Crystal Evolution of Calcium Silicate Minerals Synthesized by Calcium Silicon Slag and Silica Fume with Increase of Hydrothermal Synthesis Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. Phase Evolution of Calcium Silicate Minerals with Increase of Hydrothermal Synthesis Temperature

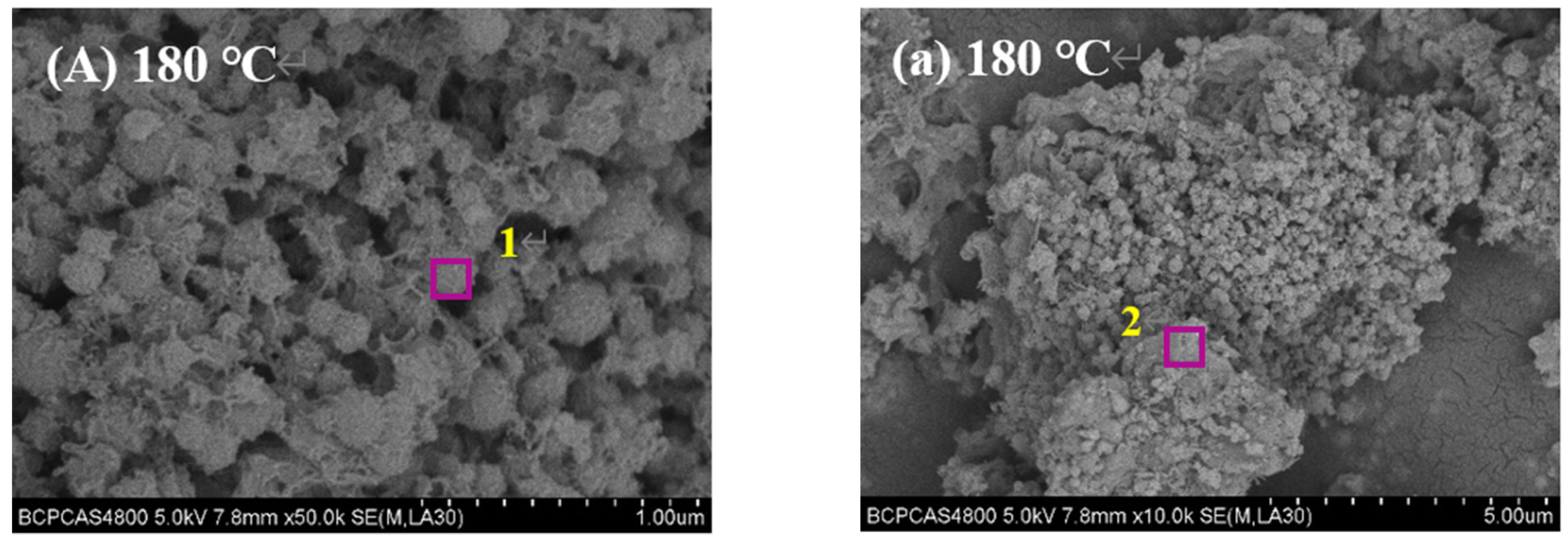

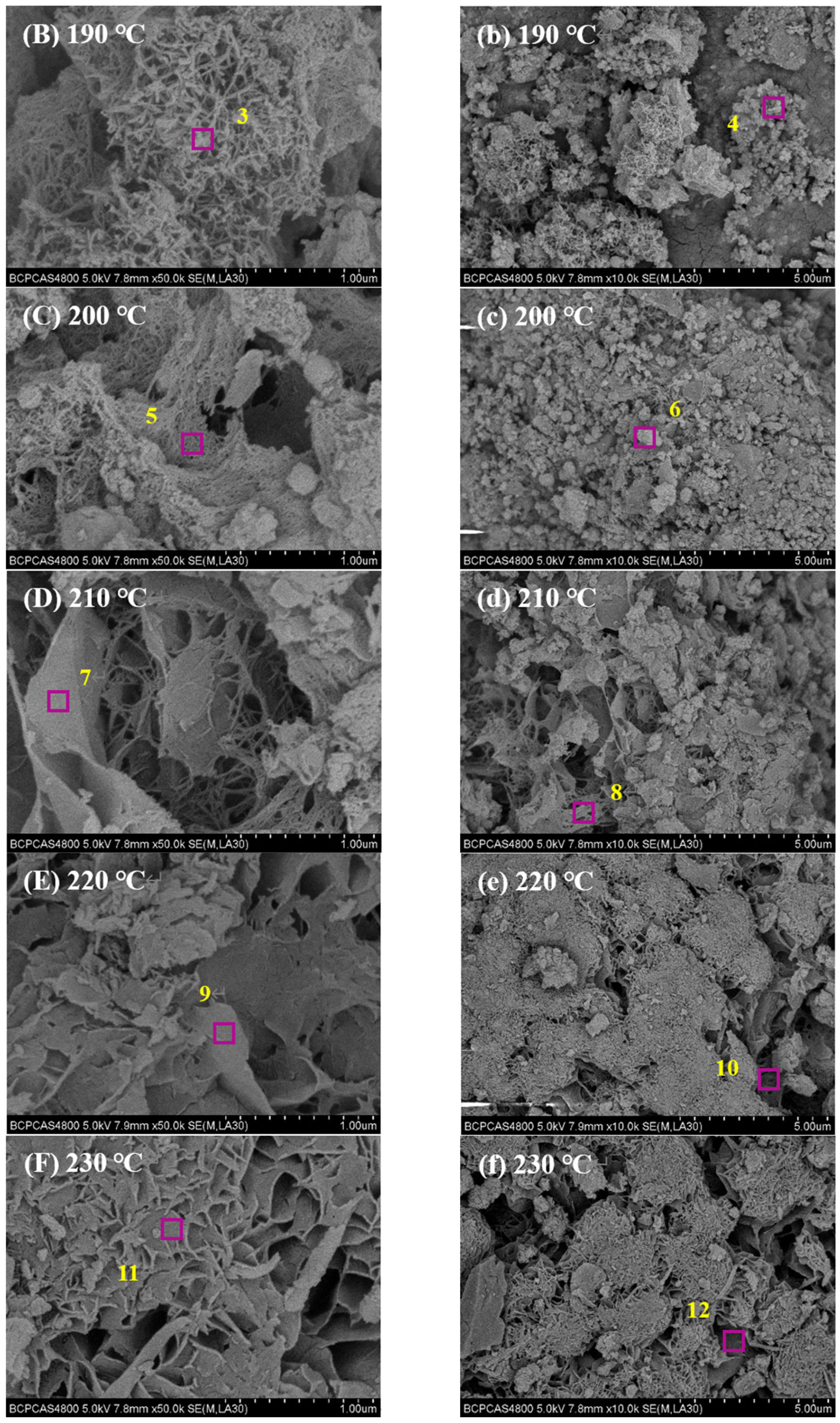

3.2. Micromorphology Evolution of Calcium Silicate Minerals with Increase of Hydrothermal Synthesis Temperature

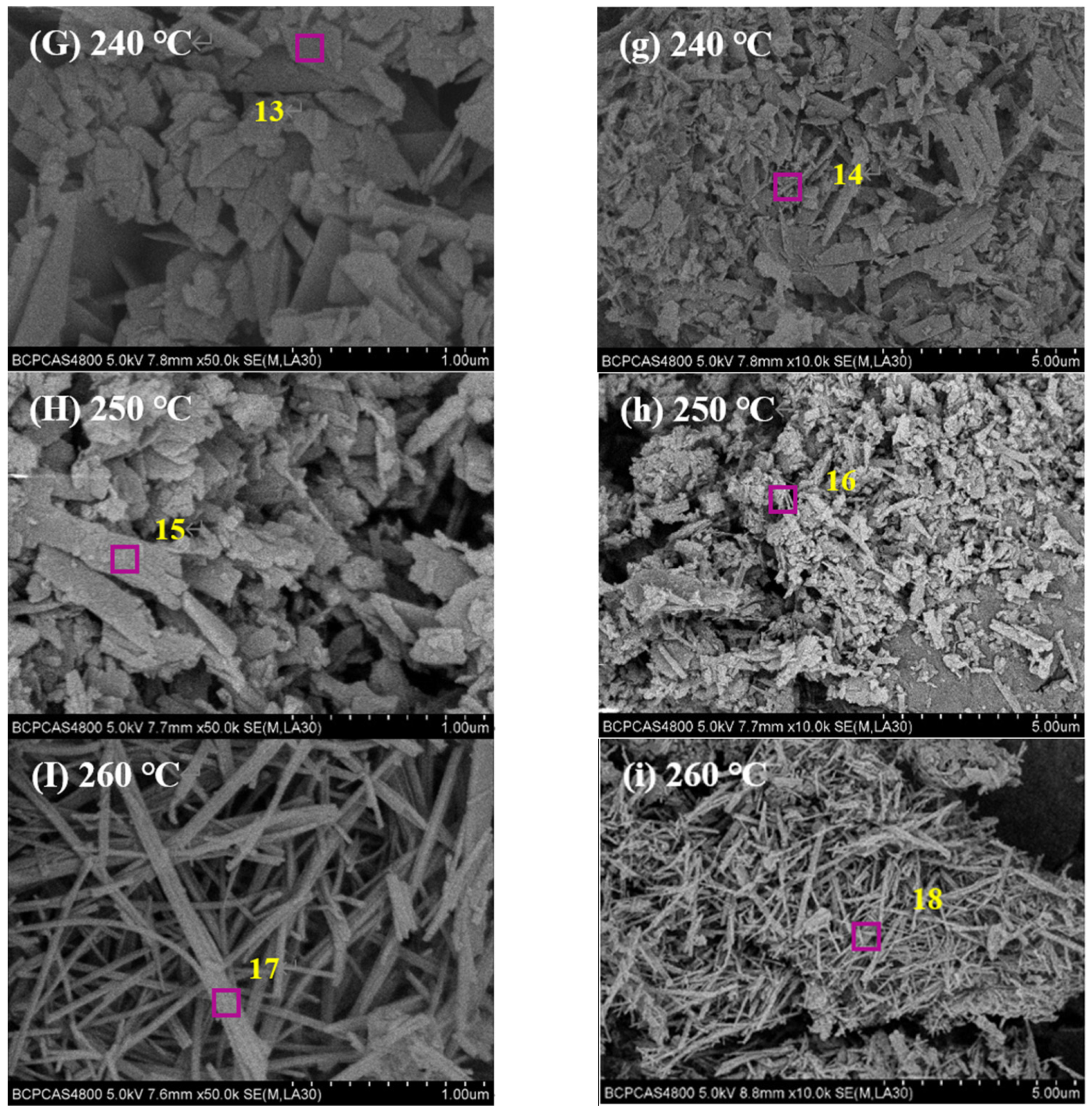

3.3. Micropore Parameters Evolution of Calcium Silicate Minerals with Increase of Hydrothermal Synthesis Temperature

4. Conclusions

- (1)

- The main reaction mechanism of hydrothermal synthesis is that β-dicalcium silicate contained in CSS, firstly hydrates to generate amorphous