Influence of Thin Film Deposition on AFM Cantilever Tips in Adhesion and Young’s Modulus of MEMS Surfaces

Abstract

1. Introduction

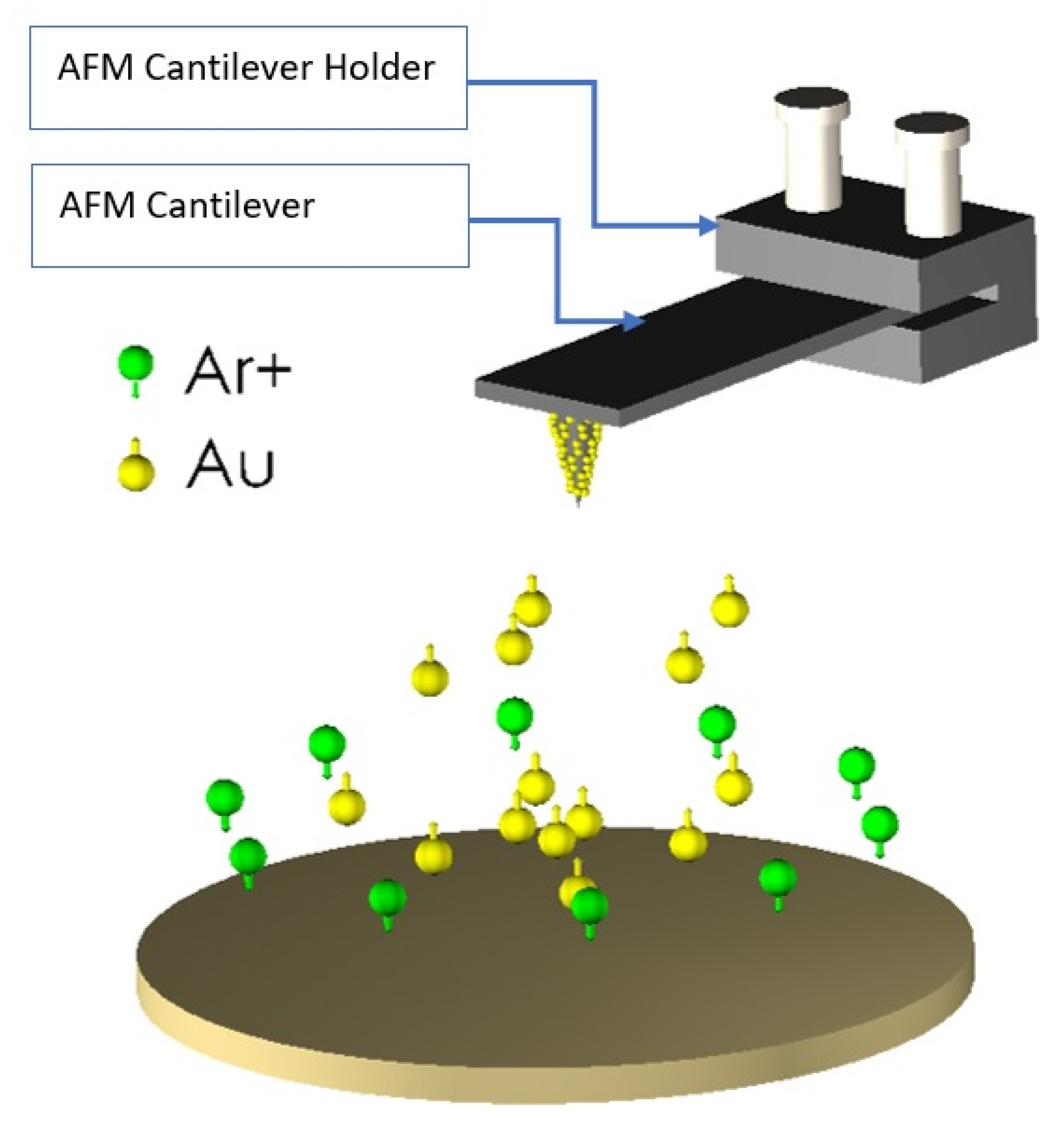

2. Materials and Methods

