Analysis of the Influence of GMAW Process Parameters on the Properties and Microstructure of S32001 Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

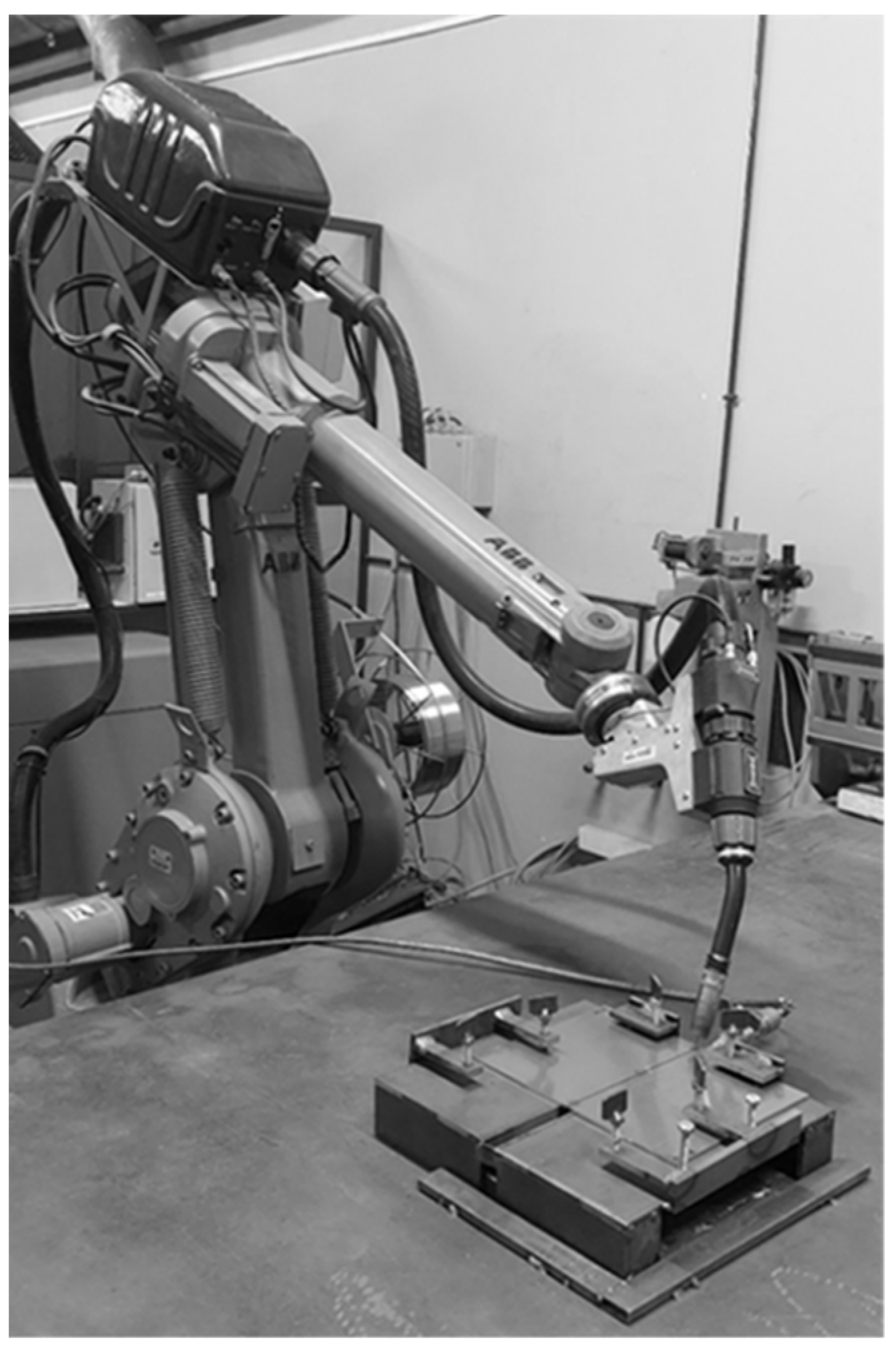

2.2.1. Welding

2.2.2. Microstructural Characterization and Grain Size

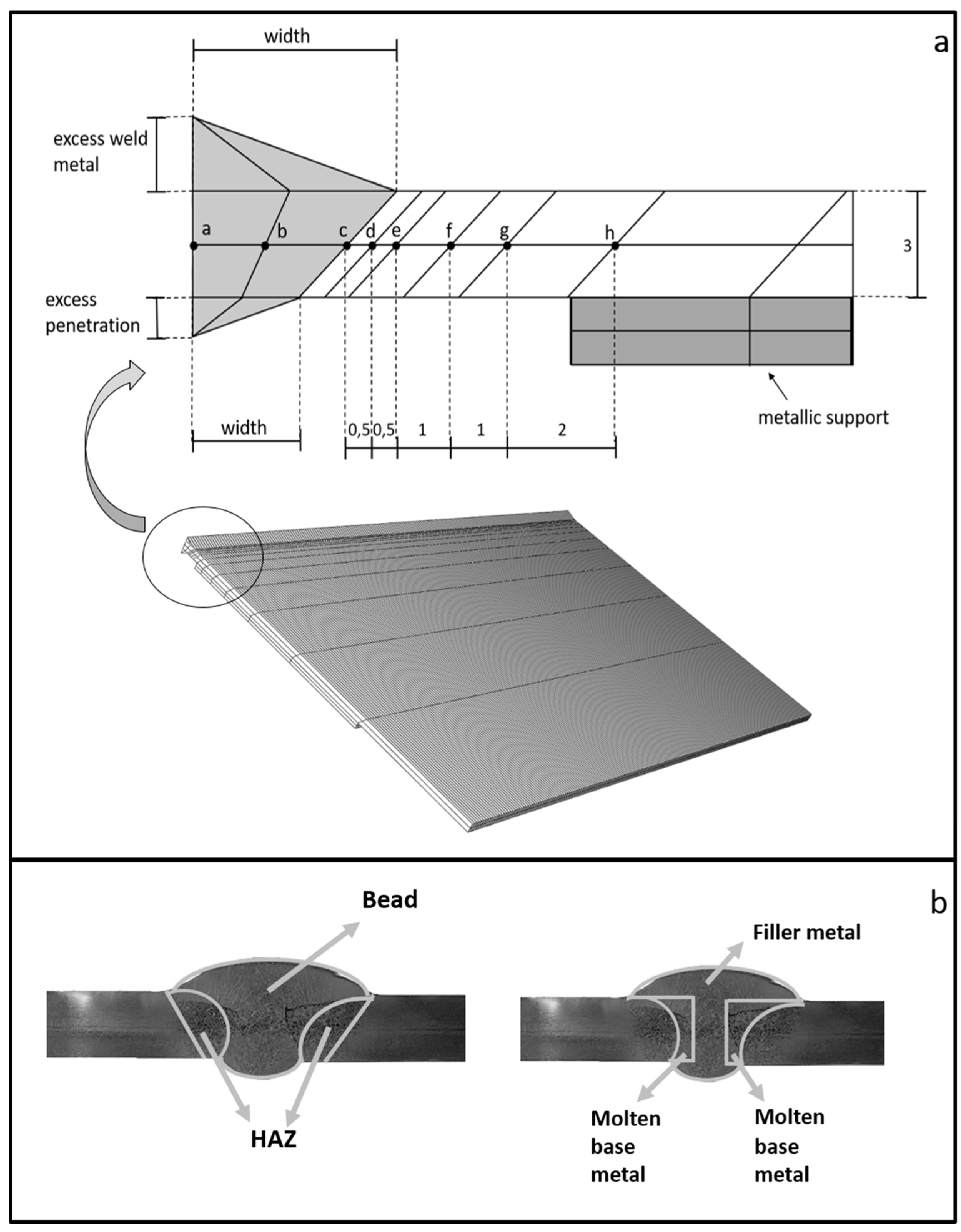

2.2.3. Vickers Hardness, Tensile Testing, and Weld Dimensions

2.2.4. Finite Element Modeling

