The Optical and Thermo-Optical Properties of Non-Stoichiometric Silicon Nitride Layers Obtained by the PECVD Method with Varying Levels of Nitrogen Content

Abstract

:1. Introduction

2. Materials and Methods

2.1. Technology and Samples

2.2. Characterization Methods

3. Results

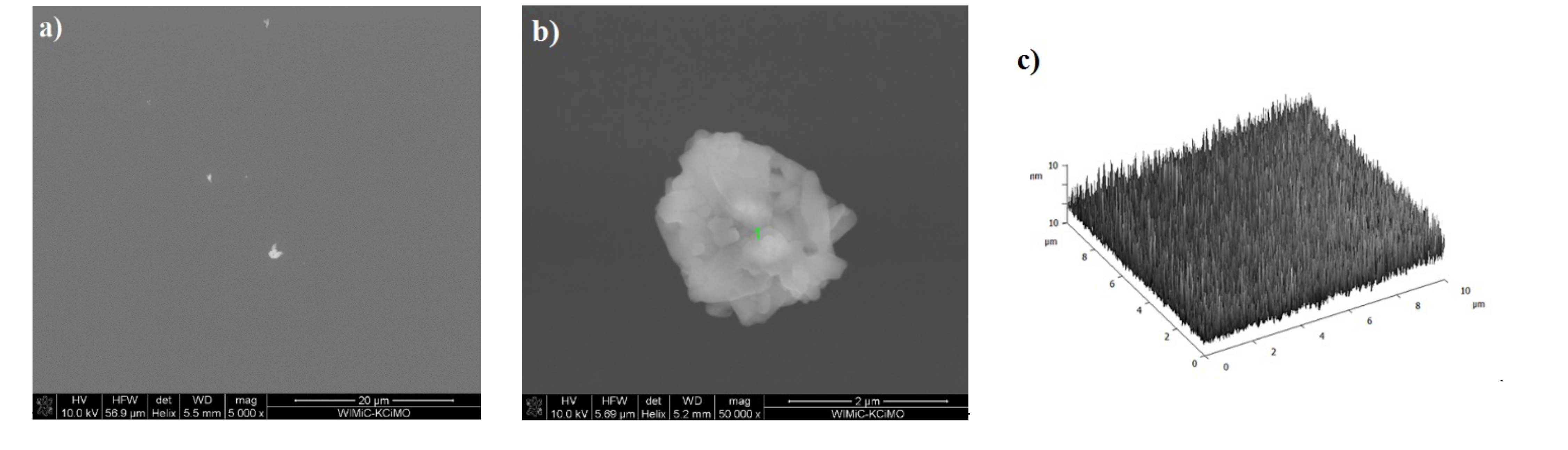

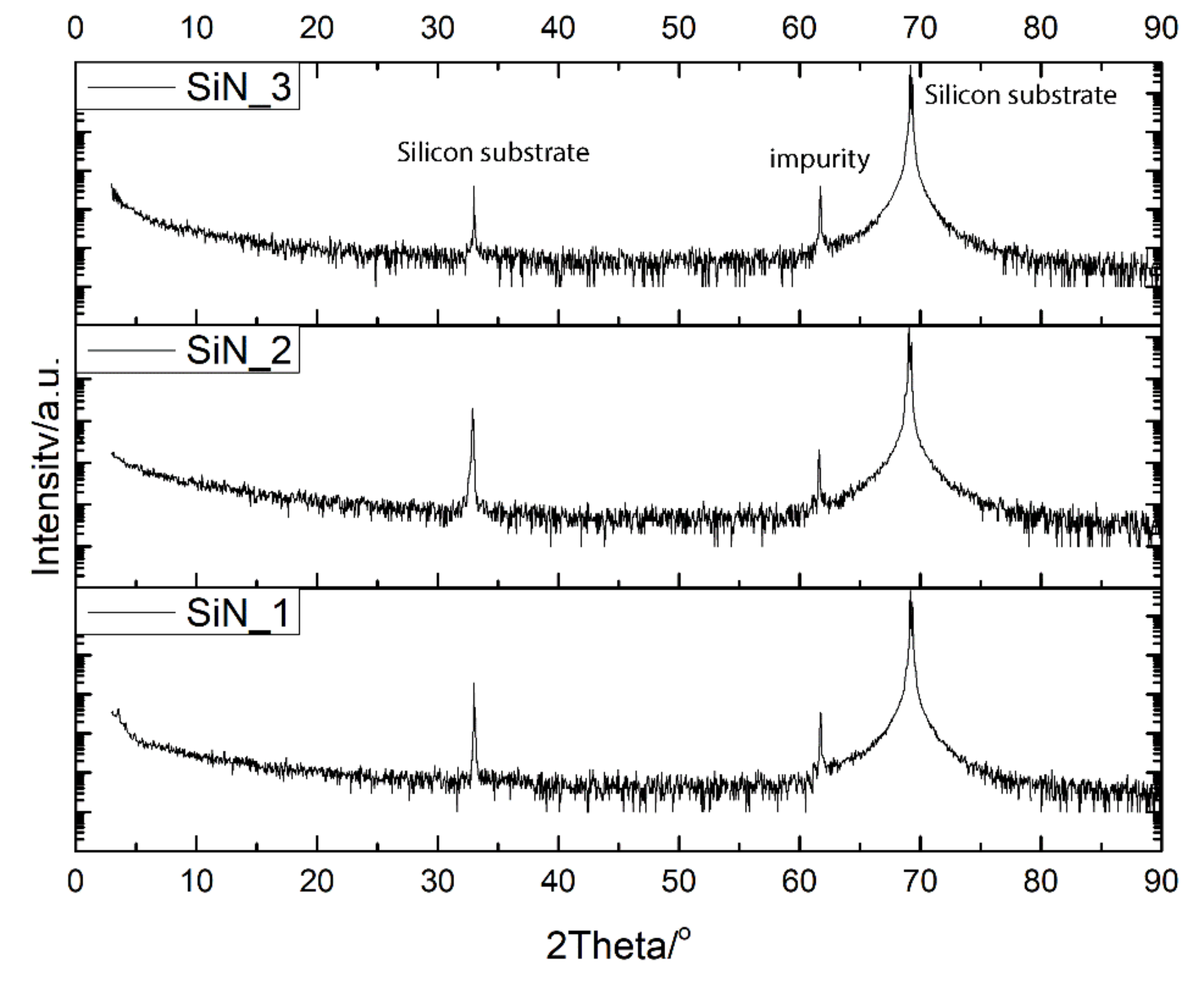

3.1. Morphology and Chemical Structure of Layers

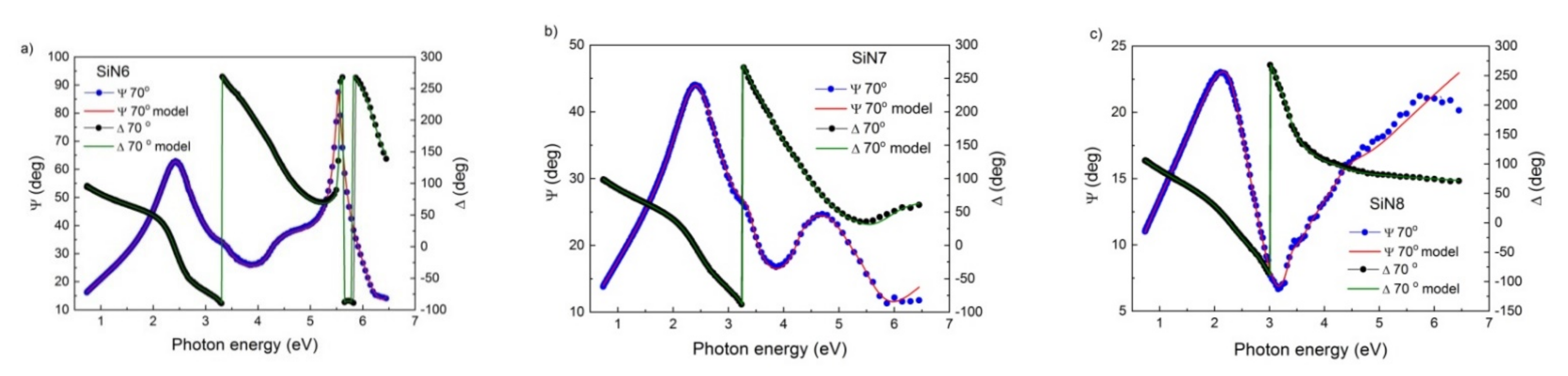

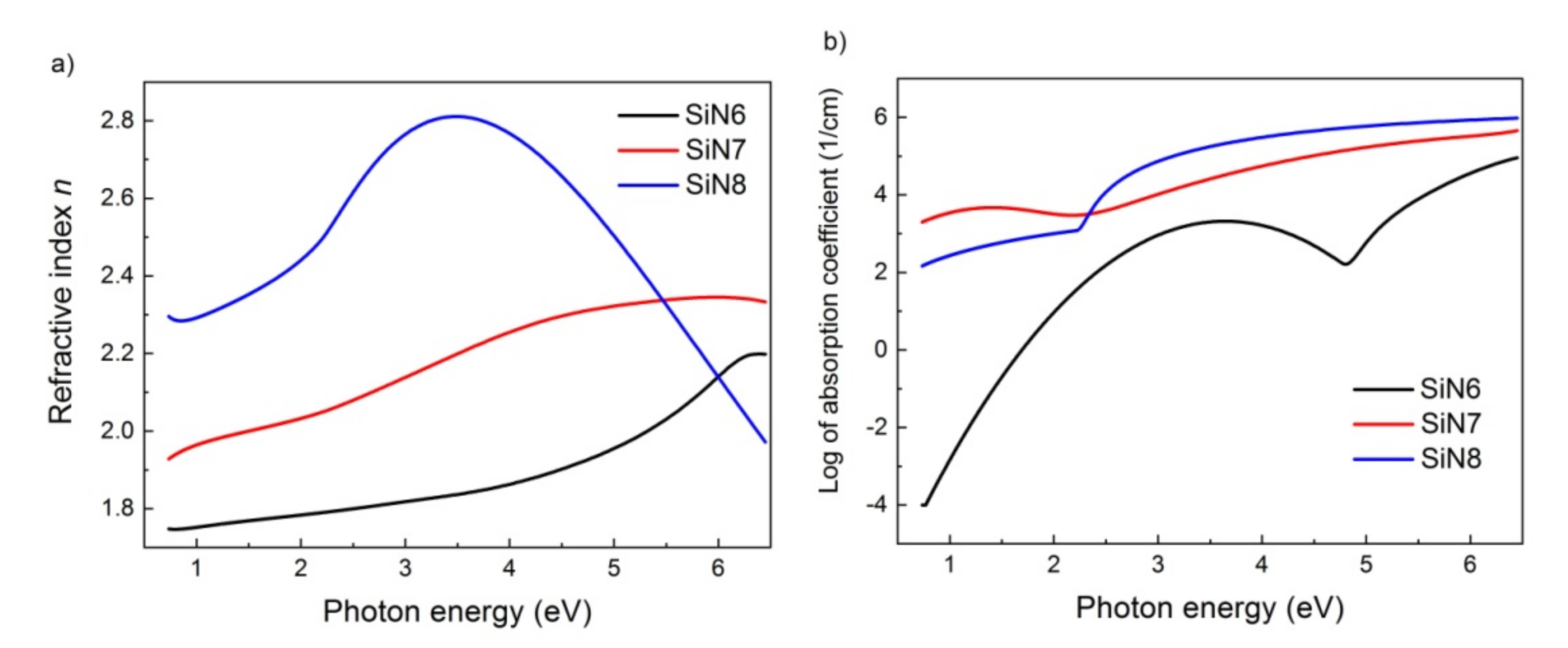