C–S–H and Ca(OH)2, and the environment of system is induced to strong alkaline. Therefore, the highly polymerized Si–O bond of SF are broken under the polarization of OH− to form (SiO4) of Q0. At condition of high temperature and high press, amorphous C–S–H, Ca(OH)2 and (SiO4) of Q0 react each other to gradually produce various of calcium silicate minerals with higher and higher C/S molar ratio with increase of synthesis temperature.

- (2)

- With the increase of synthesis temperature, crystal evolution order of calcium silicate mineral synthesized by CSS and SF is cocoon-like C–S–H, mesh-like C–S–H, large flake-like gyrolite, small flake-like gyrolite, petal-like gyrolite, square flake-like calcium silicate hydroxide hydrate, and strip-like tobermorite.

- (3)

- With the increase of synthesis temperature, the APV, APD and SSA of the synthesis products show a change trend of first increase and then decrease. The APV, APD and SSA are closely related to the main crystal of synthesis products. However, because petal-like gyrolite is semi-closed pores, it’s APV and SSA are relatively higher, but it’s APD is relatively lower.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daming, Z.; Jiang, C. Effects of surface modification of β-CaSiO3 on electrospun poly (butylenesuccinate)/β-CaSiO3 composite fibers. Mater. Chem. Phys. 2009, 118, 379–384. [Google Scholar]

- Fang, D.; Huang, L.; Fang, Z.; Zhang, Q.; Shen, Q.; Li, Y.; Xu, X.; Ji, F. Evaluation of porous calcium silicate hydrate derived from carbide slag for removing phosphate from wastewater. Chem. Eng. J. 2018, 354, 1–11. [Google Scholar] [CrossRef]

