Molecular Dynamics Study on Mechanical Properties of Nanopolycrystalline Cu–Sn Alloy

Abstract

:1. Introduction

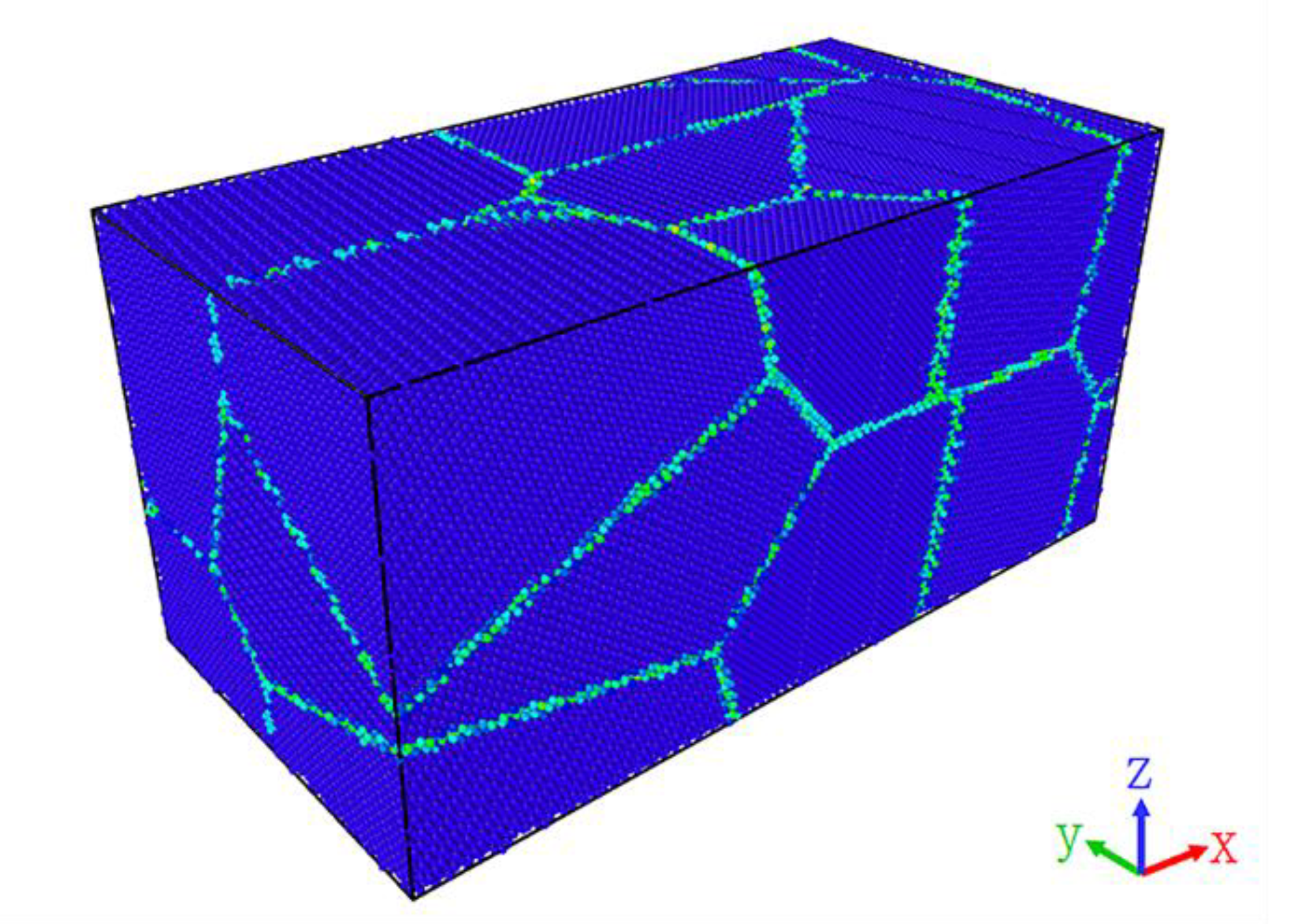

2. Simulation Methods