3.2. Optical Studies

4. Conclusions

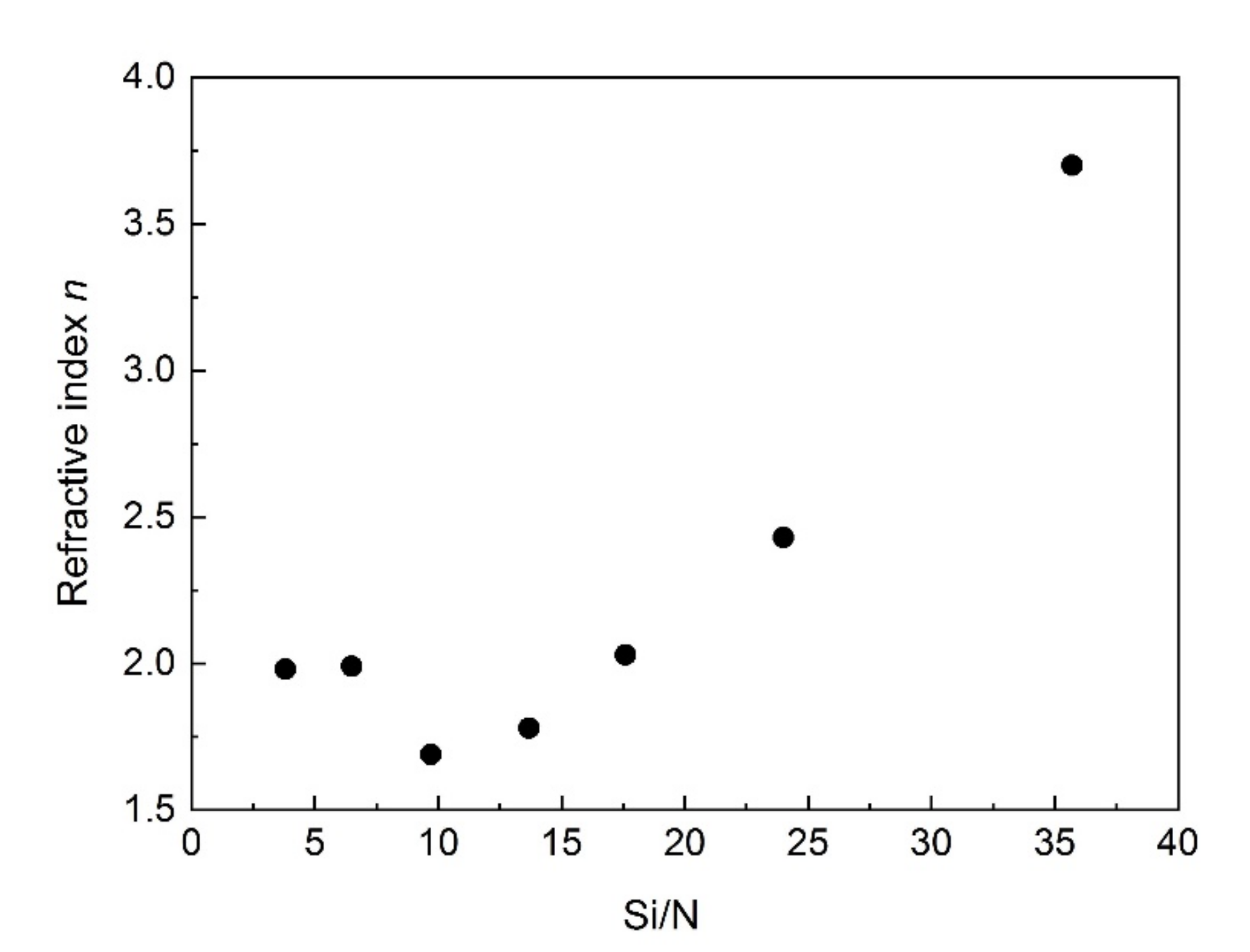

- Refractive indices of the SiN layers in a wide range from 1.8 to 3.7 strongly depend on the volumetric composition of Si and N components. Measurement results