Pipelines are the preferred transport medium for hydrocarbons since they are cost-effective and secure. Regardless of the maintenance and preventative strategies used, pipelines will inevitably deteriorate over time, compromising its integrity. Hence, the integrity of a pipeline must be assessed regularly, to ensure that it can sustain operational pressures. Otherwise, catastrophic failures may occur causing operations to be disrupted [

1]. Various corrosion assessment methods, such as the DNV-RP-F101 and ASME B31G, are available to assess the integrity of pipelines periodically.

Single corrosion defects and interacting corrosion defects are the two most prevalent forms of corrosion categories. A single corrosion defect is one that is isolated and does not interact with surrounding defects [

1]. Interacting corrosion defects, on the other hand, are described as corrosion defects that interact with surrounding defects. This research focuses on interacting corrosion defects that are circumferentially aligned. Circumferentially aligned interacting corrosion defects are those that are separated by full-wall thickness in the pipe’s hoop direction.

Circumferential interacting defects are more complex compared to single defects due to the interaction amongst them. The failure pressure is significantly less than that caused by a single defect. The presence of a defect causes a disturbance in the hoop stress distribution in a pipeline. The region that is affected by this disturbance in stress and strain fields of the pipeline is called area of influence of defect. When adjacent defects are present, the area of influence of the defects overlap. As such, the failure pressure of the pipe with interacting corrosion defect is lower compared to the failure pressure of single defects [

2,

3,

4].

1.1. Overview of Corrosion Defects

Corrosion is the deterioration of a metal because of electrochemical interactions between a material and its environment. Localized corrosion is one of the most harmful types of corrosion in hydrocarbon pipelines because the metal deteriorates at a rapid rate [

5]. This type of corrosion causes the material to crack or perforate, resulting in rapid structure collapse [

