Residual Impact Performance of ECC Subjected to Sub-High Temperatures

Abstract

:1. Introduction

2. Experiential Study

2.1. Materials and Mixtures

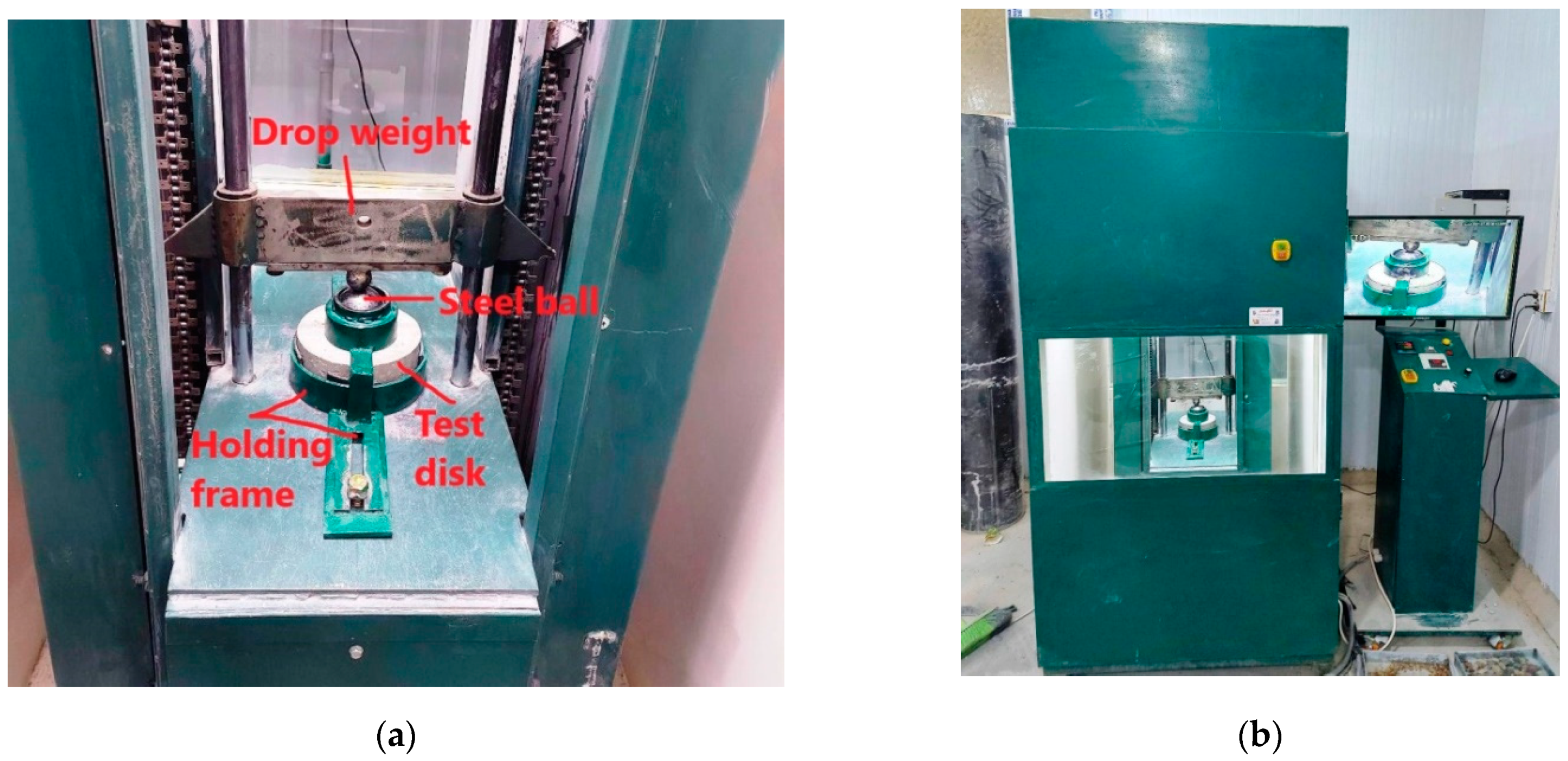

2.2. Tests and Procedures

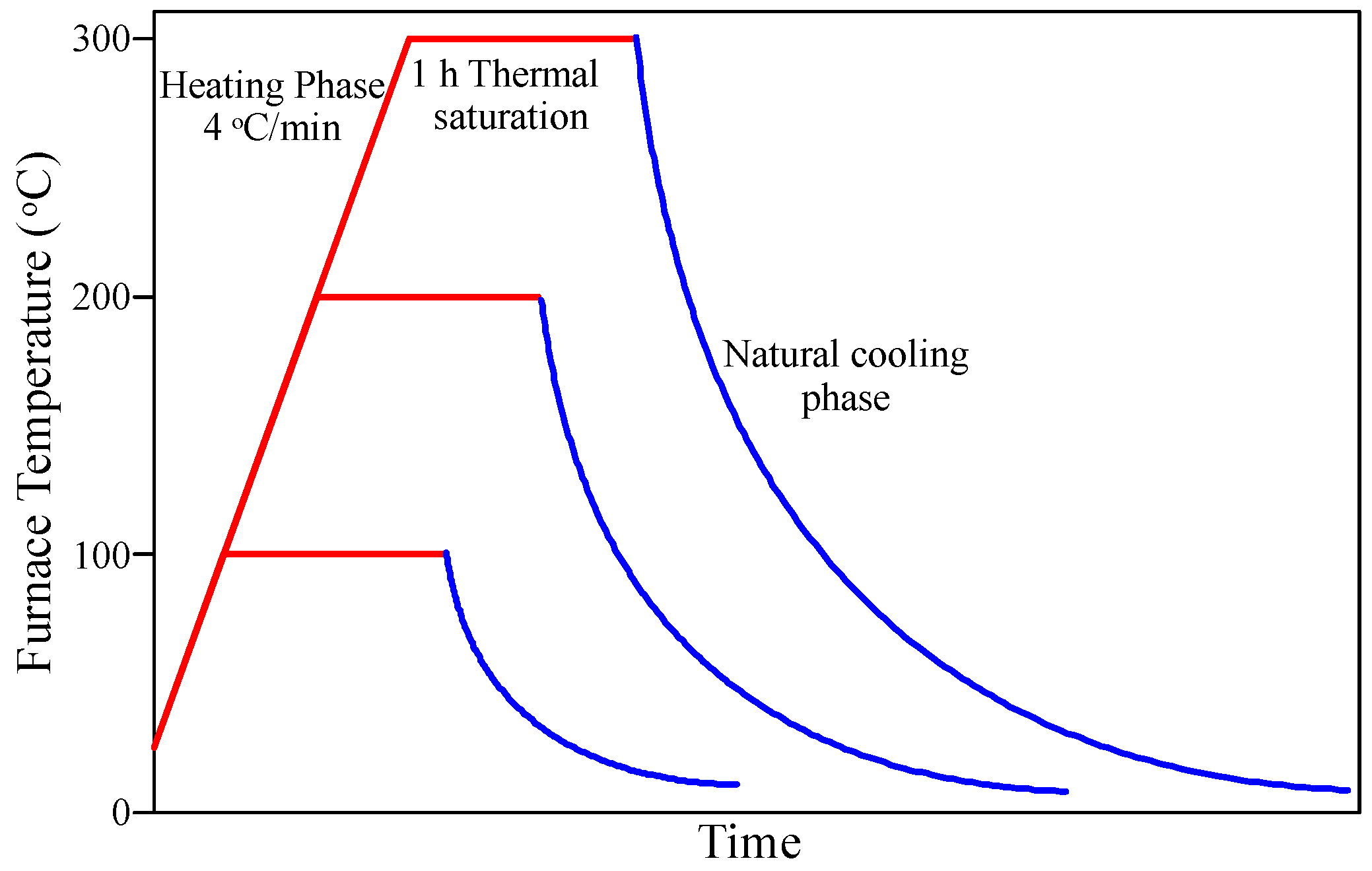

2.3. Furnace Heating

3. Compressive Strength Results

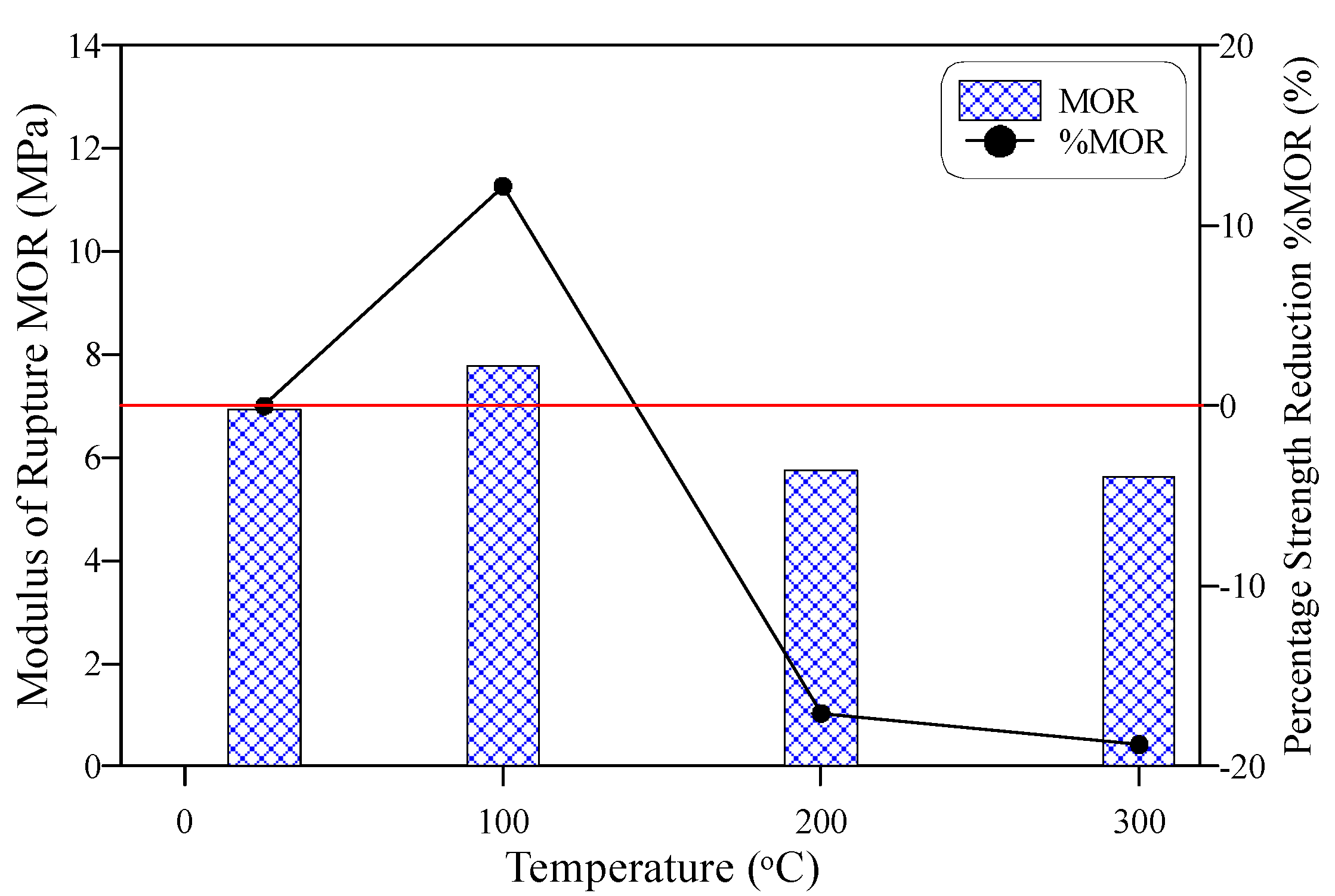

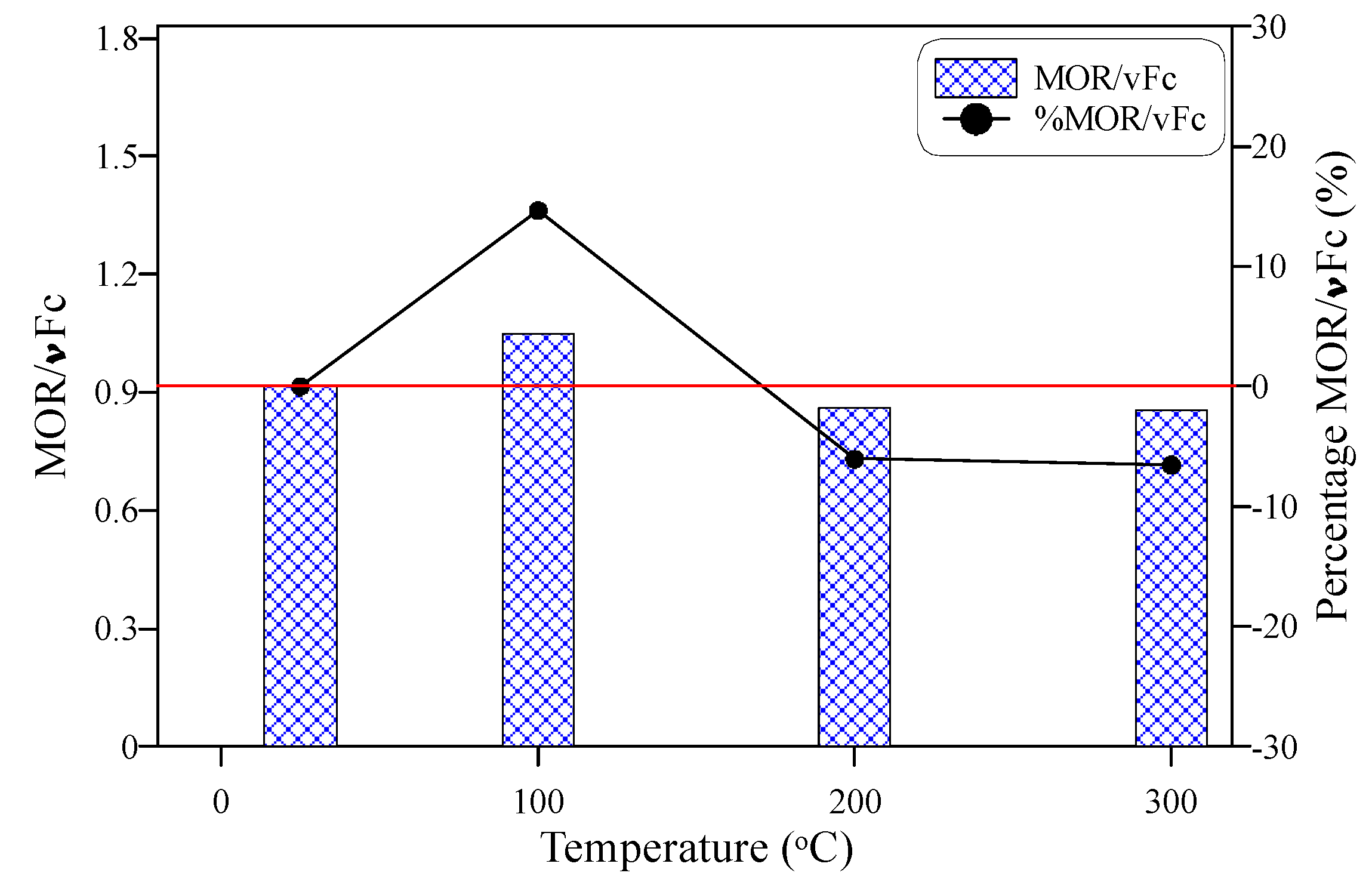

4. Flexural Strength Results

5. Repeated Impact Strength Results

