Research on Performance of SBS-PPA and SBR-PPA Compound Modified Asphalts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

2.1.2. PPA

2.1.3. Polymer Modifier

2.1.4. Schemes of Modified Asphalt with PPA and SBS/SBR Compound Ratio

2.2. Specimen Preparation

- (1)

- The neat asphalt was heated to 150 °C until it became fluid before mixing;

- (2)

- The weighed SBS/SBR particles were added into the asphalt and conducted high-speed shear at the speed of 4500 rpm for 30 min;

- (3)

- Then, the weighed PPA was added into the prepared modified asphalt and conducted high-speed shear at the speed of 4500 rpm for 30 min;

- (4)

- The sheared PPA and SBS/SBR compound modified asphalt were put into an oven at 180 °C for swelling and developing for 1 h; therefore, PPA and SBS/SBR compound modified asphalt was prepared, then the prepared PPA and SBS/SBR compound modified asphalt was poured into corresponding containers for storage.

2.3. Experimental Program

2.3.1. DSR Test

2.3.2. BBR Test

2.3.3. RTFO Test

3. Results and Discussion

3.1. High-Temperature Properties

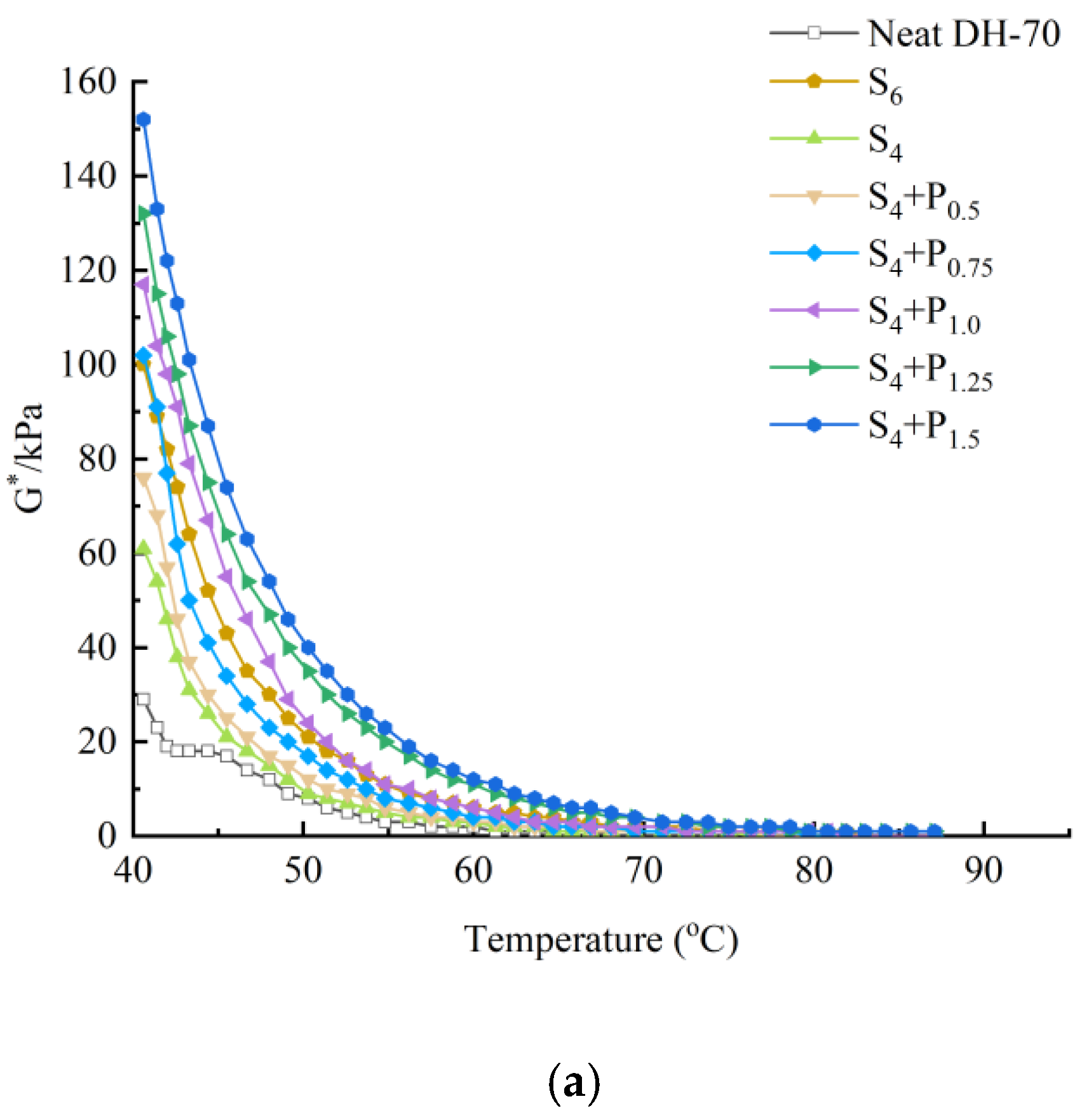

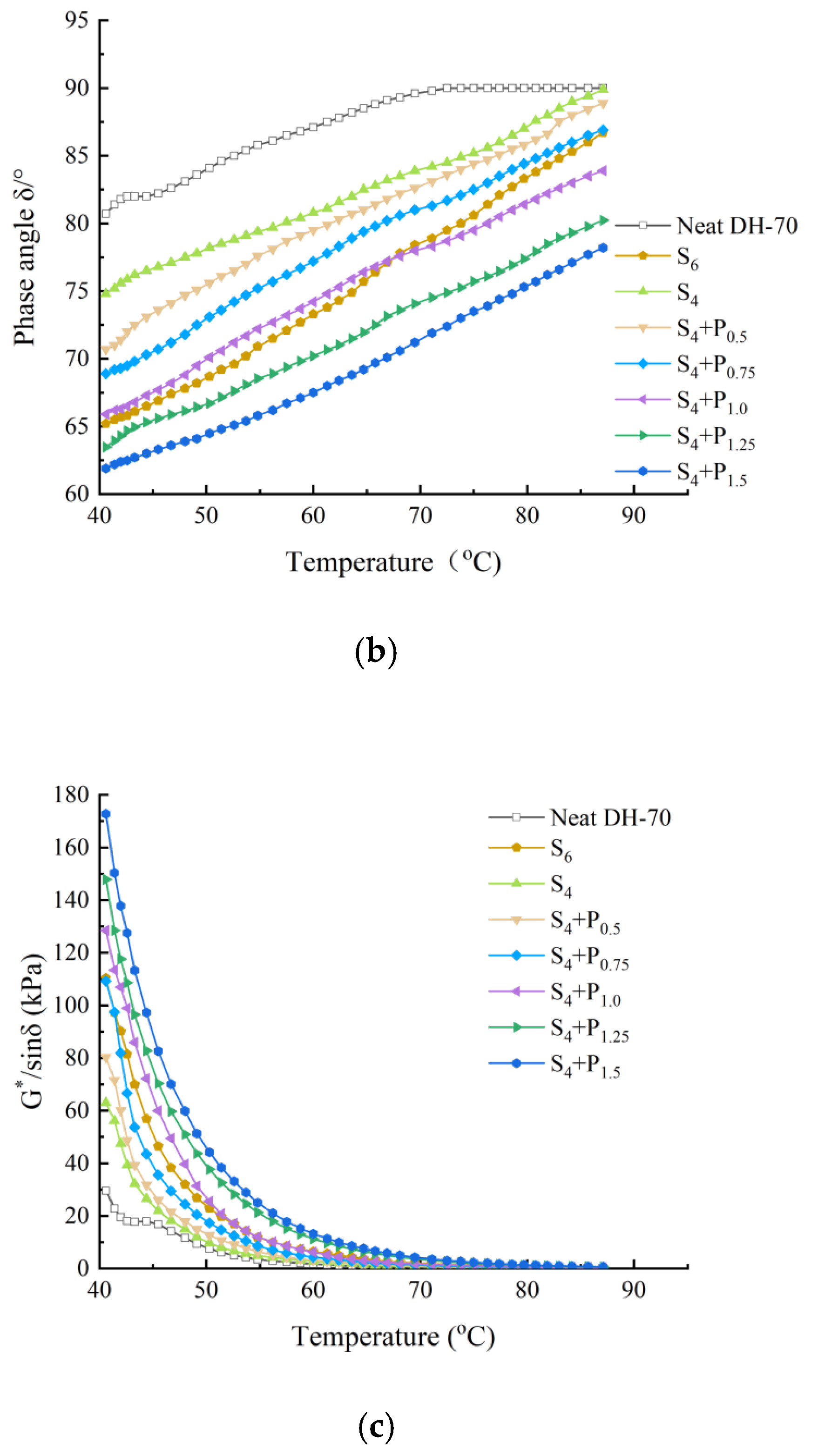

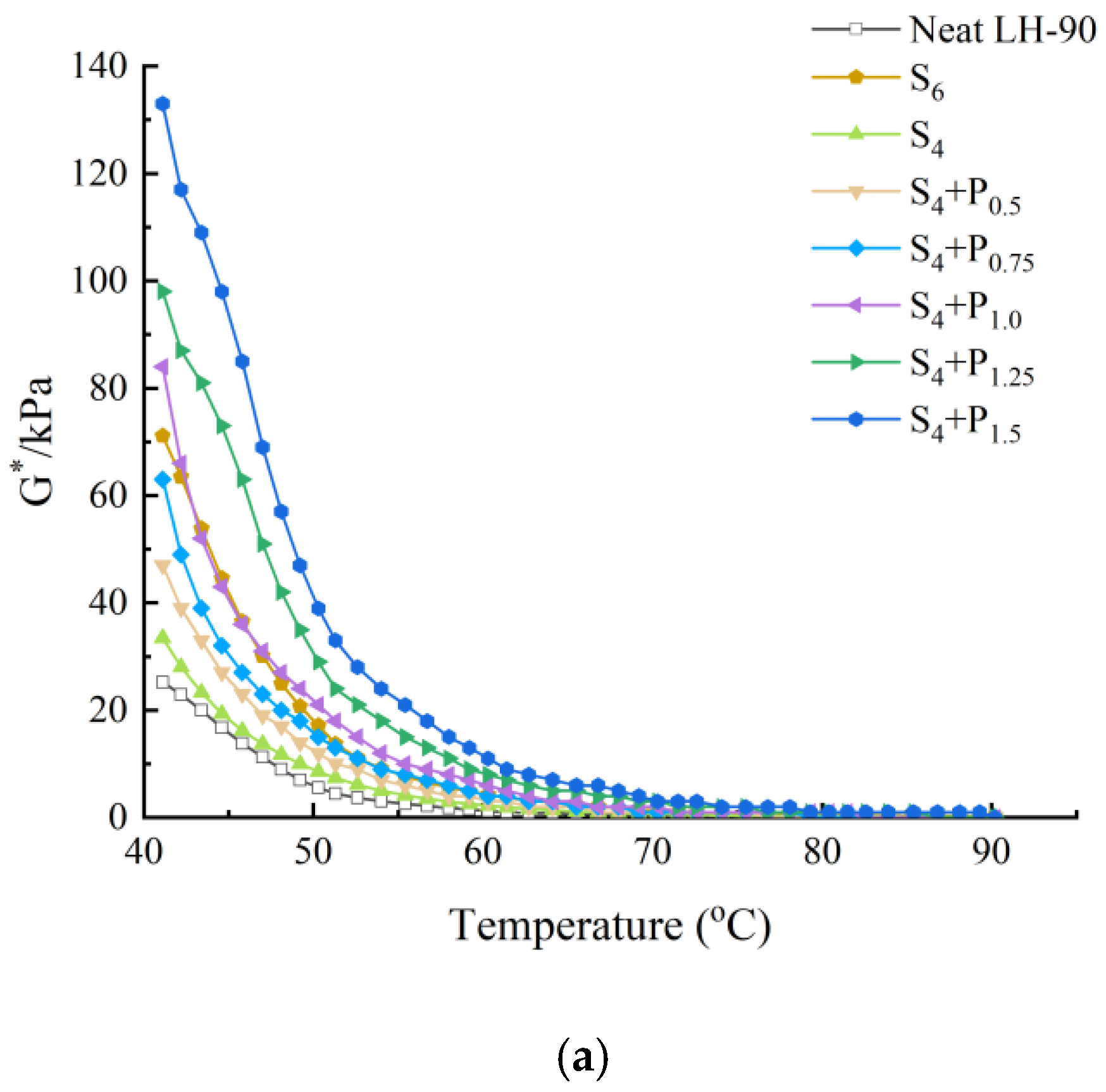

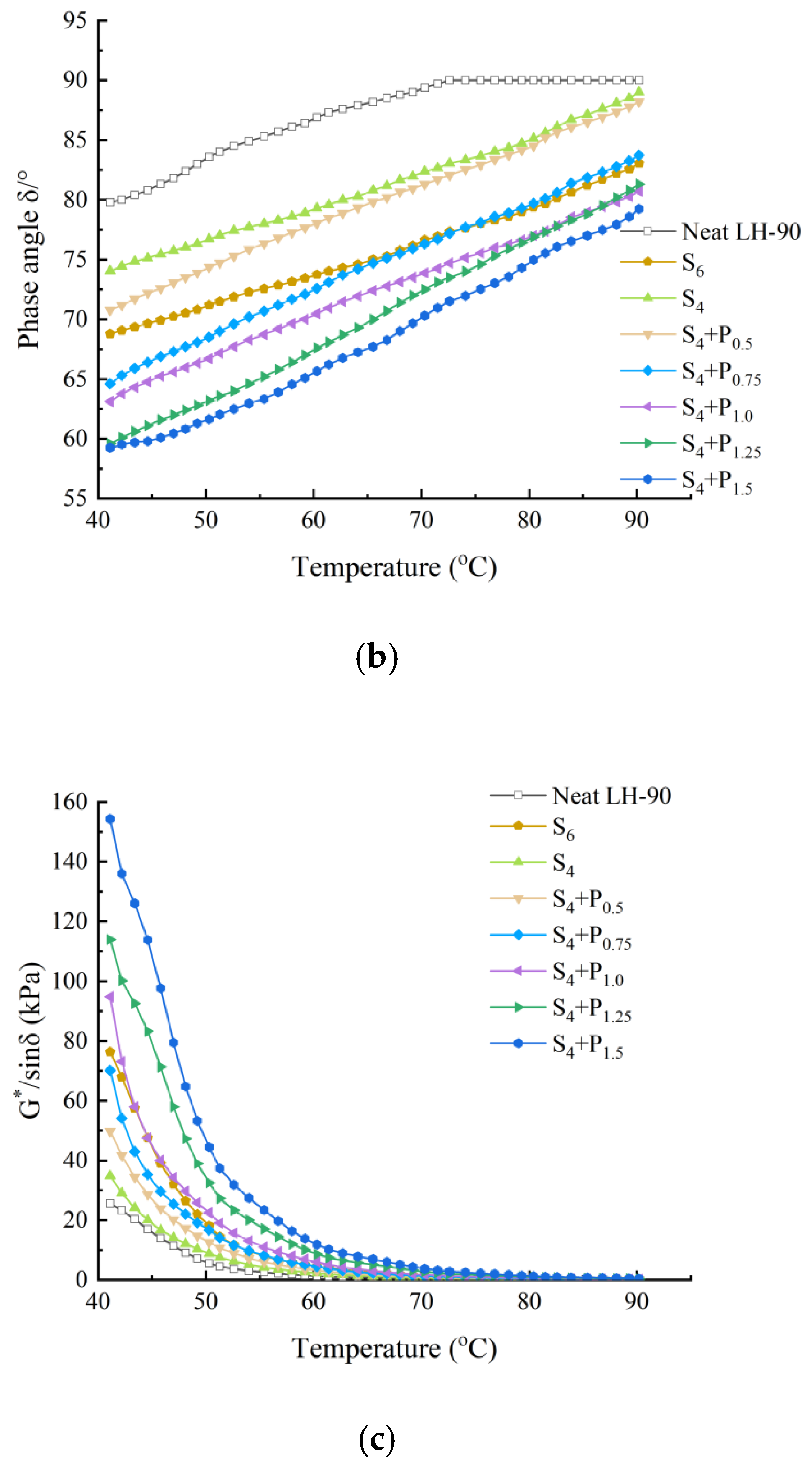

