Gel Point Determination in Resin Transfer Molding Process with Fiber Bragg Grating Inscribed in Side-Hole Elliptical Core Optical Fiber

Abstract

1. Introduction

- Detection of gel point according to a reference method (in-mold DC and temperature sensor).

- Monitoring of curing process with regular FBG.

- Monitoring of curing process with FBG inscribed in highly-birefringent side-hole fiber.

2. HB FBG Sensors

3. Manufacturing Process

4. Results

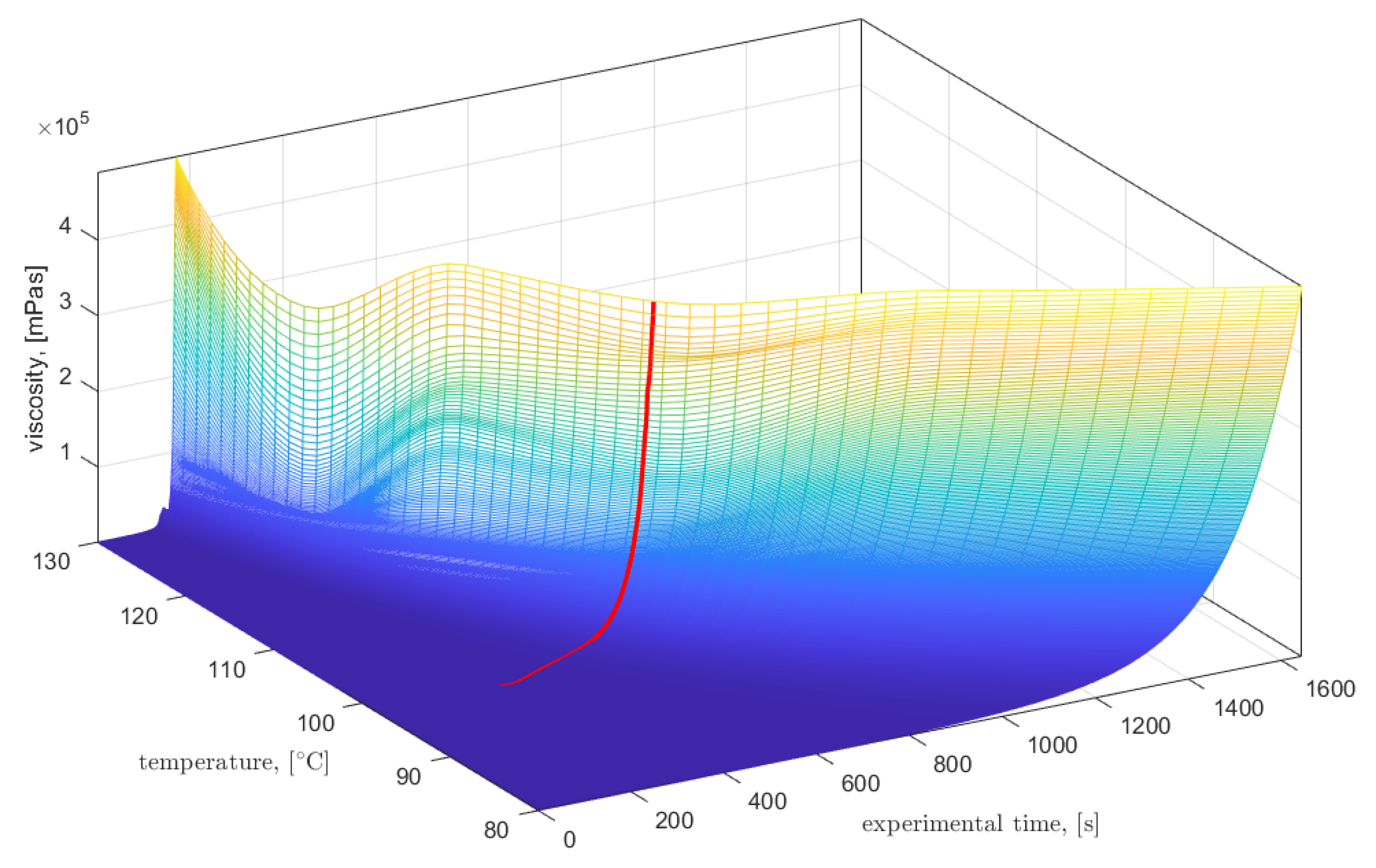

4.1. Process Monitoring with Regular In-Mold Sensors

4.2. Regular FBG Sensors

4.3. HB FBG Sensors

5. Conclusions

- Regular FBG sensors can be used to estimate the gelation point during the RTM process. However, chemical residual strain build-up in the plane of the composite is slow, so it is hard to determine precise boundaries for the gelation point. Moreover, slight changes in the temperature significantly influence the measurement; it seems that the use of regular FBG in the RTM process requires integrated temperature sensors for good compensation.

- The build-up of transversal residual strain build-up can be measured with HB FBG sensors and is more distinct than the trend observed with regular FBG sensors. Peak separation sensitivity to temperature is low. For this reason, transversal strain measurement with FBG inscribed in side-hole elliptical core fiber doesn’t require another integrated sensor for temperature compensation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konstantopoulos, S.; Fauster, E.; Schledjewski, R. Monitoring the production of FRP composites: A review of in-line sensing methods. Express Polym. Lett. 2014, 8, 823–840. [Google Scholar] [CrossRef]

- Torres, M. Parameters’ monitoring and in-situ instrumentation for resin transfer moulding: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105500. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop, J.L.P.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Blößl, Y.; Hegedüs, G.; Szebényi, G.; Tábi, T.; Schledjewski, R.; Czigany, T. Applicability of fiber Bragg grating sensors for cure monitoring in resin transfer molding processes. J. Reinf. Plast. Compos. 2021, 40, 701–713. [Google Scholar] [CrossRef]