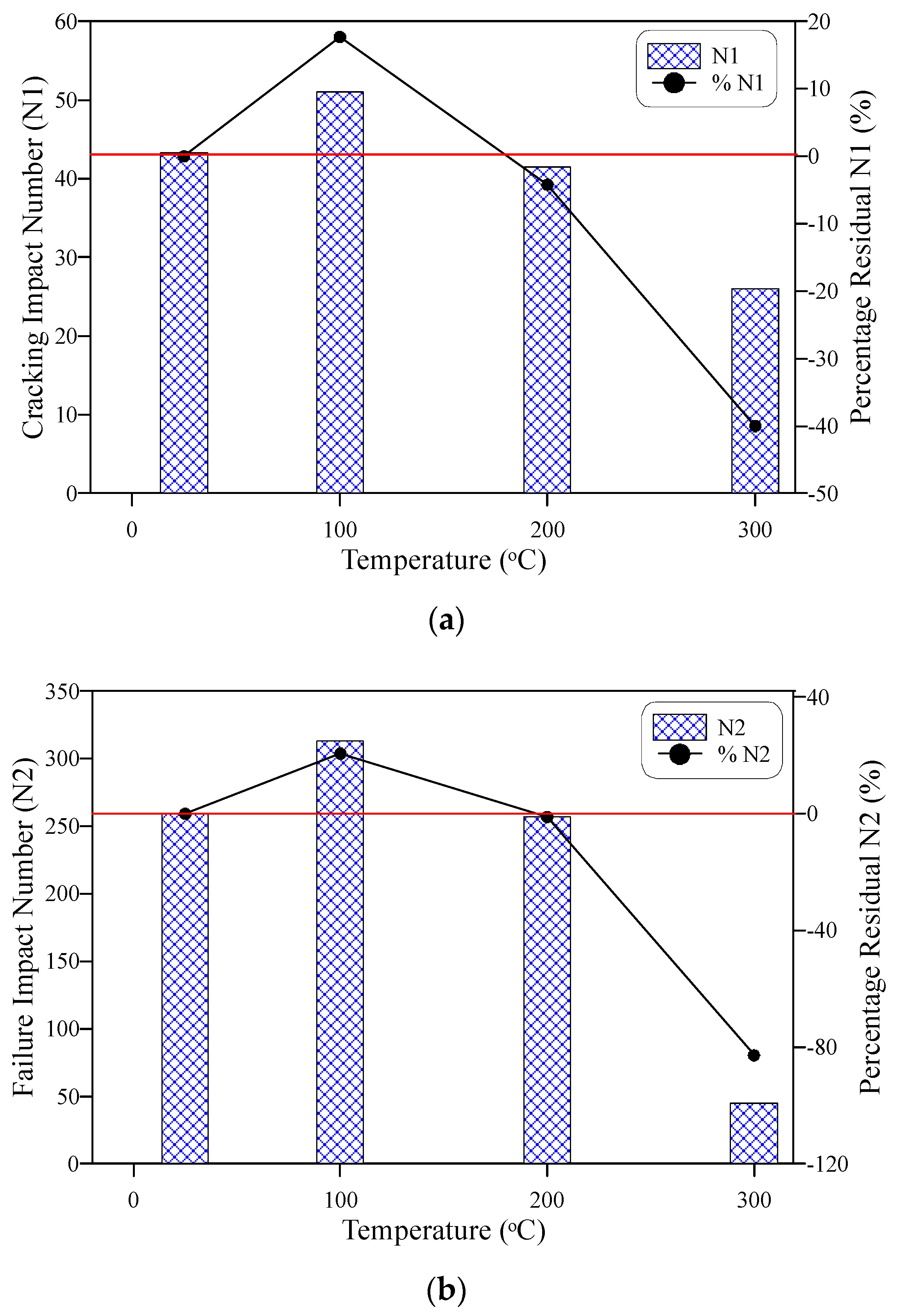

5.1. Impact Number Results

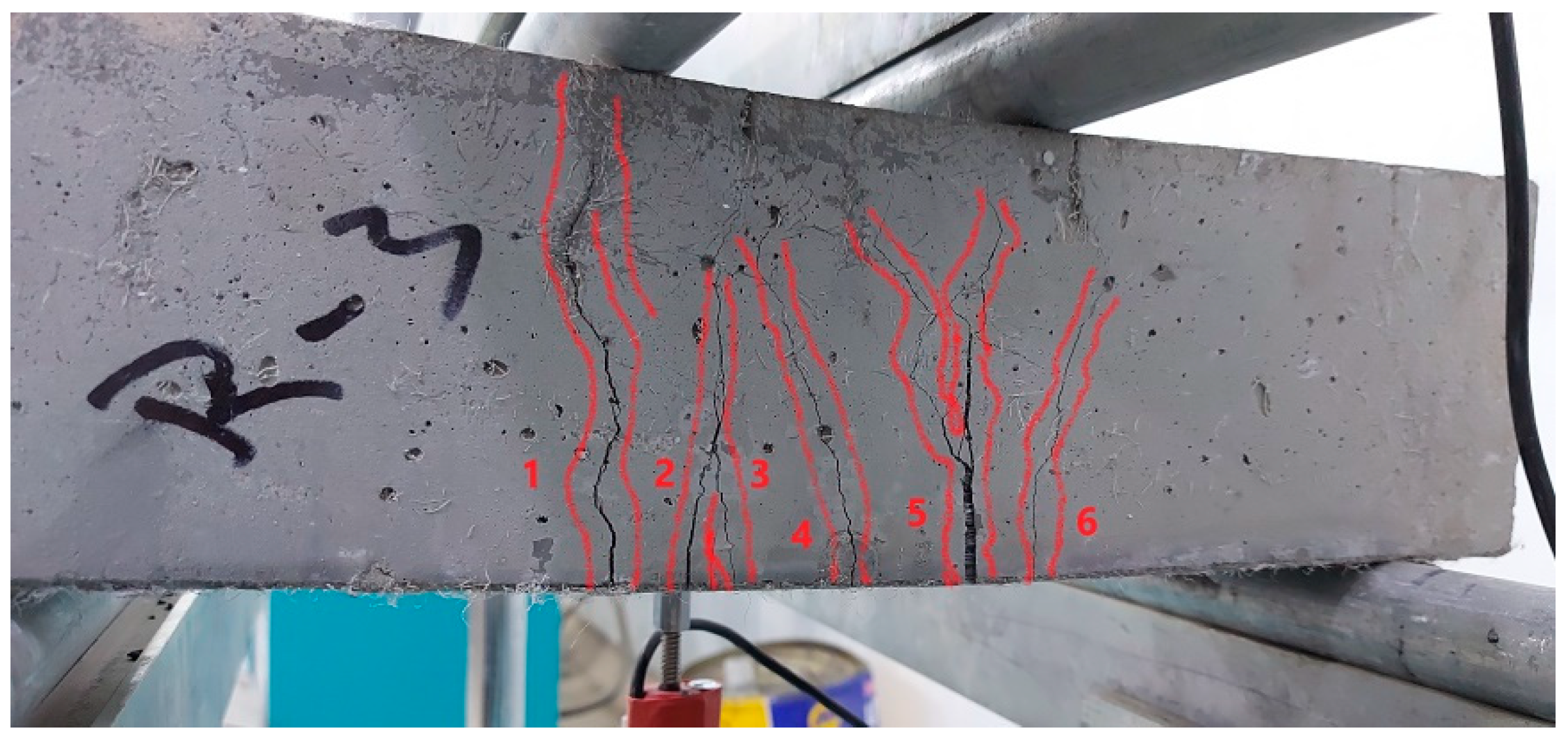

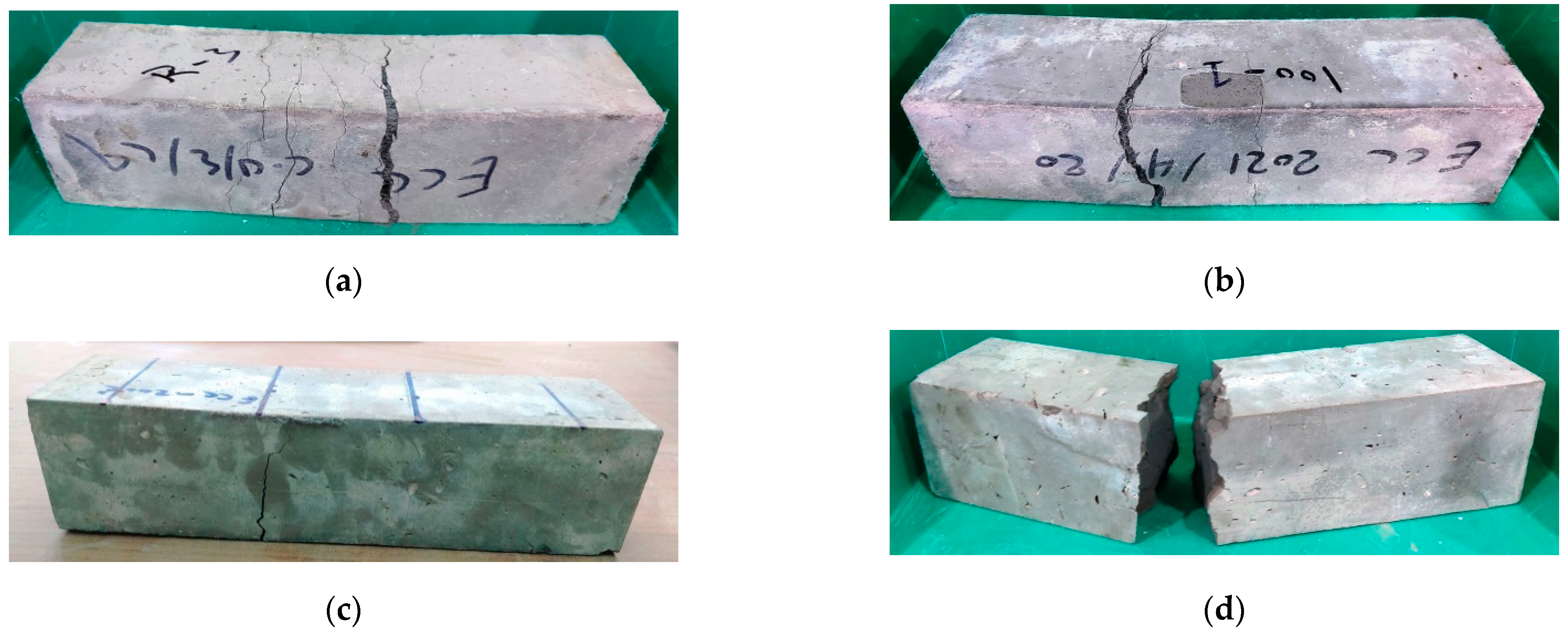

5.2. Failure of Impact Specimens

5.3. Impact Ductility

6. Conclusions

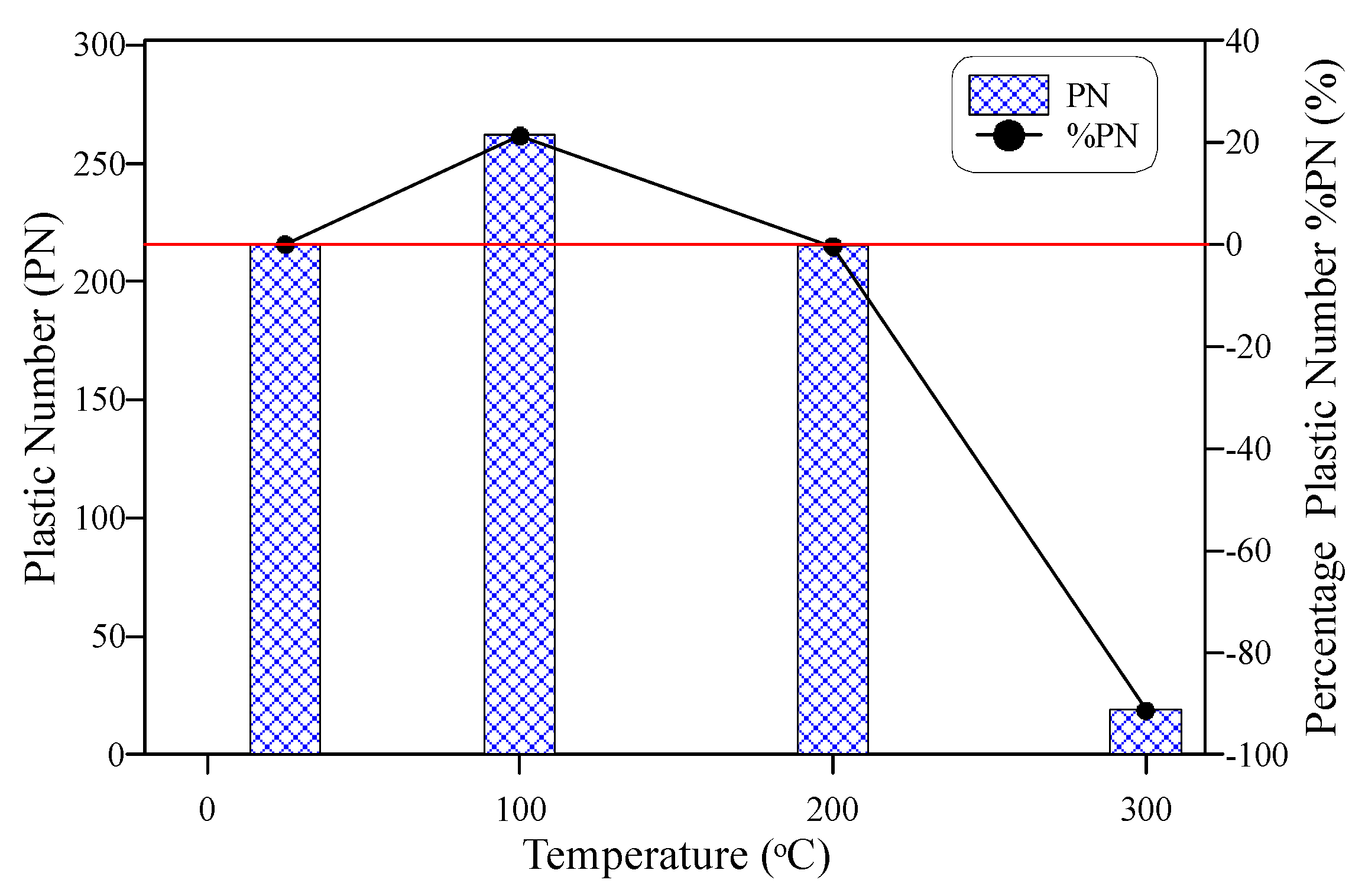

- Cracking (N1) and failure (N2) impact numbers increased after exposure to 100 °C compared to the unheated reference specimens, where N1 and N2 increased by approximately 18 and 