Influence of the Chloride Attack on the Post-Cracking Behavior of Recycled Steel Fiber Reinforced Concrete

Abstract

1. Introduction

2. Experimental Program

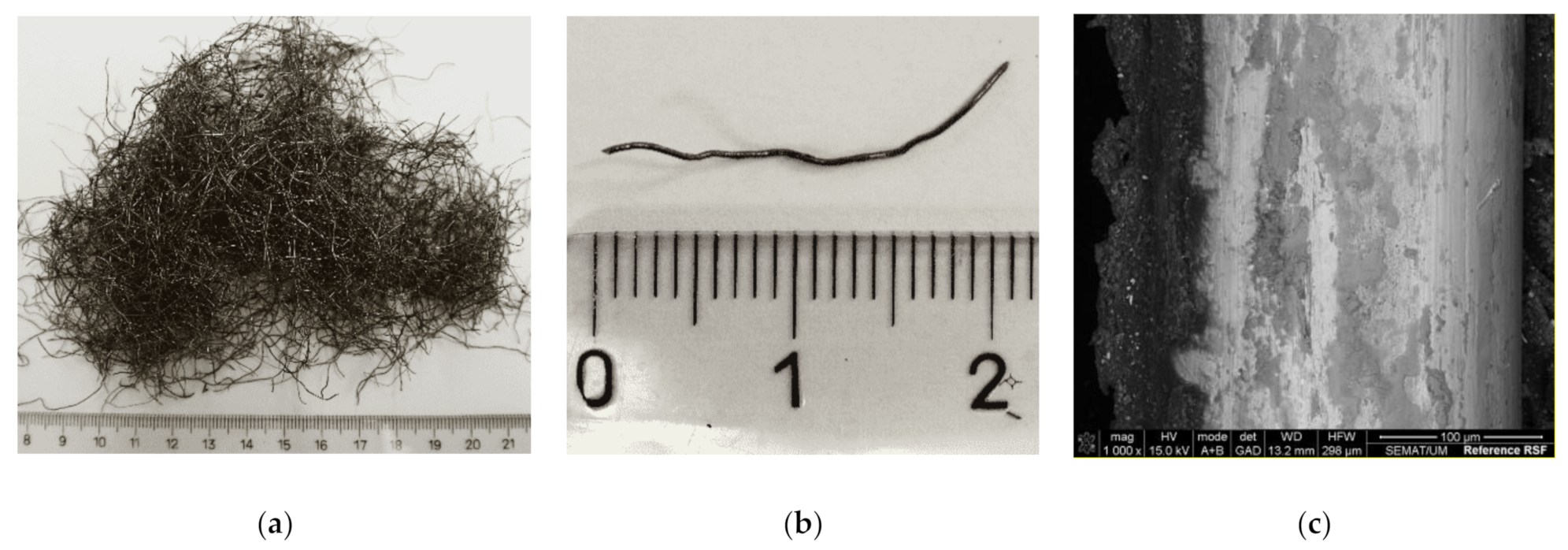

2.1. Materials and Mix Composition

2.2. Specimens Manufacture

2.3. Test Procedures

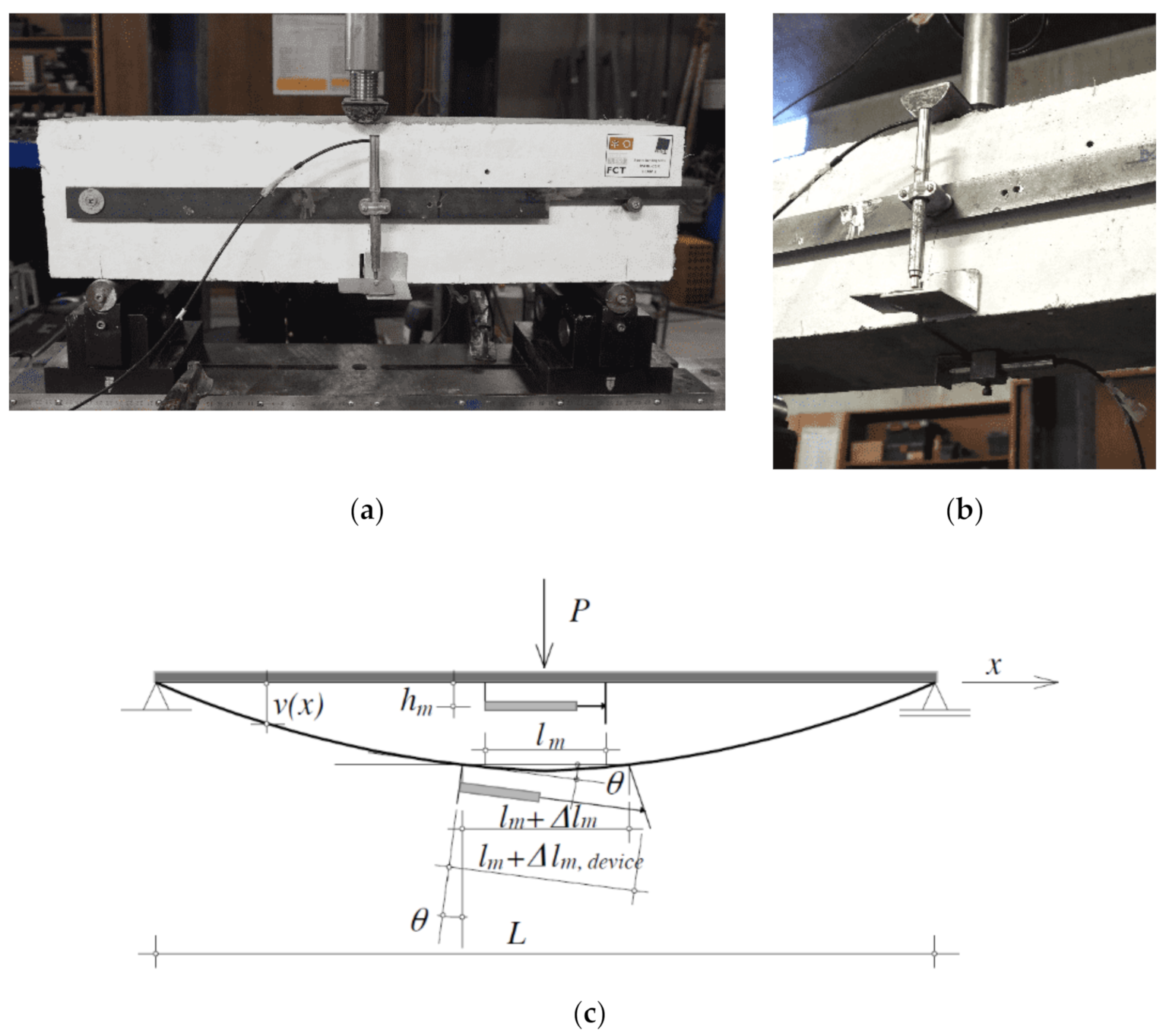

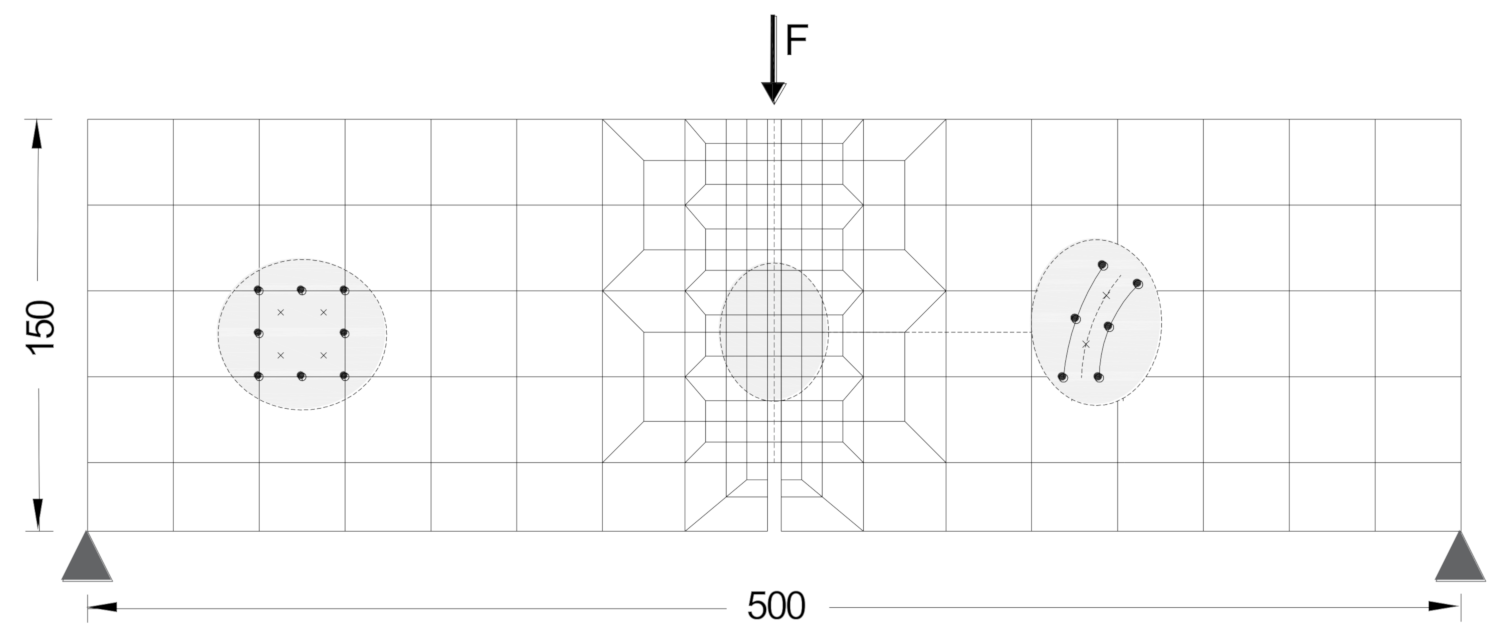

2.3.1. Mechanical Characterization of RSFRC

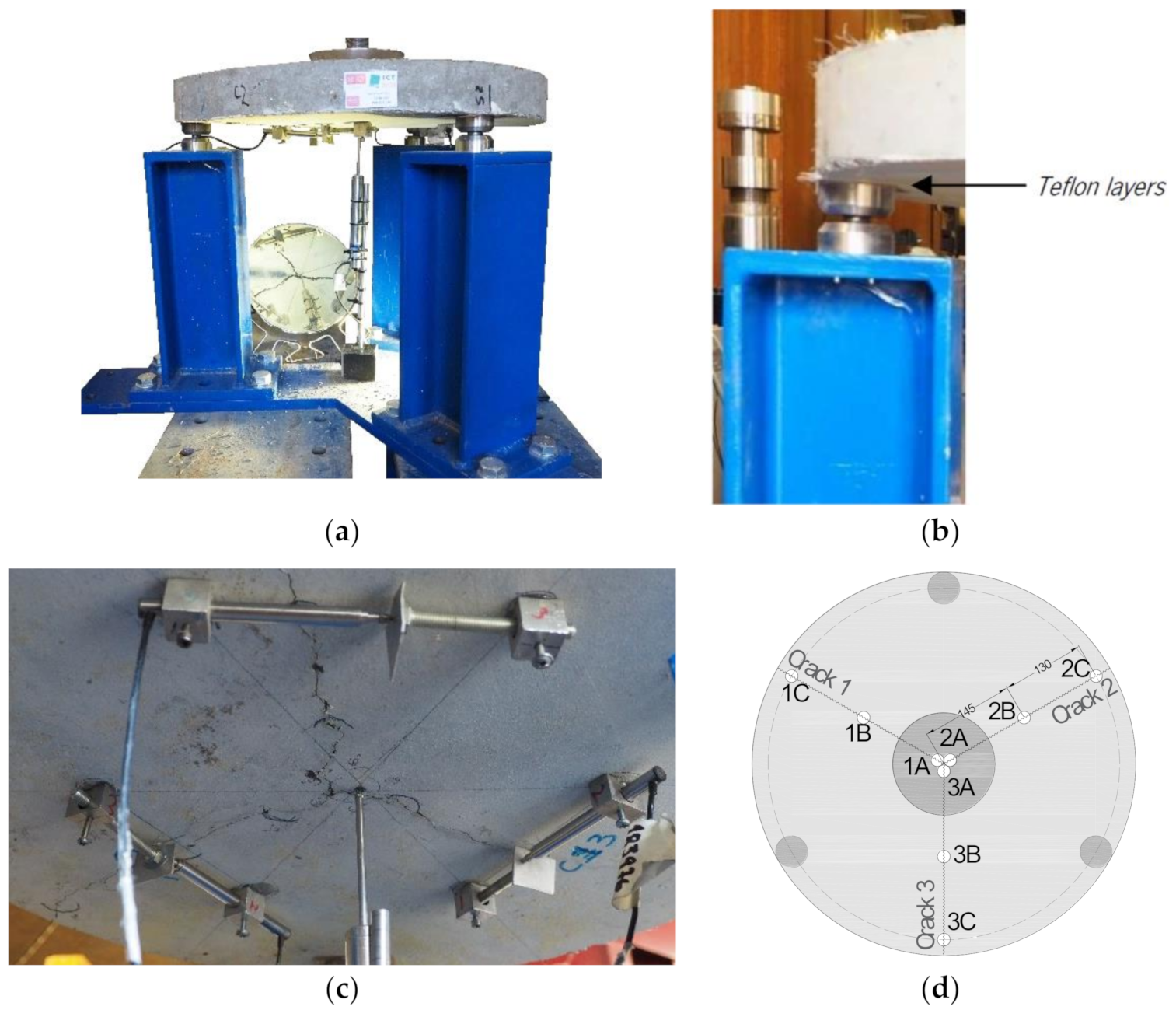

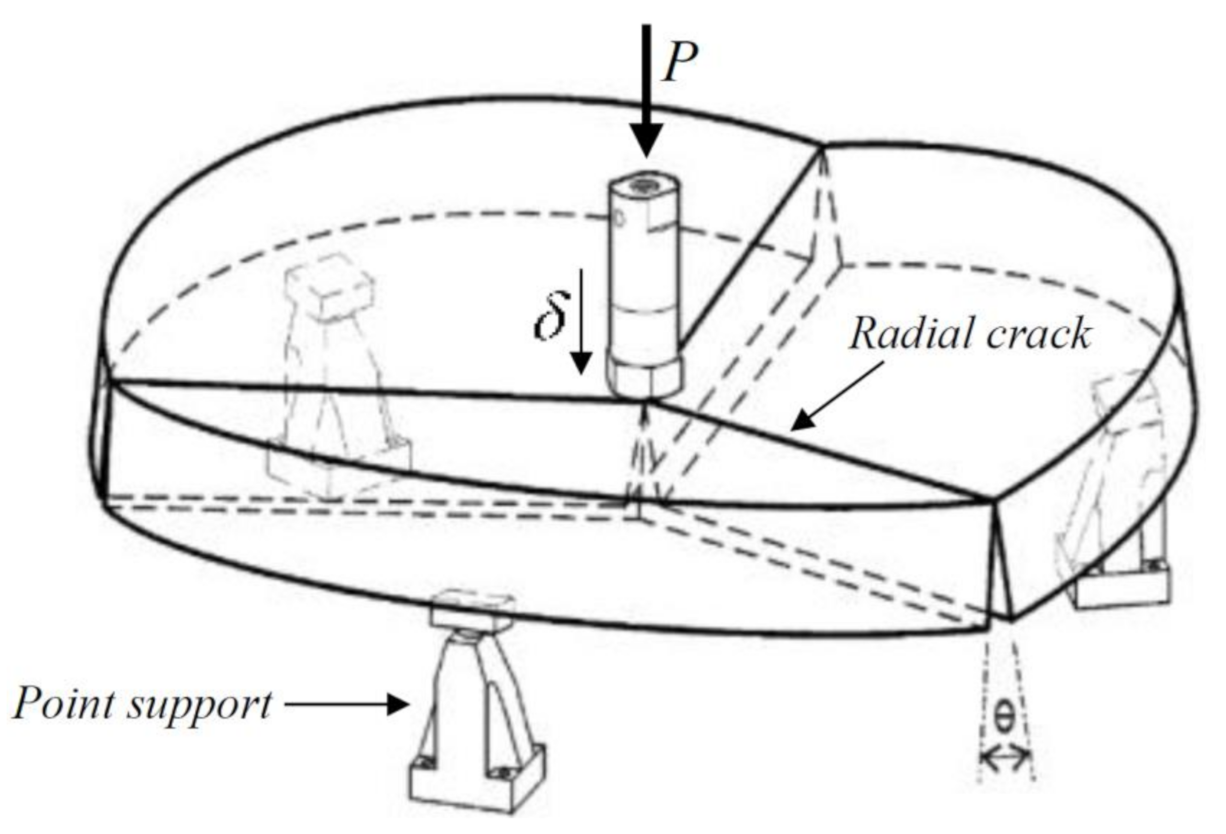

2.3.2. Round Panel Tests

