Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- -

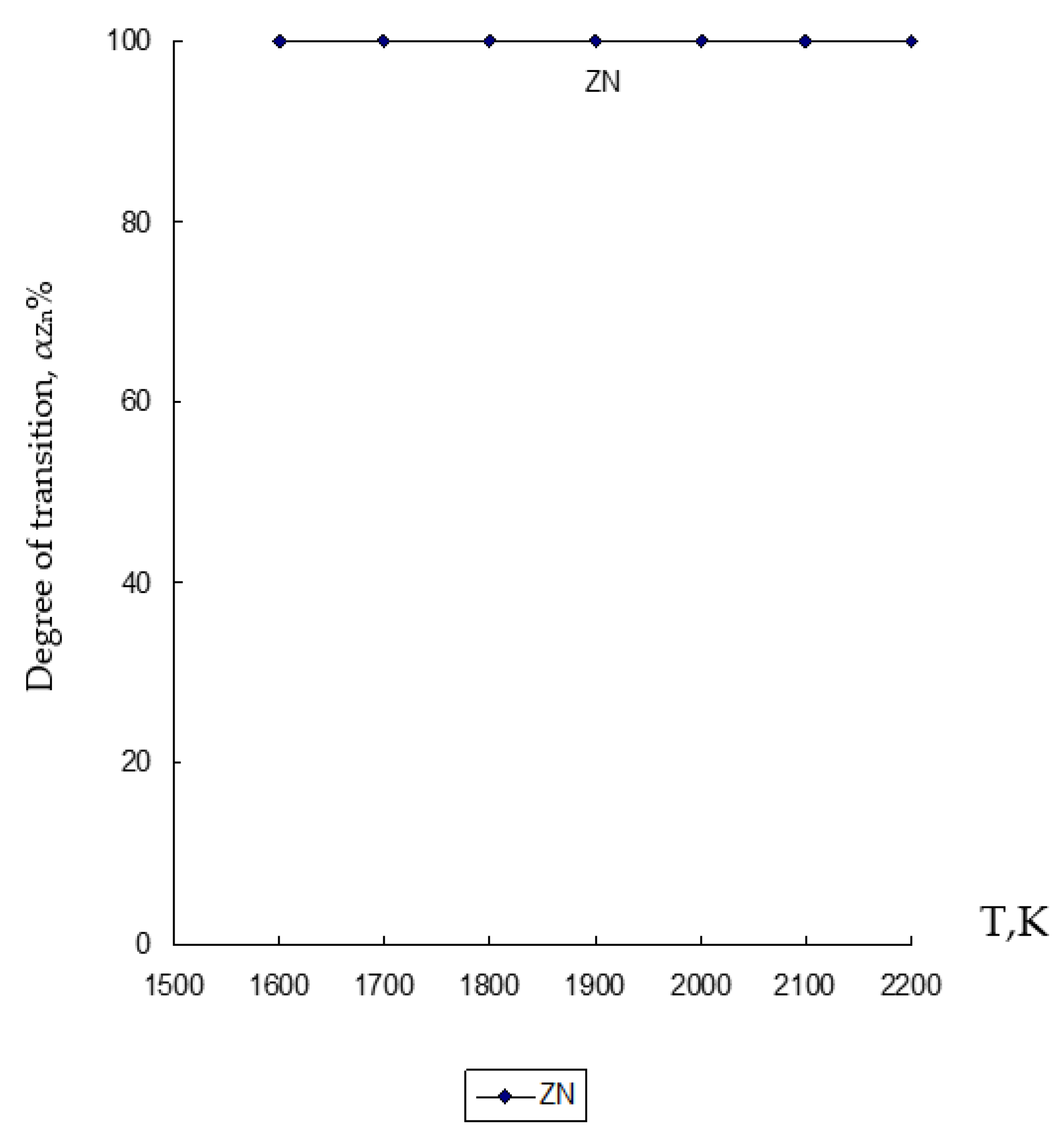

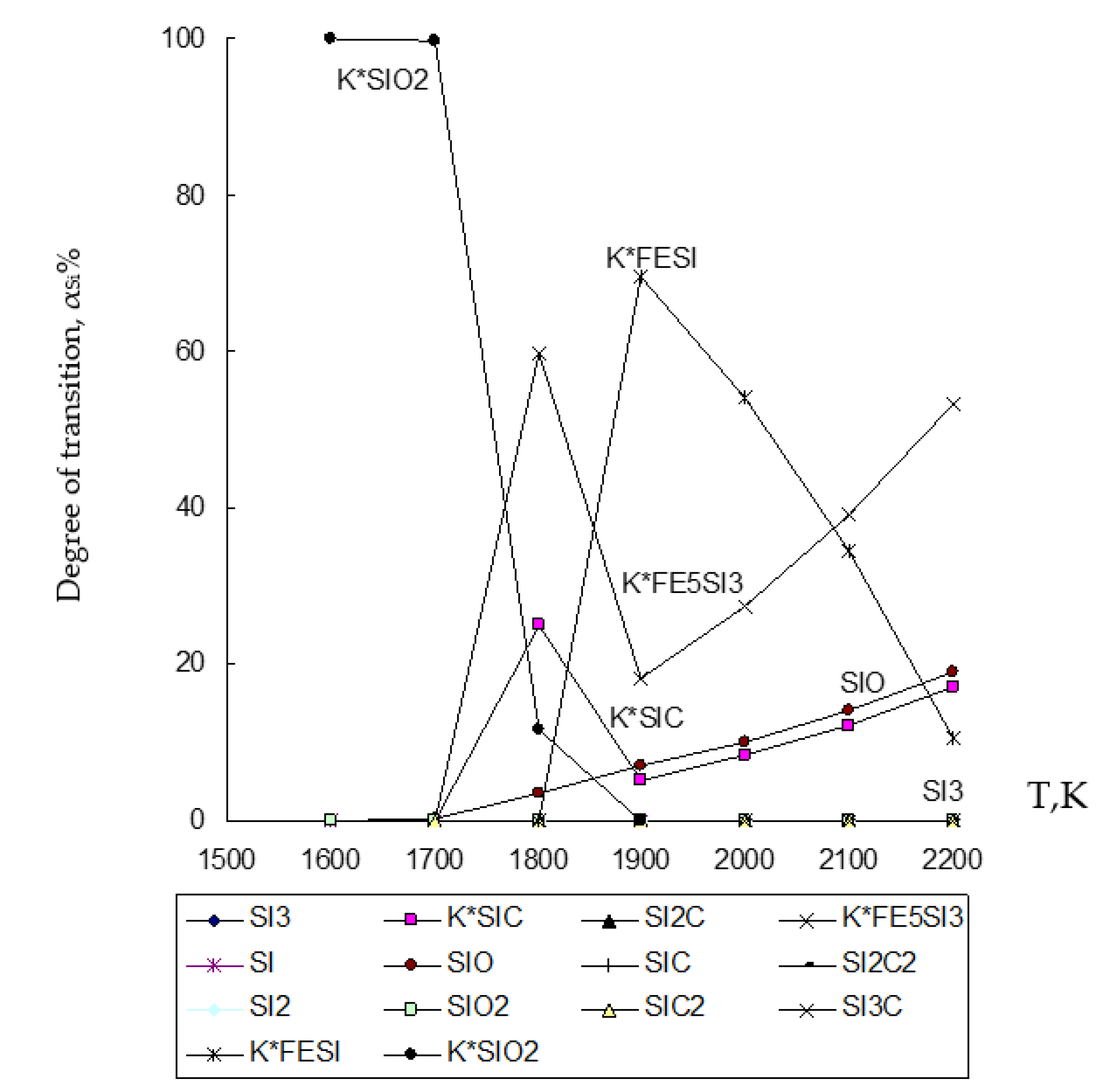

- from the clinker dump, it is possible to obtain a low-grade silicon-containing ferroalloy with a Si content in the range of 18–28% and Fe in the range of 73–82% and extract Zn into the gas phase in the range of 99–100% in the form of zinc sublimates in the optimal temperature range of 1800–1900 K;

- -

- zinc contained in the clinker can be driven into the gas phase by 100% with further capture as zinc sublimates;

- -

- technogenic waste—the clinker dump from rolling zinc oxide ores, according to its chemical and elemental compositions, can act as a secondary technogenic raw material for the metallurgical and chemical industries;

- -

- modeling of clinker utilization by electric melting in an arc furnace will contribute to its processing and, accordingly, reduce the anthropogenic impact of its dump on the biosphere of the region with a multiplicative socio-ecological and economic effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kenzhegaliev, N.A.; Umanets, V.N.; Bugayeva, G.G.; Zavalishin, V.S.; Kogut, A. Prospects for the Development of Technogenic Deposits in Kazakhstan. Available online: https://scholar.google.ru/citations?view_op=view_citation&hl=ru&user=c01tBw4AAAAJ&citation_for_view=c01tBw4AAAAJ:RYcK_YlVTxYC (accessed on 11 February 2022).