2.2.5. Alloy Dilution and Diffusion

3. Results and Discussion

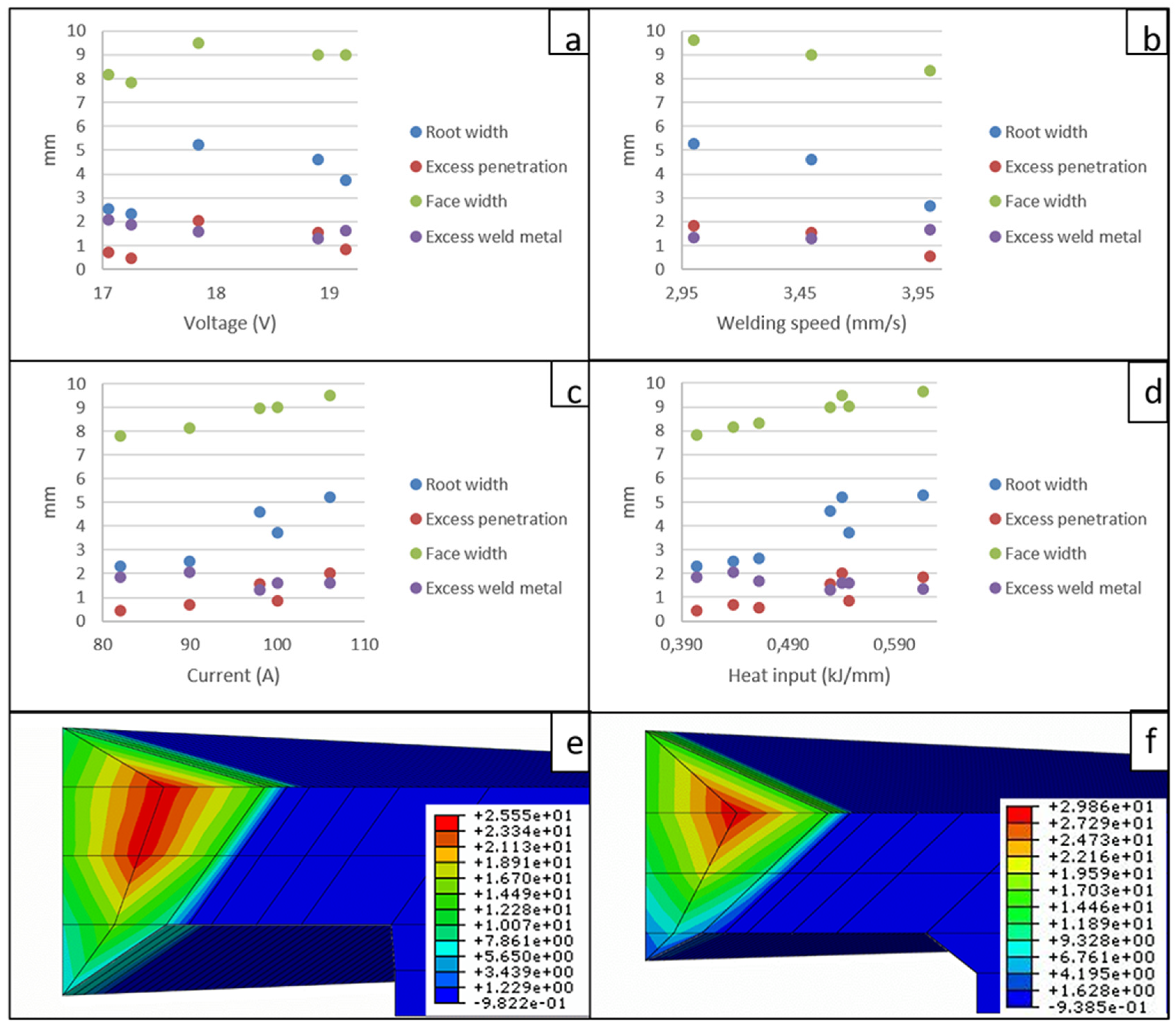

3.1. Weld Dimensions

3.2. Microstructural Characterization and Grain Size

3.3. Alloy Dilution and Diffusion

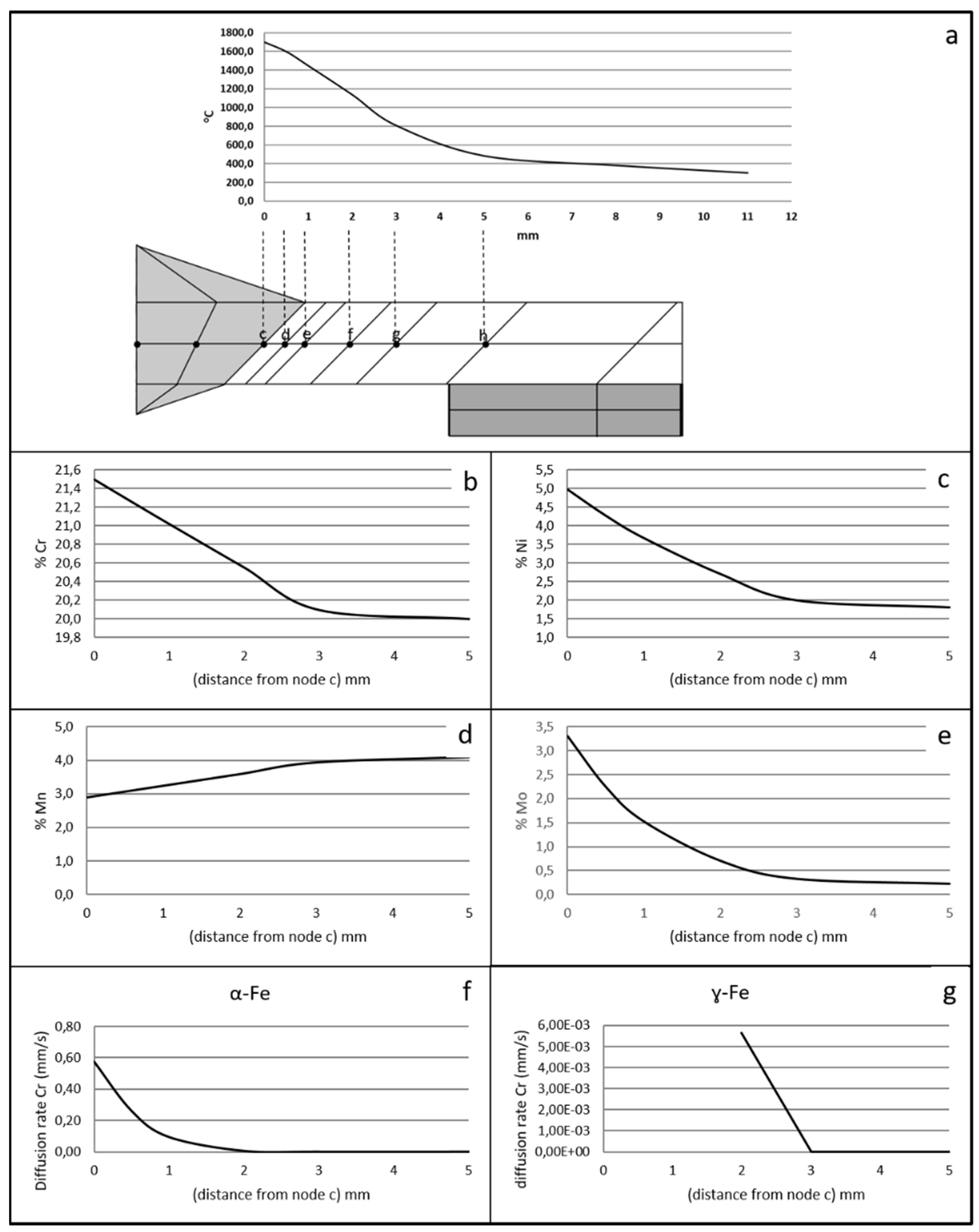

- The diffusion rate of alloying agents is favored at elevated temperatures [31].

- The ideal situation of only the ferritic matrix (α-Fe) existing between 1370 and 1201 °C was assumed.

- Two temperature ranges 1370–1201 °C and 1200–800 °C were studied.

- Between 1200 and 800 °C, the transformation of ferrite to austenite occurs linearly, reaching a ferrite percentage similar to that of the base metal, provided that at least 10 s elapse in this cooling [9].

- The calculated results of the diffusion velocity below 800 °C (according to Equation (3)) are of the order of 10−7 mm/s, so they can be disregarded. As a consequence, from node g (located 3 mm away from the bead-HAZ interface, node c) onwards, the base metal composition was achieved.

- The variation of the composition from the bead to the base metal occurs between nodes c and g because this is where the highest temperature range occurs.