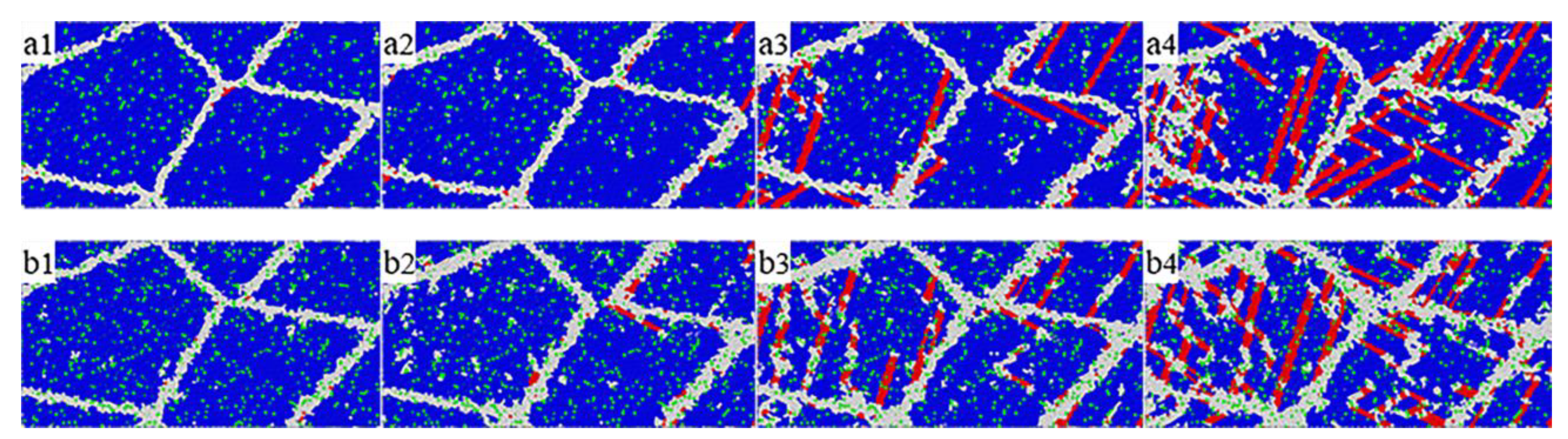

3. Results and Discussion

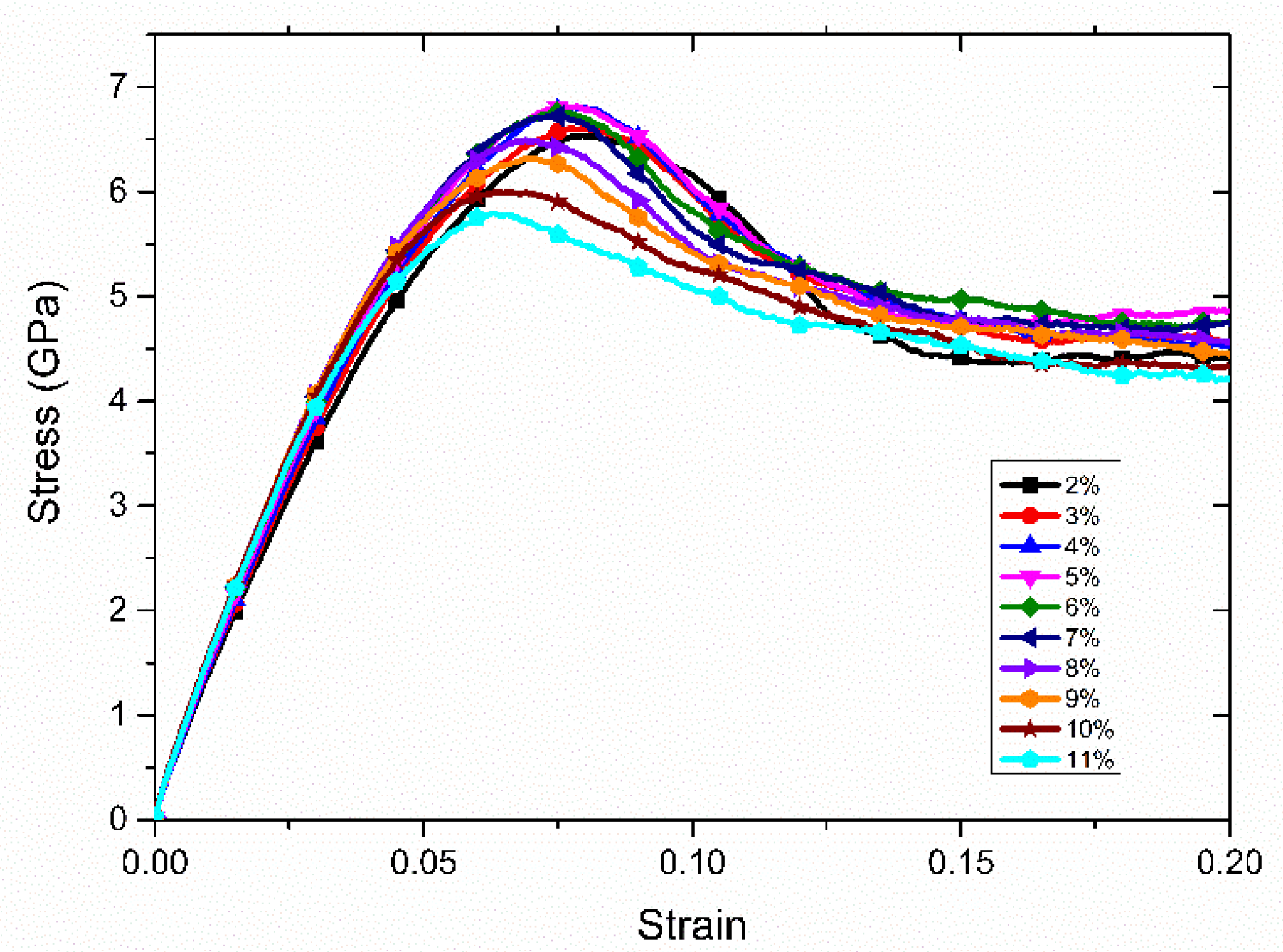

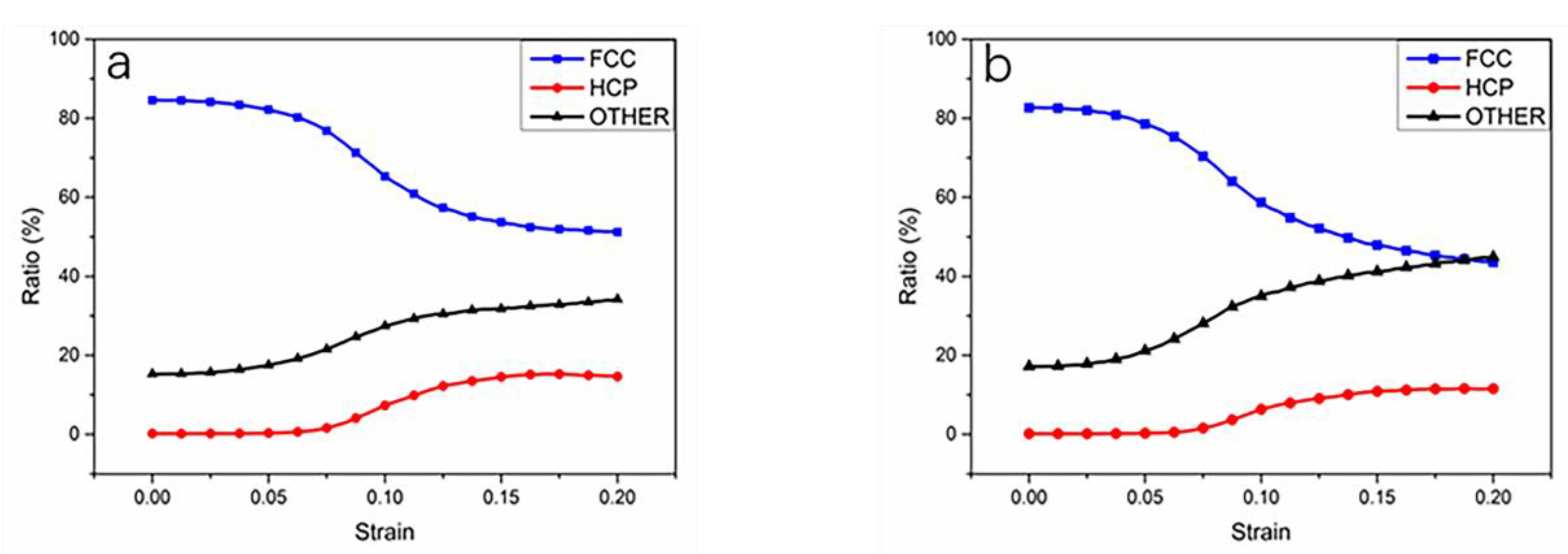

3.1. Effect of Sn Content on Properties of Nanopolycrystalline Cu–Sn Alloy

