Studies of Fracture Toughness in Concretes Containing Fly Ash and Silica Fume in the First 28 Days of Curing

Abstract

1. Introduction

2. Purpose and Scope of the Experimental Research

- Monolithic massive constructions, where the young concrete is subjected to load increases during the subsequent stages of construction of the structure as a result of which numerous technical decisions must be made depending on the instantaneous strength of the concrete or its other properties, such as time of stripping the formwork, moving the sliding formwork, allowing young concrete to be subjected to technological and assembly loads, etc.;

- Prefabricated reinforced concrete constructions, where it is important to know the interoperational strength, e.g., formwork stripping, transport, storage, shipping, assembly;

- Prestressed reinforced concrete constructions, in which it is important to know the possible short-term losses of prestressing forces or not fully cured concrete.

3. Experimental Procedure

3.1. Materials

- Specific density by pycnometric method;

- Specific surface area according to the Blaine method;

- Particle size distribution by laser granulometry using measuring device Masterizer 3000 and measuring range 0.01–3500 μm were used (Malvern Panalytical, Malvern, UK);

- Loss of ignition by burning the individual materials for one hour at 1000 °C;

- Color—visually.

- Mixture without additives (FA00+SF00);

- Mixture without FA additive and with a 10% SF additive (FA00+SF10);

- Mixture with a 10% FA additive and with a 10% SF additive (FA10+SF10);

- Mixture with a 20% FA additive and with a 10% SF additive (FA20+SF10).

- 6 cube specimens (150 mm) for compressive strength tests—fcm, according to PN-EN12390-3 [86];

- 6 cube specimens (150 mm) for splitting tensile strength tests—fctm, according to PN-EN12390-6 [87];

