Shear Performance of RC Beams Reinforced with Fe-Based Shape Memory Alloy Stirrups

Abstract

:1. Introduction

2. Experiment

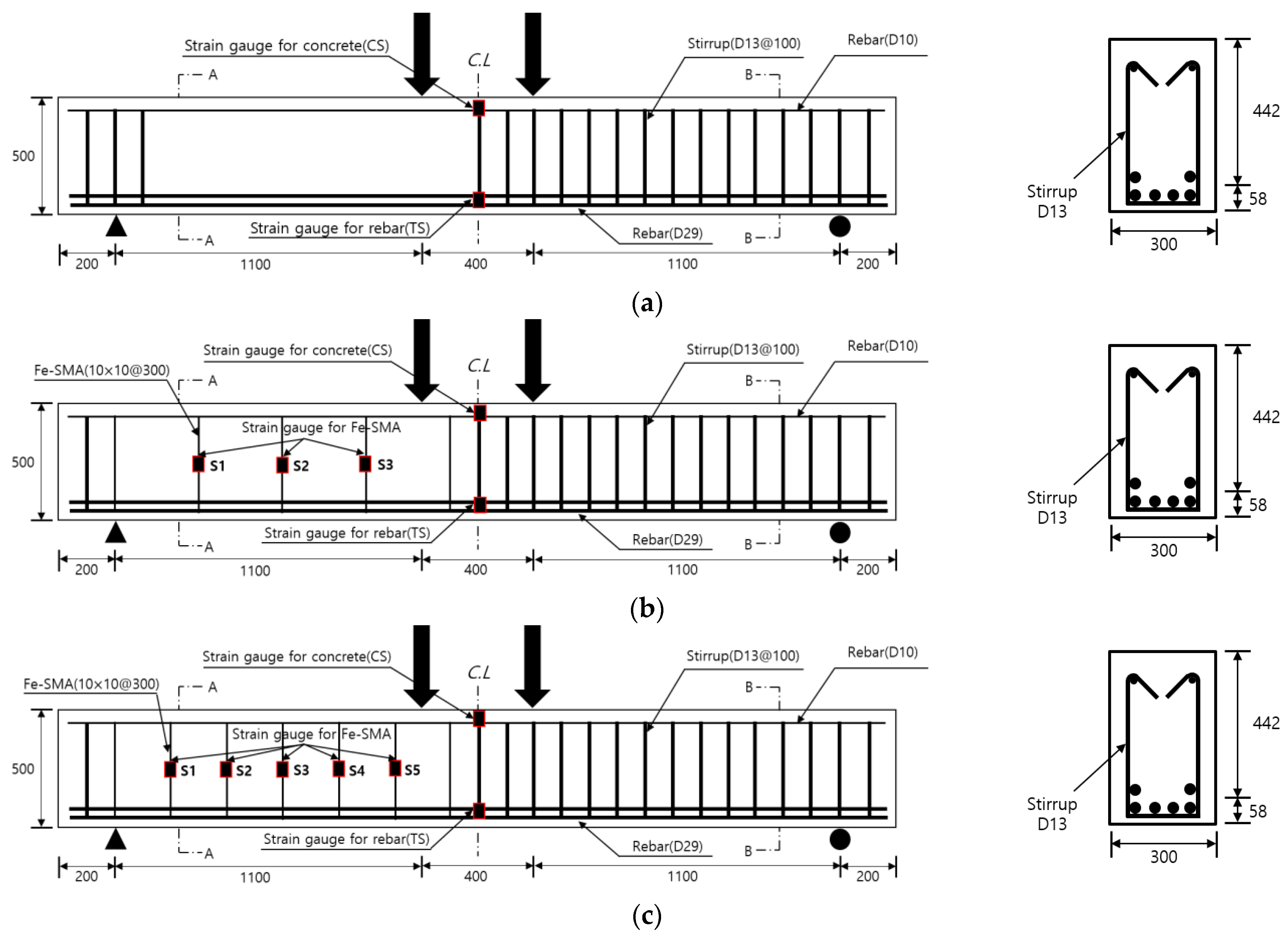

2.1. Test Specimens and Variable

2.2. Materials

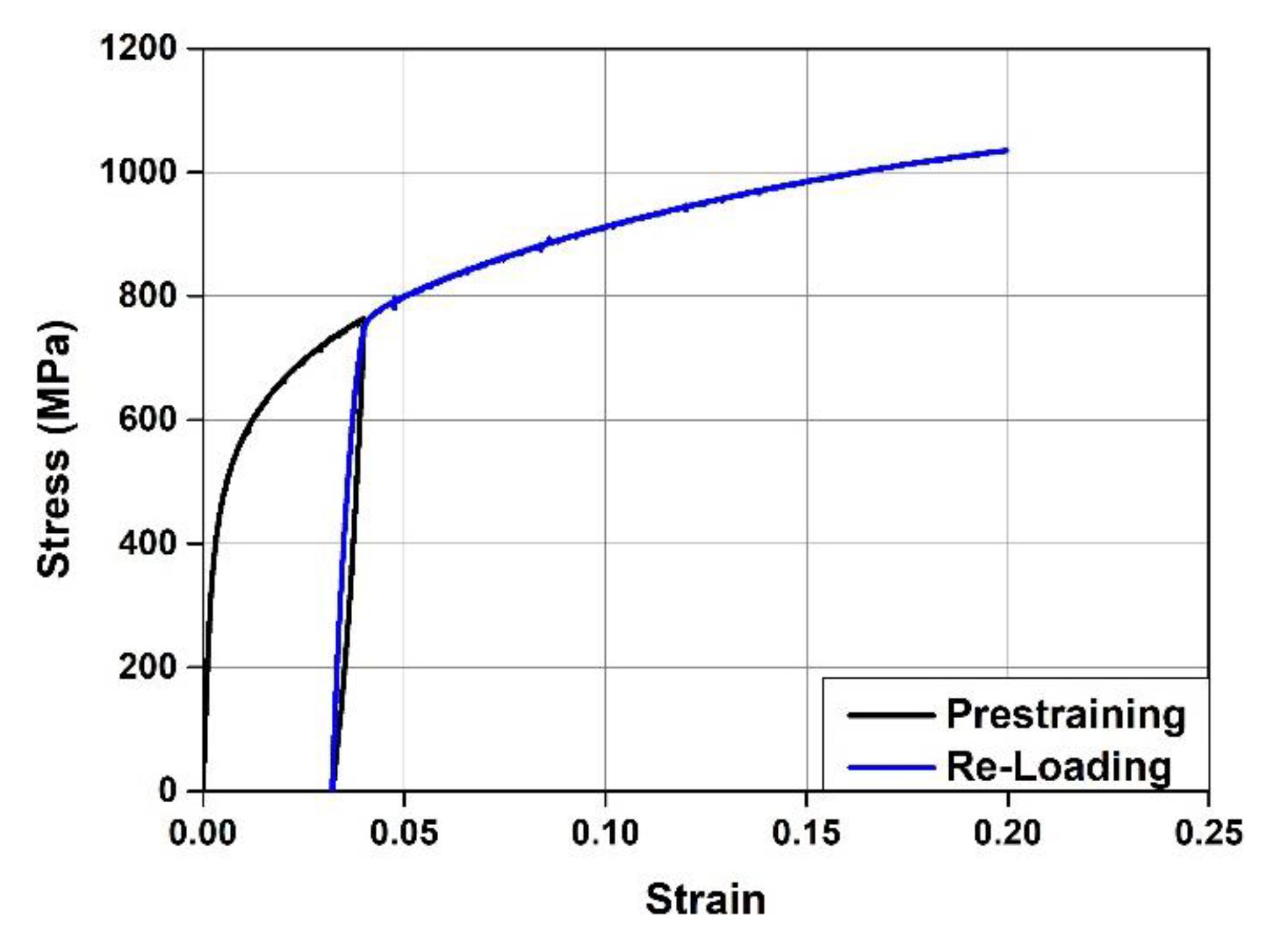

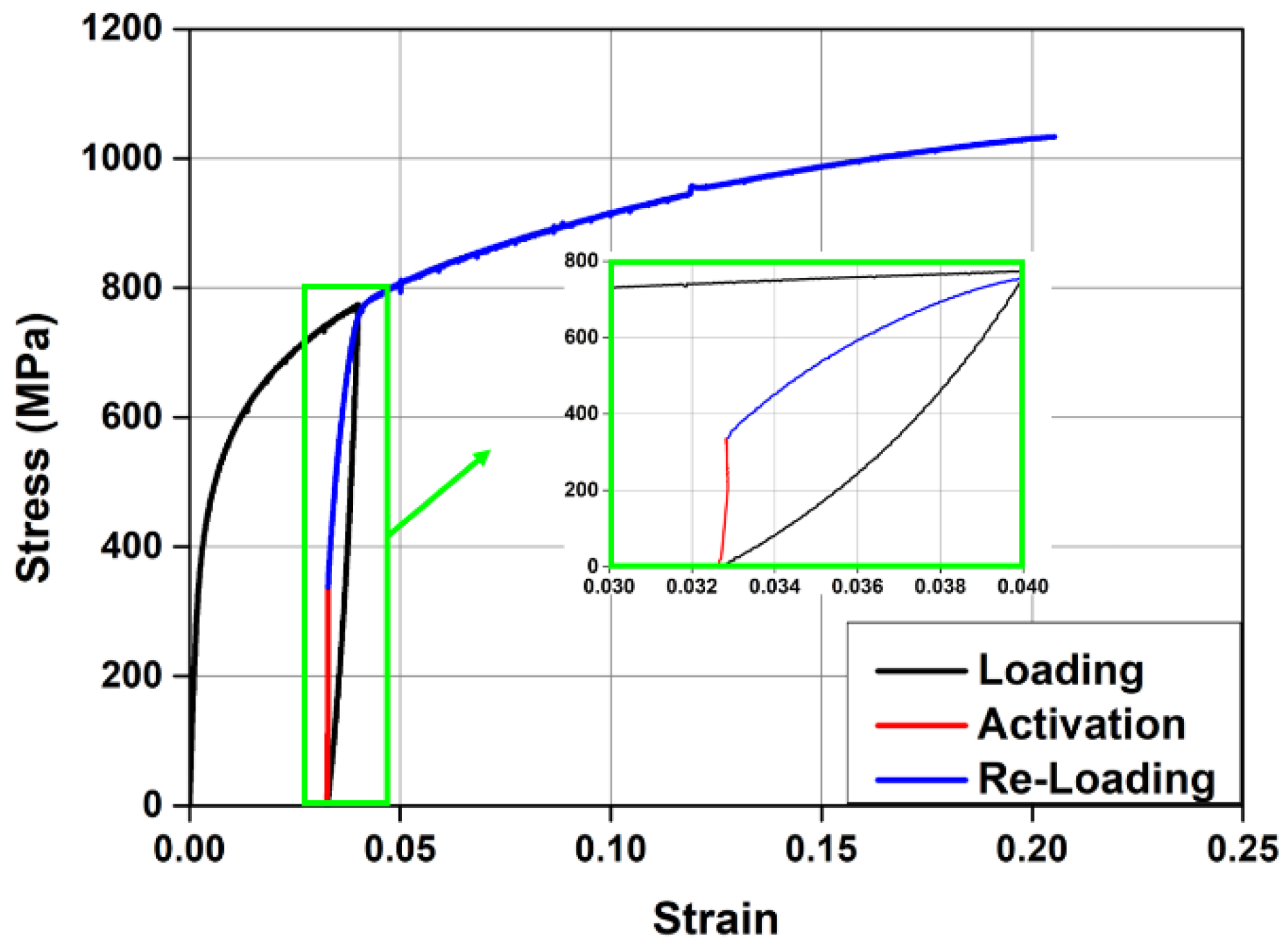

- (1)

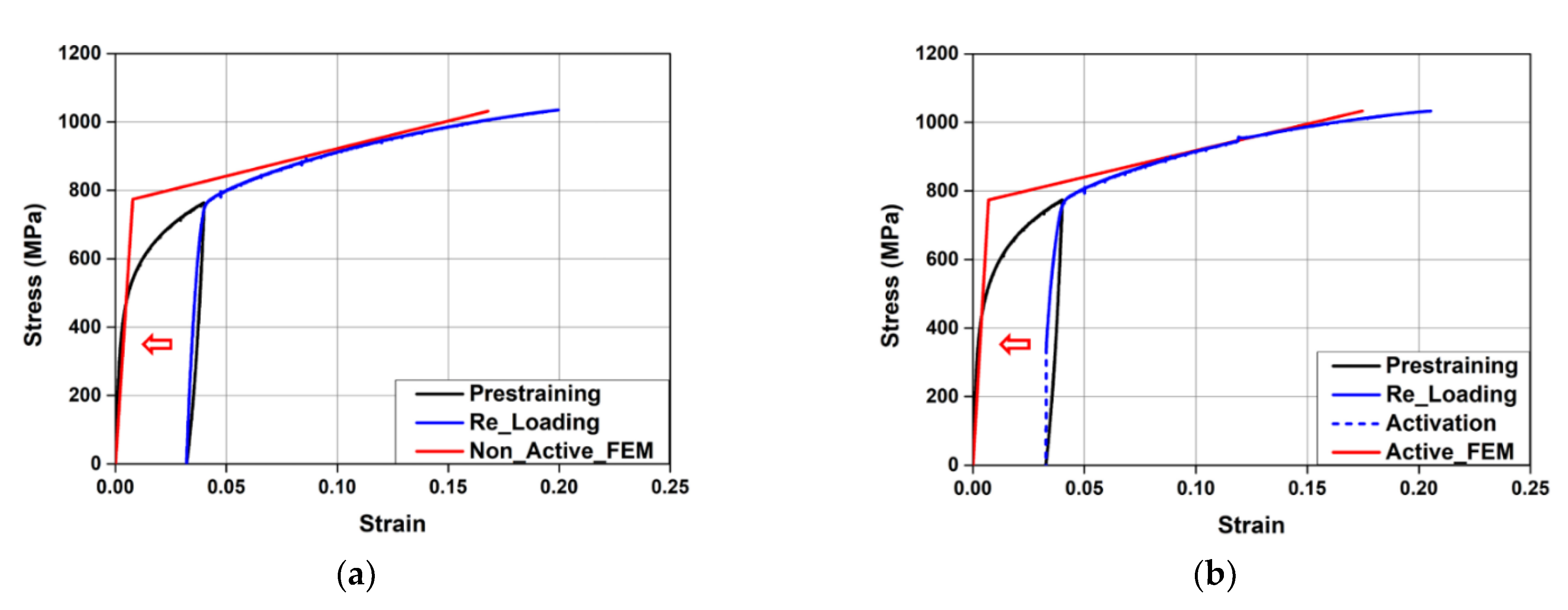

- The test piece placed in the 100 kN UTM was tensioned up to a pre-strain of 0.04 and then unloaded in the same manner as mentioned above (black line in Figure 3);

- (2)

- The test piece with the residual strain generated after unloading was subjected to a pre-stress of approximately 50 MPa to prevent the buckling caused by initial thermal expansion, and then its displacement was restrained;

- (3)

- The test piece with restrained displacement was heated to 160 °C through electrical resistance heating by supplying a current of 2 A/mm2 and then cooled to room temperature (red line in Figure 3);

- (4)

- The test piece cooled to room temperature was tensioned with a displacement control of 0.5 mm/min until it was ruptured (blue line in Figure 3). During the activation of Fe-SMA, the temperature of the test piece was measured by an infrared heat sensor, and the measured data were collected every second by the DAQ.