21%, respectively. The impact resistance in terms of N1 and N2 of ECC was almost unaffected by the exposure to 200 °C, where the percentage decrease values of N1 and N2 were limited by approximately 4 and 1%, respectively. However, exposure to 300 °C led to a significant impact resistance deterioration, which was more severe at failure than at the cracking stage with percentage decrease values of 40 and 83%, respectively.

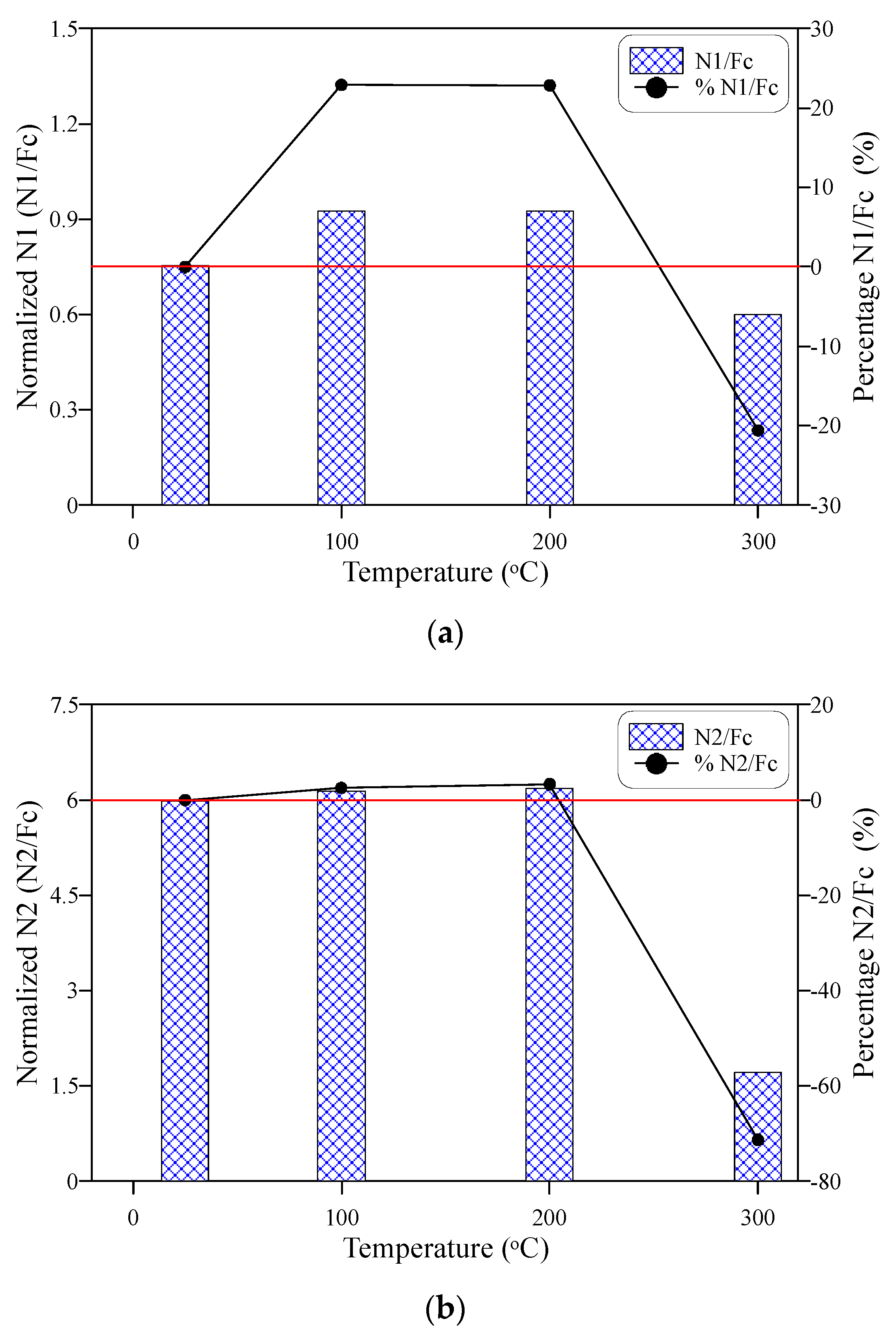

- To evaluate the influence of compressive strength on the response of cracking numbers with temperature, N1 and N2 were normalized at each temperature level by the corresponding compressive strength records at these temperatures. The normalized N1 and N2 values reflected a noticeable dependency degree of the temperature-response of N1 and N2 on that of compressive strength. The normalized N1 and N2 were almost constant at 100 and 200 °C, and both were higher than the unheated reference values, which is different behavior than that of N1 and N2 with temperature. The reductions at 300 °C were also lower for the normalized N1 and N1 cases than their corresponding N1 and N2 records. The different behaviors of normalized impact numbers from those of impact numbers reflect the noticeable degree of dependency of impact resistance on the compressive strength after exposure to temperatures of 100 to 300 °C.