- Yildiz, M.; Ozdemir, N.G.; Bektas, G.; Keulen, C.J.; Boz, T.; Sengun, E.F.; Ozturk, C.; Menceloglu, Y.Z.; Suleman, A. An experimental study on the process monitoring of resin transfer molded composite structures using fiber optic sensors. J. Manuf. Sci. Eng. Trans. ASME 2012, 134, 044502. [Google Scholar] [CrossRef]

- Chiesura, G.; Lamberti, A.; Yang, Y.; Luyckx, G.; Van Paepegem, W.; Vanlanduit, S.; Vanfleteren, J.; Degrieck, J. RTM production monitoring of the A380 hinge armdroop nose mechanism: A multi-sensor approach. Sensors 2016, 16, 866. [Google Scholar] [CrossRef]

- Canal, L.P.; Benavente, M.; Hausmann, M.; Michaud, V. Process-induced strains in RTM processing of polyurethane/carbon composites. Compos. Part A Appl. Sci. Manuf. 2015, 78, 264–273. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg grating sensors toward structural health monitoring in composite materials: Challenges and solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Montazerian, H.; Rashidi, A.; Milani, A.S.; Hoorfar, M. Integrated Sensors in Advanced Composites: A Critical Review. Crit. Rev. Solid State Mater. Sci. 2019, 45, 187–238. [Google Scholar] [CrossRef]

- Iadicicco, A.; Natale, D.; Di Palma, P.; Spinaci, F.; Apicella, A.; Campopiano, S. Strain monitoring of a composite drag strut in aircraft landing gear by fiber bragg grating sensors. Sensors 2019, 19, 2239. [Google Scholar] [CrossRef] [PubMed]

- Mieloszyk, M.; Majewska, K.; Ostachowicz, W. Application of embedded fibre Bragg grating sensors for structural health monitoring of complex composite structures for marine applications. Mar. Struct. 2021, 76, 102903. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V.M.N. Fibre Bragg Grating based strain sensors: Review of technology and applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings; Optics and Photonics; Elsevier Science: Amsterdam, The Netherlands, 2009; ISBN 9780080919911. [Google Scholar]

- Hoffman, J.; Khadka, S.; Kumosa, M. Determination of gel point and completion of curing in a single fiber/polymer composite. Compos. Sci. Technol. 2020, 188, 107997. [Google Scholar] [CrossRef]