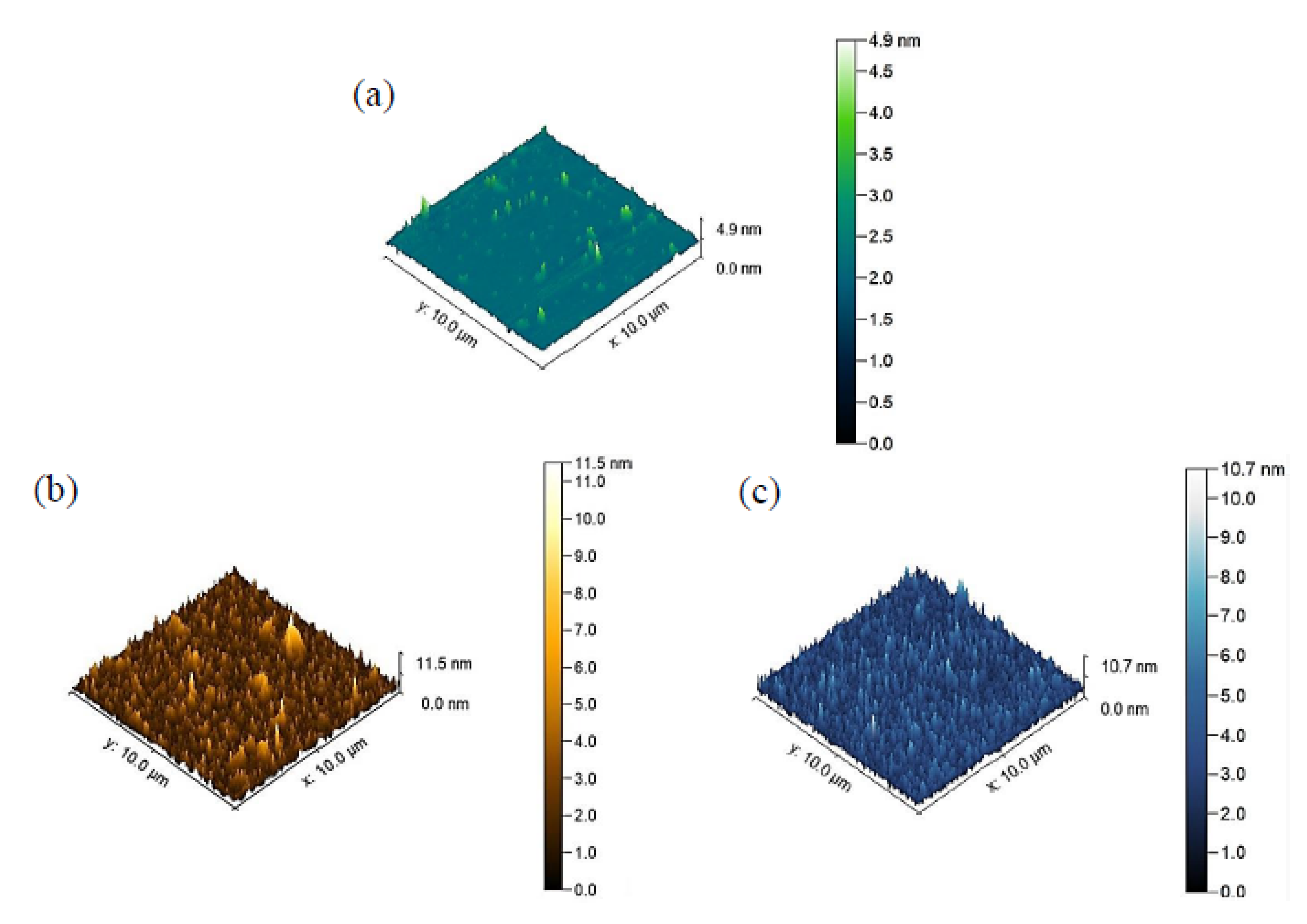

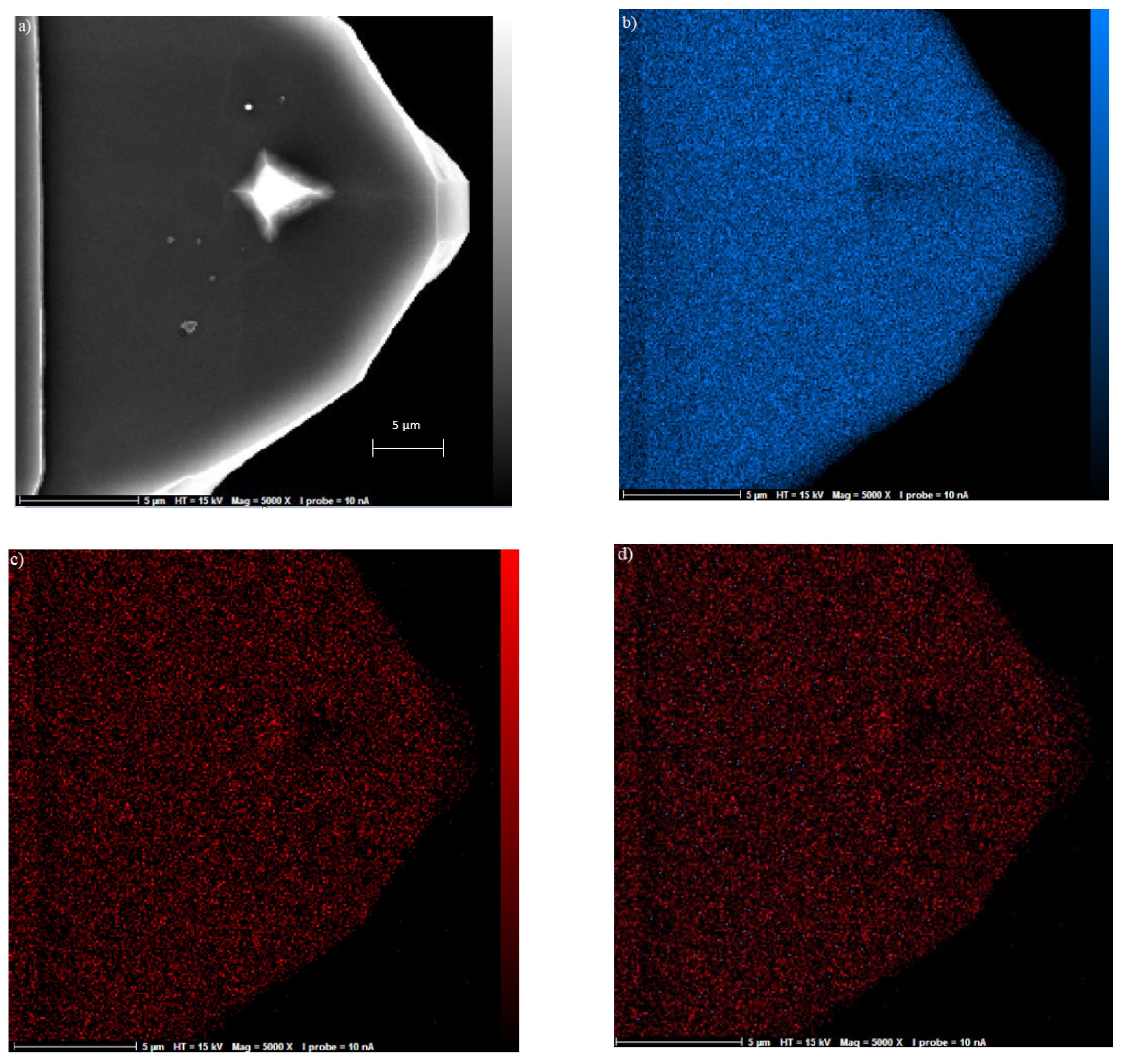

2.1. Coating of Substrates

2.2. Experimental Procedure

3. Results and Discussion

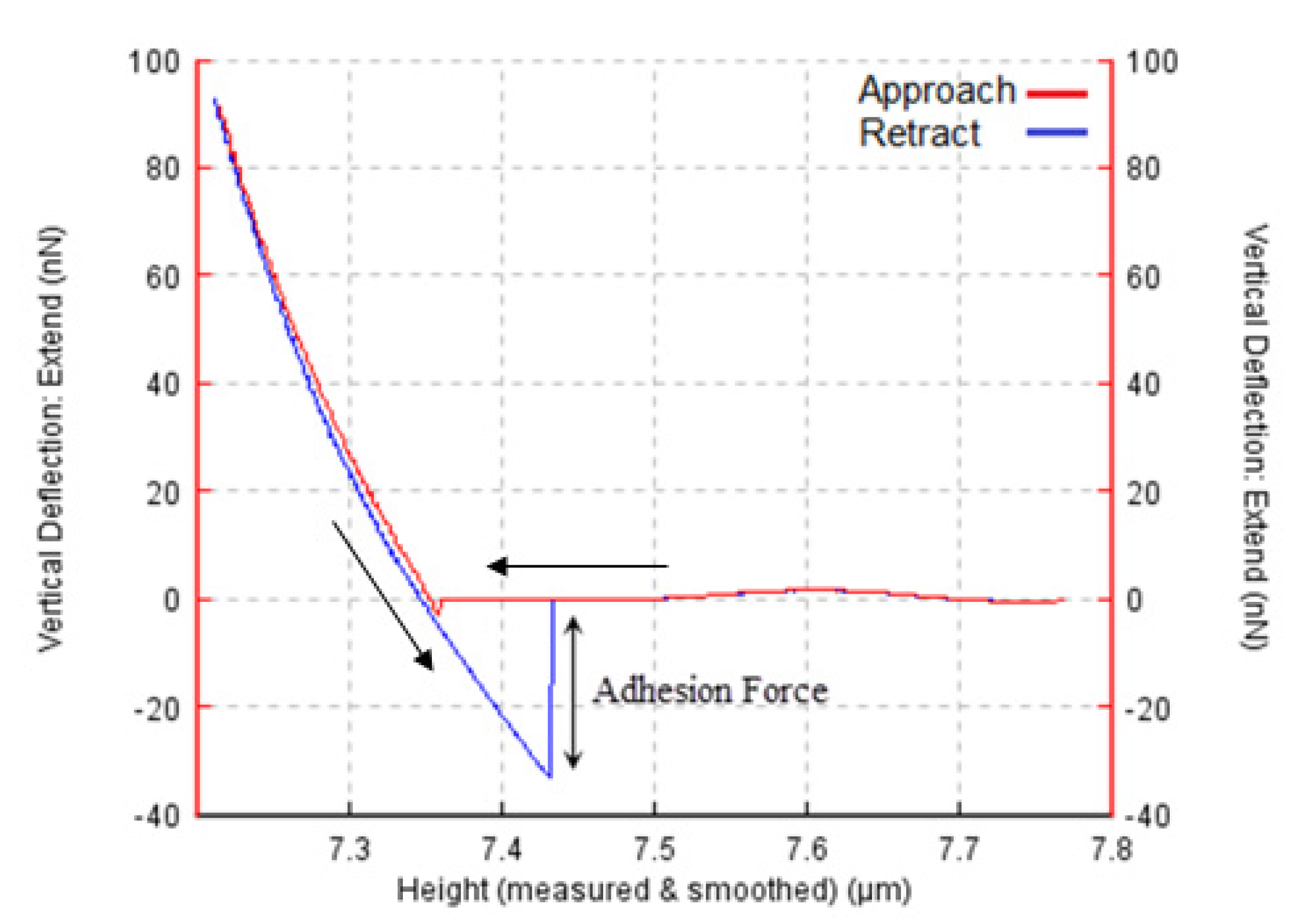

3.1. Adhesion Force

3.2. Young’s Modulus

4. Conclusions

- The deposition on the AFM tip was found to influence the adhesion force; however, the influence varied with the material of deposition on the tip and the substrate;