for SiN layers in such a wide range have not been published in the scientific literature so far.

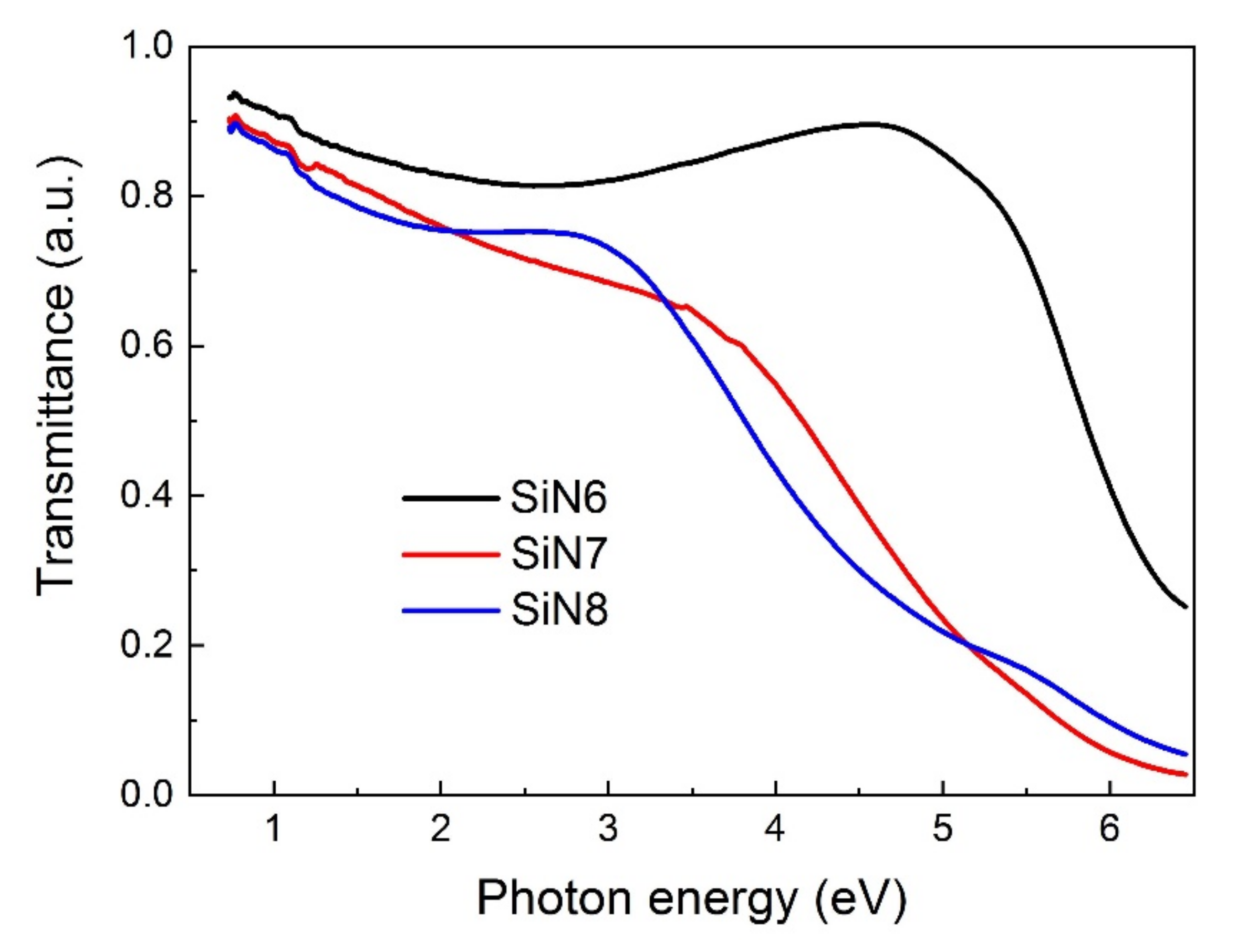

- The energy gaps of tested SiN layers determined from optical measurements range from 2.22 to 2.25 eV.