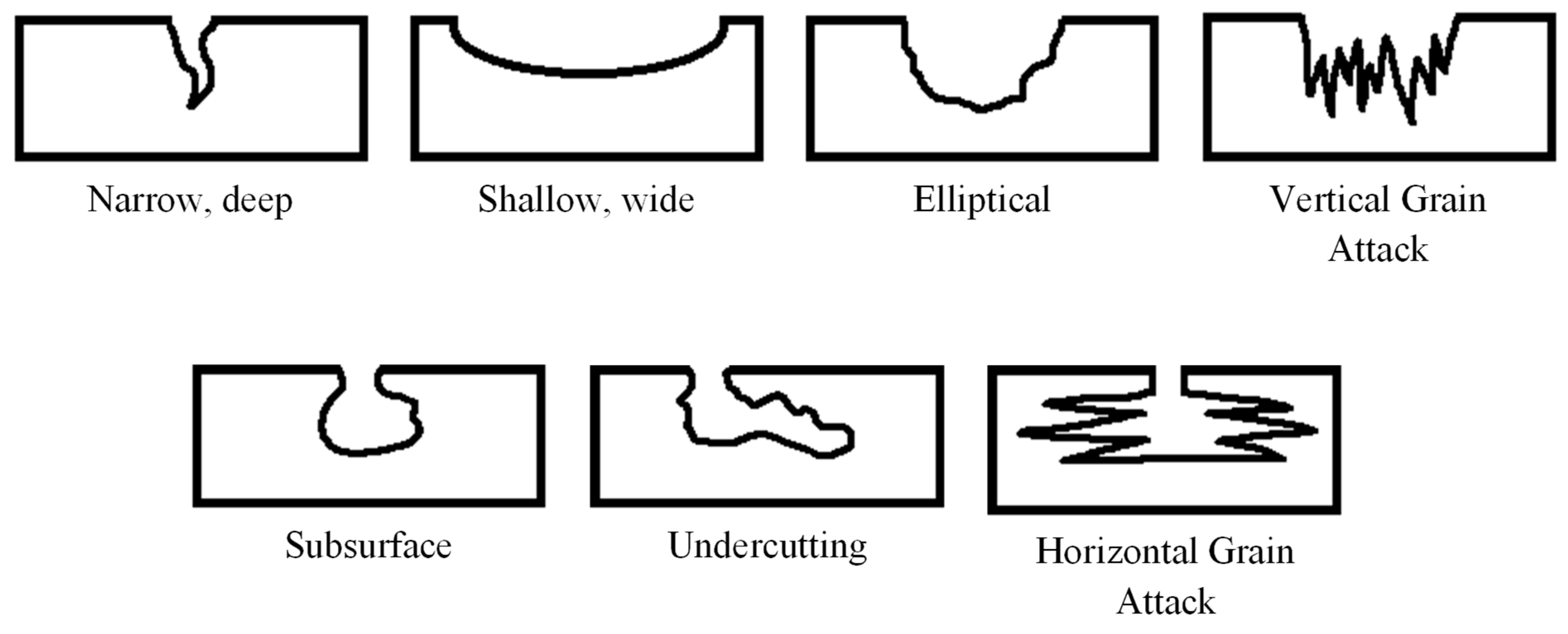

6]. There are several forms of localized corrosion in pipelines. Pitting corrosion, as illustrated in

Figure 1, is one of the most destructive forms of corrosion [

7,

8].