2.3. Test Setup

3. Experimental Result and Discussion

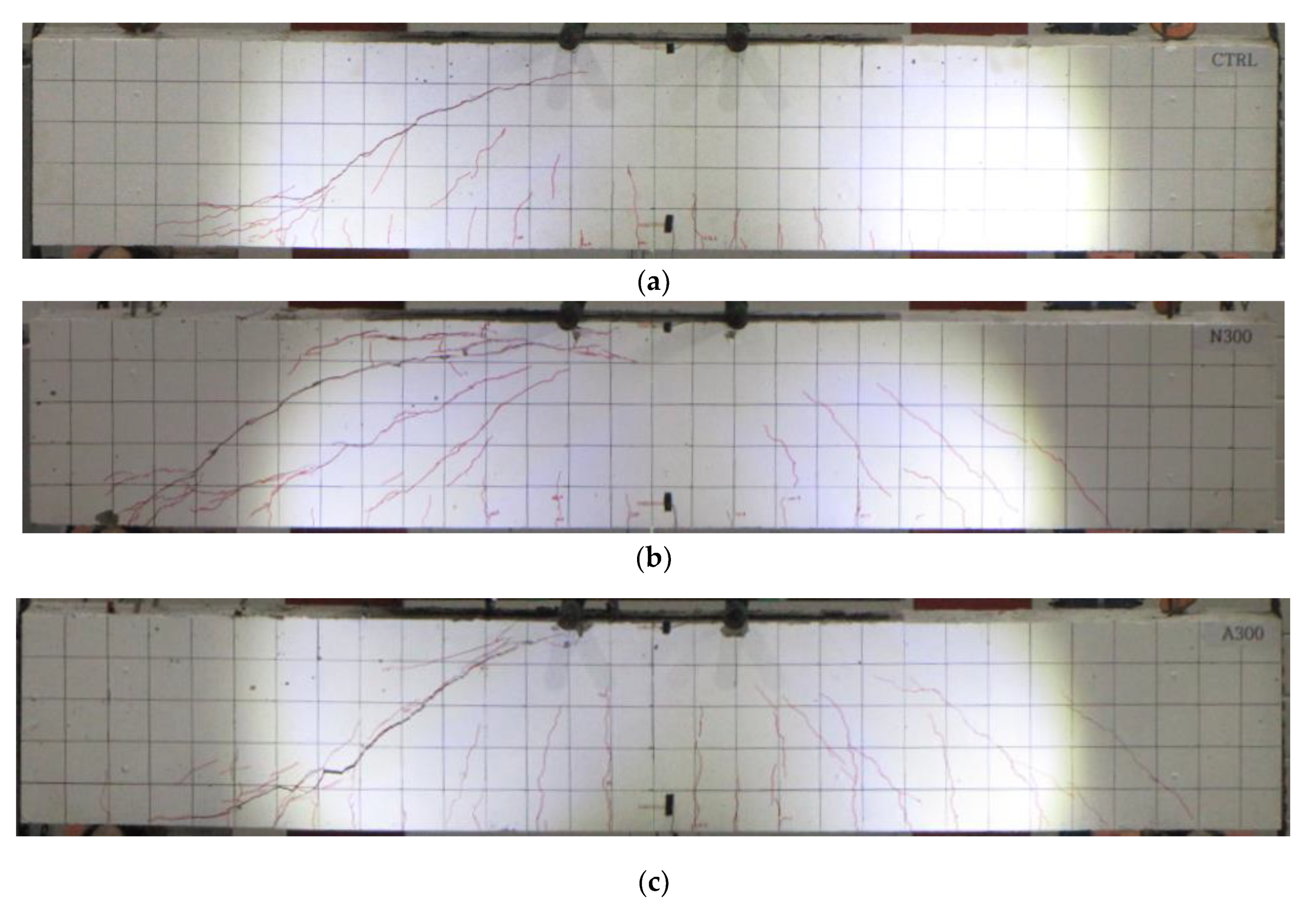

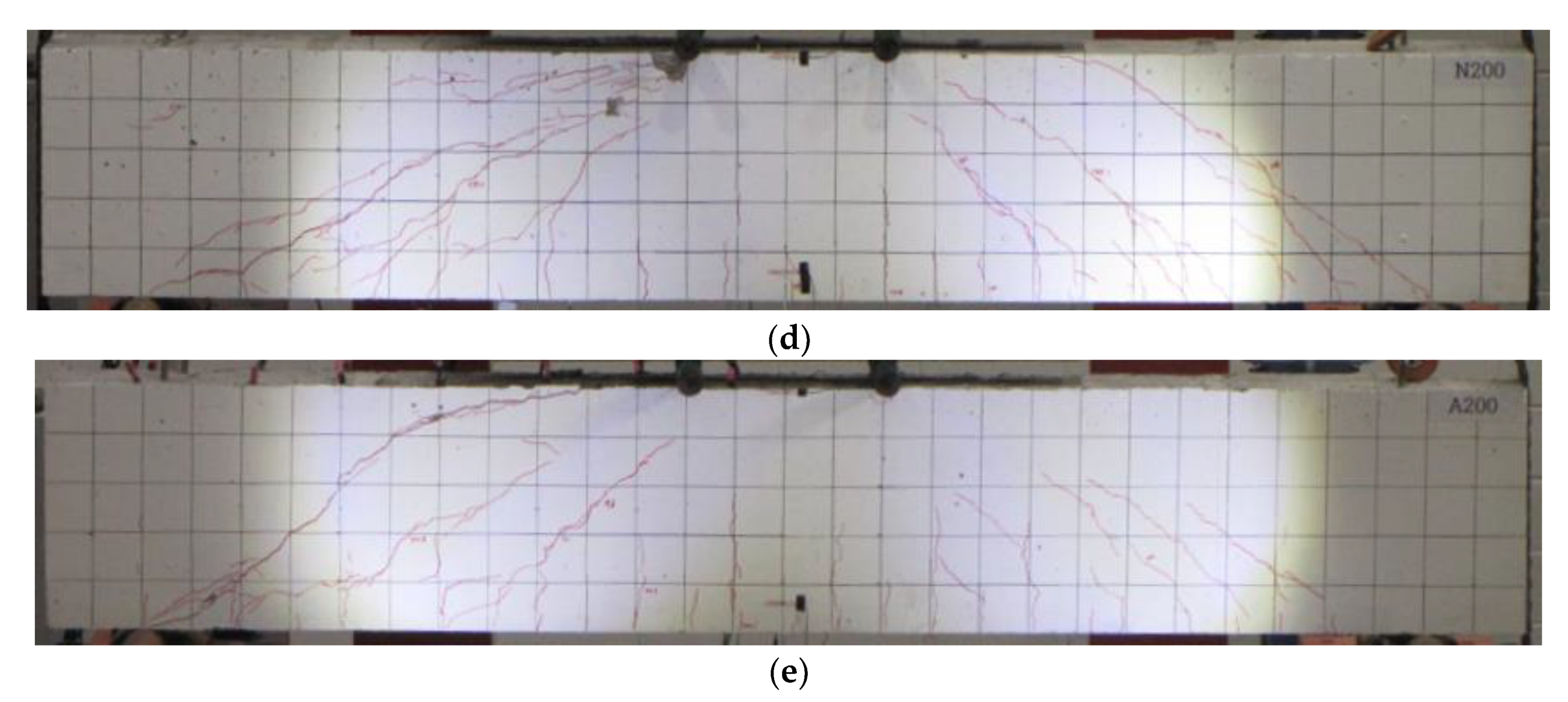

3.1. Failure Mode

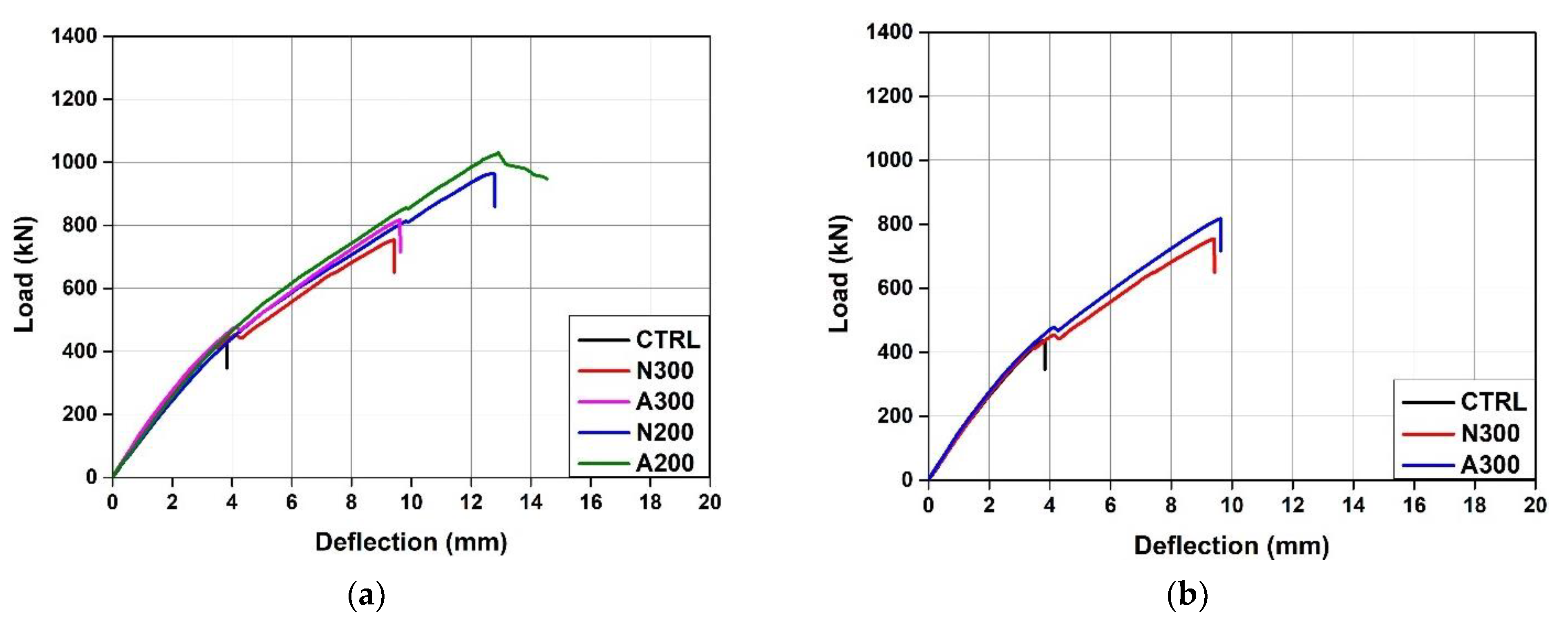

3.2. Load–Deflection Relationship

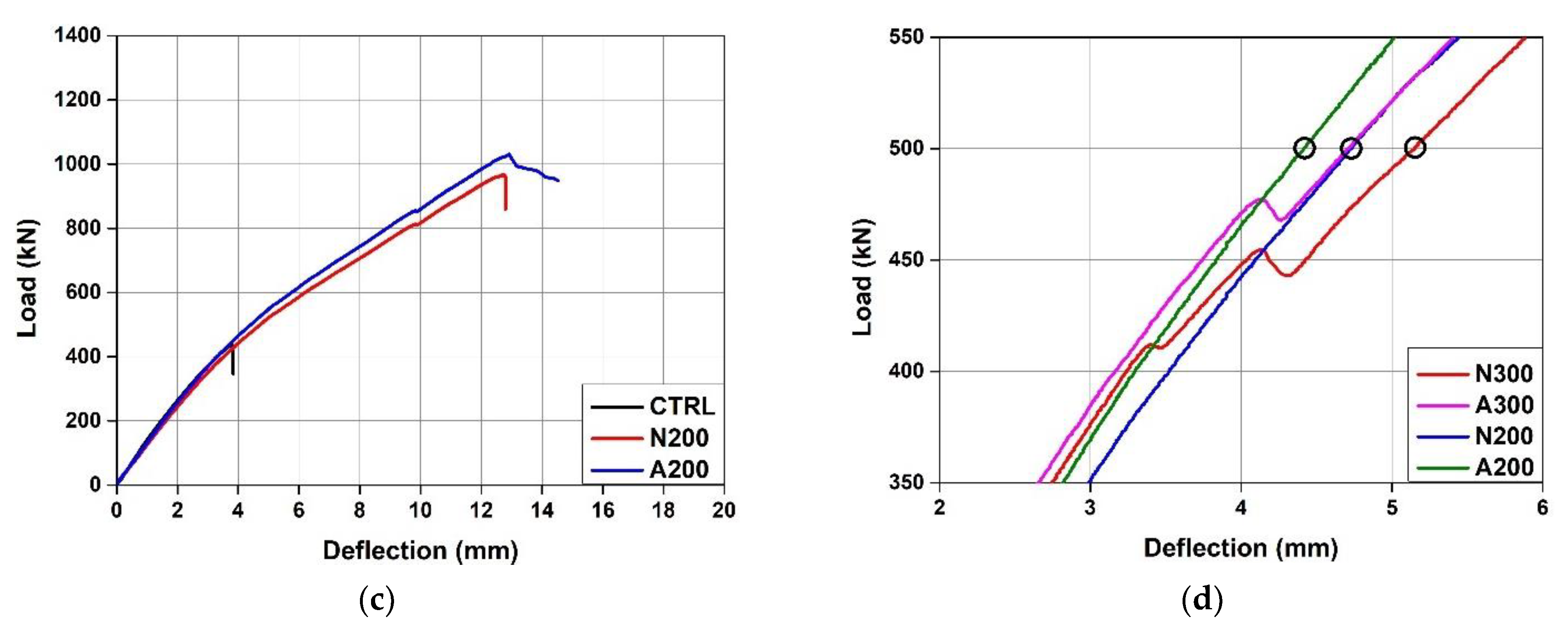

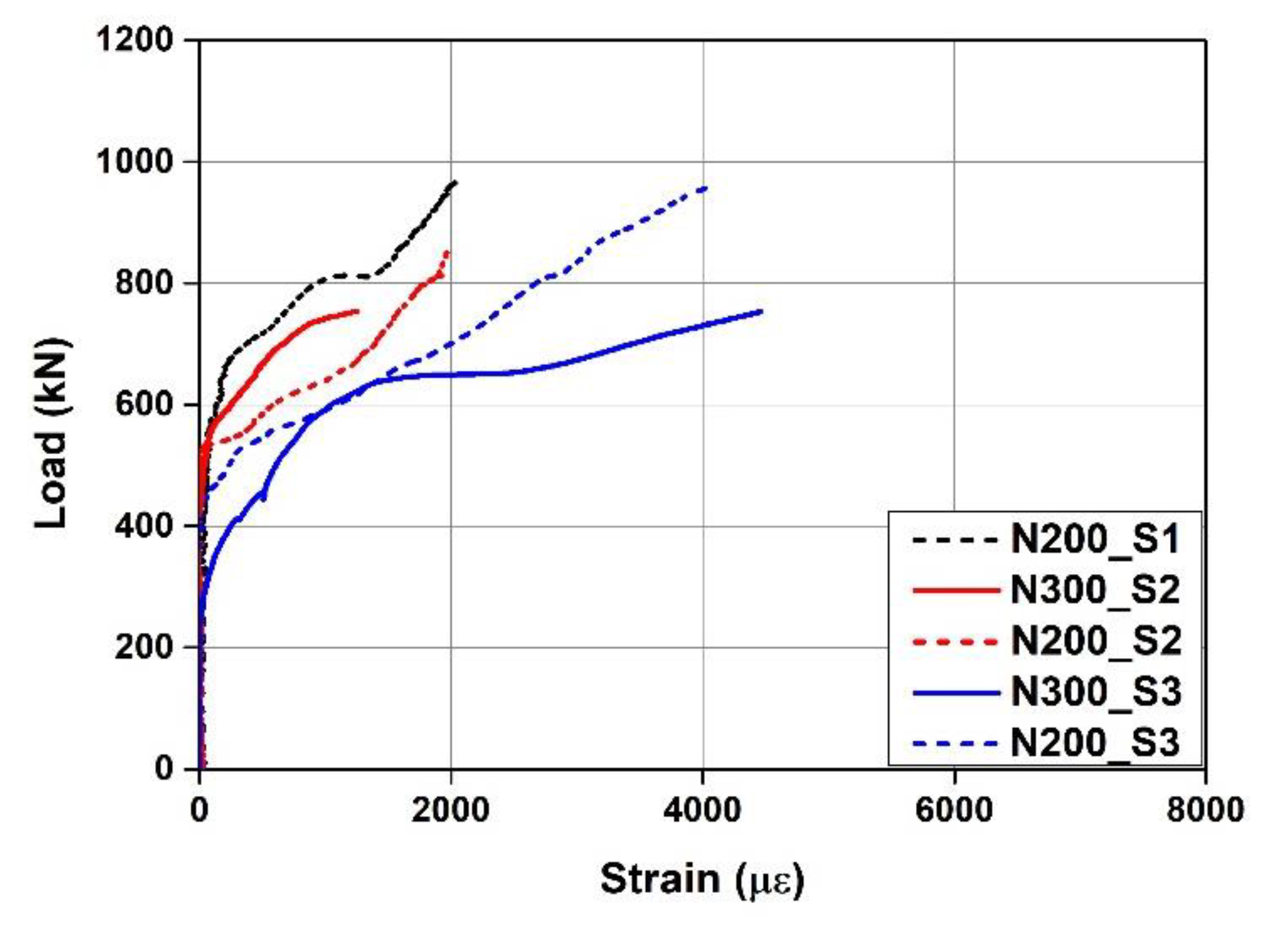

3.3. Load–Strain Relationship

4. Finite Element Simulation

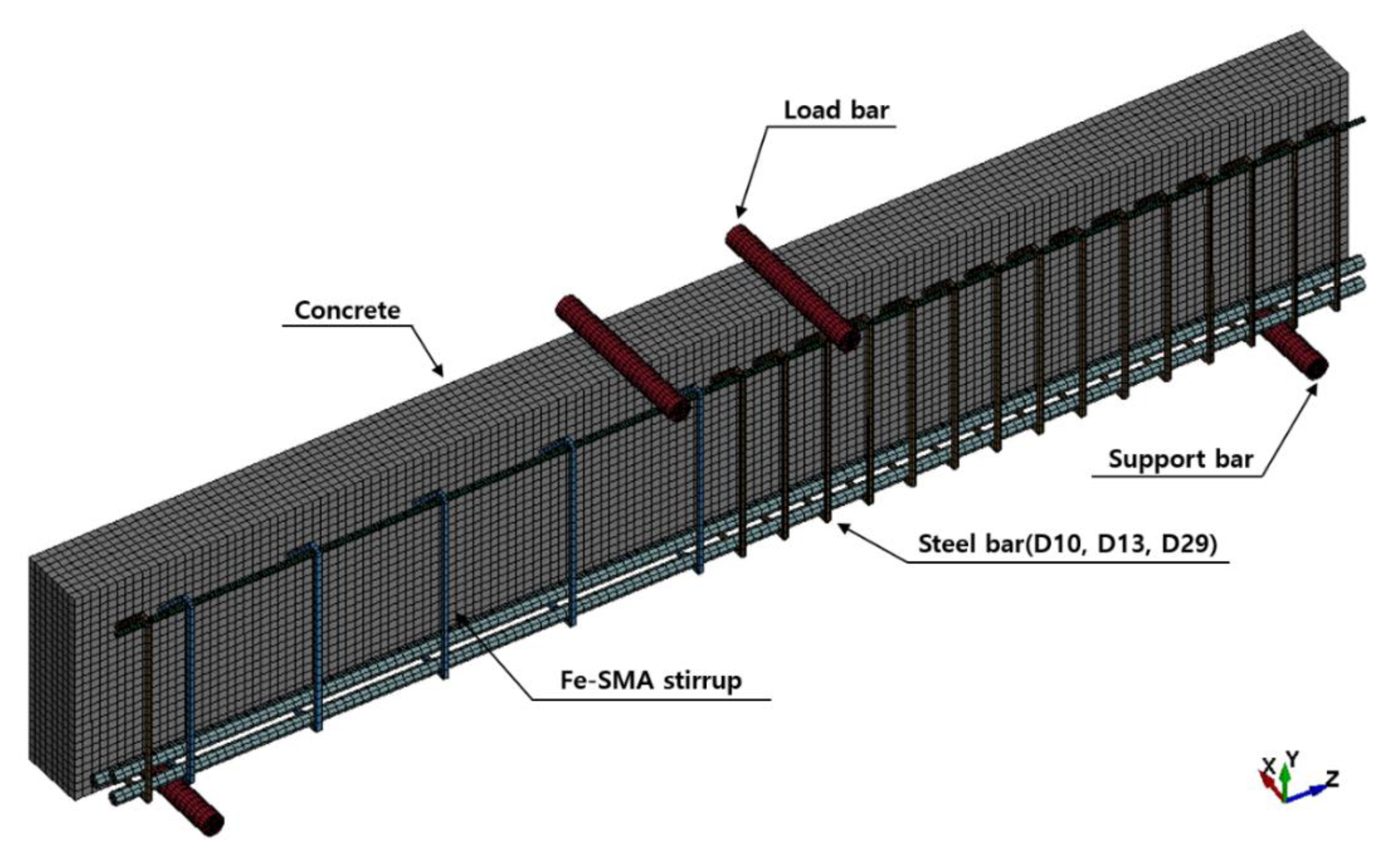

4.1. Finite Element Model

4.2. Material Model

4.3. Comparison of Experimental and Analysis Results

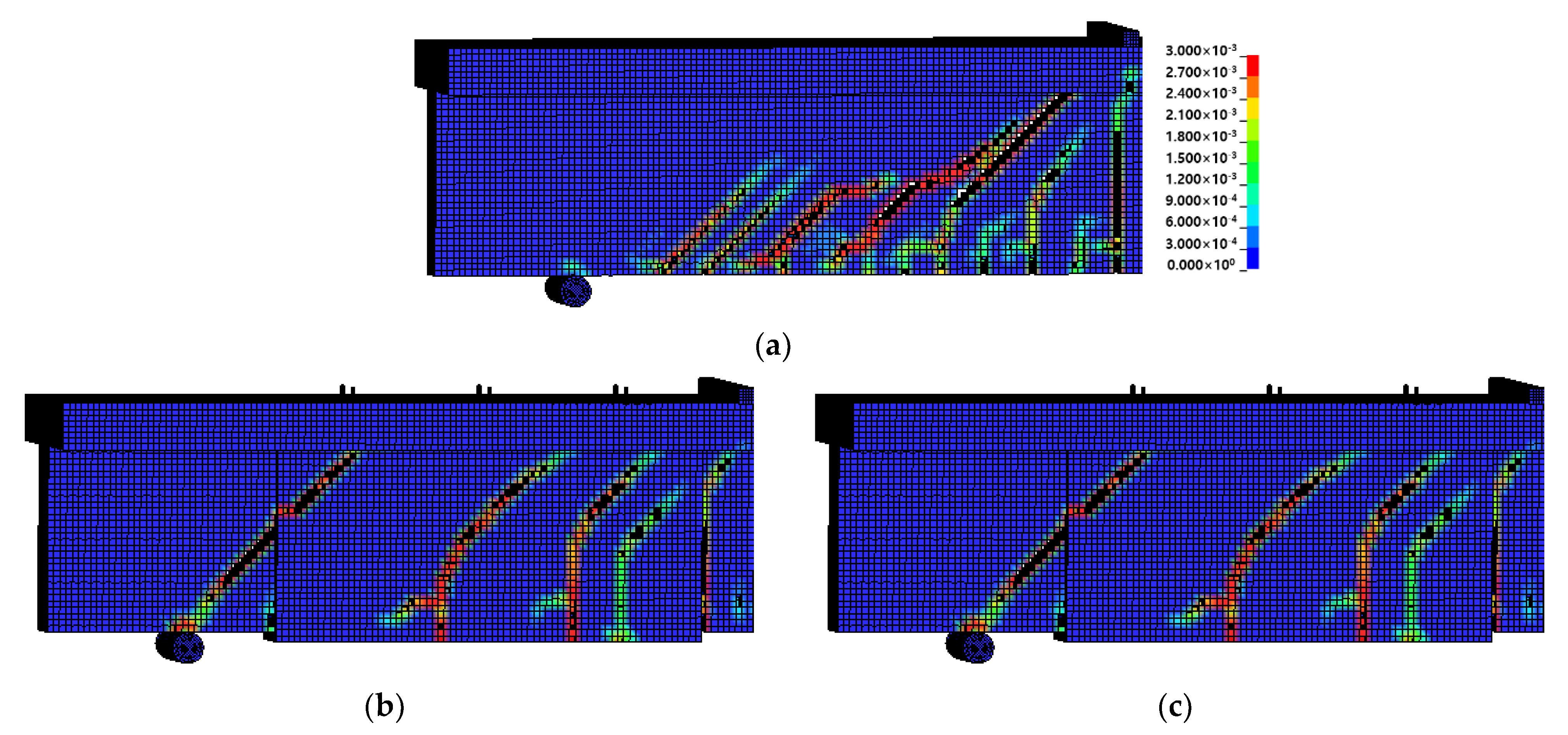

4.3.1. Failure Mode

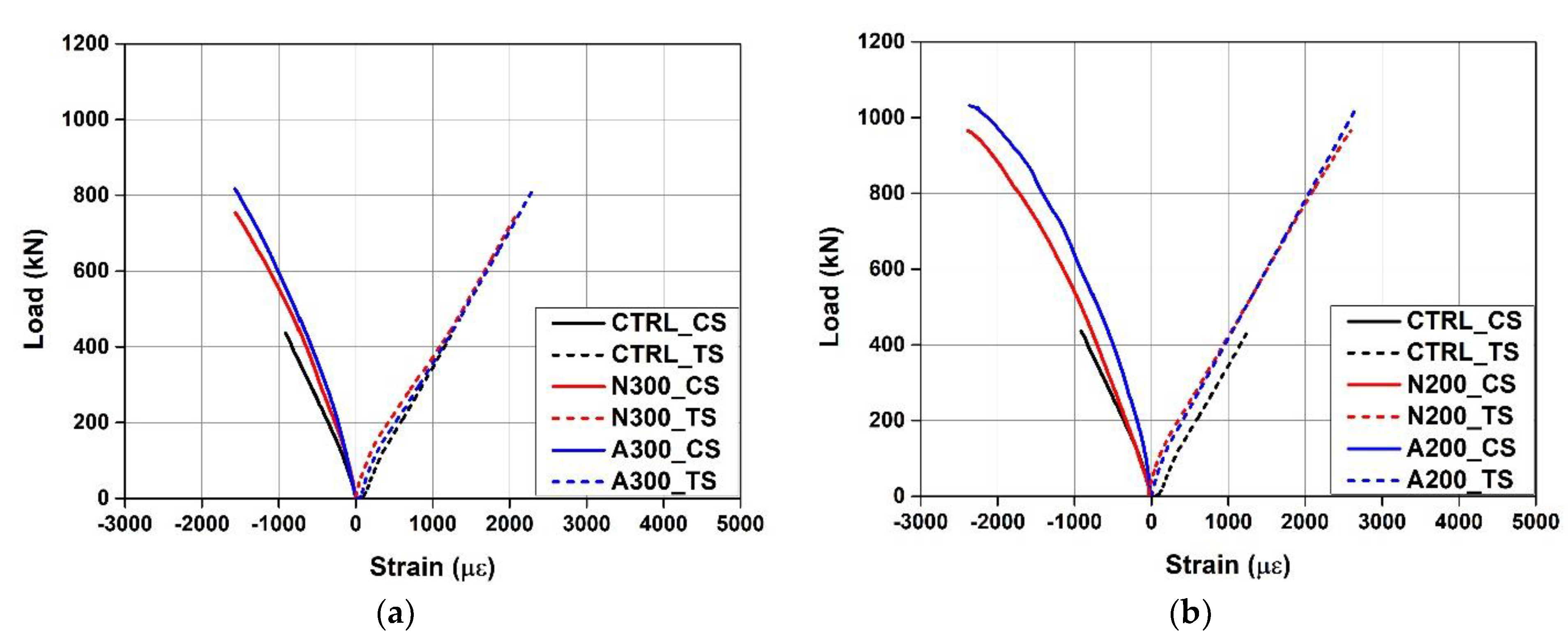

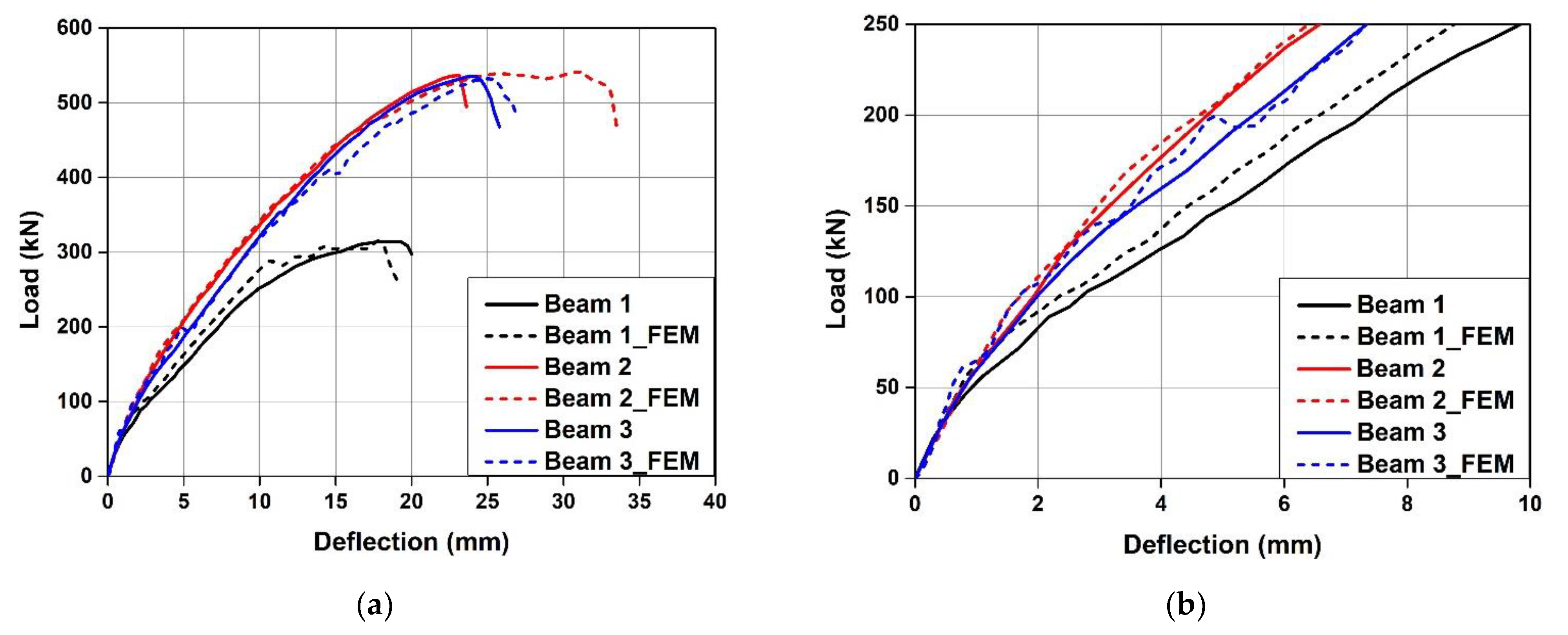

4.3.2. Load–Deflection Relationship

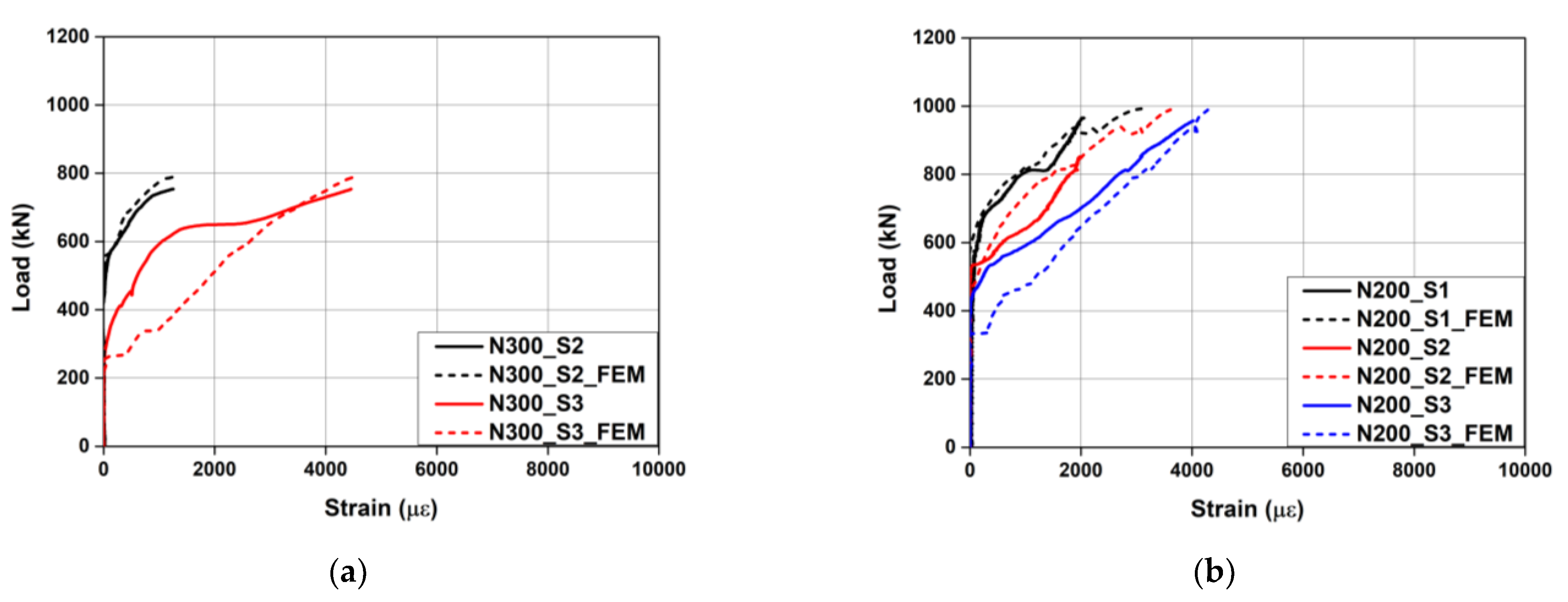

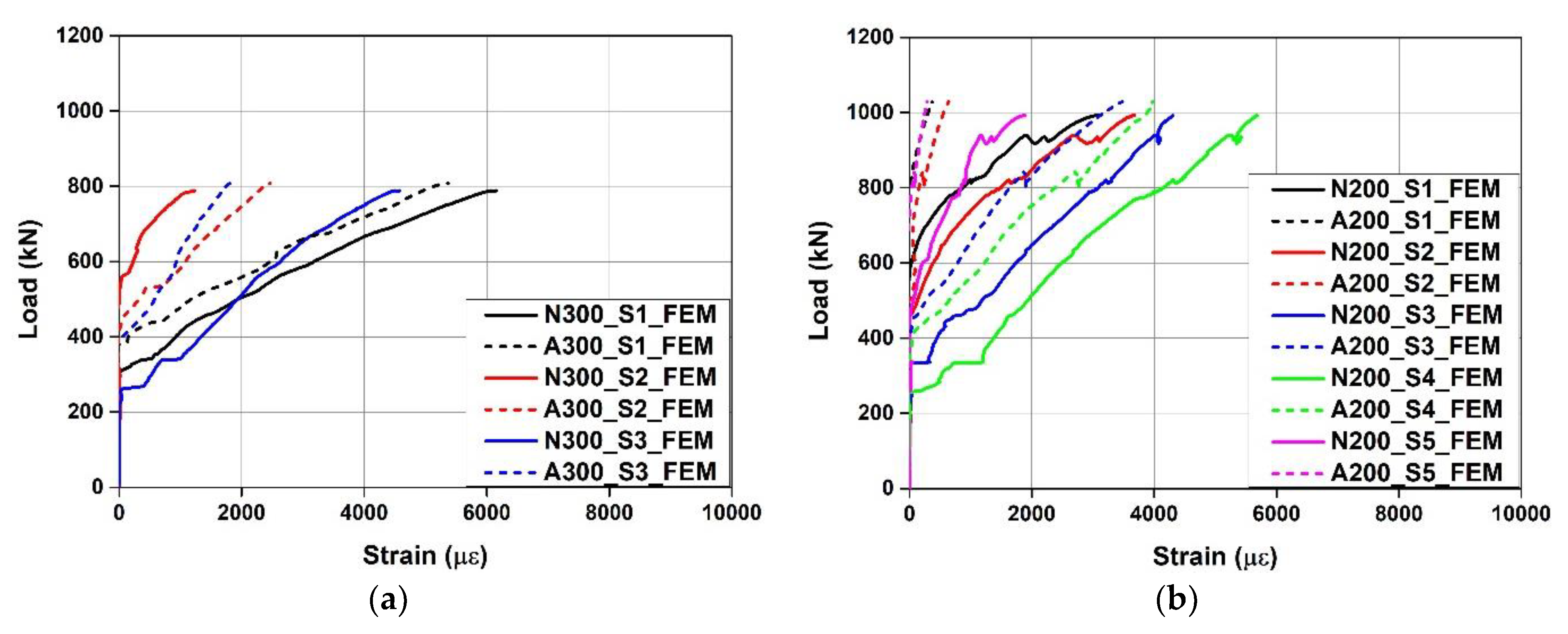

4.3.3. Load–Fe-SMA Stirrup Strain Relationship

4.4. Verification of the Analysis Model

5. Conclusions

- Shear cracking in the RC beam was delayed by Fe-SMA stirrup reinforcement, and it was confirmed that the activation of Fe-SMA reduced the number of shear cracks. Therefore, it is judged that active shear reinforcement using Fe-SMA stirrups is effective in improving the usability of members through crack control.