3.4. Phase Balance and Finite Element Modeling

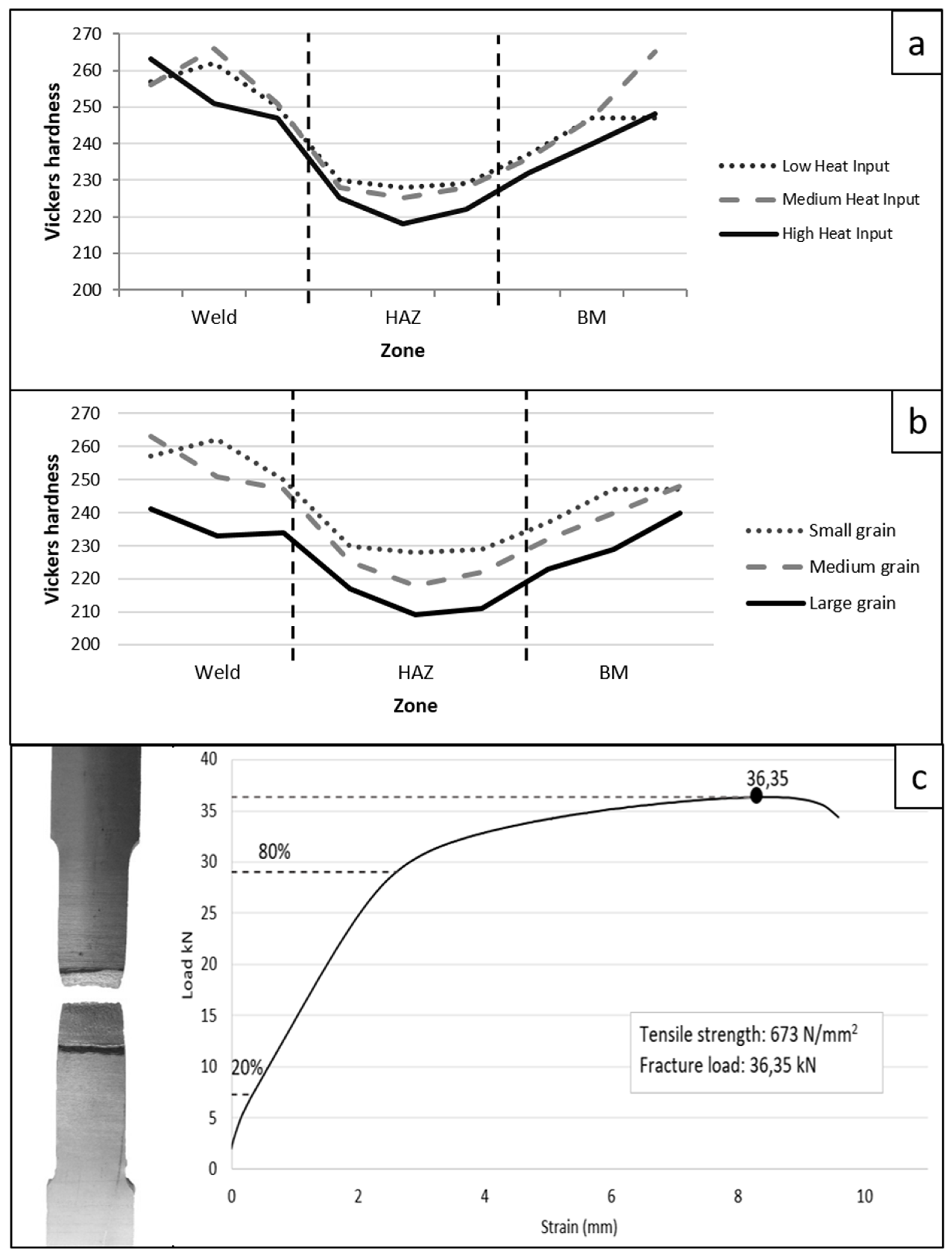

3.5. Vickers Hardness and Tensile Testing

4. Conclusions

- The microstructure obtained in the bead and in the HAZ is similar, obtaining needle-shaped austenite (Widmanstätten), allotropic austenite, and intragranular austenite, although the amount of needles found in the HAZ is lower.

- Compared to the heat input, it was observed that the parameter W/m3 better explains the phase balance behavior in the weld bead due to the parameters related to this value.