- Petrenko, E.S.; Vechkinzova, E.A.; Urazbekov, A.K. Context analysis and prospects of development of the mining and metallurgical industry of Kazakhstan. J. Int. Econ. Aff. 2019, 9, 2661–2676. [Google Scholar] [CrossRef]

- Khoroshavin, L.B.; Perepelitsyn, V.A.; Kochkin, D.K. Problems of technogenic resources. Refract. Ind. Ceram. 1998, 39, 366–368. [Google Scholar] [CrossRef]

- Satbaev, B.N.; Koketaev, A.I.; Aimbetova, O.; Shalabaev, N.T.; Satbaev, A.B. Environmental Technology for the Integrated Disposal of Man-Made Wastes of the Metallurgical Industry: Self-Curing, Chemically Resistant Refractory Mass1. Refract. Ind. Ceram. 2019, 60, 318–322. [Google Scholar] [CrossRef]

- Chukarina, Y.A.; Sopova, O.N.; Zueva, S.B.; Filimonova, O.N.; Veglio, F. Mathematical Simulation of Industrial Waste Processing. Young Sci. 2012, 2, 91–94. [Google Scholar]

- Kolesnikov, A.; Fediuk, R.; Kolesnikova, O.; Zhanikulov, N.; Zhakipbayev, B.; Kuraev, R.; Akhmetova, E.; Shal, A. Processing of Waste from Enrichment with the Production of Cement Clinker and the Extraction of Zinc. Materials 2022, 15, 324. [Google Scholar] [CrossRef]

- Baidya, R.; Ghosh, S.K.; Parlikar, U.V. Co-processing of Industrial Waste in Cement Kiln—A Robust System for Material and Energy Recovery. Procedia Environ. Sci. 2016, 31, 309–317. [Google Scholar] [CrossRef]

- Kapsalyamov, B.A. Possibility of joint manufacture of ferroalloys and nonferrous metals by an electrothermal method. Russ. Met. 2010, 2010, 1151–1155. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Kenzhibaeva, G.S.; Botabaev, N.E.; Kutzhanova, A.N.; Iztleuov, G.M.; Suigenbaeva, A.Z.; Ashirbekov, K.A.; Kolesnikova, O.G. Thermodynamic Modeling of Chemical and Phase Transformations in a Waelz Process-Slag—Carbon System. Refract. Ind. Ceram. 2020, 61, 289–292. [Google Scholar] [CrossRef]

- Vasilieva, N.V.; Fedorova, E.R. Process control quality analysis. Tsvetnye Met. 2020, 2020, 70–76. [Google Scholar] [CrossRef]

- Ferreira, W.L.; Reis, É.L.; Lima, R.M.F. Incorporation of residues from the minero-metallurgical industry in the production of clay–lime brick. J. Clean. Prod. 2015, 87, 505–510. [Google Scholar] [CrossRef][Green Version]

- Kolesnikov, A.S.; Naraev, V.N.; Natorhin, M.I.; Saipov, A.A.; Kolesnikova, O.G. Review of the processing of minerals and technogenic sulfide raw material with the extraction of metals and recovering elemental sulfur by electrochemical methods. Rasayan J. Chem. 2020, 13, 2420–2428. [Google Scholar] [CrossRef]

- Peng, Z.; Gregurek, D.; Wenzl, C.; White, J.F. Slag Metallurgy and Metallurgical Waste Recycling. JOM 2016, 68, 2313–2315. [Google Scholar] [CrossRef]

- Efremova, S.V. Scientific and technical solutions to the problem of utilization of waste from plant- and mineral-based industries. Russ. J. Gen. Chem. 2012, 82, 963–968. [Google Scholar] [CrossRef]

- Mamyrbekova, A.; Mamitova, A.D.; Mamyrbekova, A. Electrochemical Behavior of Sulfur in Aqueous Alkaline Solutions. Russ. J. Phys. Chem. A 2018, 92, 582–586. [Google Scholar] [CrossRef]

- Abisheva, Z.S.; Bochevskaya, E.G.; Zagorodnyaya, A.N.; Shabanova, T.A.; Karshigina, Z.B. Technology of phosphorus slag processing for preparation of precipitated silica. Theor. Found. Chem. Eng. 2013, 47, 428–434. [Google Scholar] [CrossRef]

- Myrzabekov, B.E.; Bayeshov, A.B.; Makhanbetov, A.B.; Mishra, B.; Baigenzhenov, O.S. Dissolution of Platinum in Hydrochloric Acid Under Industrial-Scale Alternating Current Polarization. Metall. Mater. Trans. B 2018, 49, 23–27. [Google Scholar] [CrossRef]