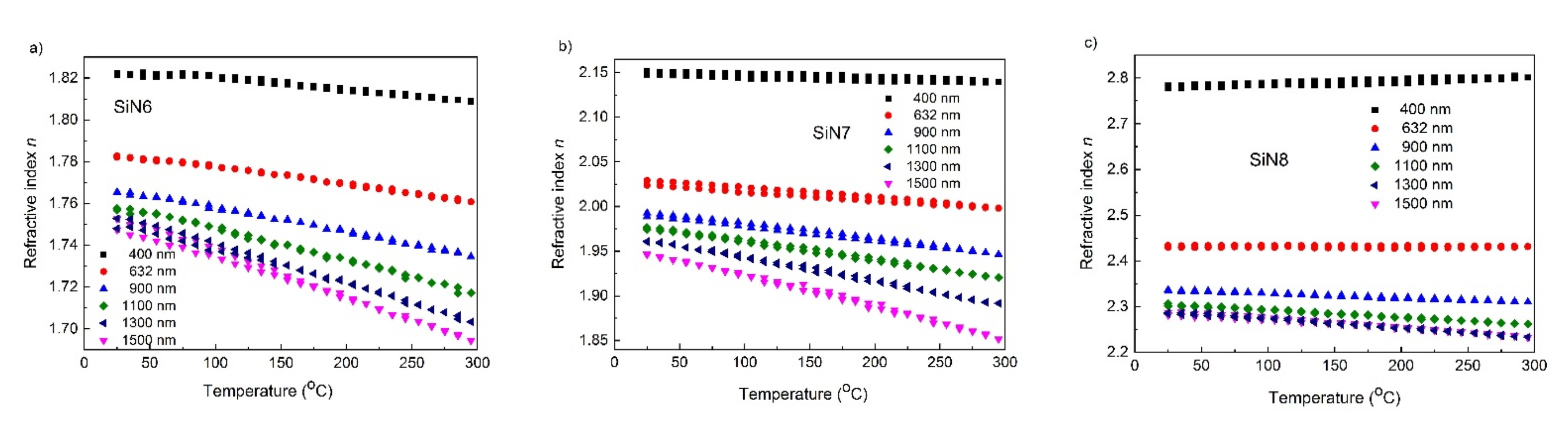

- Thermo-optical parameters of the SiN layers strongly depended on the technological process.

- The values of the TOC parameter obtained for the samples prepared with a double frequency of radiation were negative, while the thermo-optical coefficient was positive for SiN layers deposited for one frequency of PACVD radiation.

- Thermo-optical measurements showed that after annealing up to 300 C and subsequent cooling, the value of optical parameters of layers returned to the initial values, which indicate the reversibility of their thermal properties and thermal stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Aberle, A.G.; Hezel, R. Progress in low-temperature surface passivation of silicon solar cells using remote-plasma silicon nitride. Prog. Photovolt. 1997, 5, 29–50. [Google Scholar] [CrossRef]

- Lipiński, M. Silicon Nitride for Photovoltaic Application. Arch. Mater. Sci. Eng. 2010, 46, 69–87. [Google Scholar]

- Dekkers, H.; De Wolf, S.; Agostinelli, G.; Duerinckx, F.; Beaucarne, G. Requirements of PECVD SiNx:H layers for bulk passivation of mc-Si. Sol. Energy Mater. Sol. Cells 2006, 90, 3244–3250. [Google Scholar] [CrossRef]

- Lelièvre, J.F.; Kafle, B.; Saint-Cast, P.; Brunet, P.; Magnan, R.; Hernandez, E.; Poliquen, S.; Massines, F. Efficient silicon nitride SiNx:H antireflective and passivation layers deposited by atmospheric pressure PECVD for silicon solar cells. Prog. Photovolt. 2019, 27, 1007–1019. [Google Scholar] [CrossRef]

- Aberle, A.G. Surface passivation of crystalline silicon solar cells: A review. Prog. Photovolt. Res. Appl. 2000, 8, 473–487. [Google Scholar] [CrossRef]

- Schmidt, J.; Kerr, M. Highest-quality surface passivation of low-resistivity p-type silicon using stiochiometric PECVD silicon nitride. Sol. Energy Mater. Sol. Cells 2001, 65, 585–591. [Google Scholar] [CrossRef] [Green Version]

- Lipiński, M.; Panek, P.; Kluska, S.; Zięba, P.; Szyszka, A.; Paszkiewicz, B. Defect passivation of multicrystalline silicon solar cells by silicon nitride coatings. Mater. Sci.-Pol. 2006, 24, 1003–1007. [Google Scholar]