- Huiquan, L.; Junbo, H.; Chenye, W.; Bao, W.; Sun, Z. Removal of sodium (Na2O) from alumina extracted coal fly ash by a mild hydrothermal process. Hydrometallurgy 2015, 153, 1–5. [Google Scholar]

- Paradiso, P.; Santos, R.L.; Horta, R.B.; Lopes, J.; Ferreira, P.; Colaço, R. Formation of nanocrystalline tobermorite in calcium silicate binders with low C/S ratio. Acta Mater. 2018, 152, 7–15. [Google Scholar] [CrossRef]

- Hossain, S.K.S.; Roy, P.K. Development of sustainable calcium silicate board: Utilization of different solid wastes. Boletín Soc. Española Cerámica Vidr. 2019, 58, 274–284. [Google Scholar] [CrossRef]

- Bu, J.; Gonzalez Teresa, R.; Brown, K.G. Adsorption mechanisms of cesium at calcium-silicate-hydrate surfaces using molecular dynamics simulations. J. Nucl. Mater. 2019, 515, 35–51. [Google Scholar] [CrossRef]

- Liu, J.H.; Zhang, M.Y.; Lu, Z.Q. Study on application of new silicate fillers extracted from fly ash in paper making. Tianjin Pap. Mak. 2013, 4, 7–12. [Google Scholar]

- Qingfu, L.; Shilong, Z.; Junming, S. Study on properties of styrene butadiene rubber filled by active calcium silicate. J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.) 2013, 28, 95–99. [Google Scholar]

- Leite, F.H.G.; Almeida, T.F.; Faria, R.T., Jr.; Holanda, J.N.F. Synthesis and characterization of calcium silicate insulating material using avian eggshell waste. Ceram. Int. 2017, 43, 4674–4679. [Google Scholar] [CrossRef]

- Richardson, I.G. Tobermorite/jennite and tobermorite/calcium hydroxide-based models for the structure of C-S-H: Applicability to hardened pastes of tricalcium silicate, β-dicalcium silicate, Portland cement, and blends of Portland cement with blast-furnace slag. Cem. Concr. Res. 2004, 34, 1733–1777. [Google Scholar] [CrossRef]

- Ma, J.; Qin, G.; Zhang, Y. Heavy metal removal from aqueous solutions by calcium silicate powder from waste coal fly-ash. J. Clean. Prod. 2018, 182, 776–782. [Google Scholar] [CrossRef]

- Liu, L.; Liu, S.; Peng, H. Surface charge of mesoporous calcium silicate and its adsorption characteristics for heavy metal ions. Solid State Sci. 2020, 99, 106072. [Google Scholar] [CrossRef]

- Liu, Y.; Jia, H.; Zhang, G. Synthesis and humidity control performances of natural opoka based porous calcium silicate hydrate. Adv. Powder Technol. 2019, 30, 2733–2741. [Google Scholar] [CrossRef]

- Lee, C.; Alvarez, P.J.J.; Kim, H. Phosphorous recovery from sewage sludge using calcium silicate hydrates. Chemosphere 2018, 193, 1087–1093. [Google Scholar] [CrossRef] [PubMed]

- Van, N.D.; Imasawa, K.; Hama, Y. Influence of hydrothermal synthesis conditions and carbonation on physical properties of xonotlite-based lightweight material. Constr. Build. Mater. 2022, 321, 126328. [Google Scholar]

- Shiyue, H.; Huiquan, L.; Shaopeng, L. Kinetics of desilication process of fly ash with high aluminum from Kinetics of desilication process of fly ash with high aluminum from. Chin. J. Nonferrous Met. 2014, 24, 1888–1894. [Google Scholar]

- Yang, Z.; Kang, D.; Zhang, D.; Yan, C.; Zhang, J. Crystal transformation of calcium silicate minerals synthesized by calcium silicate slag and silica fume with increase of C/S molar ratio. J. Mater. Res. Technol. 2021, 15, 4185–4192. [Google Scholar]

- Guan, W.; Ji, F.; Fang, Z.; Fang, D.; Cheng, Y.; Yan, P.; Chen, Q. Low hydrothermal temperature synthesis of porous calcium silicate hydrate with enhanced reactivity SiO2. Ceram. Int. 2014, 40, 4415–4420. [Google Scholar] [CrossRef]