- Medina, D.; Anderson, C.G. A Review of the Cyanidation Treatment of Copper-Gold Ores and Concentrates. Metals 2020, 10, 897. [Google Scholar] [CrossRef]

- Lis, T.; Nowacki, K.; Zelichowska, M.; Kania, H. Innovation in metallurgical waste management. Metalurgija 2015, 54, 283–285. [Google Scholar]

- Borisov, D.; Stefanov, B.; Stoyanov, S.K. An algorithm for metallurgical waste minimization. J. Chem. Technol. Metall. 2014, 49, 99–105. [Google Scholar]

- Uzhkenov, B.S. Mineral raw materials base of the Republic of Kazakhstan: Condition, prospects of exploration. Gorn. Zhurnal 2011, 9, 8–10. [Google Scholar]

- Rybak, J.; Kongar-syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of Backfill Materials Based on Industrial Waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- Kolesnikov, A.S.; Zhakipbaev, B.Y.; Zhanikulov, N.N.; Kolesnikova, O.G.; Akhmetova, K.; Kuraev, R.M.; Shal, A.L. Review of technogenic waste and methods of its processing for the purpose of complex utilization of tailings from the enrichment of non-ferrous metal ores as a component of the raw material mixture in the production of cement clinker. Rasayan J. Chem. 2021, 14, 997–1005. [Google Scholar] [CrossRef]

- Guan, J.; Wang, Y.; Cheng, L.; Xie, Y.; Zhang, L. Fabrication and characterization of Short silicon nitride fibers from direct nitridation of ferrosilicon in N2 atmosphere. Materials 2018, 11, 2003. [Google Scholar] [CrossRef] [PubMed]

- Janerka, K.; Kostrzewski, Ł.; Stawarz, M.; Jezierski, J. The importance of SiC in the process of melting ductile iron with a variable content of charge materials. Materials 2020, 13, 1231. [Google Scholar] [CrossRef] [PubMed]

- Ziatdinov, M.; Zhukov, A.; Promakhov, V. Combustion synthesis of composition ferroalloys. Materials 2018, 11, 2117. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Su, Y.; Xu, G.; Chen, Y.; You, G. Research Progress on Controlled Low-Strength Materials: Metallurgical Waste Slag as Cementitious Materials. Materials 2022, 15, 727. [Google Scholar] [CrossRef]

- Legemza, J.; Findorák, R.; Bul’ko, B.; Briančin, J. New approach in research of quartzes and quartzites for ferroalloys and silicon production. Metals 2021, 11, 670. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Dydek, K.; Boczkowska, A. An experimental study of possible post-war ferronickel slag waste disposal in szklary (Lower silesian, poland) as partial aggregate substitute in concrete: Characterization of physical, mechanical, and thermal properties. Materials 2021, 14, 2552. [Google Scholar] [CrossRef]

- Jordanov, N.B.; Georgiev, I.; Karamanov, A. Sintered glass-ceramics, self-glazed materials and foams from metallurgical waste slag. Materials 2021, 14, 2263. [Google Scholar] [CrossRef]

- Mróz, J.; Konstanciak, A.; Warzecha, M.; Więcek, M.; Hutny, A.M. Research on reduction of selected iron-bearing waste materials. Materials 2021, 14, 1914. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Moreno-López, E.R.; Corpas-Iglesias, F.A. Determination of the chemical, physical and mechanical characteristics of electric arc furnace slags and environmental evaluation of the process for their utilization as an aggregate in bituminous mixtures. Materials 2021, 14, 782. [Google Scholar] [CrossRef] [PubMed]

- Lancellotti, I.; Piccolo, F.; Traven, K.; Češnovar, M.; Ducman, V.; Leonelli, C. Alkali activation of metallurgical slags: Reactivity, chemical behavior, and environmental assessment. Materials 2021, 14, 639. [Google Scholar] [CrossRef] [PubMed]

- Famielec, S. Chromium concentrate recovery from solid tannery waste in a thermal process. Materials 2020, 13, 1533. [Google Scholar] [CrossRef] [PubMed]

- Pizoń, J.; Gołaszewski, J.; Alwaeli, M.; Szwan, P. Properties of concrete with recycled concrete aggregate containing metallurgical sludge waste. Materials 2020, 13, 1448. [Google Scholar] [CrossRef]