- The adhesion force was strongly dependent on the surface energy of both substrate and the AFM tip;

- The Hamaker constant between substrate and AFM tip was critical in adhesion force measurements. Considering that it is constant, a direct relation between the Hamaker coefficient and adhesion force in different surfaces can be established;

- The use of an AFM tip coated with gold increased the adhesion force except for gold substrate. However, using titanium-coated AFM tips could decrease the adhesion force in the case of all surfaces;

- Young’s modulus bore an inverse relationship with adhesion force for various combinations of tip and substrate materials. Increasing Young’s modulus reduced the elasticity of the cantilever, resulting in a very small beam deflection in the AFM tip and a much lower adhesion force calculated by the cantilever;

- Deposition on the substrate’s surface or AFM tip can affect the surface energy, the surface roughness, and Young’s modulus, which are the main parameters for the characterization of adhesion force.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, W.; He, J.; Peng, P.; Chen, L.; Cao, K. Reliability of Microelectromechanical Systems Devices. In Reliability and Maintenance: An Overview of Cases; Kounis, L., Ed.; IntechOpen: London, UK, 2020; p. 89. [Google Scholar] [CrossRef]

- Salehi, M.; Heidari, P.; Ruhani, B.; Kheradmand, A.; Purcar, V.; Căprărescu, S. Theoretical and experimental analysis of surface roughness and adhesion forces of MEMS surfaces using a novel method for making a compound sputtering target. Coatings 2021, 11, 1551. [Google Scholar] [CrossRef]

- Afekare, D.; Gupta, I.; Rao, D. Nanoscale investigation of silicon dioxide nanofluids and implications for enhanced oil recovery—An atomic force microscope study. J. Pet. Sci. Eng. 2020, 191, 107165. [Google Scholar] [CrossRef]

- Van Spengen, W.M.; Puers, R.; De Wolf, I. On the physics of stiction and its impact on the reliability of microstructures. J. Adhes. Sci. Technol. 2003, 17, 563–582. [Google Scholar] [CrossRef]

- Andrews, D.; Scholes, G.; Wiederrecht, G. Comprehensive Nanoscience and Technology, 1st ed.; Academic Press: Cambridge, MA, USA, 2010; p. 2774. [Google Scholar]

- Mergel, J.C.; Sahli, R.; Scheibert, J.; Sauer, R.A. Continuum contact models for coupled adhesion and friction. J. Adhes. 2018, 95, 1101–1133. [Google Scholar] [CrossRef]

- Shui, L.; Jia, L.; Li, H.; Guo, J.; Guo, Z.; Liu, Y.; Liu, Z.; Chen, X. Rapid and continuous regulating adhesion strength by mechanical micro-vibration. Nat. Commun. 2020, 11, 1583. [Google Scholar] [CrossRef]

- Peillon, S.; Autricque, A.; Redolfi, M.; Stancu, C.; Gensdarmes, F.; Grisolia, C.; Pluchery, O. Adhesion of tungsten particles on rough tungsten surfaces using Atomic Force Microscopy. J. Aerosol. Sci. 2019, 137, 105431. [Google Scholar] [CrossRef]

- Dejeu, J.; Rougeot, P.; Gauthier, M.; Boireau, W. Reduction of a micro-object's adhesion using chemical functionalization. Micro Nano Lett. 2009, 4, 74–79. [Google Scholar] [CrossRef]

- Kim, E.; Kojima, M.; Mae, Y.; Arai, T. High-Speed Manipulation of Microobjects Using an Automated Two-Fingered Microhand for 3D Microassembly. Micromachines 2020, 11, 534. [Google Scholar] [CrossRef]

- Jing, H.; Sinha, S.; Sachar, H.S.; Das, S. Interactions of gold and silica nanoparticles with plasma membranes get distinguished by the van der Waals forces: Implications for drug delivery, imaging, and theranostics. Colloids Surf. B Biointerfaces 2019, 177, 433–439. [Google Scholar] [CrossRef]

- Dziadkowiec, J.; Javadi, S.; Bratvold, J.E.; Nilsen, O.; Røyne, A. Surface Forces Apparatus measurements of interactions between rough and reactive calcite surfaces. Langmuir 2018, 34, 7248–7263. [Google Scholar] [CrossRef]

- Ishida, N.; Matsuo, K.; Imamura, K.; Craig, V.S. Hydrophobic attraction measured between asymmetric hydrophobic surfaces. Langmuir 2018, 34, 3588–3596. [Google Scholar] [CrossRef]

- Shao, G.; Ware, H.O.T.; Huang, J.; Hai, R.; Li, L.; Sun, C. 3D printed magnetically-actuating micro-gripper operates in air and water. Addit. Manuf. 2021, 38, 101834. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN-(Zr, Al, Si) N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Katainen, J.; Paajanen, M.; Ahtola, E.; Pore, V.; Lahtinen, J. Adhesion as an interplay between particle size and surface roughness. J. Colloid Interface Sci. 2006, 304, 524–529. [Google Scholar] [CrossRef]