- Ghosh, H.; Mitra, S.; Saha, H.; Datta, S.K.; Banerjee, C. Argon plasma treatment of silicon nitride (SiN) for improved antireflection coating on c-Si solar cells. Mater. Sci. Eng. B 2017, 215, 29–36. [Google Scholar] [CrossRef]

- Lin, P.T.; Singh, V.; Lin, H.Y.G.; Tiwald, T.; Kimerling, L.C.; Agarwal, A.M. Low-stress Silicon Nitride Platform for Mid-infrared Broadband and Monolithically Integrated Microphotonics. Adv. Opt. Mater. 2013, 1, 732–739. [Google Scholar] [CrossRef]

- Nunomura, S.; Sakata, I.; Sato, A.; Lozach, M.; Misawa, T.; Itagaki, N.; Shiratani, M. Passivating antireflection coating of crystalline silicon using i/n a-Si:H/SiNtrilayer. J. Phys. Chem. Sol. 2021, 156, 110127. [Google Scholar] [CrossRef]

- Kluska, S.; Hejduk, K.; Drabczyk, K.; Lipiński, M. Optical properties and passivation effects of silicon nitride three layer stack deposited by plasma enhanced chemical vapor deposition. Phys. Status Solidi A 2016, 213, 1839–1847. [Google Scholar] [CrossRef]

- Sood, A.K.; Zeller, J.W.; Sood, A.W.; Pethuraja, G.G.; Welser, R.E.; Efstathiadis, H.; Sampath, A.V.; Dhar, N.K. Development of nanostructured antireflection coating for infrared sensing applications. Proc. SPIE 2019, 11129, 111290I. [Google Scholar] [CrossRef]

- Yoshinaga, S.; Ishikawa, Y.; Kawamura, Y.; Nakai, Y.; Uraoka, Y. The optical properties of silicon-rich silicon nitride prepared by plasma enhanced chemical vapor deposition. Mater. Sci. Semicond. Proc. 2019, 90, 54–58. [Google Scholar] [CrossRef]

- Cho, S.-K.; Cho, T.-Y.; Lee, W.J.; Ryu, J.; Lee, J.H. Structural and gas barrier properties of hydrogenated silicon nitride thin films prepared by roll-to-roll microwave plasma-enhanced chemical vapor deposition. Vacuum 2021, 188, 110167. [Google Scholar] [CrossRef]

- Jurzecka-Szymacha, M.; Boszkowicz, P.; Tkacz-Śmiech, K. Silicon nitride layers of various N-content: Technology, properties and structure. Thin Solid Films 2011, 520, 1308–1312. [Google Scholar] [CrossRef]

- Song, H.; Seo, S.; Chang, H. Study on SiN and SiCN film production using PE-ALD process with high-density multi-ICP source at low temperature. Curr. Appl. Phys. 2018, 18, 1436–1440. [Google Scholar] [CrossRef]

- Thi, T.C.; Koyama, K.; Ohdaira, K.; Matsumura, H. Passivation characteristics of SiNx/a-Si and SiNx/Si-rich-SiNx stacked layers on crystalline silicon. Sol. Energy Mater. Sol. Cells 2012, 100, 169–173. [Google Scholar] [CrossRef]

- Sahu, R.; Palei, S.; Choi, J.; Ji, H.Y.; Kim, K. Silicon solar cells with nitrogen-rich SiNx/Si interfacial passivation by low-energy nitrogen-ion implantation. Sol. Energy Mater. Sol. Cells 2021, 220, 110858. [Google Scholar] [CrossRef]

- Debieu, O.; Nalini, R.P.; Cardin, J.; Portier, X.; Perrière, J.; Gourbilleau, F. Structural and optical characterization of pure Si-rich nitride thin films. Nanoscale Res. Lett. 2013, 8, 31–44. [Google Scholar] [CrossRef] [Green Version]

- Ng, D.K.T.; Wang, Q.; Wang, T.; Ng, S.-K.; Toh, Y.-T.; Lim, K.-P.; Yang, Y.; Tan, D.T.H. Exploring High Refractive Index Silicon-Rich Nitride Films by Low-Temperature Inductively Coupled Plasma Chemical Vapor Deposition and Applications for Integrated Waveguides. Appl. Mater. Interfaces 2015, 7, 21884–21889. [Google Scholar] [CrossRef]

- Claassen, W.A.P.; Valkenburg, W.G.J.N.; Willemsen, M.F.C.; Wijgert, W.M.V.D. Influence of deposition temperature, gas pressure, gas phase composition and RF frequency on composition and mechanical stress of plasma silicon nitride layers. J. Electrochem. Soc. 1985, 132, 893–898. [Google Scholar] [CrossRef]

- Karouta, F.; Vora, K.; Tian, J.; Jagadish, C. Structural, compositional and optical properties of PECVD silicon nitride layers. J. Phys. D Appl. Phys. 2012, 45, 445301–445311. [Google Scholar] [CrossRef]