- Liu, M.; Ma, G.; Zhang, X.; Liu, J.; Wang, Q. Preparation of black ceramic tiles using waste copper slag and stainless steel slag of electric arc furnace. Materials 2020, 13, 776. [Google Scholar] [CrossRef]

- Fechet, R.; Zlagnean, M.; Moanta, A.; Ciobanu, L. Mining Wastes—Sampling, processing and using in manufacture portland cement. Rom. J. Miner. Depos. 2010, 84, 67–70. [Google Scholar]

- Taimasov, B.T.; Sarsenbayev, B.K.; Khudyakova, T.M.; Kolesnikov, A.S.; Zhanikulov, N.N. Development and testing of low-energy-intensive technology of receiving sulphate-resistant and road portlandcement. Eurasian Chem. J. 2017, 19, 347–355. [Google Scholar] [CrossRef]

- Kolesnikov, A.S. Kinetic investigations into the distillation of nonferrous metals during complex processing of waste of metallurgical industry. Russ. J. Non-Ferr. Met. 2015, 56, 1–5. [Google Scholar] [CrossRef]

- Satbaev, B.; Yefremova, S.; Zharmenov, A.; Kablanbekov, A.; Yermishin, S.; Shalabaev, N.; Satbaev, A.; Khen, V. Rice husk research: From environmental pollutant to a promising source of organo-mineral raw materials. Materials 2021, 14, 4119. [Google Scholar] [CrossRef]

- Nadirov, K.S.; Zhantasov, M.K.; Sakybayev, B.A.; Orynbasarov, A.K.; Bimbetova, G.Z.; Sadyrbayeva, A.S.; Kolesnikov, A.S.; Ashirbayev, H.A.; Zhantasova, D.M.; Tuleuov, A.M. The study of the gossypol resin impact on adhesive properties of the intermediate layer of the pipeline three-layer rust protection coating. Int. J. Adhes. Adhes. 2017, 78, 195–199. [Google Scholar] [CrossRef]

- Khudyakova, T.M.; Kolesnikov, A.S.; Zhakipbaev, B.E.; Kenzhibaeva, G.S.; Kutzhanova, A.N.; Iztleuov, G.M.; Zhanikulov, N.N.; Kolesnikova, O.G.; Mynbaeva, E. Optimization of Raw Material Mixes in Studying Mixed Cements and Their Physicomechnical Properties. Refract. Ind. Ceram. 2019, 60, 76–81. [Google Scholar] [CrossRef]

- Koteleva, N.; Kuznetsov, V.; Vasilyeva, N. A simulator for educating the digital technologies skills in industry. Part one. dynamic simulation of technological processes. Appl. Sci. 2021, 11, 10885. [Google Scholar] [CrossRef]

- Stoianova, A.; Vasilyeva, N. Production Process Data as a Tool for Digital Transformation of Metallurgical Companies. In Proceedings of the XIV International Scientific Conference “INTERAGROMASH 2021”, Rostov-on-Don, Russia, 24–26 February 2021; Springer: Cham, Switzerland, 2021; Volume 246, pp. 780–787. [Google Scholar] [CrossRef]

- Boikov, A.V.; Savelev, R.V.; Payor, V.A.; Potapov, A.V. Evaluation of bulk material behavior control method in technological units using dem. Part 2. CIS Iron Steel Rev. 2020, 20, 3–6. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; de Lima, T.E.S.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Chernysheva, N.; Lesovik, V.; Fediuk, R.; Vatin, N. Improvement of performances of the gypsum-cement fiber reinforced composite (GCFRC). Materials 2020, 13, 3847. [Google Scholar] [CrossRef]

- Tolstoy, A.; Lesovik, V.; Fediuk, R.; Amran, M.; Gunasekaran, M.; Vatin, N.; Vasilev, Y. Production of Greener High-Strength Concrete Using Russian Quartz Sandstone Mine Waste Aggregates. Materials 2020, 13, 5575. [Google Scholar] [CrossRef]

- Fediuk, R.; Mosaberpanah, M.A.; Lesovik, V. Development of fiber reinforced self-compacting concrete (FRSCC): Towards an efficient utilization of quaternary composite binders and fibers. Adv. Concr. Constr. 2020, 9, 387–395. [Google Scholar]

- Volodchenko, A.A.; Lesovik, V.S.; Cherepanova, I.A.; Volodchenko, A.N.; Zagorodnjuk, L.H.; Elistratkin, M.Y. Peculiarities of non-autoclaved lime wall materials production using clays. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 022021. [Google Scholar] [CrossRef]