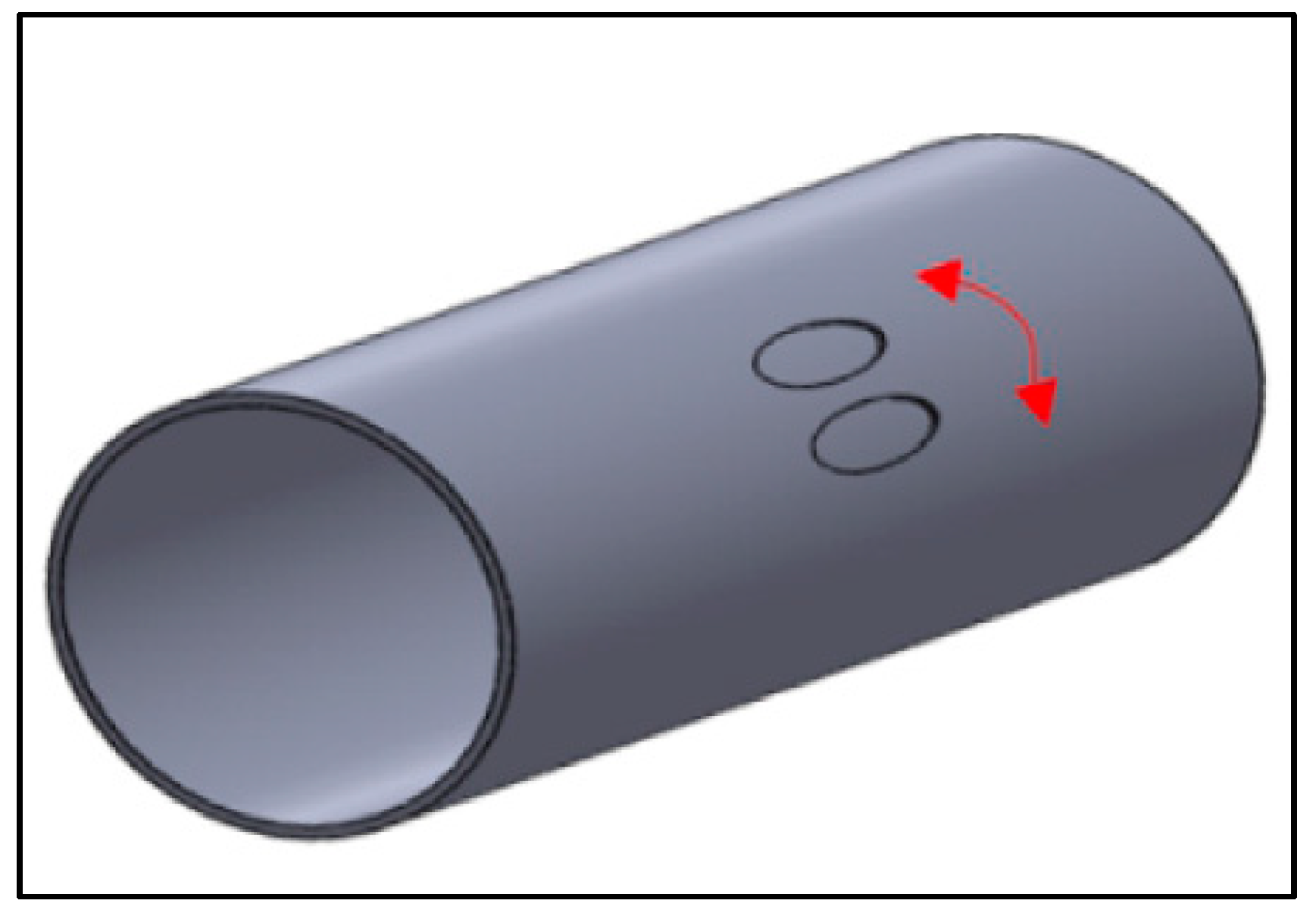

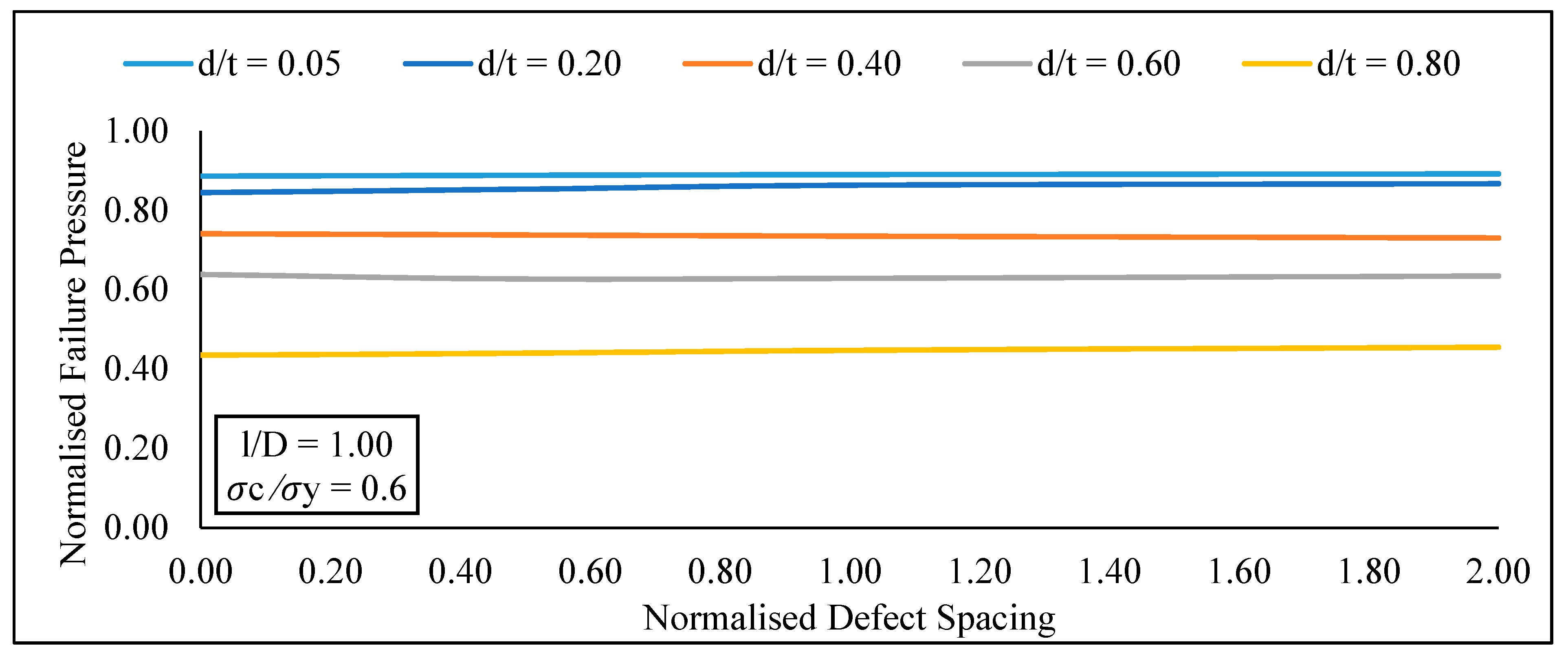

In the presence of two corrosion defects in close proximity, an interaction between the defects exist and this interaction is influenced by the spacing between the defects [

10,

11,

12,

13]. Circumferentially aligned corrosion defects are separated by full wall thickness in the circumferential direction of the pipe, as illustrated in

Figure 2. As the defect spacing is increased, the overlap region of influence decreases causing the failure pressure of the pipeline to increase. Beyond a certain defect spacing the interaction between the two defects ceases to exist as the overlap region is no longer present [

10,

13,

14]. This point is known as the interaction limit. Beyond the interaction limit, the defects are treated as isolated defects (single defects).

