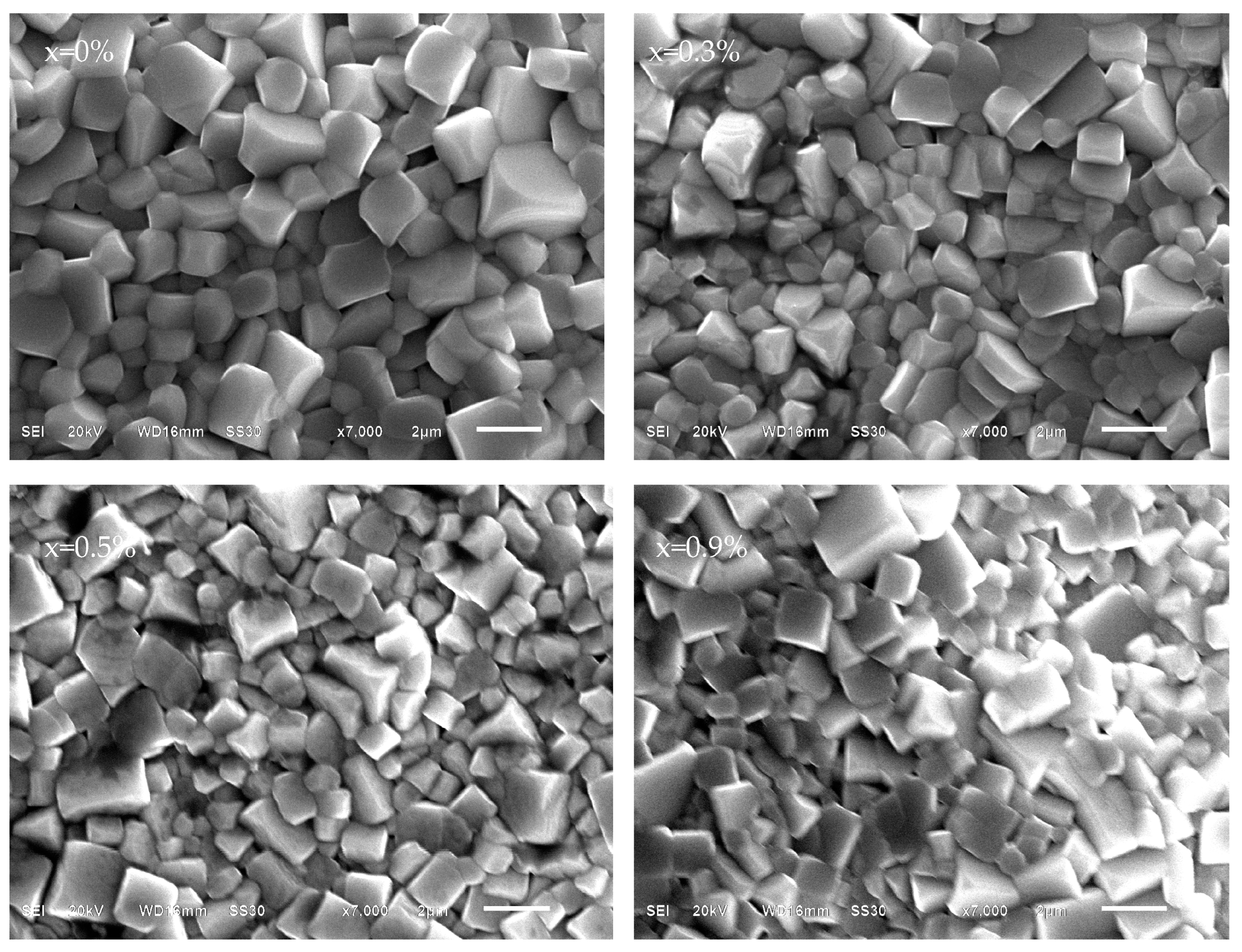

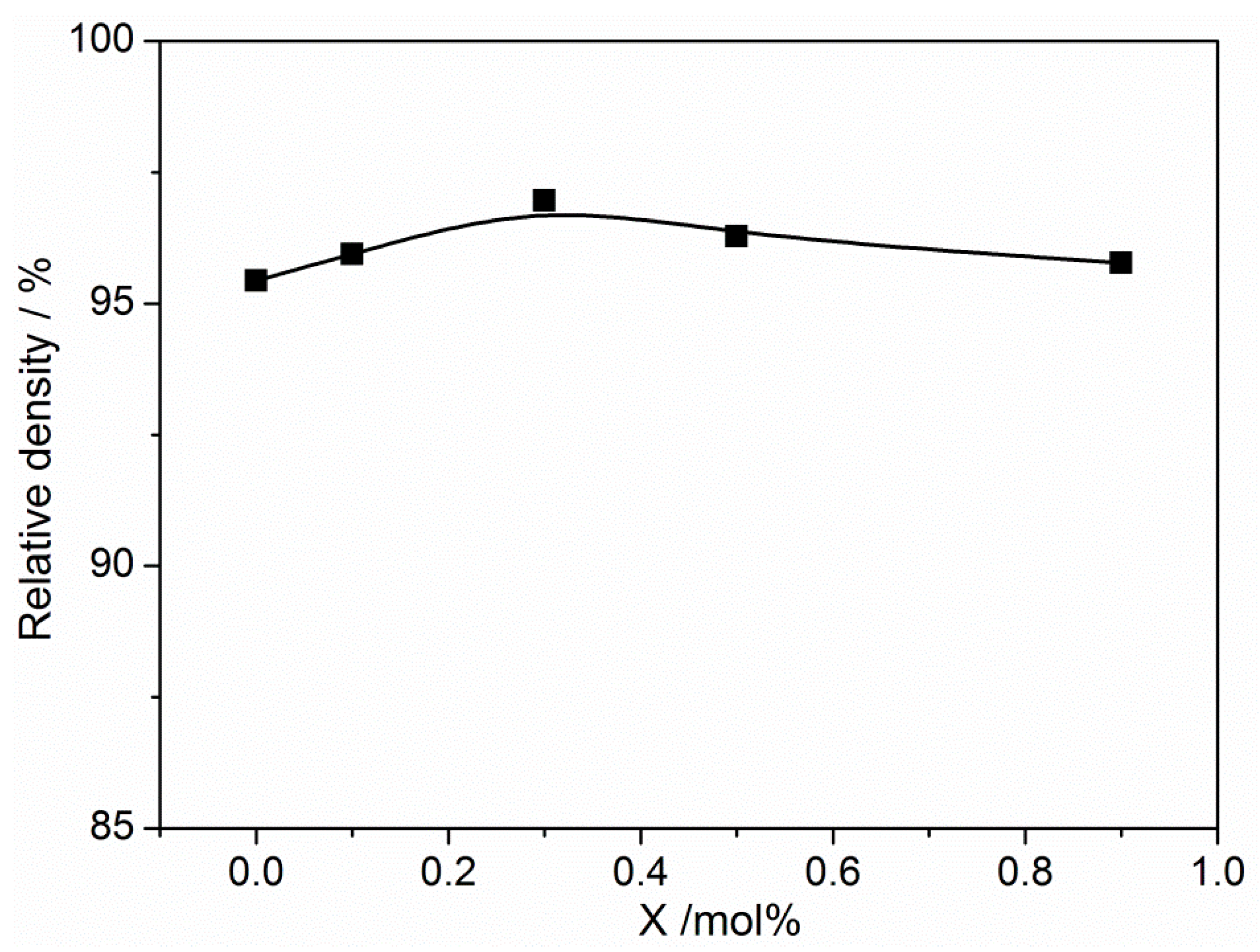

3.1. Structure

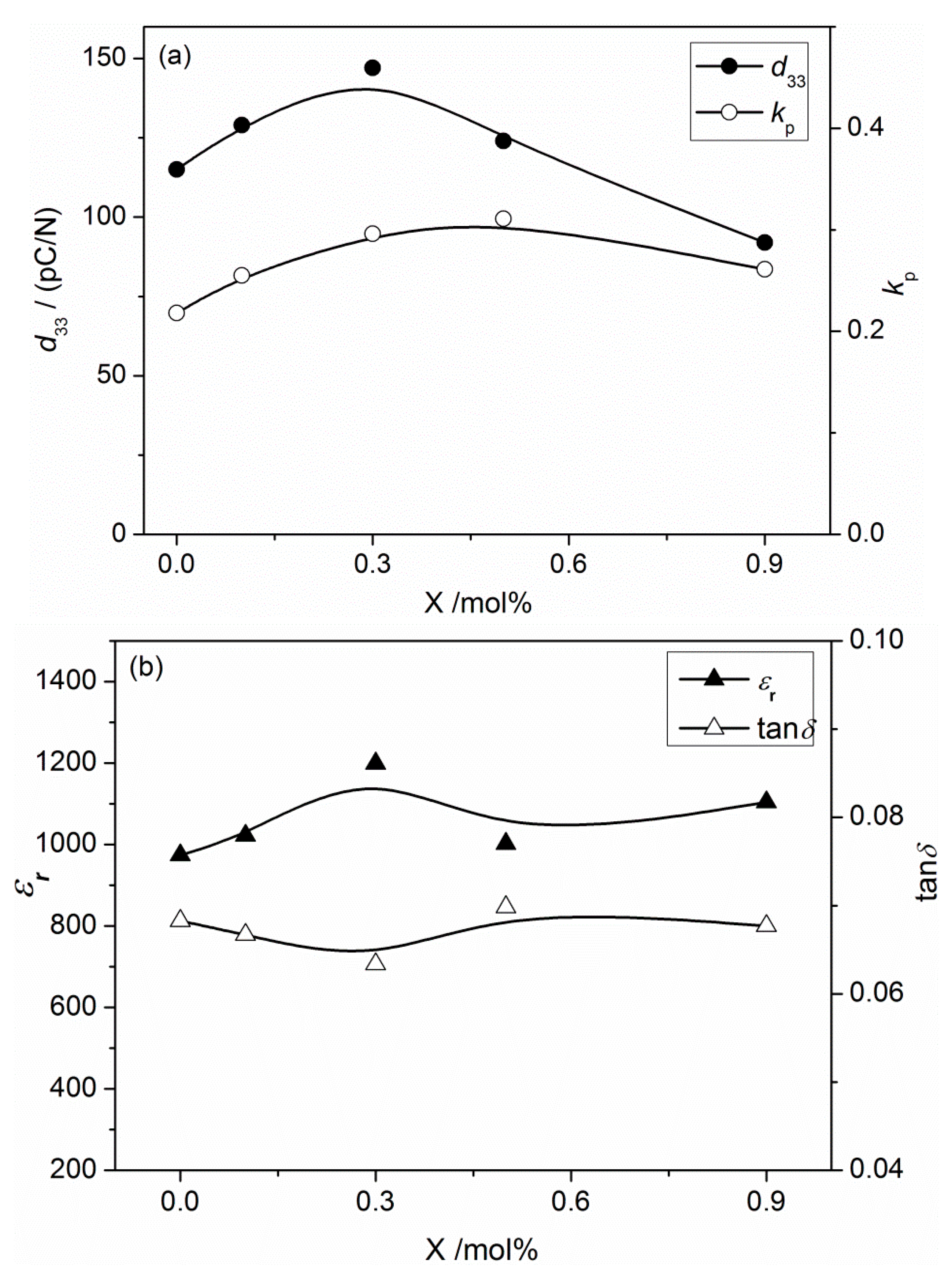

3.2. Electrical Properties

3.3. Dielectric Properties

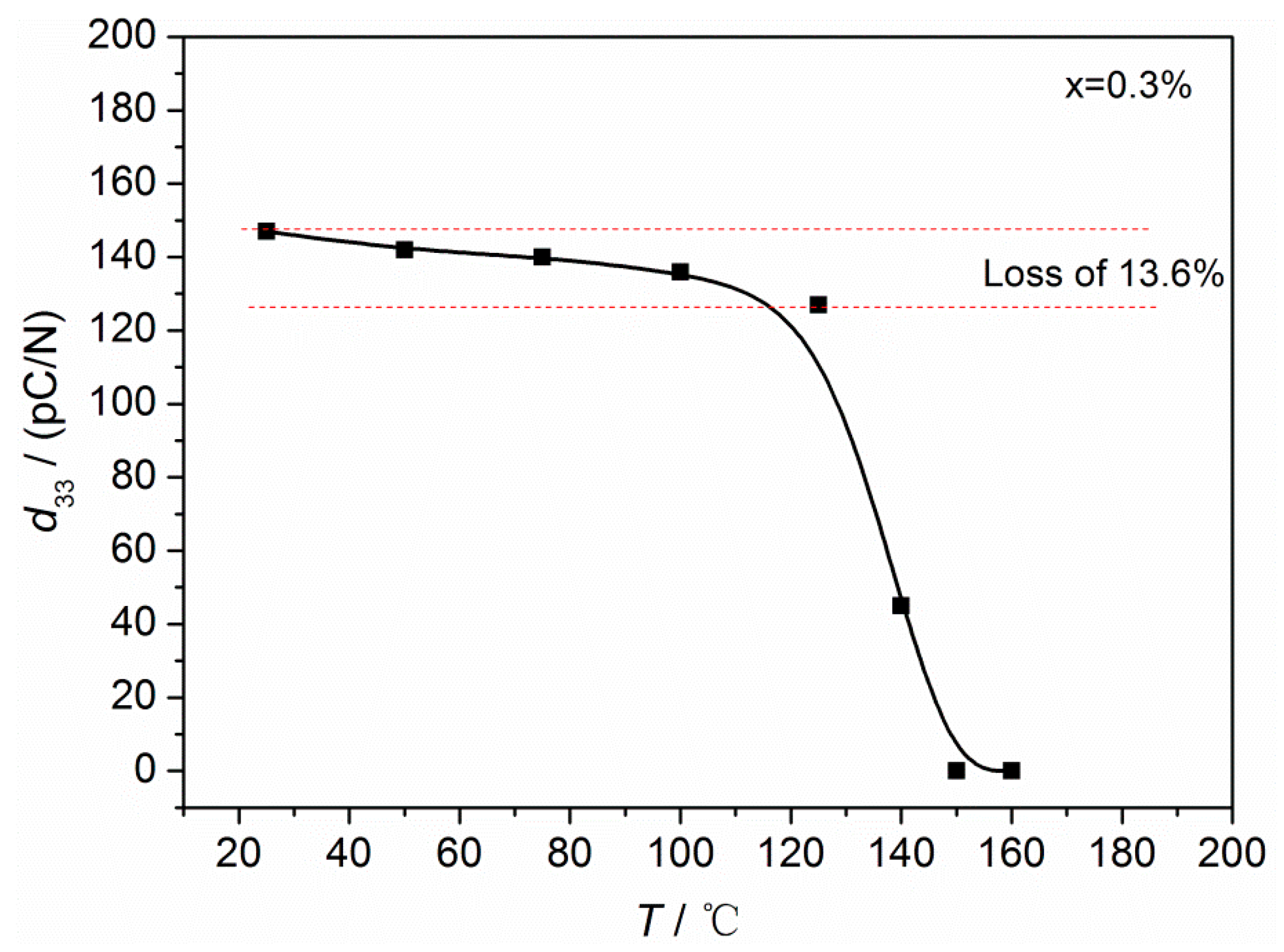

3.4. Thermal Instability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Shen, Z.Y.; Zhang, B.P.; Li, J.F. (K, Na)NbO3-based Lead-free Piezoceramics: Status, Prospects and Challenges. J. Inorg. Mater. 2014, 29, 13–22. [Google Scholar] [CrossRef]

- Guo, R.; Cross, L.E.; Park, S.E.; Noheda, B.; Cox, D.E.; Shirane, G. Origin of the High Piezoelectric Response in PbZr1−xTixO3. Phys. Rev. Lett. 2000, 84, 5423–5426. [Google Scholar] [CrossRef] [PubMed]