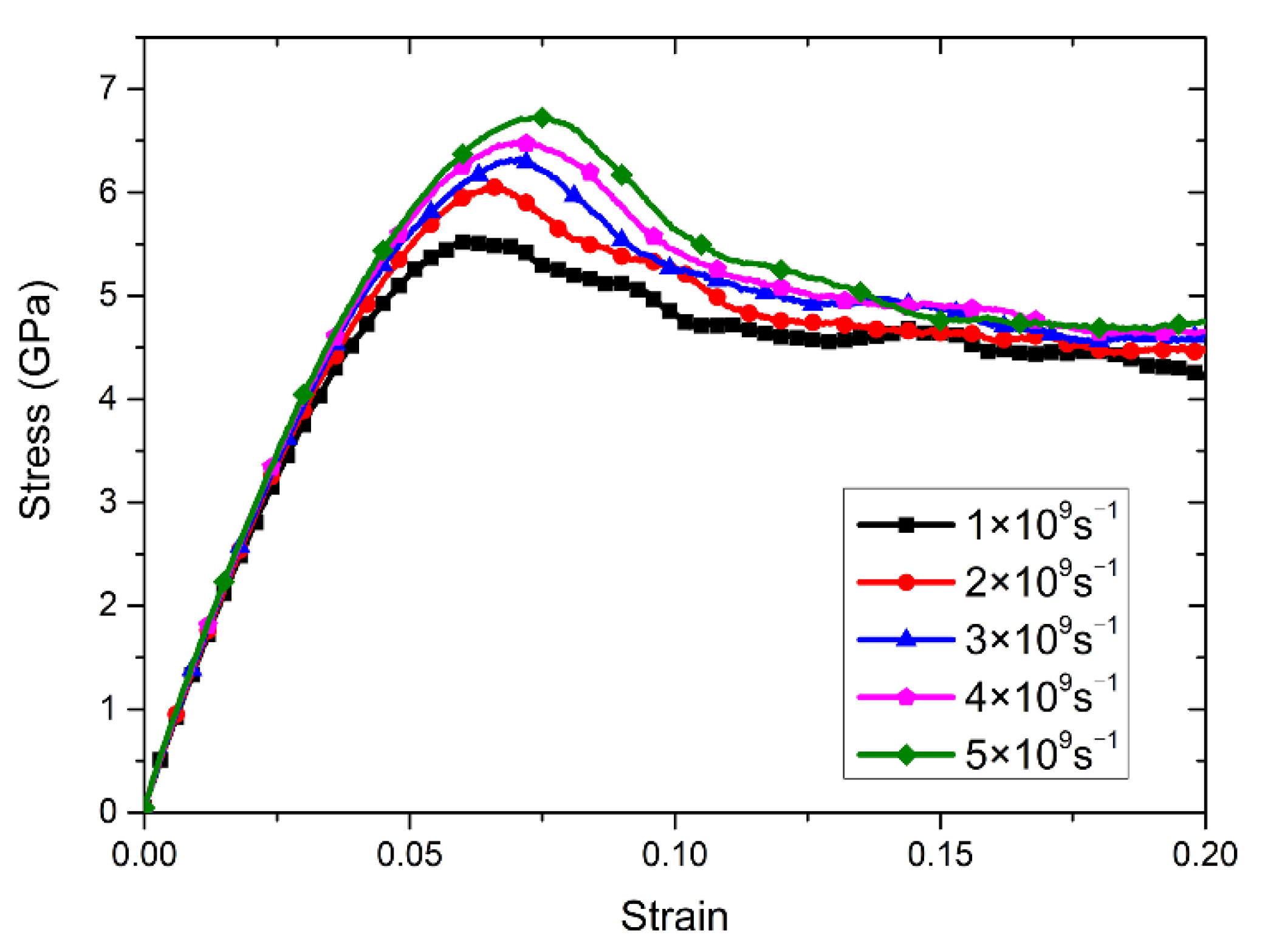

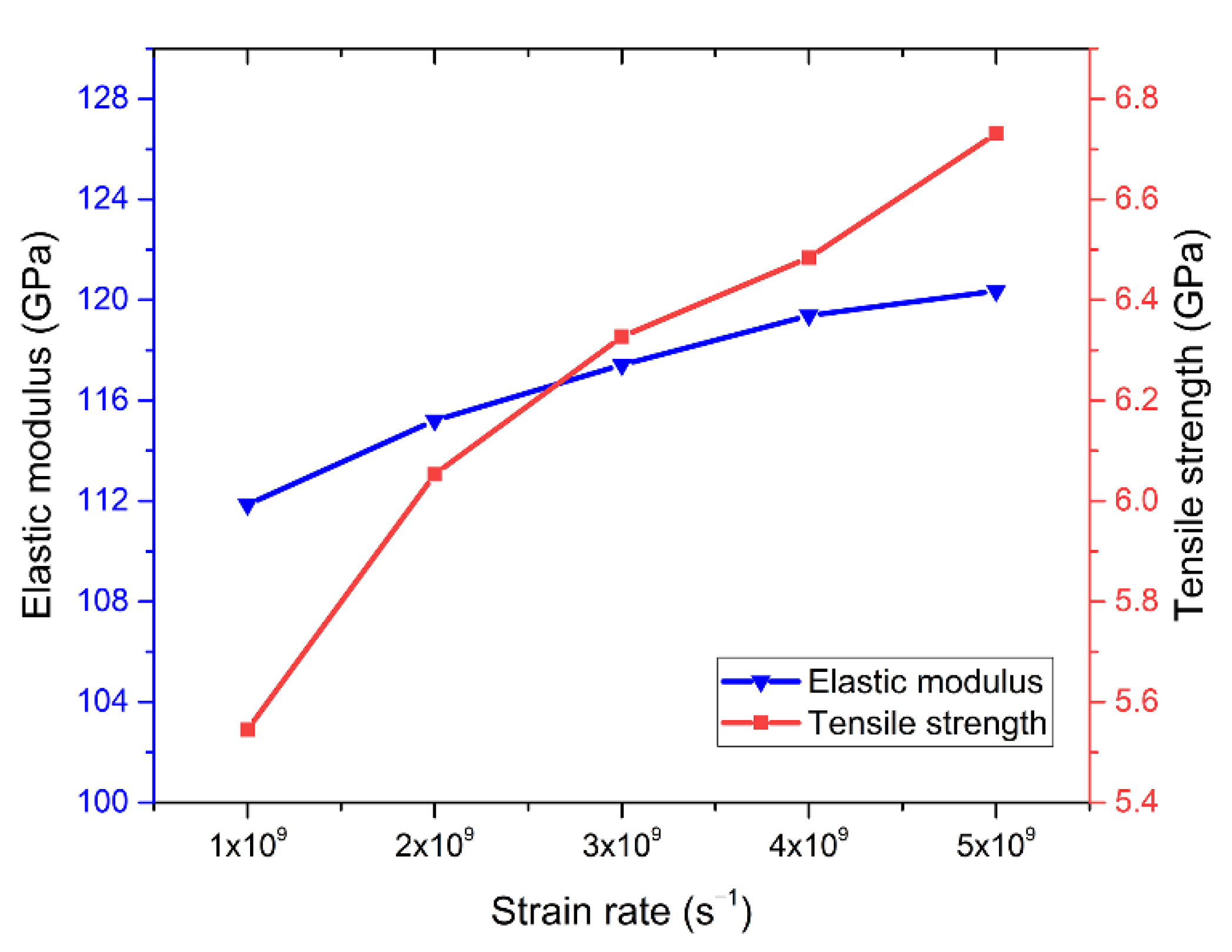

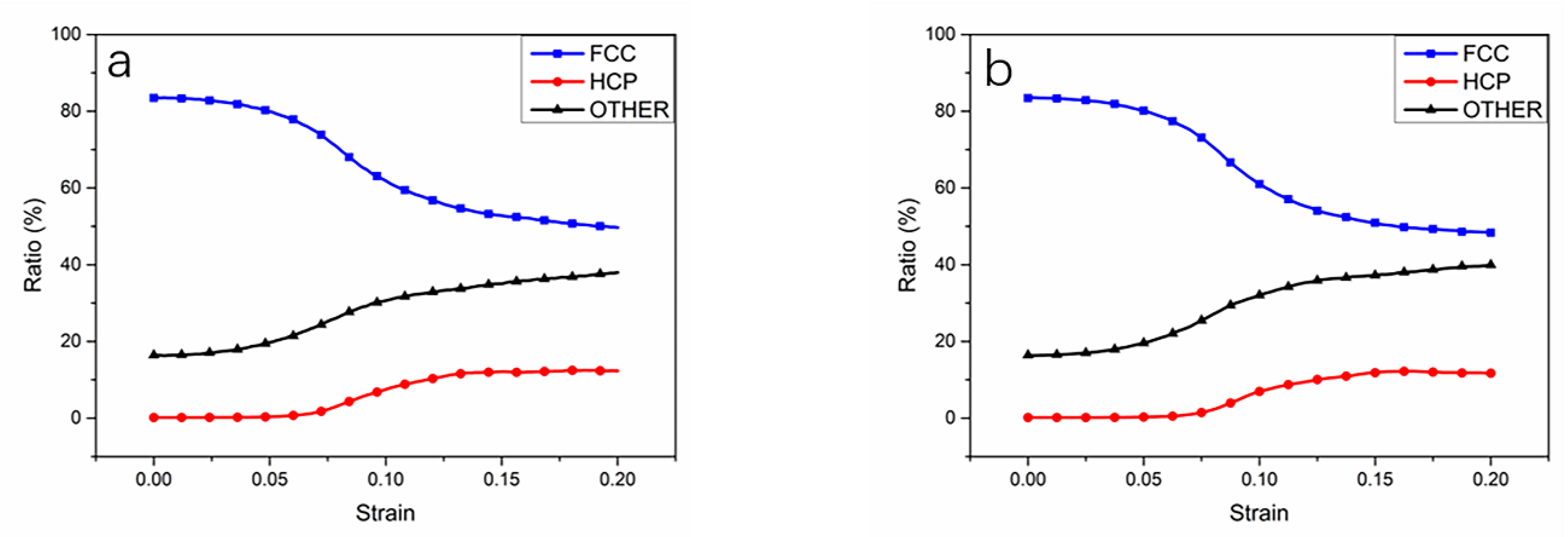

3.2. Effect of Strain Rate on Properties of Nanopolycrystalline Cu–Sn Alloy

4. Conclusions

- (1)

- Sn content has a significant effect on the mechanical properties of nanopolycrystalline Cu–Sn alloy. The elastic modulus and tensile strength of the material depend on the proportion of Sn in the alloy. The results demonstrate that the addition of Sn reduces the ductility of nanopolycrystalline Cu–Sn alloy. However, the elastic modulus and tensile strength of nanopolycrystalline Cu–Sn alloy are improved by increasing the Sn content initially, but they will be reduced when the Sn content exceeds 4% and 8%, respectively.