- Utelbaeva, A.B.; Ermakhanov, M.N.; Zhanabai, N.Z.; Utelbaev, B.T.; Mel’Deshov, A.A. Hydrogenation of benzene in the presence of ruthenium on a modified montmorillonite support. Russ. J. Phys. Chem. A 2013, 87, 1478–1481. [Google Scholar] [CrossRef]

- Volokitina, I.E.; Volokitin, A.V. Evolution of the Microstructure and Mechanical Properties of Copper during the Pressing–Drawing Process. Phys. Met. Met. 2018, 119, 917–921. [Google Scholar] [CrossRef]

- Volokitina, I.E.; Kurapov, G.G. Effect of Initial Structural State on Formation of Structure and Mechanical Properties of Steels Under ECAP. Met. Sci. Heat Treat. 2018, 59, 786–792. [Google Scholar] [CrossRef]

- Pestunova, N.P.; Ognev, Y.G. Physico-chemical research in metallurgy of lead and zinc. Sci. Work. 1980, 36, 37–42. [Google Scholar]

- Abdeev, M.A.; Yusupova, A.I.; Piskunov, V.M.; Kolesnikov, A.V. Extraction of Valuable Components from Dump Products of Heavy Non-Ferrous Metals; Tsvetmetinformation: Moscow, Russia, 1980; pp. 1–48. [Google Scholar]

- Topchaev, V.P.; Khodov, N.V.; Davidson, A.N.; Eputaev, G.A. The use of clinker coke to intensify the welting process. Non-Ferr. Met. 1972, 1, 23–24. [Google Scholar]

- Kolesnikov, A.V.; Pusko, A.G.; Divak, A.A. The effect of calcium and magnesium compounds on zinc distillation in the production of zinc whitewash. Non-Ferr. Met. 1977, 6, 15–17. [Google Scholar]

- Snurnikov, A.P. Complex Use of Mineral Resources in Non-Ferrous Metallurgy; Metallurgy: Moscow, Russia, 1965; pp. 1–358. [Google Scholar]

- Mitrofanov, S.I.; Meshchaninova, V.I. Combined Processes of Processing of Non-Ferrous Metal Ores; Subsoil: Moscow, Russia, 1998; pp. 1–230. [Google Scholar]

- Fetterolf, L.D. Electric melting of zinc clinker on mirror cast iron at the New Jersey Zinc plant. In Proceedings of the 28th Conference on Electric Melting, New York, NY, USA, 10–14 February 1970; Volume 2, pp. 409–422. [Google Scholar]

- Kasivadi, M.; Kimarlin, G. Arme World Symposium on Zinc Mining and Metallurgy Jead; American Institute of Mining, Metallurgical and Petroleum Engineers: New York, NY, USA, 1970; Volume 2, pp. 430–442. [Google Scholar]

- Sanakulov, K.S.; Khasanov, A.S. Processing of Copper Production; Fan Publication: Tashkent, Uzbekistan, 2007; pp. 1–255. [Google Scholar]

- Ospanov, S.S. Chloride Technology of Processing of Lead-Zinc Industrial Products and Hard-to-Enrich Ores: Abstract; Candidate of Technical Sciences: Alma-Ata, Kazakhstan, 1985; pp. 1–29. [Google Scholar]

- Karpov, Y.A.; Baranovskaya, V.B. Issues of standardization of the methods of chemical analysis in metallurgy. Ind. Lab. Diagn. Mater. 2019, 85, 5–14. [Google Scholar] [CrossRef]