- The distribution of the heat flow toward the base metal is conditioned by the dimensions and geometry of the bead, which influences the thermal cycles undergone by the material and, consequently, the phase balance obtained.

- To determine the geometry of the bead, it is necessary to study the influence of the parameters: voltage, current, and welding speed, individually and jointly by means of the heat input value.

- The mathematical model developed for diffusion allows the chemical composition at each node of the mesh to be obtained and, consequently, the behavior of the material to be predicted. In this way, the characteristics of the welded joint can be improved to suit the required needs.

- The t12/8 determines the cooling rate in the HAZ and, therefore, the phase balance. So, by controlling the cooling rate (which is conditioned by the heat input and bead geometry), a more balanced phase balance can be obtained in this zone.

- The HAZ is the most weakened zone during the welding process due to the increased grain size and higher ferrite content, which leads to a loss of hardness and tensile strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bain, E.C.; Griffiths, W.E. An introduction to the iron-chromium-nickel alloys. Trans. Aime 1927, 75, 166–211. [Google Scholar]

- Columbus Stainless. Technical Brochure. Duplex Stainless Steel. Available online: https://www.columbus.co.za/downloads/Duplexes.pdf (accessed on 2 June 2021).

- Cedinox. Available online: https://www.cedinox.es/export/sites/cedinox/es/.galleries/DOCUMENTOS-Fichas-tecnicas-Tipos-de-Acero/DOCUMENTOS-Fichas-Acero-Duplex/ACX920-14482-2201.pdf (accessed on 2 June 2021).

- Aracil, M. Soldadura y Corte de los Aceros Inoxidables, Cedinox; Asociación para la Investigación y Desarrollo del Acero: Madrid, Spain, 2018. [Google Scholar]

- Prospector. Available online: https://metals.ulprospector.com/es/datasheet/e215332/nitronic-19d (accessed on 5 April 2021).

- Korkmaz, E.; Meran, C. Mechanical properties and microstructure characterization of GTAW of micro-alloyed hot rolled ferritic XPF800 steel. Eng. Sci. Technol. Int. J. 2021, 1, 503–513. [Google Scholar] [CrossRef]

- Kumar, S.; Nath, S.K. Studies on microstructure and mechanical properties of simulated heat affected zone in a micro alloyed steel. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2014, 8, 1056–1059. [Google Scholar]

- American Society for Metals. ASM Metals Handbook; Welding Brazing and Soldering; ASM International: Almere, The Netherlands, 1994; Volume 6. [Google Scholar]

- American Welding Society. Welding Handbook, 9th ed.; American Welding Society: Miami, FL, USA, 2011; Volume 4. [Google Scholar]

- da Fonseca, G.S.; Rodrigues Barbosa, L.O.; Ferreira, E.A.; Xavier, C.R.; de Castro, J.A. Microstructural, mechanical, and electrochemical analysis of duplex and superduplex stainless steels welded with the autogenous TIG process using different heat input. Metals 2017, 7, 538. [Google Scholar] [CrossRef]

- Welding Handbook Committee. Welding Handbook, 9th ed.; American Welding Society: Miami, FL, USA, 2001; Volume 1. [Google Scholar]

- UNE-EN 1011-1; Comité técnico AEN/CTN 14 Soldadura y Técnicas Conexas, Cesol. Recomendaciones Para el Soldeo de Materiales Metálicos. Paste 1: Guía General para el Soldeo por arco. European Standard: Brussels, Belgium, 2010.

- Volume I: A–H Abaqus Keywords Reference Manual; Version 6.5.; SIMULIA Dassault Systemes: Johnston, RI, USA, 2004.

- NikelAlloy. Available online: https://nickelalloys.es/duplex-superduplex/2209-er2209-22-9-3-n-l/ (accessed on 5 February 2022).

- UNE-EN ISO 15614-1:2018; Comité Técnico CTN 14 Soldadura y Técnicas Conexas, Cesol. “Especificación y Cualificación de los Procedimientos de Soldeo para los Materiales Metálicos”. European Standard: Brussels, Belgium, 2018.

- ASM International. ASM Handbook, 9th ed.; Metallography and Microstructures; ASM International: Almere, The Netherlands, 1985; Volume 9. [Google Scholar]

- George Vander Voort. Color Metallography. Available online: https://www.georgevandervoort.com/color-metallography/ (accessed on 23 March 2020).