2.3.2.1. Test Setup

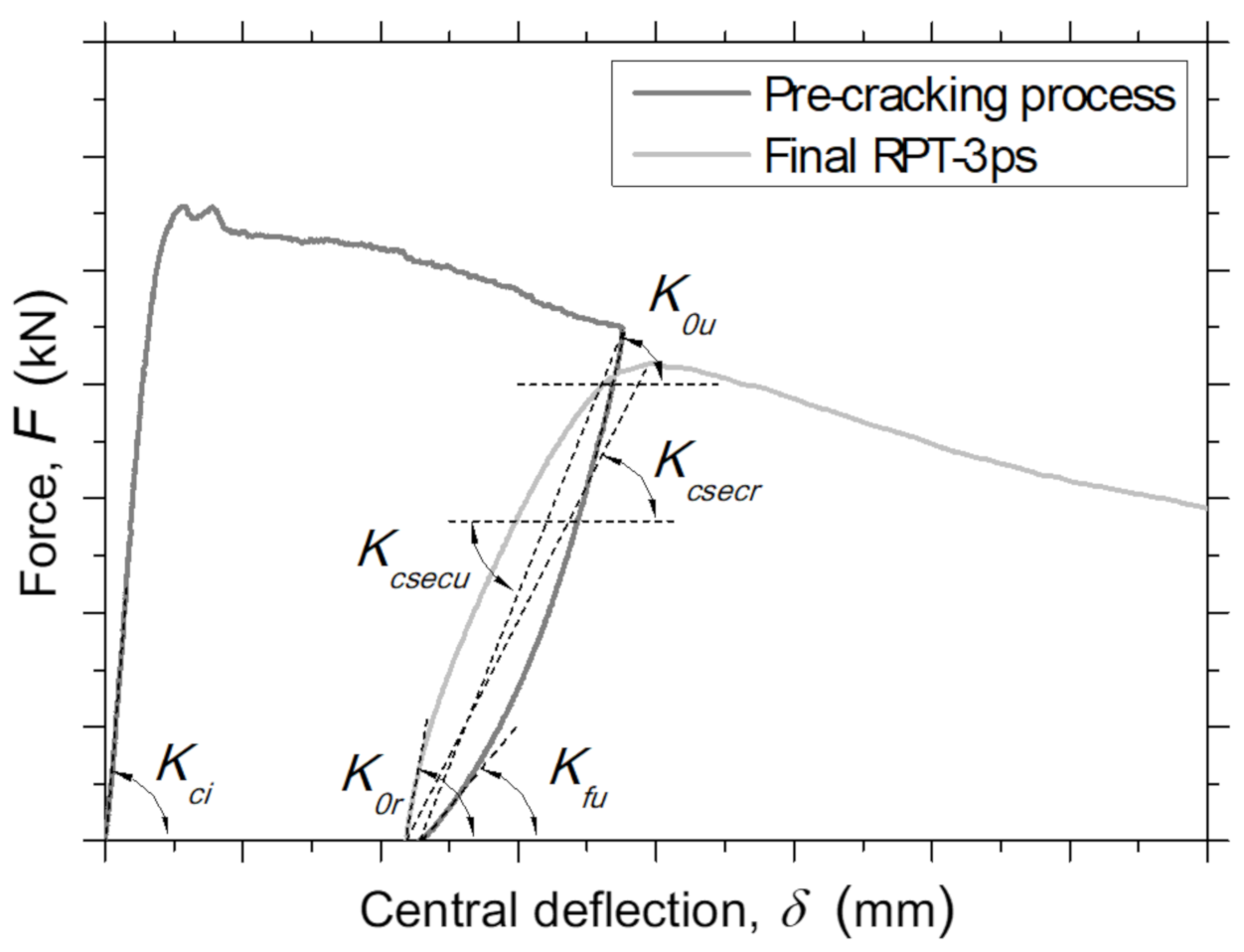

2.3.2.2. Pre-Cracking Process

2.3.2.3. Environmental Exposure

2.3.2.4. Fiber Distribution/Orientation

3. Results and Discussion

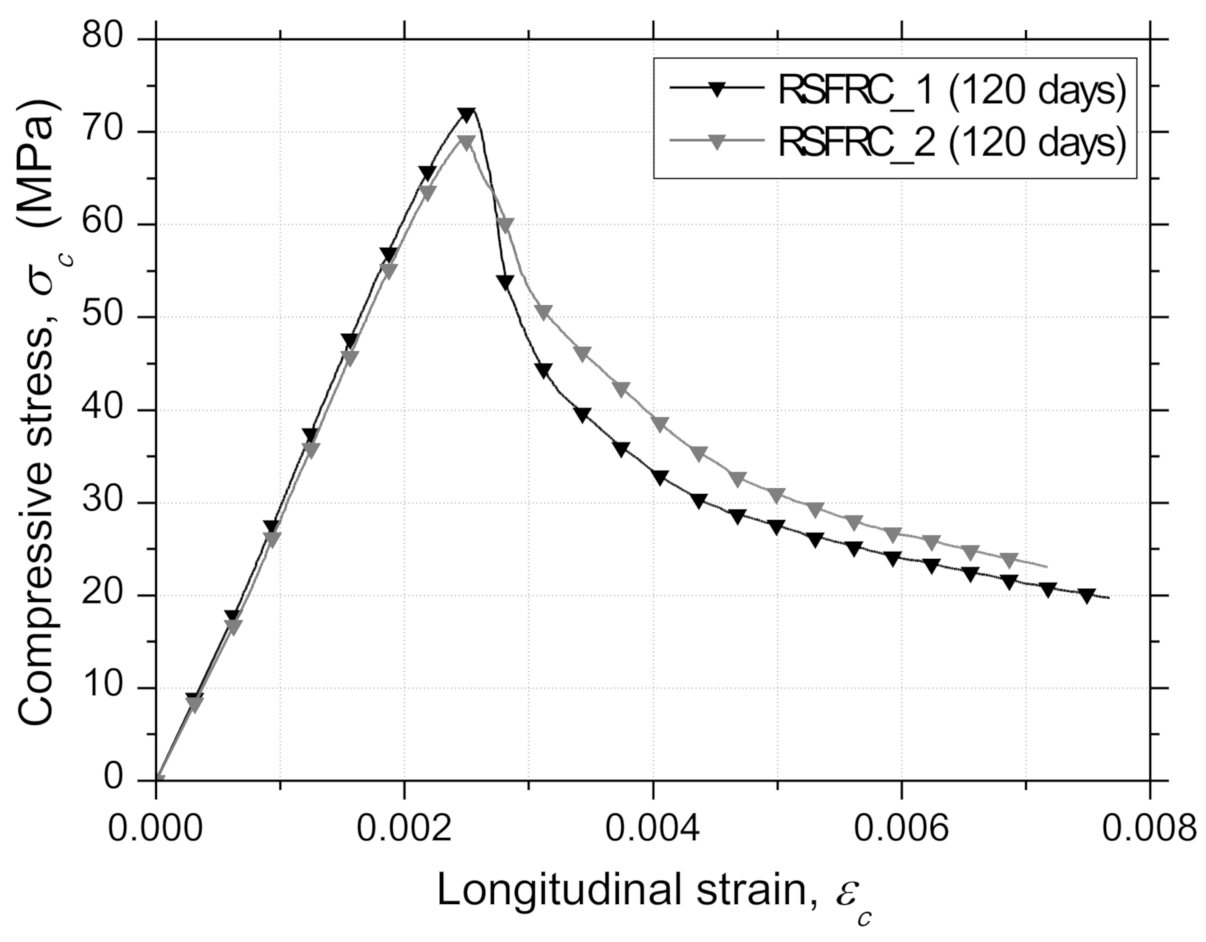

3.1. Compressive Behavior of RSFRC

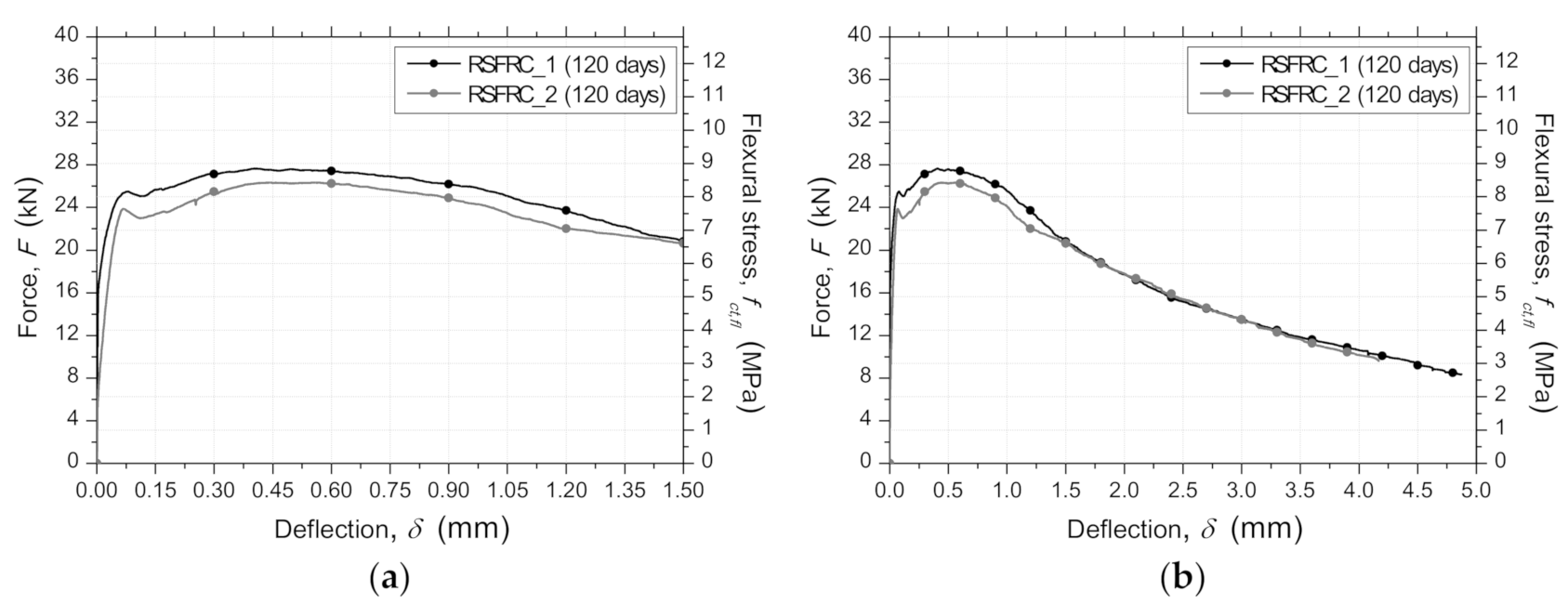

3.2. Flexural Behavior of RSFRC

3.3. Round Panel Tests under Chloride Attack

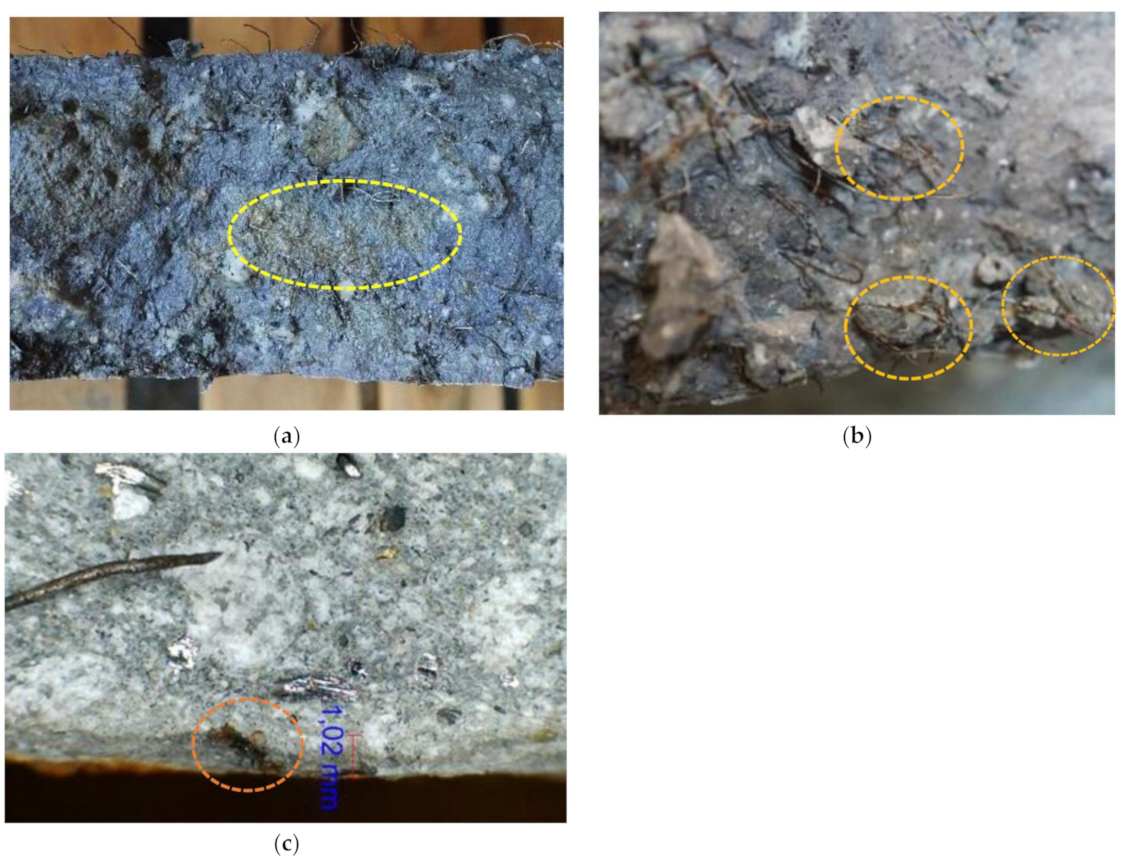

3.3.1. Chloride Penetration into RSFRC Panels

3.3.2. Evaluation of Crack Width Measurements

