Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings

Abstract

:1. Introduction

2. Carbon Reinforced Concrete Composites

2.1. Materials

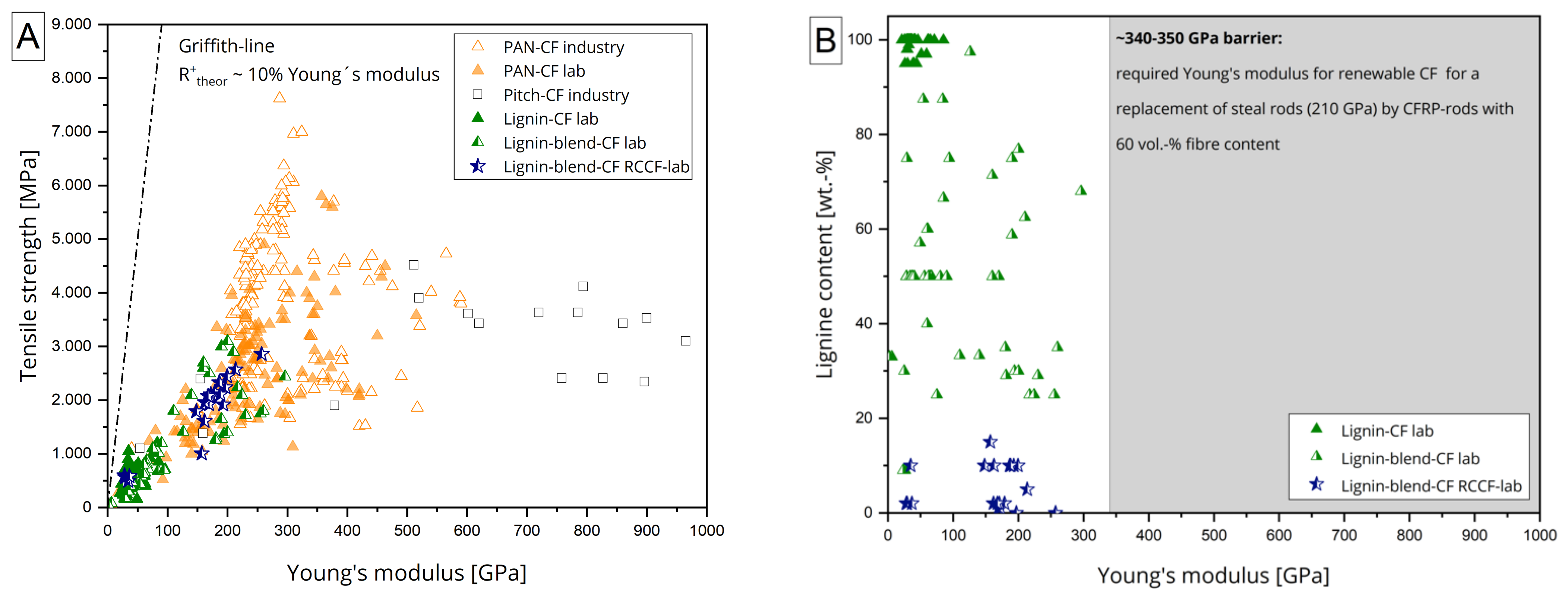

2.1.1. Low-Cost Carbon Fibres

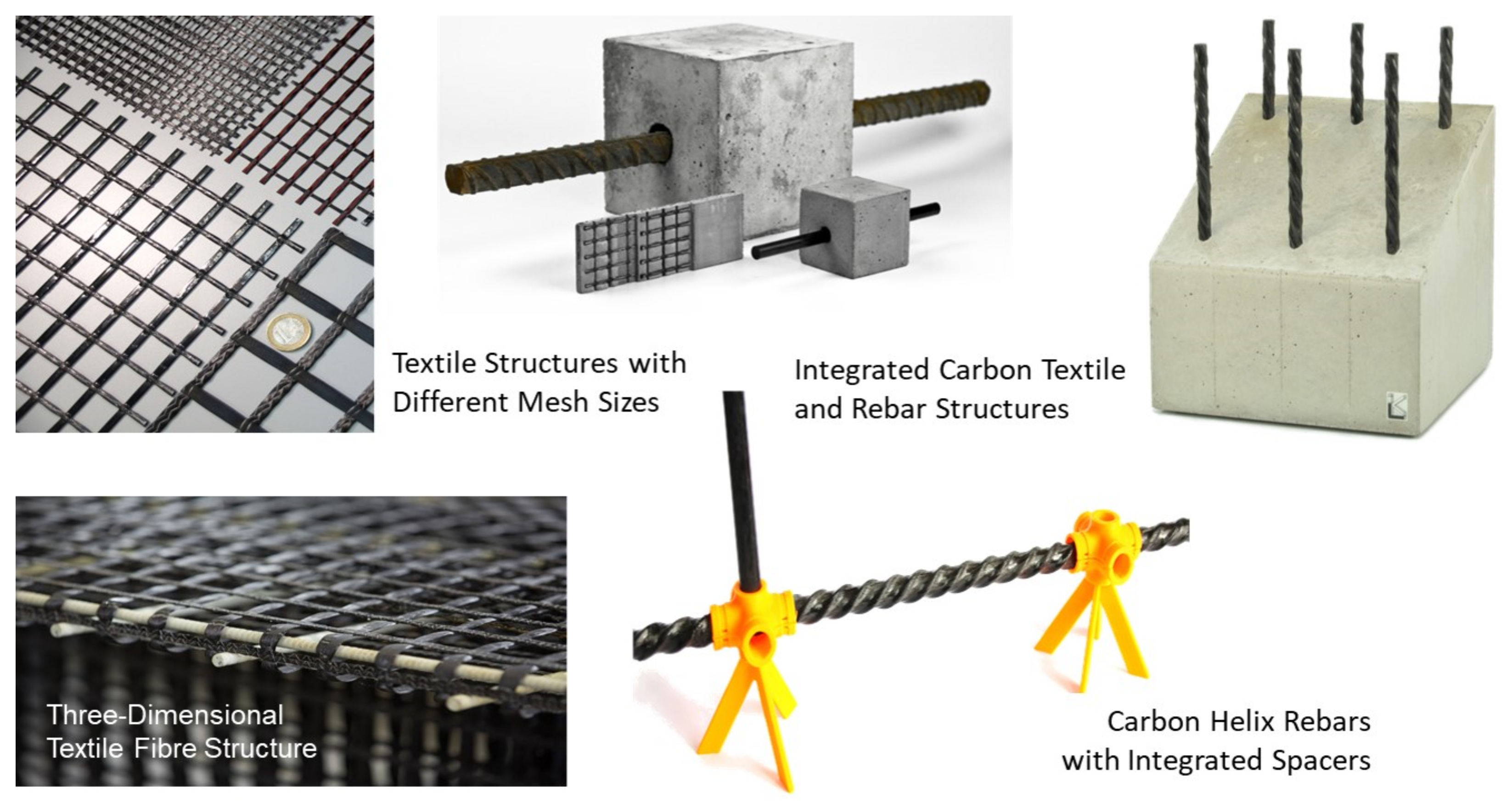

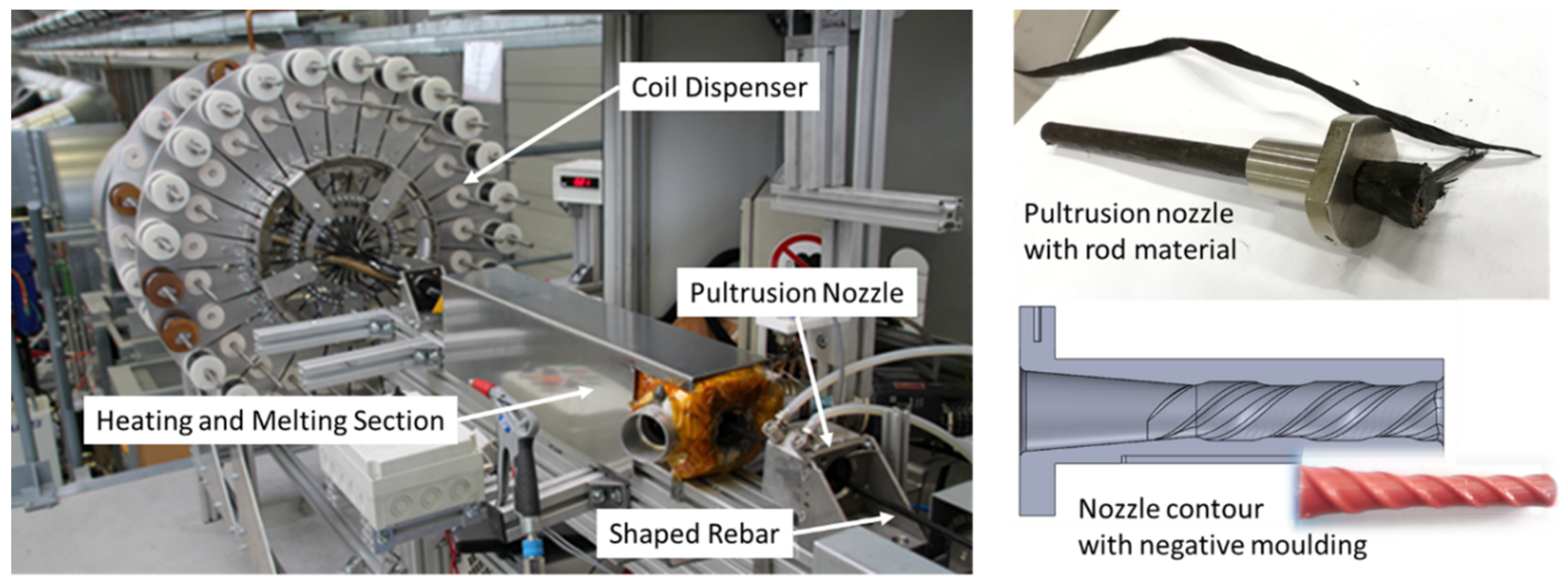

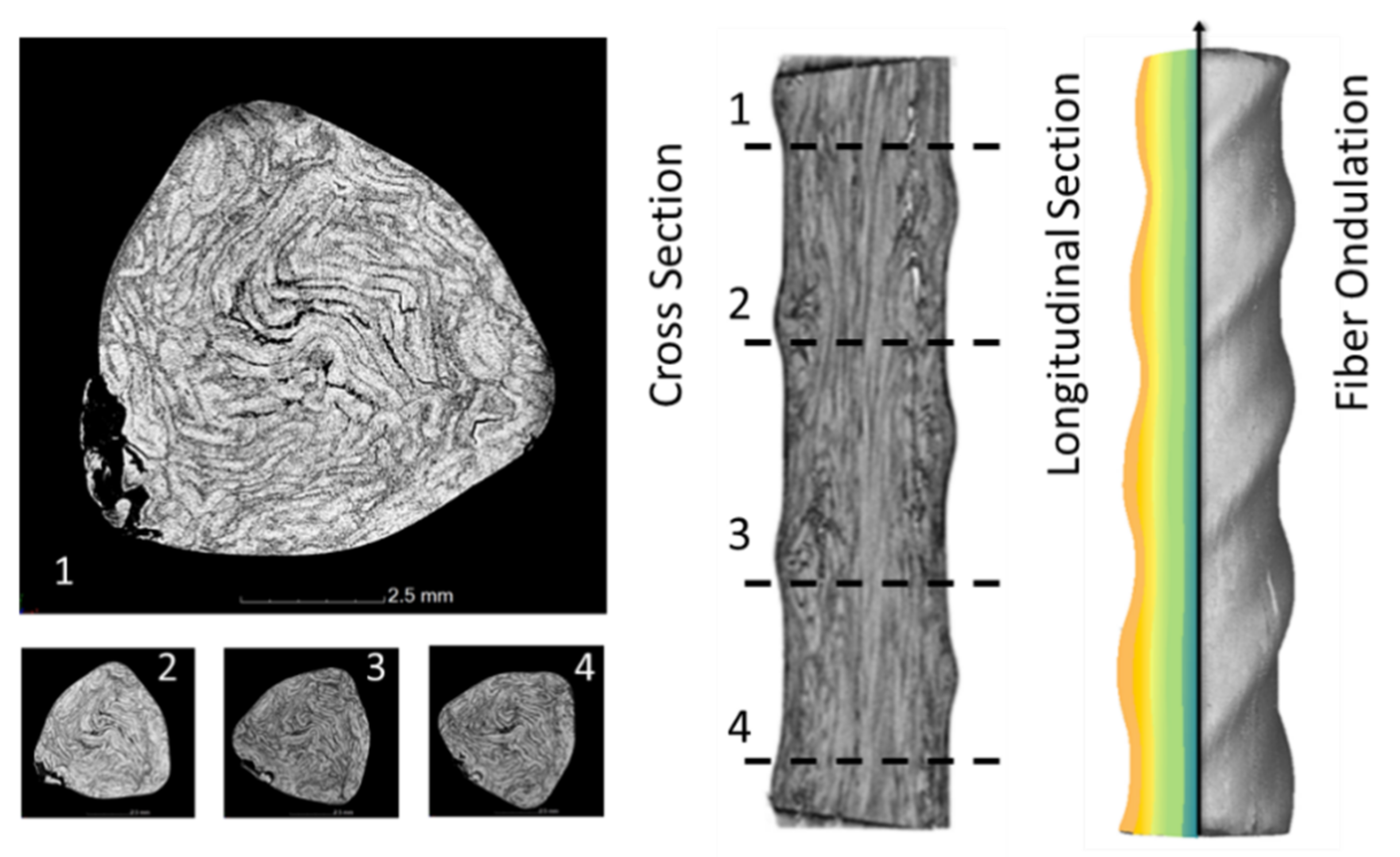

2.1.2. CF-Based Reinforcement Systems

2.1.3. Aerogel-Based Insulation

2.2. CRC Structural Systems

2.3. Environmental Benefit of CRC Technology

3. Energy-Efficient CRC-Based Façade Elements