- UNE-EN ISO 643:2020; CTN 36 Siderurgia, Cesol. Aceros. Determinación Micrográfica del Tamaño de Grano Aparente. European Standard: Brussels, Belgium, 2020.

- UNE-EN ISO 6507-1:2018; Comité Técnico CTN 7 Ensayos de Materiales Cesol. Materiales metálicos. Ensayo de Dureza Vickers. Parte 1 Método de Ensayo. European Standard: Brussels, Belgium, 2018.

- UNE-EN ISO 5817:2014; Comité Técnico AEN/CTN 14 Soldadura y Técnicas Conexas, Cesol. Uniones Soldadas por Fusión en Acero, Níquel, Titanio y sus Aleaciones (Excluido el Soldeo por haz de Electrones) Niveles de Calidad para las Imperfecciones. European Standard: Brussels, Belgium, 2014.

- UNE-EN ISO 6892-1:2017; Comité Técnico CTN 7 Ensayos de Materiales, Cesol. Materiales Metálicos. Ensayo de Tracción. Parte 1: Método de Ensayo a Temperatura Ambiente. European Standard: Brussels, Belgium, 2017.

- Abas, R.H.A.; Taieh, N.K. Experimental study of the thermal diffusivity and heat capacity concerning some duplex stainless steel. Khwarizmi Eng. J. 2015, 11, 51–61. [Google Scholar]

- MakeItFrom. Available online: https://www.makeitfrom.com/material-properties/EN-1.4482-X2CrMnNiMoN21-5-3-Stainless-Steel (accessed on 15 January 2021).

- Romaní, G.; Portolés, A. Modelo tridimensional de Simulación por MEF para Estudiar la Influencia de Variables Esenciales de Soldadura Robotizada GMAW en Uniones a Tope Planas; Conference Book EUROJOIN6: Madrid, Spain, 2006; ISBN 84-934316-0-5. [Google Scholar]

- Meseguer, J.L.; Portolés, A.; Martínez-Conesa, E.J. Electrical parameters optimisation on welding geometry in the 6063-T alloy using the Taguchi methods. Int. J. Advenced Manuf. Technol. 2018, 98, 2449–2460. [Google Scholar] [CrossRef]

- Meseguer Valdenebro, J.L.; Martínez-Conesa, E.J.; Portolés, A. Numerical-experimental validation of the welding thermal cycle carried out with the MIG welding process on a 6063-T5 aluminium tubular profile. Therm. Sci. Int. Sci. J. 2019, 23, 3639–3650. [Google Scholar]

- Dong, J.P.; Zhang, M.L.J. Computational modeling of weld residual stresses and distorsions—An integrated framework and industrial applications. Mater. Sci. 1998, 311–336. [Google Scholar]

- Dong, Y.; Hong, J.K.; Tsai, C.L.; Dong, P. Finite element modeling of residual stresses in austenitic stainless steel pipe girth welds. Weld. J. 1997, 76. [Google Scholar]

- Sun, Y.L.; Obasi, G.; Hamelin, C.; Vasileiou, A.; Flint, T.; Balakrishnan, J.; Smith, M.; Francis, J. Effects of dilution on alloy content and microstructure in multi-pass steel welds. J. Mater. Processing Technol. 2019, 265, 71–86. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C. Smithells Metals Reference Book; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Askeland, D.R. Ciencia e Ingeniería de los Materiales; Cengage Learning: Santa Fe, Mexico, 2001. [Google Scholar]

- Vega, J.B.M. Alfa de Cronbach—Psicometría con R. 4 4 2018. Available online: https://medium.com/@jboscomendoza/alfa-de-cronbach-psicometr%C3%ADa-con-r-55d3154806cf (accessed on 3 January 2021).