- Khoun, L.; De Oliveira, R.; Michaud, V.; Hubert, P. Investigation of process-induced strains development by fibre Bragg grating sensors in resin transfer moulded composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 274–282. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Small-diameter optical fibre sensor embedment for ambient temperature cure monitoring and residual strain evaluation of CFRP composite laminates produced by vacuum-assisted resin infusion. CEAS Space J. 2021, 13, 353–367. [Google Scholar] [CrossRef]

- Moretti, L.; Olivier, P.; Castanié, B.; Bernhart, G. Experimental study and in-situ FBG monitoring of process-induced strains during autoclave co-curing, co-bonding and secondary bonding of composite laminates. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106224. [Google Scholar] [CrossRef]

- Minakuchi, S. In situ characterization of direction-dependent cure-induced shrinkage in thermoset composite laminates with fiber-optic sensors embedded in through-thickness and in-plane directions. J. Compos. Mater. 2015, 49, 1021–1034. [Google Scholar] [CrossRef]

- Chehura, E.; James, S.W.; Staines, S.; Groenendijk, C.; Cartie, D.; Portet, S.; Hugon, M.; Tatam, R.P. Production process monitoring and post-production strain measurement on a full-size carbon-fibre composite aircraft tail cone assembly using embedded optical fibre sensors. Meas. Sci. Technol. 2020, 31, 105204. [Google Scholar] [CrossRef]

- Rufai, O.; Chandarana, N.; Gautam, M.; Potluri, P.; Gresil, M. Cure monitoring and structural health monitoring of composites using micro-braided distributed optical fibre. Compos. Struct. 2020, 254, 112861. [Google Scholar] [CrossRef]

- Collombet, F.; Torres, M.; Douchin, B.; Crouzeix, L.; Grunevald, Y.H.; Lubin, J.; Camps, T.; Jacob, X.; Luyckx, G.; Wu, K.T. Multi-instrumentation monitoring for the curing process of a composite structure. Meas. J. Int. Meas. Confed. 2020, 157, 107635. [Google Scholar] [CrossRef]

- Sonnenfeld, C.; Sulejmani, S.; Geernaert, T.; Eve, S.; Lammens, N.; Luyckx, G.; Voet, E.; Degrieck, J.; Urbanczyk, W.; Mergo, P.; et al. Microstructured optical fiber sensors embedded in a laminate composite for smart material applications. Sensors 2011, 11, 2566–2579. [Google Scholar] [CrossRef] [PubMed]

- Geernaert, T.; Luyckx, G.; Voet, E.; Nasilowski, T.; Chah, K.; Becker, M.; Bartelt, H.; Urbanczyk, W.; Wojcik, J.; De Waele, W.; et al. Transversal load sensing with fiber Bragg gratings in microstructured optical fibers. IEEE Photonics Technol. Lett. 2009, 21, 6–8. [Google Scholar] [CrossRef]

- Chehura, E.; Skordos, A.A.; Ye, C.C.; James, S.W.; Partridge, I.K.; Tatam, R.P. Strain development in curing epoxy resin and glass fibre/epoxy composites monitored by fibre Bragg grating sensors in birefringent optical fibre. Smart Mater. Struct. 2005, 14, 354–362. [Google Scholar] [CrossRef]

- Sonnenfeld, C.; Luyckx, G.; Collombet, F.; Grunevald, Y.-H.; Douchin, B.; Crouzeix, L.; Torres, M.; Geernaert, T.; Sulejmani, S.; Eve, S.; et al. Embedded fiber Bragg gratings in photonic crystal fiber for cure cycle monitoring of carbon fiber-reinforced polymer materials. In Micro-Structured and Specialty Optical Fibres II; Kalli, K., Kanka, J., Mendez, A., Eds.; SPIE: Bellingham, DC, USA, 2013; Volume 8775, pp. 1–10. [Google Scholar]

- Wachtarczyk, K.; Gąsior, P.; Kaleta, J.; Anuszkiewicz, A.; Bender, M.; Schledjewski, R.; Mergo, P.; Osuch, T. In-Plane Strain Measurement in Composite Structures with Fiber Bragg Grating Written in Side-Hole Elliptical Core Optical Fiber. Materials 2021, 15, 77. [Google Scholar] [CrossRef]