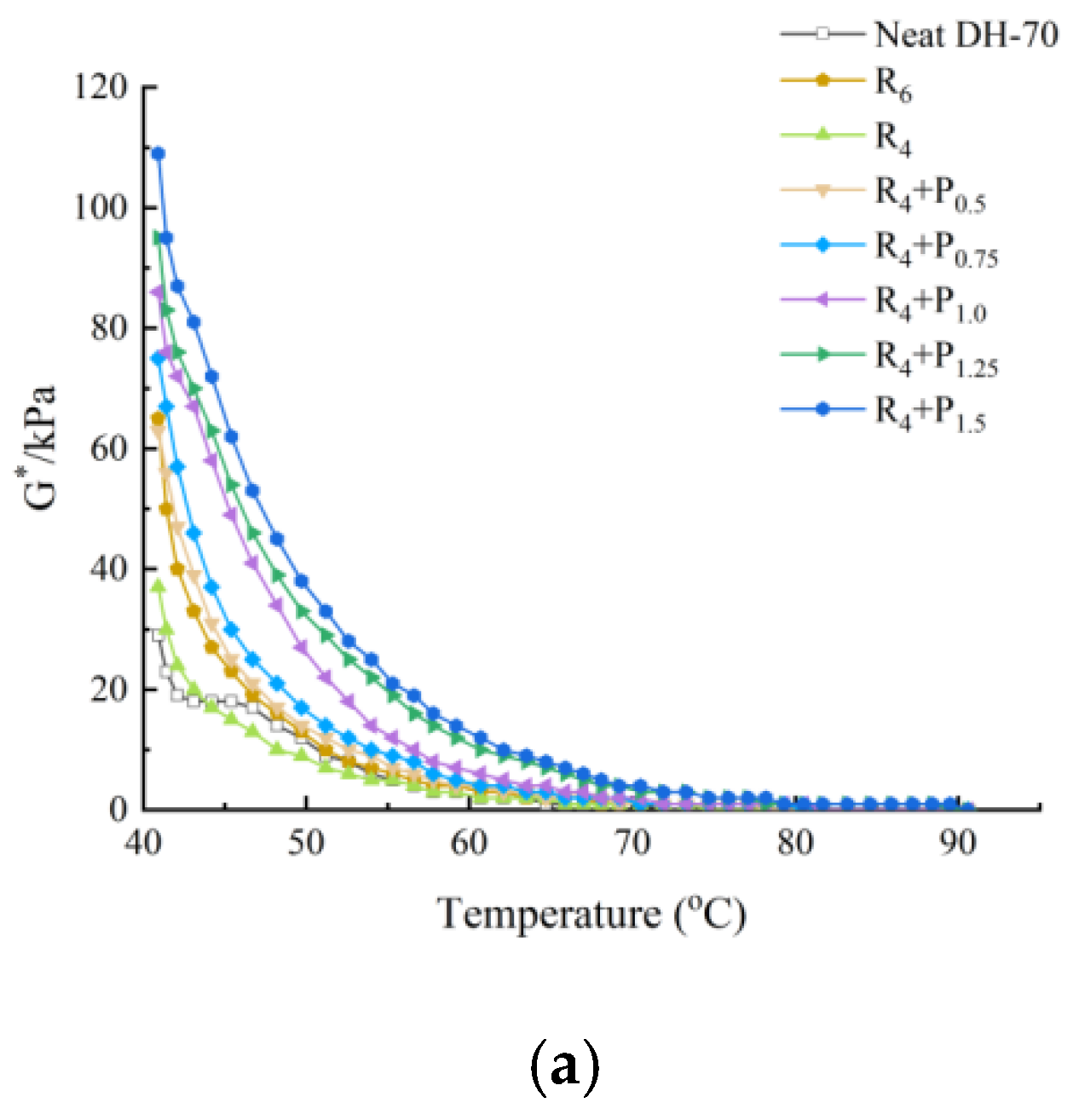

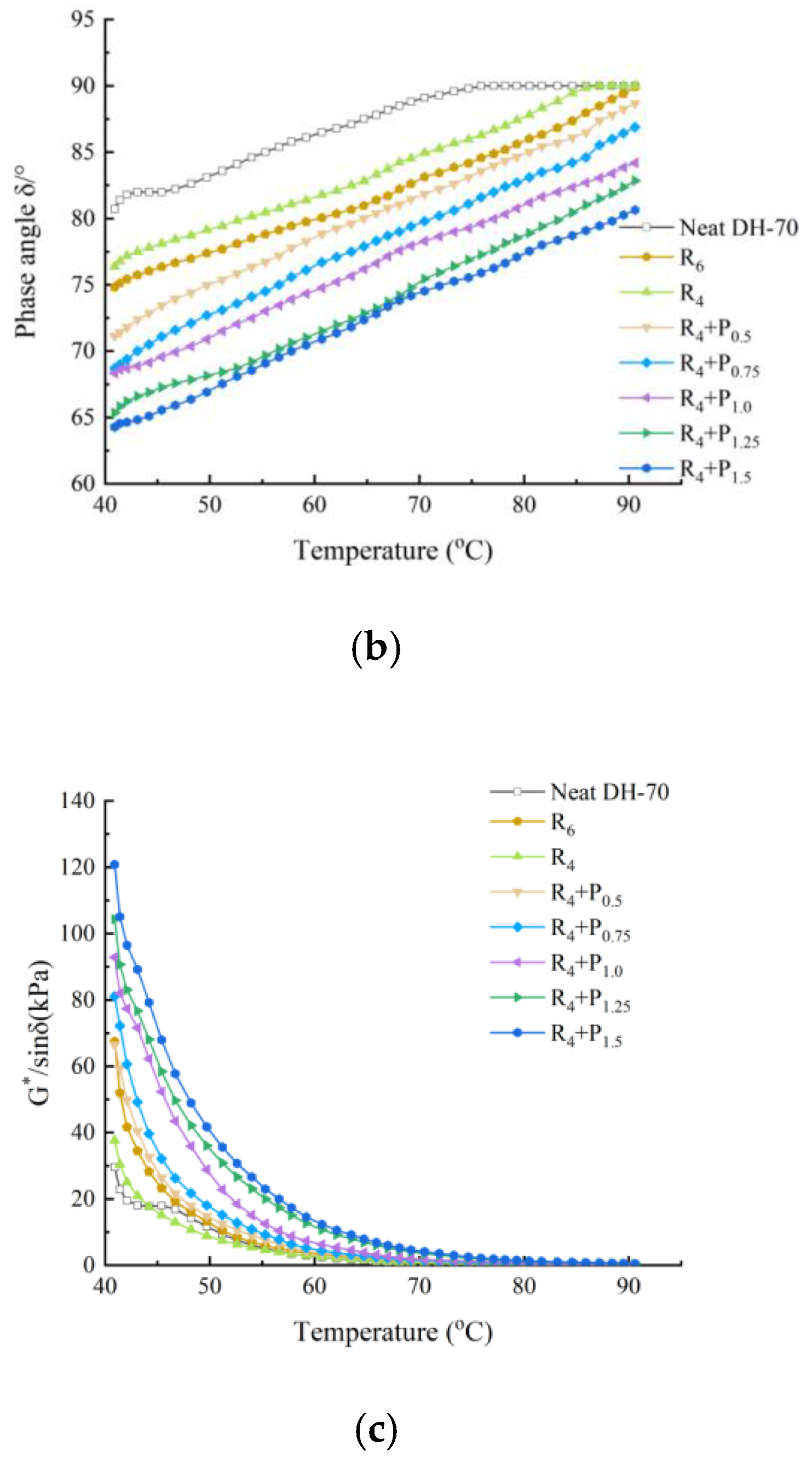

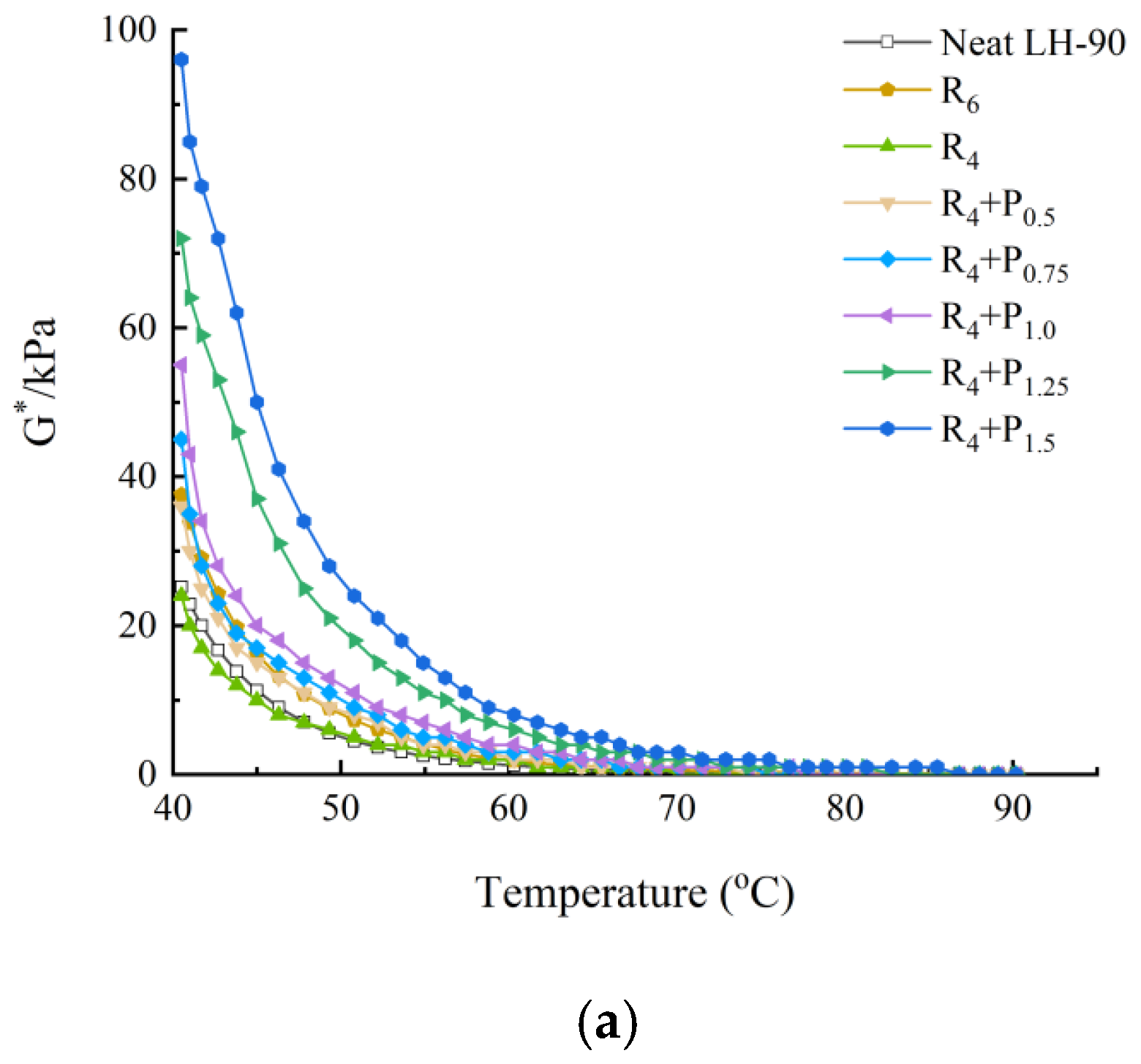

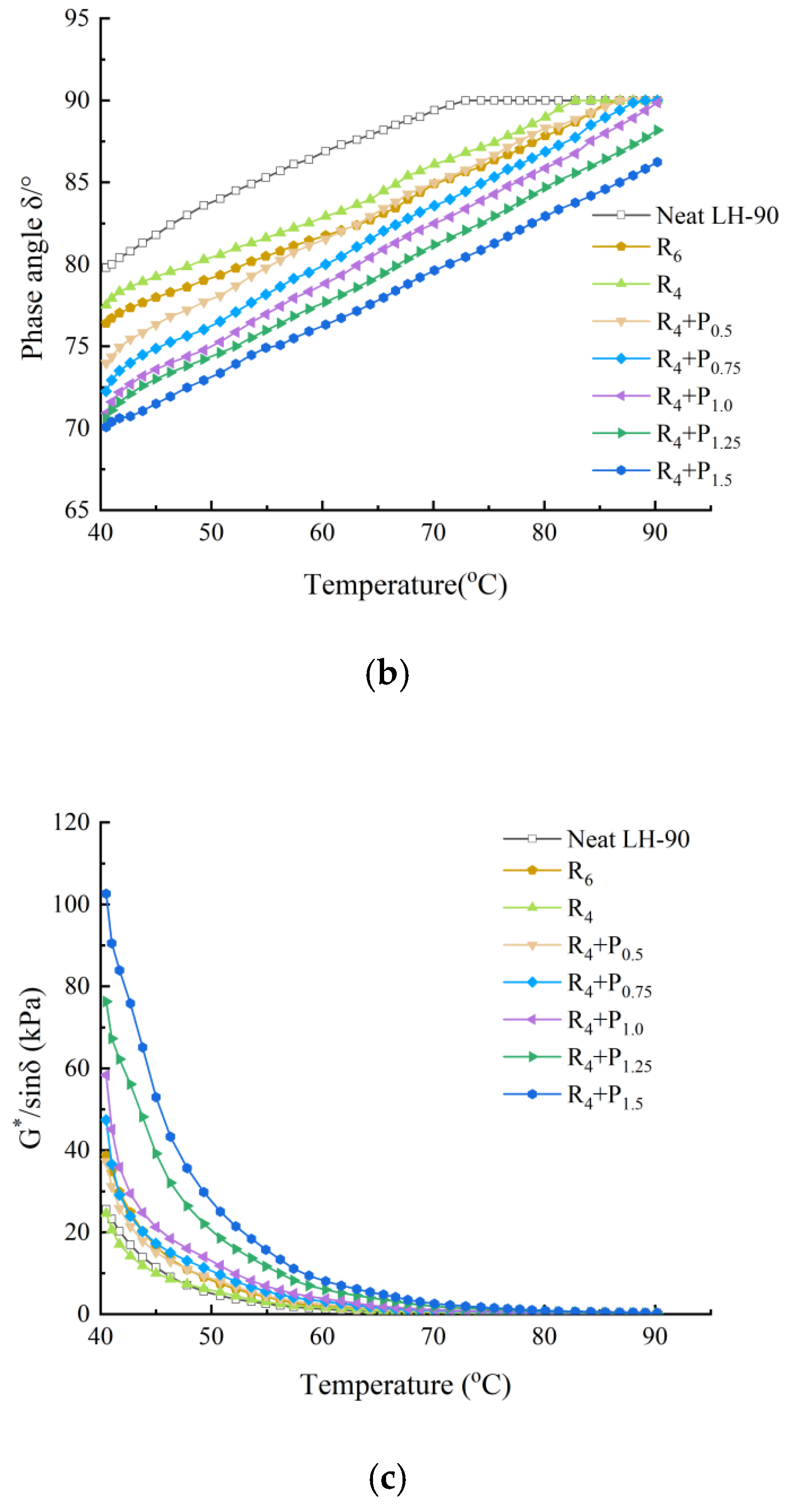

3.1.1. Temperature Sweep Test

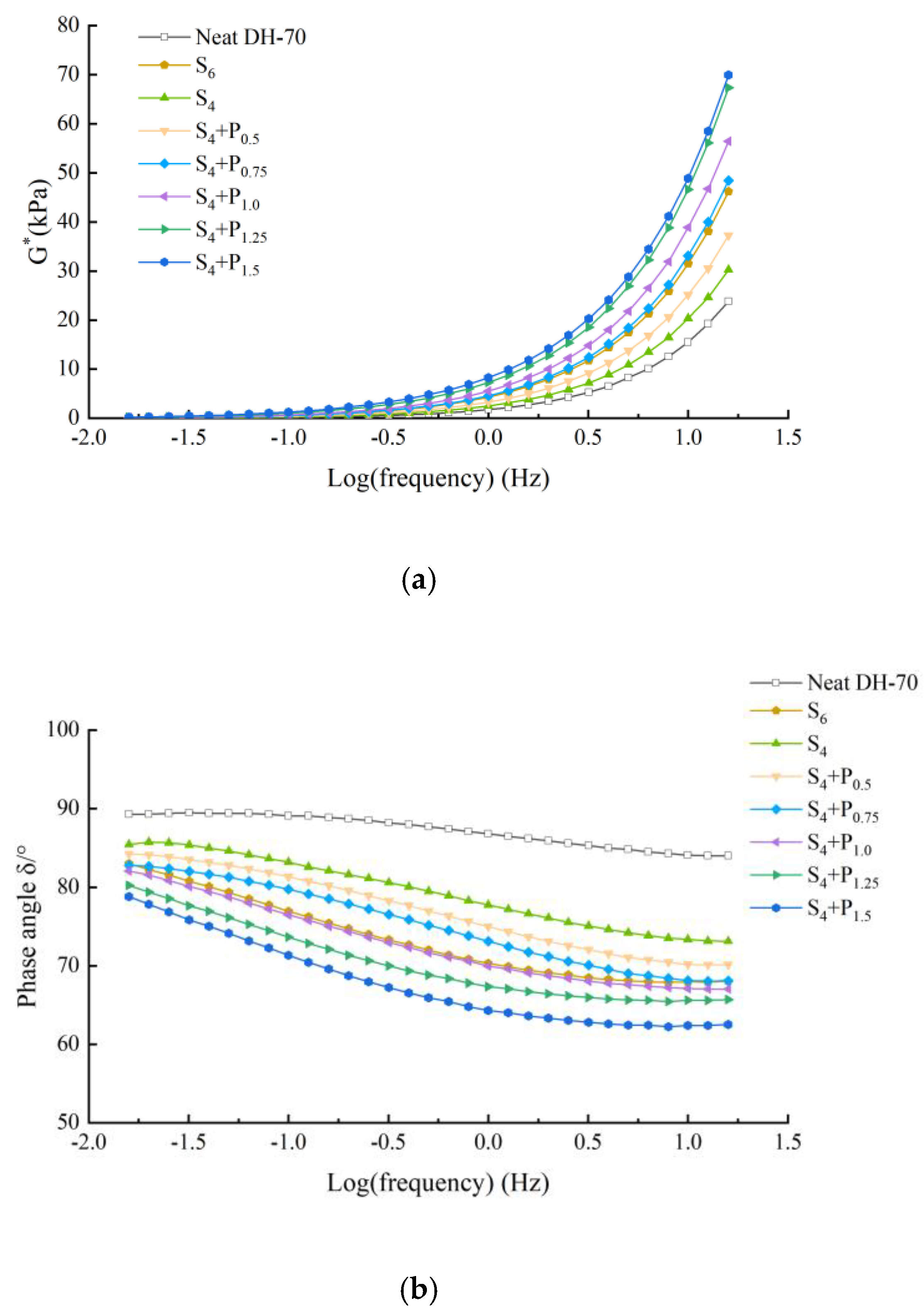

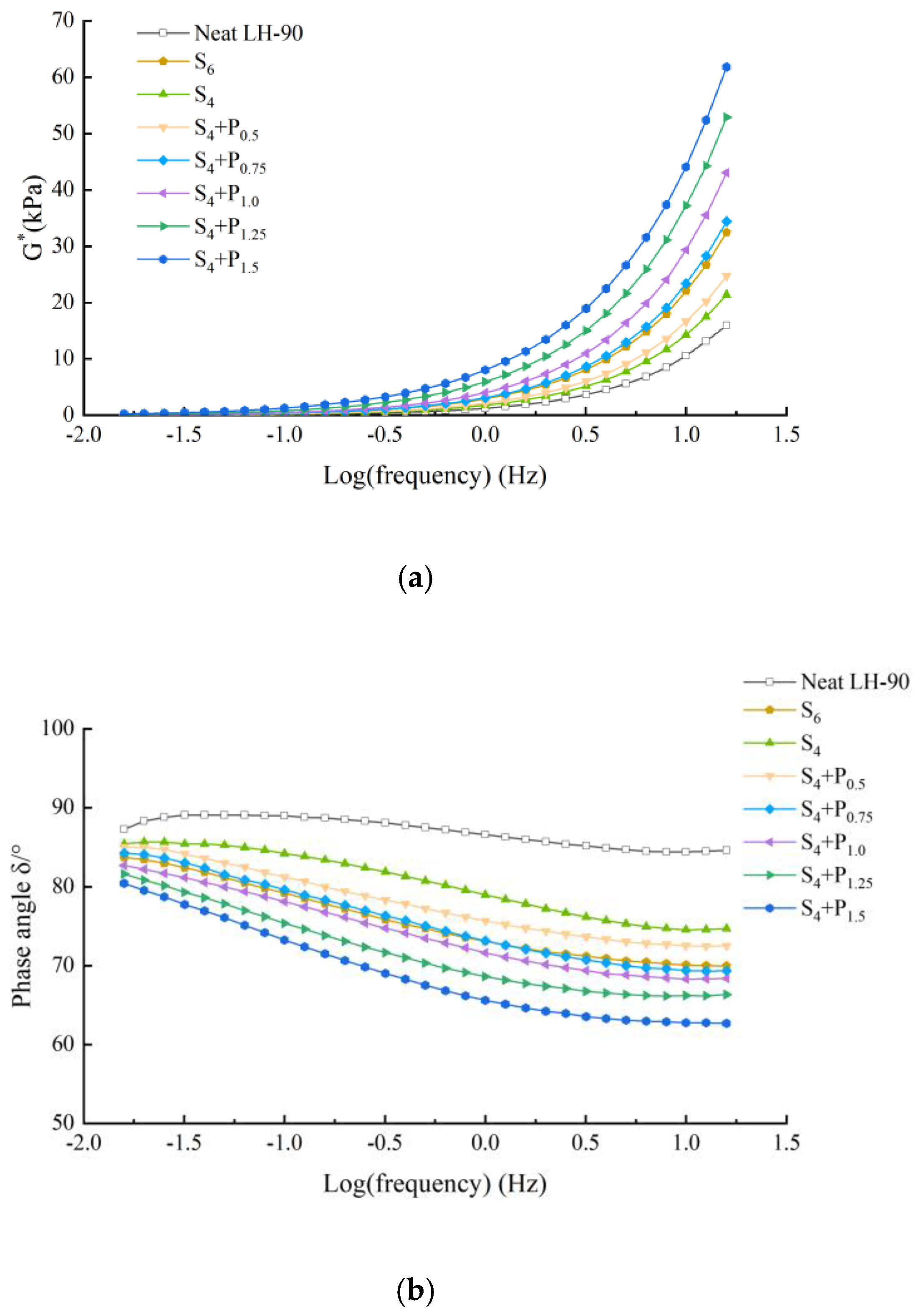

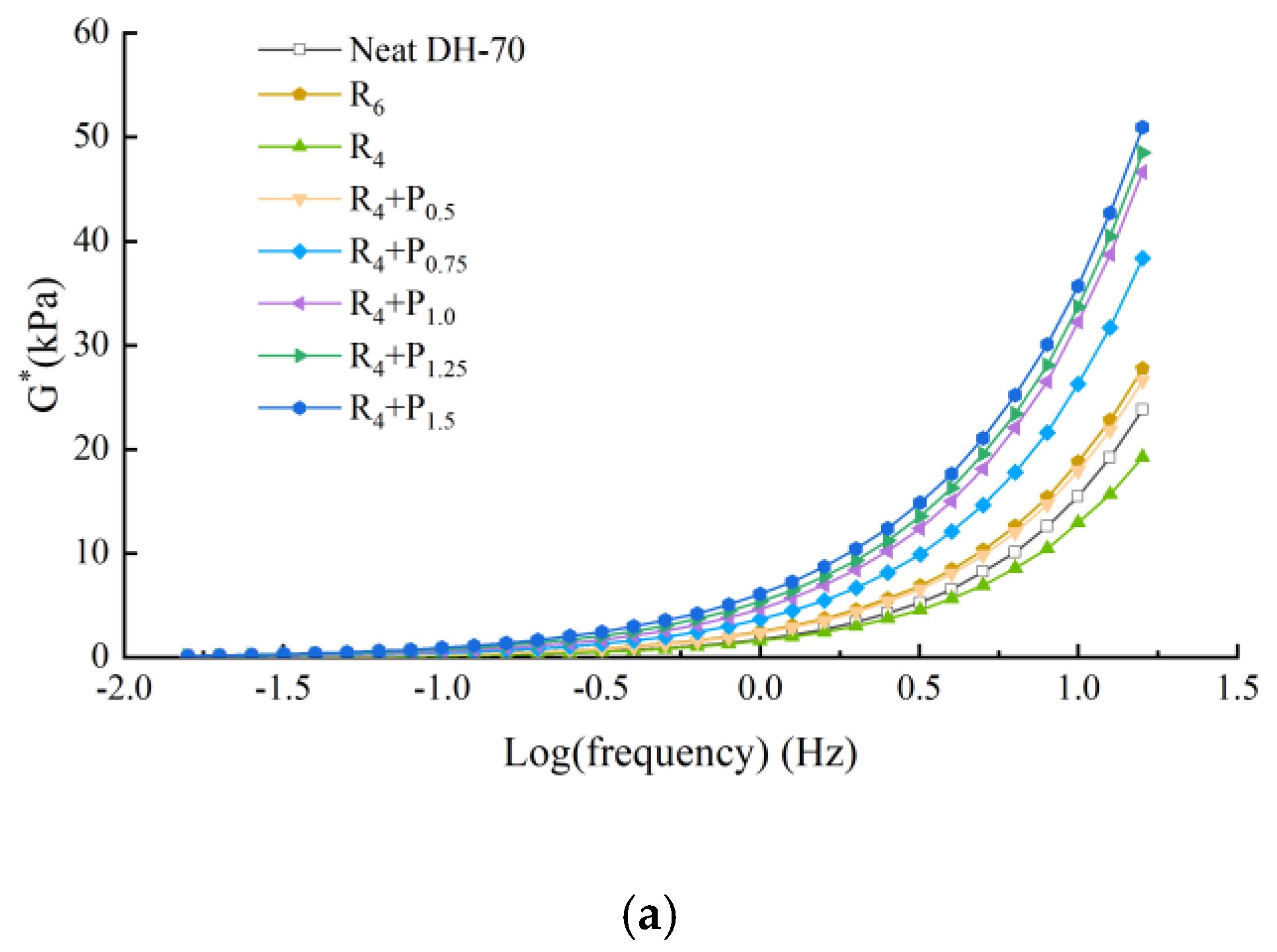

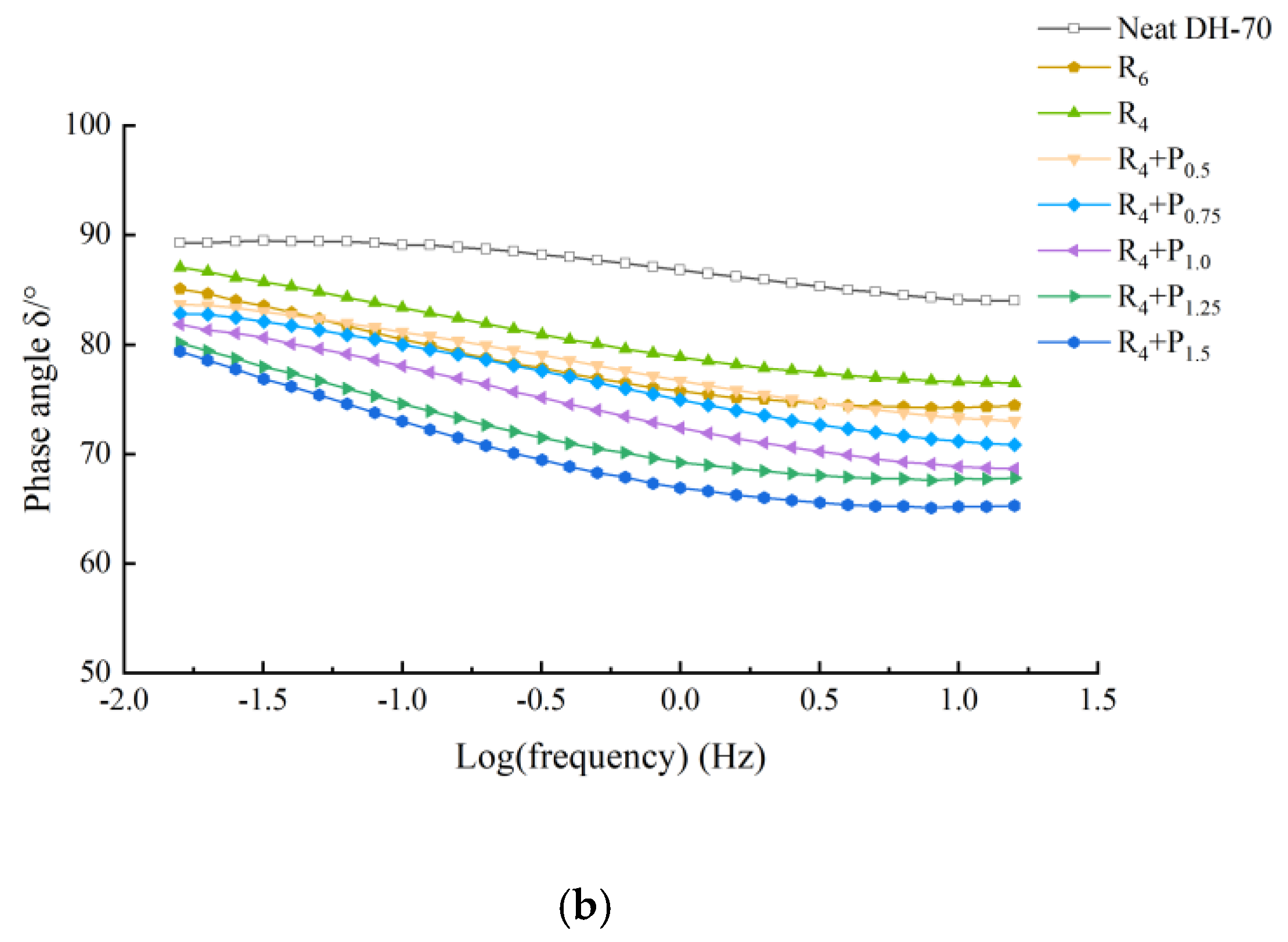

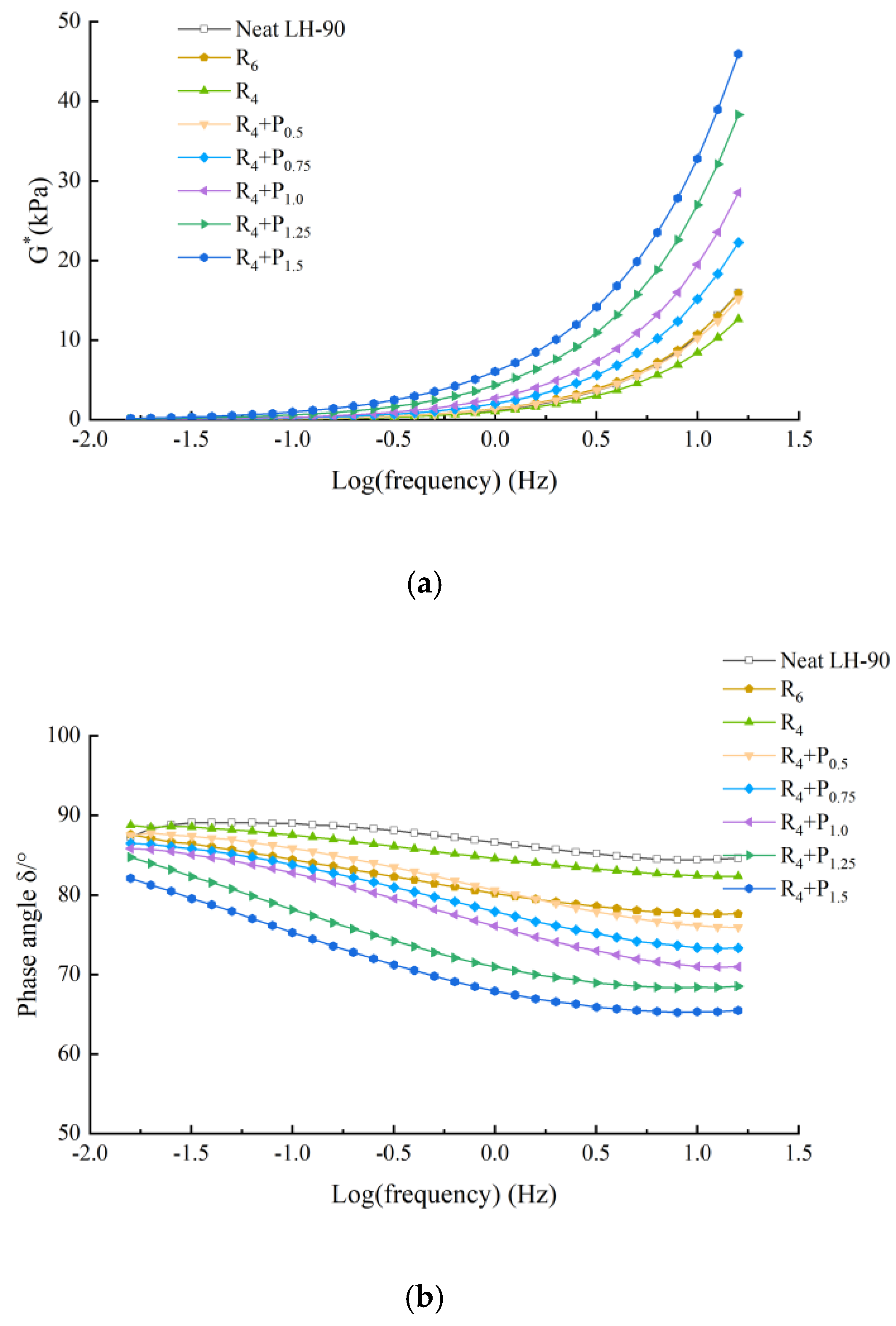

3.1.2. Frequency Sweep Test

