Performance Analysis of Three Side Roughened Solar Air Heater: A Preliminary Investigation

Abstract

:1. Introduction

2. MCDM-TOPSIS Approach

- ▪

- First step: In this study, the responses such as Nusselt number (Nu), collector heat removal factor, and collector efficiency factor are taken as favorable attributes. So, attempts are made to maximize these parameters. Based on the equation provided below the response matrix is standardized.where i = 1…. m and j = 1…. n., bij represents the actual ith value of jth experiment and Qij represents the correlated standardized value.

- ▪

- Second step: Equal and uniform weight is assigned to all three objectives, hence the weighted normalized matrix, is assigned at 0.33. This weight is multiplied with the normalized matrix obtained through Equation (1); therefore the relation is given by Equation (2).where Uij is the weighted normalized matrix and Wi marks the weight of the jth attribute.Uij = Wi × Qij

- ▪

- Third step: The positive best result (PBR) and negative best result (NBR) are estimated using Equations (3) and (4).X+ = (X1+, X2+, X𝑛+) for all the upper valuesX− = (X1−, X2−, X𝑛−) for all the lower values

- ▪

- Fourth step: The positive best result (PBR) and negative ideal solution (NIS) are estimated by utilizing the following equations.where i = 1, 2 … n.

- ▪

- Fifth step: The following relation is used to estimate the closeness factor (CF)