- Varbai, B.; Pickle, T.; Májlinger, K. Effect of heat input and role of nitrogen on the phase evolution of 2205 duplex stainless steel weldment. Int. J. Press. Vessel. Pip. 2019, 176. [Google Scholar] [CrossRef]

- Muthupandi, V.; Srinivasan, P.B.; Seshadri, S.K.; Sundaresan, S. Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater. Sci. Eng. A 2003, 358, 9–16. [Google Scholar] [CrossRef]

- Cunat, P.-J. Alloying Elements in Stainless Steel and Other Chromium-Containing Alloys. Euro Inox 2004, 1–24. [Google Scholar]

| Material | C | Mn | Si | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| S32001 | 0.016 | 4.1 | 0.56 | 0.026 | 0.004 | 20 | 1.8 | 0.22 | 0.14 |

| ER2209 | 0.01 | 1.45 | 0.45 | 0.015 | 0.015 | 23.2 | 8.6 | 3.3 | 0.17 |

| Coupon | Welding Speed (mm/s) | Wire Feed Speed (m/min) | Current (A) | Voltage (V) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| 1 | 3.5 | 2.75 | 98 | 18.9 | 0.423 |

| 2 | 3 | 2.75 | 98 | 18.9 | 0.494 |

| 3 | 4 | 2.75 | 98 | 18.9 | 0.370 |

| 4 | 3.5 | 2.4 | 82 | 17.25 | 0.323 |

| 5 | 3.5 | 3.25 | 106 | 17.85 | 0.432 |

| 6 | 3.5 | 2.75 | 90 | 17.05 | 0.351 |

| 7 | 3.5 | 2.75 | 100 | 19.15 | 0.438 |

| Coupon | Root Dimensions (mm) | Face Dimensions (mm) | ||

|---|---|---|---|---|

| Width | Excess Penetration | Width | Excess Weld Metal | |

| 1 | 4.6 | 1.5 | 8.9 | 1.3 |

| 2 | 5.3 | 1.8 | 9.6 | 1.4 |

| 3 | 2.7 | 0.5 | 8.3 | 1.7 |

| 4 | 2.3 | 0.4 | 7.8 | 1.9 |

| 5 | 5.2 | 2.1 | 9.5 | 1.6 |

| 6 | 2.5 | 0.7 | 8.2 | 2.1 |

| 7 | 3.7 | 0.9 | 9.1 | 1.6 |

| Coupon | BM Dilution % | Cr | Ni | Mn | Mo |

|---|---|---|---|---|---|

| 1 | 53.3 | 21.5 | 5.0 | 2.9 | 1.7 |

| 2 | 53.0 | 21.5 | 5.0 | 2.9 | 1.7 |

| 3 | 49.5 | 21.6 | 5.2 | 2.8 | 1.8 |

| 4 | 46.6 | 21.7 | 5.4 | 2.7 | 1.9 |

| 5 | 50.3 | 21.6 | 5.2 | 2.8 | 1.8 |

| 6 | 45.5 | 21.7 | 5.5 | 2.7 | 1.9 |

| 7 | 52.2 | 21.5 | 5.1 | 2.8 | 1.7 |

| Coupon | Tensile Strength (N/mm2) | Fracture Load (kN) | Joint Efficiency (%) |

|---|---|---|---|

| 1 | 690 | 34.74 | 91.55 |

| 2 | 698.5 | 34.86 | 92.68 |

| 3 | 687 | 36.75 | 91.2 |

| 4 | 689.4 | 35.28 | 91.47 |

| 5 | 672 | 34.32 | 89.16 |

| 6 | 688.1 | 34.09 | 91.3 |

| 7 | 673 | 36.35 | 89.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chacón-Fernández, S.; Portolés García, A.; Romaní Labanda, G. Analysis of the Influence of GMAW Process Parameters on the Properties and Microstructure of S32001 Steel. Materials 2022, 15, 6498. https://doi.org/10.3390/ma15186498

Chacón-Fernández S, Portolés García A, Romaní Labanda G. Analysis of the Influence of GMAW Process Parameters on the Properties and Microstructure of S32001 Steel. Materials. 2022; 15(18):6498. https://doi.org/10.3390/ma15186498

Chicago/Turabian StyleChacón-Fernández, Sandra, Antonio Portolés García, and Gerardo Romaní Labanda. 2022. "Analysis of the Influence of GMAW Process Parameters on the Properties and Microstructure of S32001 Steel" Materials 15, no. 18: 6498. https://doi.org/10.3390/ma15186498

APA StyleChacón-Fernández, S., Portolés García, A., & Romaní Labanda, G. (2022). Analysis of the Influence of GMAW Process Parameters on the Properties and Microstructure of S32001 Steel. Materials, 15(18), 6498. https://doi.org/10.3390/ma15186498