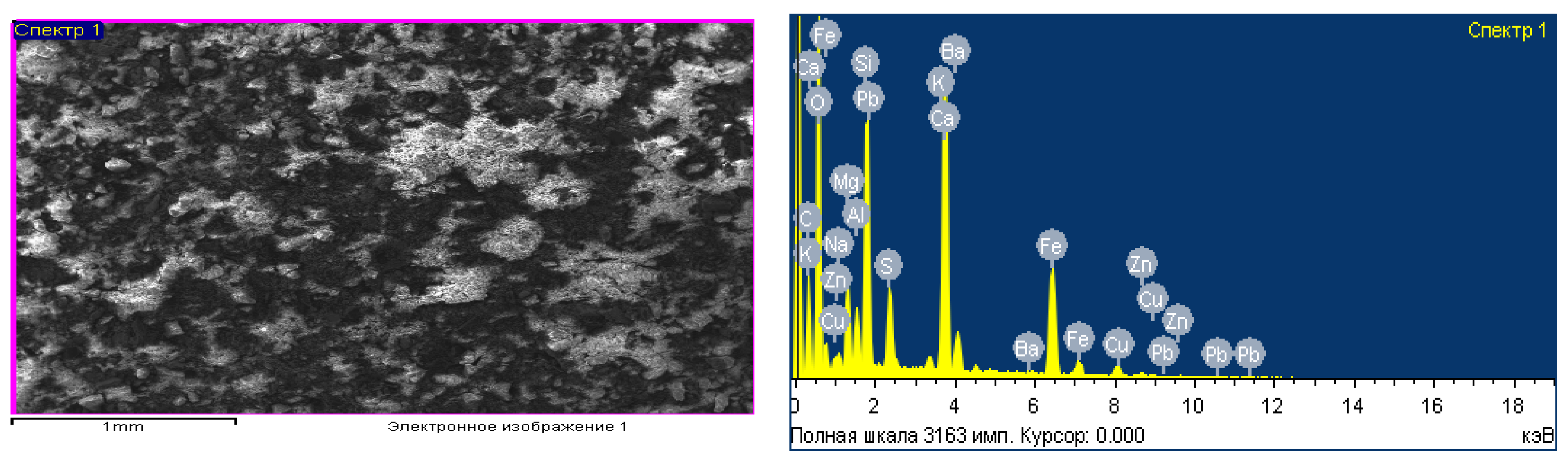

- Lifshin, E.; Morris, W.G.; Bolon, R.B. The Scanning Electron Microscope and its Applications in Metallurgy. JOM 2017, 21, 43–50. [Google Scholar] [CrossRef]

- Trusov, B.G. Code system for simulation of phase and chemical equilibriums at higher temperatures. Eng. J. Sci. Innov. 2012, 1, 240–249. [Google Scholar]

- Trusov, B.G. Simulation of Kinetics of Chemical Conversions: Thermodynamic Approach. Her. Bauman Mosc. State Tech. Univ. Nat. Sci. 2005, 3, 26–38. [Google Scholar]

- Grudinsky, P.I.; Zinoveev, D.V.; Dyubanov, V.G.; Kozlov, P.A. State of the Art and Prospect for Recycling of Waelz Slag from Electric Arc Furnace Dust Processing. Inorg. Mater. Appl. Res. 2019, 10, 1220–1226. [Google Scholar] [CrossRef]

- Vogelbacher, M.; Keller, S.; Zehm, W.; Matthes, J. Advanced Methods for Kiln-Shell Monitoring to Optimize the Waelz Process for Zinc Recycling. Processes 2021, 9, 1062. [Google Scholar] [CrossRef]

- Panshin, A.M.; Shakirzyanov, R.M.; Izbrekht, P.A.; Zatonskiy, A.V. Basic ways of improvement of zinc production at JSC “Chelyabinsk Zinc Plant”. Tsvetnye Met. 2015, 5, 19–21. [Google Scholar] [CrossRef]

- Sariev, O.; Kim, S.; Zhumagaliev, Y.; Kelamanov, B.; Sultanov, M.; Nurgali, N. Viscosity and crystallization temperature of ferroalloy slags from Kazakhstan ore. Metalurgija 2020, 59, 525–528. [Google Scholar]

- Zhuniskaliyev, T.; Nurumgaliyev, A.; Zayakin, O.; Mukhambetgaliyev, Y.; Kuatbay, Y.; Mukhambetkaliyev, A. Investigation and comparison of the softening temperature of manganese ores used for the production of complex ligatures based on Fe-Si-Mn-Al. Metalurgija 2020, 59, 521–524. [Google Scholar]

- Kuatbay, Y.; Nurumgaliyev, A.; Shabanov, Y.; Zayakin, O.; Gabdullin, S.; Zhuniskaliyev, T. Melting of high-carbon ferrochrome using coal of the saryadyr deposit. Metalurgija 2022, 61, 367–370. [Google Scholar]

- Sariev, O.; Kelamanov, B.; Zhumagaliyev, Y.; Kim, S.; Abdirashit, A.; Almagambetov, M. Remelting the high-carbon ferrochrome dust in a direct current arc furnace (DCF). Metalurgija 2020, 59, 533–536. [Google Scholar]

- Klyuev, S.V.; Khezhev, T.A.; Pukharenko, Y.V.; Klyuev, A.V. Fibers and their properties for concrete reinforcement. Mater. Sci. Forum 2018, 945, 125–130. [Google Scholar] [CrossRef]

