Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods

Abstract

1. Introduction

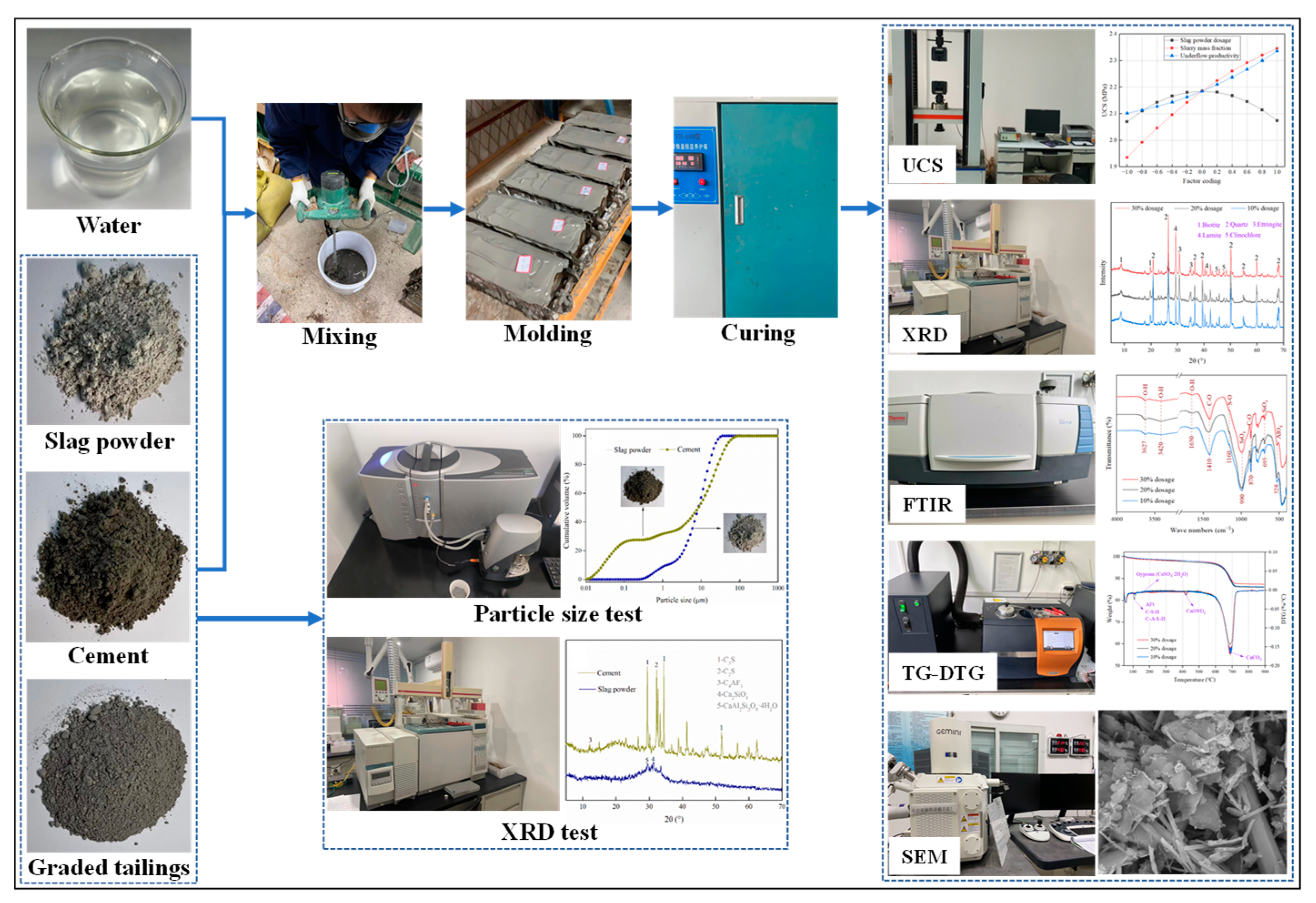

2. Materials and Methods

2.1. Materials

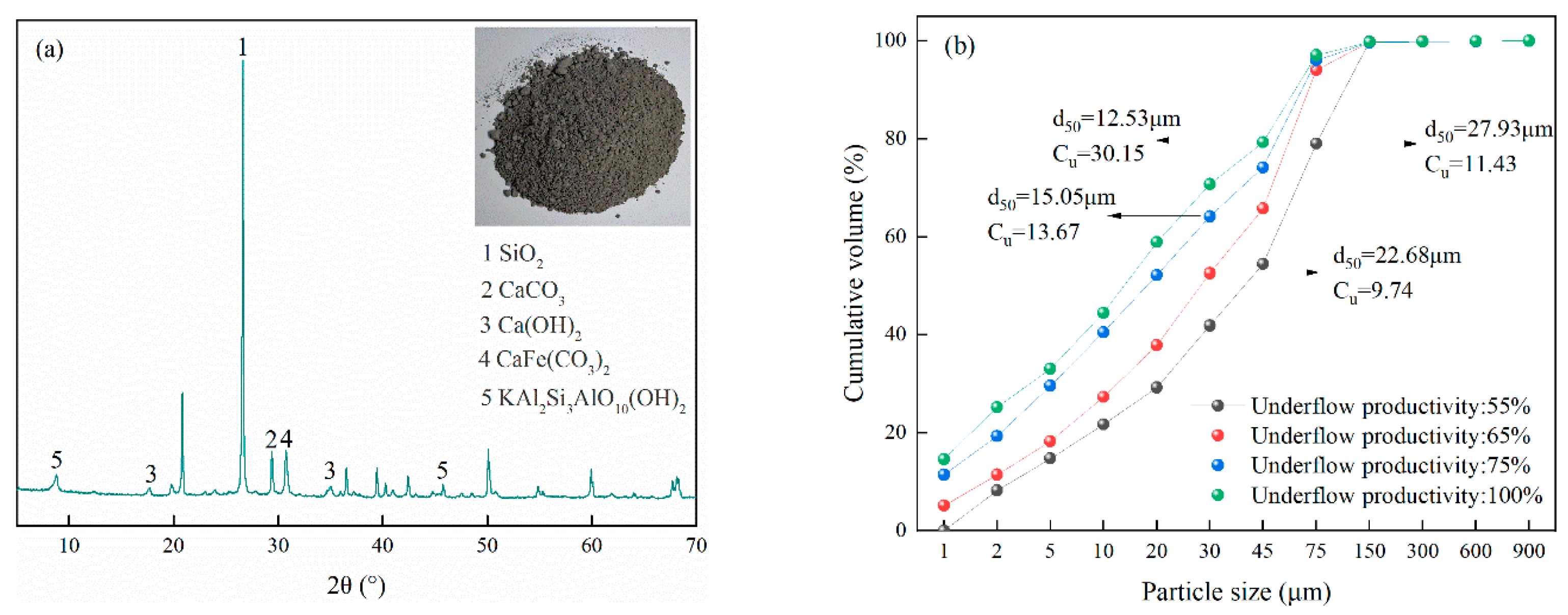

2.1.1. Tailings

2.1.2. Composite Cementitious Materials

- (1)

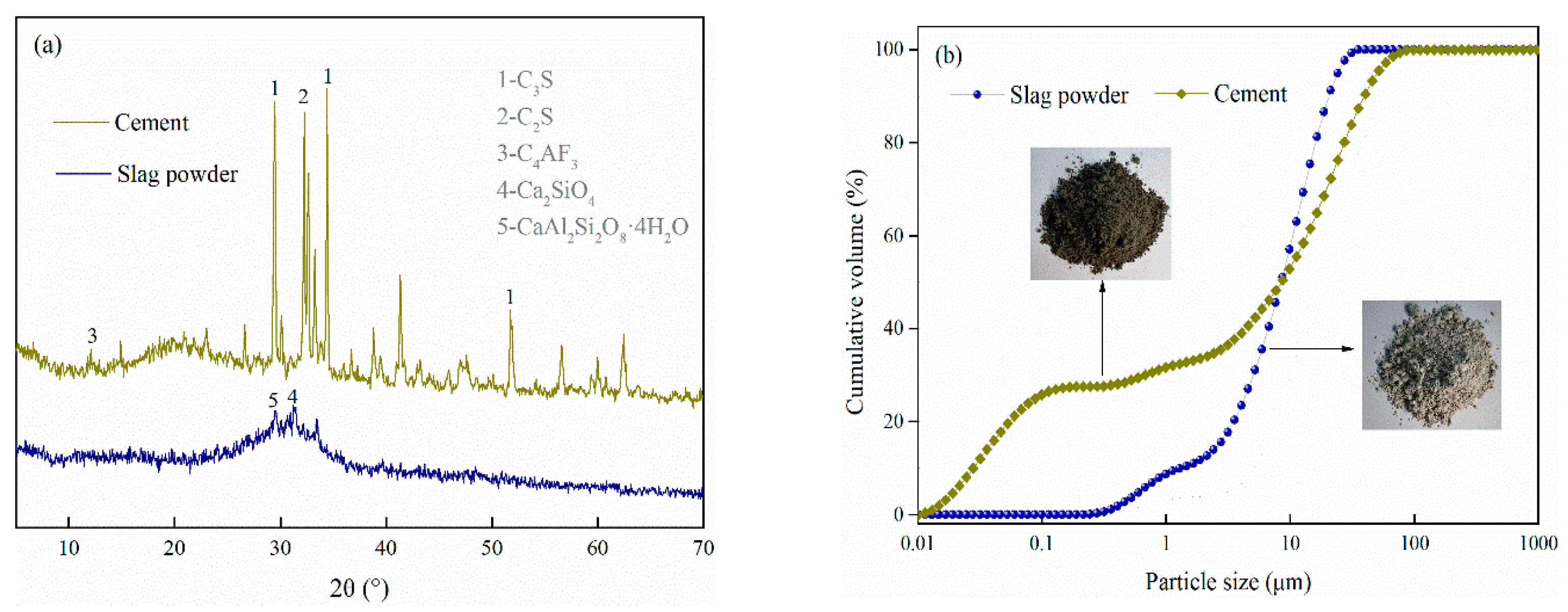

- This study employed cement as the binder, sourced from the same mine as the tailings to ensure experimental materials are in line with field conditions, thereby enhancing the applicability of the research. According to Figure 2b, it can be seen that the particle size of the cement is slightly smaller than that of the tailings, resulting in a larger specific surface area. This cement displays an initial setting time of 150 min, followed by a final setting time of 220 min. The 28 d compressive strength and flexural strength of the cement are 54.3 MPa and 8.7 MPa. As shown in Figure 2a, the main phase components of cement are C3S, C2S, and C4AF, indicating that the cement possesses strong hydrolytic capabilities.

- (2)

- Slag powder was used as the supplementary cementitious and active material. It has a specific surface area of 440 m2/kg and a density of 2.9 g/cm3. As shown in Table 1, the alkalinity coefficient of slag powder M0 = 1.17 > 1; the quality coefficient K = 2.27 > 1.8; the activity coefficient Ma = 1.57 > 1 [34]. This indicates that it is an alkaline slag with high activity. From the XRD results in Figure 2, it is clear that the slag powder contains a few crystalline phase substances with low crystallinity, mainly calcium aluminosilicate, dicalcium aluminosilicate, dicalcium silicate, and calciclite feldspar.

2.2. Methods

- (1)

- Uniaxial compressive strength test (UCS test): When the specimen was cured for a specific time, the UCS was tested using a WDW-2000 automatic pressure testing machine. To ensure the accuracy of the experimental results, three samples were prepared for each group of tests, and their UCS values were measured separately. The average value of the three samples was taken as the UCS of the corresponding mix proportion for that group.

- (2)

- X-ray diffraction test (XRD test): SCPB specimens were ground into powder and analyzed for their mineral phases using an X-ray diffractometer to determine the fractions of hydration products under different affecting factors. The equipment model used for XRD was a Bruker D8 Focus Bragg-Brentano diffractometer. The XRD test was conducted within the 2θ range of 5~70°, with a data collection rate of 7 s/step and a step size of 0.03°.