- Wodecka-Dus, B.; Goryczka, T.; Adamczyk-Habrajska, M.; Bara, M.; Dzik, J.; Szalbot, D. Dielectric and Electrical Properties of BLT Ceramics Modified by Fe Ions. Materials 2020, 13, 5623. [Google Scholar] [PubMed]

- Craciun, E.M.; Rabaea, A.; Das, S. Cracks Interaction in a Pre-Stressed and Pre-Polarized Piezoelectric Material. J. Mech. 2020, 36, 177–182. [Google Scholar] [CrossRef]

- Zulhadjri; Wendari, T.P.; Ikhram, M.; Putri, Y.E.; Septiani, U.; Imelda. Enhanced dielectric and ferroelectric responses in La3+/Ti4+ co-substituted SrBi2Ta2O9 Aurivillius phase. Ceram. Int. 2022, 48, 10328–10332. [Google Scholar] [CrossRef]

- Song, A.; Wang, J.; Song, J.; Zhang, J.; Li, Z.; Zhao, L. Antiferroelectricity and ferroelectricity in A-site doped silver niobate lead-free ceramics. J. Eur. Ceram. Soc. 2021, 41, 1236–1243. [Google Scholar] [CrossRef]

- Smolenskii, G.A.; Isupov, V.A.; Agranovskaya, A.I.; Krainik, N.N. Ferroelectrics with diffuse phase transitions. Sov. Phys. Solid State 1961, 2, 2584–2594. [Google Scholar]

- Takenaka, T. Piezoelectric properties of some lead-free ferroelectric ceramics. Ferroelectrics 1999, 230, 87–98. [Google Scholar]

- Takenaka, T.; Nagata, H. Present status of non-lead-based piezoelectric ceramics. Key Eng. Mater. 1999, 157, 57–63. [Google Scholar]

- Tadashi, T.; Kei-ichi, M.; Koichiro, S. (Bi1/2Na1/2)TiO3-BaTiO3 System for Lead-Free Piezoelectric Ceramics. Jpn. J. Appl. Phys. 1991, 30, 2236. [Google Scholar]

- Hong, C.-H.; Fan, Z.; Tan, X.; Kang, W.-S.; Ahn, C.W.; Shin, Y.; Jo, W. Role of sodium deficiency on the relaxor properties of Bi1/2Na1/2TiO3-BaTiO3. J. Eur. Ceram. Soc. 2018, 38, 5375–5381. [Google Scholar] [CrossRef]

- Lin, D.; Xiao, D.; Zhu, J.; Yu, P.; Yan, H.; Li, L. Synthesis and piezoelectric properties of lead-free piezoelectric [Bi0.5(Na1−x−yKxLiy)0.5]TiO3 ceramics. Mater. Lett. 2004, 58, 615–618. [Google Scholar] [CrossRef]