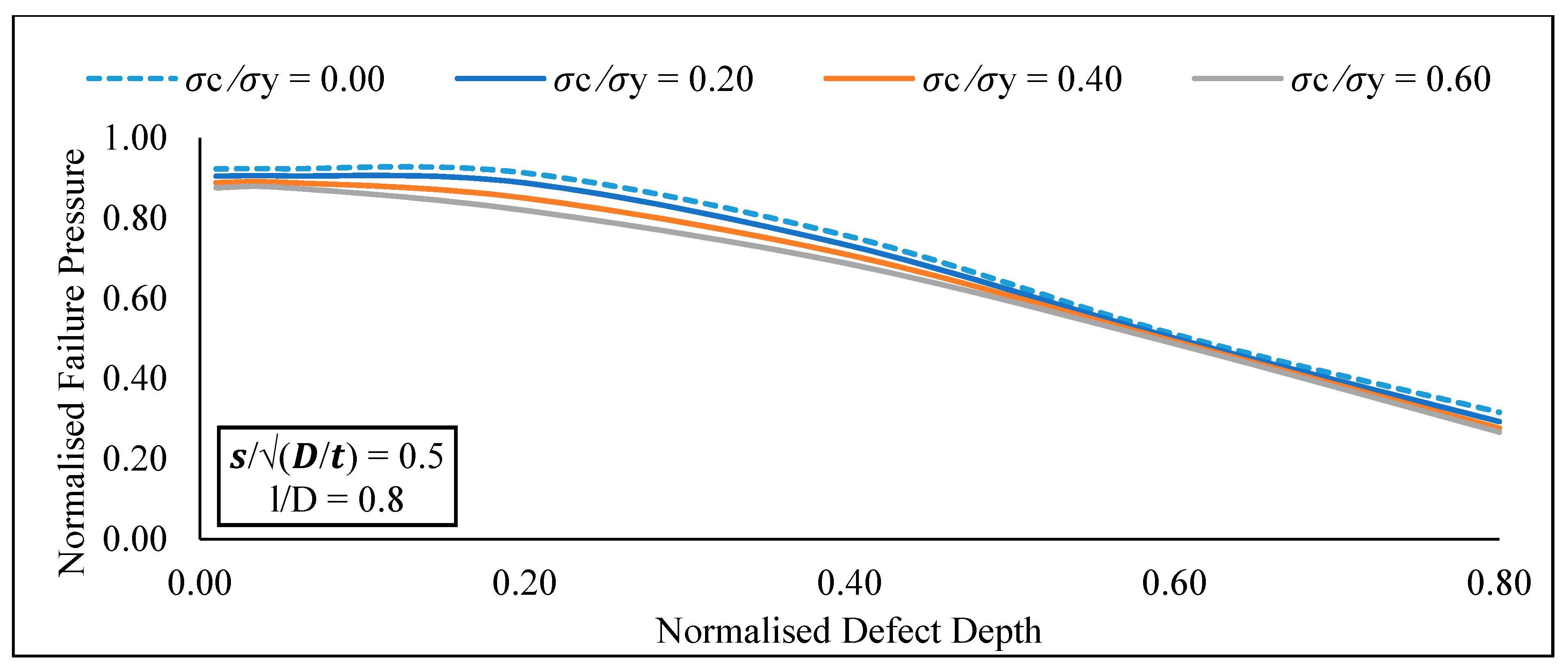

This condition is more severe in the presence of compressive stress in the longitudinal direction, which causes the build-up of strain at the location of defect (critical zone) [

16]. Premature failure of the pipe occurs when the stress at the critical point exceeds the material’s true ultimate tensile strength. As such, to maintain a safe and efficient operation, the integrity of a pipeline must be evaluated from time to time [

17,

18,

19].

1.2. Conventional Pipeline Integrity Assessment Methods for Corroded Pipes

It has been well established that interacting defects cause more harm to a pipeline than a single defect, as it significantly reduces the failure pressure of the pipeline [

1,

11,

13,

20,

21,

22,

23,

24]. In most cases, pipelines are subjected to both internal pressure and longitudinal compressive stress, due to the temperature of the transported fluid, Poisson’s effect, as well as ground topology and movement.