- The specimens heated to 100 °C exhibited a ductile failure similar to that of the unheated specimens, which was characterized by the fracturing of the central zone of the top surface followed by surface multi-cracking and finally failed by the widening of one or more major cracks. Oppositely, the specimens exposed to 300 °C exhibited a sudden brittle failure without central fracturing or pre-failure multi-cracking. This behavior is attributed to the deterioration of the material microstructure and the complete melting of fibers. On the other hand, a kind of transition failure state between ductile and brittle failures was noticed for the specimens heated to 200 °C, where a weaker central fracturing zone was observed associated with wider cracks.

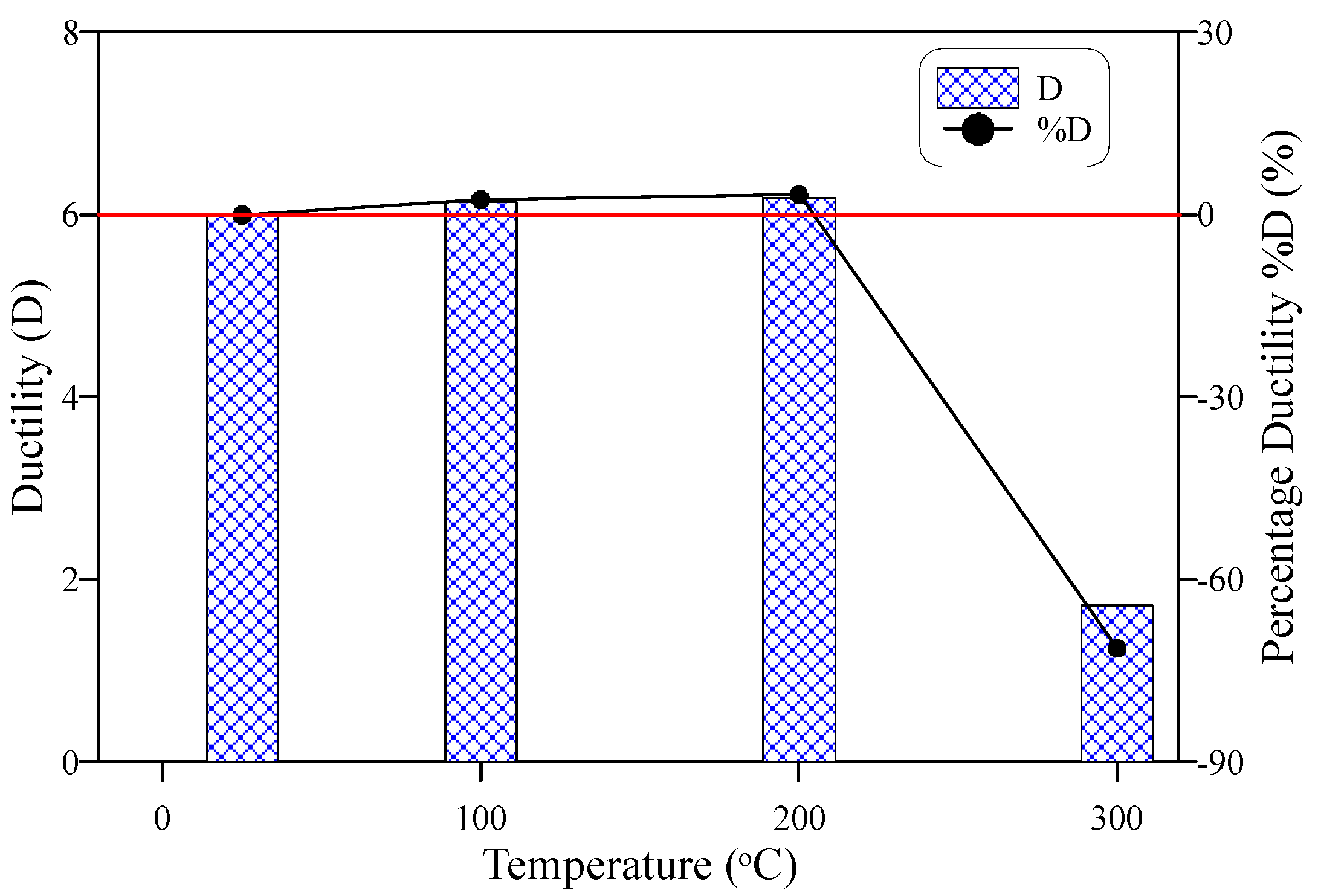

- The ductility index was comparable for the unheated specimens and those subjected to 100 and 200 °C, which was approximately 6 with only a minor difference of about 3%. This result is attributed to the behaviors of N1 and N2 with temperature, where the exposure to these temperature levels did not lead to any significant deterioration in the impact resistance. However, the sharp drop of the failure impact number after exposure to 300 °C reduced the impact ductility significantly to less than 30% of the unheated value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, V.C.; Leung, C.K.Y. Steady-state and multiple cracking of short random fiber composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. From micromechanics to structural engineering: The design of cementitious composites for civil engineering applications. J. Struct. Mech. Earthq. Eng. 1993, 10, 37–48. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C.; Stang, H.; Krenchel, H. Micromechanics of crack bridging in fibre-reinforced concrete. Mater. Struct. 1993, 26, 486–494. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Multiple cracking sequence and saturation in fiber reinforced cementitious composites. Concr. Res. Technol. 1998, 9, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. Engineered Cementitious Composites (ECC)-Materials, Structural, and Durability Performance; University of Michigan: Ann Arbor, MI, USA, 2007. [Google Scholar]

- Sahmaran, M.; Lachemi, M.; Hossain, K.M.A.; Ranade, R.; Li, V.C. Influence of aggregate type and size on ductility and mechanical properties of engineered cementitious composites. ACI Mater. J. 2009, 106, 308. [Google Scholar]

- Choi, W.-C.; Yun, H.-D.; Kang, J.-W.; Kim, S.-W. Development of recycled strain-hardening cement-based composite (SHCC) for sustainable infrastructures. Compos. Part B Eng. 2012, 43, 627–635. [Google Scholar] [CrossRef]

- Said, S.H.; Razak, H.A.; Othman, I. Strength and deformation characteristics of engineered cementitious composite slabs with different polymer fibres. J. Reinf. Plast. Compos. 2015, 34, 1950–1962. [Google Scholar] [CrossRef]

- Lu, C.; Li, V.C.; Leung, C.K.Y. Flaw characterization and correlation with cracking strength in Engineered Cementitious Composites (ECC). Cem. Concr. Res. 2018, 107, 64–74. [Google Scholar] [CrossRef]

- Abid, S.R.; Hilo, A.; Daek, Y.H. Experimental tests on the underwater abrasion of engineered cementitious composites. Constr. Build. Mater. 2018, 171, 779–792. [Google Scholar] [CrossRef]

- Ding, C.; Guo, L.; Chen, B.; Xu, Y.; Cao, Y.; Fei, C. Micromechanics theory guidelines and method exploration for surface treatment of PVA fibers used in high-ductility cementitious composites. Constr. Build. Mater. 2019, 196, 154–165. [Google Scholar] [CrossRef]