3. Experimental Strategy

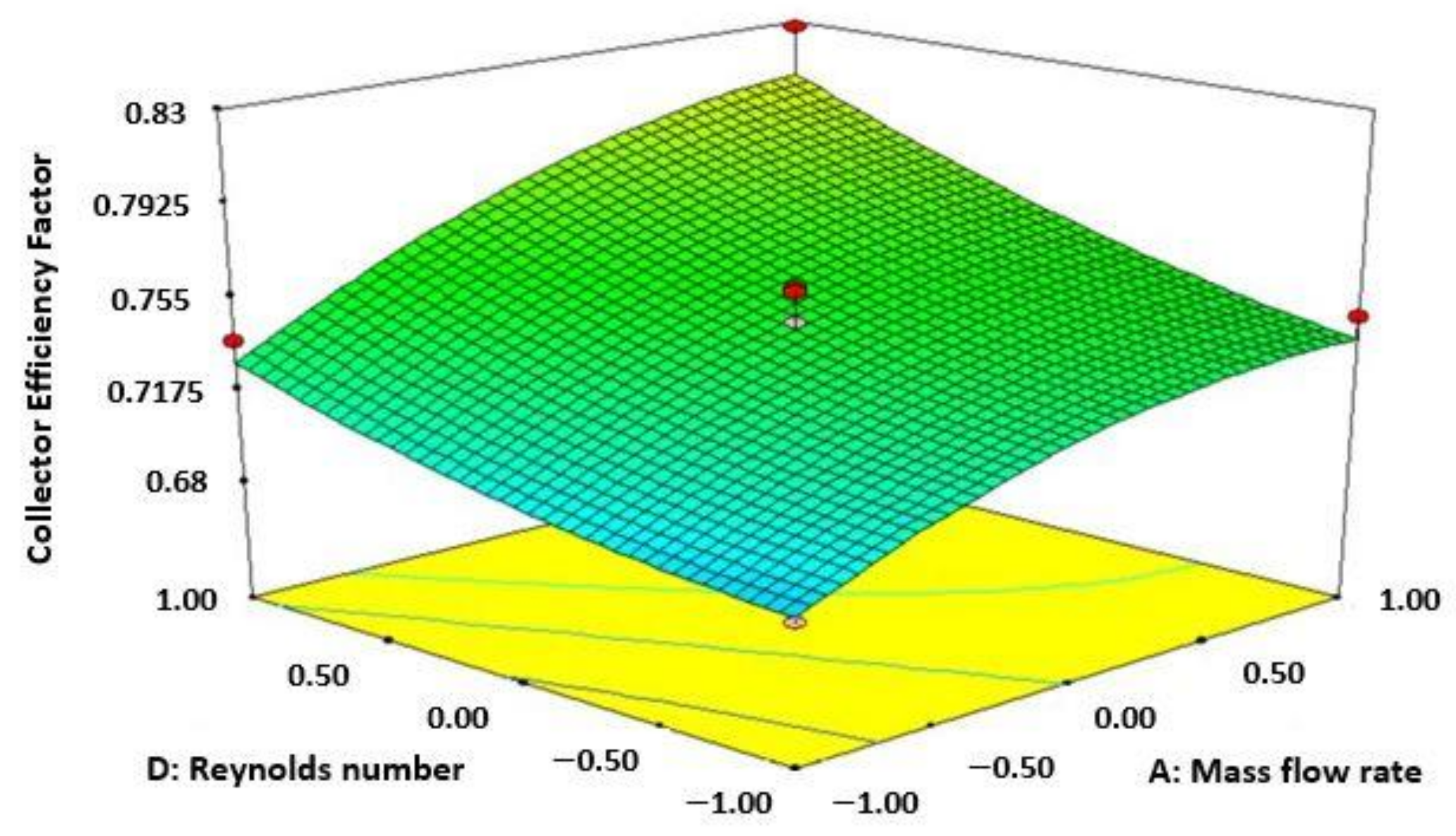

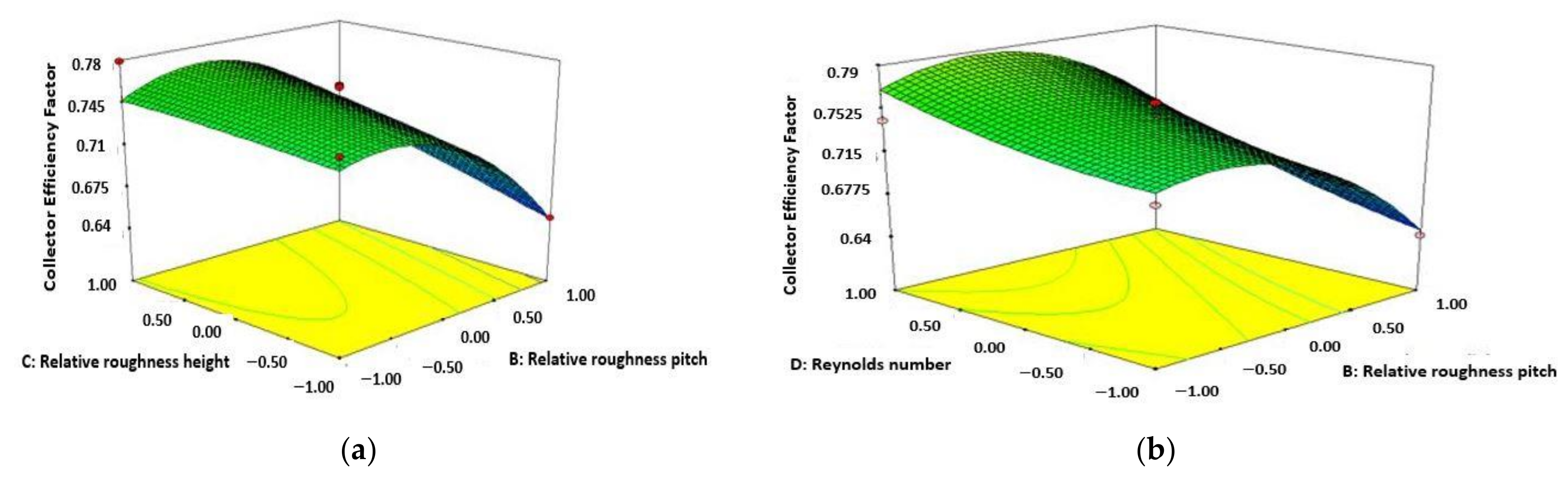

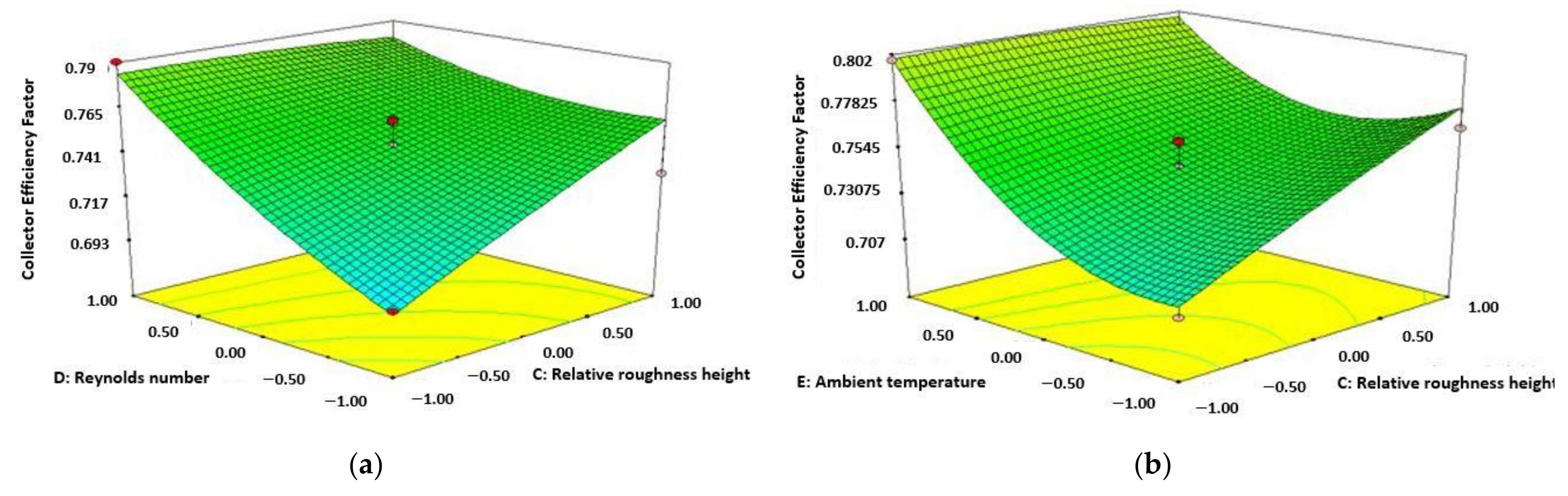

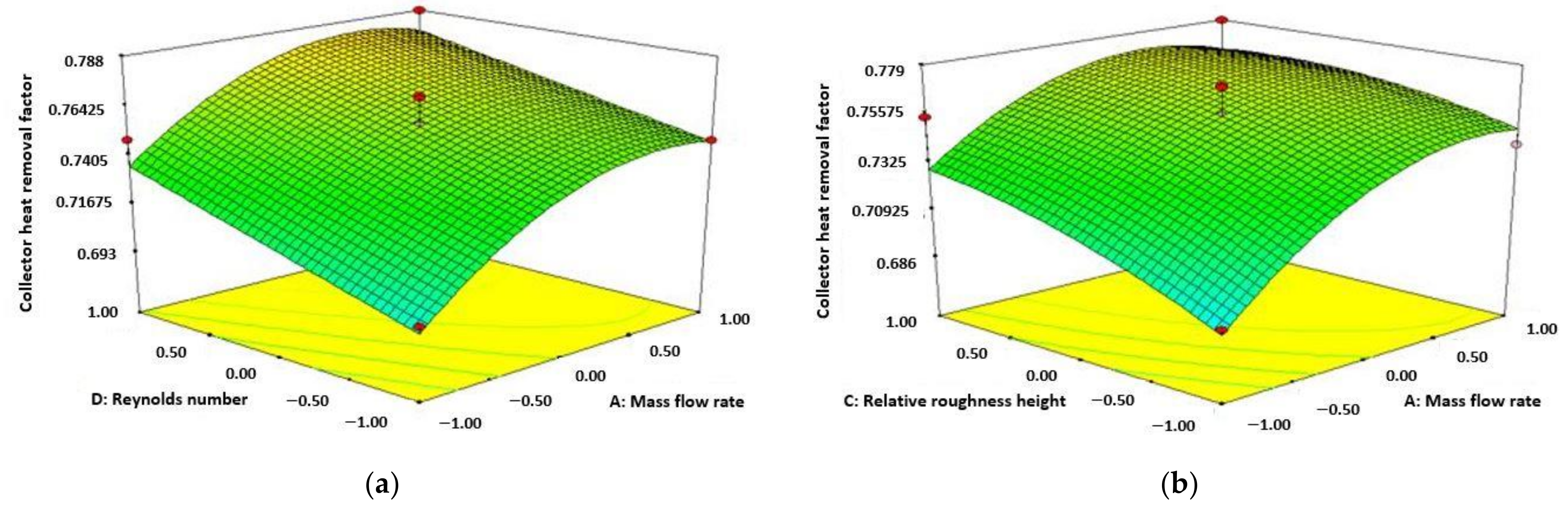

4. Results and Discussions

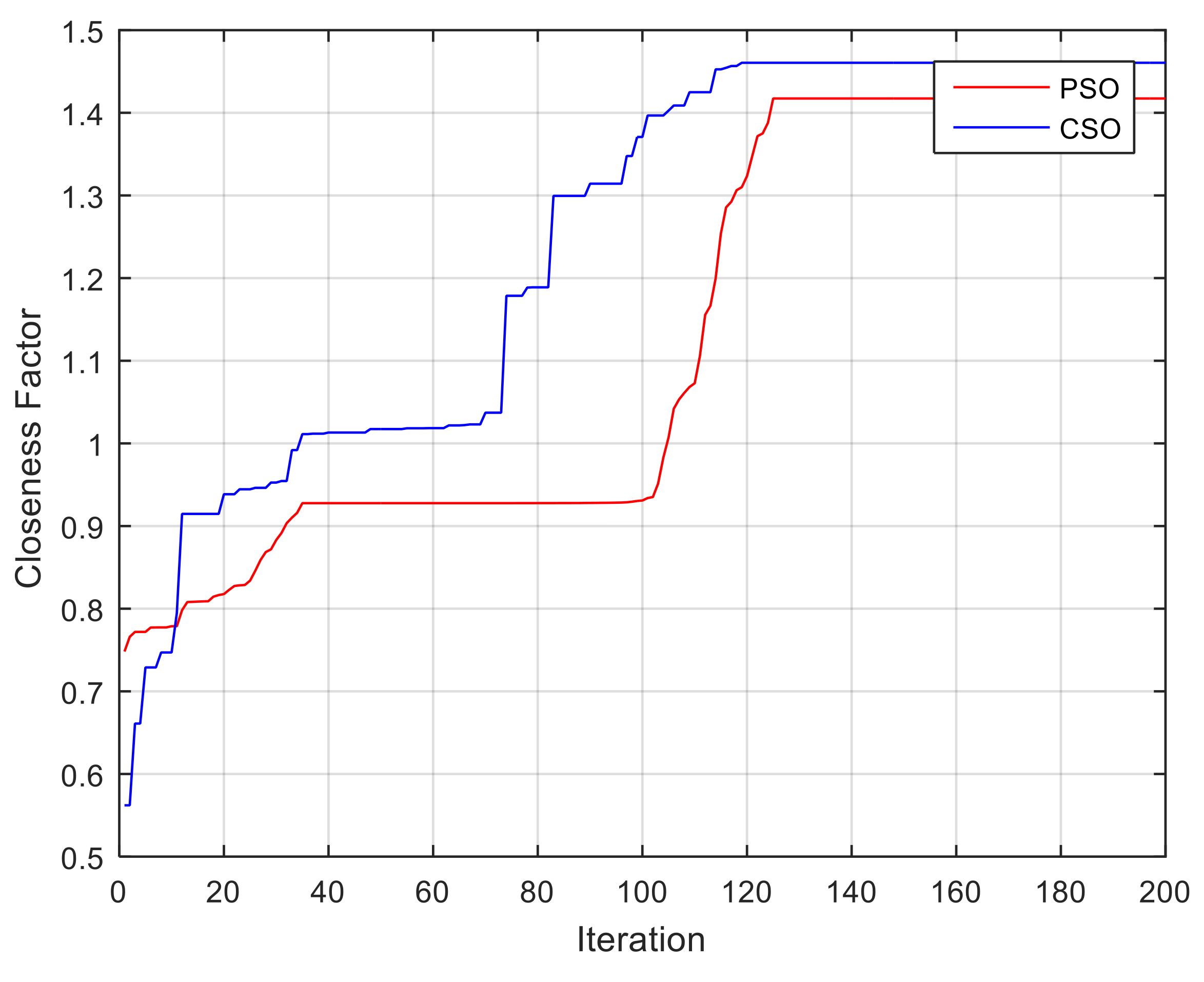

4.1. Proposed Cuckoo Search

- ▪

- The cuckoo search optimization algorithm depends on three conditions.

- ▪

- Every cuckoo lays a single egg at a time and throws its egg in a random nest.

- ▪

- The high quality of eggs which is considered as the best solution in the best nest will carry forward to the next generation.

- ▪

- The host bird is exposed to the alien egg with a probability (Pa ∈ (0, 1)).

4.2. Proposed Cuckoo Search with Levy Flights Approach

| Algorithm 1: Cuckoo Search Optimization (CSO). |

| Start Objective function f(x) Random generation of initial population of n host nests xi (i = 1, 2, …, n) While (t < Max Generation); Get a cuckoo randomly by Levy flights; Evaluate its fitness F(i); Choose a nest among n (Let the nest, j) randomly; The new solution is to replace j; end A probability (pa) of worse nests are unrestrained and a new nest is constructed; The best solutions are stored, i.e., the nests having the quality solution Solutions to be ranked and find the current best; end while end Result |

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 3rd ed.; Wiley Interscience: New York, NY, USA, 2006. [Google Scholar]

- Prasad, B.N.; Saini, J.S. Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol. Energy 1988, 41, 555–560. [Google Scholar] [CrossRef]

- Prasad, B.N.; Saini, J.S. Optimal thermo-hydraulic performance of artificially roughened solar air heaters. Sol. Energy 1991, 47, 91–96. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, A.P.; Tech, A.M.; Singh, O.P. Performance of characteristics of a new curved double-pass counter flow solar air heater. Energy 2022, 239, 121886. [Google Scholar] [CrossRef]

- Arya, N.; Kumar, R.; Goel, V. Role of artificial roughness in the performance improvement of solar air heaters. In Advances in Energy and Combustion; Gupta, A.K., De, A., Agarwal, S.K., Kushari, A., Runchal, A.K., Eds.; Green Energy and Technology; Springer: Singapore, 2022; pp. 555–578. [Google Scholar] [CrossRef]