Various corrosion assessment methods have been developed to assess the integrity of a pipeline under various conditions to ensure safe operations. Failure pressure predictions based on conventional corrosion assessment codes such as the ASME B31G, Modified B31G, SHELL 92, RSTRENG, PCORRC, and DNV-RP-F101, are conservative, leading to premature pipeline repairs and replacements [

25]. Of all the codes that are being used in the industry for failure pressure prediction of corroded pipes subjected to combined loading, the DNV-RP-F101 code (DNV) is most comprehensive [

23,

26,

27,

28,

29,

30].

Over the years, various studies have been carried out to develop accurate interaction rules based on corrosion defect categories such as longitudinal interacting defects, circumferential interacting defects, or single defects. The interaction rule applied for circumferentially aligned interacting defects in commonly used corrosion assessment codes in the industry are presented in

Table 1.

Among the assessment methods used in the industry, DNV is known to be the most comprehensive method. However, since the validation of the DNV approach was based on burst tests carried out on pipes of grades API 5L X45 to API 5L X65, it was designed primarily to examine the integrity of medium toughness pipelines. When applied to a high toughness pipelines, it results in inaccurate and overly conservative predictions [

3,

27]. Besides, this method is only applicable for interacting defects (longitudinal and circumferential) subjected to internal pressure only.

1.3. Finite Element Method as a Reliable Pipeline Failure Pressure Prediction Tool

As current corrosion assessment methods for high toughness pipelines are conservative, the finite element method (FEM) is widely applied. FEM allows non-linear structural analysis, as structures that are subjected to large displacements result in geometrical change. This enables accurate prediction of failure pressure, as it accounts for strain hardening, and plastic and elastic deformation of the material [

32,

33].

The failure pressure accuracy evaluated using FEM is heavily dependent on the right selection of model features, boundary conditions, and material parameters [

14]. The model’s meshing size has a significant impact on the result accuracy. Meshes that are smaller in size produce higher accuracy but consume greater time to simulate. As such, optimization of the pipe model is important to reduce simulation time while maintaining the result accuracy [

34]. If any of the components are inadequately specified, the FEM findings will be incorrect, resulting in incorrect failure pressure estimates. As such, before beginning a large-scale parametric investigation utilizing FEM, the method must first be validated against full-scale burst tests. Various studies have proven that FEM results in predictions that are close to real-world data [

3,

13,

26,

27,

32]. In addition, it has been categorized as a Level 3 evaluation method for pipeline failure pressure prediction [

24].