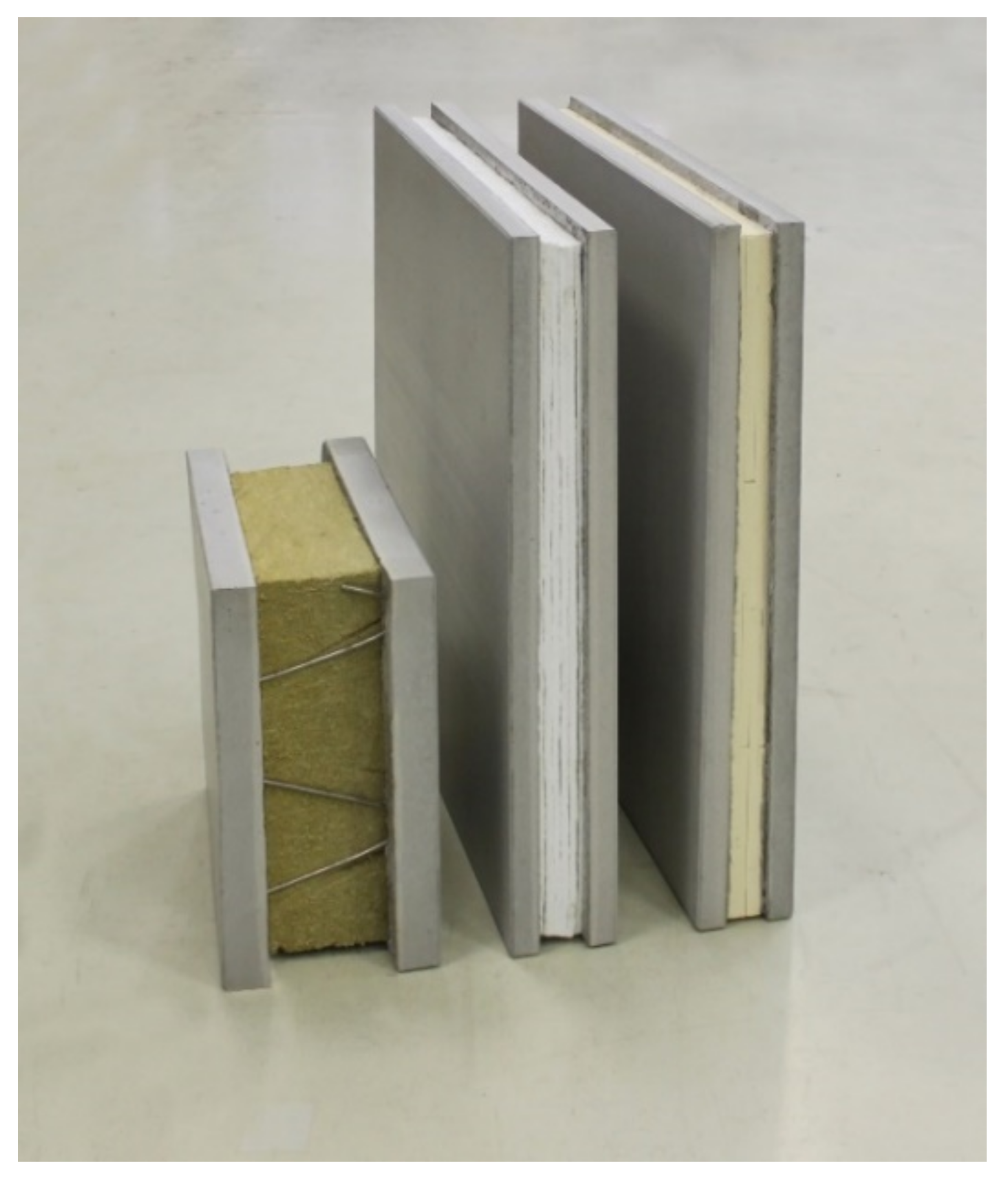

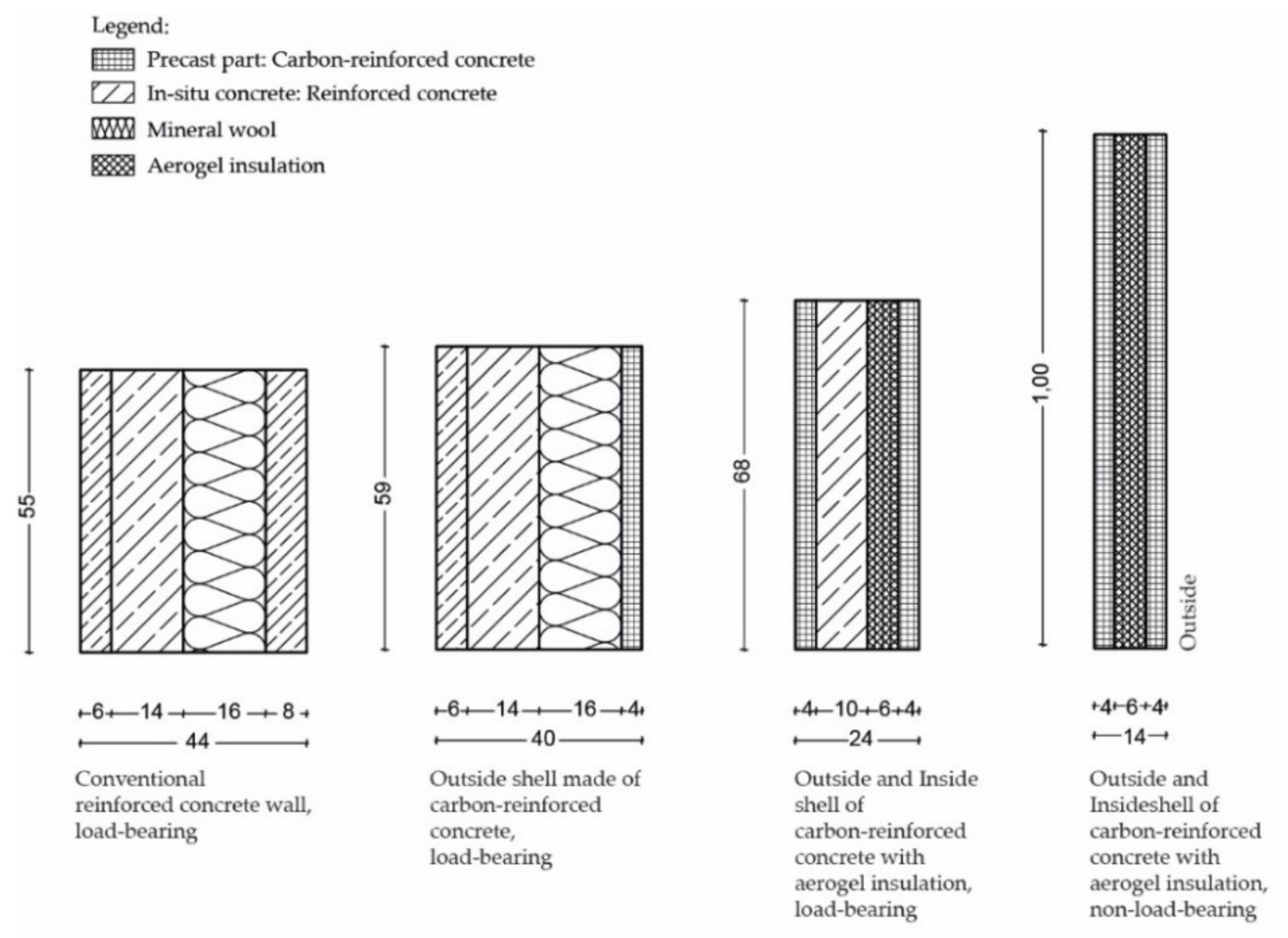

3.1. Conventional Sandwich Elements

3.2. Sandwich Elements with CRC Layers and Aerogel Insulation Core (Slentite®/Slentex®)

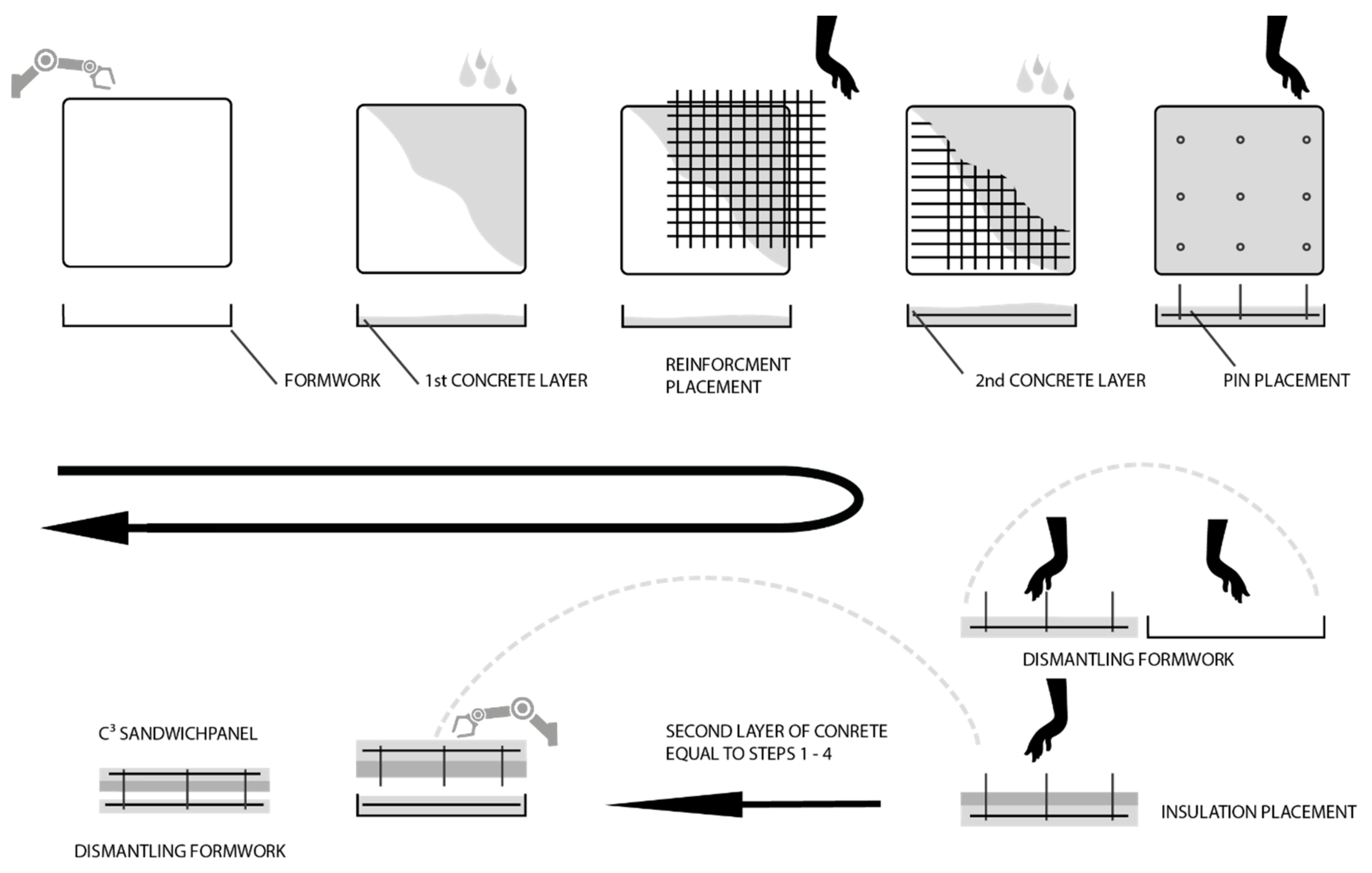

3.2.1. Structure of the Elements

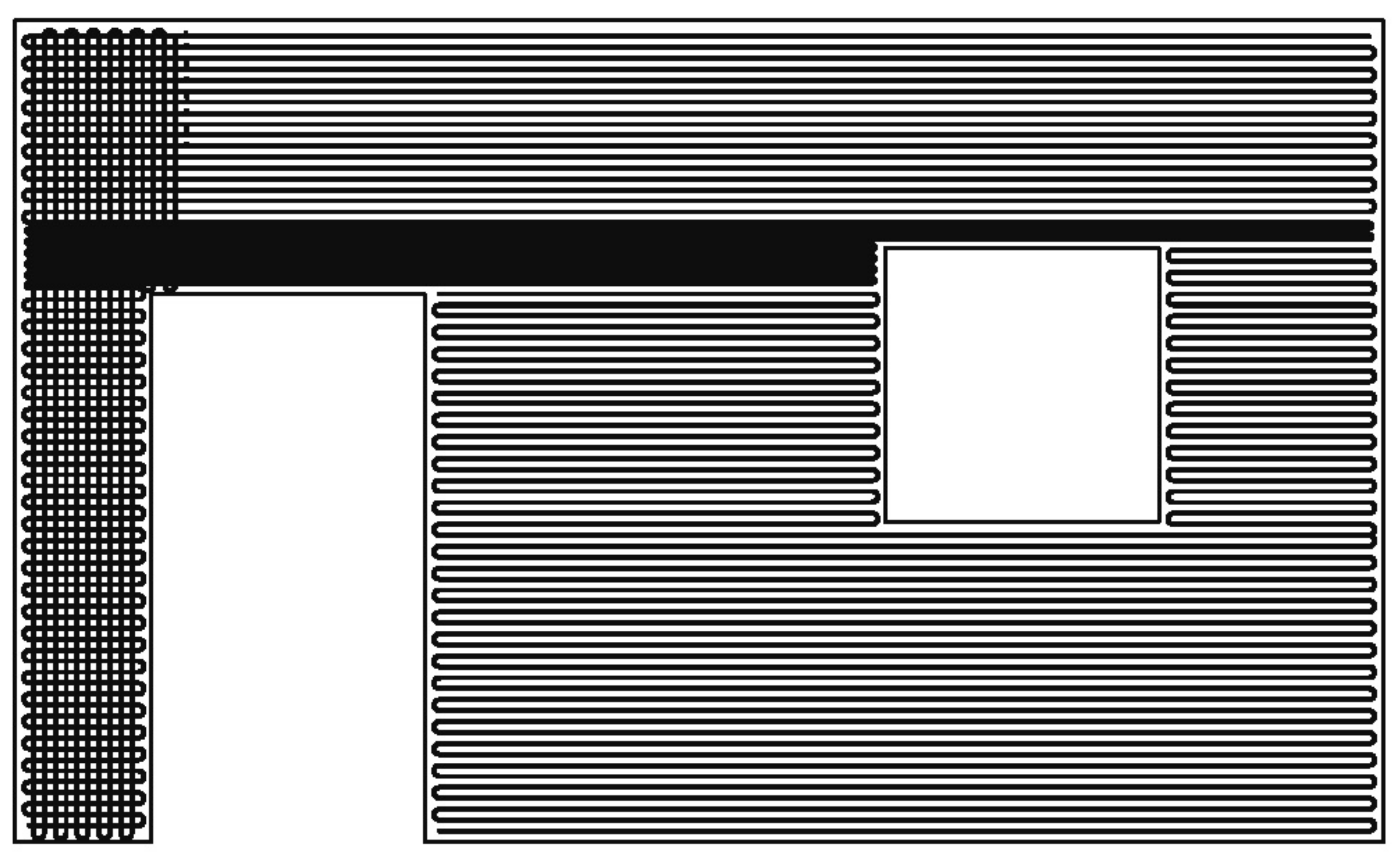

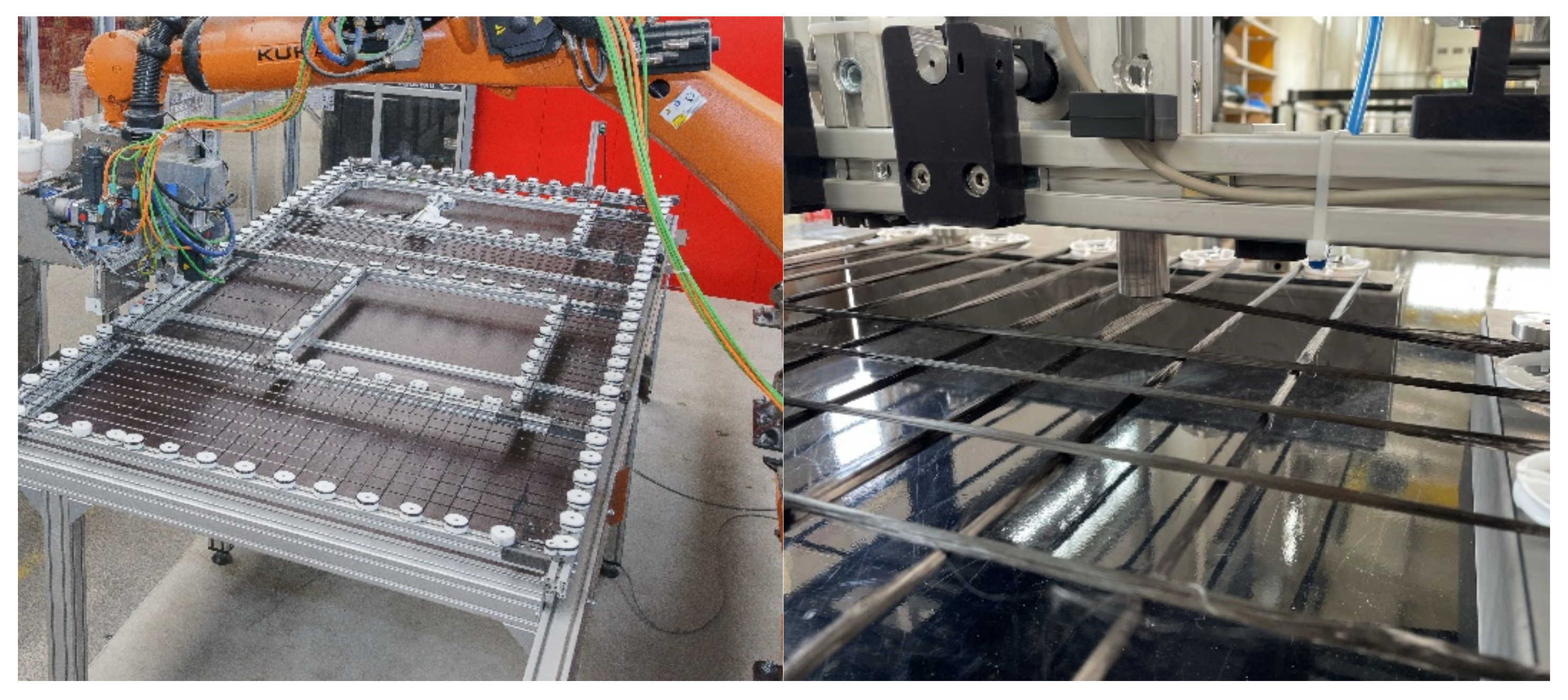

3.2.2. Handling of Carbon Fibre Grids

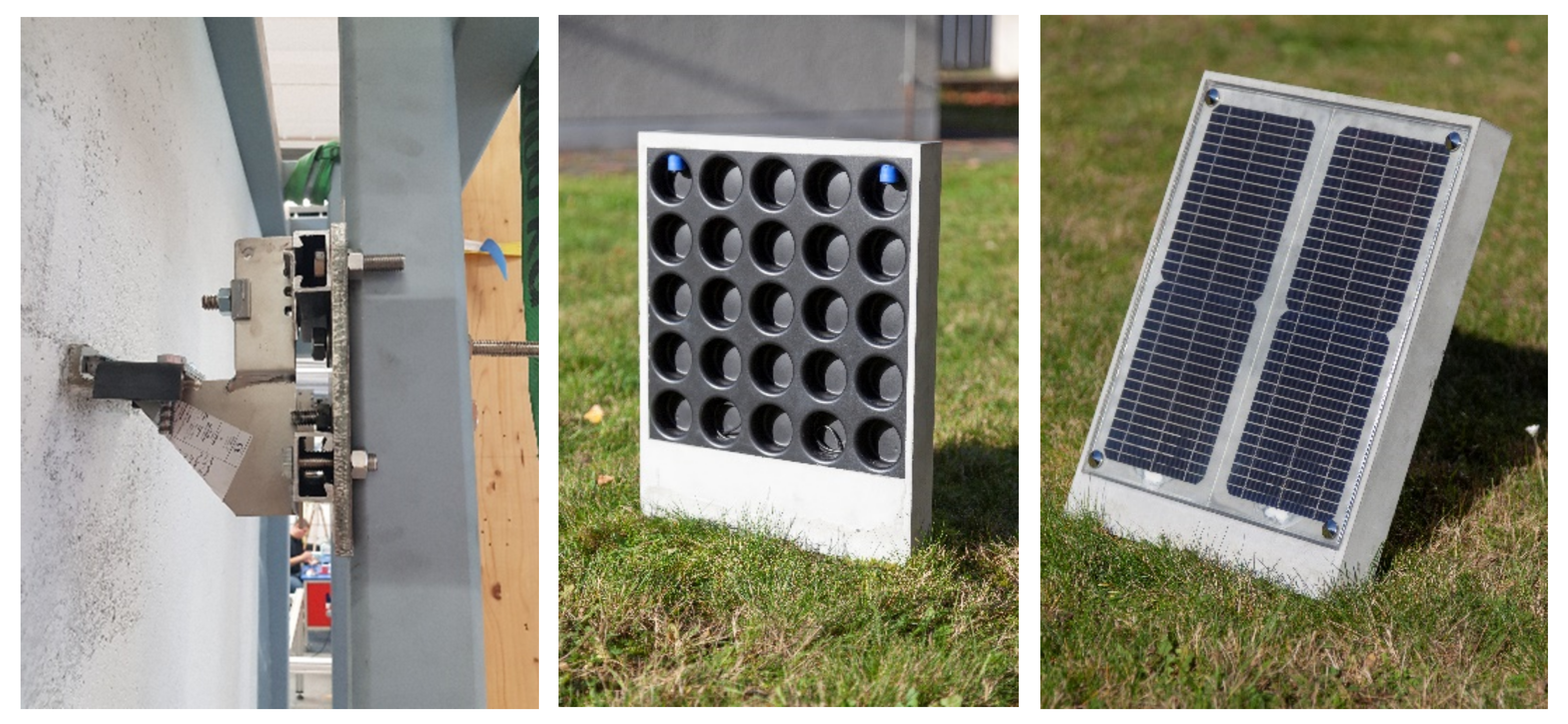

4. Improvement of the CRC Technology towards nZEB

4.1. Concept: Cellular Lightweight Concrete (CLC) with Aerogels

