Effects of Microwave Heating and Long-Term Aging on the Rheological and Chemical Properties of Recovered Bitumen

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Manufacturing of Specimens

2.2. Aging Modes of the Bitumen Samples

- Mode I: bitumen used for the SMA manufacturing under method (1) was aged using hot air and UV light to simulate a long-term aging of 6 years of service life. In total, using this aged bitumen, eight SMA test specimens were prepared and tested.

- Mode II: bitumen within SMA cores only reproduced the short-term aging conditions during pavement construction. In total, eight SMA test specimens were evaluated under this mode.

2.3. Microwave Heating and Long-Term Aging Cycles

2.4. Rheological Properties of Bitumen by DSR Tests

2.5. Quantification of the Rheological Aging Indexes

2.6. Chemical Properties of Bitumen by FTIR Tests

2.7. Summary Description of the Tested Bitumen Samples

3. Results and Discussion

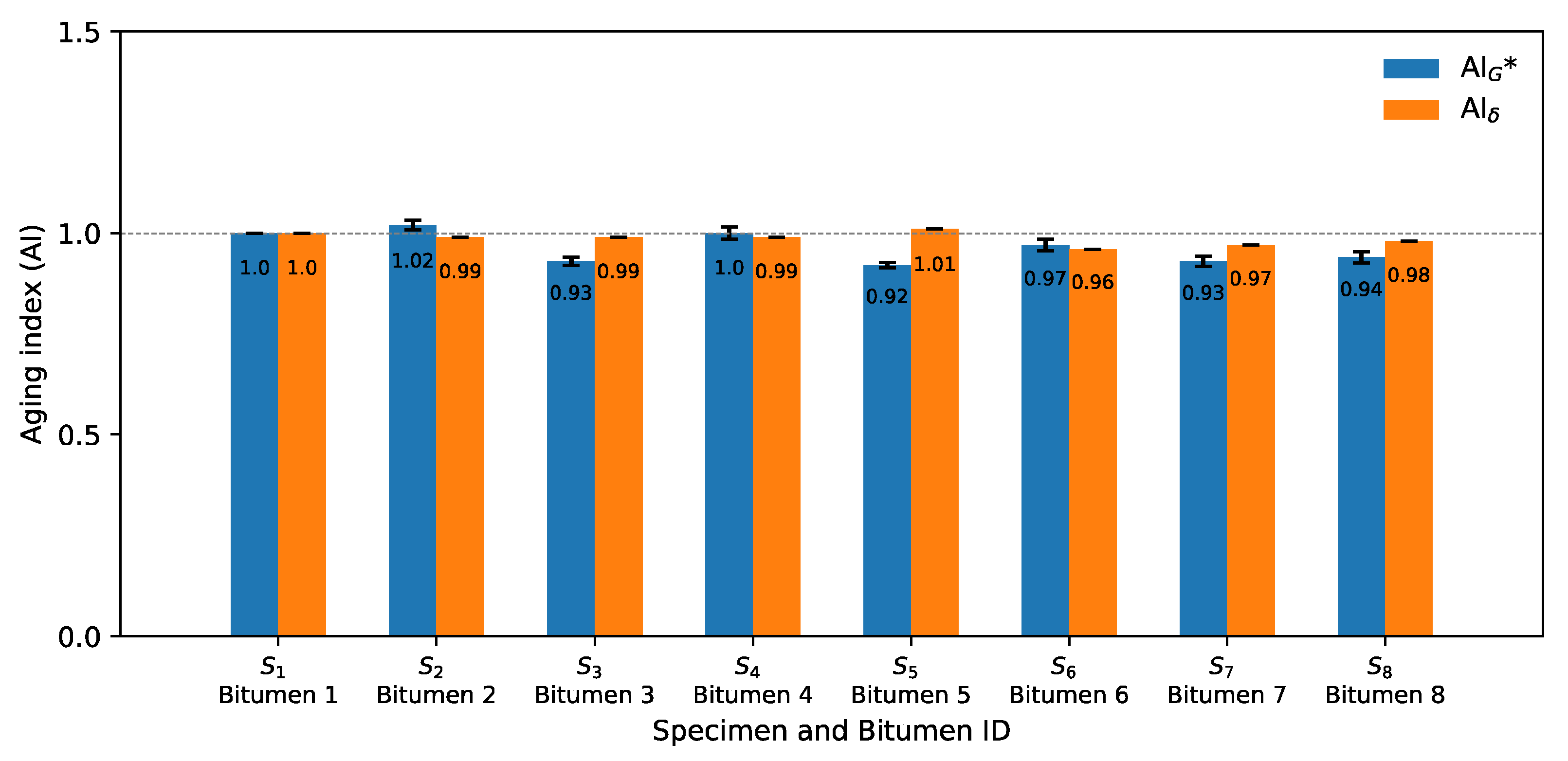

3.1. Effect of the Microwave Heating and Long-Term Aging on Bitumen from Mode I

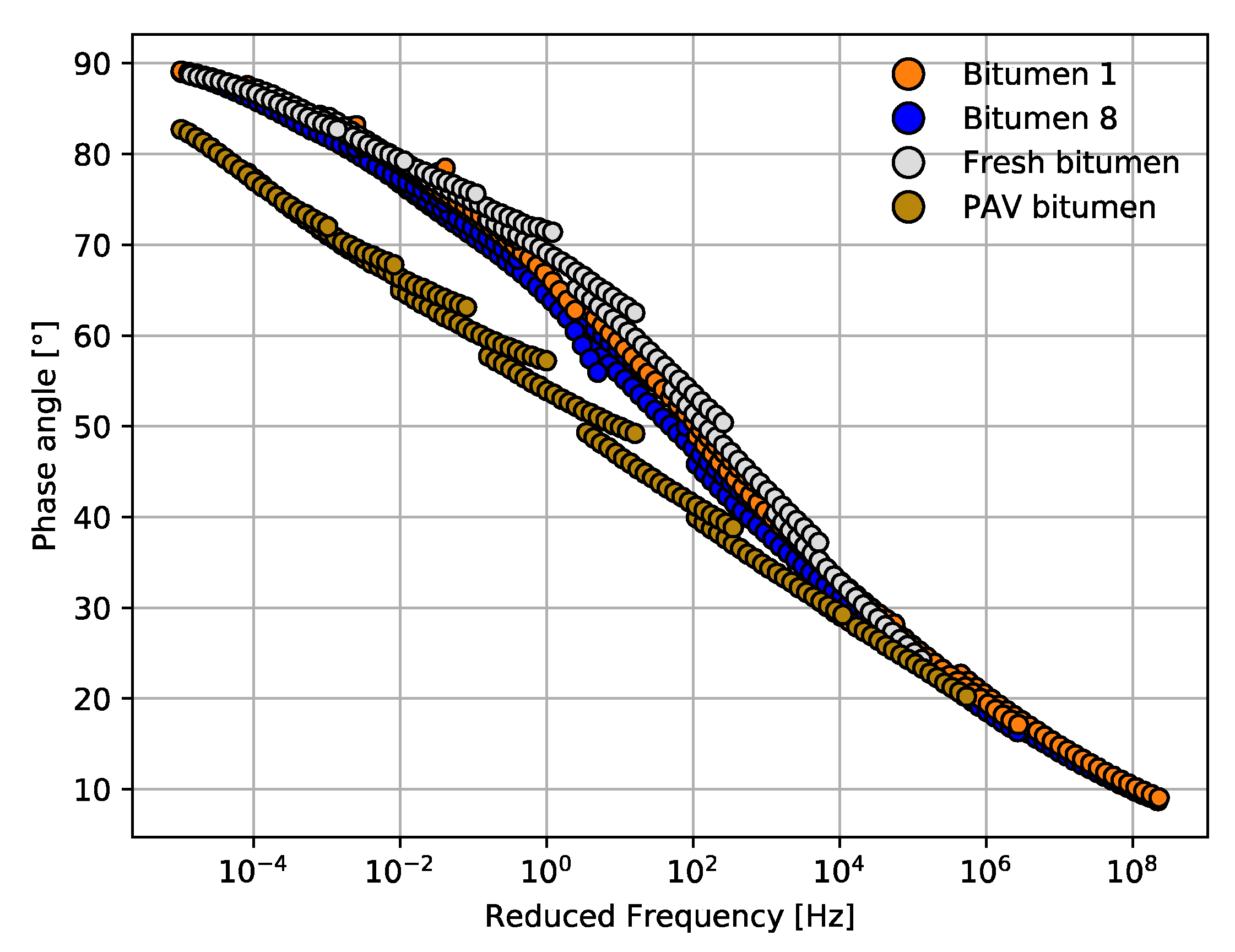

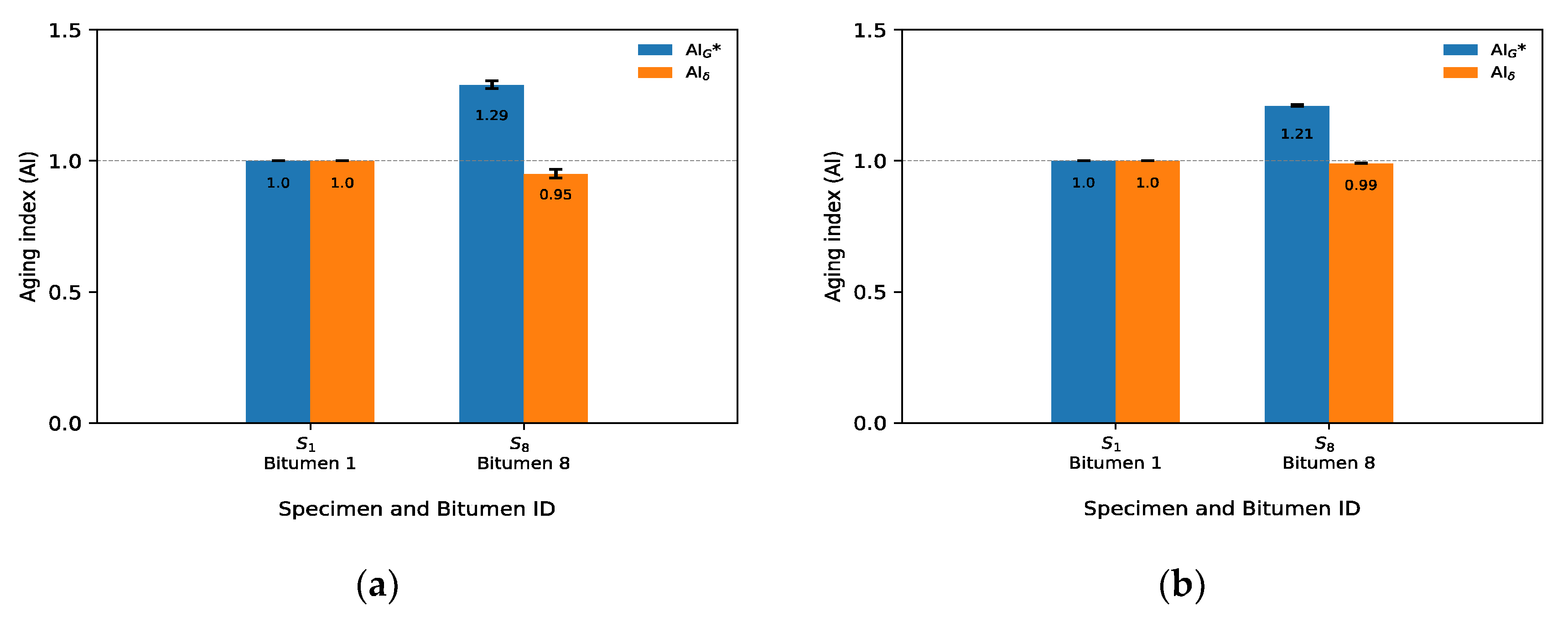

3.1.1. Effect on the Rheological Properties of Bitumen Samples from Mode I

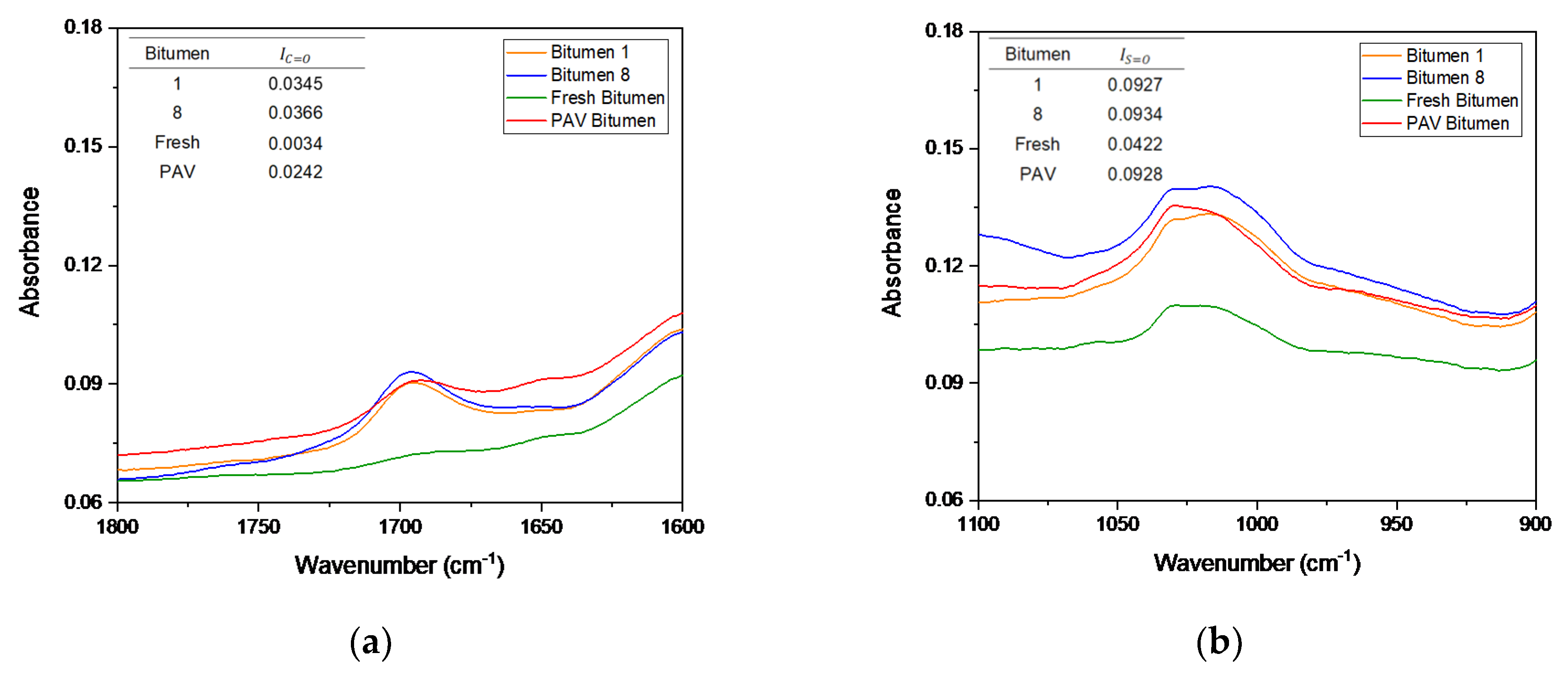

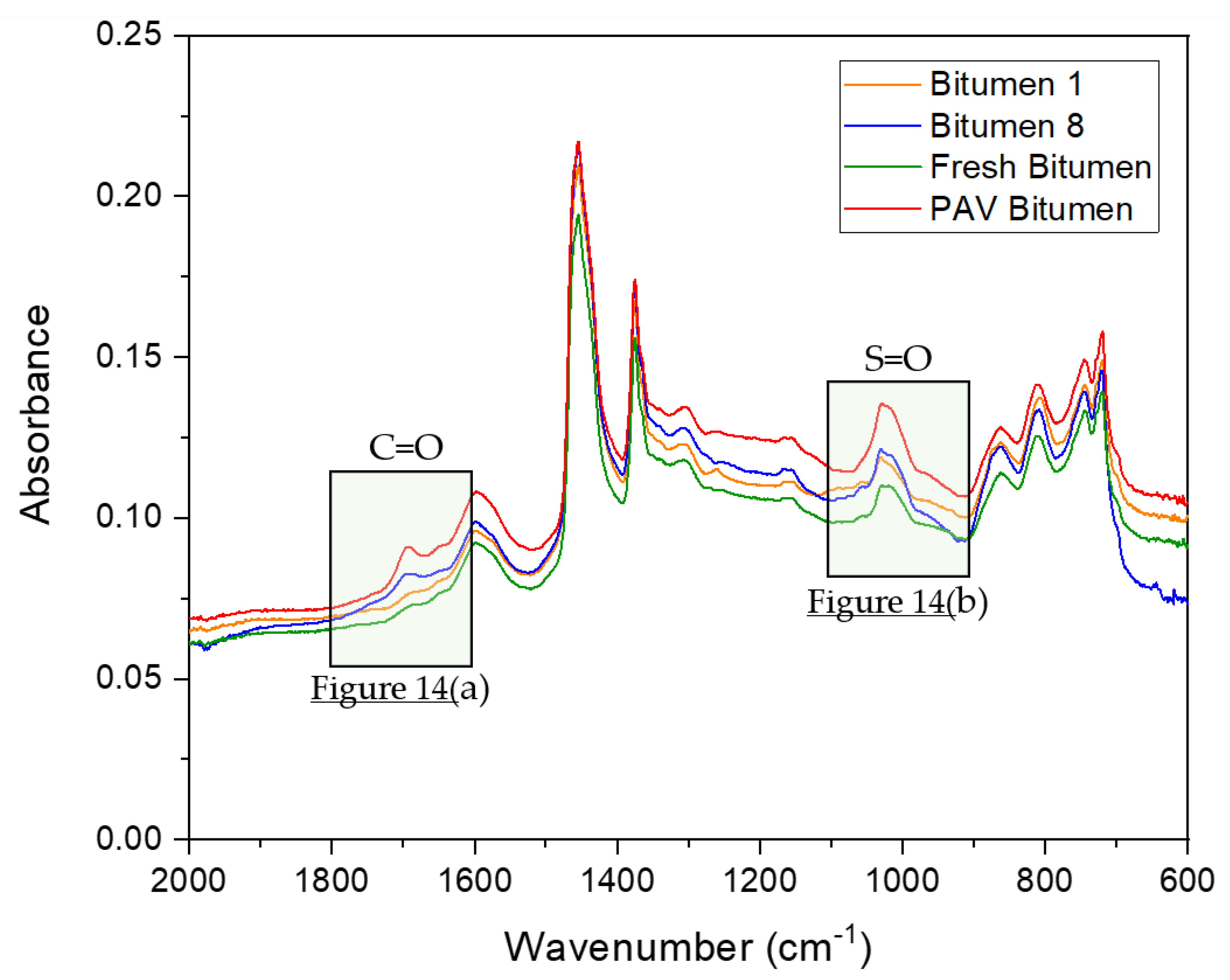

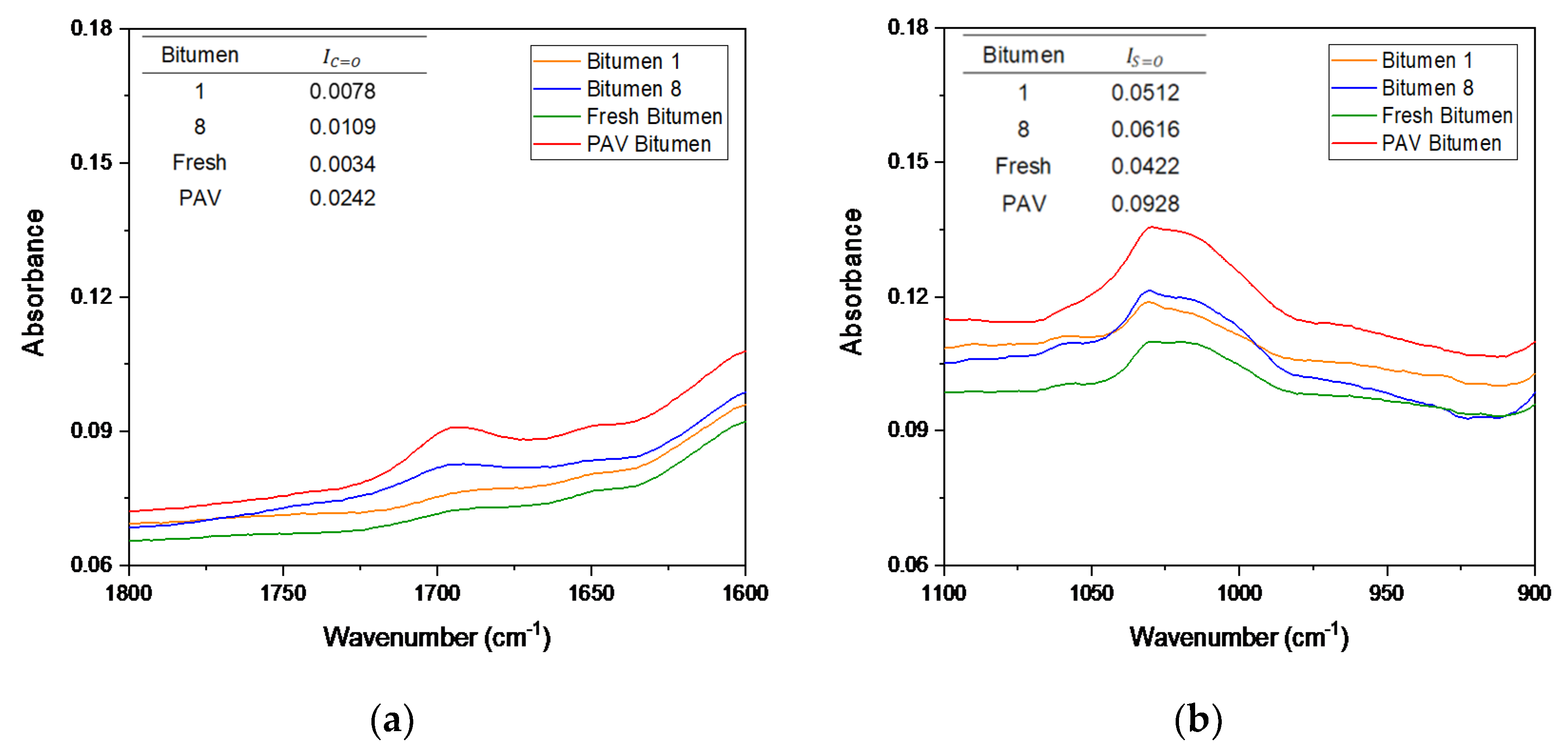

3.1.2. Effect on the Chemical Properties of Bitumen Samples from Mode I

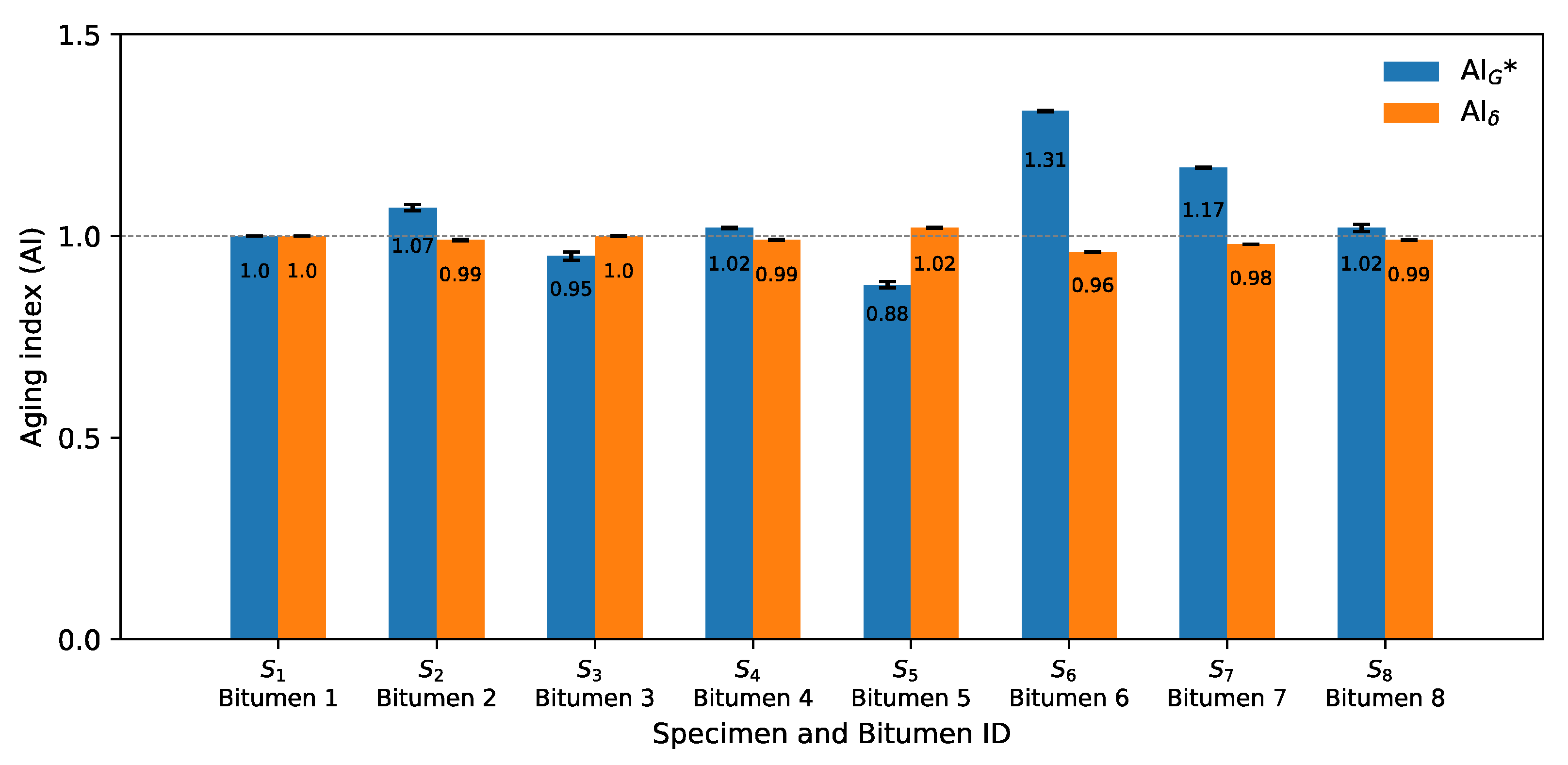

3.2. Effect of the Microwave Heating and Long-Term Aging on Bitumen from Mode II

3.2.1. Effect on the Rheological Properties of Bitumen Samples from Mode II

3.2.2. Effect on the Chemical Properties of Bitumen Samples from Mode II