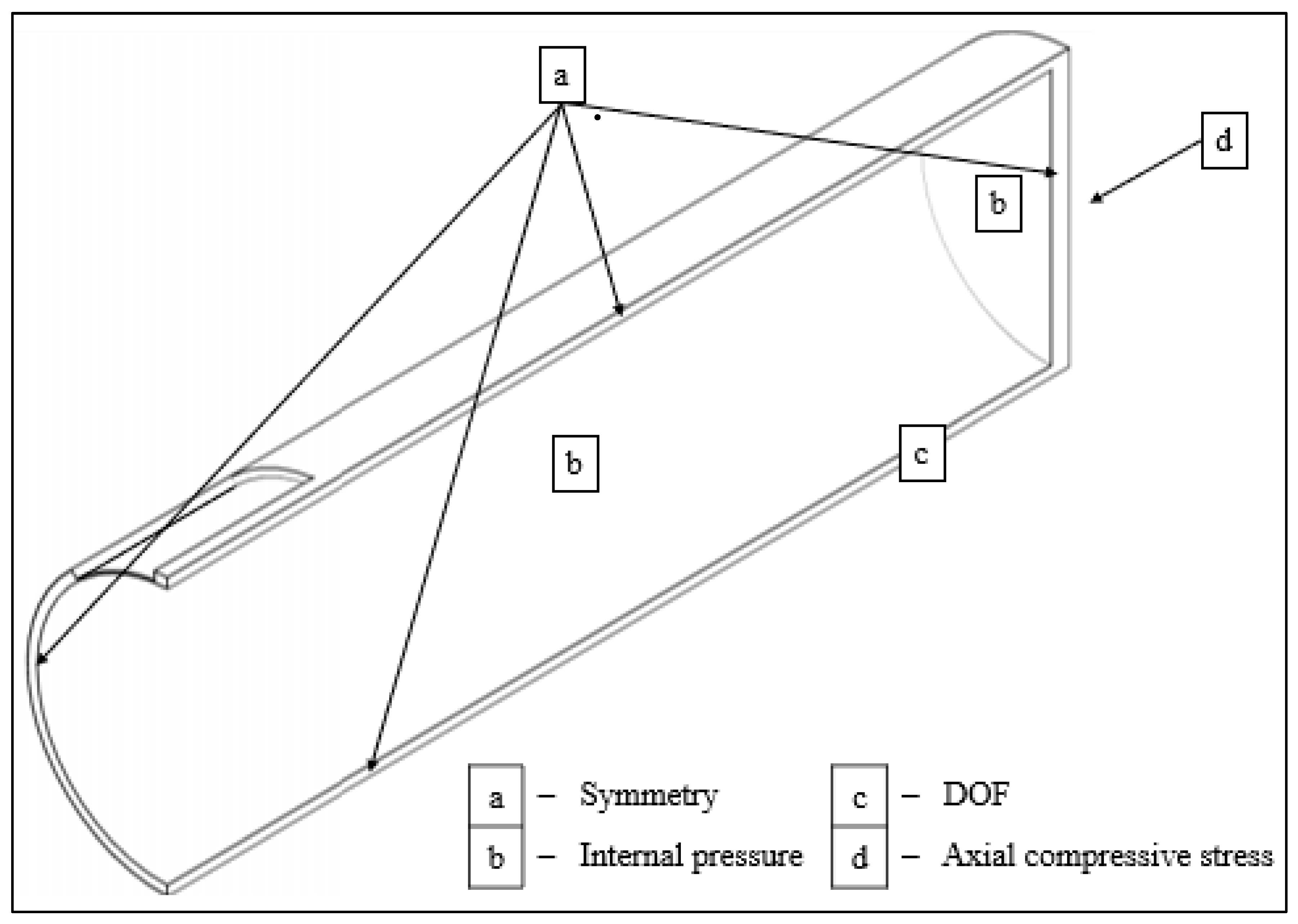

Quarter models with symmetric boundary conditions (to treat the pipe as a whole) are commonly used to shorten the computation time of a finite element (FE) simulation. Nevertheless, a single simulation run could take several hours. As a result, utilising FEM for parametric studies to estimate the corroded pipe failure pressure subjected to combined loading is time consuming. In time-critical scenarios, a quicker response time means prevention of disastrous failures, reduced damage and cost of repair.

FEM has been widely applied for predicting the failure pressure or residual strength of a corroded pipeline. Lee et al. [citation] utilised FEM to assess the failure of an API 5L X65 gas pipe at multiple corrosion defect regions. Belachew et al. [

32] utilised FEM for burst test analysis of a corroded API 5L X52 grade steel pipe. It was found that commercial codes for pipeline capacity assessment are conservative. Similarly, Arumugam et al. [

26] utilised FEM for failure pressure analysis and development of equations to predict the failure pressure of API 5L X52 pipelines with single corrosion defects.