- Samuelson, G.M.; Mark, M. The correlations between physical and electrical properties of PECVD SiN with their composition ratios. J. Electrochem. Soc. 1982, 129, 1773–1778. [Google Scholar] [CrossRef]

- Claassen, W.A.P.; Valkenburg, W.G.J.N.; Habraken, F.H.P.M.; Tamminga, Y. Characterization of Plasma Silicon Nitride Layers. J. Electrochem. Soc. 1983, 130, 2419–2423. [Google Scholar] [CrossRef]

- Kim, D.S.; Yoon, S.G.; Jang, G.E.; Suh, S.J.; Kim, H.; Yoon, D.H. Refractive index properties of SiN thin films and fabrication of SiN optical waveguide. J. Electroceramics 2006, 17, 315–318. [Google Scholar] [CrossRef]

- Tompkins, H.G.; McGahan, W.A. Spectroscopic Ellipsometry and Reflectometry; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jellison, G.E.; Modine, F.A. Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett. 1996, 69, 371. [Google Scholar] [CrossRef]

- Jellison, G.E.; Merkulov, V.I.; Puretzky, A.A.; Geohegan, D.B.; Eres, G.; Lowndes, D.H.; Caughman, J.B. Characterization of thin-film amorphous semiconductors using spectroscopic ellipsometry. Thin Solid Film. 2000, 377–378, 68–73. [Google Scholar] [CrossRef]

- Nosidlak, N.; Jaglarz, J.; Danel, A. Ellipsometric studies for thin polymer layers of organic photovoltaic cells. J. Vac. Sci. Technol. B 2019, 37, 062402. [Google Scholar] [CrossRef]

- Budai, J.; Hanyecz, I.; Szilágyi, E.; Tóth, Z. Ellipsometric study of SixC films: Analysis of Tauc–Lorentz and Gaussian oscillator models. Thin Solid Film. 2011, 59, 2985–2988. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Electronic structure of the amorphous oxide semiconductor a-InGaZnO4-x: Tauc-Lorentz optical model and origins of subgap states. Phys. Status Solidi A 2009, 206, 860–867. [Google Scholar] [CrossRef]

- Woollam, J.A. CompleteEASE™ Data Analysis Manual; JA Woollam Co. Inc.: Lincoln, NE, USA, 2009. [Google Scholar]

- Prod’homme, L. A new approach to the thermal change in the refractive index of glasses. Phys. Chem. Glasses 1960, 1, 119–122. [Google Scholar]

- Jaglarz, J.; Jurzecka-Szymacha, M.; Kluska, S. Film materials on a-SiNx:H with high refractive index obtained by plasma enhanced chemical vapour deposition technology. Thin Solid Film. 2019, 669, 564–570. [Google Scholar] [CrossRef]

- Bustarret, E.; Bensouda, M.; Habrard, M.C.; Bruyère, J.C.; Poulin, S.; Gujrathi, S.C. Configuration statistics in a-SixNyHz alloys: A quantitative bonding analysis. Phys. Rev. B 1988, 38, 8171–8184. [Google Scholar] [CrossRef]

- Giorgis, F.; Giuliani, F.; Pirri, C.; Tresso, E.M.; Summonte, C.; Rizzoli, R.; Galloni, R.; Desalvo, A.; Rava, P. Optical, structural and electrical properties of device-quality hydrogenated amorphous silicon-nitride films deposited by plasma-enhanced chemical vapour deposition. Philos. Mag. B 1998, 77, 925–944. [Google Scholar] [CrossRef]

- Cheng, Q.; Xu, S.; Ostrikov, K. Controlled-bandgap silicon nitride nanomaterials: Deterministic nitrogenation in high-density plasmas. J. Mater. Chem. 2010, 20, 5853–5859. [Google Scholar] [CrossRef] [Green Version]

- Krückel, C.J.; Fülöp, A.; Ye, Z.; Andrekson, P.A.; Torres-Company, V. Optical bandgap engineering in nonlinear silicon nitride waveguides. Opt. Express 2017, 25, 15370–15380. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Feng, X.; Wang, Y.; Guo, M.; Qi, H.; Wei, Z.; Bi, K. Significantly improved measurement accuracy in determining the thermal expansion coefficient of single layer graphene. Diam. Relat. Mater. 2020, 109, 108007. [Google Scholar] [CrossRef]

- Liu, Z.; Shen, Z.; Liu, G.; He, L.; Mu, R.; Xu, Z. Sm-doped Gd2Zr2O7 thermal barrier coatings: Thermal expansion coefficient, structure and failure. Vacuum 2021, 190, 110314. [Google Scholar] [CrossRef]

- Gumbleton, R.; Cuenca, J.A.; Klemencic, G.M.; Jones, N.; Porch, A. Evaluating the coefficient of thermal expansion of additive manufactured AlSi10Mg using microwave techniques. Addit. Manuf. 2019, 30, 100841. [Google Scholar] [CrossRef]