- (2)

- The strain rate weakly influenced the elastic modulus of nanopolycrystalline Cu–7Sn alloy, but the tensile strength and ductility are obviously enhanced with an increasing strain rate. The tensile strength increases with the increase of the strain rate, and the strain rate has a significant strengthening effect on the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karthik, M.; Abhinav, J.; Shankar, K.V. Morphological and Mechanical Behaviour of Cu–Sn Alloys—A review. Met. Mater. Int. 2021, 27, 1915–1946. [Google Scholar] [CrossRef]

- Huang, W.; Chai, L.; Li, Z.; Yang, X.; Guo, N.; Song, B. Evolution of microstructure and grain boundary character distribution of a tin bronze annealed at different temperatures. Mater Charact. 2016, 114, 204–210. [Google Scholar] [CrossRef]

- Hui, J.; Feng, Z.; Fan, W.; Yuan, X. The influence of power spinning and annealing temperature on microstructures and properties of Cu-Sn alloy. Mater. Charact. 2018, 144, 611–620. [Google Scholar] [CrossRef]

- Wu, T.; Yuan, D.; Huang, H.; Wang, W.; Xiao, X.; Li, M.; Yang, B. Enhanced mechanical strength of Cu–Sn alloy by Mg addition. Mater. Res. Express 2021, 8, 016541. [Google Scholar] [CrossRef]

- Mu, D.; Nan, P.H.; Wang, J.Y.; Song, G.D.; Luo, W.G. Metallurgical and Chemical Characterization of Bronze Remains Found at the Houhe Site in Shanxi Province, China. JOM 2015, 67, 1659–1666. [Google Scholar] [CrossRef]

- Sun, F.; Yin, Z. The interfacial Cu–Sn intermetallic compounds (IMCs) growth behavior of Cu/Sn/Cu sandwich structure via induction heating method. J. Mater. Sci.-Mater. Electron. 2019, 30, 18878–18884. [Google Scholar] [CrossRef]

- Qi, X.; Chen, Z.; Yan, T.; Fichthorn, K.A. Growth Mechanism of Five-Fold Twinned Ag Nanowires from Multiscale Theory and Simulations. ACS Nano 2019, 13, 4647–4656. [Google Scholar] [CrossRef] [PubMed]

- Magomedov, M.N. Changes in the structure of the Au–Fe alloy with a change in the concentration and with a decrease of the nanocrystal size. Solid State Sci. 2021, 120, 106721. [Google Scholar] [CrossRef]

- So, S.-M.; Kim, K.-Y.; Lee, S.-J.; Yu, Y.-J.; Lim, H.-A.; Oh, M.-S. Effects of Sn content and hot deformation on microstructure and mechanical properties of binary high Sn content Cu–Sn alloys. Mater. Sci. Eng. A 2020, 796, 140054. [Google Scholar] [CrossRef]

- Jang, H.W.; Hong, J.W. Influence of Zinc Content on the Mechanical Behaviors of Cu-Zn Alloys by Molecular Dynamics. Materials 2020, 13, 2062. [Google Scholar] [CrossRef]

- Dou, Y.; Luo, H.; Jiang, Y.; Tang, X. Effects of Alloying Elements on the Stacking Fault Energies of Ni58Cr32Fe10 Alloys: A First-Principle Study. Metals 2019, 9, 1163. [Google Scholar] [CrossRef] [Green Version]

- Joy, J.; Jadhav, M.; Sahane, D.; Davis, D.; Singh, S. Elemental effect on formation of solid solution phase in CoCrFeNiX and CoCuFeNiX (X = Ti, Zn, Si, Al) high entropy alloys. Mater. Sci. Technol. 2019, 35, 1700–1707. [Google Scholar] [CrossRef]

- Becker, H.; Pantleon, W. Work-hardening stages and deformation mechanism maps during tensile deformation of commercially pure titanium. Comput. Mater. Sci. 2013, 76, 52–59. [Google Scholar] [CrossRef]

- Dupont, V.; Germann, T.C. Strain rate and orientation dependencies of the strength of single crystalline copper under compression. Phys. Rev. B 2012, 86, 71–75. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-Y.; Lee, S.-I.; Hwang, B. Effect of strain rate on tensile and serration behaviors of an austenitic Fe-22Mn-0.7C twinning-induced plasticity steel. Mater. Sci. Eng. A 2018, 711, 22–28. [Google Scholar] [CrossRef]

