Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling

Abstract

:1. Introduction

2. Experimental Conditions and Methods

2.1. Specimens and Experimental Process

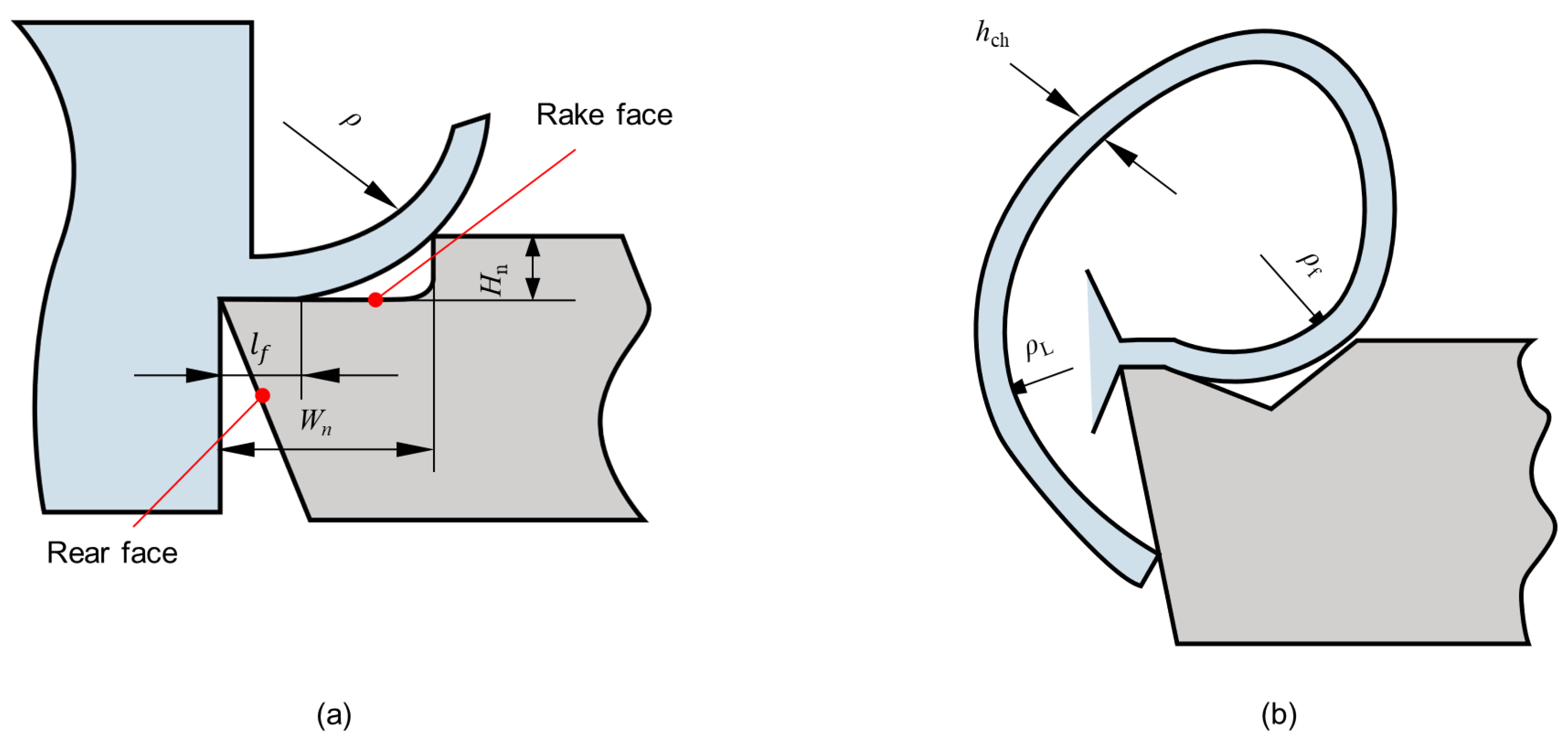

2.2. Structure of the Tool

3. Results and Discussion

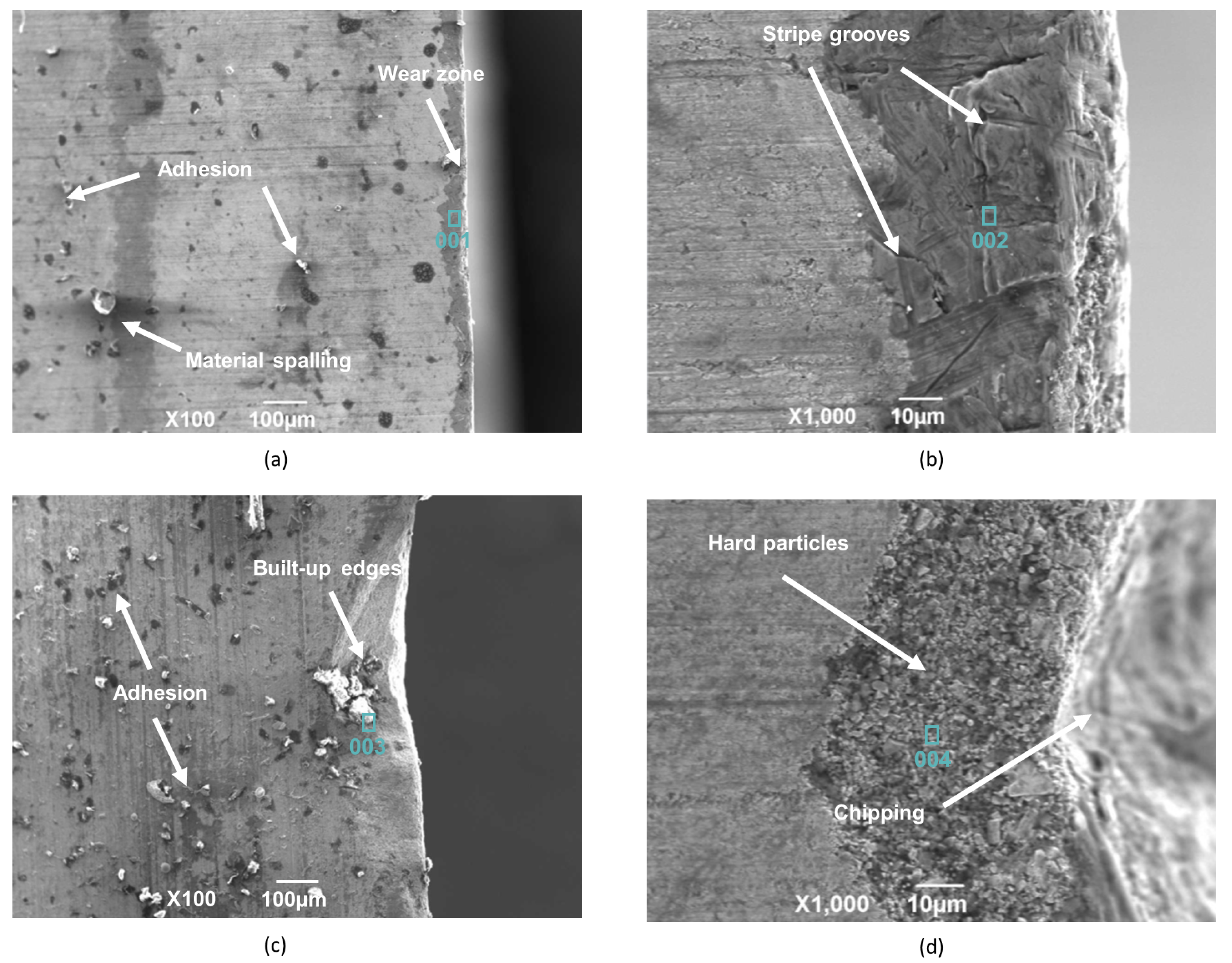

3.1. Chip Morphologies and Tool Wear

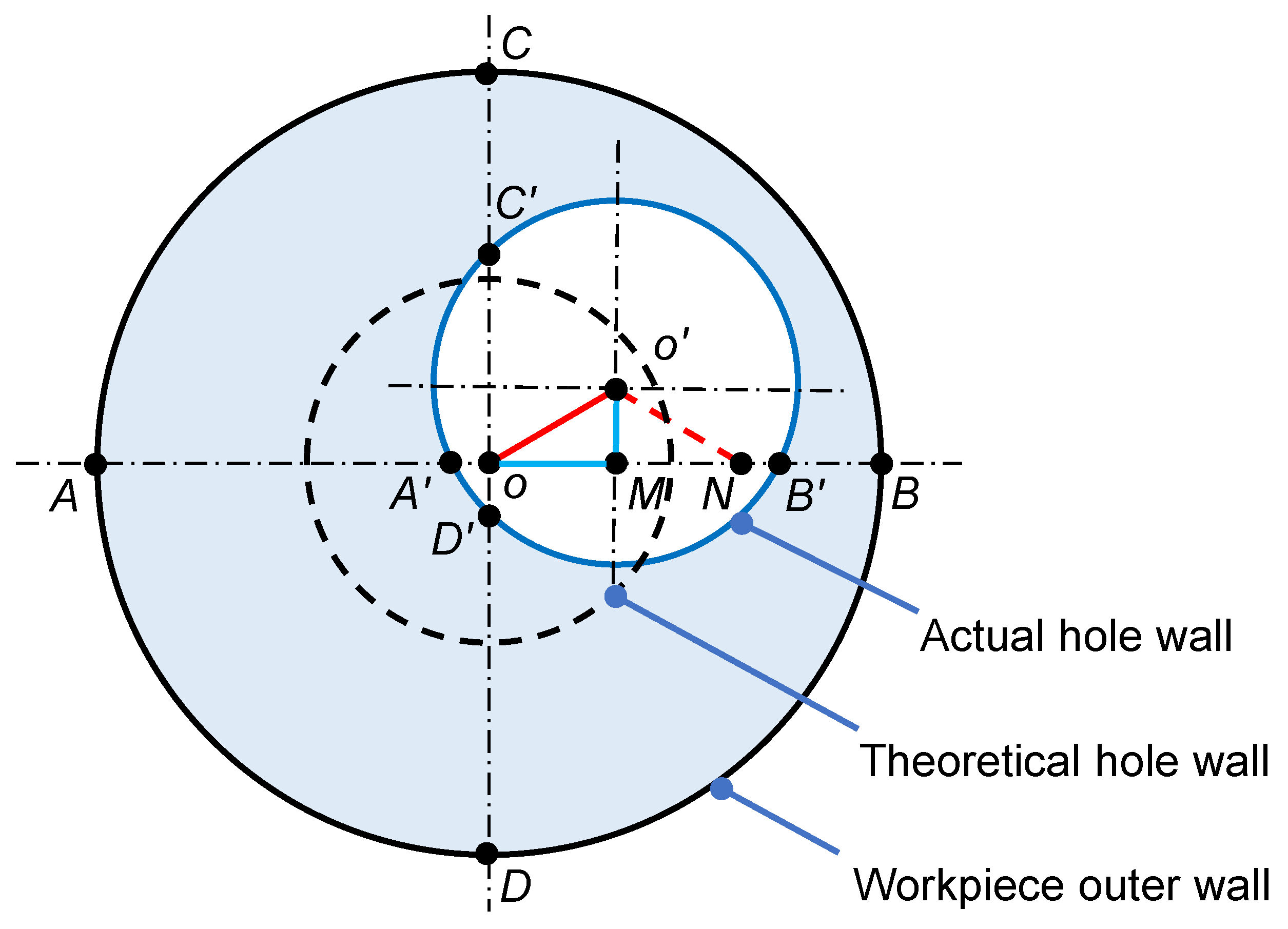

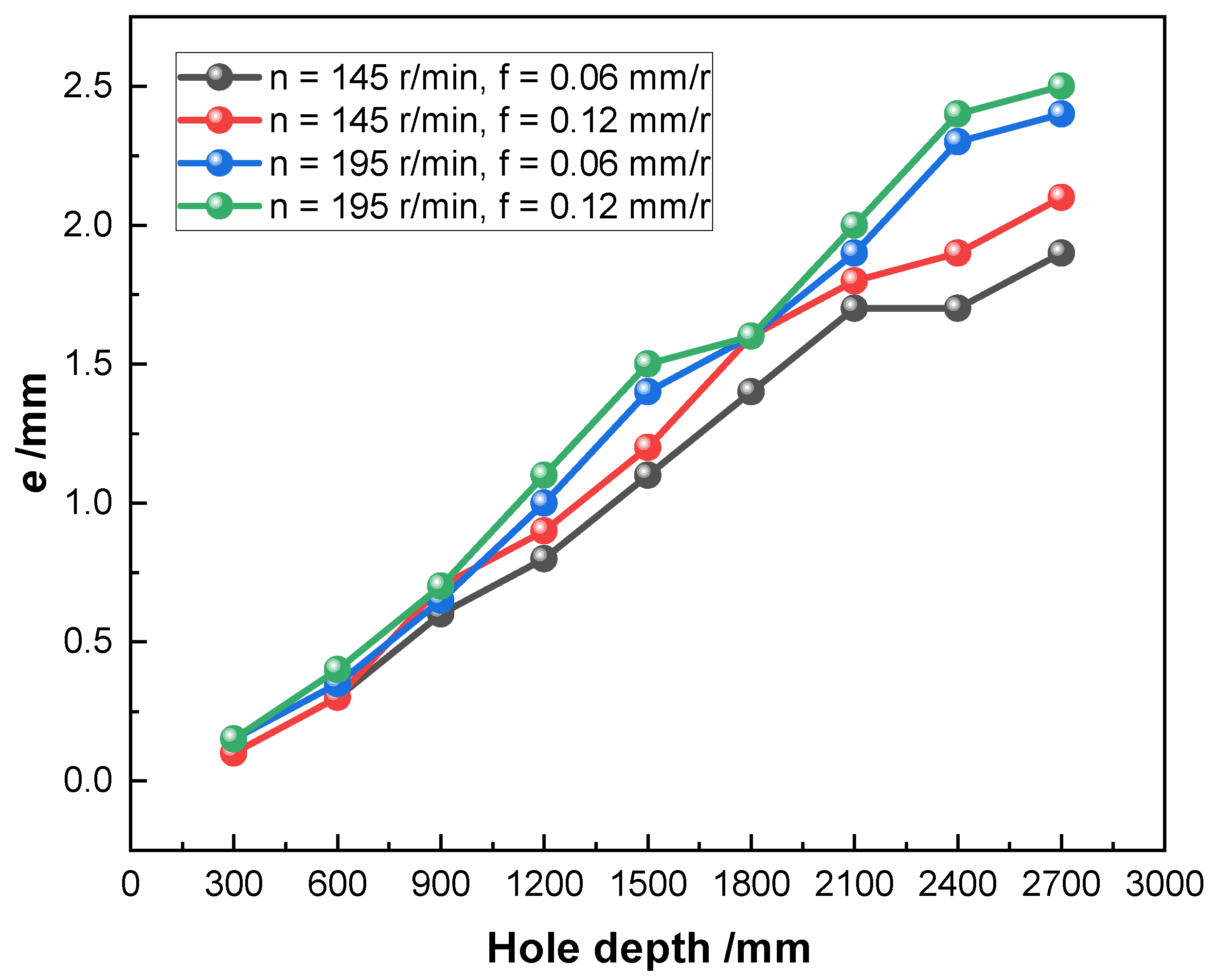

3.2. Hole-Axis Deflection