3.3.3. Force–Central Deflection Relationship

3.3.4. Energy Absorption–Central Deflection Relationships

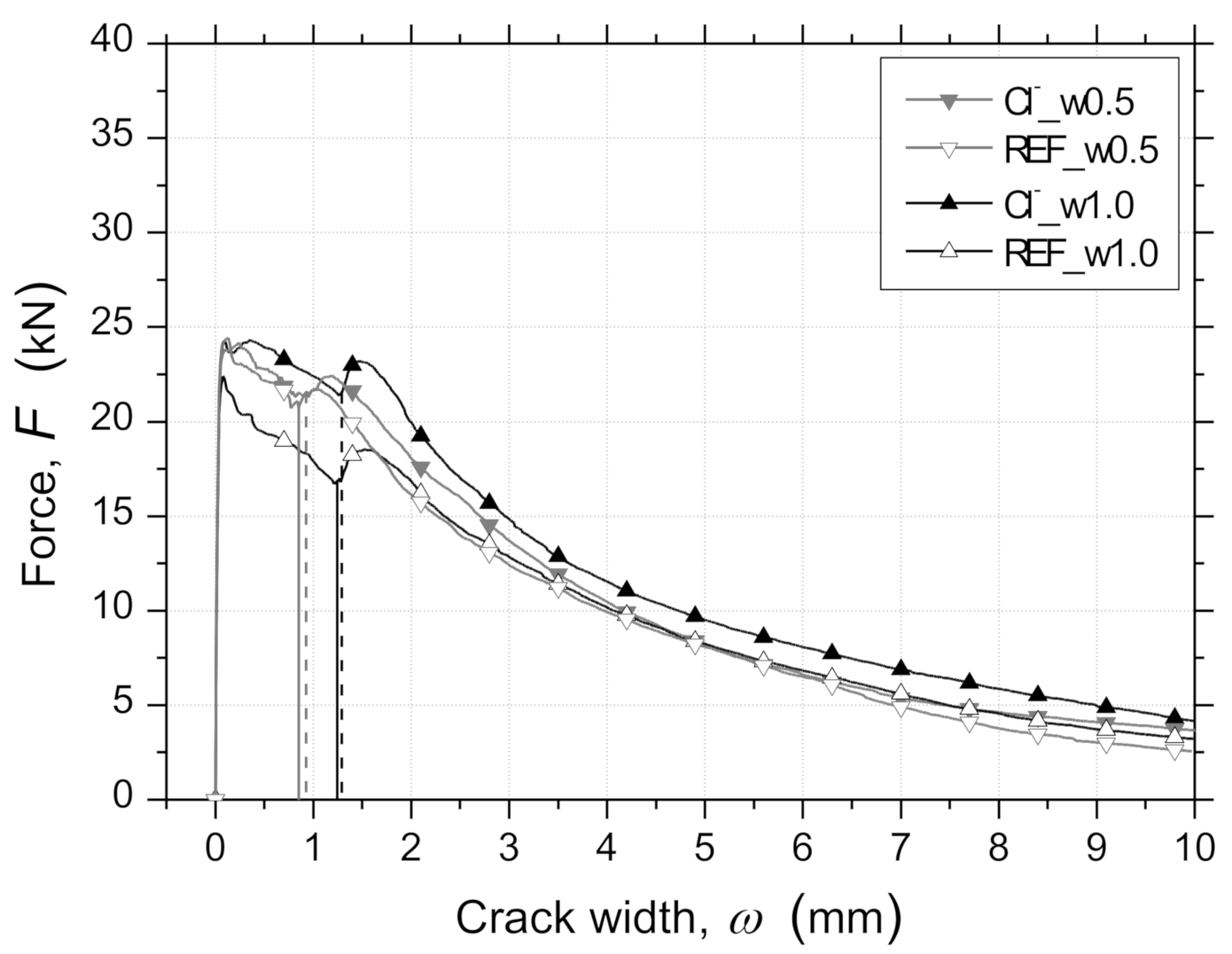

3.3.5. Force–Crack Width Relationships

3.3.6. Fiber Distribution/Orientation Profile

4. Numerical Simulations

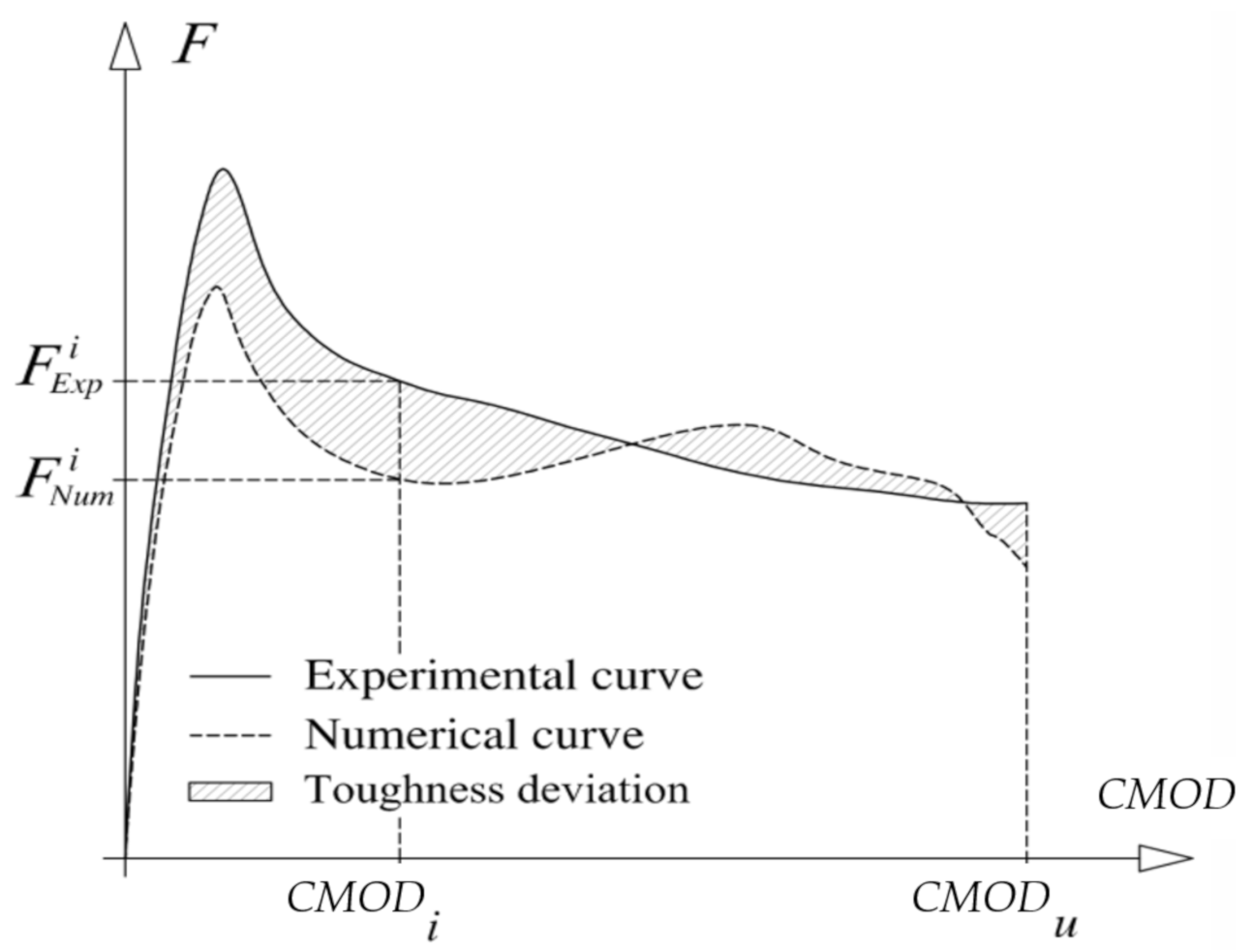

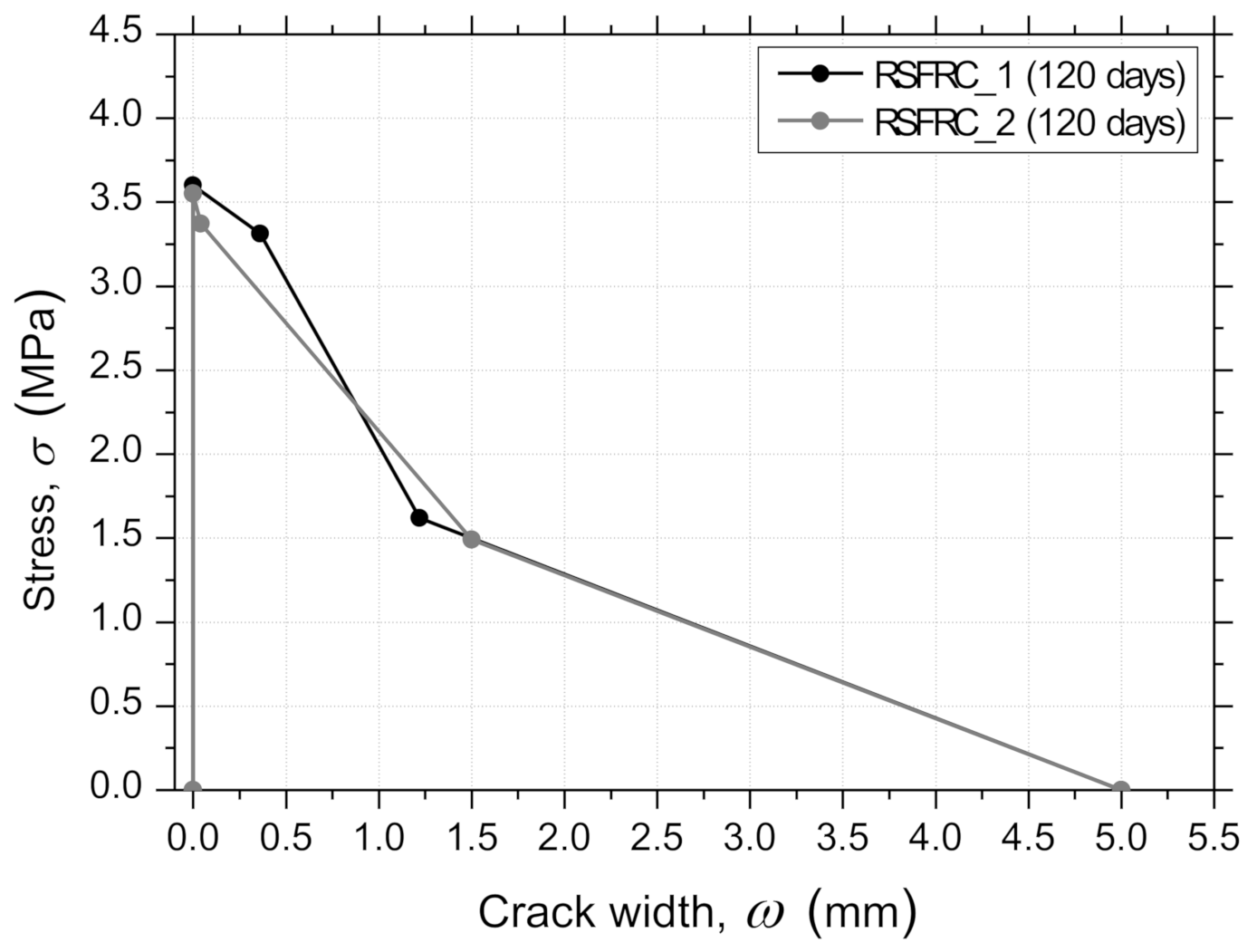

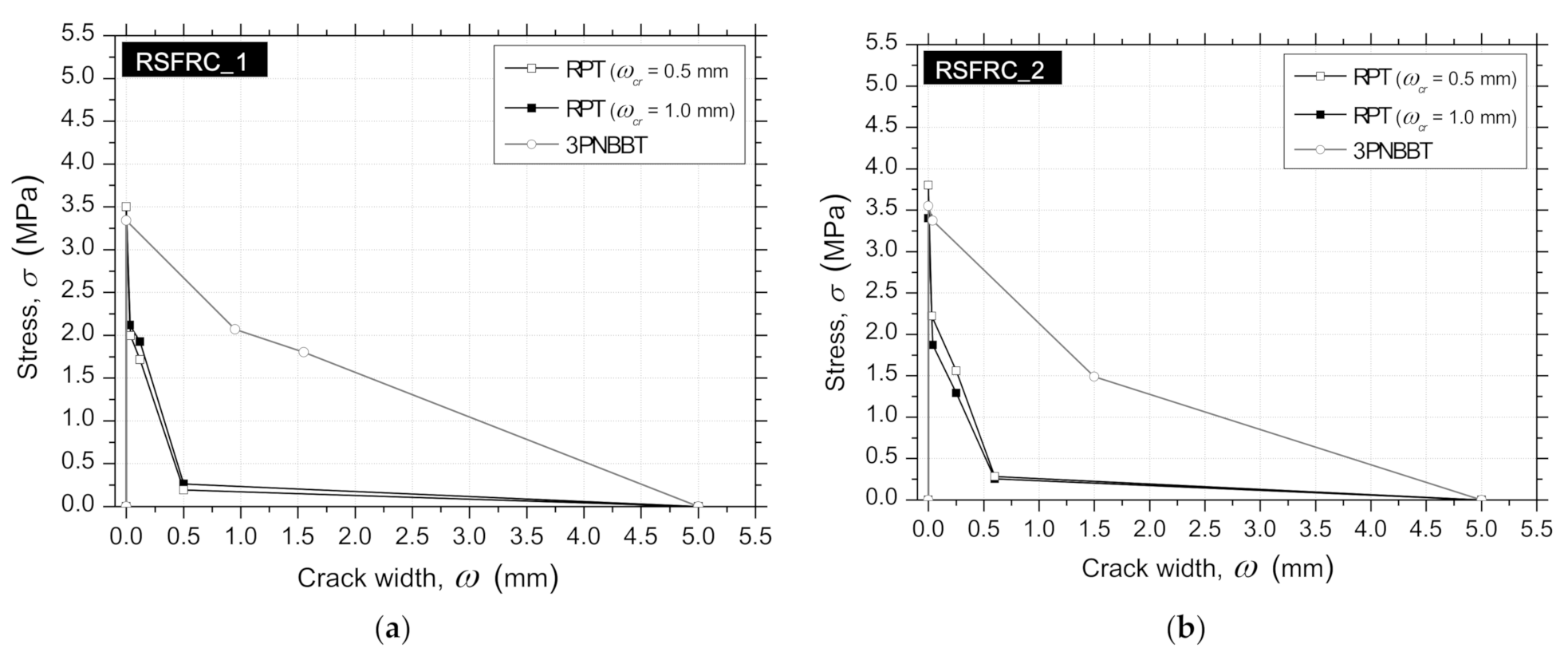

4.1. Evaluation of the Mode I Fracture Parameters from Inverse Analysis of 3PNBBT

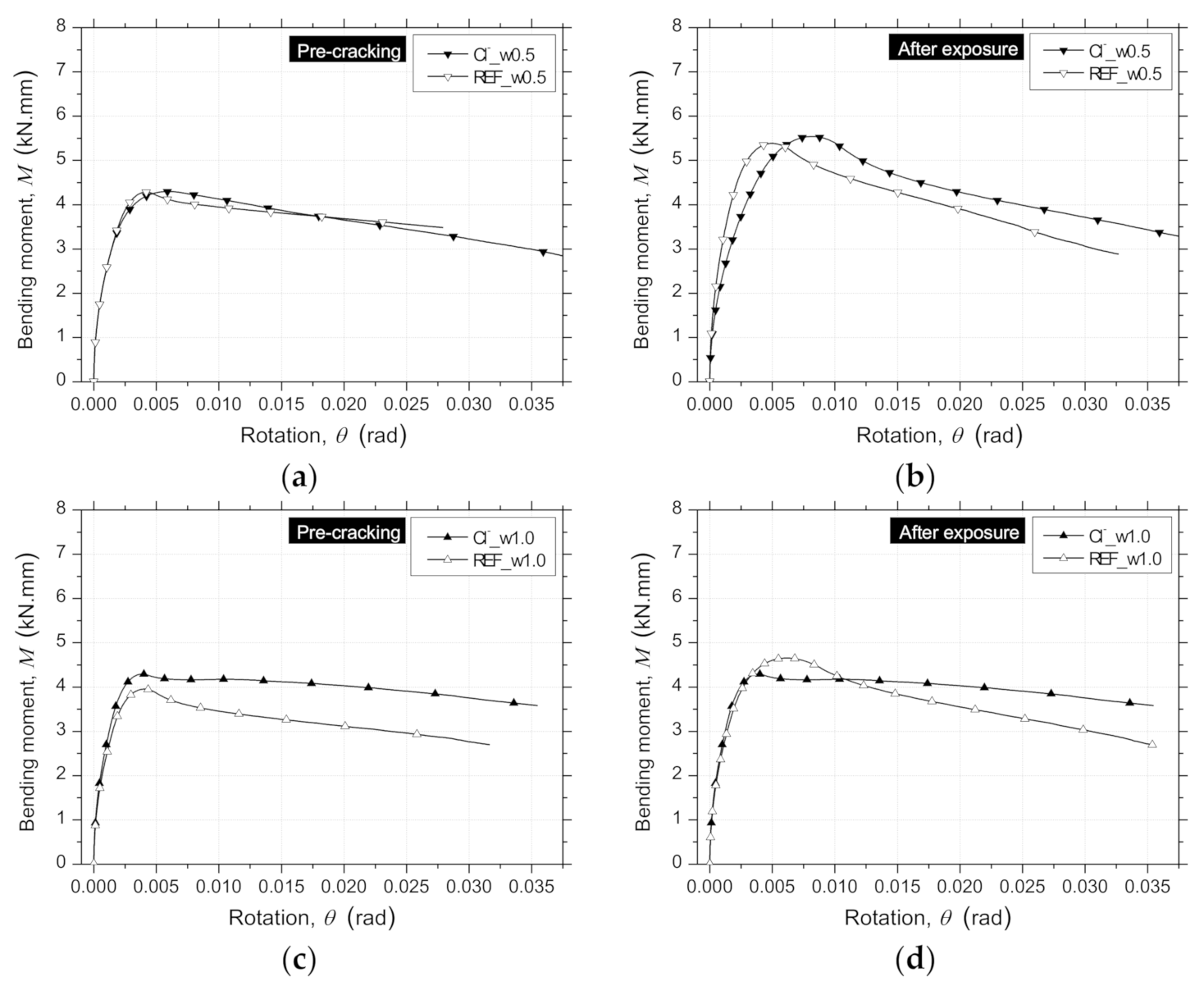