- Saurav, S.; Sahu, M.M. Heat transfer and thermal efficiency of solar air heater having artificial roughness: A review. Int. J. Renew. Energy Res. 2013, 3, 498–508. [Google Scholar] [CrossRef]

- Shakya, U.; Saini, R.P.; Singhal, M.K. A review on artificial roughness geometry for enhancement of heat transfer and friction characteristics on roughened duct of solar air heater. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 279–287. [Google Scholar]

- Singh, H.; Singh, H.; Kishore, C. CFD numerical investigation of Heat transfer characteristics of Y-shaped solar air heater. Mater. Today Proc. 2021, 52, 2003–2013. [Google Scholar] [CrossRef]

- Yadav, A.S.; Bhagoria, J.L. A CFD based thermo-hydraulic performance analysis of an artificially roughened solar air heater having equilateral triangular sectioned rib roughness on the absorber plate. Int. J. Heat Mass Transf. 2014, 70, 1016–1039. [Google Scholar] [CrossRef]

- Yadav, A.S.; Bhagoria, J.L. A numerical investigation of square sectioned transverse rib roughened solar air heater. Int. J. Therm. Sci. 2014, 79, 111–131. [Google Scholar] [CrossRef]

- Gawande, V.B.; Dhoble, A.S.; Zodpe, D.B. Effect of roughness geometries on heat transfer enhancement in solar thermal systems—A review. Renew. Sustain. Energy Rev. 2014, 32, 347–378. [Google Scholar] [CrossRef]

- Chabane, F.; Moummi, N.; Benramache, S. Experimental study of heat transfer and thermal performance with longitudinal fins of solar air heater. J. Adv. Res. 2014, 5, 183–192. [Google Scholar] [CrossRef] [Green Version]

- Prasad, B.N.; Behura, A.K.; Prasad, L. Fluid flow and heat transfer analysis for heat transfer enhancement in three sided artificially roughened solar air heater. Sol. Energy 2014, 105, 27–35. [Google Scholar] [CrossRef]

- Prasad, B.N.; Kumar, A.; Singh, K.D.P. Optimization of thermo hydraulic performance in three sides artificially roughened solar air heaters. Sol. Energy 2015, 111, 313–319. [Google Scholar] [CrossRef]

- Nems, M.; Kasperski, J. Experimental investigation of concentrated solar air-heater with internal multiple-fin array. Renew. Energy 2016, 97, 722–730. [Google Scholar] [CrossRef]