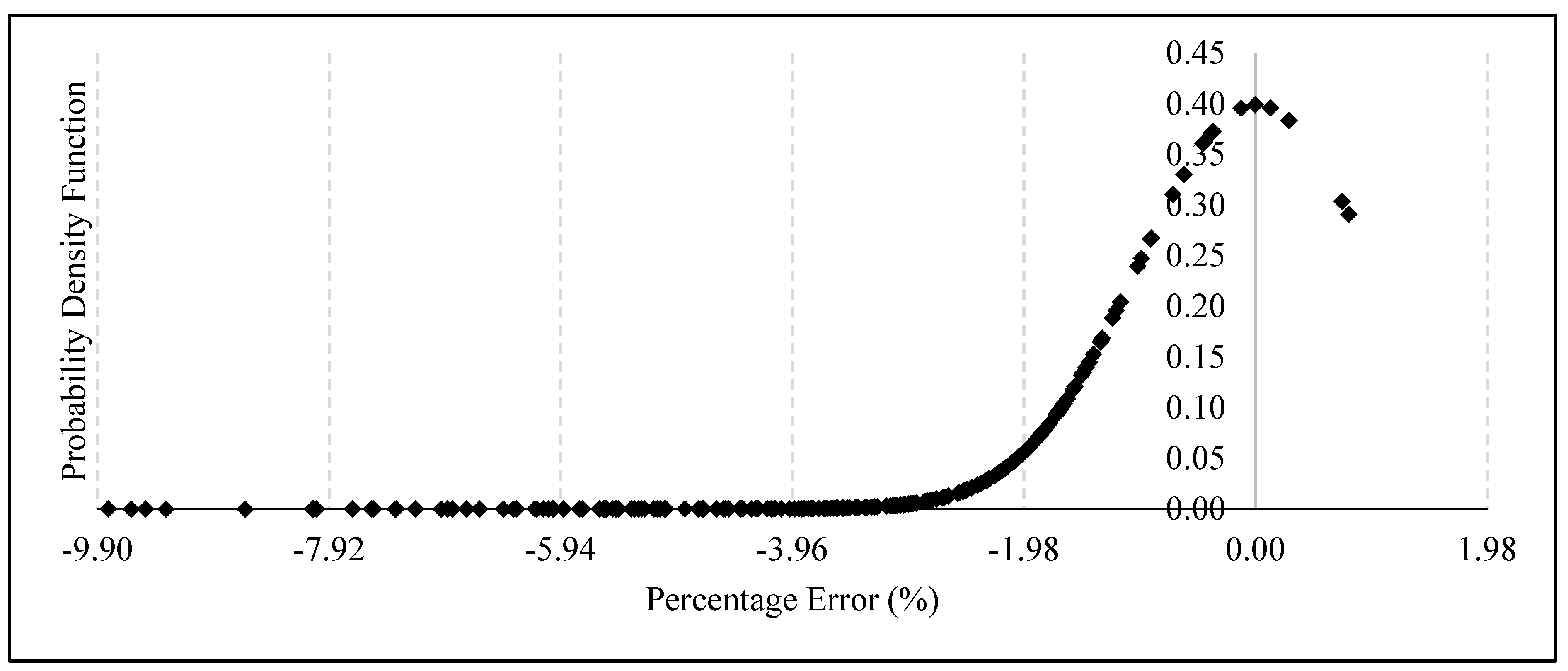

The training data in the study conducted by Xu et al. [

35] was generated using FEM for the development of an ANN to predict the failure pressure of a corroded pipe. FEM could predict failure pressure of pipelines with a relative error percentage of less than 1%. As such, it can be said that FEM results in accurate predictions, and hence, a reliable method to obtain training data for the development of an ANN.

1.4. Application of Artificial Neural Network as Corroded Pipeline Failure Pressure Prediction Tool

An ANN is an interconnected collection of simple processing elements called nodes, with processing capability of the network stored in the inter-unit connection strengths called weights, trained by learning a set of data patterns [

36]. An ANN can learn, recognise, and make inferences from complex, non-linear data without instructions [

37]. It can learn from a set of training data (including noisy data). Weights and biases are imposed to neurons in the neural network layers. They are reinitialized until the network gives accurate results [

38]. It is very important that the training dataset has enough inputs and outputs to make the neural network’s output accurate. [

39].

For failure pressure assessment, the use of ANN has improved with time, resulting in improved practical applications. Researchers considered the physical, operational, and mechanical elements that impact a pipeline’s residual strength in early ANN implementations [

40]. Obtaining large training datasets for such scenarios, however, is difficult. In their study, Shirzad et al. [

41] and Senouci et al. [

42] emphasised that without reliable data, an ANN with adequate accuracy and robustness cannot be obtained.

In this approach, the issue of having a limited amount of reliable data (usually burst tests) can be overcome using FEM to generate training data for the ANN model [