3.3. Relationship between Chemical and Rheological Results from Mode I and II

4. Conclusions

- Microwave heating and long-term aging have no significant effect on the aging performance of G* and for aged asphalt mixtures. However, the rheological properties of bitumen showed minor aging effects with microwave heating and long-term aging cycles for newer asphalt mixtures.

- It was expected that modified AASHTO R30 would promote the oxidation process, increasing G* and decreasing δ gradually; however, the long-term standard did not oxidize the samples as expected. The study of microwave aging together with aging by modified AASHTO R30 did not permit to clearly differentiate the aging due to microwave heating and the AASHTO R30 accelerated procedure.

- According to the FTIR results, as the microwave heating and long-term aging cycles increased, the carbonyl and sulfoxide indices increased in both phases. Therefore, bitumen aging influences chemical changes in bitumen, including the formation of carbonyl and sulfoxide compounds.

- It was possible to confirm that changes in the molecular composition of the samples varied the viscoelastic properties of the bitumen, as shown in DSR tests.

- A strong relationship could be observed between the chemical and rheological results, showing that both properties are good indicators to evaluate bitumen aging.

- Overall, this study confirmed that microwave heating is a valuable alternative for the maintenance of asphalt pavements, without severely affecting the rheological and chemical properties of bitumen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Effect of RAP and fibers addition on asphalt mixtures with self-healing properties gained by microwave radiation heating. Constr. Build. Mater. 