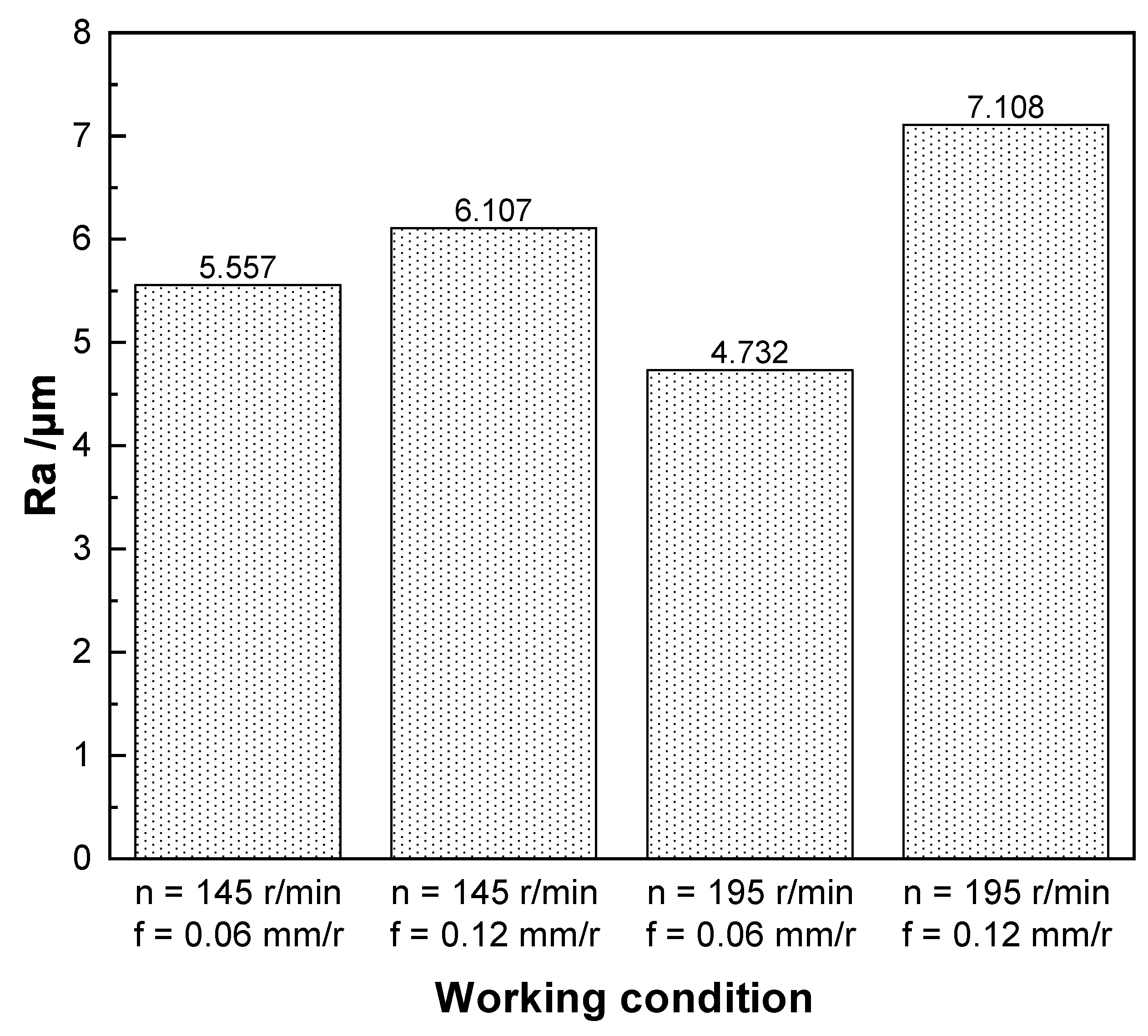

3.3. Hole Surface Roughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, P.; Wei, Z.; Gu, X.; Cui, F.; Mao, W. Influences of cold rolling, recrystallization and surface effect on the transformation textures in a TA10 titanium alloy. J. Phys. Conf. Ser. 2019, 1270, 012037. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Li, Y.; Su, B.; Luo, L.; Wang, L.; Huang, H.; Su, Y.; Guo, J. Enhanced strength and corrosion resistance in