- Zhao, W.; Lv, Y.; Zhou, Q.; Yan, W. Collision-adhesion mechanism of particles and dust deposition simulation on solar PV modules. Renew. Energy 2021, 176, 169–182. [Google Scholar] [CrossRef]

- Sabooni, S.; Ahmadi, M.; Galinmoghaddam, E.; Westerwaal, J.; Boelsma, C.; Zoestbergen, E.; Song, G.M.; Pei, Y.T. Fundamentals of the adhesion of physical vapor deposited ZnMg-Zn bilayer coatings to steel substrates. Mater. Des. 2020, 190, 108560. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, X.; Zhao, Z.; Gao, J.; Zhou, Y.; Gao, P.; Guo, Y.-Y.; Lv, Z. Evaluation of the adhesion and failure mechanism of the hard CrN coatings on different substrates. Surf. Coat. Technol. 2019, 364, 35–143. [Google Scholar] [CrossRef]

- Isaifan, R.J.; Johnson, D.; Ackermann, L.; Figgis, B.; Ayoub, M. Evaluation of the adhesion forces between dust particles and photovoltaic module surfaces. Sol. Energy Mater. Sol. Cells 2019, 191, 413–421. [Google Scholar] [CrossRef]

- Morita, S.; Giessibl, F.J.; Meyer, E.; Wiesendanger, R. Noncontact Atomic Force Microscopy, 1st ed.; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Butt, H.-J.; Kappl, M. Surface and Interfacial Forces, 2nd ed.; Wiley Online Library: Hoboken, NJ, USA, 2010; pp. 1–359. [Google Scholar]

- Krieg, M.; Fläschner, G.; Alsteens, D.; Gaub, B.M.; Roos, W.H.; Wuite, G.J.L.; Gaub, H.E.; Gerber, C.; Dufrêne, Y.F.; Müller, D.J. Atomic force microscopy-based mechanobiology. Nat. Rev. Phys. 2019, 1, 41–57. [Google Scholar] [CrossRef]

- Colaço, R.; Carvalho, P. Atomic force microscopy in bioengineering applications. In Scanning Probe Microscopy in Nanoscience and Nanotechnology; Bhushan, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 3, pp. 397–430. [Google Scholar] [CrossRef]

- Khatiwada, D.; Lamichhane, S.K. A Brief overview of AFM force distance spectroscopy. Himal. Phys. 2011, 2, 80–83. [Google Scholar] [CrossRef][Green Version]

- Kolahdoozan, M.; Kiani, A.; Heidari, P.; Oveissi, S. Investigating the effect of varying coating thickness on the surface roughness and adhesion forces of MEMS surfaces utilizing a theoretical and experimental approach. Appl. Surf. Sci. 2019, 481, 531–539. [Google Scholar] [CrossRef]

- Kim, T.; Min, C.; Jung, M.; Lee, J.; Park, C.; Kang, S. Design methodology for nano-engineered surfaces to control adhesion: Application to the anti-adhesion of particles. Appl. Surf. Sci. 2016, 389, 889–893. [Google Scholar] [CrossRef]

- Ono, K.; Mizushima, Y.; Furuya, M.; Kunihisa, R.; Tsuchiya, N.; Fukuma, T.; Iwata, A.; Matsuki, A. Direct Measurement of Adhesion Force of Individual Aerosol Particles by Atomic Force Microscopy. Atmosphere 2020, 11, 489. [Google Scholar] [CrossRef]

- Ghodssi, R.; Lin, P. MEMS Materials and Processes Handbook; Springer Science & Business Media: Cham, Switzerland, 2011; Volume 1, pp. 1–196. [Google Scholar]

- Rusu, F.; Pustan, M.; Bîrleanu, C.; Müller, R.; Voicu, R.; Baracu, A. Analysis of the surface effects on adhesion in MEMS structures. Appl. Surf. Sci. 2015, 358, 634–640. [Google Scholar] [CrossRef]

- Qadir, M.; Li, Y.; Wen, C. Ion-substituted calcium phosphate coatings by physical vapor deposition magnetron sputtering for biomedical applications: A review. Acta Biomater. 2019, 89, 14–32. [Google Scholar] [CrossRef]

- Maugis, D. Adhesion of spheres: The JKR-DMT transition using a Dugdale model. J. Colloid Interface Sci. 1992, 150, 243–269. [Google Scholar] [CrossRef]

- Jian-Min, Z.; Fei, M.; Ke-Wei, X. Calculation of the surface energy of FCC metals with modified embedded-atom method. Chin. Phys. 2004, 13, 1082. [Google Scholar] [CrossRef]

- Butt, H.-J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef]

- Lomboy, G.; Sundararajan, S.; Wang, K.; Subramaniam, S. A test method for determining adhesion forces and Hamaker constants of cementitious materials using atomic force microscopy. Cem. Concr. Res. 2011, 41, 1157–1166. [Google Scholar] [CrossRef]

- Liu, Y.; Song, C.; Lv, G.; Chen, N.; Zhou, H.; Jing, X. Determination of the attractive force, adhesive force, adhesion energy and Hamaker constant of soot particles generated from a premixed methane/oxygen flame by AFM. Appl. Surf. Sci. 2018, 433, 450–457. [Google Scholar] [CrossRef]