- (3)

- Fourier transform infrared spectroscopy test (FT-IR test): When a beam of infrared rays of different wavelengths is irradiated onto the molecules of a substance, an infrared absorption spectrum is formed because different substances absorb infrared rays of specific wavelengths [35,36]. Based on the spectral bands, the structural composition of the substance to be measured is inferred and the intensity of the absorption bands is used to obtain the content of the substance. The FT-IR testing was performed using a Bruker Tensor 27 instrument.

- (4)

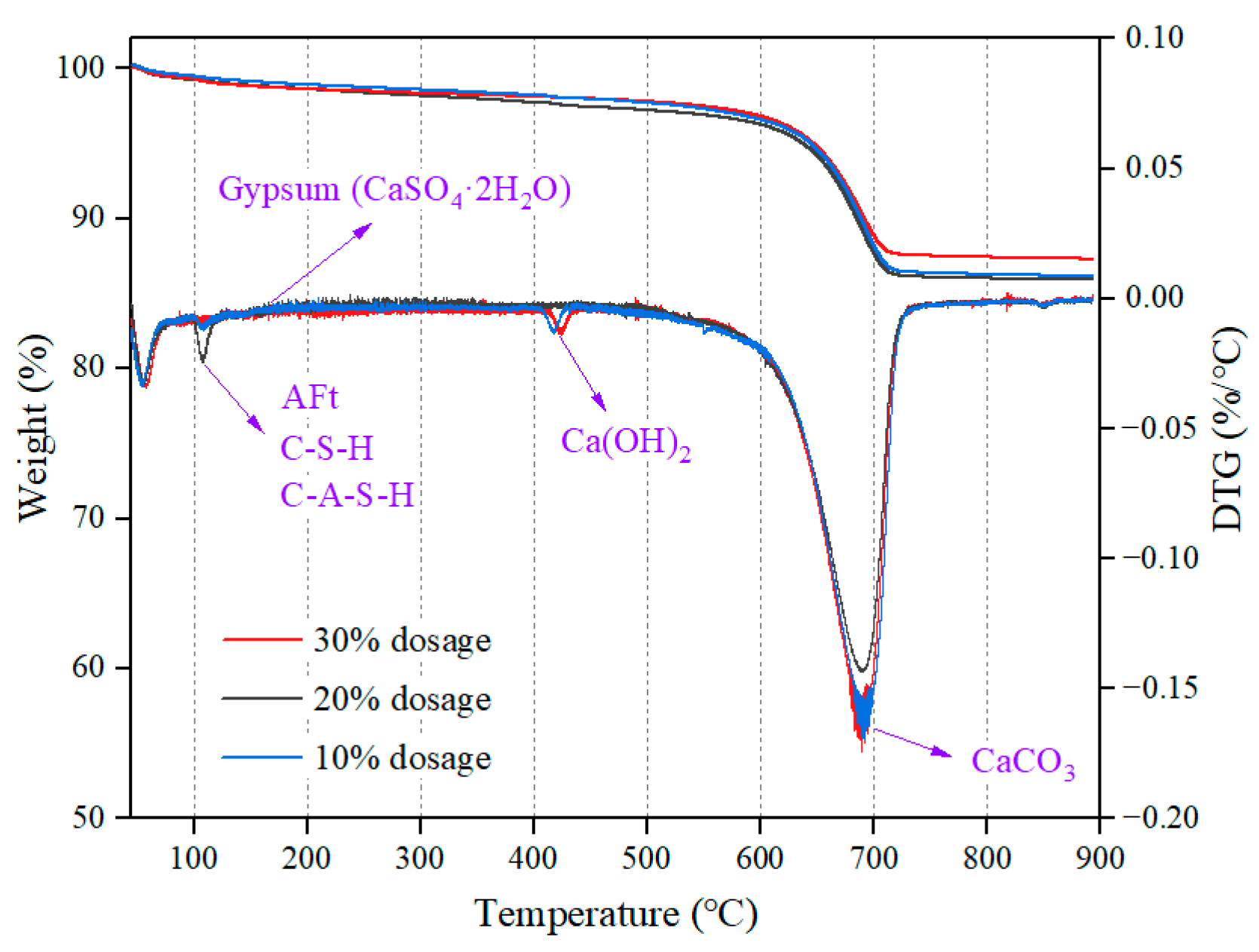

- Thermogravimetry and differential thermogravimetry test (TG-DTG test): The TG curve reflects the mass change of a substance with temperature, and the DTG curve represents the rate of change of the mass of a substance as a function of time and temperature [37,38]. When the mass loss is low, the steps on the TG curve are not significant. The TG-DTG testing was conducted using the STA409C high-temperature thermal analyzer developed by NETZSCH, a German company. At this time, the analysis needs to be performed using the DTG curve. In this test, the initial temperature was 20 °C and the temperature increase rate was 10 °C/min, stopping when it reached 900 °C.

- (5)

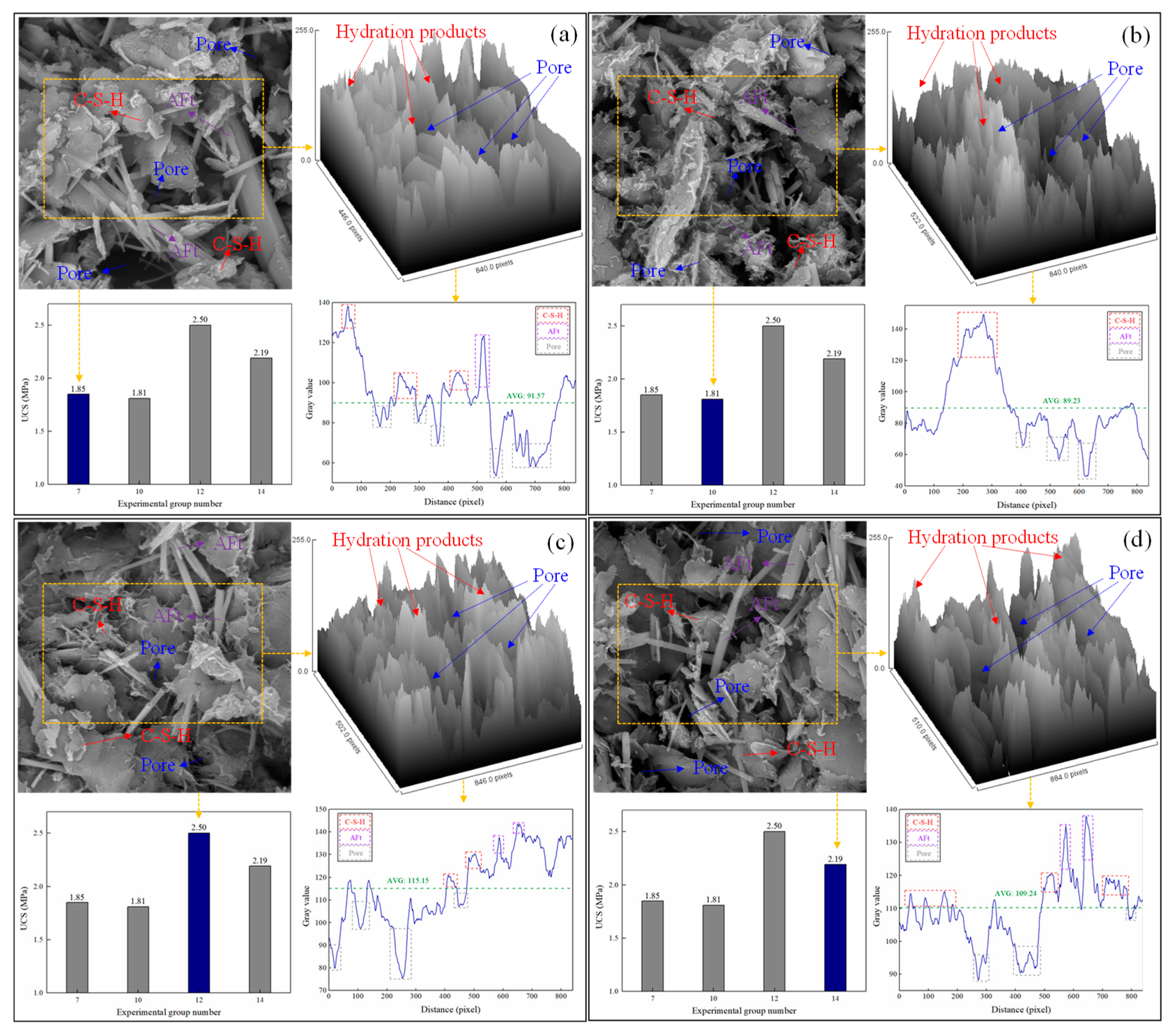

- Scanning electron microscopy test (SEM test): SEM is a widely used method for observing microscopic structures. In this study, this method was employed to observe the distribution of pores in the microstructure of SCPB under different mix proportions. Additionally, Image J software was utilized to conduct grayscale analysis of the microstructure, in order to compare the compactness of different SCPB samples. Furthermore, SEM was utilized to observe the hydration products in SCPB, which aided in analyzing the degree of hydration reactions in different samples [39,40].