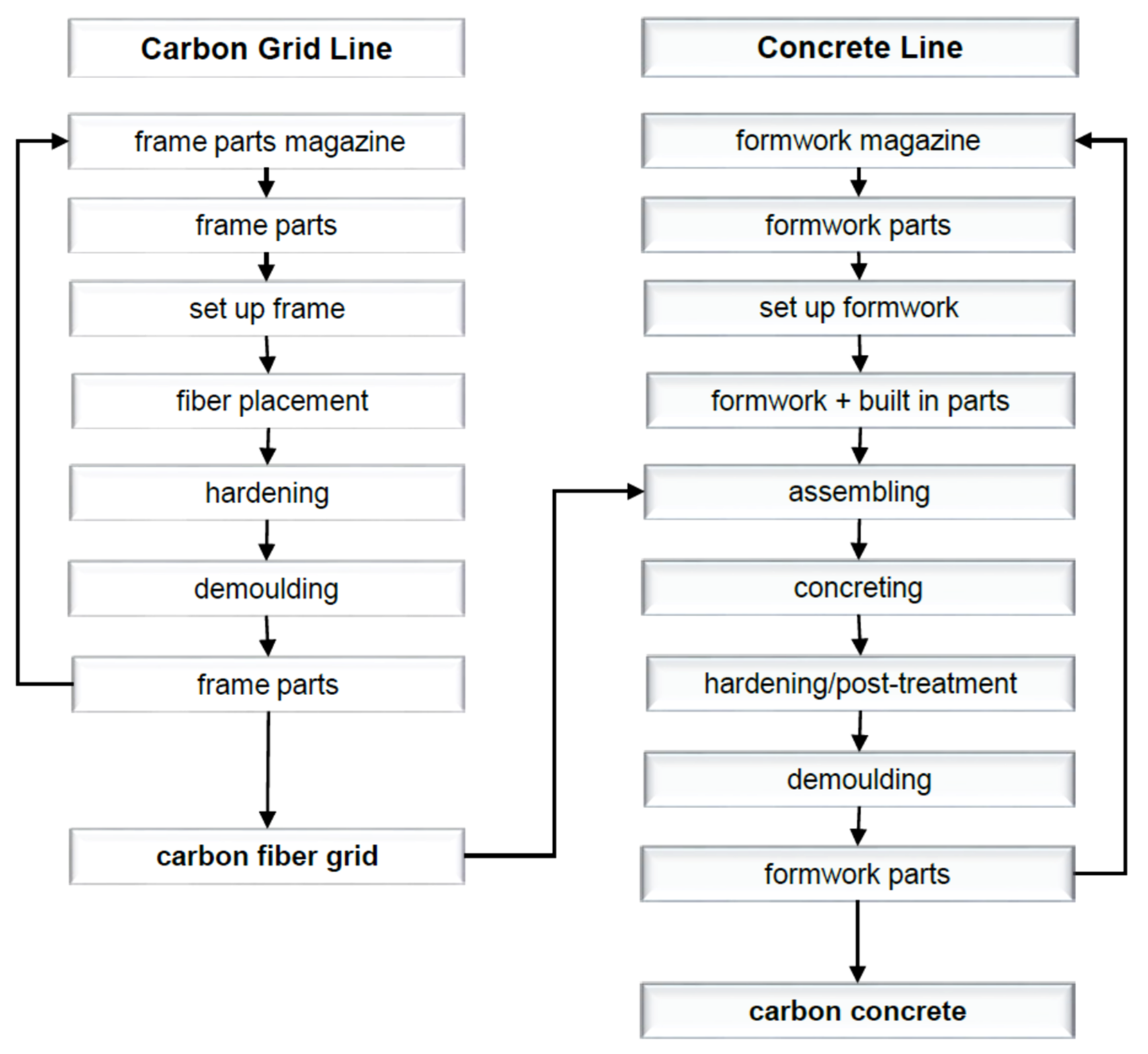

4.2. Production

5. Conclusions

- -

- substituting conventional raw materials with renewable materials,

- -

- structural optimization,

- -

- deconstruction, reuse and recycling and

- -

- cost-efficient automated manufacturing processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Court of Auditors. Energy Efficiency in Buildings: Greater Focus on Cost-Effectiveness Still Needed; Special Report, Nr. 11, 2020; Publications Office: Luxemburg, 2020. [Google Scholar] [CrossRef]