- Gupta, S.; Carrillo, F.; Li, C.; Pruitt, L.; Puttlitz, C. Adhesive forces significantly affect elastic modulus determination of soft polymeric materials in nanoindentation. Mater. Lett. 2007, 61, 448–451. [Google Scholar] [CrossRef]

- Sun, Y.; Akhremitchev, B.; Walker, G.C. Using the adhesive interaction between atomic force microscopy tips and polymer surfaces to measure the elastic modulus of compliant samples. Langmuir 2004, 20, 5837–5845. [Google Scholar] [CrossRef]

- Persson, B.N.; Scaraggi, M. Theory of adhesion: Role of surface roughness. J. Chem. Phys. 2014, 141, 124701. [Google Scholar] [CrossRef]

| Deposited Material | Argon Gas Pressure (mbar) | Final Pressure (mbar) | Voltage (V) | Temperature (°C) | Deposition Rate (Å/s) | Target-Substrate Distance (mm) |

|---|---|---|---|---|---|---|

| Gold | 6.4 × 10−3 | 2.5 × 10−5 | 500 | 54 | 2.43 | 130 |

| Titanium | 6.4 × 10−3 | 2.5 × 10−5 | 750 | 54 | 1.7 | 130 |

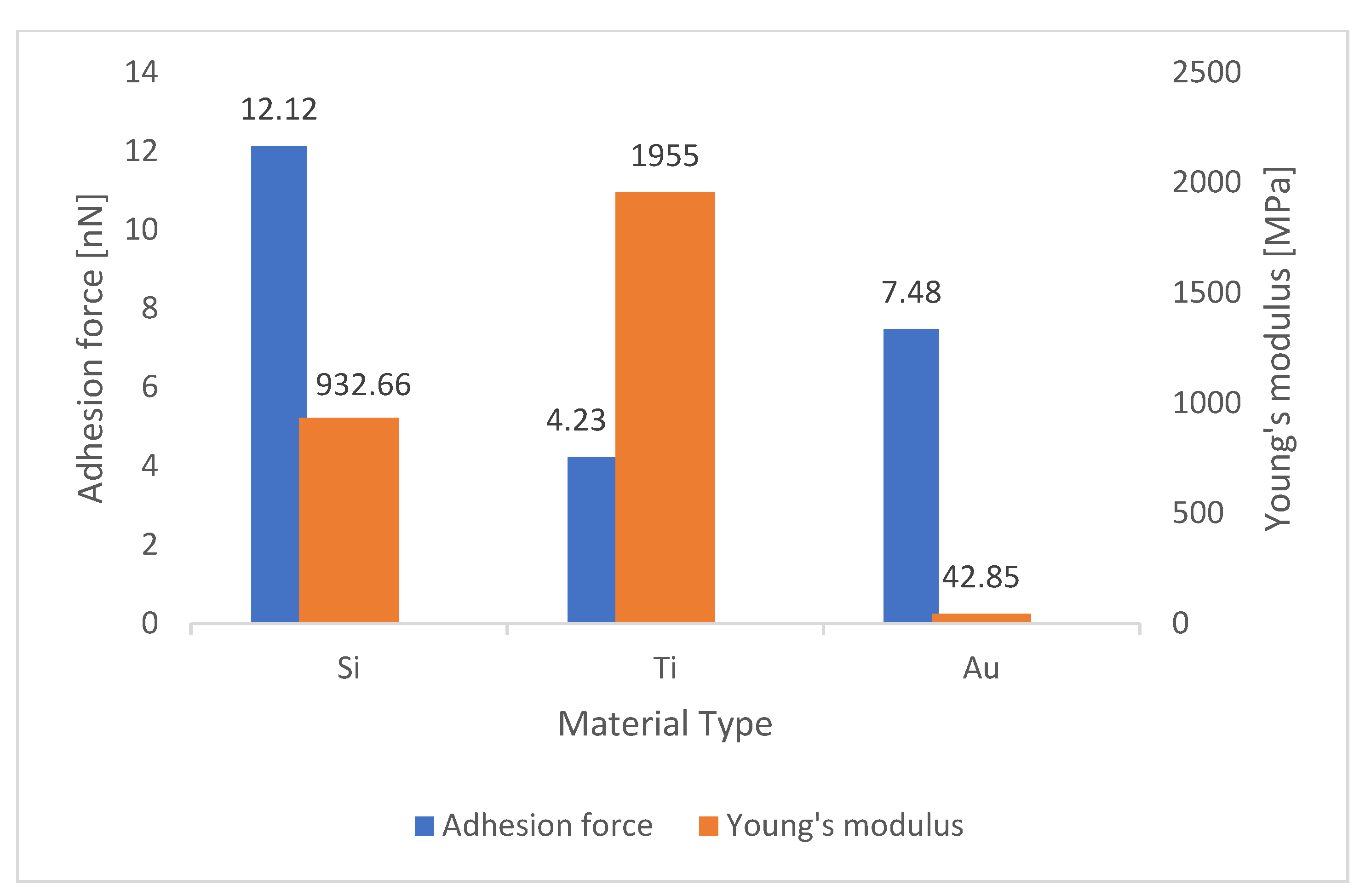

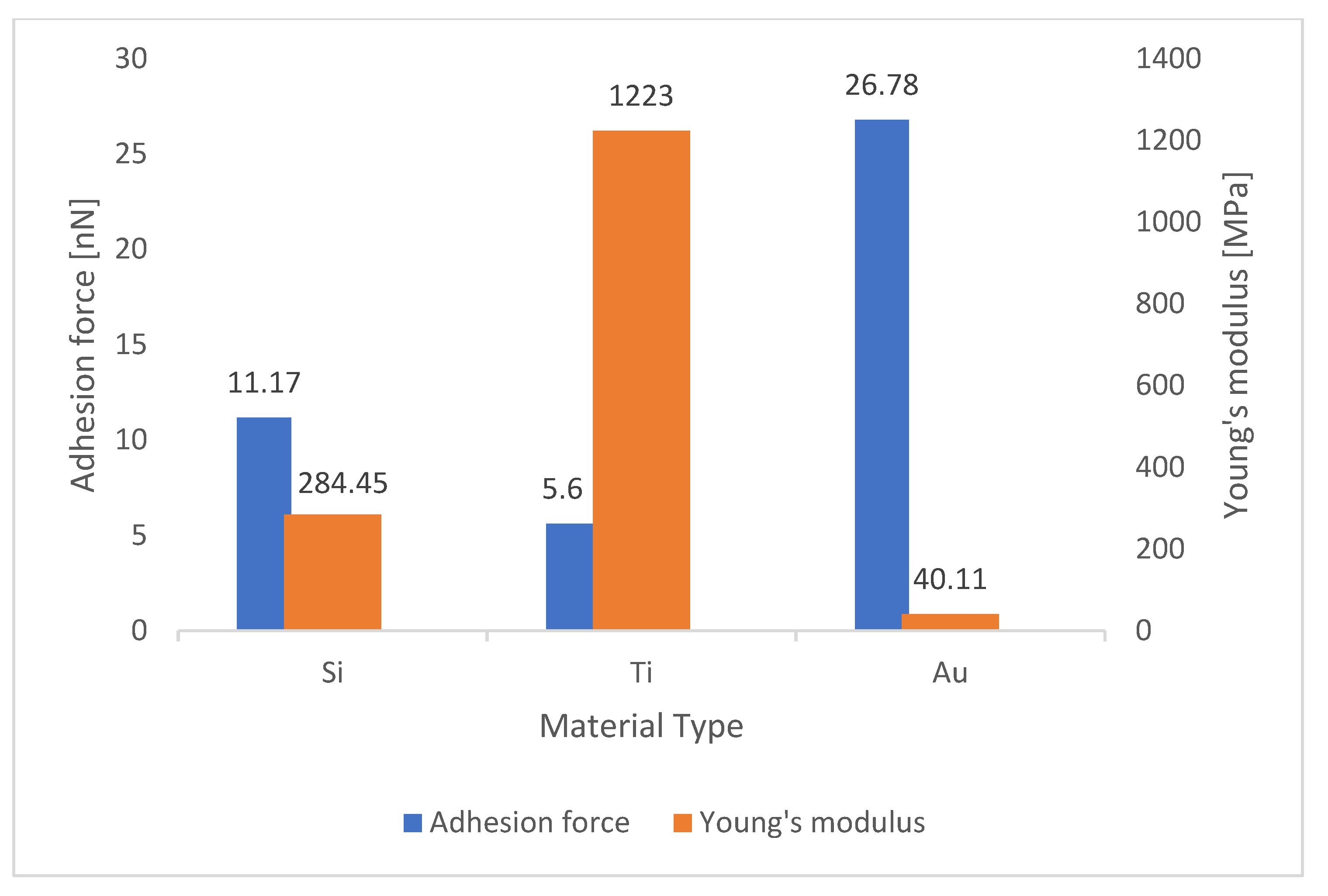