as-cast TA10 alloys via interstitial carbon solute. Mater. Res. Express 2022, 9, 046510. [Google Scholar] [CrossRef]

- Tang, X.; Wang, S.; Qian, L.; Li, Y.; Lin, Z.; Xu, D.; Zhang, Y. Corrosion behavior of nickel base alloys, stainless steel and titanium alloy in supercritical water containing chloride, phosphate and oxygen. Chem. Eng. Res. Des. 2015, 100, 530–541. [Google Scholar] [CrossRef]

- Li, J.N.; Liu, Z.Y.; Liu, Q.; Tian, Y. Microstructure and Oxidation Resistance of Laser-induced Stellite Base Composites on a TA10 Alloy. Lasers in Eng. 2019, 44, 217–225. [Google Scholar]

- Baumann, A.; Oezkaya, E.; Schnabel, D.; Biermann, D.; Eberhard, P. Cutting-fluid flow with chip evacuation during deep-hole drilling with twist drills. Eur. J. Mech. B/Fluids 2021, 89, 473–484. [Google Scholar] [CrossRef]

- Felinks, N.; Rinschede, T.; Biermann, D.; Stangier, D.; Tillmann, W.; Fuß, M.; Abrahams, H. Investigation into deep hole drilling of austenitic steel with advanced tool solutions. Int. J. Adv. Manuf. Technol. 2022, 118, 1087–1100. [Google Scholar] [CrossRef]

- Biermann, D.; Bleicher, F.; Heisel, U.; Klocke, F.; Möhring, H.C.; Shih, A. Deep hole drilling. CIRP Ann. 2018, 67, 673–694. [Google Scholar] [CrossRef]

- Chandar, J.B.; Nagarajan, L.; Kumar, M.S. Recent Research Progress in Deep Hole Drilling Process: A Review. Surf. Rev. Lett. 2021, 28, 1–21. [Google Scholar] [CrossRef]