2.3. Experiment Design

3. Analysis of Experimental Results

3.1. UCS

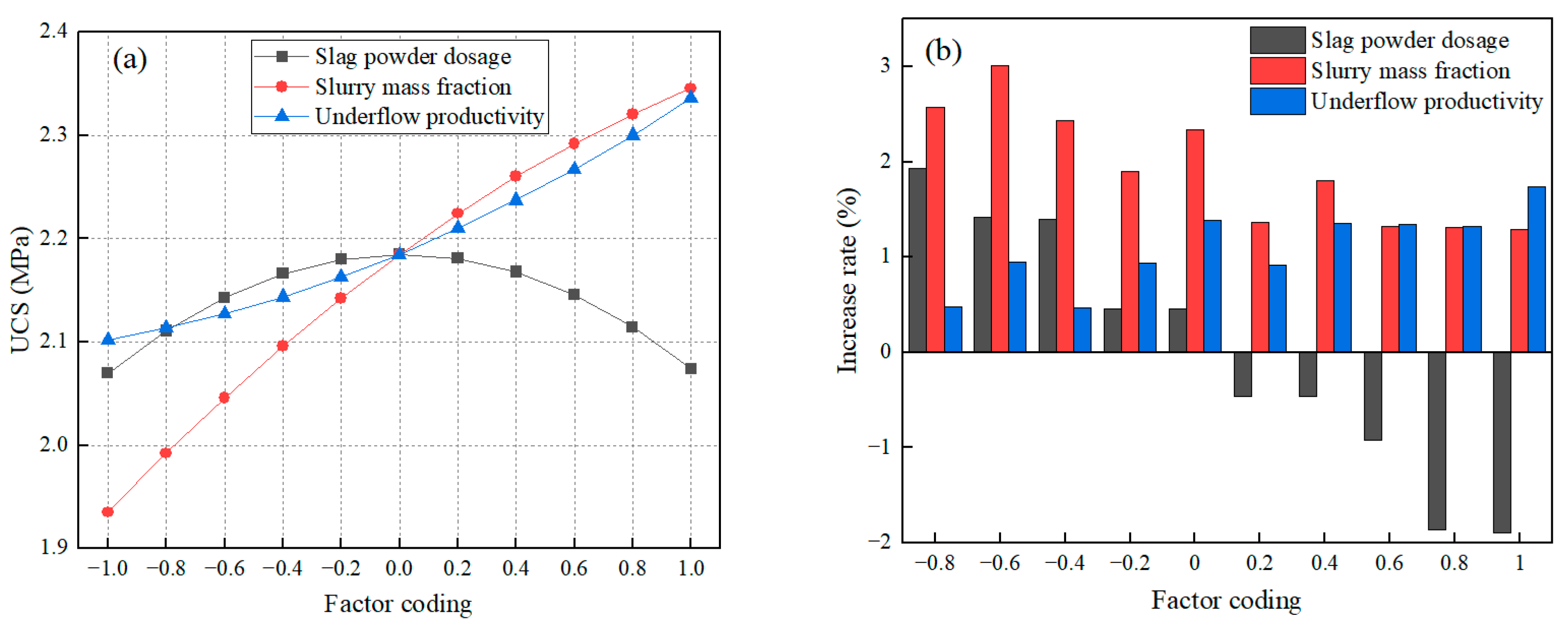

3.1.1. Single Factor Effect on UCS

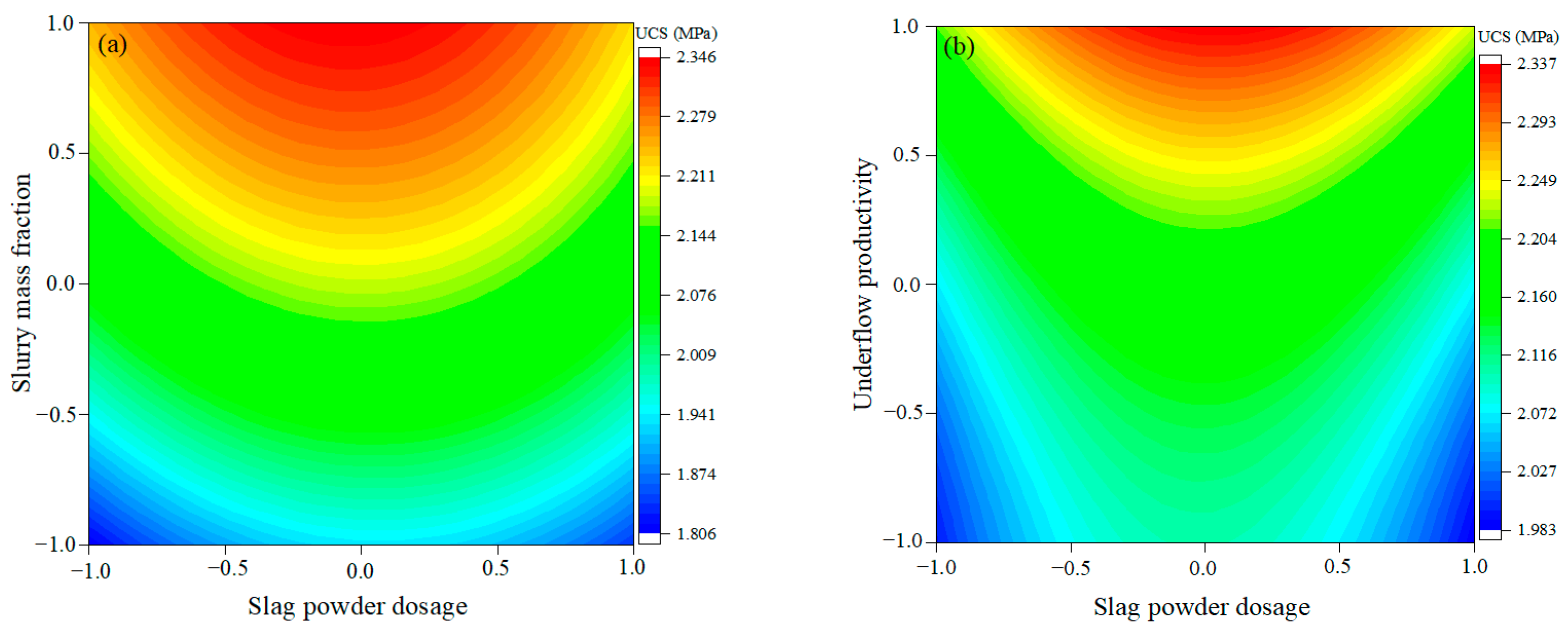

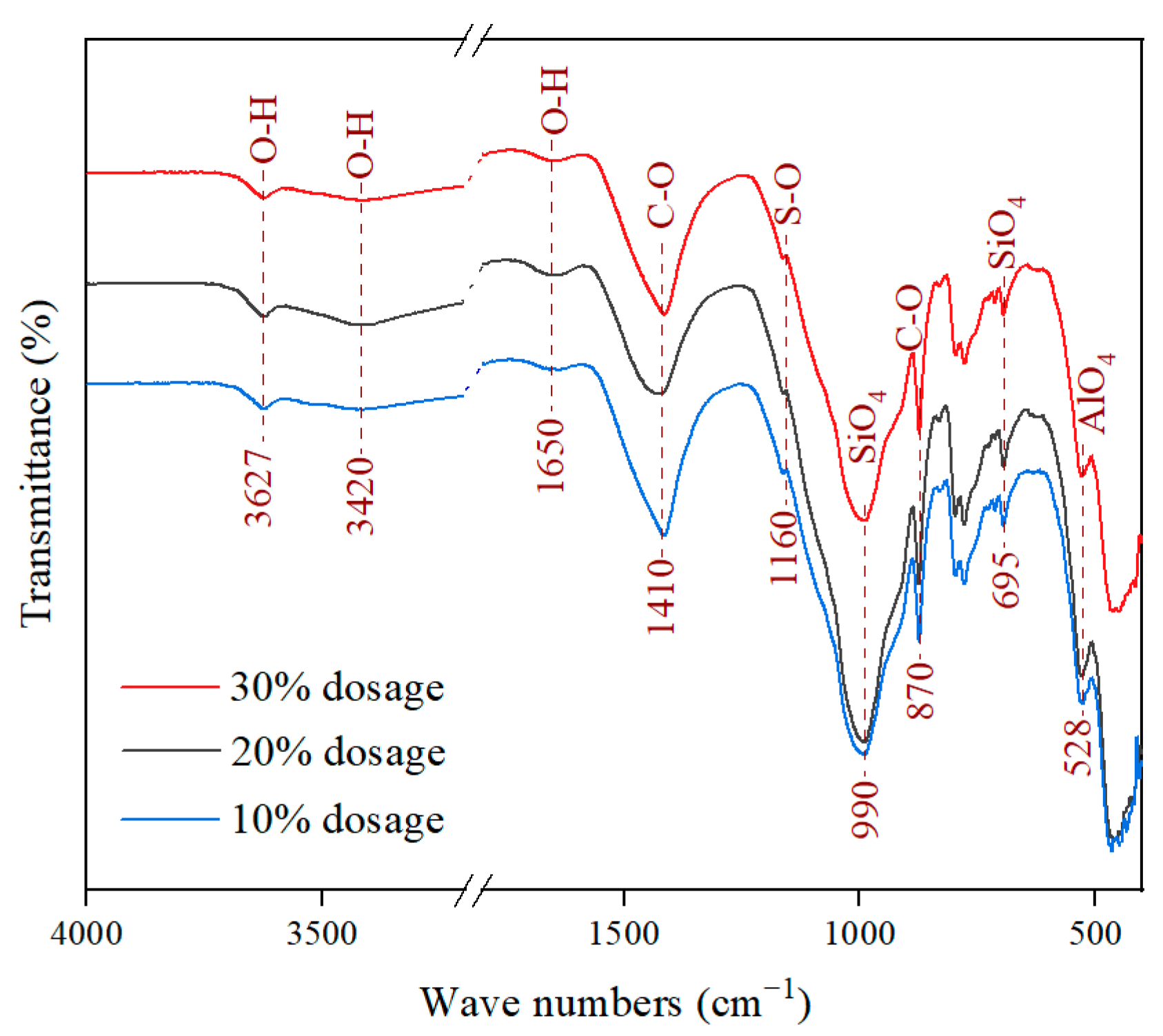

3.1.2. The Effect of Multifactor Coupling on UCS

3.2. Micro Products

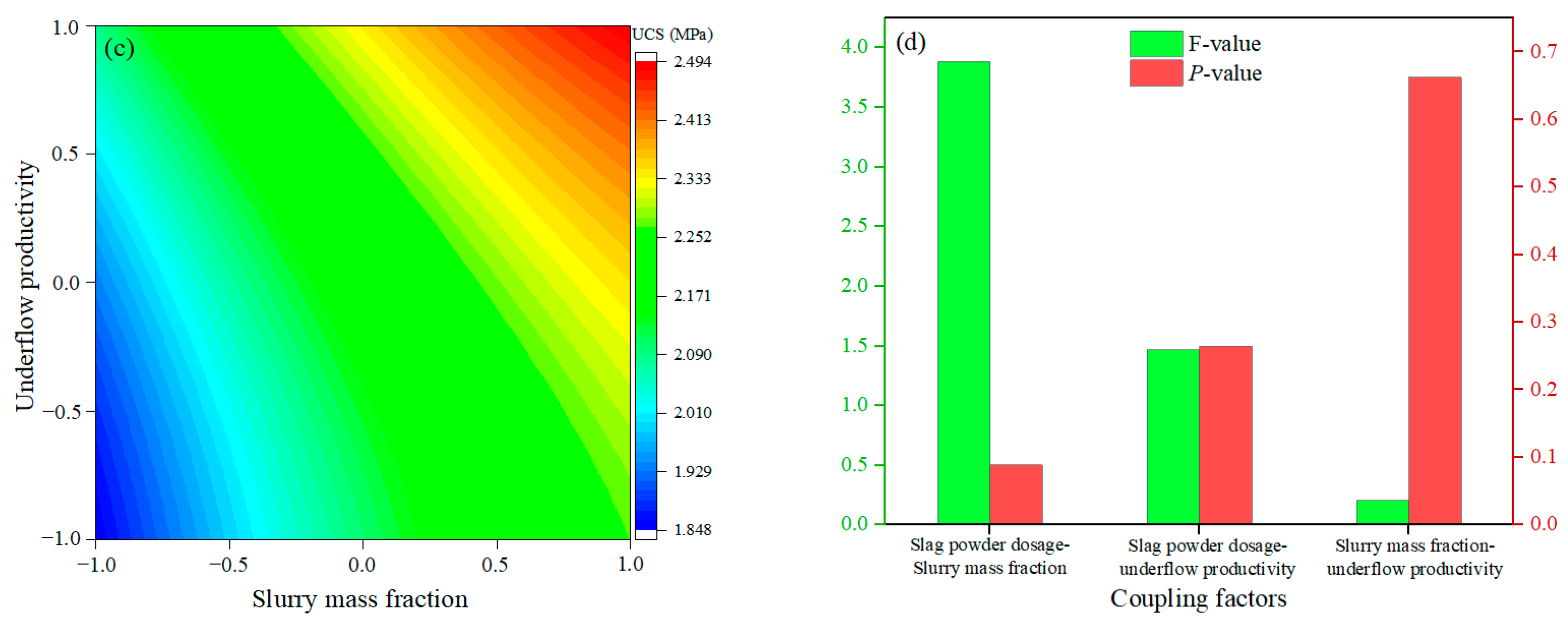

3.2.1. XRD

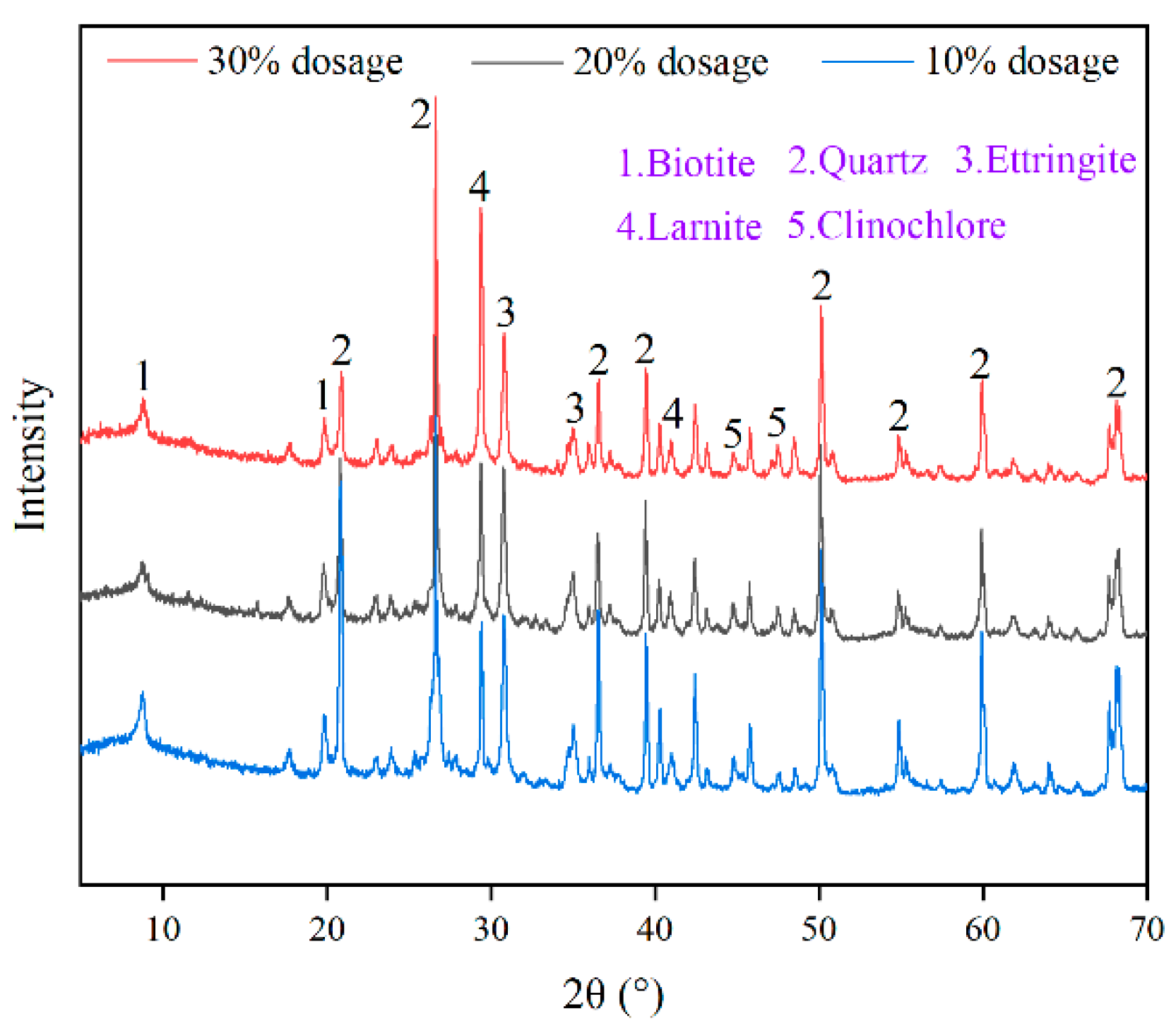

3.2.2. FT-IR

3.2.3. TG-DTG

3.3. Microstructure