- Compared to the specimen reinforced with Fe-SMA stirrups at a spacing of 300 mm, the strain of the specimen reinforced at a spacing of 200 mm under a load increased by 52%. A decrease in reinforcement spacing from 300 to 200 mm increased the shear strength of the specimen by 27.1%.

- The activation of the Fe-SMA stirrups increased the shear strength by approximately 7.6%. Therefore, it is judged that the introduction of active confining pressure through Fe-SMA stirrup activation is effective in improving the usability and shear strength of structural members.

- The FE analysis model proposed in this study accurately predicted the failure mode of the RC beam actively confined through Fe-SMA, and the ultimate load of the members as predicted through the analysis differed from the experiment results by less than 5%. Therefore, the proposed FE analysis model can effectively predict the shear performance of RC members constructed with Fe-SMA stirrups.

- The Fe-SMA stirrups used in this study can be constructed in the same manner as conventional shear reinforcement that uses rebar stirrups. The introduction of active confining pressure through Fe-SMA activation is expected to effectively improve the usability and strength of the structure.

- In this study, a limited number of experimental variables such as the Fe-SMA stirrup activation and reinforcement spacing were considered for evaluating the shear performance of concrete beams reinforced with Fe-SMA stirrups. To address the limitations of this study, it is judged that future research that considers more variables such as concrete compressive strength, stirrup cross-sectional area, shear span ratio, heating temperature, and long-term effects should be additionally performed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, S.-W.; Kim, S.-T.; Han, S.-M. Characteristics and application of ultra high performance cementitious composite. Mag. Korea Concr. Inst. Int. 2006, 18, 15–21. [Google Scholar]

- Behbahani, H.; Nematollahi, B. Steel Fiber Reinforced Concrete: A Review. In Proceedings of the International Conference on Structural Engineering Construction and Management (ICSECM2011), Kandy, SriLanka, 15–17 December 2011. [Google Scholar]

- Yang, K.-H.; Chung, H.-S. The influence of minimum shear reinforcement ratio on the shear behavior of reinforced concrete deep beams. J. Arch. Inst. Korea Struct. Constr. 2005, 21, 29–36. [Google Scholar]

- Park, S.-G. Shear Strengthening Effect of Damaged Reinforced Concrete Beams Using Externally Post-Tensioning Steel Rods. Master’s Thesis, Kyungpook National University, Daegu, Korea, 2018. [Google Scholar]