2018, 159, 164–174. [Google Scholar] [CrossRef]

- Kim, Y.; Little, D.N.; Asce, F.; Lytton, R.L.; Asce, F.P.E. Fatigue and Healing Characterization of Asphalt Mixtures. J. Mater. Civil Eng. 2003, 15, 75–83. [Google Scholar] [CrossRef]

- Rochlani, M.; Leischner, S.; Falla, G.C.; Wang, D.; Caro, S.; Wellner, F. Influence of filler properties on the rheological, cryogenic, fatigue and rutting performance of mastics. Constr. Build. Mater. 2019, 227, 116974. [Google Scholar] [CrossRef]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook; ICE Virtual Library: London, UK, 2015. [Google Scholar]

- Miró, R.; Martínez, A.H.; Moreno-Navarro, F.; del Carmen Rubio-Gámez, M. Effect of ageing and temperature on the fatigue behaviour of bitumens. Mater. Des. 2015, 86, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Sandoval, G.; Thenoux, G.; Molenaar, A.A.A.; Gonzalez, M. The antioxidant effect of grape pomace in asphalt binder. Int. J. Pavement Eng. 2016, 20, 163–171. [Google Scholar] [CrossRef]

- Gallego, J.; Del Val, M.A.; Contreras, V.; Páez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Miao, P.; Wang, S.; Liu, W. Improving microwave absorption efficiency of asphalt mixture by enriching Fe3O4 on the surface of steel slag particles. Mater. Struct. Constr. 2017, 50. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Serpell, R.; Valdés Vidal, G.; González, A.; Schlangen, E. Effect of fibres addition on the physical and mechanical properties of asphalt mixtures with crack-healing purposes by microwave radiation. Constr. Build. Mater. 2016, 127, 369–382. [Google Scholar] [CrossRef]