- Priyam, A.; Chand, P. Thermal and thermo hydraulic performance of wavy finned absorber solar air heater. Sol. Energy 2016, 130, 250–259. [Google Scholar] [CrossRef]

- Singh, S. Performance evaluation of a novel solar air heater with arched absorber plate. Renew. Energy 2017, 114, 879–886. [Google Scholar] [CrossRef]

- Ghritlahre, H.K.; Prasad, R.K. Exergetic performance prediction of solar air heater using MLP, GRNN and RBF models of artificial neural network technique. J. Environ. Manag. 2018, 223, 566–575. [Google Scholar] [CrossRef]

- Ghritlahre, H.K.; Prasad, R.K. Investigation of thermal performance of unidirectional flow porous bed solar air heater using MLP, GRNN and RBF models of ANN technique. Therm. Sci. Eng. Prog. 2018, 6, 226–235. [Google Scholar] [CrossRef]

- Ghritlahre, H.K.; Chandrakar, P.; Ahmad, A. Application of ANN model to predict the performance of solar air heater using relevant input parameters. Sustain. Energy Technol. Assess. 2020, 40, 100764. [Google Scholar] [CrossRef]

- Abuşka, M. Energy and exergy analysis of solar air heater having new design absorber plate with conical surface. Appl. Therm. Eng. 2018, 131, 115–124. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Al-Sood, M.A.; Omara, Z.M.; Bek, M.A.; Kabeel, A.E. Performance evaluation of a new counter flow double pass solar air heater with turbulators. Sol. Energy 2018, 173, 398–406. [Google Scholar] [CrossRef]

- Matheswaran, M.M.; Arjunan, T.V.; Somasundaram, D. Analytical investigation of solar air heater with jet impingement using energy and exergy analysis. Sol. Energy 2018, 161, 25–37. [Google Scholar] [CrossRef]

- Bakri, B.; Eleuch, O.; Ketata, A.; Driss, S.; Driss, Z.; Benguesmia, H. Study of the turbulent flow in a newly solar air heater test bench with natural and forced convection modes. Energy 2018, 161, 1028–1041. [Google Scholar] [CrossRef]

- Poole, M.R.; Shah, S.B.; Boyette, M.D.; Grimes, J.L.; Stikeleather, L.F. Evaluation of landscape fabric as a solar air heater. Renew. Energy 2018, 127, 998–1003. [Google Scholar] [CrossRef]

- Priyam, A.; Chand, P. Effect of wavelength and amplitude on the performance of wavy finned absorber solar air heater. Renew. Energy 2018, 119, 690–702. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Ramiar, A.; Ranjbar, A.A. Numerical investigation of natural convection solar air heater with different fins shape. Renew. Energy 2018, 117, 488–500. [Google Scholar] [CrossRef]

- Ansari, M.; Bazargan, M. Optimization of flat plate solar air heaters with ribbed surfaces. Appl. Therm. Eng. 2018, 136, 356–363. [Google Scholar] [CrossRef]

- Singh, A.P.; Singh, O.P. Performance enhancement of a curved solar air heater using CFD. Sol. Energy 2018, 174, 556–569. [Google Scholar] [CrossRef]

- Singh, I.; Singh, S. A review of artificial roughness geometries employed in solar air heaters. Int. J. Renew. Sustain. Energy Rev. 2018, 92, 405–425. [Google Scholar] [CrossRef]

- Jia, B.; Liu, F.; Wang, D. Experimental study on the performance of spiral solar air heater. Sol. Energy 2019, 182, 16–21. [Google Scholar] [CrossRef]

- Eswaramoorthy, M. A Comparative Experimental Study on Flat and V Groove Receiver Plates of a Solar Air Heater for Drying Applications. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 37, 68–75. [Google Scholar] [CrossRef]

- Jin, D.; Quan, S.; Zuo, J.; Xu, S. Numerical investigation of heat transfer enhancement in a solar air heater roughened by multiple V-shaped ribs. Renew. Energy 2019, 134, 78–88. [Google Scholar] [CrossRef]

- Jain, P.K.; Lanjewar, A. Overview of V-RIB geometries in solar air heater and performance evaluation of a new V-RIB geometry. Renew. Energy 2019, 133, 77–90. [Google Scholar] [CrossRef]

- Kumar, A.; Layek, A. Nusselt number and friction factor correlation of solar air heater having twisted-rib roughness on absorber plate. Renew. Energy 2019, 130, 687–699. [Google Scholar] [CrossRef]

- Patel, S.S.; Lanjewar, A. Experimental and numerical investigation of solar air heater with novel V-rib geometry. J. Energy Storage 2019, 21, 750–764. [Google Scholar] [CrossRef]

- Saravanakumar, P.T.; Somasundaram, D.; Matheswaran, M.M. Thermal and thermo-hydraulic analysis of arc shaped rib roughened solar air heater integrated with fins and baffles. Sol. Energy 2019, 180, 360–371. [Google Scholar] [CrossRef]

- Sharma, S.; Dutta, V.; Eswaramoorthy, M. An Experimental Investigation on multi-V and protrusion element on absorber plate of solar air heater. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 2742–2750. [Google Scholar] [CrossRef]

- Jain, S.K.; Agrawal, G.D.; Misra, R. Heat transfer augmentation using multiple gaps in arc-shaped ribs roughened solar air heater: An experimental study. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 3345–3356. [Google Scholar] [CrossRef]

- Thakur, S.; Thakur, N.S. Investigational analysis of roughened solar air heater channel having W-shaped ribs with symmetrical gaps along with staggered ribs. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 2019, 1–16. [Google Scholar] [CrossRef]

- Kumar, A.; Behura, A.K.; Saboor, S.; Gupta, H.K. Comparative study of W-shaped roughened solar air heaters by using booster mirror. Mater. Today Proc. 2021, 46, 5675–5680. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A.; Dey, K.; Aman, A. Exergy and energy analysis of sensible heat storage based double pass hybrid solar air heater. Sustain. Energy Technol. Assess. 2022, 49, 101714. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, R.; Kumar, S.; Thapa, S.; Sethi, M.; Fekete, G.; Singh, T. Impact of artificial roughness variation on heat transfer and friction characteristics of solar air heating system. Alex. Eng. J. 2022, 6, 481–491. [Google Scholar] [CrossRef]

- Haldar, A.; Varsheny, L.; Verma, P. Effect of roughness parameters on performance of solar air heater having artificial wavy roughness using CFD. Renew. Energy 2022, 184, 266–279. [Google Scholar] [CrossRef]

- Muthukumaran, J.; Senthil, R. Experimental performance of a solar air heater using straight and spiral absorber tubes with thermal energy storage. J. Energy Storage 2022, 45, 103796. [Google Scholar] [CrossRef]

- Tandel, H.U.; Modi, K.V. Experimental assessment of double-pass solar air heater by incorporating perforated baffles and solar water heating system. Renew. Energy 2022, 183, 385–405. [Google Scholar] [CrossRef]

- El-Said, E.M.S.; Gohar, M.A.; Ali, A.; Abdelaziz, G.B. Performance enhancement of a double pass solar air heater by using curved reflector: Experimental investigation. Appl. Therm. Eng. 2022, 202, 117867. [Google Scholar] [CrossRef]