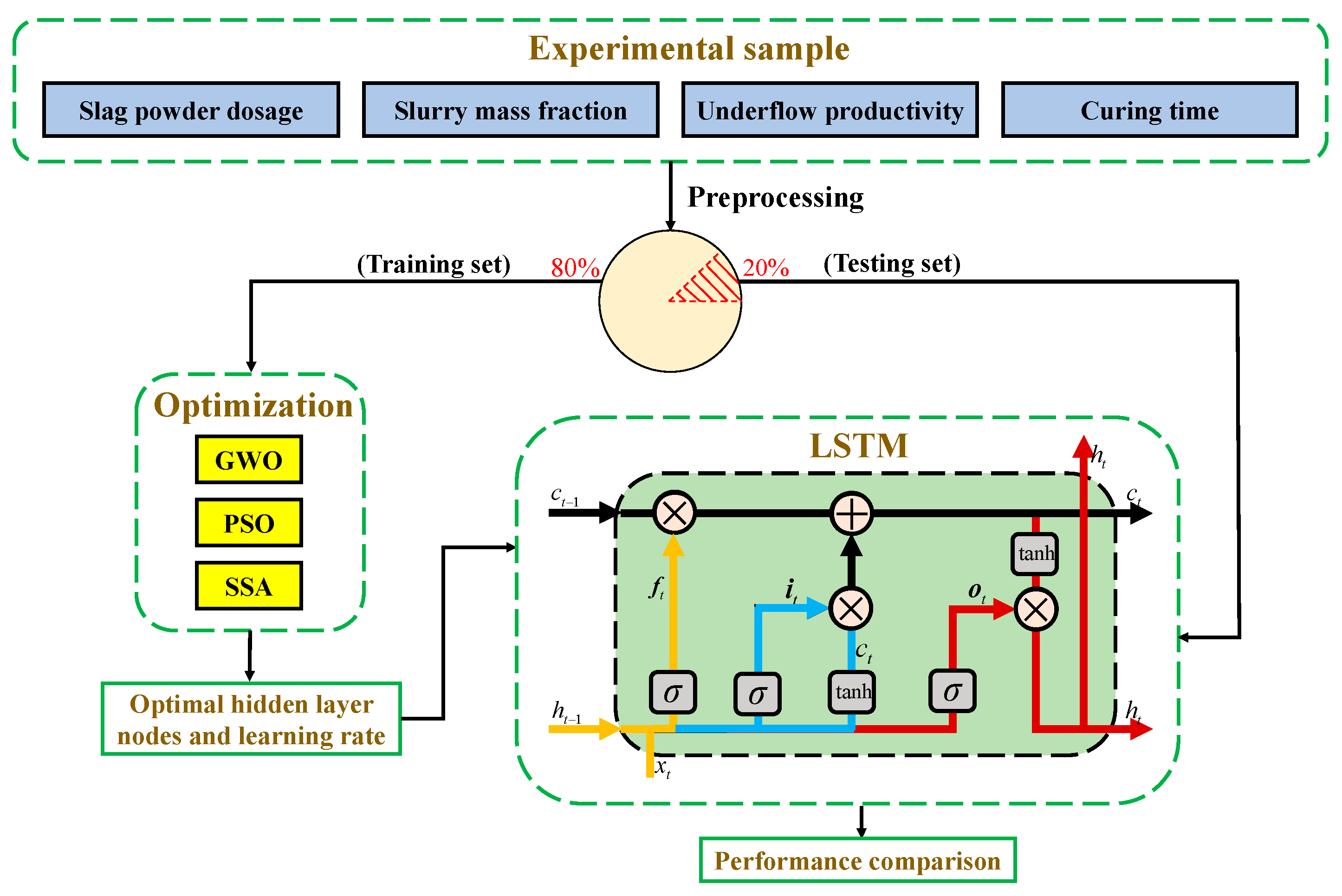

4. Prediction and Optimization Based on Machine Learning

4.1. Comparison and Selection of Networks

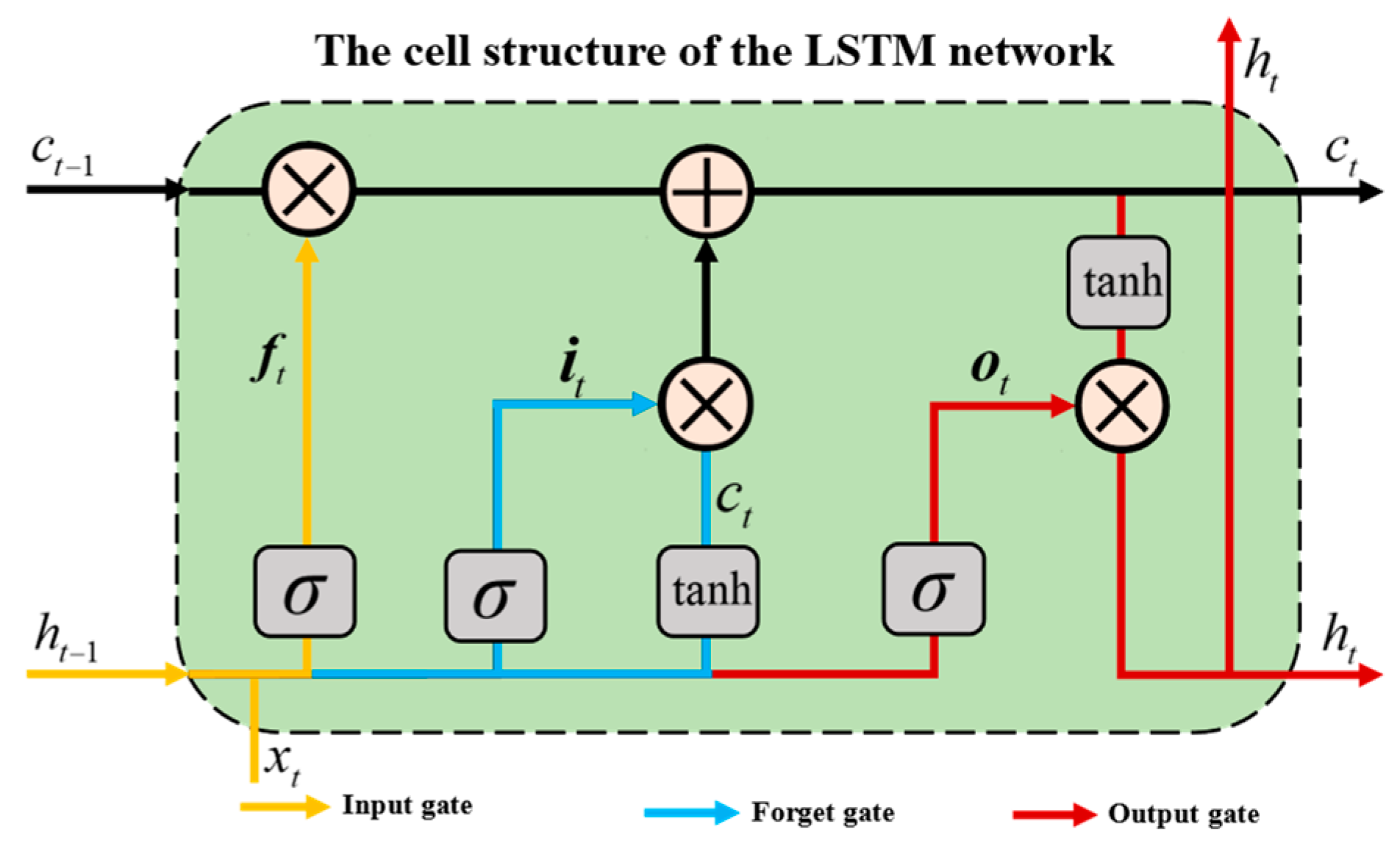

4.1.1. Long Short-Term Memory Neural Network

4.1.2. Performance Metrics

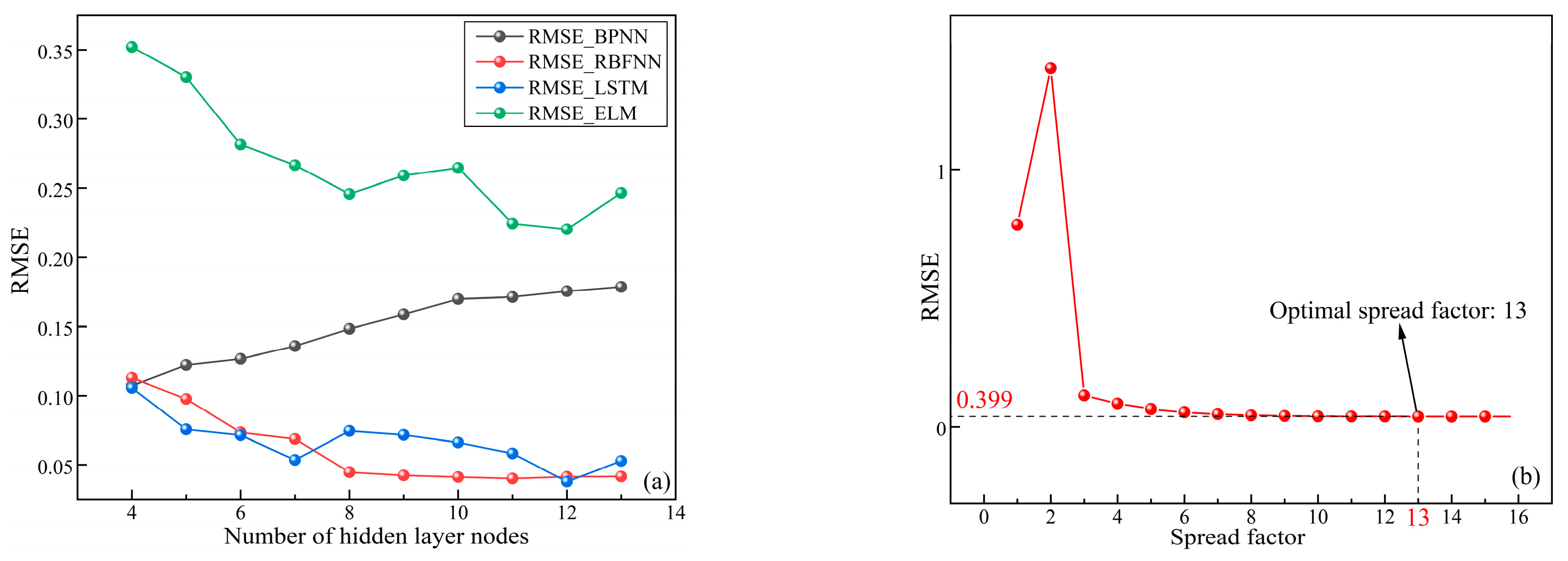

4.1.3. Adjustment of Parameters in Different Neural Network

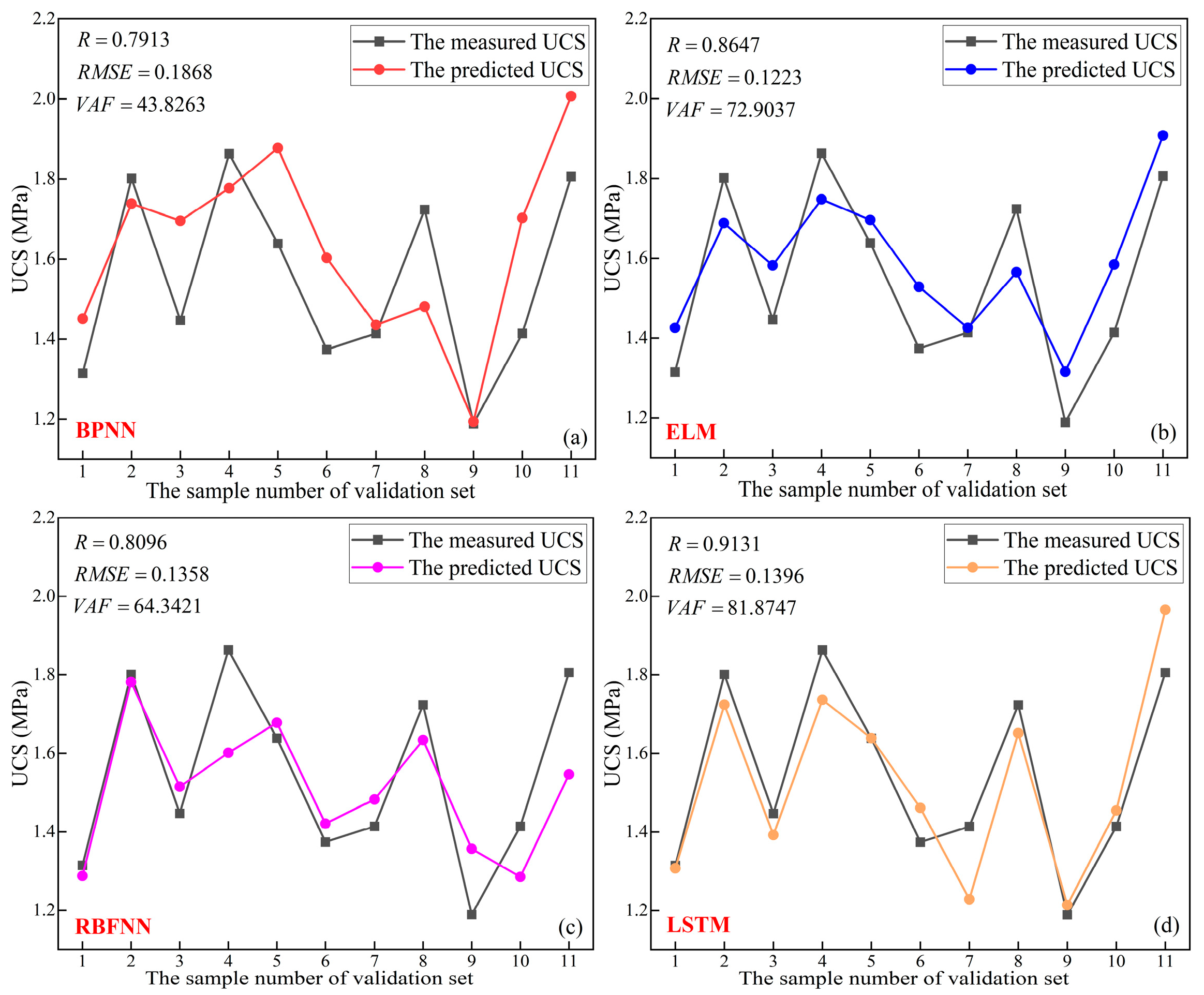