- Ogur, E.; Botti, R.; Bortolotti, M.; Colombo, P.; Vakifahmetoglu, C. Synthesis and additive manufacturing of calcium silicate hydrate scaffolds. Mater. Res. Technol. 2021, 11, 1142–1151. [Google Scholar] [CrossRef]

- Pengxu, C.; Guanghui, L.; Jun, L. Alkali-reinforced hydrothermal synthesis of lathy tobermorite fibers using mixture of coal fly ash and lime. Constr. Build. Mater. 2020, 238, 117655. [Google Scholar]

- Camerini, R.; Poggi, G.; Ridi, F.; Baglioni, P. The kinetic of calcium silicate formation from and calcium hydroxide nanoparticles. Colloid Interface Sci. 2022, 605, 33–43. [Google Scholar] [CrossRef] [PubMed]

- Bensted, J.; Barnes, P. Structure and Performance of Cements, 2nd ed.; Applied Science Publishers: London, UK, 1983; pp. 67–69. [Google Scholar]

- Drochytka, R.; Černý, V. Influence of fluidized bed combustion fly ash admixture on hydrothermal synthesis of tobermorite in the mixture with quartz sand, high temperature fly ash and lime. Constr. Build. Mater. 2020, 230, 117033. [Google Scholar] [CrossRef]

- Ríos, C.A.; Williams, C.D.; Fullen, M.A. Hydrothermal synthesis of hydrogarnet and tobermorite at 175 °C from kaolinite and metakaolinite in the CaO–Al2O3–SiO2–H2O system: A comparative study. Appl. Clay Sci. 2009, 43, 228–237. [Google Scholar] [CrossRef]

- Różycka, A.; Kotwica, Ł. Effect of alkali on the synthesis of single phase gyrolite in the system CaO-quartz-H2O. Constr. Build. Mater. 2020, 239, 117799. [Google Scholar] [CrossRef]

- Ganyu, Z.; Huiquan, L.; Shaopeng, L.; Xinjuan, X.; Xingrui, W. Crystallization of calcium silicate at elevated temperatures in highly alkaline system of Na2O–CaO–SiO2–H2O. Mater. Prod. Eng. 2017, 25, 1539–1544. [Google Scholar]

- Wenzel, O.; Schwotzer, M.; Müller, E.; Chakravadhanula, V.S.K.; Scherer, T.; Gerdes, A. Investigating the pore structure of the calcium silicate hydrate phase. Mater. Charact. 2017, 133, 133–137. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | Fe2O3 | Al2O3 | CaO | MgO | Na2O | K2O | SO3 | P2O5 | F | Cl |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CSS | 29.26 | 2.53 | 5.30 | 55.50 | 3.61 | 2.58 | 0.36 | 0.73 | 0.14 | - | 0.42 |

| SF | 72.15 | 1.16 | 0.59 | 7.50 | 7.43 | 0.68 | 4.20 | 3.17 | 0.56 | 1.74 | 0.82 |

| No. | Phase | Chemical Formula | PDF Card No. | Main 2θ (°) |

|---|---|---|---|---|

| A | β-dicalcium silicate | β-2CaO·SiO2 | 01-083-0460 | 23.190, 32.169, 41.174 |

| B | calcite | CaCO3 | 01-072-1937 | 29.369, 39.370, 48.452 |

| C | crystalline C–S–H | C–S–H | 00-002-0068 | 30.168, 31.589, 37.281 |

| D | gyrolite | Ca4(Si6O15)(OH)2·3H2O | 00-042-1425 | 21.065, 28.227, 31.797 |

| E | tobermorite | 5CaO·6SiO2·5H2O | 00-045-1480 | 16.251, 30.044, 31.867 |

| F | calcium silicate hydroxide hydrate | Ca4.5Si6O15(OH)2·3H2O | 00-043-1488 | 35.817, 36.782, 45.291 |

| Microcosmic Region | Micromorphology | Atom Molar Ratio (%) | Corresponding Phase | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O | Al | Si | Ca | Na | Mg | Fe | C | |||

| 1 | cocoon-like | 63.54 | 0.52 | 17.15 | 16.42 | 0.24 | 0.81 | 1.32 | - | crystalline C–S–H |