- Dutta, P.P.; Goswami, P.; Sharma, A.; Baruah, M.G. Computational Performance Analysis of the Perforated and Flat Plates Double Pass Solar Air Heaters. In Advances in Thermo Fluids and Renewable Energy; Mahanta, P., Kalita, P., Paul, A., Banerjee, A., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022; pp. 549–556. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Behura, A.K.; Singh, M.; Prasad, B.N.; Kumar, A.; Dwivedi, G.; Verma, P. Parametric performance optimization of three sides roughened solar air heater. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S. Engineering optimisation by cuckoo search. Int. J. Math. Model. Numer. Optim. 2010, 1, 330–343. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S. Cuckoo search via Lévy flights. In Proceedings of the 2009 World Congress on Nature & Biologically Inspired Computing (NaBIC), Coimbatore, India, 9–11 December 2009; pp. 210–214. [Google Scholar]

- Chiroma, H.; Herawan, T.; Fister, I., Jr.; Fister, I.; Abdulkareem, S.; Shuib, L.; Abubakar, A. Bio-inspired computation: Recent development on the modifications of the cuckoo search algorithm. Appl. Soft Comput. 2017, 61, 149–173. [Google Scholar] [CrossRef]

- Saeed, A.; Gul, T. Bioconvection casson nanofluid flow together with Darcy-Forchheimer due to a rotating disc with thermal radiation and Arrhenius activation energy. SN Appl. Sci. 2021, 3, 78. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Satpathy, M.P.; Mahapatra, S.S.; Singh, M.R. Optimization of cryo-treated EDM variables using TOPSIS-based TLBO algorithm. Sadhana 2018, 43, 51–69. [Google Scholar] [CrossRef] [Green Version]

- Jadhav, P.S.; Mohanty, C.P.; Hotta, T.K.; Gupta, M. An optimal approach for improving the machinability of Nimonic C-263 super alloy during cryogenic assisted turning. J. Manuf. Processes 2020, 58, 693–705. [Google Scholar] [CrossRef]

- Behura, A.K.; Prasad, B.N.; Prasad, L. Heat transfer, friction factor and thermal performance of three sides artificially roughened solar air heaters. Sol. Energy 2016, 130, 46–59. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Mahapatra, M.; Singh, R. A particle swarm approach for multi-objective optimization of electrical discharge machining process. J. Intell. Manuf. 2016, 27, 1171–1190. [Google Scholar] [CrossRef]

- Shastri, R.K.; Mohanty, C.P. Sustainable electrical discharge machining of Nimonic C263 super alloy. Arab. J. Sci. Eng. 2021, 46, 7273–7293. [Google Scholar] [CrossRef]

| Process Parameters | Unit | Symbols | −1 | Levels | 1 |

|---|---|---|---|---|---|

| Mass flow rate | Kg/s | A | 0.011 | 0.0175 | 0.0248 |

| Pitch of relative roughness | mm | B | 10 | 15 | 20 |

| Height of relative roughness | mm | C | 0.0135 | 0.0225 | 0.0247 |

| Re number | D | 5000 | 10,000 | 13,000 | |

| Atmospheric temperature | °C | E | 27 | 30 | 32 |

| Sl. No | A | B | C | D | E | Collector Heat Removal Factor | Collector EfficiencyFactor | Nusselt Number | Closeness Factor (CF) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 0 | 0 | 0.698 | 0.692 | 50.9 | 0.730813 |