4.2. Evaluation of the Mode I Fracture Parameters from Inverse Analysis of RPT-3ps

5. Conclusions

- After 90 days of chloride attack, the cracked surfaces of pre-cracked RSFRC panels with crack widths up to 1 mm were completely penetrated by chlorides during the immersion period, and corrosion products were visible in the RSFs located in the cracked surfaces;

- Significant differences may occur in the progress of the three crack widths in round panels during RPT-3ps due to fiber distribution of RSFs at crack surfaces, with an inherent influence on the energy absorption of RSFRC panels;

- The stiffness parameters obtained in RSFRC panels indicate that the adopted corrosion induction conditions for RSFs had a negligible effect on the post-cracking behavior of cracked RSFRC up to a crack width of 1 mm;

- The RPT-3ps revealed small differences between the post-cracking behavior of pre-cracked panels submitted to 90 days of chloride attack and the corresponding pre-cracked reference panels;

- A high percentage of RSFs failed by rupture in all test series of RPT-3ps, which is indicative of a negligible effect of chloride attack;

- No significant differences were detected in terms of the fiber orientation factor, between reference panels and panels submitted to chloride attack;

- Comparing the relationships of the RSFRC representative of the RPT-3ps, obtained by inverse analysis procedure for pre-cracking stage and after environmental exposure, the chloride attack for 90 days of dry–wet chloride cycles had a negligible effect on the post-cracking behavior of pre-cracked RSFRC panels with crack widths up to 1 mm;