| 2 | block-like | 58.72 | 0.21 | 0.10 | 20.04 | - | 0.10 | 0.10 | 20.73 | calcite |

| 3 | mesh-like | 63.36 | 0.52 | 17.22 | 16.72 | 0.35 | 0.81 | 1.02 | - | crystalline C–S–H |

| 4 | granular-like | 54.42 | 1.75 | 14.76 | 27.02 | 0.56 | 1.13 | 0.36 | - | β-dicalcium silicate |

| 5 | mesh-like | 65.72 | 0.33 | 16.95 | 16.23 | 0.12 | 0.44 | 0.21 | - | crystalline C–S–H |

| 6 | block-like | 57.72 | 0.53 | 0.21 | 20.46 | - | 0.21 | 0.24 | 20.63 | calcite |

| 7 | large flake-like | 67.32 | 0.15 | 19.25 | 12.42 | 0.21 | 0.52 | 0.13 | - | gyrolite |

| 8 | mesh-like | 66.52 | 0.33 | 16.15 | 16.23 | 0.12 | 0.44 | 0.21 | - | crystalline C–S–H |

| 9 | small flake-like | 64.25 | 0.44 | 19.05 | 12.34 | 0.13 | 2.23 | 1.56 | - | gyrolite |

| 10 | mesh-like | 65.72 | 0.33 | 16.95 | 16.23 | 0.12 | 0.44 | 0.21 | - | crystalline C–S–H |

| 11 | petal-like | 67.44 | 0.12 | 20.35 | 11.03 | 0.65 | 0.36 | 0.05 | - | gyrolite |

| 12 | small flake-like | 64.15 | 0.44 | 18.45 | 12.64 | 0.23 | 2.23 | 1.56 | - | gyrolite |

| 13 | square flake-like | 64.07 | 0.05 | 20.67 | 13.41 | 0.34 | 1.27 | 0.19 | - | calcium silicate hydroxide hydrate |

| 14 | strip-like | 66.22 | 0.33 | 17.45 | 15.23 | 0.12 | 0.44 | 0.21 | - | tobermorite |

| 15 | square flake-like | 65.27 | 0.19 | 19.47 | 13.09 | 0.27 | 1.66 | 0.05 | - | calcium silicate hydroxide hydrate |

| 16 | strip-like | 64.67 | 0.36 | 18.35 | 15.42 | 0.45 | 0.52 | 0.23 | - | tobermorite |

| 17 | strip-like | 65.34 | 0.34 | 17.28 | 15.37 | 0.26 | 0.41 | 1.00 | - | tobermorite |

| 18 | strip-like | 66.23 | 0.26 | 17.91 | 14.83 | 0.14 | 0.32 | 0.31 | - | tobermorite |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Zhang, D.; Jiao, Y.; Fang, C.; Kang, D.; Yan, C.; Zhang, J. Crystal Evolution of Calcium Silicate Minerals Synthesized by Calcium Silicon Slag and Silica Fume with Increase of Hydrothermal Synthesis Temperature. Materials 2022, 15, 1620. https://doi.org/10.3390/ma15041620

Yang Z, Zhang D, Jiao Y, Fang C, Kang D, Yan C, Zhang J. Crystal Evolution of Calcium Silicate Minerals Synthesized by Calcium Silicon Slag and Silica Fume with Increase of Hydrothermal Synthesis Temperature. Materials. 2022; 15(4):1620. https://doi.org/10.3390/ma15041620

Chicago/Turabian StyleYang, Zhijie, De Zhang, Yang Jiao, Chengyang Fang, Dong Kang, Changwang Yan, and Ju Zhang. 2022. "Crystal Evolution of Calcium Silicate Minerals Synthesized by Calcium Silicon Slag and Silica Fume with Increase of Hydrothermal Synthesis Temperature" Materials 15, no. 4: 1620. https://doi.org/10.3390/ma15041620

APA StyleYang, Z., Zhang, D., Jiao, Y., Fang, C., Kang, D., Yan, C., & Zhang, J. (2022). Crystal Evolution of Calcium Silicate Minerals Synthesized by Calcium Silicon Slag and Silica Fume with Increase of Hydrothermal Synthesis Temperature. Materials, 15(4), 1620. https://doi.org/10.3390/ma15041620