- Huang, C.; Jing, W.; Liu, K.; Zhang, Y.; Peng, G. Demodulation of Fiber Bragg Grating Sensor Using Cross-correlation Algorithm. IEEE Photonics Technol. Lett. 2007, 19, 707–709. [Google Scholar] [CrossRef]

- Hergan, P. Entwicklung Einer Modellbasierten Fertigungstechnik zur Intrinsischen Herstellung von Hybriden Verbundwerkstoffen. Ph.D. Dissertation, Montanuniversität Leoben, Leoben, Austria, 2019. [Google Scholar]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 9780470423837. [Google Scholar]

- bto-epoxy GmbH, Epoxy System Epinal IR 77.55-A1-IH 77.55-B1. Datasheet, 2015.

- Lamberti, A.; Vanlanduit, S.; De Pauw, B.; Berghmans, F. Influence of fiber bragg grating spectrum degradation on the performance of sensor interrogation algorithms. Sensors 2014, 14, 24258–24277. [Google Scholar] [CrossRef]

| Used Type of FBG | Material | Manufacturing Process | Detected Strain | Goal of Study | Ref. |

|---|---|---|---|---|---|

| SM FBG | Neat epoxy resin | Curing in the oven temperature | Axial | Detection of neat resin cure process stages with FBG sensors and thermocouples | [17] |

| SM FBG | Flax-fiber twill with bio-epoxy | Resin Transfer Molding | Axial | Increasing of repeatability of process monitoring | [4] |

| SM FBG | Biaxial GF reinforcement, epoxy resin | Resin Transfer Molding | Axial | Monitoring of RTM process stages (flow front, curing) | [5] |

| SM FBG | GF mat, epoxy resin | Resin Transfer Molding | Axial | Detection of gel point and residual strain | [6] |

| SM FBG (small and regular diameter) | Unidirectional CF, epoxy resin | Vacuum infusion | Axial | Comparison of performance of FBG inscribed in 150 µm and 80 µm single-mode fibers | [19] |

| SM FBG | Unidirectional CF prepregs | Autoclave curing | Transversal, axial | Measurement of direction-dependent shrinkage with FBGs in plane and inserted transversally to the surface of prepreg stack | [21] |

| HB FBG (bow-tie fiber) SM FBG | CF placed by dry-fiber placement method | Infusion and autoclave curing, | Transversal, axial | Measurement of transversal and axial residual strain during the curing | [22] |

| HB FBG (bow-tie fiber) | Unidirectional GF prepregs | Open-air curing | Transversal | Detection of gel point and of cure with HB FBG | [27] |

| HB FBG (microstructured fiber) | Symmetric CF laminate, epoxy resin | Autoclave curing | Transversal | Measurement of final transversal-strain measurement after the curing process | [28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wachtarczyk, K.; Bender, M.; Fauster, E.; Schledjewski, R.; Gąsior, P.; Kaleta, J. Gel Point Determination in Resin Transfer Molding Process with Fiber Bragg Grating Inscribed in Side-Hole Elliptical Core Optical Fiber. Materials 2022, 15, 6497. https://doi.org/10.3390/ma15186497

Wachtarczyk K, Bender M, Fauster E, Schledjewski R, Gąsior P, Kaleta J. Gel Point Determination in Resin Transfer Molding Process with Fiber Bragg Grating Inscribed in Side-Hole Elliptical Core Optical Fiber. Materials. 2022; 15(18):6497. https://doi.org/10.3390/ma15186497

Chicago/Turabian StyleWachtarczyk, Karol, Marcel Bender, Ewald Fauster, Ralf Schledjewski, Paweł Gąsior, and Jerzy Kaleta. 2022. "Gel Point Determination in Resin Transfer Molding Process with Fiber Bragg Grating Inscribed in Side-Hole Elliptical Core Optical Fiber" Materials 15, no. 18: 6497. https://doi.org/10.3390/ma15186497

APA StyleWachtarczyk, K., Bender, M., Fauster, E., Schledjewski, R., Gąsior, P., & Kaleta, J. (2022). Gel Point Determination in Resin Transfer Molding Process with Fiber Bragg Grating Inscribed in Side-Hole Elliptical Core Optical Fiber. Materials, 15(18), 6497. https://doi.org/10.3390/ma15186497