- The constitutive laws of the RSFRC representative of the 3PNBBT overestimated the post-cracking behavior of RSFRC comparing with the constitutive laws of the RSFRC representative of the RPT-3ps.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barros, J.A.O.; Frazão, C.; Caggiano, A.; Folino, P.; Martinelli, E.; Xargay, H.; Zamanzadeh, Z.; Lourenço, L. Recent Advances on Green Concrete for Structural Purposes—The Contribution of the EU-FP7 Project EnCoRe. In Cementitious Composites Reinforced with Recycled Fibres, 1st ed.; Barros, J.A.O., Ferrara, L., Martinelli, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; Chapter 8; pp. 141–195. [Google Scholar]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Bogas, J. Durability of recycled steel fiber reinforced concrete in chloride environment. Fibers 2019, 7, 111. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, J.A.; Toptan, F. An experimental study on the corrosion susceptibility of Recycled Steel Fiber Reinforced Concrete. Cement Concrete Comp. 2019, 96, 138–153. [Google Scholar] [CrossRef]

- Liew, K.W.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, L. Influence of Tire-Recycled Steel Fibers on Strength and Flexural Behavior of Reinforced Concrete. Hindawi Adv. Mater. Sci. Eng. 2020, 6363105. [Google Scholar] [CrossRef]

- Carrillo, J.; Lizarazo-Marriaga, J.; Lamus, F. Properties of Steel Fiber Reinforced Concrete Using Either Industrial or Recycled Fibers from Waste Tires. Fibers Polym. 2020, 21, 2055–2067. [Google Scholar] [CrossRef]

- Salehian, H.; Barros, J.A.O.; Taheri, M. Evaluation of the influence of post-cracking response of steel fibre reinforced concrete (SFRC) on load carrying capacity of SFRC panels. Constr. Build. Mater. 2014, 73, 289–304. [Google Scholar] [CrossRef]

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Compos. B Eng. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Figueiredo, F.P.; Barros, J.A.O.; Ventura-Gouveia, A. Nonlinear Analysis of offshore Wind Towers in prefabricated segments of prestressed Fibre Reinforced Concrete. In Proceedings of the 3rd RILEM Spring Convention 2020: Ambitioning a Sustainable Future for Built Environment: Comprehensive Strategies for Unprecedented Challenges, Guimarães, Portugal, 9–14 March 2020. [Google Scholar]

- Gowda, C.C.; Figueiredo, F.P.; Barros, J.A.O.; Ventura-Gouveia, A. Numerical analyses of the connections between representative SFRC prestressed segments of off-shore wind towers. In Proceedings of the 3rd RILEM Spring Convention 2020: Ambitioning a Sustainable Future for Built Environment: Comprehensive Strategies for Unprecedented Challenges, Guimarães, Portugal, 9–14 March 2020. [Google Scholar]

- Granju, J.-L.; Balouch, S.U. Corrosion of steel fibre reinforced concrete from the cracks. Cem. Concr. Res. 2005, 35, 572–577. [Google Scholar] [CrossRef]

- Nordström, E. Durability of Sprayed Concrete—Steel Fibre Corrosion in Cracks. Ph.D. Thesis, Department of Civil and Environmental Engineering, Division of Structural Engineering, Luleå University of Technology, Luleå, Sweden, 2005. [Google Scholar]

- Yoon, I. Chloride Penetration through Cracks in High- Performance Concrete and Surface Treatment System for Crack Healing. Hindawi Adv. Mater. Sci. Eng. 2012, 294571. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion resistance of steel fibre reinforced concrete—A literature review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Homma, D.; Mihashi, H.; Nishiwaki, T. Self-healing Capability of Fibre Reinforced Cementitious Composites. J. Adv. Concr. Technol. 2009, 7, 217–228. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Camões, A.; Alves, A.C.; Rocha, L. Corrosion effects on pullout behavior of hooked steel fibers in self-compacting concrete. Cem. Concr. Res. 2016, 79, 112–122. [Google Scholar] [CrossRef]

- Nonato da Silva, C.A.; Ciambella, J.; Barros, J.A.O.; Costa, I.G. Analytical bond model for general type of reinforcements of finite embedment length in cracked cement based materials. Int. J. Solids Struct. 2019, 167, 36–47. [Google Scholar] [CrossRef]

- Švec, O.; Zirgulis, G.; Bolander, J.E.; Stang, H. Influence of formwork surface on the orientation of steel fibres within self-compacting concrete and on the mechanical properties of cast structural elements. Cem. Concr. Comp. 2014, 50, 60–72. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Barros, J.A.O.; Soltanzadeh, F.; Sena-Cruz, J.M. Deflection and cracking behavior of SFRSCC beams reinforced with hybrid prestressed GFRP and steel reinforcements. Eng. Struct. 2016, 125, 546–565. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Barros, J.A.O.; Cunha, V.M.C.F. Relation between fibre distribution and post-cracking behaviour in steel fibre reinforced self-compacting concrete panels. Cem. Concr. Res. 2013, 51, 57–66. [Google Scholar] [CrossRef]

- Salehian, H. Evaluation of the Performance of Steel Fibre Reinforced Self-Compacting Concrete in Elevated Slab Systems; from the Material to the Structure. Ph.D. Thesis, Department of Civil Engineering, School of Engineering of the University of Minho, Guimarães, Portugal, 2015. [Google Scholar]

- EN 197-1:2011. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; CEN: Brussels, Belgium, 2011. [Google Scholar]

- Barros, J.; Pereira, E.; Santos, S. Lightweight panels of steel fibre reinforced self-compacting concrete. J. Mater. Civ. Eng. 2007, 19, 295–304. [Google Scholar] [CrossRef]

- Pereira, E. Steel Fibre Reinforced Self-Compacting Concrete: From material to mechanical behaviour. In Dissertation for Pedagogical and Scientific Aptitude Proofs; Department Civil Engineering, University of Minho: Guimarães, Portugal, 2006; 188p. [Google Scholar]

- Bogas, J.A.; Real, S. A review on the carbonation and chloride penetration resistance of structural lightweight aggregate concrete. Materials 2019, 12, 3456. [Google Scholar] [CrossRef]

- ASTM C1550-08. Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel); ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Minelli, F.; Plizzari, G.A. Fiber reinforced concrete characterization through round panel test—Part I: Experimental study. In Proceedings of the FraMCoS-7 International Conference, Fracture Mechanics of Concrete and Concrete Structures—High Performance, Fiber Reinforced Concrete, Special Loadings and Structural Applications, Korea Concrete Institute, Jeju, Korea, 23–28 May 2010. [Google Scholar]

- EN 12390-3:2011. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; CEN: Brussels, Belgium, 2011. [Google Scholar]

- EN 12390-13:2014. Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression; CEN: Brussels, Belgium, 2014. [Google Scholar]

- EN 14651:2005 + A1:2007. Test Method for Metallic Fibre Concrete. Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual); CEN: Brussels, Belgium, 2007. [Google Scholar]

- MC2010. CEB fib Model Code 2010—Final Draft; fib: Lausanne, Switzerland, 2011. [Google Scholar]

- Spasojević, A. Structural Implications of Ultra-High Performance Fibre-Reinforced Concrete in Bridge Design. Ph.D. Thesis, Faculté de L’Environnement Naturel, Architectural et Construit, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2008. [Google Scholar]

- Mangat, P.S.; Gurusamy, K. Steel fibre reinforced concrete for marine applications. In Proceedings of the 4th International Conference on Behaviour of Offshore Structures, Delft, The Netherlands, 1–5 July 1985; pp. 867–879. [Google Scholar]

- Abrishambaf, A. Creep Behaviour of Cracked Steel Fibre Reinforced Self-Compacting Concrete Laminar Structures. Ph.D. Thesis, Department of Civil Engineering, School of Engineering of the University of Minho, Guimarães, Portugal, 2015. [Google Scholar]

- Cunha, V.M.C.F. Steel Fibre Reinforced Self-Compacting Concrete (from Micro-Mechanics to Composite Behaviour). Ph.D. Thesis, Department of Civil Engineering, School of Engineering of the University of Minho, Guimarães, Portugal, 2010. [Google Scholar]

- Soroushian, P.; Lee, C.D. Distribution and orientation of fibers in steel fiber reinforced concrete. ACI Mater. J. 1990, 87, 433–439. [Google Scholar]

- Barros, J.A.O. Debilities and strengths of FEM-based constitutive models for the material nonlinear analysis of steel fiber reinforced concrete structures. In Proceedings of the 9th International Conference on Fracture Mechanics of Concrete and Concrete Structures, FraMCoS-9, Berkeley, CA, USA, 29 May–1 June 2016. [Google Scholar]