| 2 | 1 | −1 | 0 | 0 | 0 | 0.745 | 0.755 | 55.8 | 0.514159 |

| 3 | −1 | 1 | 0 | 0 | 0 | 0.631 | 0.639 | 43.7 | 0.919987 |

| 4 | 1 | 1 | 0 | 0 | 0 | 0.685 | 0.699 | 48.8 | 0.776373 |

| 5 | 0 | 0 | −1 | −1 | 0 | 0.705 | 0.695 | 50.2 | 0.669547 |

| 6 | 0 | 0 | 1 | −1 | 0 | 0.74 | 0.73 | 54.9 | 0.498939 |

| 7 | 0 | 0 | −1 | 1 | 0 | 0.749 | 0.789 | 57.4 | 0.371548 |

| 8 | 0 | 0 | 1 | 1 | 0 | 0.805 | 0.755 | 60.2 | 0.338904 |

| 9 | 0 | −1 | 0 | 0 | −1 | 0.749 | 0.744 | 59.1 | 0.454069 |

| 10 | 0 | 1 | 0 | 0 | −1 | 0.669 | 0.665 | 45.1 | 0.911269 |

| 11 | 0 | −1 | 0 | 0 | 1 | 0.791 | 0.799 | 58.3 | 0.37341 |

| 12 | 0 | 1 | 0 | 0 | 1 | 0.729 | 0.725 | 51.9 | 0.648318 |

| 13 | −1 | 0 | −1 | 0 | 0 | 0.689 | 0.679 | 45.9 | 0.796169 |

| 14 | 1 | 0 | −1 | 0 | 0 | 0.748 | 0.741 | 54.9 | 0.486216 |

| 15 | −1 | 0 | 1 | 0 | 0 | 0.754 | 0.714 | 50.4 | 0.600135 |

| 16 | 1 | 0 | 1 | 0 | 0 | 0.779 | 0.799 | 53.2 | 0.433297 |

| 17 | 0 | 0 | 0 | −1 | −1 | 0.77 | 0.76 | 46.8 | 0.604707 |

| 18 | 0 | 0 | 0 | 1 | −1 | 0.795 | 0.785 | 54.1 | 0.416158 |

| 19 | 0 | 0 | 0 | −1 | 1 | 0.791 | 0.781 | 47.9 | 0.546663 |

| 20 | 0 | 0 | 0 | 1 | 1 | 0.819 | 0.869 | 57.1 | 0.274772 |

| 21 | 0 | −1 | −1 | 0 | 0 | 0.741 | 0.747 | 56.5 | 0.50565 |

| 22 | 0 | 1 | −1 | 0 | 0 | 0.699 | 0.649 | 44.1 | 0.875914 |

| 23 | 0 | −1 | 1 | 0 | 0 | 0.759 | 0.779 | 57.1 | 0.448278 |

| 24 | 0 | 1 | 1 | 0 | 0 | 0.702 | 0.722 | 54.1 | 0.624424 |

| 25 | −1 | 0 | 0 | −1 | 0 | 0.696 | 0.686 | 52.1 | 0.641054 |

| 26 | 1 | 0 | 0 | −1 | 0 | 0.741 | 0.748 | 49.1 | 0.601537 |

| 27 | −1 | 0 | 0 | 1 | 0 | 0.748 | 0.738 | 50.9 | 0.570786 |

| 28 | 1 | 0 | 0 | 1 | 0 | 0.788 | 0.828 | 66.3 | 0.114451 |

| 29 | 0 | 0 | −1 | 0 | −1 | 0.717 | 0.707 | 53.9 | 0.563956 |

| 30 | 0 | 0 | 1 | 0 | −1 | 0.755 | 0.765 | 52.1 | 0.510247 |

| 31 | 0 | 0 | −1 | 0 | 1 | 0.759 | 0.799 | 57.2 | 0.380239 |

| 32 | 0 | 0 | 1 | 0 | 1 | 0.783 | 0.793 | 60.3 | 0.275463 |

| 33 | −1 | 0 | 0 | 0 | −1 | 0.709 | 0.699 | 43.1 | 0.783184 |

| 34 | 1 | 0 | 0 | 0 | −1 | 0.741 | 0.745 | 58.5 | 0.404511 |

| 35 | −1 | 0 | 0 | 0 | 1 | 0.719 | 0.749 | 57.2 | 0.446054 |