- European Commission. European Climate Law. In Official Journal of the European Union; European Commission: Luxemburg, 2021. [Google Scholar]

- EU nZEB. Report on Nearly Zero-Energy Buildings. Available online: https://epb.center/epb-standards/energy-performance-buildings-directive-epbd/ (accessed on 13 May 2021).

- C3—Carbon Concrete Composite, e.V. About C3—Carbon Concrete Composite. 2019. Available online: https://www.bauen-neu-denken.de/en/#about-c3 (accessed on 26 November 2021).

- Frenzel, M.; Curbach, M. Cube Box—First prefabricated carbon-reinforced concrete building—Design, production and precast element assembly. BFT Int. 2021, 87, 43. [Google Scholar]

- Frenzel, M.; Zschau, N. Precast components with carbon reinforced concrete—“BOX” prototype. CPI—Concr. Plant Int. 2020, 5, 146–157. [Google Scholar]

- Beckmann, B.; Bielak, J.; Bosbach, S.; Scheerer, S.; Schmidt, C.; Hegger, J.; Curbach, M. Collaborative research on carbon reinforced concrete structures in the CRC/TRR 280 project. Civ. Eng. Des. 2021, 3, 99–109. [Google Scholar] [CrossRef]

- Curbach, M.; Schladitz, F.; Weselek, J.; Zobel, R. Eine Vision wird Realität: Der Betonbau der Zukunft ist nachhaltig, leicht, flexibel und formbar—Dank Carbon. Der Prüfingenieur. 2017, 51, 20–35. [Google Scholar]

- Müller, E.; Scheerer, S.; Curbach, M. Material and space saving carbon concrete elements. Civ. Eng. Des. 2019, 1, 3–9. [Google Scholar] [CrossRef]

- Hering Bau GmbH & Co. KG. Allgemeine Bauaufsichtliche Zulassung Z-10.3-723: Fassadenplatten “Betoshell Neo 30” Aus Textilbeton Zur Verwendung Bei Vorgehängten Hinterlüfteten Außenwandbekleidungen; Hering Bau GmbH: Zettlitz, Germany, 2007. [Google Scholar]