4.1.4. Comparison of Prediction Results of Different Neural Networks

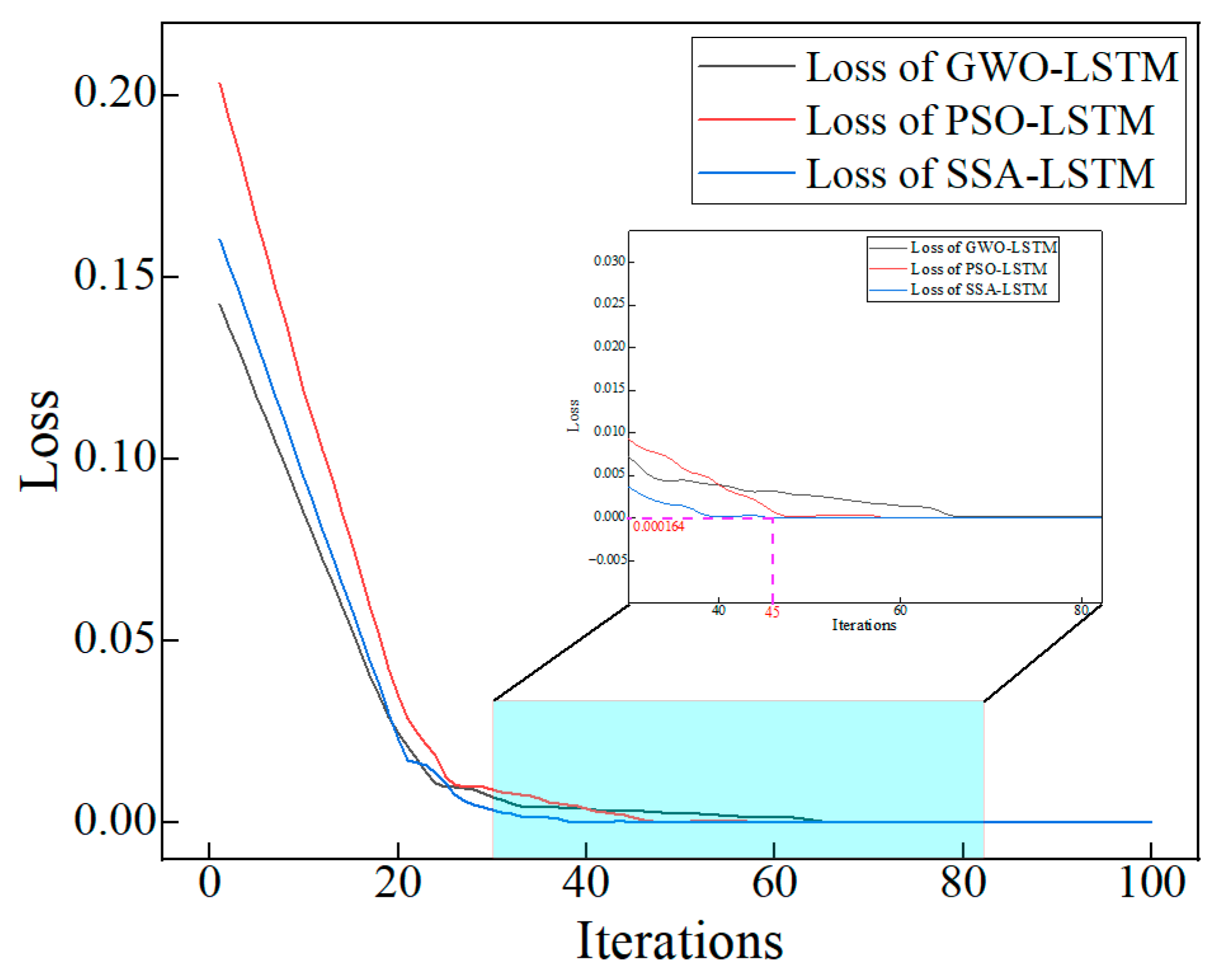

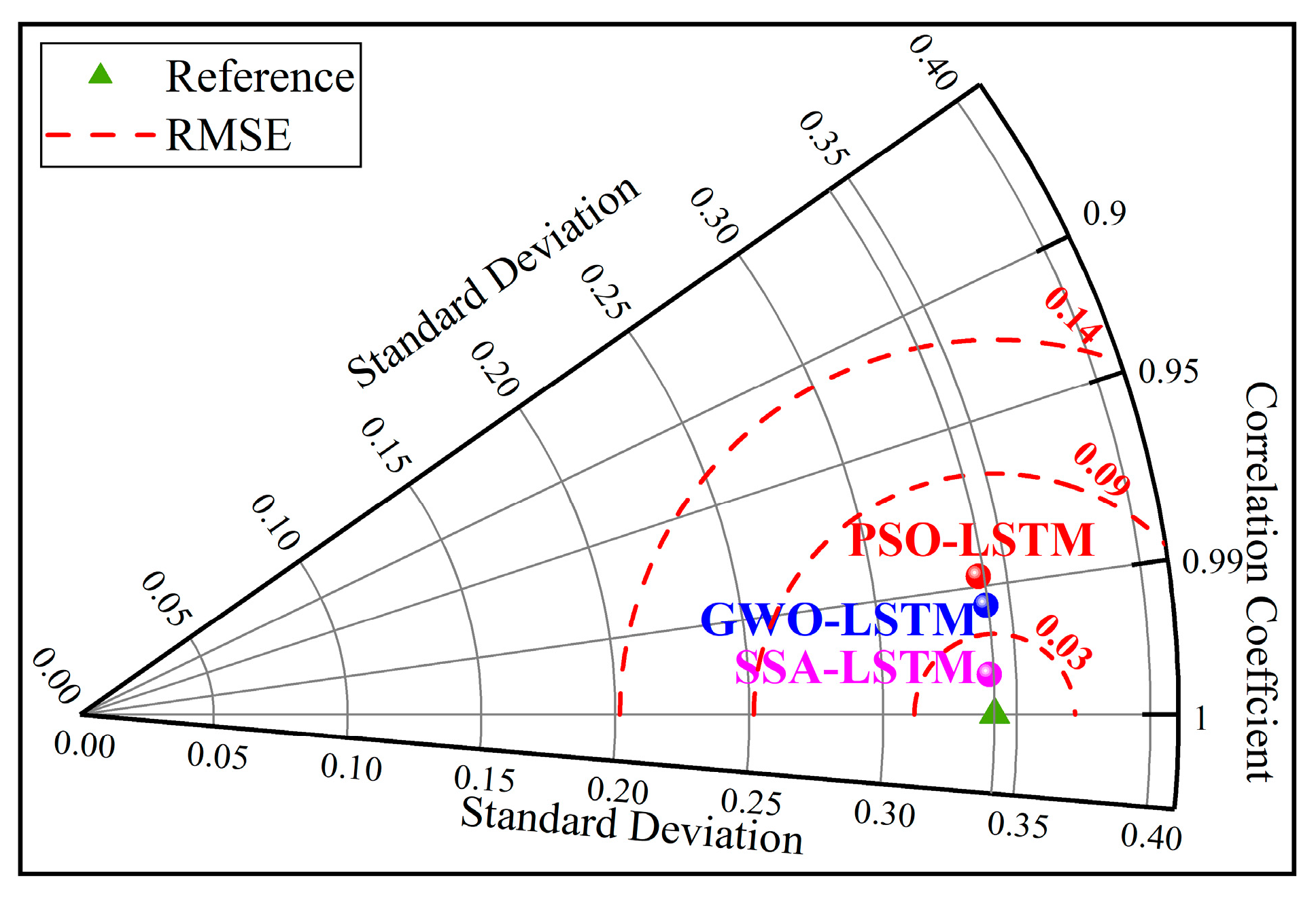

4.2. Optimization of LSTM

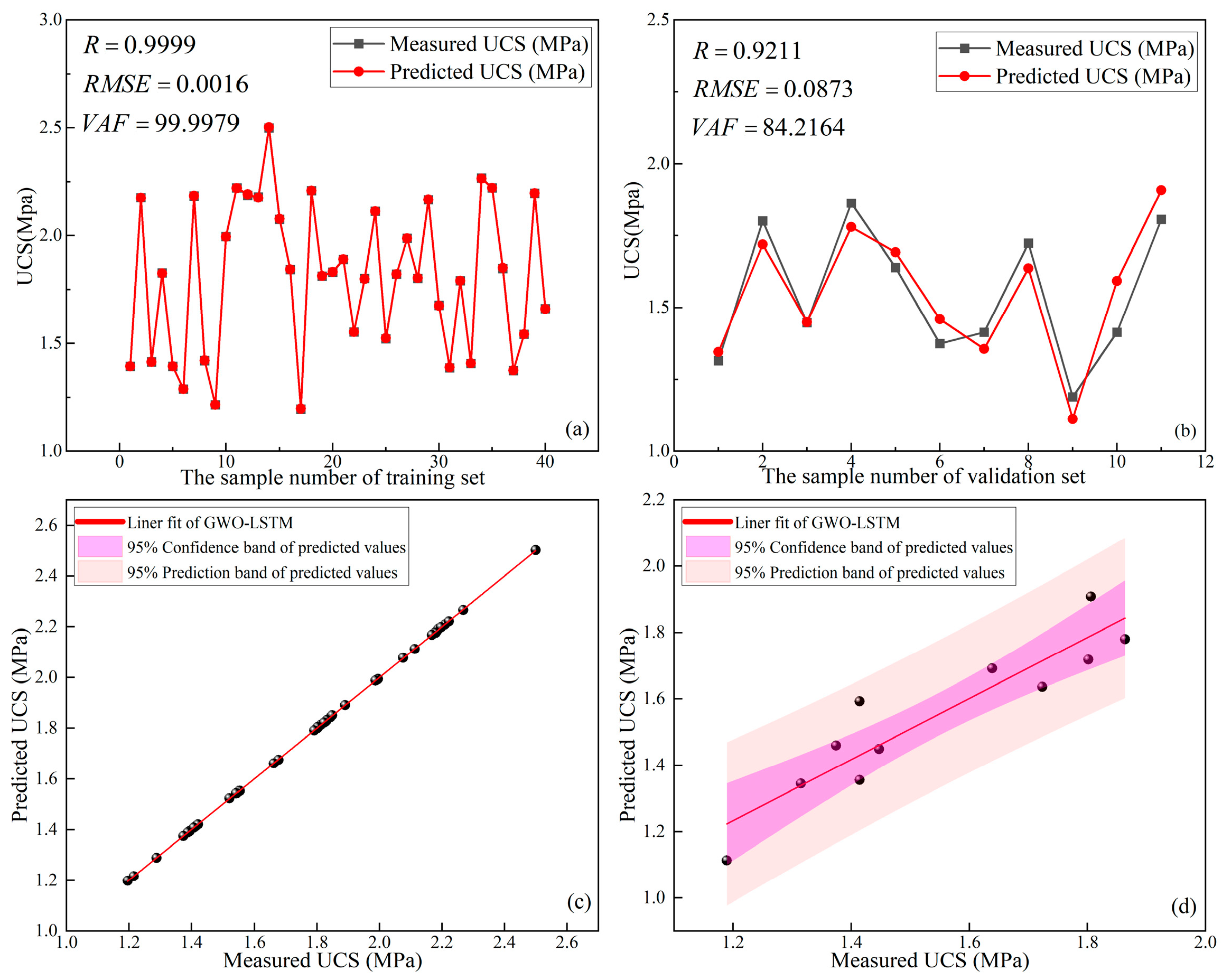

4.2.1. Results of GWO-LSTM

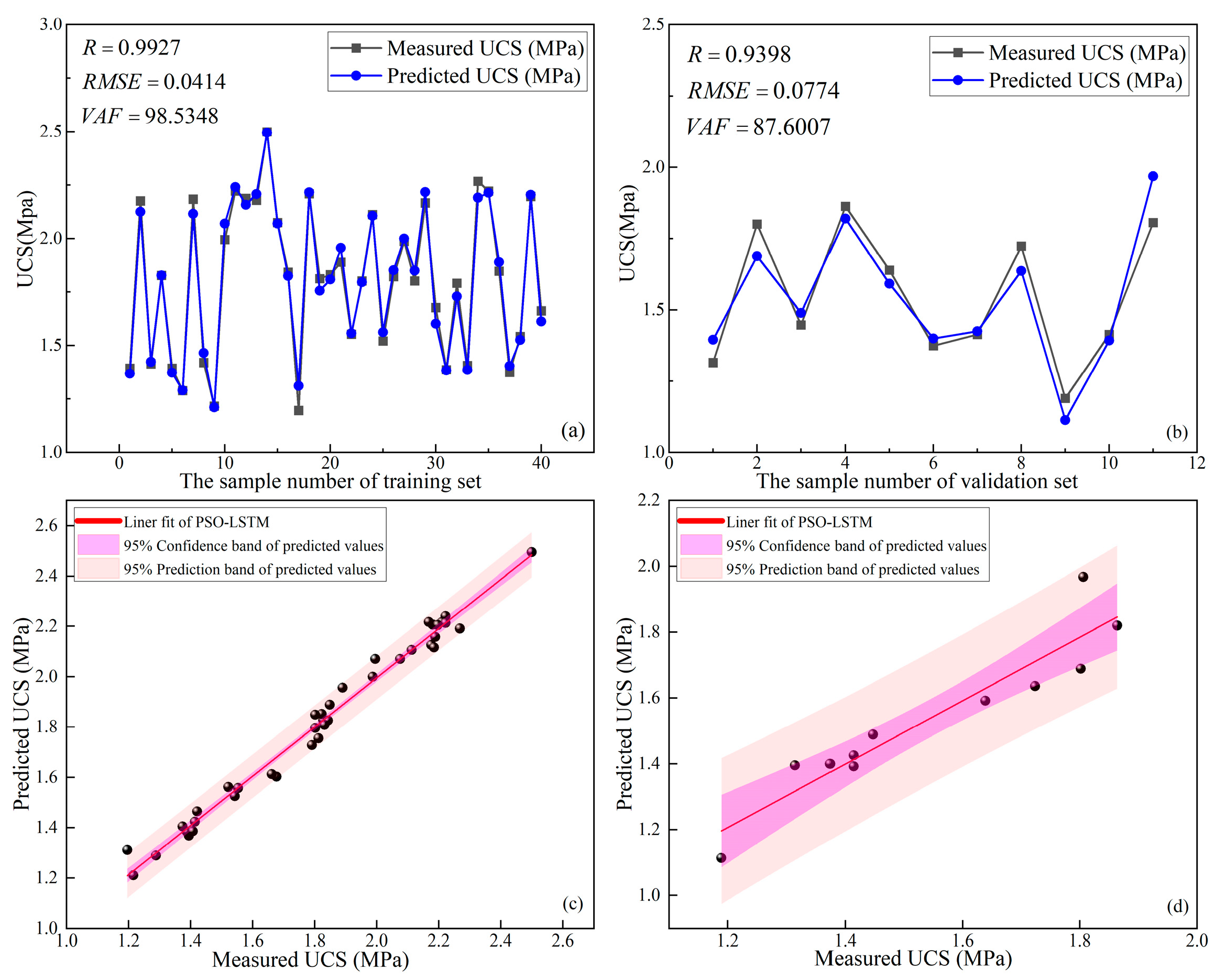

4.2.2. Results of PSO-LSTM

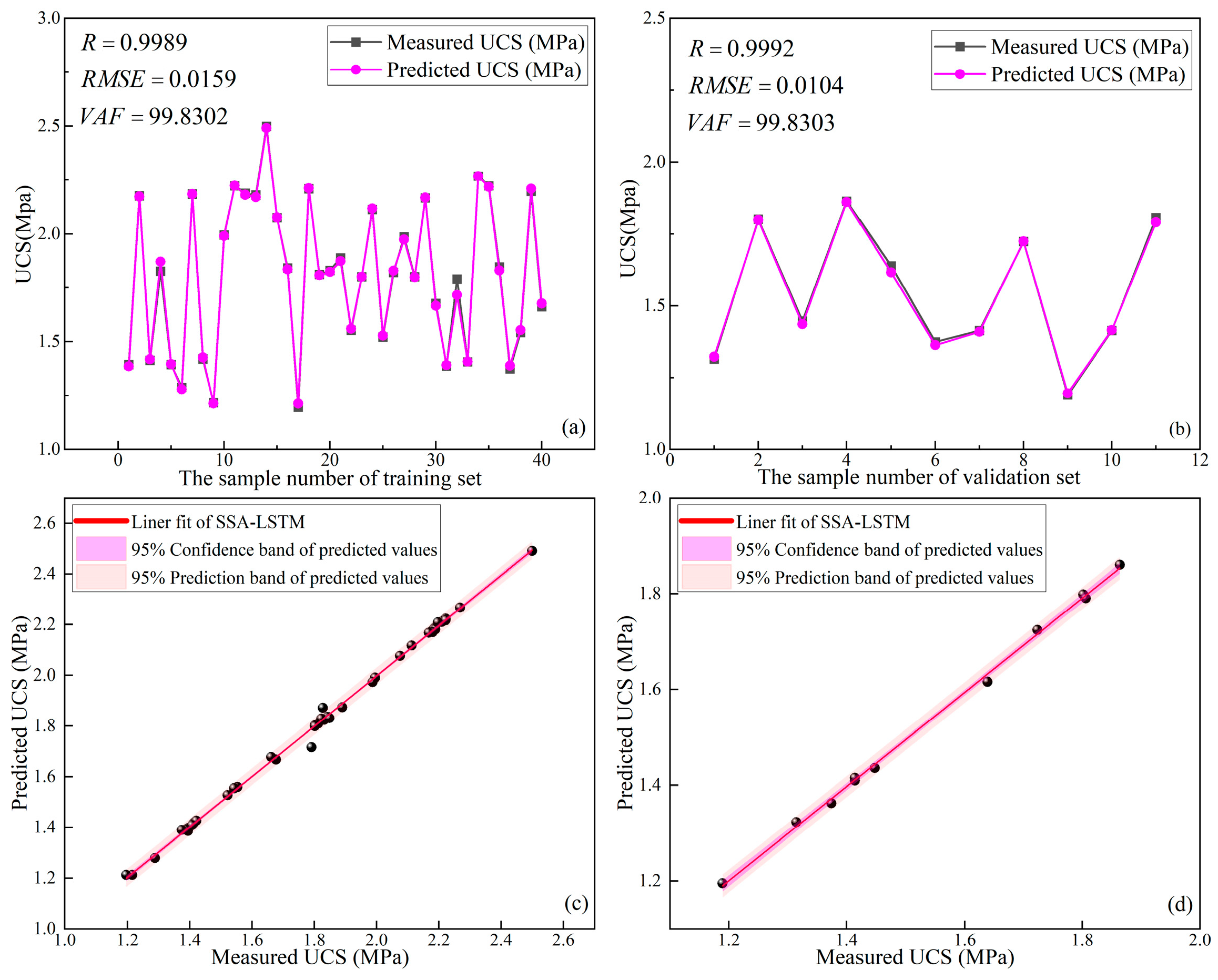

4.2.3. Results of SSA-LSTM

4.2.4. Analysis and Discussion of Results

5. Conclusions

- (1)

- The strength of SCPB exhibited an initial increase followed by a decrease with an increase in slag powder dosage. It showed an increase with the rise in slurry mass fraction and a decrease with the increase in underflow productivity. The combined influence of slag powder dosage and slurry mass fraction had the most pronounced effect on UCS, whereas the coupling effect of slurry mass fraction and underflow productivity had the least impact on UCS.