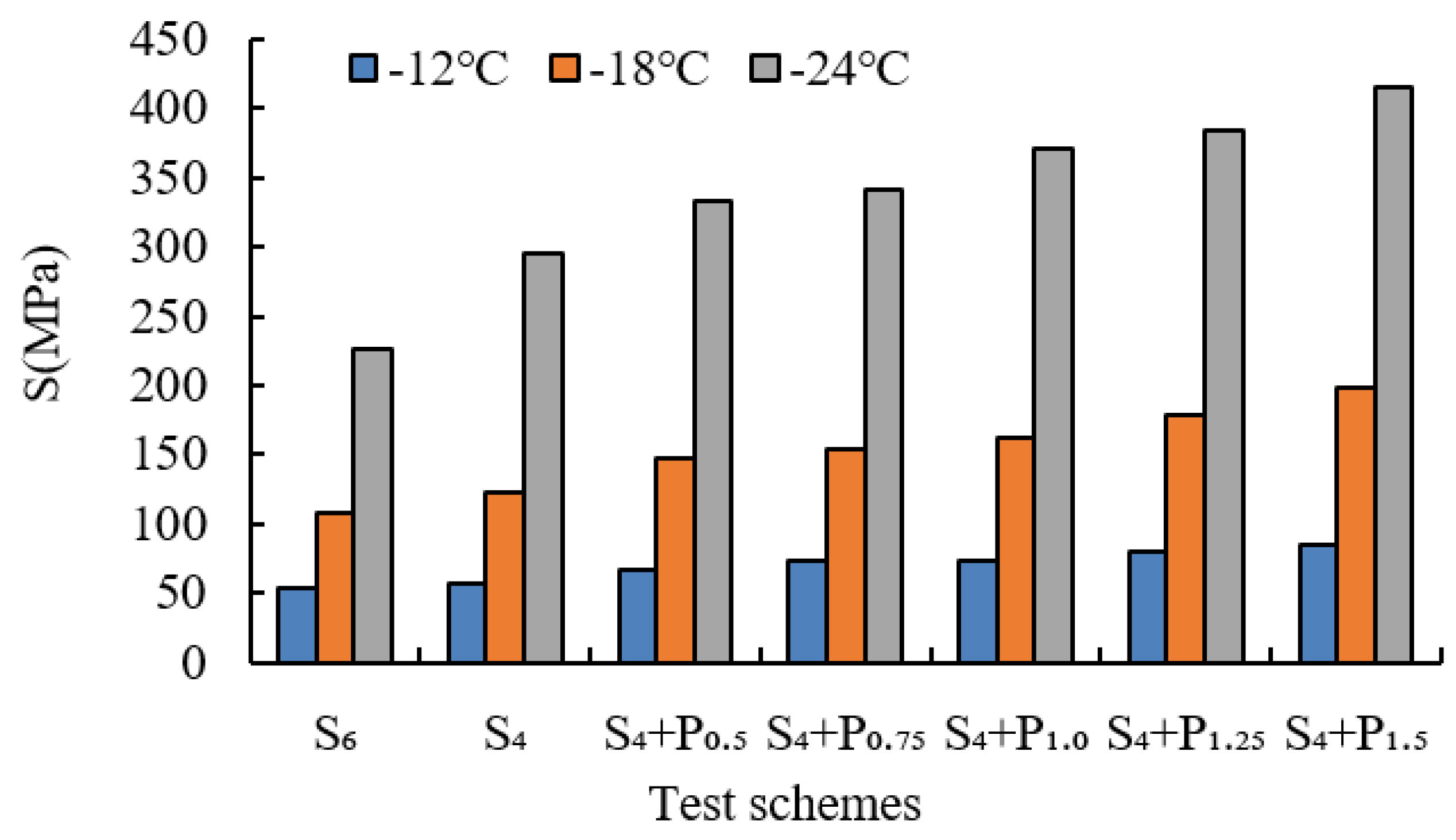

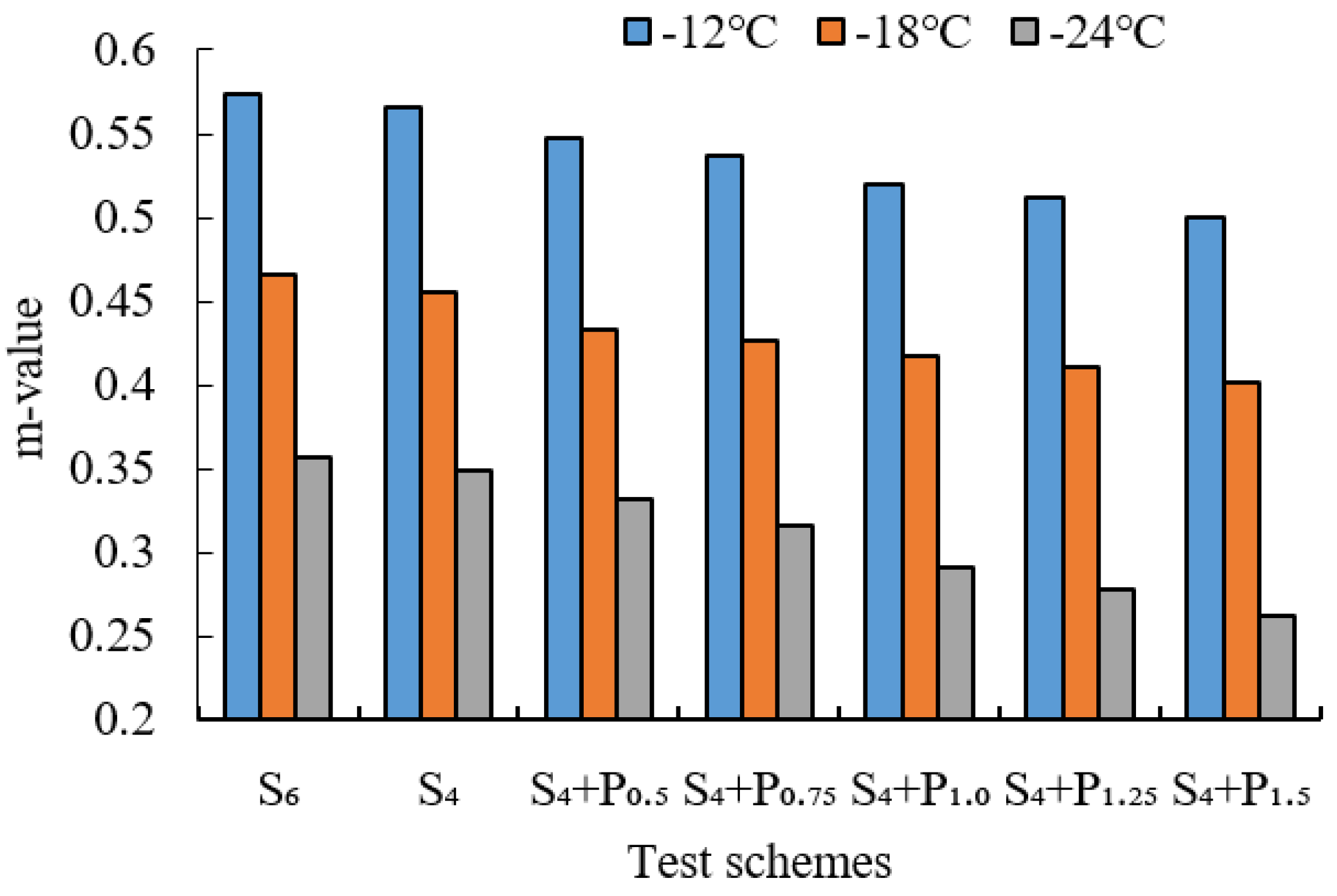

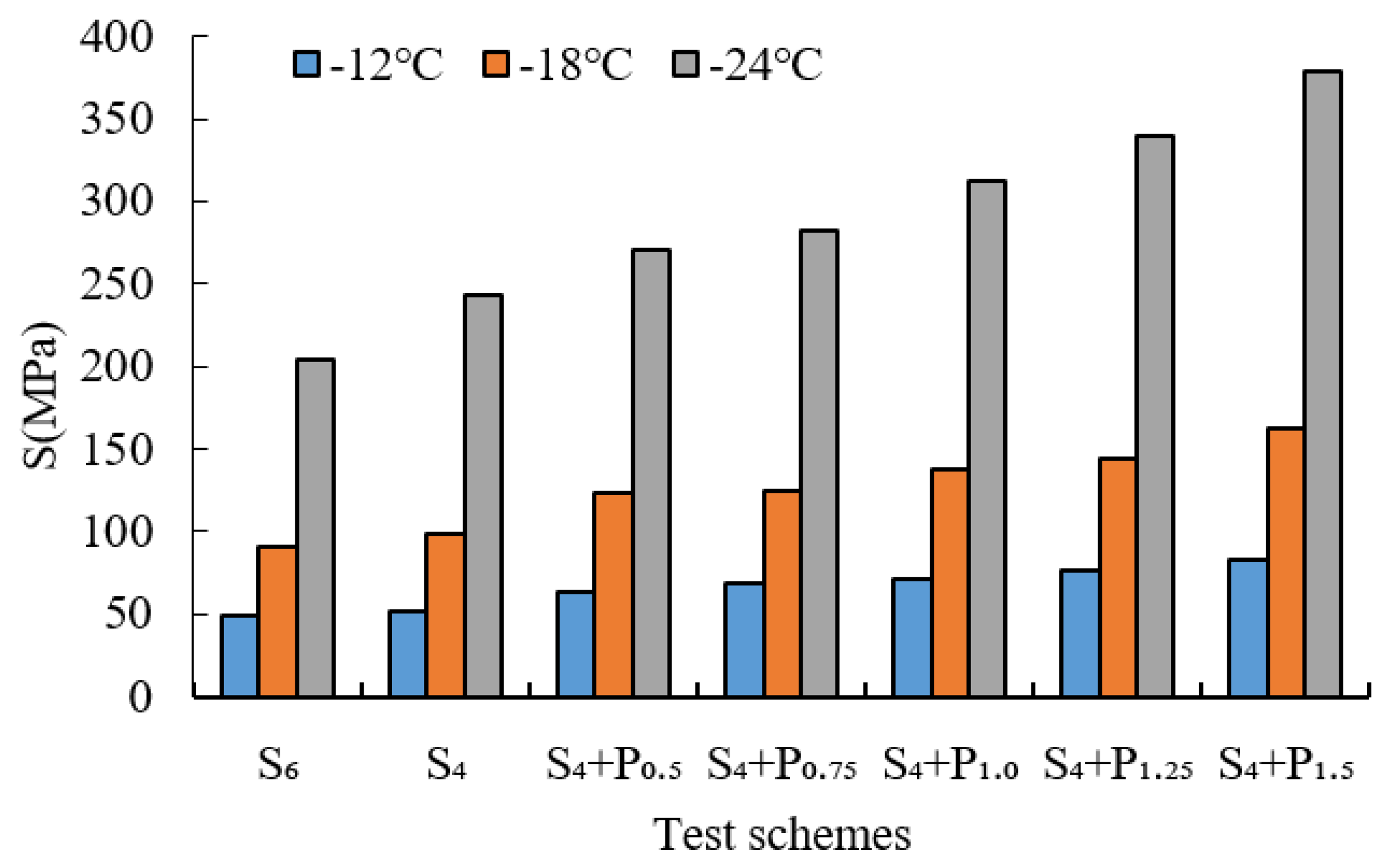

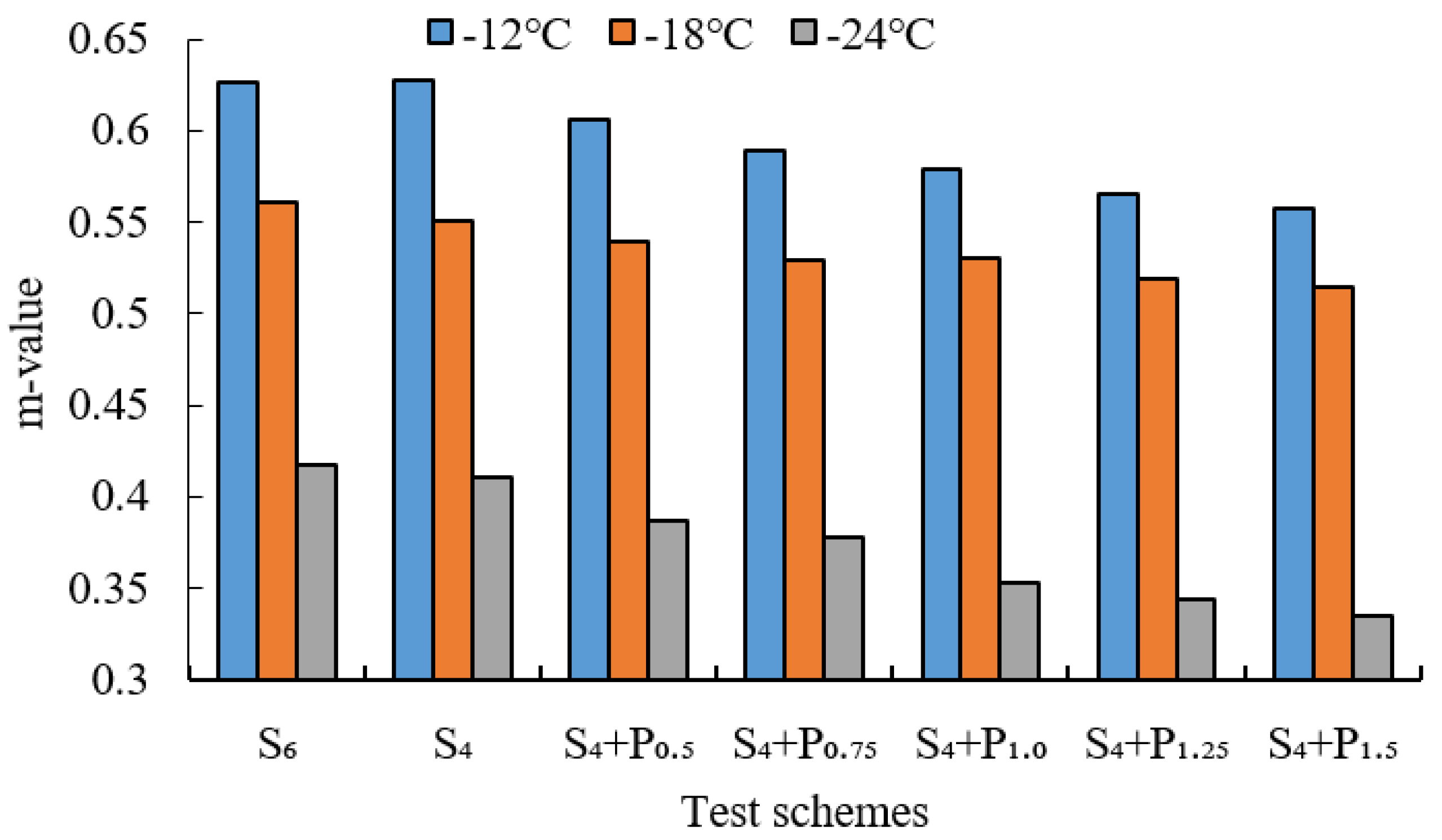

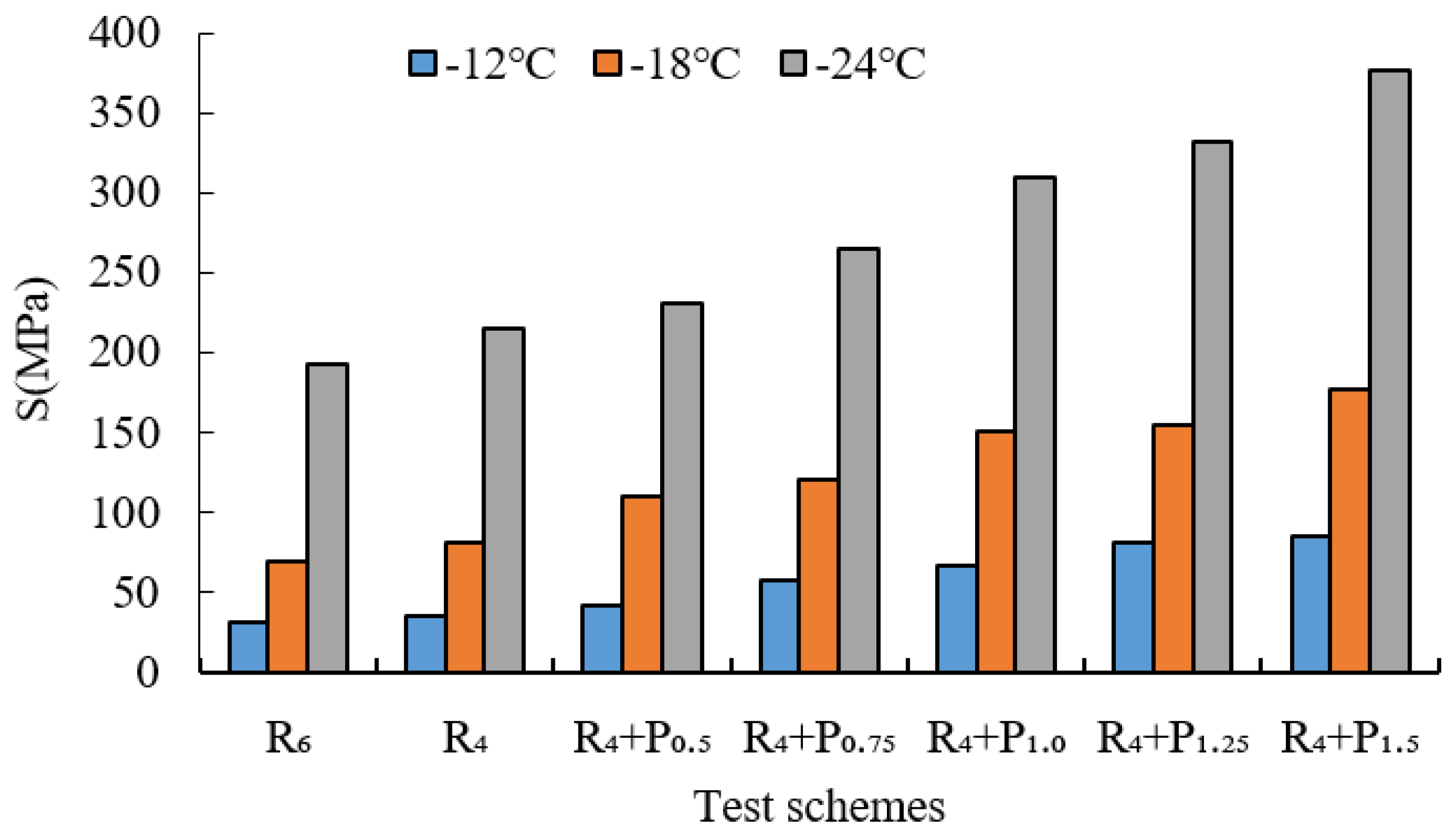

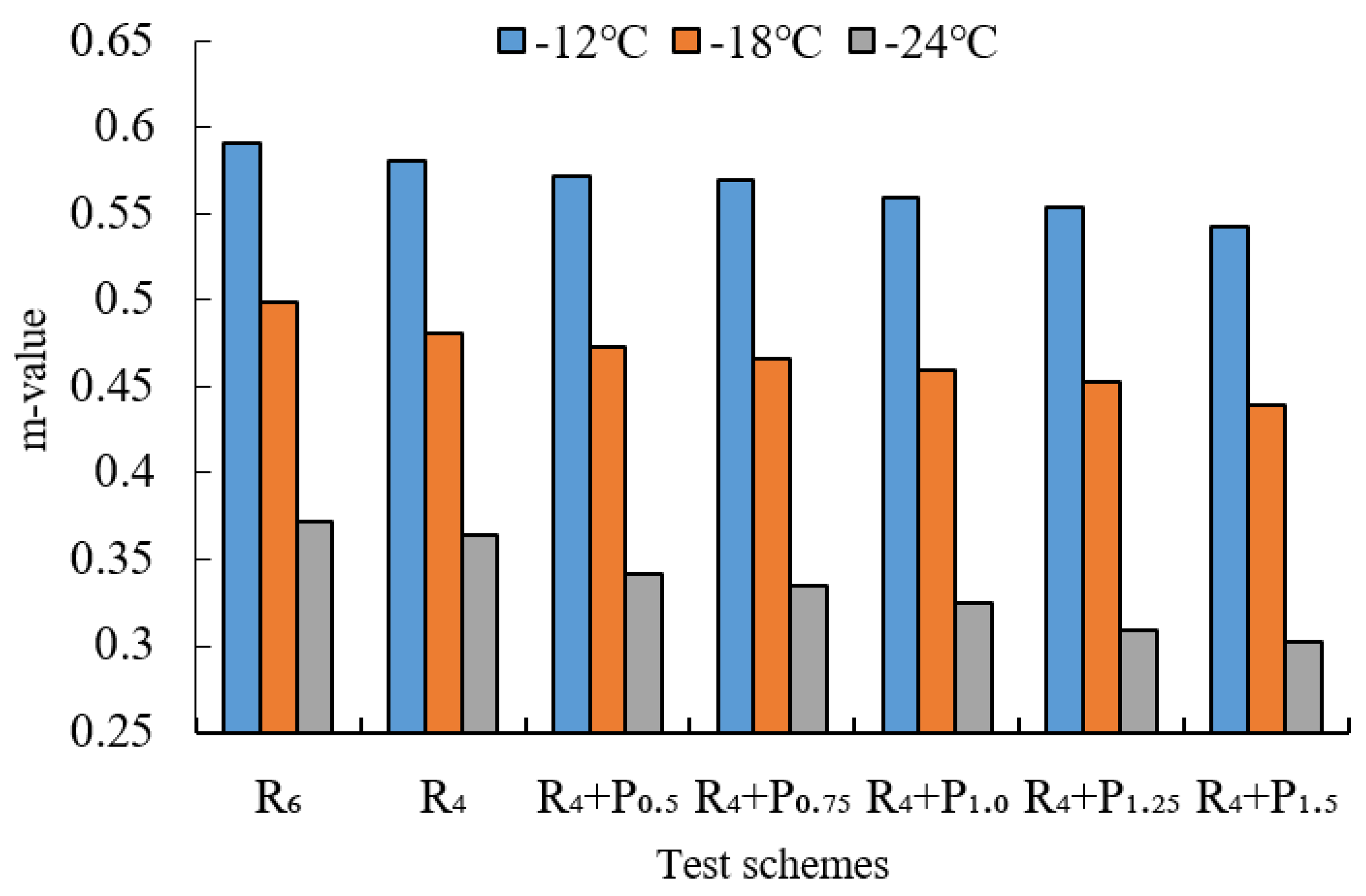

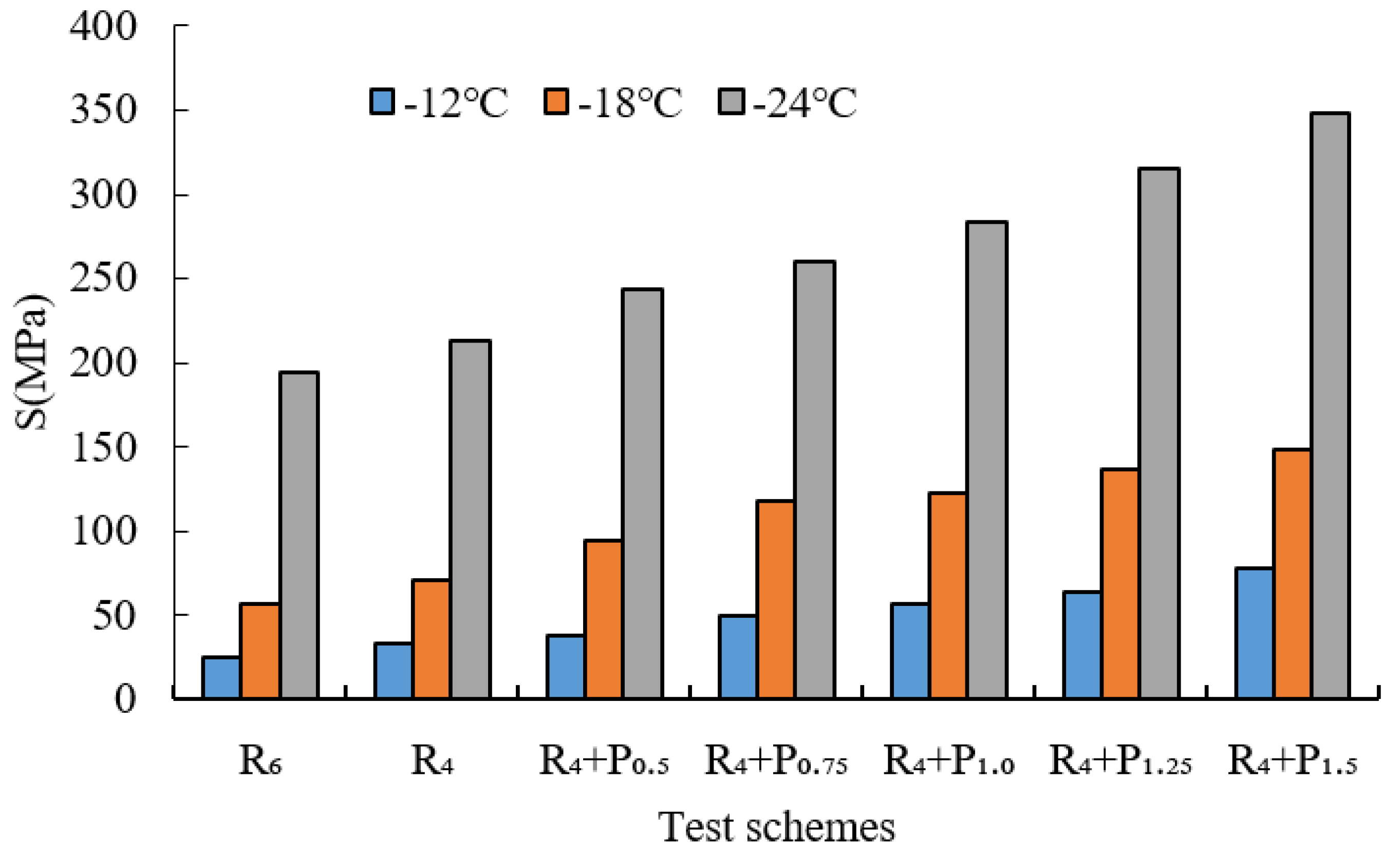

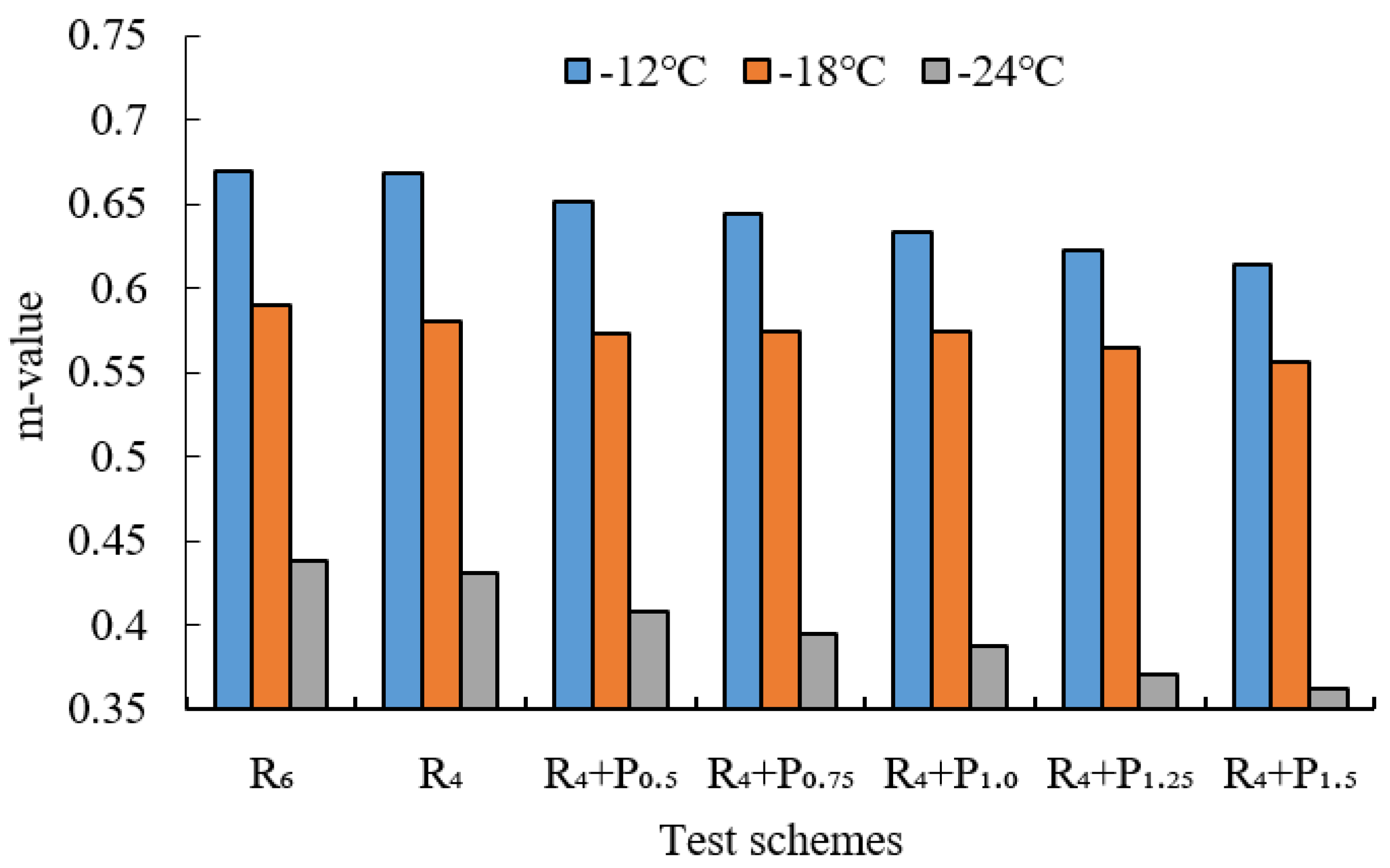

3.2. Low-Temperature Properties

3.3. Temperature Sensitivity

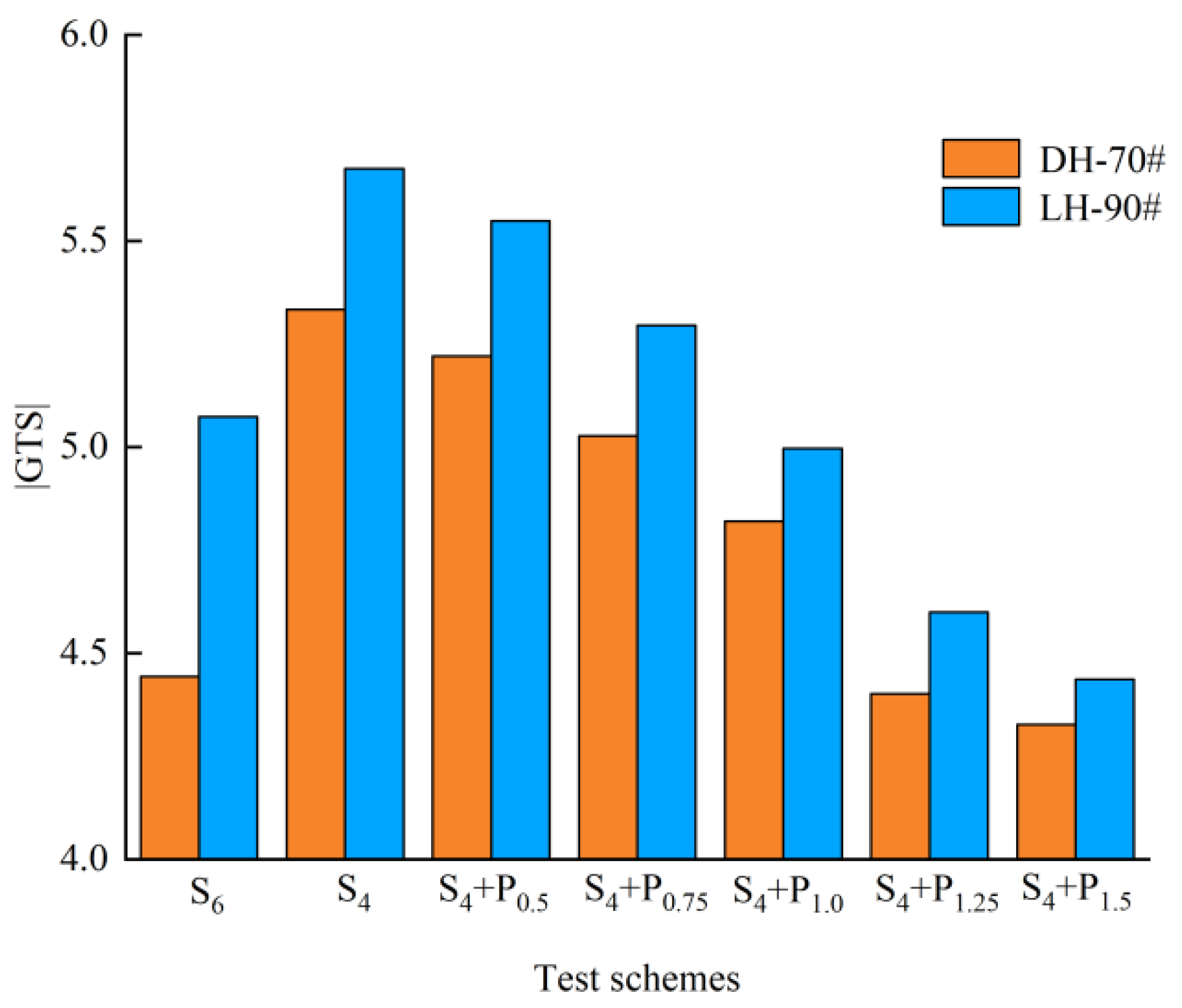