- Ahmed, I.; Manzur, T.; Efaz, H.; Mahmood, T. Experimental Study on Bond Performance of Epoxy Coated Bars and Uncoated Deformed Bars in Concrete; Bangladesh University of Engineering & Technology: Dhaka, Bangladesh, 2017. [Google Scholar]

- Saricimen, H.; Mohammad, M.; Quddus, A.; Shameem, M.; Barry, M.-S. Effectiveness of concrete inhibitors in retarding rebar corrosion. Cement Concr. Compos. 2002, 23, 89–100. [Google Scholar] [CrossRef]

- Nilson, A.H. Design of Prestressed Concrete, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1987; pp. 255–277. [Google Scholar]

- Muttoni, A. Some innovative prestressed concrete structures in Switzerland. In Proceedings of the Keynote Lecture at the 23rd Symposium on Developments in Prestressed Concrete, Japan Prestressed Concrete Institute, Morioka, Japan, 23–24 October 2014. [Google Scholar]

- Colajanni, P.; Recupero, A.; Spinella, N. Increasing the flexural capacity of RC beams using steel angles and pre-tensioned stainless steel ribbons. Struct. Concr. 2016, 17, 848–857. [Google Scholar] [CrossRef]

- Collins, M.P.; Mitchell, D. Prestressed concrete structures. ACI Struct. J. 1991, 18, 517–518. [Google Scholar]