- Taheri, M.; Barros, J.A.O.; Salehian, H. Integrated approach for the prediction of crack width and spacing in flexural FRC members with hybrid reinforcement. Eng. Struct. 2020, 110208. [Google Scholar] [CrossRef]

- Zamanzadeh, Z.; Lourenço, L.; Barros, J. Recycled Steel Fiber Reinforced Concrete failing in bending and in shear. Constr. Build. Mater. 2015, 85, 195–207. [Google Scholar] [CrossRef]

- Azevedo, A.F.M.; Barros, J.A.O.; Sena-Cruz, J.M.; Gouveia, A.V. Software in structural engineering education and design. In Proceedings of the III Portuguese-Mozambican Conference of Engineering, Maputo, Mozambique, 19–21 August 2003; pp. 81–92. [Google Scholar]

- Tran, V.N.G.; Bernard, E.S.; Beasley, A.J. Constitutive Modeling of Fiber Reinforced Shotcrete Panels. J. Eng. Mech. 2005, 131, 512–521. [Google Scholar] [CrossRef]

- Basto, C.A.A.; Barros, J.A.O. Numeric Simulation of Sections Submitted to Bending. In Technical Report 08-DEC/E-46; Department of Civil Engineering, School of Engineering of the University of Minho: Guimarães, Portugal, 2008; 73p. [Google Scholar]

| C (kg) | FA (kg) | FS (kg) | CS (kg) | CG (kg) | W (L) | SP (L) | Cf (kg) | W/C * |

|---|---|---|---|---|---|---|---|---|

| 400 | 200 | 148 | 735 | 597 | 173 | 7.2 | 75.8 | 0.43 |

| Test Series | RSFRC Batch | (mm) | Exposure Conditions of Panels before RPT-3ps |

|---|---|---|---|

| Cl−_w0.5 | RSFRC_1 | 0.5 | 90 days of dry-wet cycles in 3.5 wt% NaCl solution |

| Cl−_w1.0 | 1.0 | ||

| REF_w0.5 | RSFRC_2 | 0.5 | 90 days of tap water immersion |

| REF_w1.0 | 1.0 |

| RSFRC Batch | Density (kg/m3) | ||||

|---|---|---|---|---|---|

| RSFRC_1 | 2335.68 (1.04) | 34.68 (8.22) | 72.90 (2.41) | 0.0025 (2.89) | 0.19 (10.53) |

| RSFRC_2 | 2330.69 (0.61) | 32.74 (4.98) | 68.96 (3.37) | 0.0025 (4.65) | 0.20 (5.83) |

| RSFRC Batch | fR,1 (MPa) | fR,2 (MPa) | fR,3 (MPa) | fR,4 (MPa) |

|---|---|---|---|---|

| RSFRC_1 | 8.86 (10.89) | 7.57 (13.62) | 5.71 (16.58) | 4.60 (14.83) |

| RSFRC_2 | 8.43 (19.89) | 7.14 (25.73) | 6.18 (18.54) | 4.66 (23.93) |

| Test Series | (mm) | (kN/mm) | |||||

|---|---|---|---|---|---|---|---|

| Cl−_w0.5 | 0.59 (13.83) | 65.67 (7.98) | 0.46 (11.25) | 0.09 (0.86) | 0.44 (17.79) | 0.23 (7.66) | 0.17 (12.67) |

| REF_w0.5 | 0.58 (5.85) | 71.60 (15.65) | 0.46 (6.37) | 0.10 (23.65) | 0.53 (19.96) | 0.23 (9.43) | 0.22 (8.93) |

| Cl−_w1.0 | 0.85 (6.94) | 62.27 (6.24) | 0.42 (13.55) | 0.08 (12.95) | 0.49 (24.78) | 0.19 (16.82) | 0.17 (10.80) |

| REF_w1.0 | 0.89 (4.39) | 68.77 (18.52) | 0.39 (12.95) | 0.07 (7.93) | 0.38 (8.46) | 0.19 (14.10) | 0.15 (19.64) |

| Test Series | Panel Thickness (mm) | (J) | (J) | (J) | (J) | (Fibers/cm2) | ||

|---|---|---|---|---|---|---|---|---|

| Cl−_w0.5 | 63.17 | 204.23 | 368.23 | 533.69 | 627.50 | 7.35 (88% *) | 0.628 | 0.361 |

| REF_w0.5 | 64.92 | 187.52 | 306.35 | 427.24 | 509.51 | 7.68 (80% *) | 0.617 | 0.377 |

| Cl−_w1.0 | 64.13 | 200.94 | 359.01 | 507.61 | 598.53 | 8.42 (73% *) | 0.614 | 0.413 |

| REF_w1.0 | 65.45 | 171.95 | 291.42 | 407.27 | 472.62 | 8.65 (78% *) | 0.595 | 0.424 |

| Average CoV (%) | 64.42 1.54 | 191.16 7.69 | 331.25 11.49 | 468.95 13.05 | 552.04 13.22 | 8.03 (80% *) 7.62 | 0.614 2.24 | 0.394 7.53 |

| Density | Poisson’s Ratio | Young’s Modulus | Tensile Strength | Fracture Mode I Parameters |

|---|---|---|---|---|

| ρ = 2.34 × 10−5 N/mm3 | Inverse analysis | Inverse analysis |

| Concrete Mixtures | fct (MPa) | σ1 (MPa) | σ2 (MPa) | ω1 (mm) | ω2 (mm) | ωu (mm) | Gf (N/mm) | e (%) |

|---|---|---|---|---|---|---|---|---|

| RSFRC_1 | 3.60 | 3.31 | 1.62 | 0.36 | 1.22 | 5.00 | 6.43 | 1.15 |

| RSFRC_2 | 3.55 | 3.37 | 1.49 | 0.04 | 1.50 | 5.00 | 6.30 | 0.71 |

| Test Stage | Series | fct (MPa) | σ1 (MPa) | σ2 (MPa) | σ3 (MPa) | ω1 (mm) | ω2 (mm) | ω3 (mm) | ωu (mm) | Gf (N/mm) | e (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pre-cracking stage ωcr = 0.5 mm | Cl− | 3.40 | 2.36 | 1.97 | 0.34 | 0.06 | 0.12 | 0.50 | 5.00 | 1.50 | 3.88 |

| REF | 3.80 | 2.22 | 1.56 | 0.29 | 0.03 | 0.25 | 0.60 | 5.00 | 1.46 | 3.41 | |

| After environmental exposure | Cl− | 5.00 | 2.33 | 1.00 | 0.55 | 0.04 | 0.25 | 0.50 | 5.00 | 1.91 | 0.23 |

| REF | 4.30 | 1.91 | 0.56 | 0.52 | 0.05 | 0.26 | 0.60 | 5.00 | 1.73 | 0.07 | |

| Pre-cracking stage ωcr = 1.0 mm | Cl− | 3.90 | 2.40 | 2.46 | 0.55 | 0.03 | 0.09 | 0.50 | 5.00 | 2.08 | 2.78 |

| REF | 3.40 | 1.87 | 1.29 | 0.26 | 0.04 | 0.25 | 0.60 | 5.00 | 1.27 | 3.58 | |

| After environmental exposure | Cl− | 5.30 | 2.60 | 0.98 | 0.58 | 0.03 | 0.26 | 0.50 | 5.00 | 2.02 | 0.38 |

| REF | 3.80 | 1.98 | 0.67 | 0.57 | 0.05 | 0.30 | 0.60 | 5.00 | 1.91 | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frazão, C.; Barros, J.; Bogas, J.A. Influence of the Chloride Attack on the Post-Cracking Behavior of Recycled Steel Fiber Reinforced Concrete. Materials 2021, 14, 1279. https://doi.org/10.3390/ma14051279

Frazão C, Barros J, Bogas JA. Influence of the Chloride Attack on the Post-Cracking Behavior of Recycled Steel Fiber Reinforced Concrete. Materials. 2021; 14(5):1279. https://doi.org/10.3390/ma14051279

Chicago/Turabian StyleFrazão, Cristina, Joaquim Barros, and José Alexandre Bogas. 2021. "Influence of the Chloride Attack on the Post-Cracking Behavior of Recycled Steel Fiber Reinforced Concrete" Materials 14, no. 5: 1279. https://doi.org/10.3390/ma14051279

APA StyleFrazão, C., Barros, J., & Bogas, J. A. (2021). Influence of the Chloride Attack on the Post-Cracking Behavior of Recycled Steel Fiber Reinforced Concrete. Materials, 14(5), 1279. https://doi.org/10.3390/ma14051279