| 36 | 1 | 0 | 0 | 0 | 1 | 0.791 | 0.799 | 53.1 | 0.427346 |

| 37 | 0 | −1 | 0 | −1 | 0 | 0.778 | 0.723 | 50.1 | 0.628746 |

| 38 | 0 | 1 | 0 | −1 | 0 | 0.648 | 0.641 | 55.1 | 0.69826 |

| 39 | 0 | −1 | 0 | 1 | 0 | 0.748 | 0.743 | 70.5 | 0.272485 |

| 40 | 0 | 1 | 0 | 1 | 0 | 0.741 | 0.697 | 48.6 | 0.72102 |

| 41 | 0 | 0 | 0 | 0 | 0 | 0.755 | 0.745 | 57.5 | 0.413875 |

| 42 | 0 | 0 | 0 | 0 | 0 | 0.769 | 0.759 | 54.5 | 0.372734 |

| 43 | 0 | 0 | 0 | 0 | 0 | 0.745 | 0.735 | 57.3 | 0.447615 |

| 44 | 0 | 0 | 0 | 0 | 0 | 0.768 | 0.758 | 54.3 | 0.378996 |

| 45 | 0 | 0 | 0 | 0 | 0 | 0.743 | 0.733 | 55.4 | 0.442263 |

| 46 | 0 | 0 | 0 | 0 | 0 | 0.768 | 0.758 | 54.5 | 0.379459 |

| Sum of | Mean | F | p-Value | |||

|---|---|---|---|---|---|---|

| Source | Squares | Df | Square | Value | Prob > F | |

| Model | 0.068 | 17 | 4.00 × 10−3 | 17.45 | <0.0001 | Significant |

| A-Mass flow rate | 8.74 × 10−3 | 1 | 8.74 × 10−3 | 38.18 | <0.0001 | |

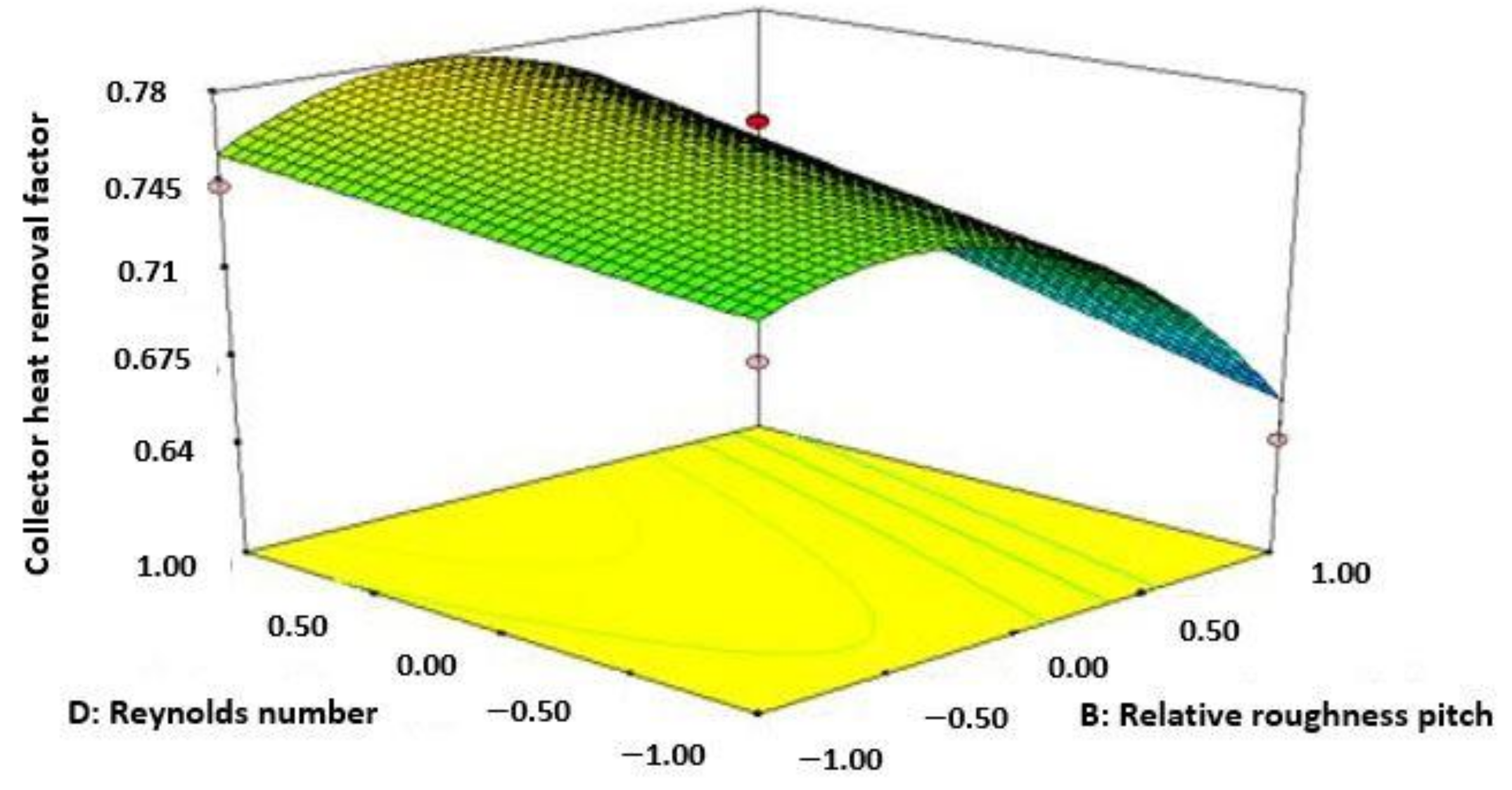

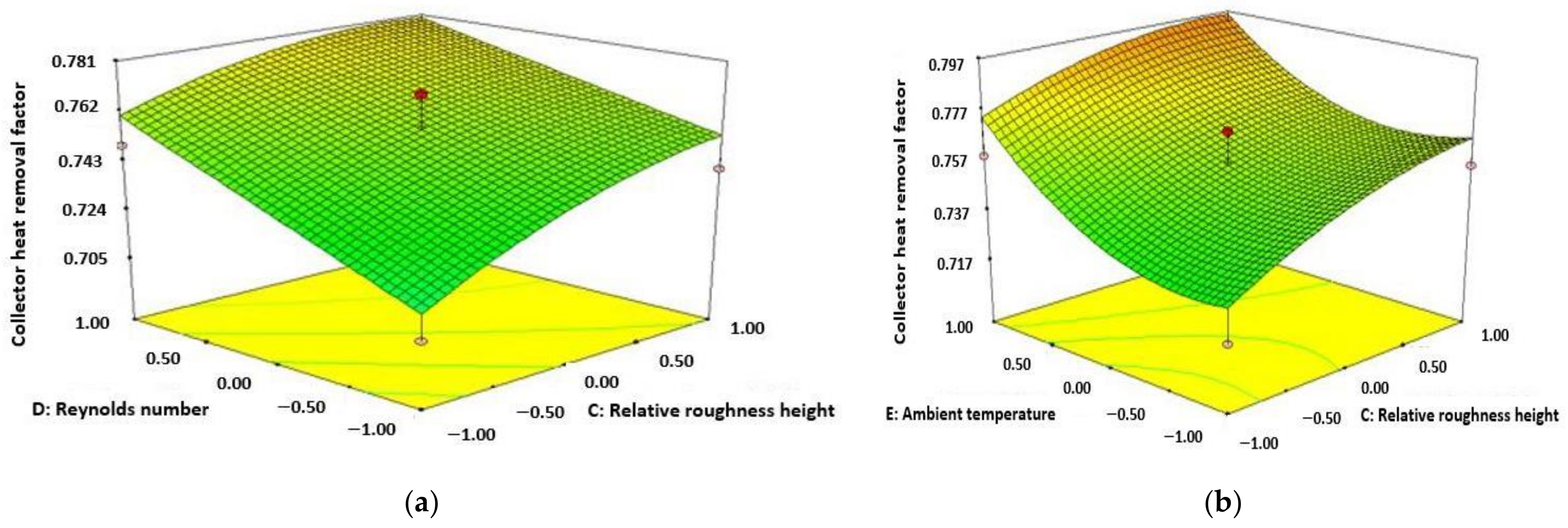

| B-Relative roughness pitch | 0.016 | 1 | 0.016 | 69.61 | <0.0001 | |

| C-Relative roughness height | 4.56 × 10−3 | 1 | 4.56 × 10−3 | 19.9 | 0.0001 | |

| D- Re number | 6.56 × 10−3 | 1 | 6.56 × 10−3 | 28.65 | <0.0001 | |

| E-Ambient temperature | 4.80 × 10−3 | 1 | 4.80 × 10−3 | 20.94 | <0.0001 | |

| AC | 2.89 × 10−4 | 1 | 2.89 × 10−4 | 1.26 | 0.2708 | |

| AE | 4.00 × 10−4 | 1 | 4.00 × 10−4 | 1.75 | 0.197 | |

| BC | 5.63 × 10−5 | 1 | 5.63 × 10−5 | 0.25 | 0.624 | |

| BD | 3.78 × 10−3 | 1 | 3.78 × 10−3 | 16.52 | 0.0004 | |

| BE | 8.10 × 10−5 | 1 | 8.10 × 10−5 | 0.35 | 0.5568 | |

| CD | 1.10 × 10−4 | 1 | 1.10 × 10−4 | 0.48 | 0.4935 | |

| CE | 4.90 × 10−5 | 1 | 4.90 × 10−5 | 0.21 | 0.6472 | |

| A2 | 4.99 × 10−3 | 1 | 4.99 × 10−3 | 21.8 | <0.0001 | |

| B2 | 0.012 | 1 | 0.012 | 50.32 | <0.0001 | |

| C2 | 2.56 × 10−4 | 1 | 2.56 × 10−4 | 1.12 | 0.2993 | |

| D2 | 7.74 × 10−4 | 1 | 7.74 × 10−4 | 3.38 | 0.0766 | |

| E2 | 1.15 × 10−3 | 1 | 1.15 × 10−3 | 5.04 | 0.0328 | |

| Residual | 6.41 × 10−3 | 28 | 2.29 × 10−4 | |||

| Lack of Fit | 5.69 × 10−3 | 23 | 2.47 × 10−4 | 1.71 | 0.2892 | not significant |