- (2)

- The generation of hydration products of SCPB with slag powder dosage of 20% was the highest, for the following reasons. The CH generated by the hydration of cement caused complete depolymerization of the glass bodies of slag powder, and released AlO45− and Ca2+. These ions fully reacted with gypsum in the cement to produce a large quantity of hydration products, and the consumption of CH by slag powder further promotes the hydration of the cement.

- (3)

- The LSTM model developed in this study demonstrates the highest prediction accuracy for the strength of SCPB under multi-factor conditions. The model achieved R, RMSE, and VAF values of 0.9131, 0.1396, and 81.8747, respectively. Through optimization using the SSA algorithm, the LSTM model’s performance was further enhanced, resulting in an improvement of 9.4% in R, 88.6% in RMSE, and 21.9% in VAF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, H.; Qi, C.; Chen, Q.; Gan, D.; Xue, Z.; Hu, Y. A new procedure for recycling waste tailings as cemented paste backfill to underground stopes and open pits. J. Clean. Prod. 2018, 188, 601–612. [Google Scholar] [CrossRef]

- Sun, W.; Wu, D.; Liu, H.; Qu, C. Thermal, mechanical and ultrasonic properties of cemented tailings backfill subjected to microwave radiation. Constr. Build. Mater. 2021, 313, 125535. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effects of packing density and water film thickness on the fluidity behaviour of cemented paste backfill. Powder Technol. 2020, 359, 27–35. [Google Scholar] [CrossRef]

- Yan, B.; Zhu, W.; Hou, C.; Yilmaz, E.; Saadat, M. Characterization of early age behavior of cemented paste backfill through the magnitude and frequency spectrum of ultrasonic P-wave. Constr. Build. Mater. 2020, 249, 118733. [Google Scholar] [CrossRef]

- Hu, J.; Ren, Q.; Yang, D.; Ma, S.; Shang, J.; Ding, X.; Luo, Z. Cross-scale characteristics of backfill material using NMR and fractal theory. Trans. Nonferrous Met. Soc. 2020, 30, 1347–1363. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Shi, Y.; Cheng, L.; Tao, M.; Tong, S.; Yao, X.; Liu, Y. Using modified quartz sand for phosphate pollution control in cemented phosphogypsum (PG) backfill. J. Clean. Prod. 2021, 283, 124652. [Google Scholar] [CrossRef]

- Wu, J.; Jing, H.; Yin, Q.; Meng, B.; Han, G. Strength and ultrasonic properties of cemented waste rock backfill considering confining pressure, dosage and particle size effects. Constr. Build. Mater. 2020, 242, 118132. [Google Scholar] [CrossRef]

- Hu, Y.; Li, K.; Zhang, B.; Han, B. Development of Cemented Paste Backfill with Superfine Tailings: Fluidity, Mechanical Properties, and Microstructure Characteristics. Materials. 2023, 16, 1951. [Google Scholar] [CrossRef]

- Zhou, N.; Zhang, J.; Ouyang, S.; Deng, X.; Dong, C.; Du, E. Feasibility study and performance optimization of sand-based cemented paste backfill materials. J. Clean. Prod. 2020, 259, 120798. [Google Scholar] [CrossRef]

- Liu, H.; Hou, C.; Li, L.; Du, J.; Yan, B. Experimental investigation on flow properties of cemented paste backfill through L-pipe and loop-pipe tests. J. Cent. South Univ. 2021, 28, 2830–2842. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Cui, L.; Si, Z.; Wang, H. Effect of external sulfate attack on the mechanical behavior of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120968. [Google Scholar] [CrossRef]

- Wu, D.; Deng, T.; Zhao, R. A coupled THMC modeling application of cemented coal gangue-fly ash backfill. Constr. Build. Mater. 2018, 158, 326–336. [Google Scholar] [CrossRef]

- Liu, Z.; Takasu, K.; Koyamada, H.; Suyama, H. A study on engineering properties and environmental impact of sustainable concrete with fly ash or GGBS. Constr. Build. Mater. 2022, 316, 125776. [Google Scholar] [CrossRef]

- Li, J.; Zhang, S.; Wang, Q.; Ni, W.; Li, K.; Fu, P.; Hu, W.; Li, Z. Feasibility of using fly ash—Slag-based binder for mine backfilling and its associated leaching risks. J. Hazard. Mater. 2020, 400, 123191. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, K.; Li, H.; Wang, D.; Wang, L.; Zhang, G. Dispersion properties of fly ash—Slag powders under the different environment. Constr. Build. Mater. 2021, 296, 123649. [Google Scholar] [CrossRef]

- Zhai, M.; Zhao, J.; Wang, D.; Wang, Y.; Wang, Q. Hydration properties and kinetic characteristics of blended cement containing lithium slag powder. J. Build. Eng. 2021, 39, 102287. [Google Scholar] [CrossRef]

- Langenderfer, M.J.; Fahrenholtz, W.G.; Chertopalov, S.; Zhou, Y.; Mochalin, V.N.; Johnson, C.E. Detonation synthesis of silicon carbide nanoparticles. Ceram. Int. 2020, 46, 6951–6954. [Google Scholar] [CrossRef]

- Wang, C.; Wei, X.; Ren, D.; Wang, X.; Xu, W. High-throughput map design of creep life in low-alloy steels by integrating machine learning with a genetic algorithm. Mater. Des. 2022, 213, 110326. [Google Scholar] [CrossRef]

- Wang, W.; Wang, H.; Zhou, J.; Fan, H.; Liu, X. Machine learning prediction of mechanical properties of braided-textile reinforced tubular structures. Mater. Des. 2021, 212, 110181. [Google Scholar] [CrossRef]

- Li, R.; Jin, M.; Paquit, V.C. Geometrical defect detection for additive manufacturing with machine learning models. Mater. Des. 2021, 206, 109726. [Google Scholar] [CrossRef]

- Cook, R.; Han, T.; Childers, A.; Ryckman, C.; Khayat, K.; Ma, H.; Huang, J.; Kumar, A. Machine learning for high-fidelity prediction of cement hydration kinetics in blended systems. Mater. Des. 2021, 208, 109920. [Google Scholar] [CrossRef]

- Li, E.; Zhou, J.; Shi, X.; Jahed Armaghani, D.; Yu, Z.; Chen, X.; Huang, P. Developing a hybrid model of salp swarm algorithm-based support vector machine to predict the strength of fiber-reinforced cemented paste backfill. Eng. Comput. 2021, 37, 3519–3540. [Google Scholar] [CrossRef]

- Qi, C.; Chen, Q.; Fourie, A.; Zhang, Q. An intelligent modelling framework for mechanical properties of cemented paste backfill. Miner. Eng. 2018, 123, 16–27. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Zhang, Q. A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill. J. Clean. Prod. 2018, 183, 566–578. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.; Chen, X.; Zhou, J.; Qi, C.; Chen, Q.; Rao, D. Artificial intelligence model for studying unconfined compressive performance of fiber-reinforced cemented paste backfill. Trans. Nonferrous Met. Soc. 2021, 31, 1087–1102. [Google Scholar] [CrossRef]

- Qi, C.; Chen, Q.; Dong, X.; Zhang, Q.; Yaseen, Z.M. Pressure drops of fresh cemented paste backfills through coupled test loop experiments and machine learning techniques. Powder Technol. 2020, 361, 748–758. [Google Scholar] [CrossRef]

- Qi, C.; Chen, Q.; Fourie, A.; Tang, X.; Zhang, Q.; Dong, X.; Feng, Y. Constitutive modelling of cemented paste backfill: A data-mining approach. Constr. Build. Mater. 2019, 197, 262–270. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q. Neural network and particle swarm optimization for predicting the unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 159, 473–478. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, X.; Chen, Q.; Bin, F.; Wang, Y.; Wei, W. Strength Investigation of the Silt-Based Cemented Paste Backfill Using Lab Experiments and Deep Neural Network. Adv. Mater. Sci. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Zhang, B.; Li, K.; Hu, Y.; Ji, K.; Han, B. Prediction of Backfill Strength Based on Support Vector Regression Improved by Grey Wolf Optimization. J. Shanghai Jiaotong Univ. Sci. 2022, 4, 1–9. [Google Scholar] [CrossRef]

- Zhang, B.; Li, K.; Zhang, S.; Hu, Y.; Han, B. A Modeling Method for Predicting the Strength of Cemented Paste Backfill Based on a Combination of Aggregate Gradation Optimization and LSTM. J. Renew. Mater. 2022, 10, 3539. [Google Scholar] [CrossRef]

- Hu, Y.; Li, K.; Zhang, B.; Han, B. Effects of mixing time and nano silica on some properties of superfine-tailings cemented paste backfill. Constr. Build. Mater. 2023, 378, 131188. [Google Scholar] [CrossRef]

- Saroha, B.; Kumar, A.; Raman Maurya, R.; Lal, M.; Kumar, S.; Kumar Rajor, H.; Bahadur, I.; Singh Negi, D. Adsorption of cysteine on metal(II) octacynaomolybdate(IV) at different pH values: Surface complexes characterization by FT-IR, SEM with EDXA, CHNS and Langmuir isotherm analysis. J. Mol. Liq. 2022, 349, 118197. [Google Scholar] [CrossRef]

- Yellareddy, P.; Kumar, C.N.S.S.; Gowrisankar, M.; Babu, S.; Rathnam, M.V. Study on molecular interactions of binary mixtures of 2,6 dimethyl cyclohexanone with substituted anilines at T = (303.15–313.15) K through thermodynamic properties and FT-IR spectra and correlation with the Jouyban—Acree model. J. Mol. Liq. 2021, 343, 117708. [Google Scholar] [CrossRef]

- Lv, G.; Chang, P.; Xing, X.; Jiang, W.; Jean, J.; Li, Z. Investigation of intercalation of diphenhydramine into the interlayer of smectite by XRD, FTIR, TG-DTG analyses and molecular simulation. Arab. J. Chem. 2017, 10, 855–861. [Google Scholar] [CrossRef]

- Mo, W.; Wu, Z.; He, X.; Qiang, W.; Wei, B.; Wei, X.; Wu, Y.; Fan, X.; Ma, F. Functional group characteristics and pyrolysis/combustion performance of fly ashes from Karamay oily sludge based on FT-IR and TG-DTG analyses. Fuel 2021, 296, 120669. [Google Scholar] [CrossRef]

- Martínez-Ortiz-De-Montellano, C.; Torres-Acosta, J.F.D.J.; Sandoval-Castro, C.A.; Fourquaux, I.; Hoste, H. Scanning electron microscopy of different vulval structures in a Mexican Haemonchus contortus isolate. Vet. Parasitol. Reg. Stud. Rep. 2021, 26, 100640. [Google Scholar] [CrossRef]

- Souza, B.D.D.O.; Arcos, J.J.E.; Nakamura, C.V.; Nagashima, L.A.; Sano, A.; Ono, M.A.; Itano, E.N. In vitro Arthrographis kalrae biofilm formation: Scanning electron microscopy and cytotoxic analysis. J. Microbiol. Immunol. Infect. 2021, 55, 973–976. [Google Scholar] [CrossRef]