- González, A.; Valderrama, J.; Norambuena-Contreras, J. Microwave crack healing on conventional and modified asphalt mixtures with different additives: An experimental approach. Road Mater. Pavement Des. 2019, 20, S149–S162. [Google Scholar] [CrossRef]

- Ayar, P.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The healing capability of asphalt pavements: A state of the art review. J. Clean. Prod. 2016, 113, 28–40. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. The prospect of microwave heating: Towards a faster and deeper crack healing in asphalt pavement. Processes 2021, 9, 507. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; González, Á. Assessment of self-healing asphalt pavement fatigue life using analytical Jc approach and laboratory results. Constr. Build. Mater. 2021, 304. [Google Scholar] [CrossRef]

- González, A.; Norambuena-Contreras, J.; Storey, L.; Schlangen, E. Self-healing properties of recycled asphalt mixtures containing metal waste: An approach through microwave radiation heating. J. Environ. Manag. 2018, 214, 242–251. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Meijide, B.; Ajam, H.; Lastra-González, P.; Garcia, A. Effect of ageing and RAP content on the induction healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 179, 468–476. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez, A.; Concha, J.L.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef] [Green Version]

- García, A.; Schlangen, E.; Van De Ven, M.; Van Vliet, D. Induction heating of mastic containing conductive fibers and fillers. Mater. Struct. 2010, 44, 499–508. [Google Scholar] [CrossRef] [Green Version]

- García, A.; Norambuena-Contreras, J.; Partl, M.N. A parametric study on the influence of steel wool fibers in dense asphalt concrete. Mater. Struct. 2013, 47, 1559–1571. [Google Scholar] [CrossRef]

- Liu, Q.; Schlangen, E.; Van De Ven, M.; Van Bochove, G.; Van Montfort, J. Evaluation of the induction healing effect of porous asphalt concrete through four point bending fatigue test. Constr. Build. Mater. 2012, 29, 403–409. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez-Torre, I. Influence of the microwave heating time on the self-healing properties of asphalt mixtures. Appl. Sci. 2017, 7, 1076. [Google Scholar] [CrossRef] [Green Version]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Flores, G.; Gallego, J.; Giuliani, F.; Autelitano, F. Aging of asphalt binder in hot pavement rehabilitation. Constr. Build. Mater. 2018, 187, 214–219. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Q.; Wu, S.; Ye, Q.; Sun, Y.; Schlangen, E. Investigation of the optimal self-healing temperatures and healing time of asphalt binders. Constr. Build. Mater. 2016, 113, 1029–1033. [Google Scholar] [CrossRef]

- Amani, S.; Kavussi, A.; Karimi, M.M. Effects of aging level on induced heating-healing properties of asphalt mixes. Constr. Build. Mater. 2020, 263, 120105. [Google Scholar] [CrossRef]

- Yalcin, E. Effects of microwave and induction heating on the mechanical and self-healing characteristics of the asphalt mixtures containing waste metal. Constr. Build. Mater. 2021, 286, 122965. [Google Scholar] [CrossRef]

- Wu, S.; Yang, J.; Yang, R.; Zhu, J.; Liu, S. Investigation on Microwave Heating Technology for Rutting Maintenance in Asphalt Pavement. J. Test. Eval. 2018, 48, 20180034. [Google Scholar] [CrossRef]

- Airey, G.D. Use of Black Diagrams to Identify Inconsistencies in Rheological Data Use of Black Diagrams to Identify Inconsistencies in Rheological Data. Road Mater. Pavement Des. 2002, 3, 403–424. [Google Scholar] [CrossRef]

- Ge, D.; Chen, S.; You, Z.; Yang, X.; Yao, H.; Ye, M.; Yap, Y.K. Correlation of DSR Results and FTIR’s Carbonyl and Sulfoxide Indexes: Effect of Aging Temperature on Asphalt Rheology. J. Mater. Civ. Eng. 2019, 31, 04019115. [Google Scholar] [CrossRef]

- European Commitee for Standarization. EN 12697-4: Bituminous Mixtures.Test Methods for Hot Mix Asphalt. Bitumen Recovery: Fractionating Column; British Standard Institution: London, UK, 2013. [Google Scholar]

- European Commitee for Standarization. Bitumen and Bituminous Binders—Accelerated Long-Term Ageing Conditioning by a Pressure Ageing Vessel (PAV) (EN 14769); British Standard Institution: London, UK, 2012. [Google Scholar]

- American Association of State Highway and Transportation (AASHTO). Standard Practice for Mixture Conditioning of Hot-Mix Asphalt (HMA) (AASHTO R30); British Standard Institution: London, UK, 2002. [Google Scholar]

- Elwardany, M.D.; Yousefi Rad, F.; Castorena, C.; Kim, Y.R. Evaluation of asphalt mixture laboratory long-term ageing methods for performance testing and prediction. Road Mater. Pavement Des. 2017, 18, 28–61. [Google Scholar] [CrossRef]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Rosli, M.; Hasan, M. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 1–8. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Cheng, L.; Yu, J.; Zhao, Q.; Wu, J.; Zhang, L. Chemical, rheological and aging characteristic properties of Xinjiang rock asphalt-modified bitumen. Constr. Build. Mater. 2020, 240, 117908. [Google Scholar] [CrossRef]