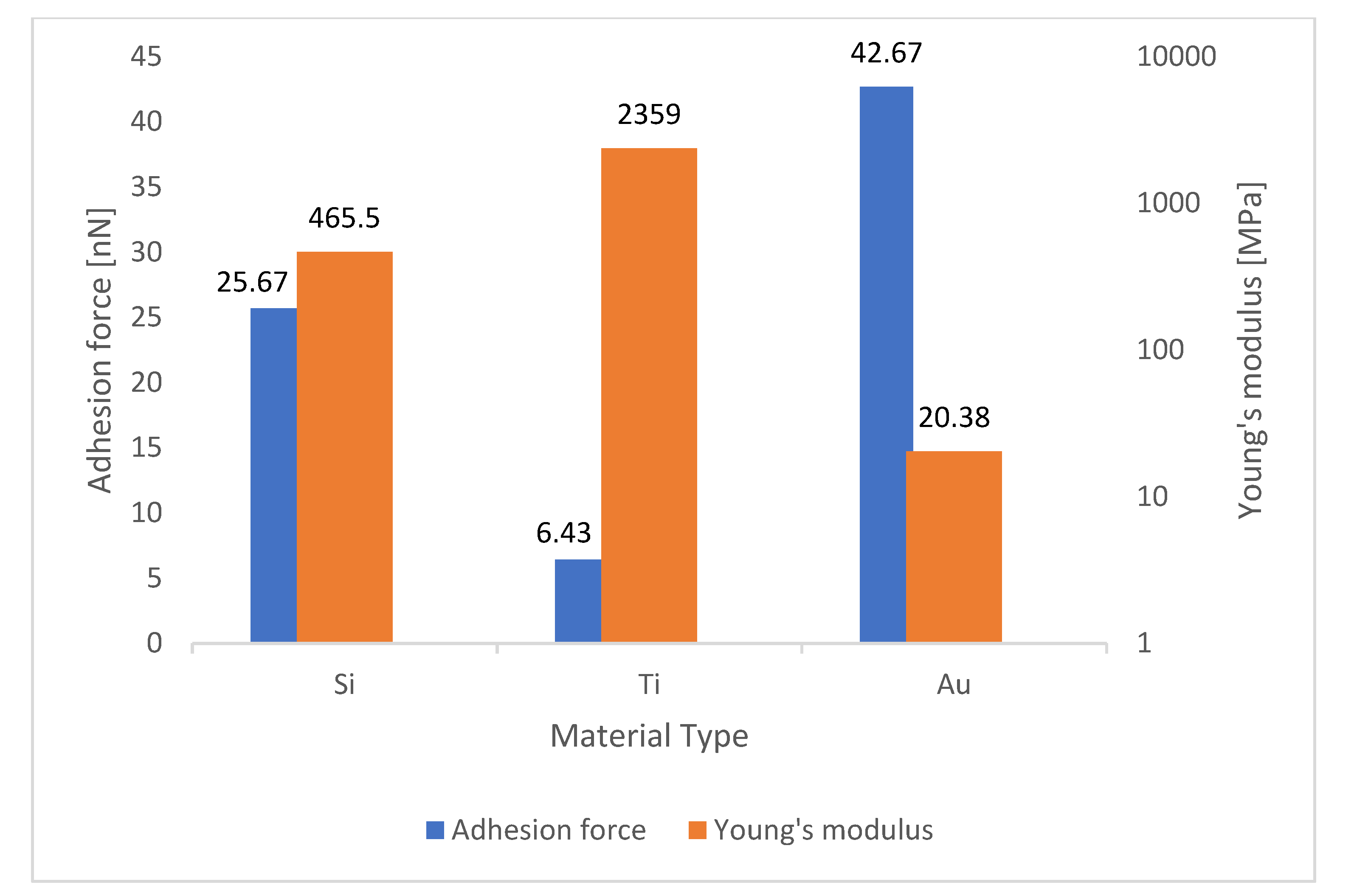

| Substrate Material | Adhesion Force Based on the Tip Material (nN) | ||

|---|---|---|---|

| Gold | Titanium | Silicon (Uncoated) | |

| Gold | 7.48 | 4.23 | 10.12 |

| Silver | 26.78 | 5.60 | 11.17 |

| Silicon | 42.67 | 6.43 | 25.67 |

| Tip Materials | Surface Energy (J/m2) | Substrate Materials | Surface Energy (J/m2) |

|---|---|---|---|

| Si-Si | 0.26 | Si-Au | 2.7 |

| Si-Au | 2.7 | Si-Ag | 1.5 |

| Si-Ti | 1.16 | Si-Si | 0.26 |

| Surface | Hamaker Coefficient (A/10−20 J) |

|---|---|

| Au–Au | 40.00 |

| Au–Ti | 32.86 |

| Au–Si | 35.55 |

| Ag–Au | 44.72 |

| Ag–Ti | 36.74 |

| Ag–Si | 39.75 |

| Si–Au | 35.55 |

| Si–Ti | 29.12 |

| Si–Si | 31.60 |

| Substrate Material | Young’s Modulus Based on the Tip Material (MPa) | ||

|---|---|---|---|

| Gold | Titanium | Silicon (Uncoated) | |

| Gold | 42.85 | 1955 | 932.66 |

| Silver | 40.11 | 1223 | 284.45 |