- Ramadan, S.; Gaillet, L.; Tessier, C.; Idrissi, H. Detection of stress corrosion cracking of high-strength steel used in prestressed concrete structures by acoustic emission technique. Appl. Surf. Sci. 2008, 254, 2255–2261. [Google Scholar] [CrossRef]

- Czaderski, C.; Shahverdi, M.; Michels, J. Iron based shape memory alloys as shear reinforcement for bridge girders. Constr. Buil. Mater. 2021, 274, 121793. [Google Scholar] [CrossRef]

- Shirani, M.; Kadkhodaei, M. One dimensional constitutive model with transformation surfaces for phase transition in shape memory alloys considering the effect of loading history. Int. J. Solids Struct. 2015, 81, 117–129. [Google Scholar] [CrossRef]

- Rojob, H.; El-Hacha, R. Self-prestressing using iron-based shape memory alloy for flexural strengthening of reinforced concrete beams. ACI Struct. J. 2017, 114, 523–532. [Google Scholar] [CrossRef]

- Hong, K.-N.; Lee, S.-G.; Yeon, Y.-M.; Jung, K.-S. Flexural response of reinforced concrete beams strengthened with near-surface-mounted Fe-based shape-memory alloy strips. Int. J. Concr. Struct. Mater. 2018, 12, 651–663. [Google Scholar] [CrossRef]

- Branco, M.; Guerreiro, L.; Mahesh, K.K.; Fernandes, B. Effect of load cycling on the phase transformations in Ni-Ti wires for civil engineering applications. Constr. Build. Mater. 2012, 36, 508–519. [Google Scholar] [CrossRef]