3,

33]. In a study conducted by Xu et al. [

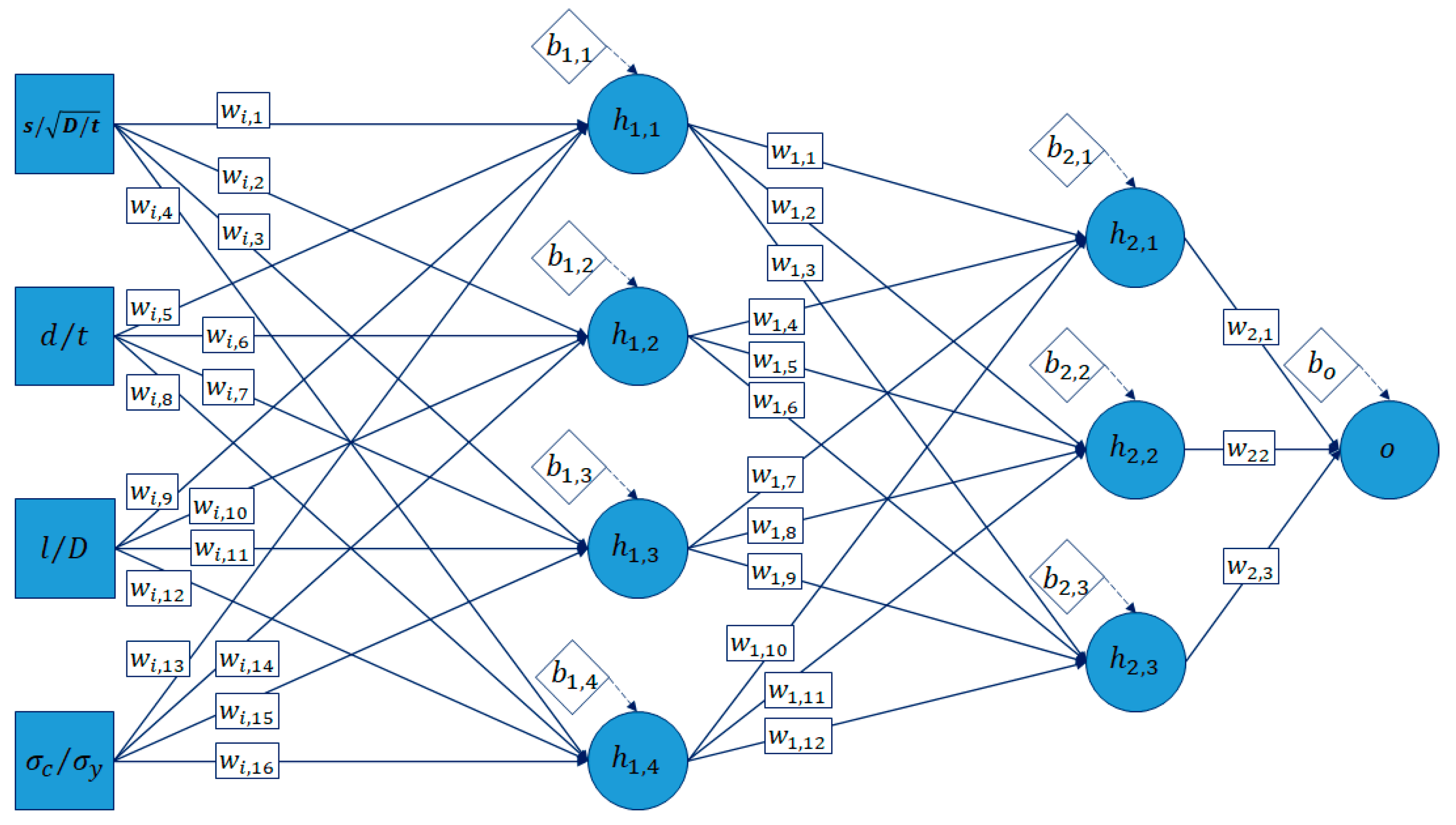

12], a feed forward neural network was utilised with a backpropagation algorithm to predict the corroded (interacting defects) pipe failure pressure. FEM was used to generate training data for the neural network. Four neurons were used in the input layer, five neurons in the hidden layer, and one neuron in the output layer. The input parameters are the normalized defect length, depth, longitudinal spacing, and circumferential spacing. The number of neurons in the hidden layer was calculated using Equation (1), where

is the number of hidden neurons,

is the number of inputs while

is the number of outputs. The neural network was validated against burst tests, and it was found that the ANN can predict the failure pressure of a corroded pipe to a high accuracy.

In this study, an empirical equation for the failure pressure prediction of a corroded API 5L X80 pipeline with circumferentially aligned interacting corrosion defects subjected to internal pressure and longitudinal compressive stress was developed. Then, a correlation between the geometry of a defect and the pressure at which it failed in an API 5L X80 pipeline was determined. As for the empirical equation, weights and biases of an ANN trained with FEM data were used to develop the equation. The equation was then tested against arbitrary FE models.