| Silicon | 20.38 | 2359 | 465.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidari, P.; Salehi, M.; Ruhani, B.; Purcar, V.; Căprărescu, S. Influence of Thin Film Deposition on AFM Cantilever Tips in Adhesion and Young’s Modulus of MEMS Surfaces. Materials 2022, 15, 2102. https://doi.org/10.3390/ma15062102

Heidari P, Salehi M, Ruhani B, Purcar V, Căprărescu S. Influence of Thin Film Deposition on AFM Cantilever Tips in Adhesion and Young’s Modulus of MEMS Surfaces. Materials. 2022; 15(6):2102. https://doi.org/10.3390/ma15062102

Chicago/Turabian StyleHeidari, Pedram, Majid Salehi, Behrooz Ruhani, Violeta Purcar, and Simona Căprărescu. 2022. "Influence of Thin Film Deposition on AFM Cantilever Tips in Adhesion and Young’s Modulus of MEMS Surfaces" Materials 15, no. 6: 2102. https://doi.org/10.3390/ma15062102

APA StyleHeidari, P., Salehi, M., Ruhani, B., Purcar, V., & Căprărescu, S. (2022). Influence of Thin Film Deposition on AFM Cantilever Tips in Adhesion and Young’s Modulus of MEMS Surfaces. Materials, 15(6), 2102. https://doi.org/10.3390/ma15062102