- ASTM-D7175-15. Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer 1. Annu. B Stand 2017, 1–16. [Google Scholar] [CrossRef]

- Chailleux, E.; Ramond, G.; Such, C.; de La Roche, C. A mathematical-based master-curve construction method applied to complex modulus of bituminous materials. Road Mater. Pavement Des. 2006, 7, 75–92. [Google Scholar] [CrossRef]

- Dondi, G.; Vignali, V.; Pettinari, M.; Mazzotta, F.; Simone, A.; Sangiorgi, C. Modeling the DSR complex shear modulus of asphalt binder using 3D discrete element approach. Constr. Build. Mater. 2014, 54, 236–246. [Google Scholar] [CrossRef]

- Booshehrian, A.; Mogawer, W.S.; Bonaquist, R. How to Construct an Asphalt Binder Master Curve and Assess the Degree of Blending between RAP and Virgin Binders. J. Mater. Civ. Eng. 2013, 25, 1813–1821. [Google Scholar] [CrossRef]

- Gonzalez-Torre, I.; Norambuena-Contreras, J. Recent advances on self-healing of bituminous materials by the action of encapsulated rejuvenators. Constr. Build. Mater. 2020, 258, 119568. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Y.; Li, Y.; Li, C.; Song, W.; Li, H.; Li, C.; Shu, B.; Nie, S. The effect of UV irradiation on the chemical structure, mechanical and self-healing properties of asphalt mixture. Materials 2019, 12, 2424. [Google Scholar] [CrossRef] [Green Version]

- Jing, R.; Varveri, A.; Liu, X.; Scarpas, A.; Erkens, S. Laboratory and Field Aging Effect on Bitumen Chemistry and Rheology in Porous Asphalt Mixture. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 365–374. [Google Scholar] [CrossRef] [Green Version]

- Zeng, W.; Wu, S.; Wen, J.; Chen, Z. The temperature effects in aging index of asphalt during UV aging process. Constr. Build. Mater. 2015, 93, 1125–1131. [Google Scholar] [CrossRef]

- Yuhong Wang, P.E.; Wen, Y.; Zhao, K.; Chong, D.; Wong, A.S.T. Evolution and locational variation of asphalt binder aging in long-life hot-mix asphalt pavements. Constr. Build. Mater. 2014, 68, 172–182. [Google Scholar] [CrossRef]

- Wu, J. The Influence of Mineral Aggregates and Binder. 2009. Available online: http://awww.ukdctn.org/research/groups/ntec/documents/theses/wu,jiantao(jed)thesis15-6-09.pdf (accessed on 1 October 2021).

- Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Xu, W.; Yu, J.; Yu, H. Effect of aging on chemical and rheological properties of bitumen. Polymers 2018, 10, 1345. [Google Scholar] [CrossRef] [Green Version]

- Qin, Q.; Schabron, J.F.; Boysen, R.B.; Farrar, M.J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Petersen, J.C.; Glaser, R. Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Petersen, J.C. A Review of the Fundamentals of Asphalt Oxidation: Chemical, Physicochemical, Physical Property, and Durability Relationships. 2009. Available online: https://trid.trb.org/view/902386 (accessed on 1 October 2021).

| Symbology | Description |

|---|---|

| Bitumen 1 | Bitumen sample recovered from SMA without stages of aging 1 |

| Bitumen 2–8 | Bitumen samples recovered from SMA test specimens exposed to different microwave and oven stages of aging 1 |

| Fresh Bitumen | Virgin bitumen sample without any treatment |

| PAV Bitumen | Bitumen sample aged using the pressure aging vessel (PAV) method |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, M.; Canon, G.; Leischner, S.; Rochlani, M.; Norambuena-Contreras, J.; González, A. Effects of Microwave Heating and Long-Term Aging on the Rheological and Chemical Properties of Recovered Bitumen. Materials 2021, 14, 7787. https://doi.org/10.3390/ma14247787

Fernández M, Canon G, Leischner S, Rochlani M, Norambuena-Contreras J, González A. Effects of Microwave Heating and Long-Term Aging on the Rheological and Chemical Properties of Recovered Bitumen. Materials. 2021; 14(24):7787. https://doi.org/10.3390/ma14247787

Chicago/Turabian StyleFernández, Matías, Gustavo Canon, Sabine Leischner, Mrinali Rochlani, José Norambuena-Contreras, and Alvaro González. 2021. "Effects of Microwave Heating and Long-Term Aging on the Rheological and Chemical Properties of Recovered Bitumen" Materials 14, no. 24: 7787. https://doi.org/10.3390/ma14247787

APA StyleFernández, M., Canon, G., Leischner, S., Rochlani, M., Norambuena-Contreras, J., & González, A. (2021). Effects of Microwave Heating and Long-Term Aging on the Rheological and Chemical Properties of Recovered Bitumen. Materials, 14(24), 7787. https://doi.org/10.3390/ma14247787