- Wang, B.; Xiao, X.; Astakhov, V.P.; Liu, Z. The effects of stress triaxiality and strain rate on the fracture strain of Ti6Al4V. Eng. Fract. Mech. 2019, 219, 106627. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, Y.; Zhang, F.; He, Y.; Yan, Y. Element proportion effect on internal stress from interfaces and other microstructural components in Cu–Pb alloys. Mol. Simul. 2019, 45, 815–824. [Google Scholar] [CrossRef]

- Fazeli, S.; Vahedpour, M.; Khatiboleslam Sadrnezhaad, S. Effect of copper content on tensile mechanical properties of ternary NiTiCu alloy nanowire: Molecular dynamics simulation. Mater. Today Proc. 2018, 5, 1552–1555. [Google Scholar] [CrossRef]

- Shen, L.-M. Combined grain size, strain rate and loading condition effects on mechanical behavior of nanocrystalline Cu under high strain rates. Acta Mech. Sin. 2012, 28, 1125–1132. [Google Scholar] [CrossRef]

- Li, W.; Wang, X.; Gao, L.; Lu, Y.; Wang, W. Atomic Study on Tension Behaviors of Sub-10 nm NanoPolycrystalline Cu-Ta Alloy. Materials 2019, 12, 3913. [Google Scholar] [CrossRef] [Green Version]

- Chang, L.; Zhou, C.-Y.; Wen, L.-L.; Li, J.; He, X.-H. Molecular dynamics study of strain rate effects on tensile behavior of single crystal titanium nanowire. Comput. Mater. Sci. 2017, 128, 348–358. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, K.; Chen, Z.Q. Strain rate effect on plastic deformation of nanocrystalline copper investigated by molecular dynamics. Mater. Sci. Eng. A 2015, 648, 23–30. [Google Scholar] [CrossRef]

- Derlet, P.M.; Van Swygenhoven, H. Atomic positional disorder in fcc metal nanocrystalline grain boundaries. Phy. Rev. B 2003, 67, 014202. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 2010, 18, 2154–2162. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Baskes, M.I. Modified embedded-atom potentials for cubic materials and impurities. Phys. Rev. B 1992, 46, 2727–2742. [Google Scholar] [CrossRef]

- Huang, C.; Peng, X.; Yang, B.; Chen, X.; Li, Q.; Yin, D.; Fu, T. Effects of strain rate and annealing temperature on tensile properties of nanocrystalline diamond. Carbon 2018, 136, 320–328. [Google Scholar] [CrossRef]

- Tsuzuki, H.; Branicio, P.S.; Rino, J.P. Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput. Phy. Commun. 2007, 177, 518–523. [Google Scholar] [CrossRef]

- Sun, B.; Ouyang, W.; Ren, J.; Mi, L.; Guo, W. Fcc→bcc→hcp successive phase transformations in the strained ultrathin copper film: A molecular dynamic simulation study. Mater. Chem. Phys. 2019, 223, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Sainath, G.; Choudhary, B.K. Formation of pentagonal atomic chains in BCC Fe nanowires. Mater. Res. Expr. 2016, 3, 125022. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Zhao, J.; Wang, P.; Li, X.; Liu, Y.; Fu, X. Molecular Dynamics Study on Mechanical Properties of Nanopolycrystalline Cu–Sn Alloy. Materials 2021, 14, 7782. https://doi.org/10.3390/ma14247782

Zhang G, Zhao J, Wang P, Li X, Liu Y, Fu X. Molecular Dynamics Study on Mechanical Properties of Nanopolycrystalline Cu–Sn Alloy. Materials. 2021; 14(24):7782. https://doi.org/10.3390/ma14247782

Chicago/Turabian StyleZhang, Guodong, Junsheng Zhao, Pengfei Wang, Xiaoyu Li, Yudong Liu, and Xinyue Fu. 2021. "Molecular Dynamics Study on Mechanical Properties of Nanopolycrystalline Cu–Sn Alloy" Materials 14, no. 24: 7782. https://doi.org/10.3390/ma14247782

APA StyleZhang, G., Zhao, J., Wang, P., Li, X., Liu, Y., & Fu, X. (2021). Molecular Dynamics Study on Mechanical Properties of Nanopolycrystalline Cu–Sn Alloy. Materials, 14(24), 7782. https://doi.org/10.3390/ma14247782