- Portal, N.W.; Lundgren, K.; Wallbaum, H.; Malaga, K. Sustainable potential of textile-reinforced concrete. J. Mater. Civ. Eng. 2015, 27, 04014207. [Google Scholar] [CrossRef]

- Laiblová, L.; Pešta, J.; Kumar, A.; Hájek, P.; Fiala, C.; Vlach, T.; Kočí, V. Environmental impact of textile reinforced concrete facades compared to conventional solutions—LCA case study. Materials 2019, 12, 3194. [Google Scholar] [CrossRef] [Green Version]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-Gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Scope, C.; Guenther, E.; Schütz, J.; Mielecke, T.; Mündecke, E.; Schultze, K.; Saling, P. Aiming for life cycle sustainability assessment of cement-based composites: A trend study for wall systems of carbon concrete: Dresden Nexus Conference 2020—Session 4—Circular economy for building with secondary construction materials to minimise resource use and land use. Civ. Eng. Des. 2020, 2, 143–158. [Google Scholar] [CrossRef]

- Kopf, F.; Kortman, J.; Jehle, P. Recycling and reuse of carbon fiber reinforcement. In Proceedings of the Seventh International Conference on Structural Engineering, Mechanics and Computation (SEMC 2019), Cape Town, South Africa, 2–4 September 2019; CRC Pres: Boca Raton, FL, USA, 2019; pp. 1543–1547. [Google Scholar] [CrossRef]

- Meek, N.; Penumadu, D.; Hosseinaei, O.; Harper, D.; Young, S.; Rials, T. Synthesis and characterization of lignin carbon fiber and composites. Compos. Sci. Technol. 2016, 137, 60–68. [Google Scholar] [CrossRef]

- Souto, F.; Calado, V.; Pereira, N., Jr. Lignin-Based carbon fiber: A current overview. Mater. Res. Exp. 2018, 5, 072001. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, P.; Zhang, Y.; Zhang, X.; Jiang, Y. From waste cotton linter: A renewable environment-friendly biomass based carbon fibers preparation. ACS Sustain. Chem. Eng. 2016, 4, 5585–5593. [Google Scholar] [CrossRef]

- Favier, A.; De Wolf, C.; Scrivener, K.; Habert, G. A Sustainable Future for the European Cement and Concrete Industry—Technology Assessment for Full Decarbonisation of the Industry by 2050; European Climate Foundation (ECF): Zurich, Switzerland, 2018; Available online: https://europeanclimate.org/a-sustainable-future-for-the-europeancement-and-concrete-industry-technology-assessment-for-fulldecarbonisation-of-the-industry-by-2050/ (accessed on 5 November 2018).

- Wiens, U.; Omercic, M.; Becke, A. Nachhaltig Bauen mit Beton—Roadmap des DAfStb Für Einen Klimagerechten und Ressourceneffizienten Betonbau. In Proceedings of the 8th Jahrestagung des DAfStb, Berlin, Germany, 28 September 2021; German Standardization Commission: Berlin, Germany.

- Schlüter, D.; Riegelmann, P.; Scheerer, S.; Curbach, M. Bauteiloptimierung durch Funktionsintegration. Beton-und Stahlbetonbau 2020, 115, 598–606. [Google Scholar] [CrossRef]

- Gohs, U.; Böhm, R.; Brünig, H.; Fischer, D.; Leopold, A.-K.; Malanin, M.; Müller, M.-T.; Cherif, C.; Richter, M.; Wolz, D.S.J.; et al. Influence of gas atmosphere on electron-induced reactions of polyacrylonitrile homopolymer powder at elevated temperature. Radiat. Phys. Chem. 2019, 158, 94–102. [Google Scholar] [CrossRef]

- Gohs, U.; Böhm, R.; Brünig, H.; Fischer, D.; Häussler, L.; Kirsten, M.; Malanin, M.; Müller, M.-T.; Cherif, C.; Wolz, D.S.J.; et al. Electron beam treatment of polyacrylonitrile copolymer above the glass transition temperature in air and nitrogen atmosphere. Radiat. Phys. Chem. 2018, 156, 22–30. [Google Scholar] [CrossRef]

- Richter, M.; Richter, B.; Hund, R.D.; Böhm, R.; Jäger, H.; Cherif, C. Polyacrylonitrile-Lignin blends as precursors for porous carbon fibers. In Proceedings of the 19th World Textile Conference on Textiles at the Crossroads (AUTEX 2019), Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Jäger, H.; Cherif, C.; Kirsten, M.; Behnisch, T.; Wolz, D.S.; Böhm, R.; Gude, M. Influence of processing parameters on the properties of carbon fibres—An overview. Mater. Werkst. 2016, 47, 1044–1057. [Google Scholar] [CrossRef]

- Boehm, R.; Thieme, M.; Wohlfahrt, D.; Wolz, D.S.; Richter, B.; Jäger, H. Reinforcement systems for carbon concrete composites based on low-cost carbon fibers. Fibers 2018, 6, 56. [Google Scholar] [CrossRef] [Green Version]

- De Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2020, 281, 123558. [Google Scholar] [CrossRef]

- Hülsmeier, F.; Kahnt, A.; Grauer, O.; Huth, S.; Kirmse, S.; Tietze, M. Vakuumgedämmte Fassadenelemente aus Textilbeton, Abschlussbericht, Forschungsinitiative Zukunft Bau; Fraunhofer IRB: Stuttgart, Germany, 2013; Volume 2872. [Google Scholar]

- Günther, E.; Bichlmair, S.L.; Fricke, M. Internal wall insulation with a new aerogel panel: SLENTITE for energetic retrofit in historic buildings. In Proceedings of the 12th Nordic Symposium on Building Physics, Les Ulis, France, 7–9 September 2000. [Google Scholar] [CrossRef]

- BASF SE. Homepage, Performance Polymers. Available online: https://plastics-rubber.basf.com/global/en/performance_polymers/topics/innovating_with_slentite.html (accessed on 17 June 2021).

- Nelson, S.; Mueller, U.; Carderquist, C.; Malaga, K.; Hallingberg, P. Foam concrete-aerogel composite for thermal insulation in lightweight sandwich facade elements. In Construction Innovations: Research into Practice: Concrete 2015, Proceedings of the 27th Biennial National Conference of the Concrete Institute of Australia in Conjunction with the 69th RILEM Week, Melbourne, VIC, Australia, 30 August–2 September 2015; Concrete Institute of Australia: North Sydney, NSW, Australia, 2015; pp. 1355–1362. [Google Scholar]

- Schnellenbach-Held, M.; Welsch, T.; Fickler, S.; Milow, B.; Ratke, L. Entwicklung von Hochleistungsaerogelbeton. Beton-und Stahlbetonbau 2016, 111, 555–563. [Google Scholar] [CrossRef]

- Nunna, S.; Blanchard, P.; Buckmaster, D.; Davis, S.; Naebe, M. Development of a cost model for the production of carbon fibres. Heliyon 2019, 5, e02698. [Google Scholar] [CrossRef] [Green Version]

- Morgan, P. Carbon Fibers and Their Composites; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Cetrotherm International AG. Integrated Solutions for Carbon Fibre Production. Available online: https://www.centrotherm.de/en/industry-solutions/high-performance-fibers (accessed on 23 November 2021).