- Elkechai, O.; Manier, M.; Mercurio, J.P. Na0.5Bi0.5TiO3–K0.5Bi0.5TiO3 (NBT-KBT) system: A structural and electrical study. Phys. Status Solidi A Appl. Res. 1996, 157, 499–506. [Google Scholar]

- Wang, G.; Li, Y.; Murray, C.A.; Tang, C.C.; Hall, D.A. Thermally-induced phase transformations in Na0.5Bi0.5TiO3–KNbO3 ceramics. J. Am. Ceram. Soc. 2017, 100, 3293–3304. [Google Scholar] [CrossRef]

- Xu, Q.; Xie, J.; He, Z.; Zhang, L.; Cao, M.; Huang, X.; Lanagan, M.T.; Hao, H.; Yao, Z.; Liu, H. Energy-storage properties of Bi0.5Na0.5TiO3-BaTiO3-KNbO3 ceramics fabricated by wet-chemical method. J. Eur. Ceram. Soc. 2017, 37, 99–106. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Y.; Li, G. Structure and electrical properties of [(Na0.825K0.175)0.5Bi0.5]1+xTiO3 piezoceramics with A-site nonstoichiometry. J. Asian Ceram. Soc. 2020, 8, 1036–1042. [Google Scholar] [CrossRef]

- Song, G.H.; Zhang, F.Q.; Liu, F.; Liu, Z.F.; Li, Y.X. Electrical properties and temperature stability of SrTiO3-modified (Bi1/2Na1/2)TiO3-BaTiO3-(K1/2Na1/2)NbO3 piezoceramics. J. Am. Ceram. Soc. 2021, 104, 4049–4057. [Google Scholar] [CrossRef]

- Yang, H.B.; Tian, J.H.; Lin, Y.; Ma, J.Q. Realizing ultra-high energy storage density of lead-free 0.76Bi0.5Na0.5TiO3-0.24SrTiO3-Bi(Ni2/3Nb1/3)O3 ceramics under low electric fields. Chem. Eng. J. 2021, 418, 129337. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Y.; Mao, L.; Deng, Y.; Wang, H.; Chen, Q.; Zhu, J.; Xiao, D.; Zhu, J.; Xu, G. Microstructure and piezoelectric properties of Li-doped Bi0.5(Na0.825K0.175)0.5TiO3 piezoelectric ceramics. Phys. Status Solidi (A) 2009, 206, 1616–1619. [Google Scholar] [CrossRef]

- Grinberg, I.; Rappe, A.M. Silver solid solution piezoelectrics. Appl. Phys. Lett. 2004, 85, 1760–1762. [Google Scholar] [CrossRef]

- Joshi, A.; Bhatt, S.C. Investigation of dielectric properties and ferroelectric phase transition in lead-free AgNbO3. Mater. Today Proc. 2022, 49, 1607–1609. [Google Scholar] [CrossRef]

- Wu, L.; Xiao, D.; Zhou, F.; Teng, Y.; Li, Y. Microstructure, ferroelectric, and piezoelectric properties of (1–x−y)Bi0.5Na0.5TiO3–xBaTiO3–yBi0.5Ag0.5TiO3 lead-free ceramics. J. Alloys Compd. 2011, 509, 466–470. [Google Scholar] [CrossRef]

- Lin, D.; Kwok, K.W.; Chan, H.W.L. Ferroelectric and piezoelectric properties of Bi0.5(Na0.925−x−yLi0.075KxAgy)0.5TiO3 lead-free ceramics. J. Phys. D Appl. Phys. 2007, 40, 7523. [Google Scholar] [CrossRef]

- Liao, Y.; Xiao, D.-q.; Lin, D.; Zhu, J.; Yu, P.; Wu, L.; Wang, X.-P. Synthesis and properties of Bi0.5(Na1−x−yKxAgy)0.5TiO3 lead-free piezoelectric ceramics. Ceram. Int. 2007, 33, 1445–1448. [Google Scholar]

- Onoe, M.; Jumonji, H. Useful Formulas for Piezoelectric Ceramic Resonators and Their Application to Measurement of Parameters. J. Acoust. Soc. Am. 1967, 41, 974–980. [Google Scholar] [CrossRef]

- Jones, G.O.; Thomas, P.A. The tetragonal phase of Na0.5Bi0.5TiO3—A new variant of the perovskite structure. Acta Crystallogr. Sect. B 2000, 56, 426–430. [Google Scholar] [CrossRef]

- Jones, G.O.; Thomas, P.A. Investigation of the structure and phase transitions in the novel A-site substituted distorted perovskite compound Na0.5Bi0.5TiO3. Acta Crystallogr. Sect. B 2002, 58, 168–178. [Google Scholar] [CrossRef]