- da Costa, F.B.P.; Righi, D.P.; Graeff, A.G.; da Silva Filho, L.C.P. Experimental study of some durability properties of ECC with a more environmentally sustainable rice husk ash and high tenacity polypropylene fibers. Constr. Build. Mater. 2019, 213, 505–513. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul-Hussein, M.L.; Ali, S.H.; Kazem, A.F. Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period. Polytech. Civ. Eng. 2020, 64, 1244–1258. [Google Scholar] [CrossRef]

- Ayoob, N.S.; Abid, S.R. Analysis of abrasion rates in concrete surfaces of hydraulic structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 888, 012052. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Choi, J.; Park, S.-E.; Kim, H.; Lee, Y.; Lee, B.Y. Response of UHPFRC and HDFRC under static and high-velocity projectile impact loads. Constr. Build. Mater. 2018, 188, 399–408. [Google Scholar] [CrossRef]

- Feng, J.; Gao, X.; Li, J.; Dong, H.; He, Q.; Liang, J.; Sun, W. Penetration resistance of hybrid-fiber-reinforced high-strength concrete under projectile multi-impact. Constr. Build. Mater. 2019, 202, 341–352. [Google Scholar] [CrossRef]

- ACI 544-2R. Measurement of Properties of Fiber Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- Badr, A.; Ashour, A.F. Modified ACI drop-weight impact test for concrete. ACI Mater. J. 2005, 102, 249–255. [Google Scholar]

- Badr, A.; Ashour, A.F.; Platten, A.K. Statistical variations in impact resistance of polypropylene fibre-reinforced concrete. Int. J. Impact Eng. 2006, 32, 1907–1920. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Myers, J.J.; Tinsley, M. Impact resistance of blast mitigation material using modified ACI drop-weight impact test. ACI Mater. J. 2013, 110, 339–348. [Google Scholar]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 2020, 6, e03198. [Google Scholar] [CrossRef] [Green Version]

- Ismail, M.K.; Hassan, A.A. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers. ASCE J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Abid, S.R.; Murali, G.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Vatin, N.; Karelina, M. Impact performance of steel fiber-reinforced self-compacting concrete against repeated drop weight impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Compos. B. Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Soroushian, P.; Nagi, M.; Alhozaimy, A. Statistical variations in the mechanical properties of carbon fiber reinforced concrete. ACI Mater. J. 1992, 89, 131–138. [Google Scholar]

- Wang, W.; Chouw, N. The behavior of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Mahakavi, P.; Chithra, R. Impact resistance, microstructures and digital image processing on self-compacting concrete with hooked end and crimped steel fiber. Constr. Build. Mater. 2019, 220, 651–666. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Statistical analysis of impact strength and strength reliability of steel-polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2005, 19, 1–9. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental tests and reliability analysis of the cracking impact resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Abid, S.R.; Ali, S.H.; Goaiz, H.A.; Al-Gasham, T.S.; Kadhum, A.L. Impact resistance of steel fiber-reinforced self-compacting concrete. Mag. Civ. Eng. 2021, 105, 10504. [Google Scholar]

- Murali, G.; Abid, S.R.; Amran, Y.M.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Karthikeyan, K.; Haridharan, M.K.; Amran, M.; Siva, A. Low-velocity impact response of novel prepacked expanded clay aggregate fibrous concrete produced with carbon nano tube, glass fiber mesh and steel fiber. Constr. Build. Mater. 2021, 284, 122749. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Abdelgader, H.S.; Amran, M.Y.H.; Shekarchi, M.; Wilde, K. Repeated projectile impact tests on multi-layered fibrous cementitious composites. Inter. J. Civ. Eng. 2021, 19, 635–651. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Combined effect of multi-walled carbon nanotubes, steel fibre and glass fibre mesh on novel two-stage expanded clay aggregate concrete against impact loading. Crystals 2021, 11, 720. [Google Scholar] [CrossRef]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Amran, Y.M.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Depak, S.R.; Hariharan, K.R.; Abid, S.R.; Murali, G.; Cecchin, D.; Fediuk, R.; Amran, Y.M.; Abdelgader, H.S.; Khatib, J.M. Standard and modified falling mass impact tests on preplaced aggregate fibrous concrete and slurry infiltrated fibrous concrete. Constr. Build. Mater. 2021, 298, 123857. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A.; Lachemi, M. Performance of self-consolidating engineered cementious composite under drop-weight impact loading. ASCE J. Mater. Civ. Eng. 2019, 31, 04018400. [Google Scholar] [CrossRef]

- Brushlinsky, N.N.; Ahrens, M.; Sokolov, S.V.; Wagner, P. World Fire Statistics; Center of Fire Statistics of CTIF, International Association of Fire and Rescue Services: Ljubljana, Slovenia, 2018. [Google Scholar]

- Arna’ot, F.H.; Abbass, A.A.; Abualtemen, A.A.; Abid, S.R.; Özakça, M. Residual strength of high strength concentric column-SFRC flat plate exposed to high temperatures. Constr. Build. Mater. 2017, 154, 204–218. [Google Scholar] [CrossRef]

- Albrektsson, J.; Flansbjer, M.; Lindqvist, J.E.; Jansson, R. Assessment of Concrete Structures after Fire; SP Technical Rsearch Institute of Sweden: Borås, Sweden, 2011. [Google Scholar]

- Arna’ot, F.H.; Abid, S.R.; Özakça, M.; Tayşi, N. Review of concrete flat plate-column assemblies under fire conditions. Fire Saf. J. 2017, 93, 39–52. [Google Scholar] [CrossRef]

- Babalola, O.E.; Awoyera, P.O.; Le, D.-H.; Bendezú Romero, L.M. A review of residual strength properties of normal and high strength concrete exposed to elevated temperatures: Impact of materials modification on behaviour of concrete composite. Constr. Build. Mater. 2021, 296, 123448. [Google Scholar] [CrossRef]

- Abrams, M.S. Compressive Strength of Concrete at Temperatures to 1600 °F. Am. Concr. Inst. ACI 1971, 25, 33–58. [Google Scholar]

- Phan, L.T.; Carino, N.J. Review of mechanical properties of HSC at elevated temperatures. J. Mater. Civ. Eng. 1998, 10, 58–64. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Code provisions for high strength concrete strength-temperature relationship at elevated temperatures. Mater. Struct. 2003, 36, 91–98. [Google Scholar] [CrossRef]

- Cheng, F.P.; Kodur, V.K.R.; Wang, T.C. Stress-strain curves for high strength concrete at elevated temperatures. J. Mater. Civ. Eng. 2004, 16, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Al-Owaisy, S.R. Post heat exposure properties of steel fiber reinforced concrete. J. Eng. Sustain. Dev. 2006, 10, 194–207. [Google Scholar]

- Netinger, I.; Kesegic, I.; Guljas, I. The effect of high temperatures on the mechanical properties of concrete made with different types of aggregates. Fire Saf. J. 2011, 46, 425–430. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Chen, G.; Xie, Z. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Roufael, G.; Beaucour, A.-L.; Eslami, J.; Hoxha, D.; Noumowe, A. Influence of lightweight aggregates on the physical and mechanical residual properties of concrete subjected to high temperatures. Constr. Build. Mater. 2021, 268, 121221. [Google Scholar] [CrossRef]