- Jaglarz, J.; Jurzecka-Szymacha, M.; Kluska, S.; Tkacz-Śmiech, K. Thermo-optical properties of high-refractive-index plasma-deposited hydrogenated amorphous silicon-rich nitride films on glass. Opt. Matter. Express 2020, 10, 2749–2756. [Google Scholar] [CrossRef]

| Technique | PECVD System | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Series of Samples | Gaseous Substrate Flow [sccm] | s = [SiH4]/[NH3] | P HF [W] | Cycletime [s] | P LF [W] | Cycle Time [s] | Substrate Temperature [C] | Total Time [s] | |

| NH3 | SiH4 | ||||||||

| 1 | 29 | 4 | 0.13 | 4 | 1800 | - | - | 220 | 1800 |

| 2–5 | 20–60 | 40–80 | 0.25; 0.42; 0.6; 1; | 50 | 480 | - | - | 220 | 480 |

| 6–8 | 95, 20 *, 10 ** | 50, 460 *, 800 ** | 0.5; 23 *; 80 ** | 20 | 40 40 * 144 ** | 20 20 * - ** | 8 8 * - ** | 310 | 310 220 * 158 ** |

| Samples | SiN1 | SiN2 | SiN3 | SiN4 | SiN5 | SiN6 | SiN7 | SiN8 | SiN9 |

|---|---|---|---|---|---|---|---|---|---|

| [Si]/[N] | 2.28 | 3.50 | 5.50 | 6.50 | 9.70 | 13.68 | 17.58 | 24.00 | 35.70 |

| Wavenumber (cm−1) | Bonding | Assignment |

|---|---|---|

| 820–890 1139 2163 3343 | Si–N N–H Si–H N–H | Si–N stretching N–H bending SiH2 stretching in N3Si–H N–H in band Si2N–H |

| Sample | MSE | A | B | Eg [eV] | n 400 nm | n 632 nm | n 900 nm | n 1500 nm |

|---|---|---|---|---|---|---|---|---|

| SiN6 | 5.8 | 1.16 | 0.71 | 2.23 | 1.82 | 1.78 | 1.77 | 1.75 |

| SiN7 | 10.7 | 6.16 | 0.38 | 2.25 | 2.15 | 2.03 | 1.99 | 1.95 |

| SiN8 | 7.5 | 131.39 | 7.22 | 2.22 | 2.78 | 2.43 | 2.33 | 2.28 |

| Sample | TOC [10−5/K] | Thickness [nm] | TEC [10−3 nm/K] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| λ | ||||||||||

| 400 [nm] | 500 [nm] | 632 [nm] | 750 [nm] | 900 [nm] | 1100 [nm] | 1300 [nm] | 1500 [nm] | |||

| SiN6 | −5.16 | −7.16 | −8.28 | −9.87 | −11.80 | −15.34 | −18.84 | −22.03 | 85.07 | 7.04 |

| SiN7 | −3.17 | −5.84 | −9.66 | −12.50 | −15.86 | −20.40 | −26.33 | −34.83 | 71.42 | 6.12 |

| SiN8 | 7.61 | 6.95 | −0.64 | −4.63 | −9.72 | −16.30 | −20.75 | −20.61 | 59.73 | 6.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kluska, S.; Jurzecka-Szymacha, M.; Nosidlak, N.; Dulian, P.; Jaglarz, J. The Optical and Thermo-Optical Properties of Non-Stoichiometric Silicon Nitride Layers Obtained by the PECVD Method with Varying Levels of Nitrogen Content. Materials 2022, 15, 2260. https://doi.org/10.3390/ma15062260

Kluska S, Jurzecka-Szymacha M, Nosidlak N, Dulian P, Jaglarz J. The Optical and Thermo-Optical Properties of Non-Stoichiometric Silicon Nitride Layers Obtained by the PECVD Method with Varying Levels of Nitrogen Content. Materials. 2022; 15(6):2260. https://doi.org/10.3390/ma15062260

Chicago/Turabian StyleKluska, Stanisława, Maria Jurzecka-Szymacha, Natalia Nosidlak, Piotr Dulian, and Janusz Jaglarz. 2022. "The Optical and Thermo-Optical Properties of Non-Stoichiometric Silicon Nitride Layers Obtained by the PECVD Method with Varying Levels of Nitrogen Content" Materials 15, no. 6: 2260. https://doi.org/10.3390/ma15062260

APA StyleKluska, S., Jurzecka-Szymacha, M., Nosidlak, N., Dulian, P., & Jaglarz, J. (2022). The Optical and Thermo-Optical Properties of Non-Stoichiometric Silicon Nitride Layers Obtained by the PECVD Method with Varying Levels of Nitrogen Content. Materials, 15(6), 2260. https://doi.org/10.3390/ma15062260