- Lei, N.; Zhu, M.; Yang, P.; Wang, L.; Wang, L.; Hou, Y.; Yan, H. Effect of lattice occupation behavior of Li+ cations on microstructure and electrical properties of (Bi1/2Na1/2)TiO3-based lead-free piezoceramics. J. Appl. Phys. 2011, 109, 054102. [Google Scholar] [CrossRef]

- Shannon, R. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A Cryst. Phys. Diffr. Theor. Gen. Crystallogr. 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Akram, F.; Ahmed Malik, R.; Hussain, A.; Song, T.-K.; Kim, W.-J.; Kim, M.-H. Temperature stable dielectric properties of lead-free BiFeO3–BaTiO3 modified with LiTaO3 ceramics. Mater. Lett. 2018, 217, 16–19. [Google Scholar] [CrossRef]

- Wang, B.; Luo, L.; Ni, F.; Du, P.; Li, W.; Chen, H. Piezoelectric and ferroelectric properties of (Bi1−xNa0.8K0.2Lax)0.5TiO3 lead-free ceramics. J. Alloys Compd. 2012, 526, 79–84. [Google Scholar] [CrossRef]

- Jones, G.O.; Kreisel, J.; Thomas, P.A. A structural study of the (Na1−xKx)0.5Bi0.5TiO3 perovskite series as a function of substitution (x) and temperature. Powder Diffr. 2012, 17, 301–319. [Google Scholar] [CrossRef]

- Chen, X.; Ai, C.; Yang, Z.; Ni, Y.; Yin, X.; You, J.; Li, G. Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics. Materials 2023, 16, 3720. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, A.; Chiba, T.; Mamiya, Y.; Otsuki, E. Dielectric and Piezoelectric Properties of (Bi0.5Na0.5)TiO3–(Bi0.5K0.5)TiO3 Systems. Jpn. J. Appl. Phys. 1999, 38, 5564. [Google Scholar] [CrossRef]

- Kazushige, Y.; Yuji, H.; Hajime, N.; Tadashi, T. Electrical Properties and Depolarization Temperature of (Bi1/2Na1/2)TiO3 –(Bi1/2K1/2)TiO3 Lead-free Piezoelectric Ceramics. Jpn. J. Appl. Phys. 2006, 45, 4493. [Google Scholar]

- Li, Y.; Chen, W.; Zhou, J.; Xu, Q.; Sun, H.; Xu, R. Dielectric and piezoelecrtic properties of lead-free (Na0.5Bi0.5)TiO3–NaNbO3 ceramics. Mater. Sci. Eng. B 2004, 112, 5–9. [Google Scholar] [CrossRef]

- Sakata, K.; Takenaka, T.; Naitou, Y. Phase-Relations, Dielectric And Piezoelectric Properties Of Ceramics In the System (Bi0.5Na0.5)TiO3-PbTiO3. Ferroelectrics 1992, 131, 219–226. [Google Scholar] [CrossRef]

- Hou, Y.; Zhu, M.; Gao, F.; Wang, H.; Wang, B.; Yan, H.; Tian, C. Effect of MnO2 Addition on the Structure and Electrical Properties of Pb(Zn1/3Nb2/3)0.20(Zr0.50Ti0.50)0.80O3 Ceramics. J. Am. Ceram. Soc. 2004, 87, 847–850. [Google Scholar] [CrossRef]

- Hou, Y.D.; Chang, L.M.; Zhu, M.K.; Song, X.M.; Yan, H. Effect of Li2CO3 addition on the dielectric and piezoelectric responses in the low-temperature sintered 0.5PZN–0.5PZT systems. J. Appl. Phys. 2007, 102, 084507. [Google Scholar] [CrossRef]

- Lide, D.R.E. Handbook of Chemistry and Physics, 90th ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Zhu, M.K.; Lu, P.X.; Hou, Y.D.; Wang, H.; Yan, H. Effects of Fe2O3 addition on microstructure and piezoelectric properties of 0.2 PZN-0.8 PZT ceramics. J. Mater. Res. 2005, 20, 2670–2675. [Google Scholar]

- Uchino, K.; Nomura, S. Critical exponents of the dielectric constants in diffused-phase-transition crystals. Ferroelectrics 1982, 44, 55–61. [Google Scholar] [CrossRef]

- Jiang, X.P.; Li, L.Z.; Zeng, M.; Chan, H.L.W. Dielectric properties of Mn-doped (Na0.8K0.2)0.5Bi0.5TiO3 ceramics. Mater. Lett. 2006, 60, 1786–1790. [Google Scholar] [CrossRef]

- Thomas, N.W. A new framework for understanding relaxor ferroelectrics. J. Phys. Chem. Solids 1990, 51, 1419–1431. [Google Scholar] [CrossRef]