- Deng, Z.H.; Huang, H.Q.; Ye, B.; Wang, H.; Xiang, P. Investigation on recycled aggregate concretes exposed to high temperature by biaxial compressive tests. Constr. Build. Mater. 2020, 244, 118048. [Google Scholar] [CrossRef]

- Sultan, H.K.; Alyaseri, I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements. Constr. Build. Mater. 2020, 261, 120555. [Google Scholar] [CrossRef]

- Husem, M. The effects of high temperature on compressive and flexural strengths of ordinary and high-performance concrete. Fire Saf. J. 2006, 41, 155–163. [Google Scholar] [CrossRef]

- Al-Owaisy, S.R. Strength and elasticity of steel fiber reinforced concrete at high temperatures. J. Eng. Sustain. Dev. 2007, 11, 125–133. [Google Scholar]

- Toric, N.; Boko, I.; Peroš, B. Reduction of postfire properties of high-strength concrete. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Alimrani, N.; Balazs, G.L. Investigations of direct shear of one-year old SFRC after exposed to elevated temperatures. Constr. Build. Mater. 2020, 254, 119308. [Google Scholar] [CrossRef]

- Mehdipour, S.; Nikbin, I.M.; Dezhampanah, S.; Mohebbi, R.; Moghadam, H.; Charkhtab, S.; Moradi, A. Mechanical properties, durability and environmental evaluation of rubberized concrete incorporating steel fiber and metakaolin at elevated temperatures. J. Clean Prod. 2020, 254, 120126. [Google Scholar] [CrossRef]

- Al-Ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M. Residual repeated impact strength of concrete exposed to elevated temperatures. Crystals 2021, 11, 941. [Google Scholar] [CrossRef]

- Sahmaran, M.; Lachemi, M.; Li, V. Assessing mechanical properties and microstructure of fire-damaged engineered cementitious composites. ACI Mater. J. 2010, 107, 297–304. [Google Scholar]

- Şahmaran, M.; Özbay, E.; Yücel, H.E.; Lachemi, M.; Li, V.C. Effect of fly ash and PVA fiber on microstructural damage and residual properties of engineered cementitious composites exposed to high temperatures. J. Mater. Civ. Eng. 2011, 23, 1735–1745. [Google Scholar] [CrossRef]

- Çavdar, A. A study on the effects of high temperature on mechanical properties of fiber reinforced cementitious composites. Compos. Part B Eng. 2012, 43, 2452–2463. [Google Scholar] [CrossRef]

- Li, Q.; Gao, X.; Xu, S.; Peng, Y.; Fu, Y. Microstructure and mechanical properties of high-toughness fiber-reinforced cementitious composites after exposure to elevated temperatures. J. Mater. Civ. Eng. 2016, 28, 04016132. [Google Scholar] [CrossRef]

- Liu, J.-C.; Tan, K.H.; Fan, S.-X. Residual mechanical properties and spalling resistance of strain-hardening cementitious composite with Class C fly ash. Constr. Build. Mater. 2017, 181, 253–265. [Google Scholar] [CrossRef]

- Li, Q.-H.; Sun, C.-J.; Xu, S.-L. Thermal and mechanical properties of ultrahigh toughness cementitious composite with hybrid PVA and steel fibers at elevated temperatures. Compos. Part B Eng. 2019, 176, 107201. [Google Scholar] [CrossRef]

- Yu, Z.; Yuan, Z.; Xia, C.; Zhang, C. High temperature flexural deformation properties of engineered cementitious composites (ECC) with hybrid fiber reinforcement. Res. Appl. Mater. Sci. 2020, 2, 17–26. [Google Scholar] [CrossRef]

- Shang, X.; Lu, Z. Impact of high temperature on the compressive strength of ECC. Adv. Mater. Sci. Eng. 2014, 2014. [Google Scholar] [CrossRef] [Green Version]

- Rafiei, P.; Shokravi, H.; Mohammadyan-Yasouj, S.E.; Koloor, S.S.R.; Petru, M. Temperature impact on engineered cementitious composite containing basalt fibers. Appl. Sci. 2021, 11, 6848. [Google Scholar] [CrossRef]

- Wang, Z.-b.; Han, S.; Sun, P.; Liu, W.-k.; Wang, Q. Mechanical properties of polyvinyl alcohol-basalt hybrid fiber engineered cementitious composites with impact of elevated temperatures. J. Cent. South Univ. 2021, 28, 1459–1475. [Google Scholar] [CrossRef]

- Aslani, F.; Wang, L. Fabrication and characterization of an engineered cementitious composite with enhanced fire resistance performance. J. Clean. Prod. 2019, 221, 202–214. [Google Scholar] [CrossRef]

- Bhat, P.S.; Chang, V.; Li, M. Effect of elevated temperature on strain-hardening engineered cementitious composites. Constr. Build. Mater. 2014, 69, 370–380. [Google Scholar] [CrossRef] [Green Version]

- Horszczaruk, E.K. Hydro-abrasive erosion of high performance fiber-reinforced concrete. Wear 2009, 267, 110–115. [Google Scholar] [CrossRef]

- Abbass, A.A.; Abid, S.R.; Arnaot, F.H.; Al-Ameri, R.A.; Özakça, M. Flexural response of hollow high strength concrete beams considering different size reductions. Structures 2019, 23, 69–86. [Google Scholar] [CrossRef]

- Abbass, A.A.; Arnaot, F.H.; Abid, S.R.; Özakça, M. Flexural behavior of ECC hollow beams incorporating different synthetic fibers. Front. Struct. Civ. Eng. 2021, 15, 399–411. [Google Scholar] [CrossRef]

| Oxide (%) | Cement (%) | Fly Ash (%) |

|---|---|---|

| SiO2 | 20.08 | 56.0 |

| Fe2O3 | 3.6 | 24.81 |

| Al2O3 | 4.62 | 5.3 |

| CaO | 61.61 | 4.8 |

| MgO | 2.12 | 1.48 |

| SO3 | 2.71 | 0.36 |

| Loss on ignition (%) | 1.38 | 5.78 |

| Specific surface (m2/kg) | 368 | - |

| Specific gravity | 3.15 | 2.20 |

| Fineness (% retain in 45 μm) | - | 28.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M.; Vatin, N.I. Residual Impact Performance of ECC Subjected to Sub-High Temperatures. Materials 2022, 15, 454. https://doi.org/10.3390/ma15020454

Al-Ameri RA, Abid SR, Murali G, Ali SH, Özakça M, Vatin NI. Residual Impact Performance of ECC Subjected to Sub-High Temperatures. Materials. 2022; 15(2):454. https://doi.org/10.3390/ma15020454

Chicago/Turabian StyleAl-Ameri, Raad A., Sallal Rashid Abid, Gunasekaran Murali, Sajjad H. Ali, Mustafa Özakça, and Nikolay Ivanovich Vatin. 2022. "Residual Impact Performance of ECC Subjected to Sub-High Temperatures" Materials 15, no. 2: 454. https://doi.org/10.3390/ma15020454

APA StyleAl-Ameri, R. A., Abid, S. R., Murali, G., Ali, S. H., Özakça, M., & Vatin, N. I. (2022). Residual Impact Performance of ECC Subjected to Sub-High Temperatures. Materials, 15(2), 454. https://doi.org/10.3390/ma15020454