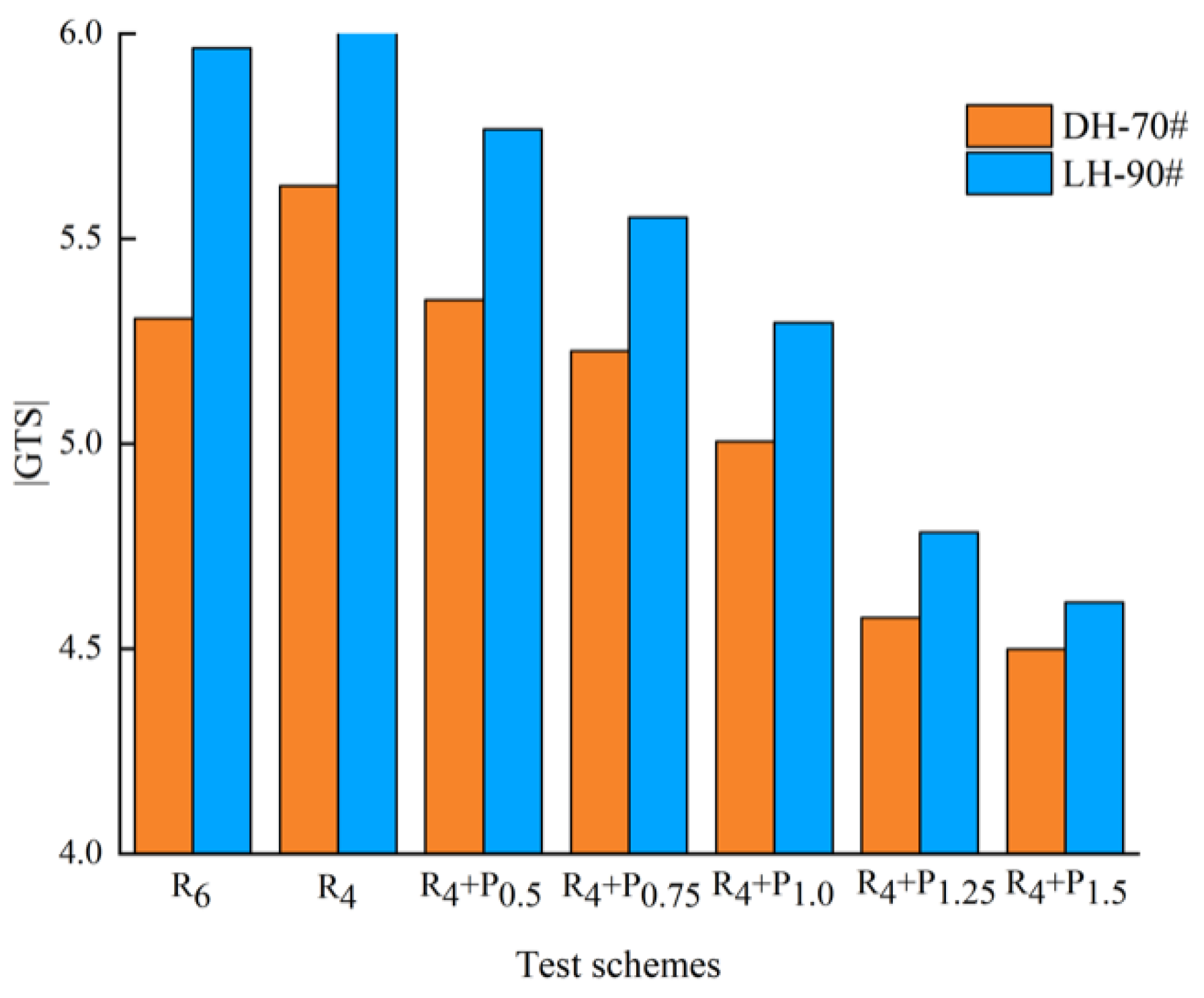

3.3.1. Complex Modulus Index (GTS) Method

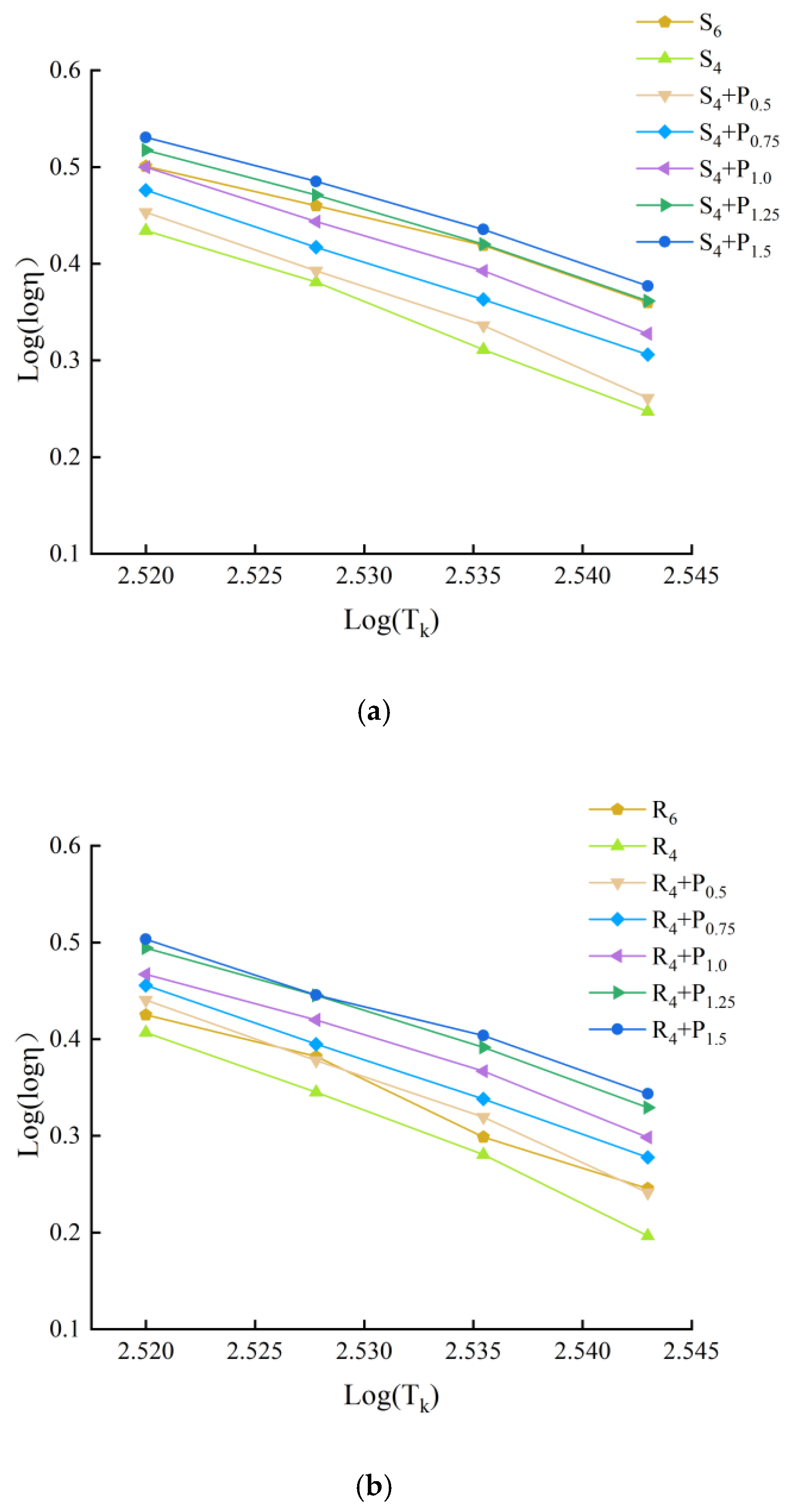

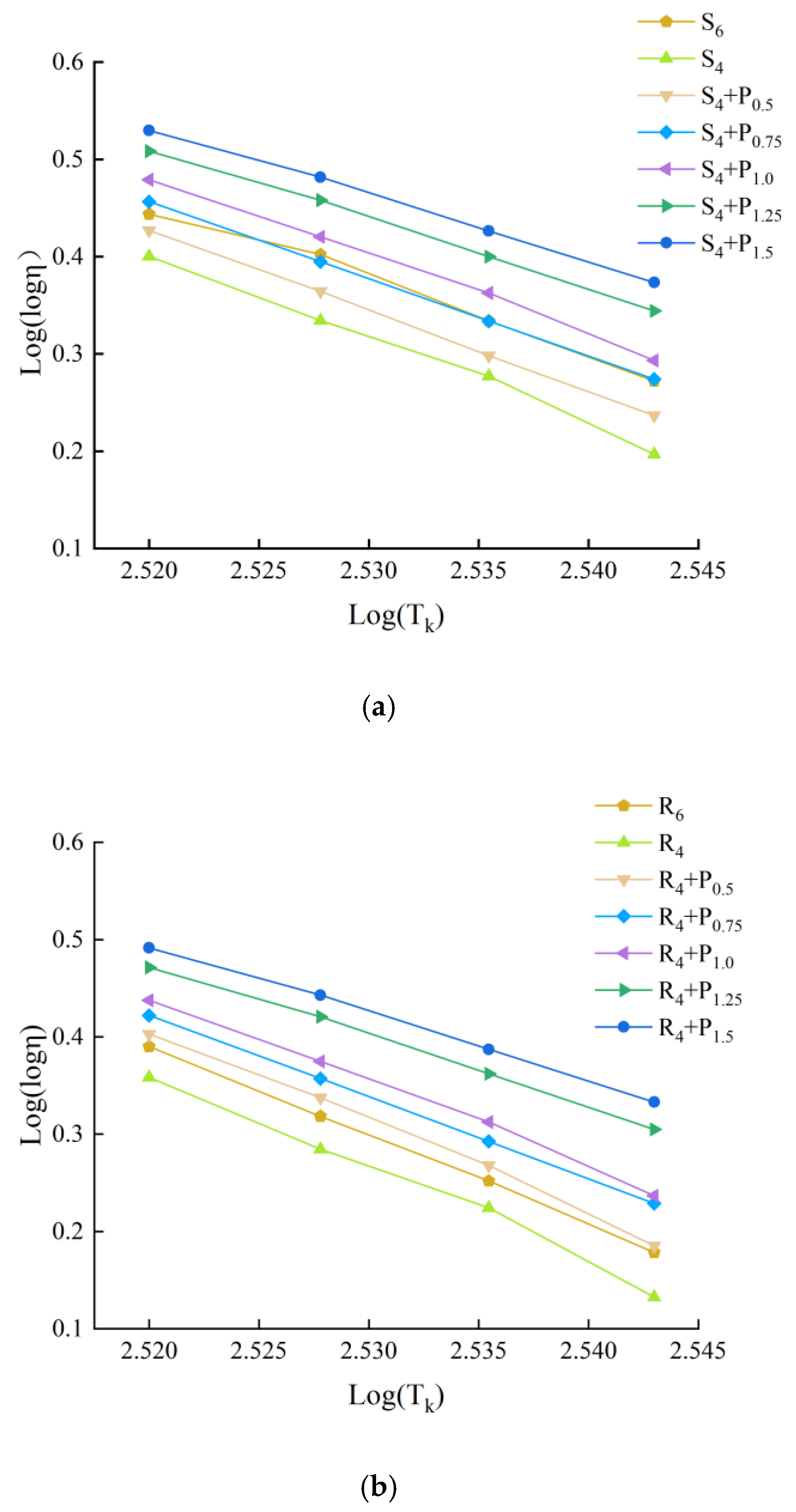

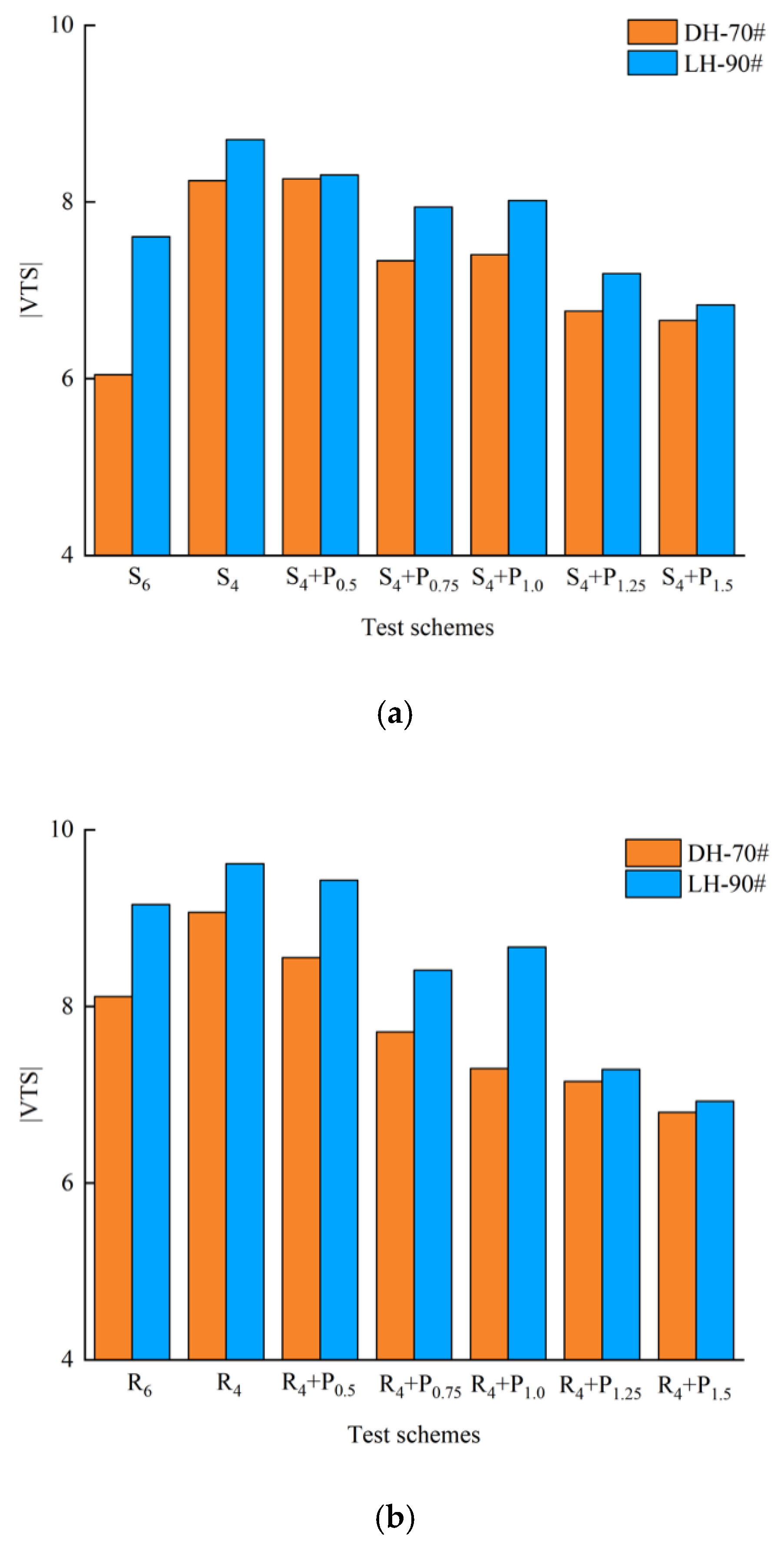

3.3.2. Viscosity Temperature Index (VTS) Method

3.4. Aging Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pei, X.; Fan, W. Effects of Amorphous Poly Alpha Olefin (APAO) and Polyphosphoric Acid (PPA) on the Rheological Properties, Compatibility and Stability of Asphalt Binder. Materials 2021, 14, 2458. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Li, X.; Kundwa, M.J.; Li, Z.; Wei, D. Evaluation of the adhesion characteristics of material composition for polyphosphoric acid and SBS modified bitumen based on surface free energy theory. Constr. Build. Mater. 2021, 266, 121022. [Google Scholar] [CrossRef]