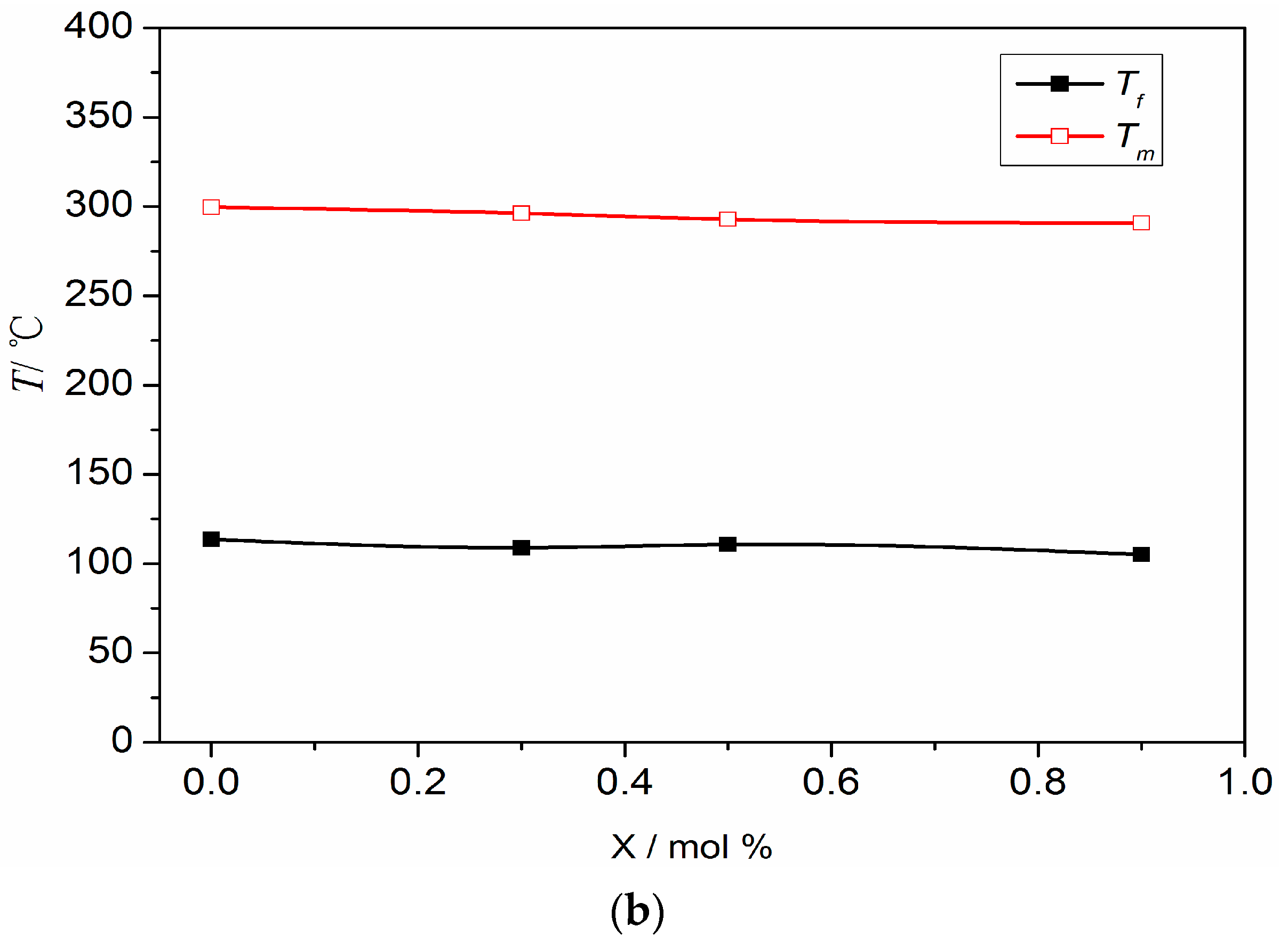

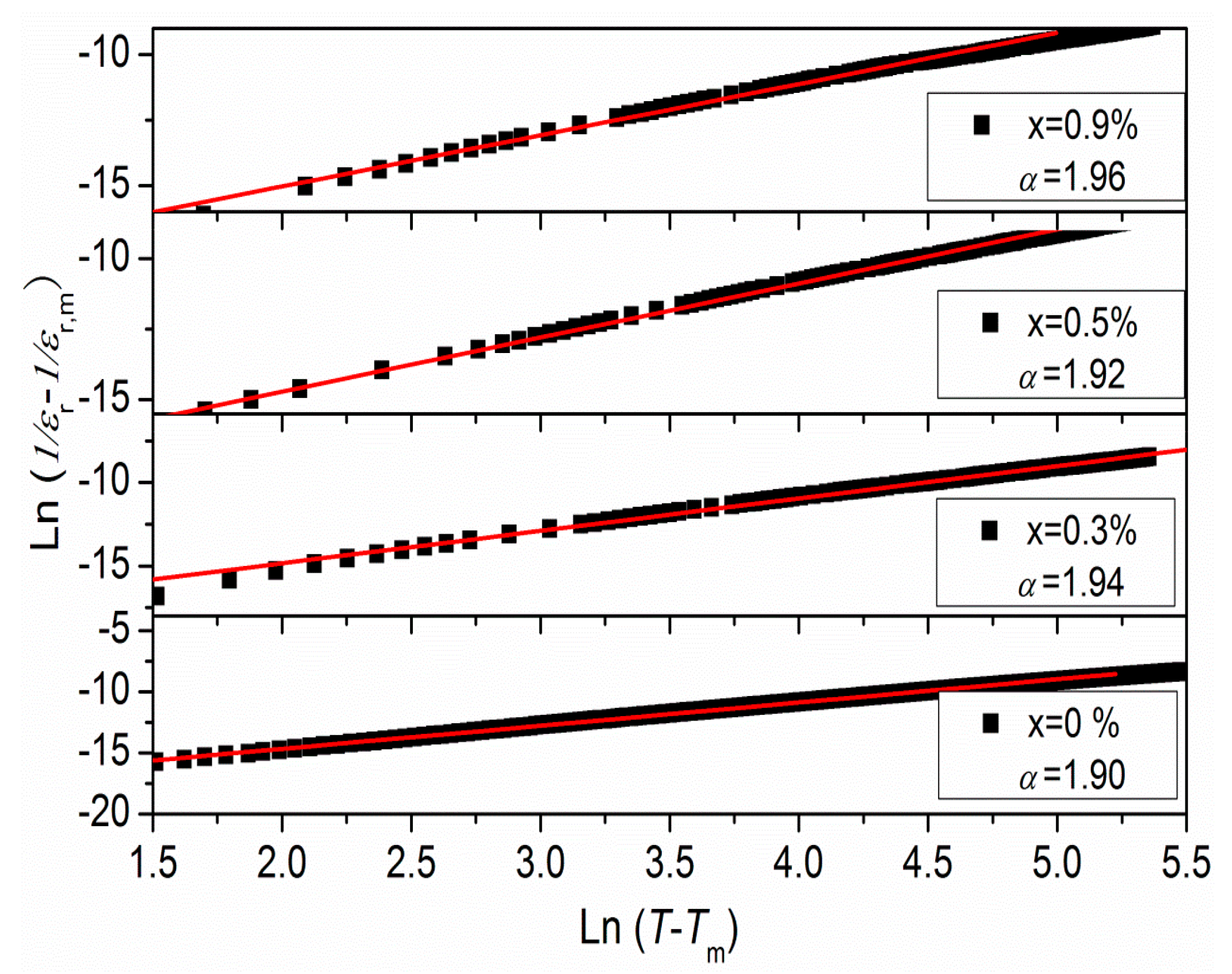

| x/% | γ | Tf/°C | Tm/°C | d33/(pC/N) | kp | εr | tanδ |

|---|---|---|---|---|---|---|---|

| 0 | 1.902 | 114 | 300 | 115 | 0.218 | 974 | 0.06827 |

| 0.3 | 1.947 | 109 | 296 | 147 | 0.296 | 1199 | 0.06337 |

| 0.5 | 1.919 | 111 | 293 | 124 | 0.311 | 1002 | 0.06983 |

| 0.9 | 1.957 | 105 | 291 | 92 | 0.261 | 1104 | 0.0677 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Liao, Y. Piezoelectric and Dielectric Properties in Bi0.5(Na,K)0.5TiO3-x Ag2O Lead-Free Piezoceramics. Materials 2023, 16, 5342. https://doi.org/10.3390/ma16155342

Chen X, Liao Y. Piezoelectric and Dielectric Properties in Bi0.5(Na,K)0.5TiO3-x Ag2O Lead-Free Piezoceramics. Materials. 2023; 16(15):5342. https://doi.org/10.3390/ma16155342

Chicago/Turabian StyleChen, Xiaoming, and Yunwen Liao. 2023. "Piezoelectric and Dielectric Properties in Bi0.5(Na,K)0.5TiO3-x Ag2O Lead-Free Piezoceramics" Materials 16, no. 15: 5342. https://doi.org/10.3390/ma16155342

APA StyleChen, X., & Liao, Y. (2023). Piezoelectric and Dielectric Properties in Bi0.5(Na,K)0.5TiO3-x Ag2O Lead-Free Piezoceramics. Materials, 16(15), 5342. https://doi.org/10.3390/ma16155342