- Begich, Y.E.; Klyuev, S.V.; Jos, V.A.; Cherkashin, A.V. Fine-grained concrete with various types of fibers. Mag. Civ. Eng. 2020, 97, 9702. [Google Scholar]

| № | Compounds, Elements | Percentage Content, % |

|---|---|---|

| 1 | CaO | 14.87 |

| 2 | SiO2 | 18.12 |

| 3 | MgO | 2.81 |

| 4 | Al2O3 | 4.75 |

| 5 | Fe2O3 | 26.98 |

| 6 | Zn | 0.94 |

| 7 | Pb | 0.12 |

| 8 | Cu | 0.11 |

| 9 | S | 1.4 |

| 10 | C | 18.6 |

| 11 | BaO | 2.4 |

| 12 | Other | 8.9 |

| T, K | 1600 | 1700 | 1800 | 1900 | 2000 | 2100 | 2200 |

|---|---|---|---|---|---|---|---|

| Compounds, % | Degree of distribution (α) of oxygen (O2), % | ||||||

| CO | 0.0219 | 0.0102 | 0.0137 | 0.0102 | 0.0063 | 0.0041 | 0.0028 |

| CO2 | 53.802 | 53.864 | 93.813 | 98.297 | 97.628 | 96.743 | 95.624 |

| C2O | 0 | 0 | 0 | 0 | 0.0000003 | 0.0000008 | 0.0000021 |

| SiO | 0.003 | 0.054 | 0.815 | 1.693 | 2.366 | 3.253 | 4.373 |

| SiO2 | 0 | 0.0000003 | 0.0000038 | 0.0000675 | 0.0000073 | 0.0000080 | 0.0000880 |

| k*SiO2 | 46.174 | 46.072 | 5.358 | 0 | 0 | 0 | 0 |

| Amount, % | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Degree of distribution (α) of carbon (C), % | |||||||

| k*C | 38.249 | 38.192 | 0 | 0 | 0 | 0 | 0 |

| C | 0 | 0 | 0 | 0 | 0 | 0 | 1.08136−7 |

| CO | 0.011 | 0.005 | 0.006 | 0.005 | 0.003 | 0.002 | 0.001 |

| CO2 | 54.025 | 54.088 | 94.202 | 98.721 | 98.037 | 97.144 | 96.021 |

| k*SiC | 0 | 0 | 5.791 | 1.273 | 1.959 | 2.852 | 3.975 |

| SiC | 0 | 0 | 0 | 0 | 0 | 0 | 3.4492−7 |

| Si3C | 0 | 0 | 0 | 0 | 0 | 3.50517−7 | 1.68534−6 |

| Si2C | 0 | 0 | 1.66238−7 | 2.26741−6 | 1.92375−5 | 0.00013 | 0.0007 |

| SiC2 | 0 | 0 | 4.66156−7 | 4.67117−6 | 3.70176−5 | 0.00024 | 0.0013 |

| Si2C2 | 0 | 0 | 0 | 0 | 0 | 2.9913−7 | 2.55166−5 |

| C2O | 0 | 0 | 0 | 0 | 2.56567−7 | 7.6273−7 | 0.0000025 |

| k*Fe3C | 7.714 | 7.714 | 0 | 0 | 0 | 0 | 0 |

| Amount, % | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolesnikov, A.; Fediuk, R.; Amran, M.; Klyuev, S.; Klyuev, A.; Volokitina, I.; Naukenova, A.; Shapalov, S.; Utelbayeva, A.; Kolesnikova, O.; et al. Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation. Materials 2022, 15, 2542. https://doi.org/10.3390/ma15072542

Kolesnikov A, Fediuk R, Amran M, Klyuev S, Klyuev A, Volokitina I, Naukenova A, Shapalov S, Utelbayeva A, Kolesnikova O, et al. Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation. Materials. 2022; 15(7):2542. https://doi.org/10.3390/ma15072542

Chicago/Turabian StyleKolesnikov, Alexandr, Roman Fediuk, Mugahed Amran, Sergey Klyuev, Alexander Klyuev, Irina Volokitina, Aigul Naukenova, Shermakhan Shapalov, Akmaral Utelbayeva, Olga Kolesnikova, and et al. 2022. "Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation" Materials 15, no. 7: 2542. https://doi.org/10.3390/ma15072542

APA StyleKolesnikov, A., Fediuk, R., Amran, M., Klyuev, S., Klyuev, A., Volokitina, I., Naukenova, A., Shapalov, S., Utelbayeva, A., Kolesnikova, O., & Bazarkhankyzy, A. (2022). Modeling of Non-Ferrous Metallurgy Waste Disposal with the Production of Iron Silicides and Zinc Distillation. Materials, 15(7), 2542. https://doi.org/10.3390/ma15072542