- Barreno-Avila, E.; Moya-Moya, E.; Pérez-Salinas, C. Rice-husk fiber reinforced composite (RFRC) drilling parameters optimization using RSM based desirability function approach. Mater. Today Proc. 2021, 49, 167–174. [Google Scholar] [CrossRef]

- Fauzi, M.A.; Arshad, M.F.; Md Nor, N.; Ghazali, E. Modeling and optimization of properties for unprocessed-fly ash (u-FA) controlled low-strength material as backfill materials. Clean. Eng. Technol. 2022, 6, 100395. [Google Scholar] [CrossRef]

- Benkirane, O.; Haruna, S.; Fall, M. Strength and microstructure of cemented paste backfill modified with nano-silica particles and cured under non-isothermal conditions. Powder Technol. 2023, 419, 118311. [Google Scholar] [CrossRef]

- Al-Moselly, Z.; Fall, M.; Haruna, S. Further insight into the strength development of cemented paste backfill materials containing polycarboxylate ether-based superplasticizer. J. Build. Eng. 2022, 47, 103859. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Reactivity of cemented paste backfill containing polycarboxylate-based superplasticizer. Miner. Eng. 2022, 188, 107856. [Google Scholar] [CrossRef]

- Altan, A.; Karasu, S.; Zio, E. A new hybrid model for wind speed forecasting combining long short-term memory neural network, decomposition methods and grey wolf optimizer. Appl. Soft Comput. 2021, 100, 106996. [Google Scholar] [CrossRef]

- Borna, K.; Ghanbari, R. Hierarchical LSTM network for text classification. SN Appl. Sci. 2019, 1, 1124. [Google Scholar] [CrossRef]

- Kumar, K.; Haider, M.T.U. Enhanced Prediction of Intra-day Stock Market Using Metaheuristic Optimization on RNN–LSTM Network. New Generat. Comput. 2021, 39, 231–272. [Google Scholar] [CrossRef]

- Weigend, A.S.; Rumelhart, D.E.; Huberman, B.A. Back-Propagation, Weight-Elimination and Time Series Prediction. In Connectionist Models; Touretzky, D.S., Elman, J.L., Sejnowski, T.J., Hinton, G.E., Eds.; Morgan Kaufmann: Burlington, MA, USA, 1991; pp. 105–116. [Google Scholar]

- Chen, S.; Cowan, C.F.N.; Grant, P.M. Orthogonal least squares learning algorithm for radial basis function networks. IEEE Trans. Neural Netw. 1991, 2, 302–309. [Google Scholar] [CrossRef]

- Guang-Bin, H.; Qin-Yu, Z.; Chee-Kheong, S. Extreme learning machine: A new learning scheme of feedforward neural networks. In Proceedings of the IEEE International Joint Conference on Neural Networks (IEEE Cat. No.04CH37541), Budapest, Hungary, 25–29 July 2004. [Google Scholar]

- Ghaleini, E.N.; Koopialipoor, M.; Momenzadeh, M.; Sarafraz, M.E.; Mohamad, E.T.; Gordan, B. A combination of artificial bee colony and neural network for approximating the safety factor of retaining walls. Eng. Comput. 2019, 35, 647–658. [Google Scholar] [CrossRef]

- Chaurasia, P.; Younis, K.; Qadri, O.S.; Srivastava, G.; Osama, K. Comparison of Gaussian process regression, artificial neural network, and response surface methodology modeling approaches for predicting drying time of mosambi (Citrus limetta) peel. J. Food Process Eng. 2019, 42, e12966. [Google Scholar] [CrossRef]

- Sivakugan, R.R.N. Prediction of paste backfill performance using artificial neural networks. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; pp. 1107–1110. [Google Scholar]

- Määttä, J.; Bazaliy, V.; Kimari, J.; Djurabekova, F.; Nordlund, K.; Roos, T. Gradient-based training and pruning of radial basis function networks with an application in materials physics. Neural Netw. 2021, 133, 123–131. [Google Scholar] [CrossRef]

- Liang, L.; Mi, H.; Guo, W.; Zhang, Y.; Ma, H.; Zhang, Z.; Li, L. Estimation of sound absorption coefficient of composite structured aluminum foam by radial basis function neural network. Appl. Acoust. 2022, 185, 108414. [Google Scholar] [CrossRef]

- Cui, Y.; Shi, J.; Wang, Z. Lazy Quantum clustering induced radial basis function networks (LQC-RBFN) with effective centers selection and radii determination. Neurocomputing 2016, 175, 797–807. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Cai, Z.; Xi, P.; Pan, Y.; Huang, G.; Zhang, T. A proposed self-organizing radial basis function network for aero-engine thrust estimation. Aerosp. Sci. Technol. 2019, 87, 167–177. [Google Scholar] [CrossRef]

- Xiong, Y.; Ohashi, S.; Nakano, K.; Jiang, W.; Takizawa, K.; Iijima, K.; Maniwara, P. Application of the radial basis function neural networks to improve the nondestructive Vis/NIR spectrophotometric analysis of potassium in fresh lettuces. J. Food Eng. 2021, 298, 110417. [Google Scholar] [CrossRef]

- Song, J.; Tang, S.; Xiao, J.; Wu, F.; Zhang, Z.M. LSTM-in-LSTM for generating long descriptions of images. Comput. Vis. Media 2016, 2, 379–388. [Google Scholar] [CrossRef]

- Rybalkin, V.; Sudarshan, C.; Weis, C.; Lappas, J.; Wehn, N.; Cheng, L. Correction to: Efficient Hardware Architectures for 1D- and MD-LSTM Networks. J. Signal Process. Syst. 2021, 93, 1467. [Google Scholar] [CrossRef]

- Wang, L.; Zhong, X.; Wang, S.; Liu, Y. Correction to: NcDLRES: A novel method for non-coding RNAs family prediction based on dynamic LSTM and ResNet. BMC Bioinform. 2021, 22, 583. [Google Scholar] [CrossRef]

- Premkumar, M.; Sowmya, R.; Umashankar, S.; Jangir, P. Extraction of uncertain parameters of single-diode photovoltaic module using hybrid particle swarm optimization and grey wolf optimization algorithm. Mater. Today Proc. 2021, 46, 5315–5321. [Google Scholar] [CrossRef]

- Deepa, G.; Mary, G.L.R.; Karthikeyan, A.; Rajalakshmi, P.; Hemavathi, K.; Dharanisri, M. Detection of brain tumor using modified particle swarm optimization (MPSO) segmentation via haralick features extraction and subsequent classification by KNN algorithm. Mater. Today Proc. 2021, 56, 1820–1826. [Google Scholar] [CrossRef]

- Ben Hmamou, D.; Elyaqouti, M.; Arjdal, E.; Chaoufi, J.; Saadaoui, D.; Lidaighbi, S.; Aqel, R. Particle swarm optimization approach to determine all parameters of the photovoltaic cell. Mater. Today Proc. 2021, 52, 7–12. [Google Scholar] [CrossRef]

- Ling, H.; Lishuan, H. An Improved Particle Swarm Optimization for Continuous Problems. In Proceedings of the 2009 Fifth International Conference on Natural Computation, Tianjian, China, 14–16 August 2009. [Google Scholar]

- Jianguo, Z.; Weijing, Y.; Yu, S.; Zhaoming, W. One Improved Method for Analytic Hierarchy Process Based on Least Deviation Method and Particle Swarm Optimization. In Proceedings of the 2007 IEEE International Conference on Control and Automation, Guangzhou, China, 30 May–1 June 2007. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control. Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

- Castro, S.L.; Wick, G.A.; Steele, M. Validation of satellite sea surface temperature analyses in the Beaufort Sea using UpTempO buoys. Remote Sens. Environ. 2016, 187, 458–475. [Google Scholar] [CrossRef]

- Gholami, H.; Mohamadifar, A.; Sorooshian, A.; Jansen, J.D. Machine-learning algorithms for predicting land susceptibility to dust emissions: The case of the Jazmurian Basin, Iran. Atmos. Pollut. Res. 2020, 11, 1303–1315. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | CaO | MgO | Fe2O3 | Al2O3 | SO3 | TiO2 |

|---|---|---|---|---|---|---|---|

| Tailings | 67.1% | 2.51% | 0.65% | 2.17% | 16.73% | 0.9% | 0.25% |

| Cement | 20.35% | 62.20% | 4.22% | 3.17% | 4.34% | 2.54% | / |

| Slag powder | 27.51% | 43.24% | 8.09% | 0.38% | 16.25% | 1.51% | 0.32% |

| Factors | Horizon Codes | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Slag powder dosage (X1) | 10 | 20 | 30 |

| Slurry mass fraction (X2) | 65 | 68 | 71 |

| Underflow productivity (X3) | 75 | 65 | 55 |

| Number | Factors/% | Measured UCS/MPa | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Y1 | Y2 | Y3 | |

| 1 | 20 | 68 | 65 | 1.39 | 1.79 | 2.17 |

| 2 | 20 | 71 | 75 | 1.45 | 1.89 | 2.27 |

| 3 | 10 | 68 | 75 | 1.31 | 1.68 | 2.00 |

| 4 | 20 | 68 | 65 | 1.41 | 1.80 | 2.18 |

| 5 | 10 | 68 | 55 | 1.37 | 1.84 | 2.20 |

| 6 | 20 | 68 | 65 | 1.41 | 1.80 | 2.18 |

| 7 | 30 | 65 | 65 | 1.22 | 1.55 | 1.85 |

| 8 | 20 | 68 | 65 | 1.39 | 1.81 | 2.18 |

| 9 | 30 | 71 | 65 | 1.41 | 1.82 | 2.21 |

| 10 | 10 | 65 | 65 | 1.19 | 1.52 | 1.81 |

| 11 | 10 | 71 | 65 | 1.42 | 1.83 | 2.22 |

| 12 | 20 | 71 | 55 | 1.64 | 2.11 | 2.50 |

| 13 | 30 | 68 | 55 | 1.39 | 1.86 | 2.22 |

| 14 | 20 | 68 | 65 | 1.41 | 1.80 | 2.19 |

| 15 | 20 | 65 | 55 | 1.37 | 1.72 | 2.07 |

| 16 | 20 | 65 | 75 | 1.20 | 1.54 | 1.83 |

| 17 | 30 | 68 | 75 | 1.29 | 1.66 | 1.99 |

| Network | Results | Rank Values | Total Rank | ||||

|---|---|---|---|---|---|---|---|

| R | RMSE | VAF | R | RMSE | VAF | ||

| BPNN | 0.7913 | 0.1868 | 43.8263 | 1 | 1 | 1 | 3 |

| ELM | 0.8647 | 0.1223 | 72.9037 | 3 | 4 | 3 | 10 |

| RBFNN | 0.8096 | 0.1358 | 64.3421 | 2 | 3 | 2 | 7 |

| LSTM | 0.9131 | 0.1396 | 81.8747 | 4 | 2 | 4 | 10 |

| Models | Initial Learning Rate | Target Error | Max Iterations | Number of Hidden Layers | Structure | Spread Factor |

|---|---|---|---|---|---|---|

| LSTM | 0.005 | 0.001 | 100 | 1 | 4-12-1 | / |

| BPNN | 4-4-1 | / | ||||

| ELM | 4-12-1 | / | ||||

| RBFNN | 4-13-1 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Li, K.; Zhang, B.; Han, B. Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods. Materials 2023, 16, 3995. https://doi.org/10.3390/ma16113995

Hu Y, Li K, Zhang B, Han B. Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods. Materials. 2023; 16(11):3995. https://doi.org/10.3390/ma16113995

Chicago/Turabian StyleHu, Yafei, Keqing Li, Bo Zhang, and Bin Han. 2023. "Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods" Materials 16, no. 11: 3995. https://doi.org/10.3390/ma16113995

APA StyleHu, Y., Li, K., Zhang, B., & Han, B. (2023). Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods. Materials, 16(11), 3995. https://doi.org/10.3390/ma16113995