- Strodick, S.; Berteld, K.; Schmidt, R.; Biermann, D.; Zabel, A.; Walther, F. Influence of cutting parameters on the formation of white etching layers in BTA deep hole drilling. tm-Tech. Mess. 2020, 87, 674–682. [Google Scholar] [CrossRef]

- Yang, S.; Tong, X.; Ma, X.; Ji, W.; Liu, X.; Zhang, Y. The guide block structure design of boring and trepanning association (BTA) deep hole drilling. Int. J. Adv. Manuf. Technol. 2018, 99, 911–918. [Google Scholar] [CrossRef]

- Kumar, M.S.; Deivanathan, R. Effect of process parameters on drilling—An overview. Mater. Today Proc. 2021, 46, 1401–1406. [Google Scholar] [CrossRef]

- Senthilkumar, N.; Tamizharasan, T.; Anandakrishnan, V. Experimental investigation and performance analysis of cemented carbide inserts of different geometries using Taguchi based grey relational analysis. Measurement 2014, 58, 520–536. [Google Scholar] [CrossRef]

- Li, Y.; Kong, J.; Du, D. Research on deformation mechanism and law of thin-walled flat parts in vacuum clamping. Int. J. Adv. Manuf. Technol. 2022, 118, 2981–2992. [Google Scholar] [CrossRef]

- Singaravel, B.; Saikrupa, C.; Sandeep, M. Analysis of Quality Parameters in Drilling of Titanium Alloy. Int. J. Veh. Struct. Syst. 2020, 12, 210–213. [Google Scholar] [CrossRef]

- Yuan, C.G.; Pramanik, A.; Basak, A.; Prakash, C.; Shankar, S. Drilling of titanium alloy (Ti6Al4V)—A review. Mach. Sci. Technol. 2021, 25, 637–702. [Google Scholar] [CrossRef]

- Prasanna, J.; Karunamoorthy, L.; Raman, M.V.; Prashanth, S.; Chordia, D.R. Optimization of process parameters of small hole dry drilling in Ti–6Al–4V using Taguchi and grey relational analysis. Measurement 2014, 48, 346–354. [Google Scholar] [CrossRef]

- Li, A.; Zhao, J.; Zhou, Y.; Chen, X.; Wang, D. Experimental investigation on chip morphologies in high-speed dry milling of titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2012, 62, 933–942. [Google Scholar] [CrossRef]

- Das, S.R.; Panda, A.; Dhupal, D. Experimental investigation of surface roughness, flank wear, chip morphology and cost estimation during machining of hardened AISI 4340 steel with coated carbide insert. Mech. Adv. Mater. Mod. Process. 2017, 3, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Liu, Y.; Han, X.; Zheng, W. Study on super-long deep-hole drilling of titanium alloy. J. Appl. Biomater. Funct. Mater. 2018, 16, 150–156. [Google Scholar] [CrossRef] [Green Version]

- Li, X.B.; Zheng, J.M.; Li, Y.; Kong, L.F.; Shi, W.C.; Guo, B. Investigation of chip deformation and breaking with a staggered teeth BTA tool in deep hole drilling. Metals 2019, 9, 46. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Zou, P.; Yang, X.; Kang, D. Study on chip morphology and surface roughness in ultrasonically assisted drilling of 304 stainless steel. Int. J. Adv. Manuf. Technol. 2020, 108, 2079–2090. [Google Scholar] [CrossRef]

- Sivaiah, P.; Bodicherla, U. Effect of surface texture tools and minimum quantity lubrication (MQL) on tool wear and surface roughness in CNC turning of AISI 52100 steel. J. Inst. Eng. (India) Ser. C 2020, 101, 85–95. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Dogra, M.; Pruncu, C.I. Evaluation of tool wear, energy consumption, and surface roughness during turning of inconel 718 using sustainable machining technique. J. Mater. Res. Technol. 2020, 9, 5794–5804. [Google Scholar] [CrossRef]

- Han, X.; Liu, Z.; Wang, T. Investigation of tool wear in pull boring of pure niobium tubes. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–11. [Google Scholar] [CrossRef]

- Abdelhafeez Hassan, A.; Li, M.J.; Mahmoud, S. On miniature hole quality and tool Wear when mechanical Drilling of Mild Steel. Arab. J. Sci. Eng. 2020, 45, 8917–8929. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Gupta, M.K.; Song, Q. Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy. Tribol. Int. 2020, 143, 106084. [Google Scholar] [CrossRef]