- Behnood, A.; Olek, J. Rheological properties of asphalt binders modified with styrene-butadiene-styrene (SBS), ground tire rubber (GTR), or polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 151, 464–478. [Google Scholar] [CrossRef]

- Ameli, A.; Khabbaz, E.H.; Babagoli, R.; Norouzi, N.; Valipourian, K. Evaluation of the effect of carbon nano tube on water damage resistance of Stone matrix asphalt mixtures containing polyphosphoric acid and styrene butadiene rubber. Constr. Build. Mater. 2020, 261, 119946. [Google Scholar] [CrossRef]

- Babagoli, R.; Ameli, A.; Shahriari, H. Laboratory evaluation of rutting performance of cold recycling asphalt mixtures containing SBS modified asphalt emulsion. Pet. Sci. Technol. 2016, 34, 309–313. [Google Scholar] [CrossRef]

- Imaninasab, R. Rutting resistance and resilient modulus evaluation of polymer-modified SMA mixtures. Pet. Sci. Technol. 2016, 34, 1483–1489. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhao, C.; Ling, J.; Wu, T.; Li, D.; Liu, J.; Sun, B. Anti-rutting performance evaluation of modified asphalt binders: A review. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 339–355. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Pei, J.; Cai, J.; Liu, T.; Wen, Y. Performance improvement and aging property of oil/SBS modified asphalt. Constr. Build. Mater. 2021, 300, 23735. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, W.; Wang, T.; Nan, G. Studies on the temperature performance of SBR modified asphalt emulsion. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; IEEE: Manhattan, NY, USA, 2011. [Google Scholar]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar] [CrossRef]

- Liang, P.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; Ren, S. Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 139, 183–192. [Google Scholar] [CrossRef]

- D’Angelo, J.A. Workshop Summary. In Polyphosphoric Acid Modification of Asphalt Binders; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Baumgardner, G.L.; Masson, J.F.; Hardee, J.R.; Menapace, A.M.; Williams, A.G. Polyphosphoric Acid Modified Asphalt: Proposed Mechanisms. Road Mater. Pavement Des. 2005, 74, 283–305. [Google Scholar]

- Nuñez, J.Y.; Domingos, M.D.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514. [Google Scholar] [CrossRef]

- Man Sze Ho, S.; Zanzotto, L.; MacLeod, D. Impact of Different Types of Modification on Low-Temperature Tensile Strength and Tcritical of Asphalt Binders. Transp. Res. Rec. 2002, 1810, 1–8. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Rossi, C.O.; Seta, L.; Lupi, F.R.; Caputo, P. Low temperature rheology of polyphosphoric acid (PPA) added bitumen. Constr. Build. Mater. 2012, 36, 592–596. [Google Scholar] [CrossRef]

- Naresh Baboo, R. Effect of Polyphosphoric Acid on Aging Characteristics of PG 64-22 Asphalt Binder; University of North Texas: Denton, TX, USA, 2010. [Google Scholar]

- Fee, D.; Maldonado, R.; Reinke, G.; Romagosa, H. Polyphosphoric Acid Modification of Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2010, 2179, 49–57. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Sengoz, B.; Topal, A.; Isikyakar, G. Morphology and image analysis of polymer modified bitumens. Constr. Build. Mater. 2009, 23, 1986–1992. [Google Scholar] [CrossRef]

- Rossi, C.O.; Spadafora, A.; Teltayev, B.; Izmailova, G.; Amerbayev, Y.; Bortolotti, V. Polymer modified bitumen: Rheological properties and structural characterization. Colloids Surf. A Physicochem. Eng. Asp. 2015, 480, 390–397. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Bahia, H.U.; Hanson, D.I.; Zeng, M.; Zhai, H.; Khatri, M.A.; Anderson, R.M. Characterization of modified asphalt binders in Superpave mix design. In Characterization of Modified Asphalt Binders in Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2001. [Google Scholar]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Strategic Highway Research Program (SHRP). Superior Performing Asphalt Pavements (Superpave): The Product of the SHRP Asphalt Research Program (SHRP-A-410); Strategic Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- YongNing, W. Effect of admixtures on properties of SBS modified asphalt mixed with polyphosphate. J. China Foreign Highw. 2018, 264–268. [Google Scholar] [CrossRef]

- Local Standards of Hebei Province. Technical Standard for Tire Crumb Asphalt Rubber and Asphalt Rubber Hot Mixture (DB13/T 1013-2009); Local Standards of Hebei Province: HuBei, China, 2009. [Google Scholar]

- Chen, H.-X.; Li, N.-L.; Zhang, Z.-Q. Temperature Susceptibility Analysis of Asphalt Binders. J. Chang. Univ. Nat. Sci. Ed. 2009, 1, 505–509. [Google Scholar]

- Rasmussen, R.O.; Lytton, R.L.; Chang, G.K. Method to Predict Temperature Susceptibility of an Asphalt Binder. J. Mater. Civ. Eng. 2002, 14, 246–252. [Google Scholar] [CrossRef]

| Technical Indexes | Units | Results | ||

|---|---|---|---|---|

| DH-70# | LH-90# | |||

| Unaged | Softening point(R&B) | °C | 53.1 | 49.2 |

| Ductility (50 mm/min, 10 °C) | cm | 39.7 | >100 | |

| Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 64.2 | 84.6 | |

| Solubility | % | 99.9 | 99.7 | |

| Density(15 °C) | g/cm3 | 1.033 | 1.042 | |

| Flash point | °C | 279 | 316 | |

| RTFO aged | Mass variation | % | 0.47 | −0.16 |

| Retained penetration ratio (25 °C) | % | 70.2 | 73.1 | |

| Retained ductility (10 °C) | cm | 14.1 | 8.7 | |

| SBS1401 | SBR | ||||

|---|---|---|---|---|---|

| Technical Index | Units | Measured Value | Technical Index | Units | Measured Value |

| S/B ratio | - | 4/6 | Granularity | Mesh No. | 10~80 |

| Oil filling rate | % | 0 | Bound styrene content | % | 10~50 |

| Volatile matter | % | ≤0.7 | Mooney viscosity | ML | 45~65 |

| Ash content | % | ≤0.2 | 300% Constant tensile stress | MPa | 15 |

| 300% Constant tensile stress | Mpa | ≥3.5 | Tensile strength | Mpa | ≥20 |

| Tensile strength | Mpa | 24 | |||

| Elongation at break | % | 730 | |||

| Shore hardness | A | 85 | |||

| Melt flow rate | g/10 min | 0.1~5.0 | |||

| No | Schemes |

|---|---|

| S6/R6 | 6% SBS/SBR Modification |

| S4/R4 | 4% SBS/SBR Modification |

| S4/R4 + P0.5 | 4% SBS/SBR + 0.5% PPA Modification |

| S4/R4 + P0.75 | 4% SBS/SBR + 0.75% PPA Modification |

| S4/R4 + P1.0 | 4% SBS/SBR + 1.0% PPA Modification |

| S4/R4 + P1.25 | 4% SBS/SBR + 1.25% PPA Modification |

| S4/R4 + P1.5 | 4% SBS/SBR + 1.5% PPA Modification |

| Asphalt Type | Polymer Modifier Type | Complex Modulus G*/kPa | Phase Angleδ/° | Recommended Scheme |

|---|---|---|---|---|

| DH-70# | SBS | S4 + P0.75 | S4 + P1.0 | S4 + P0.75 |

| SBR | R4 + P0.5 | R4 + P0.5~0.75 | R4 + P0.5 | |

| LH-90# | SBS | S4 + P0.75 | S4 + P0.75 | S4 + P0.75 |

| SBR | R4 + P0.5 | R4 + P0.5~0.75 | R4 + P0.5 |

| Asphalt Type | No | Regression Equation | Correlation Coefficient R2 | |VTS| |

|---|---|---|---|---|

| DH-70# | S6 | y = −6.0467x + 15.743 | R2 = 0.9895 | 6.0467 |

| S4 | y = −8.2404x + 21.204 | R2 = 0.9966 | 8.2404 | |

| S4 + P0.5 | y = −8.2611x + 21.274 | R2 = 0.9953 | 8.2611 | |

| S4 + P0.75 | y = −7.3347x + 18.959 | R2 = 0.9999 | 7.3347 | |

| S4 + P1.0 | y = −7.4027x + 19.156 | R2 = 0.9971 | 7.4027 | |

| S4 + P1.25 | y = −6.7658x + 17.571 | R2 = 0.9964 | 6.7658 | |

| S4 + P1.5 | y = −6.6601x + 17.317 | R2 = 0.9958 | 6.6601 | |

| R6 | y = −8.1127x + 20.876 | R2 = 0.9853 | 8.1127 | |

| R4 | y = −9.0659x + 23.258 | R2 = 0.9931 | 9.0659 | |

| R4 + P0.5 | y = −8.5545x + 22.001 | R2 = 0.995 | 8.5545 | |

| R4 + P0.75 | y = −7.7112x + 19.888 | R2 = 0.9998 | 7.7112 | |

| R4 + P1.0 | y = −7.2983x + 18.864 | R2 = 0.9911 | 7.2983 | |

| R4 + P1.25 | y = −7.1512x + 18.519 | R2 = 0.996 | 7.1512 | |

| R4 + P1.5 | y = −6.8034x + 17.647 | R2 = 0.9953 | 6.8034 | |

| LH-90# | S6 | y = −7.6056x + 19.617 | R2 = 0.9894 | 7.6056 |

| S 4 | y = −8.7073x + 22.345 | R2 = 0.9947 | 8.7073 | |

| S4 + P0.5 | y = −8.3059x + 21.359 | R2 = 0.9998 | 8.3059 | |

| S4 + P0.75 | y = −7.9426x + 20.472 | R2 = 1 | 7.9426 | |

| S4 + P1.0 | y = −8.017x + 20.684 | R2 = 0.9974 | 8.017 | |

| S4 + P1.25 | y = −7.1883x + 18.625 | R2 = 0.9988 | 7.1883 | |

| S4 + P1.5 | y = −6.8357x + 17.758 | R2 = 0.9988 | 6.8357 | |

| R6 | y = −9.1534x + 23.457 | R2 = 0.9995 | 9.1534 | |

| R4 | y = −9.6161x + 24.594 | R2 = 0.9926 | 9.6161 | |

| R4 + P0.5 | y = −9.4301x + 24.171 | R2 = 0.9962 | 9.4301 | |

| R4 + P0.75 | y = −8.4108x + 21.618 | R2 = 1 | 8.4108 | |

| R4 + P1.0 | y = −8.6712x + 22.292 | R2 = 0.9969 | 8.6712 | |

| R4 + P1.25 | y = −7.2864x + 18.836 | R2 = 0.9986 | 7.2864 | |

| R4 + P1.5 | y = −6.9272x + 17.95 | R2 = 0.9987 | 6.9272 |

| Asphalt Type | No | Retained Penetration Ratio (%) | Softening Point Increment (°C) | Mass Loss Rate (%) |

|---|---|---|---|---|

| DH-70# | S6 | 77.32 | 4.5 | 0.379 |

| S4 | 73.17 | 5.8 | 0.442 | |

| S4 + P0.5 | 75.44 | 4.7 | 0.412 | |

| S4 + P0.75 | 76.81 | 4.5 | 0.391 | |

| S4 + P1.0 | 78.24 | 4.2 | 0.357 | |

| S4 + P1.25 | 79.25 | 3.8 | 0.321 | |

| S4 + P1.5 | 80.64 | 3.1 | 0.271 | |

| LH-90# | S6 | 71.25 | 5.1 | 0.418 |

| S4 | 66.15 | 6.9 | 0.533 | |

| S4 + P0.5 | 69.03 | 5.4 | 0.435 | |

| S4 + P0.75 | 71.39 | 5.2 | 0.401 | |

| S4 + P1.0 | 73.51 | 4.8 | 0.379 | |

| S4 + P1.25 | 75.28 | 4.0 | 0.314 | |

| S4 + P1.5 | 76.78 | 3.3 | 0.258 |

| Asphalt Type | No | Retained Penetration Ratio (%) | Softening Point Increment (°C) | Mass Loss Rate (%) |

|---|---|---|---|---|

| DH-70# | R6 | 68.68 | 8.8 | 0.385 |

| R4 | 64.94 | 10.5 | 0.467 | |

| R4 + P0.5 | 67.24 | 9.5 | 0.426 | |

| R4 + P0.75 | 68.93 | 8.6 | 0.374 | |

| R4 + P1.0 | 71.11 | 6.1 | 0.318 | |

| R4 + P1.25 | 74.62 | 4.4 | 0.243 | |

| R4 + P1.5 | 75.65 | 3.7 | 0.221 | |

| LH-90# | R6 | 61.26 | 10.4 | 0.422 |

| R4 | 57.19 | 12.0 | 0.486 | |

| R4 + P0.5 | 60.24 | 10.2 | 0.452 | |

| R4 + P0.75 | 61.87 | 8.9 | 0.371 | |

| R4 + P1.0 | 65.02 | 6.6 | 0.309 | |

| R4 + P1.25 | 68.75 | 4.3 | 0.227 | |

| R4 + P1.5 | 71.96 | 3.3 | 0.172 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Shi, S.; Zhou, Y.; Chen, Z.; Yu, F.; Peng, Z.; Duan, X. Research on Performance of SBS-PPA and SBR-PPA Compound Modified Asphalts. Materials 2022, 15, 2112. https://doi.org/10.3390/ma15062112

Wei J, Shi S, Zhou Y, Chen Z, Yu F, Peng Z, Duan X. Research on Performance of SBS-PPA and SBR-PPA Compound Modified Asphalts. Materials. 2022; 15(6):2112. https://doi.org/10.3390/ma15062112

Chicago/Turabian StyleWei, Jianguo, Song Shi, Yuming Zhou, Zhiyuan Chen, Fan Yu, Zhuyi Peng, and Xurui Duan. 2022. "Research on Performance of SBS-PPA and SBR-PPA Compound Modified Asphalts" Materials 15, no. 6: 2112. https://doi.org/10.3390/ma15062112

APA StyleWei, J., Shi, S., Zhou, Y., Chen, Z., Yu, F., Peng, Z., & Duan, X. (2022). Research on Performance of SBS-PPA and SBR-PPA Compound Modified Asphalts. Materials, 15(6), 2112. https://doi.org/10.3390/ma15062112