- Muntasir Billah, A.H.M.; Shahria Alam, M. Seismic performance of concrete columns reinforced with hybrid shape memory alloy (SMA) and fiber reinforced polymer (FRP) bars. Constr. Build. Mater. 2012, 28, 730–742. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Application of shape memory alloys in civil engineering structures—Overview. limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Dong, Z.; Klotz, U.E.; Leinenbach, C.; Bergamini, A.; Czaderski, C.; Motavalli, M. A novel Fe-Mn-Si shape memory alloy with improved shape recovery properties by VC precipitation. Adv. Eng. Mater. 2009, 11, 40–44. [Google Scholar] [CrossRef]

- Leinenbach, C.; Kramer, H.; Bernhard, C.; Eifler, D. Thermo-Mechanical Properties of an Fe-Mn-Si-Cr-Ni-VC shape memory alloy with low transformation temperature. Adv. Eng Mater. 2012, 14, 62–67. [Google Scholar] [CrossRef]

- Li, K.; Dong, Z.; Liu, Y.; Zhang, L. A nely developed Fe-based shape memory alloy suitable for smart civil engineering. Smart Mater. Struct. 2013, 22, 045002. [Google Scholar] [CrossRef]

- Soroushian, P.; Ostowari, K.; Nossoni, A.; Chowdhury, H. Repair and strengthening of concrete structures through application of corrective posttensioning forces with shape memory alloys. Transp. Res. Rec. J. Transp. Res. Board 2001, 1770, 20–26. [Google Scholar] [CrossRef]

- Montoya-Coronado, L.A.; Ruiz-Pinilla, J.G.; Ribas, C.; Cladera, A. Experimental study on shear strengthening of shear critical RC beams using iron-based shape memory alloy strips. Eng. Struct. 2019, 200, 109680. [Google Scholar] [CrossRef]

- Ruiz-Pinilla, J.G.; Montoya-Coronado, L.A.; Ribas, C.; Cladera, A. Finite element modeling of RC beams externally strengthened with iron-based shape memory alloy (Fe-SMA) strips, including analytical stress-strain curves for Fe-SMA. Eng. Struct. 2020, 223, 11152. [Google Scholar] [CrossRef]

- ASTM C39/C39M-17; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- Hallquist, J.-O. LS-DYNA: Keyword User’s Manual Volume I; LS-DYNA R11; Livermore Software Technology Corporation: Livermore, CA, USA, 2017. [Google Scholar]

- Jiang, H.; Zhao, J. Calibration of the continuous surface cap model for concrete. Finite Elem. Anal. Des. 2015, 97, 1–19. [Google Scholar] [CrossRef]

- Husain, M.; Yu, J.; Wu, J. Comparisons of different approaches of modelling prestress in concrete members using LS-DYNA and Its applications. In Concrete—Innovations in Materials, Design and Structures; The International Federation for Structural Concrete: Krakow, Poland, 2019; pp. 812–819. [Google Scholar]

- Johansson, A.; Fredberg, J. Structural Behaviour of Prestressed Concrete Beams During Impact Loading. Evaluation of Concrete Maaterial Models and Modelling of Prestressed Concrete in LS-DYNA. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015. [Google Scholar]

| Specimen | Shear Reinforcement | Spacing (mm) | Activation |

|---|---|---|---|

| CTRL | - | - | - |

| N300 | Fe-SMA stirrup | 300 | Non-Activation |

| A300 | Activation | ||

| N200 | 200 | Non-Activation | |

| A200 | Activation |

| Standard | Nominal Diameter (mm) | Young’s Modulus (GPa) | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| D10 | 9.53 | 200 | 451 | 567 | 16.0 |

| D13 | 12.7 | 200 | 462 | 540 | 17.1 |

| D29 | 28.6 | 200 | 480 | 580 | 14.0 |

| Specimen | Cracking Load (kN) | Ultimate | Shear Strength | Deflection at 500 kN (mm) | ||

|---|---|---|---|---|---|---|

| Load (kN) | Deflection (mm) | VTotal (kN) | VFe-SMA (kN) | |||

| CTRL | 144.16 | 437.08 | 3.8 | 218.54 | - | - |

| N300 | 135.8 | 754 | 9.42 | 377 | 158.46 | 5.14 (100%) |

| A300 | 129.62 | 817.34 | 9.62 | 408.67 | 190.13 | 4.71 (91.6%) |

| N200 | 136.78 | 965.32 | 12.75 | 482.62 | 264.08 | 4.73 (92.0%) |

| A200 | 154.24 | 1031.28 | 12.91 | 515.64 | 297.1 | 4.41 (85.8%) |

| Concrete | ||||||

| Material model | MAT_SCHWER_MURRAY_CAP | |||||

| Density (kg/m3) | 2400 | |||||

| Compressive strength (MPa) | 46.2 | |||||

| Max. aggregate size (mm) | 25 | |||||

| Parameter | α | θ | β | γ | ||

| 13.373 | 0.33 | 0.025 | 6.89 | |||

| X | D1 | D2 | S | |||

| 104.12 | 6.11 × 10−4 | 2.225 × 10−6 | 2.0357 | |||

| Steel bars | ||||||

| Dimension | D10 | D13 | D29 | |||

| Material model | MAT_PIECEWISE_LINEAR_PLASTICITY | |||||

| Density (kg/m3) | 7850 | |||||

| Young’s modulus (MPa) | 200,000 | |||||

| Poisson’s ratio | 0.3 | |||||

| Yield strength (MPa) | 451 | 462 | 480 | |||

| Tangent modulus | 735 | 465 | 726 | |||

| Failure strain | 0.16 | 0.171 | 0.14 | |||

| Support and load rod | ||||||

| Material model | MAT_RIGID | |||||

| Density (kg/m3) | 7850 | |||||

| Young’s modulus (MPa) | 200,000 | |||||

| Poisson’s ratio | 0.3 | |||||

| Fe-SMA stirrup | ||||||

| Non-Activation | Activation | |||||

| Material model | MAT_ELASTIC_PLASTIC_THERMAL | |||||

| Density (kg/m3) | 7850 | |||||

| Young’s modulus (MPa) | 98,684 | 111,642 | ||||

| Poisson’s ratio | 0.3 | |||||

| Yield strength (MPa) | 770 | |||||

| Tangent modulus | 1036 | |||||

| Failure strain | 0.17 | |||||

| Coefficient of thermal | −21.4 × 10−6 | |||||

| Specimen | Ultimate Load | Deflection at Ultimate Load | Deflection at 500 kN | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EXP (kN) | FEM (kN) | EXP/ FEM | EXP (mm) | FEM (mm) | EXP/ FEM | EXP (mm) | FEM (mm) | EXP/ FEM | |

| CTRL | 437.08 | 436.01 | 1.002 | 3.8 | 4.10 | 0.93 | - | - | - |

| N300 | 754 | 788.63 | 0.96 | 9.42 | 9.23 | 1.02 | 5.14 | 4.49 | 1.14 |

| A300 | 817.34 | 808.13 | 1.01 | 9.62 | 8.28 | 1.16 | 4.71 | 3.94 | 1.20 |

| N200 | 965.32 | 992.49 | 0.97 | 12.75 | 15.58 | 0.82 | 4.73 | 3.97 | 1.19 |

| A200 | 1031.28 | 1028.27 | 1.003 | 12.91 | 12.70 | 1.02 | 4.41 | 3.86 | 1.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, S.-W.; Yeon, Y.-M.; Hong, K.-N. Shear Performance of RC Beams Reinforced with Fe-Based Shape Memory Alloy Stirrups. Materials 2022, 15, 1703. https://doi.org/10.3390/ma15051703

Ji S-W, Yeon Y-M, Hong K-N. Shear Performance of RC Beams Reinforced with Fe-Based Shape Memory Alloy Stirrups. Materials. 2022; 15(5):1703. https://doi.org/10.3390/ma15051703

Chicago/Turabian StyleJi, Sang-Won, Yeong-Mo Yeon, and Ki-Nam Hong. 2022. "Shear Performance of RC Beams Reinforced with Fe-Based Shape Memory Alloy Stirrups" Materials 15, no. 5: 1703. https://doi.org/10.3390/ma15051703

APA StyleJi, S.-W., Yeon, Y.-M., & Hong, K.-N. (2022). Shear Performance of RC Beams Reinforced with Fe-Based Shape Memory Alloy Stirrups. Materials, 15(5), 1703. https://doi.org/10.3390/ma15051703