- Al-Tameemi, H.A.; Al-Dulaimi, T.; Awe, M.O.; Sharma, S.; Pimenov, D.Y.; Koklu, U.; Giasin, K. Evaluation of cutting-tool coating on the surface roughness and hole dimensional tolerances during drilling of Al6061-T651 alloy. Materials 2021, 14, 1783. [Google Scholar] [CrossRef]

- Denkena, B.; Bergmann, B.; Kaiser, S.; Mücke, M.; Bolle, D. Process-parallel center deviation measurement of a BTA deep-hole drilling tool. Procedia Manuf. 2018, 24, 229–234. [Google Scholar] [CrossRef]

- Gerken, J.; Klages, N.; Biermann, D.; Denkena, B. In-process compensation of straightness deviation in BTA deep hole drilling using experimental and simulative analysis. Procedia CIRP 2020, 93, 1417–1422. [Google Scholar] [CrossRef]

- Matsuzaki, K.; Ryu, T.; Sueoka, A.; Tsukamoto, K. Theoretical and experimental study on rifling mark generating phenomena in BTA deep hole drilling process (generating mechanism and countermeasure). Int. J. Mach. Tools Manuf. 2015, 88, 194–205. [Google Scholar] [CrossRef]

- Schmidt, R.; Strodick, S.; Walther, F.; Biermann, D.; Zabel, A. Analysis of the functional properties in the bore sub-surface zone during BTA deep-hole drilling. Procedia CIRP 2020, 88, 318–323. [Google Scholar] [CrossRef]

- Zhu, Z.; Sui, S.; Sun, J.; Li, J.; Li, Y. Investigation on performance characteristics in drilling of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2017, 93, 651–660. [Google Scholar] [CrossRef]

- Wei, L.; Yang, Y.; Yang, G. Microstructure and properties of YG8 cemented carbide with different pulse currents. Rare Met. 2020, 39, 597–606. [Google Scholar] [CrossRef]

- Li, X.; Zheng, J.; Li, Y.; Kong, L.; Shi, W.; Guo, B. Modeling and distribution laws of drilling force for staggered teeth BTA deep hole drill. Math. Probl. Eng. 2018, 2018, 3691468. [Google Scholar] [CrossRef]

- Volz, M.; Abele, E.; Weigold, M. Lateral Vibrations in Deep Hole Drilling Due to Land Width Variation. J. Manuf. Mater. Process. 2020, 4, 28. [Google Scholar] [CrossRef]

| Ti | Mo | Ni | Fe | C | N | H | O |

|---|---|---|---|---|---|---|---|

| 99 | 0.2–0.4 | <0.6–0.9 | <0.30 | <0.08 | <0.03 | <0.015 | <0.25 |

| Tensile Strength (MPa) | Yield Strength (MPa) | Shrinkage (%) | Elongation (%) | Elastic Modulus (GPa) | Density (g·cm) | Thermal Conductivity (W·m·K) | Hardness (HB) |

|---|---|---|---|---|---|---|---|

| 485 | 345 | 25 | 18 | 112 | 4.54 | 19 | 260 |

| Number | n/(r/min) | f/(mm/r) | Chip Morphologies | Cutting Conditions |

|---|---|---|---|---|

| 1 | 145 | 0.06 | Long coiled chips | Slight vibration and tool wear |

| 2 | 145 | 0.12 | Short spiral chips | Vibration and tool wear |

| 3 | 195 | 0.06 | Long coiled chips | Slight vibration and severe tool wear |

| 4 | 195 | 0.12 | Short spiral chips | Severe vibration and severe tool wear |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Zheng, H.; Han, X.; Liu, Z. Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling. Materials 2022, 15, 4366. https://doi.org/10.3390/ma15124366

Feng Y, Zheng H, Han X, Liu Z. Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling. Materials. 2022; 15(12):4366. https://doi.org/10.3390/ma15124366

Chicago/Turabian StyleFeng, Yazhou, Huan Zheng, Xiaolan Han, and Zhanfeng Liu. 2022. "Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling" Materials 15, no. 12: 4366. https://doi.org/10.3390/ma15124366

APA StyleFeng, Y., Zheng, H., Han, X., & Liu, Z. (2022). Multiobjective Optimization of Cutting Parameters for TA10 Alloy Deep-Hole Drilling. Materials, 15(12), 4366. https://doi.org/10.3390/ma15124366