| Pure Error | 7.24 × 10−4 | 5 | 1.45 × 10−4 | |||

| Cor Total | 0.074 | 45 |

| Sum of | Mean | F | p-Value | |||

|---|---|---|---|---|---|---|

| Source | Squares | Df | Square | Value | Prob > F | |

| Model | 0.096 | 17 | 18.35 | <0.0001 | Significant | |

| A-Mass flow rate | 0.017 | 1 | 0.017 | 54.64 | <0.0001 | |

| B-Relative roughness pitch | 0.019 | 1 | 0.019 | 60.49 | <0.0001 | |

| C-Relative roughness height | 1 | 12.83 | 0.0013 | |||

| D-Re number | 0.012 | 1 | 0.012 | 39.42 | <0.0001 | |

| E-Ambient temperature | 0.012 | 1 | 0.012 | 40.14 | <0.0001 | |

| AC | 1 | 0.43 | 0.5169 | |||

| AD | 1 | 0.64 | 0.4309 | |||

| BC | 1 | 1.37 | 0.2518 | |||

| BD | 1 | 1.06 | 0.313 | |||

| CD | 1 | 3.88 | 0.0589 | |||

| CE | 1 | 3.34 | 0.0784 | |||

| DE | 1 | 3.23 | 0.083 | |||

| A2 | 1 | 5.77 | 0.0231 | |||

| B2 | 0.013 | 1 | 0.013 | 42.15 | <0.0001 | |

| C2 | 1 | 0.064 | 0.8022 | |||

| D2 | 1 | 1.49 | 0.2317 | |||

| E2 | 1 | 18.13 | 0.0002 | |||

| Residual | 28 | |||||

| Lack of Fit | 23 | 2.36 | 0.1723 | not significant | ||

| Pure Error | 5 | |||||

| Cor Total | 0.1 | 45 |

| Sum of | Mean | F | p-Value | |||

|---|---|---|---|---|---|---|

| Source | Squares | Df | Square | Value | Prob > F | |

| Model | 1217.58 | 17 | 71.62 | 13.76 | <0.0001 | Significant |

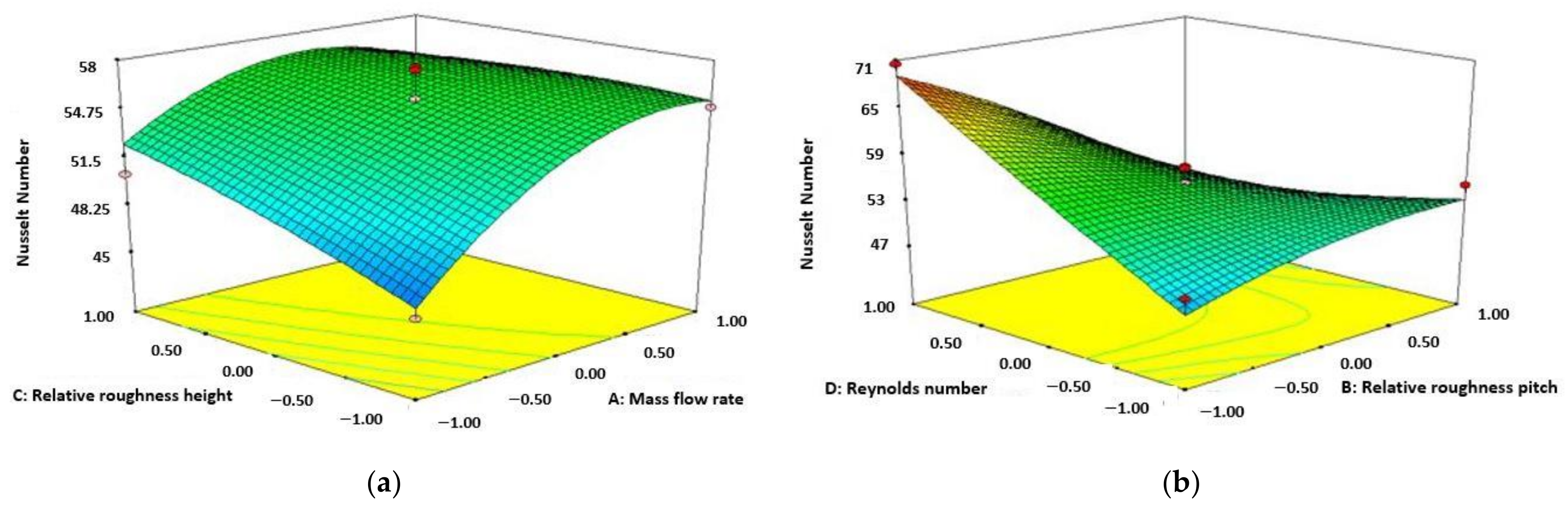

| A-Mass flow rate | 129.39 | 1 | 129.39 | 24.85 | <0.0001 | |

| B-Relative roughness pitch | 279.73 | 1 | 279.73 | 53.73 | <0.0001 | |

| C-Relative roughness height | 30.8 | 1 | 30.8 | 5.92 | 0.0216 | |

| D-Re number | 216.83 | 1 | 216.83 | 41.65 | <0.0001 | |

| E-Ambient temperature | 57.38 | 1 | 57.38 | 11.02 | 0.0025 | |

| AC | 9.61 | 1 | 9.61 | 1.85 | 0.1851 | |

| AD | 84.64 | 1 | 84.64 | 16.26 | 0.0004 | |

| AE | 95.06 | 1 | 95.06 | 18.26 | 0.0002 | |

| BC | 22.09 | 1 | 22.09 | 4.24 | 0.0488 | |

| BD | 180.9 | 1 | 180.9 | 34.75 | <0.0001 | |

| BE | 14.44 | 1 | 14.44 | 2.77 | 0.107 | |

| CE | 6 | 1 | 6 | 1.15 | 0.2921 | |

| A2 | 68.93 | 1 | 68.93 | 13.24 | 0.0011 | |

| B2 | 19.47 | 1 | 19.47 | 3.74 | 0.0633 | |

| C2 | 1.65 | 1 | 1.65 | 0.32 | 0.5774 | |

| D2 | 0.82 | 1 | 0.82 | 0.16 | 0.6947 | |

| E2 | 8.62 | 1 | 8.62 | 1.66 | 0.2088 | |

| Residual | 145.78 | 28 | 5.21 | |||

| Lack of Fit | 135.13 | 23 | 5.88 | 2.76 | 0.1312 | not significant |

| Pure Error | 10.65 | 5 | 2.13 | |||

| Cor Total | 1363.36 | 45 |

| Sum of | Mean | F | p-Value | ||||

|---|---|---|---|---|---|---|---|

| Source | Squares | Df | Square | Value | Prob > F | ||

| Model | 1.46 | 20 | 0.073 | 29.37 | <0.0001 | Significant | |

| A-Mass flow rate | 0.2 | 1 | 0.2 | 82.65 | <0.0001 | ||

| B-Relative roughness pitch | 0.34 | 1 | 0.34 | 136.68 | <0.0001 | ||

| C-Relative roughness height | 0.053 | 1 | 0.053 | 21.33 | 0.0001 | ||

| D-Re number | 0.2 | 1 | 0.2 | 82.56 | <0.0001 | ||

| E-Ambient temperature | 0.1 | 1 | 0.1 | 41.05 | <0.0001 | ||

| AB | 1 | 4.89 × 10−3 | 0.9448 | ||||

| AC | 1 | 2.07 | 0.163 | ||||

| AD | 0.043 | 1 | 0.043 | 17.53 | 0.0003 | ||

| AE | 0.032 | 1 | 0.032 | 13.07 | 0.0013 | ||

| BC | 1 | 3.8 | 0.0625 | ||||

| BD | 0.036 | 1 | 0.036 | 14.49 | 0.0008 | ||

| BE | 1 | 3.35 | 0.0791 | ||||

| CD | 1 | 1.92 | 0.1781 | ||||

| CE | 1 | 0.26 | 0.6125 | ||||

| DE | 1 | 0.7 | 0.4105 | ||||

| A2 | 0.12 | 1 | 0.12 | 48.37 | <0.0001 | ||

| B2 | 0.31 | 1 | 0.31 | 125.3 | <0.0001 | ||

| C2 | 0.013 | 1 | 0.013 | 5.16 | 0.032 | ||

| D2 | 1 | 0.061 | 0.8072 | ||||

| E2 | 1 | 0.25 | 0.623 | ||||

| Residual | 0.062 | 25 | |||||

| Lack of Fit | 0.056 | 20 | 2.49 | 0.1579 | not significant | ||

| Pure Error | 5 | ||||||

| Cor Total | 1.52 | 45 | |||||

| Process Variables | A | B | C | D | E | TOSIS Based CSO | TOSIS CF | Expt CF | % Improvement |

|---|---|---|---|---|---|---|---|---|---|

| Optimum Result | 1.46 | 0.919987 | 0.99898 | 8.58% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behura, A.K.; Mohanty, C.P.; Singh, M.R.; Kumar, A.; Linul, E.; Rajak, D.K. Performance Analysis of Three Side Roughened Solar Air Heater: A Preliminary Investigation. Materials 2022, 15, 2541. https://doi.org/10.3390/ma15072541

Behura AK, Mohanty CP, Singh MR, Kumar A, Linul E, Rajak DK. Performance Analysis of Three Side Roughened Solar Air Heater: A Preliminary Investigation. Materials. 2022; 15(7):2541. https://doi.org/10.3390/ma15072541

Chicago/Turabian StyleBehura, Aruna Kumar, Chinmaya Prasad Mohanty, Manas Ranjan Singh, Ashwini Kumar, Emanoil Linul, and Dipen Kumar Rajak. 2022. "Performance Analysis of Three Side Roughened Solar Air Heater: A Preliminary Investigation" Materials 15, no. 7: 2541. https://doi.org/10.3390/ma15072541

APA StyleBehura, A. K., Mohanty, C. P., Singh, M. R., Kumar, A., Linul, E., & Rajak, D. K. (2022). Performance Analysis of Three Side Roughened Solar Air Heater: A Preliminary Investigation. Materials, 15(7), 2541. https://doi.org/10.3390/ma15072541