- Ogale, A.A.; Zhang, M.; Jin, J. Recent advances in carbon fibers derived from biobased precursors. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef] [Green Version]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, J.M.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef]

- Arnold, U.; Brück, T.; De Palmenaer, A.; Kuse, K. Carbon capture and sustainable utilization by algal polyacrylonitrile fiber production: Process design, techno-economic analysis, and climate related aspects. Ind. Eng. Chem. Res. 2018, 57, 7922–7933. [Google Scholar] [CrossRef]

- Wohlmann, B.; Stüsgen, S. Schmelzbares Ligninderivat und Daraus Hergestellte Ligninderivatfaser. WO 2013/144123 A1, 3 October 2013. [Google Scholar]

- Press Release: Stora Enso and Cordenka Partner to Develop Bio-Based Carbon Fiber Materials. Available online: https://www.storaenso.com/cs-cz/newsroom/press-releases/2020/5/stora-enso-and-cordenka-partner-to-develop-bio-based-carbon-fiber-materials (accessed on 6 May 2020).

- Le, N.-D.; Trogen, M.; Ma, Y.; Varley, R.J.; Hummel, M.; Byrne, N. Cellulose-Lignin composite fibers as precursors for carbon fibers: Part 2—The impact of precursor properties on carbon fibers. Carbohydr. Polym. 2020, 250, 116918. [Google Scholar] [CrossRef]

- Ayoubi, M.; Sobotta, S.; Schlüter, D.; Michler, H.; Kropp, T.; Thüsing, K.; Kallnick, S.; Schumann, A. Aktive Verbinder für Bauelemente aus Carbonbeton. Bautechnik 2021, 98, 399–409. [Google Scholar] [CrossRef]

- Albert, A.; Busch, D. Stahlbetonhohlkörperdecken. Bemessungshinweise und neue Entwicklungen. In Konstruktiver Ingenieurbau KI (NR.1); Reguvis Fachmedien: Cologne, Germany, 2020; ISSN 2509-2847. [Google Scholar]

- Schlueter, D.; Scherer, S.; Uhlemann, S.; Curbach, M. Multifunctional carbon concrete—Optimization in four steps. In Proceedings of the 13th International Symposium on Ferrocement and Thin Fiber Reinroced Inorganic Matrices, Lyon, France, 21–23 June 2021. [Google Scholar]

- Vakaliuk, I.; Frenzel, M.; Curbach, M. C³ technology demonstration house—CUBE, “From digital model to realization”. In Proceedings of the IASS Annual Symposium 2020/21 and the 7th International Conference on Spatial Structures, Guilford, UK, 23–27 August 2021; Behnejad, S.A., Parke, G.A.R., Samavati, O.A., Eds.; International Association for Shell and Spatial Structures: Madrid, Spain, 2021; p. 11. [Google Scholar]

- González, V.; Barrios-Padura, A.; Molina-Huelva, M. Structural refurbishment projects. The sustainability of reinforcements using composite materials. In Sustainable Development and Renovation in Architecture, Urbanism and Engineering; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 289–299. [Google Scholar] [CrossRef]

- Garg, S.N. Shrivastava: Environmental and economic comparison of FRP reinforcements and steel reinforcements in concrete beams based on design strength parameter. In Proceedings of the UKIERI Concrete Congress, Jalandhar, India, 5–8 March 2019; Dr. B.R. Ambedkar National Institute of Technology: Jalandhar, India, 2019; p. 9. [Google Scholar]

- Kortmann, F.J. Kopf: Abbruch und Recycling von Carbonbeton. In RECYCLING Magazin; 12/2020 75; DETAIL Business Information GmbH: München, Germany, 2020; pp. 30–31. [Google Scholar]

- Kortmann, J. Carbonbeton ist wiederverwertbar. In VDI Nachrichten: Technik, Wirtschaft, Gesellschaft; 11/2021; VDI Verlag GmbH: Düsseldorf, Germany, 2021. [Google Scholar]

- Morgenweck-Marfels, G.; Kahmer, H. Betonfassaden im Thermowand-System: Entwurf, Konstruktion und Ausführung, 2nd ed.; Syspro-Gruppe Betonbauteile e. V.: Erlensee, Germany, 2010. [Google Scholar]

- Kahnt, A.; Schladitz, F.; Tietze, M.; Scheerer, S.; Curbach, M. Carbonbeton—Hochleistungsbaustoff mit Effizienzpotenzial. In Best of DETAIL Material + Oberfläche/Best of DETAIL Materials + Finishes: Highlights aus DETAIL/Highlights from DETAIL; Best of DETAIL; Schittich, C., Ed.; DETAIL: München, Germany, 2016; pp. 41–47. [Google Scholar]

- Curbach, M.; Schladitz, F.; Kahnt, A. Revolution im Bauwesen—Carbon Concrete Composite. In Ingenieurbaukunst 2015; Bundesingenieurkammer, e.V., Ed.; Wilhelm Ernst & Sohn: Berlin, Germany, 2014; pp. 172–177. [Google Scholar]

- Tietze, M.; Kahnt, A.; Grauer, O.; Rittner, S.; von Zuben, M.; Schurig, M. Automatisierte und bedarfsgerechte Carbonbewehrungsherstellung im Fertigteilwerk BWI. Die Moderne Fachzeitschrift Für Die Betonindustrie 2018, 1, 192–197. [Google Scholar]

- Kahnt, A. Die Gebäudehülle der Zukunft—Entwicklung einer Textilbetonfassade vom Baustoff bis zum Raumklima. Ph.D. Thesis, Technische Universität Dresden, Institut für Bauklimatik, Stuttgart, Germany, 2021. [Google Scholar]

- Men’Shutina, N.V.; Katalevich, A.M.; Smirnova, I. Preparation of silica-based aerogels by supercritical drying. Russ. J. Phys. Chem. B 2014, 8, 973–979. [Google Scholar] [CrossRef]

- Sun, M.; Barbero, S.R.; Johannsen, M.; Smirnova, I.; Gurikov, P. Retention characteristics of silica materials in carbon dioxide/methanol mixtures studied by inverse supercritical fluid chromatography. J. Chromatogr. A 2019, 1588, 127–136. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraft, R.; Kahnt, A.; Grauer, O.; Thieme, M.; Wolz, D.S.; Schlüter, D.; Tietze, M.; Curbach, M.; Holschemacher, K.; Jäger, H.; et al. Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings. Materials 2022, 15, 1619. https://doi.org/10.3390/ma15041619

Kraft R, Kahnt A, Grauer O, Thieme M, Wolz DS, Schlüter D, Tietze M, Curbach M, Holschemacher K, Jäger H, et al. Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings. Materials. 2022; 15(4):1619. https://doi.org/10.3390/ma15041619

Chicago/Turabian StyleKraft, Robert, Alexander Kahnt, Otto Grauer, Mike Thieme, Daniel Sebastian Wolz, Dominik Schlüter, Matthias Tietze, Manfred Curbach, Klaus Holschemacher, Hubert Jäger, and et al. 2022. "Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings" Materials 15, no. 4: 1619. https://doi.org/10.3390/ma15041619

APA StyleKraft, R., Kahnt, A., Grauer, O., Thieme, M., Wolz, D. S., Schlüter, D., Tietze, M., Curbach, M., Holschemacher, K., Jäger, H., & Böhm, R. (2022). Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings. Materials, 15(4), 1619. https://doi.org/10.3390/ma15041619