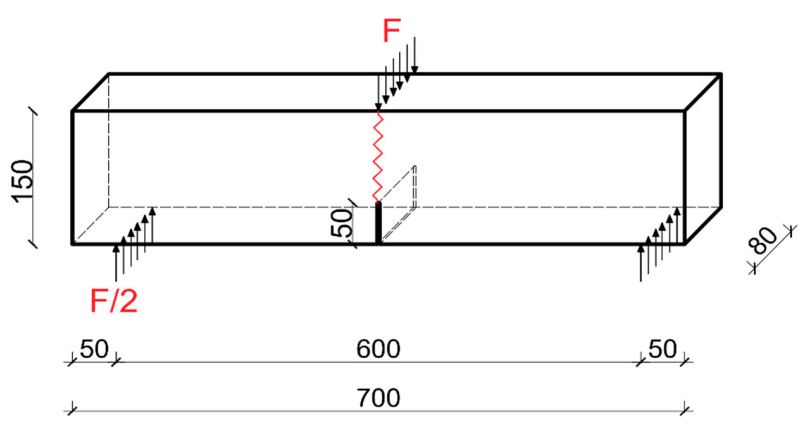

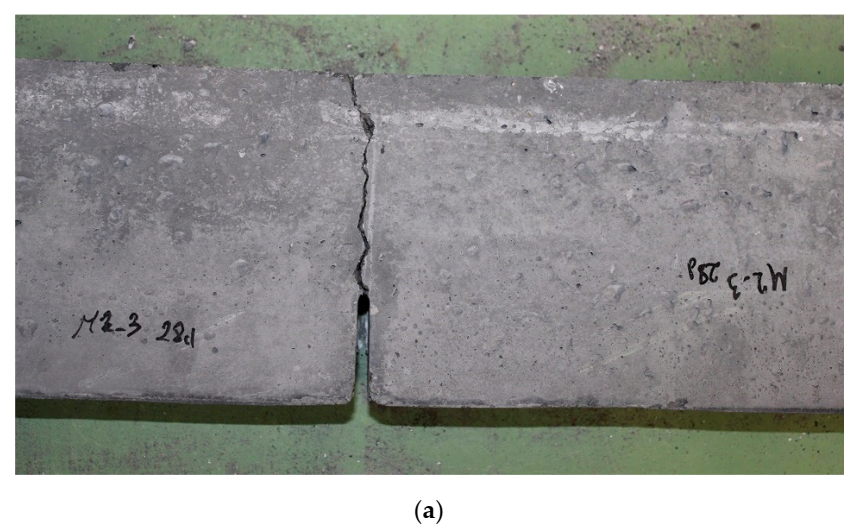

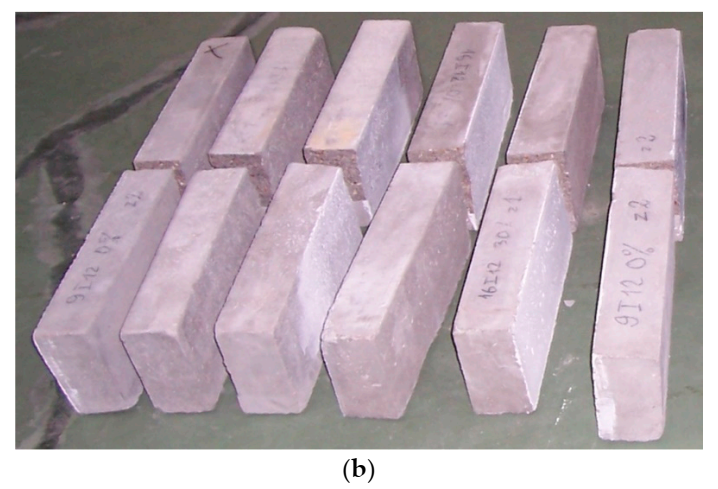

- 6 beams (80 × 150 × 700 mm with one initial crack) for fracture toughness tests at Mode I fracture—, according to RILEM draft recommendation [88].

3.2. Methods

- Maximum load obtained in the tests;

4. Results and Discussions

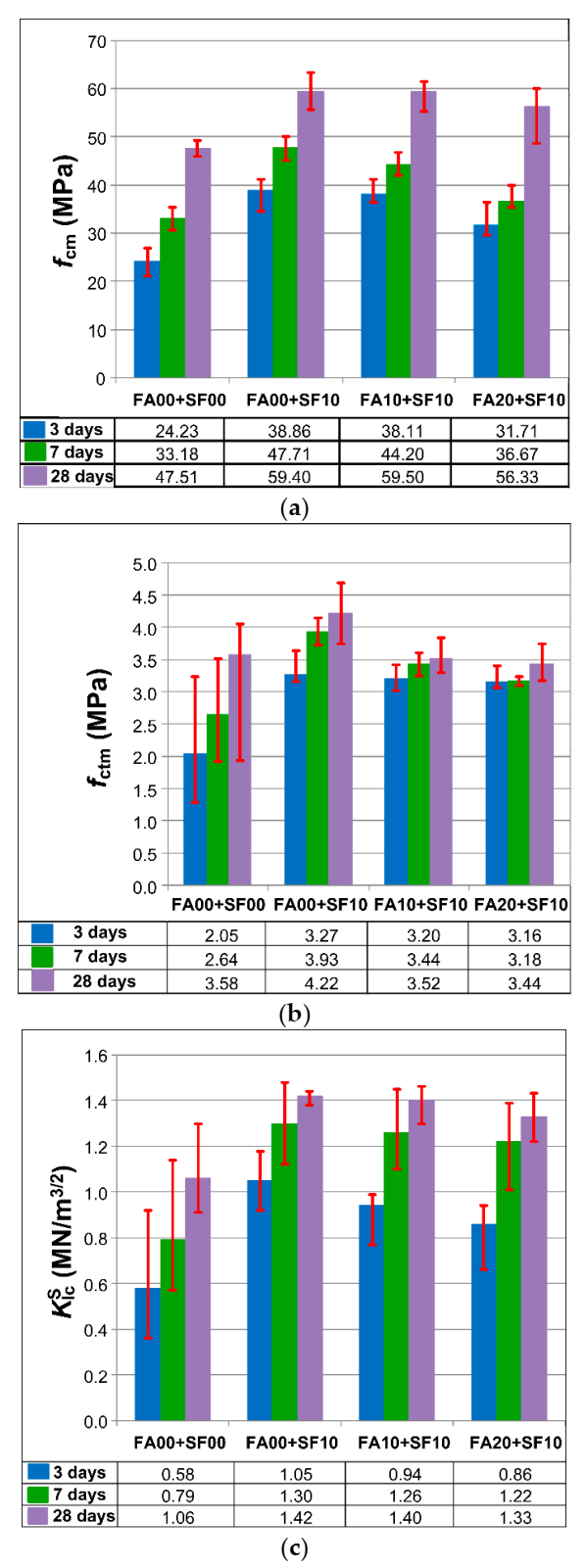

4.1. Mechanical Properties

- From 48% to 81% (after 3 days);

- From 54% to 65% (after 7 days);

- From 26% to 34% (after 28 days).

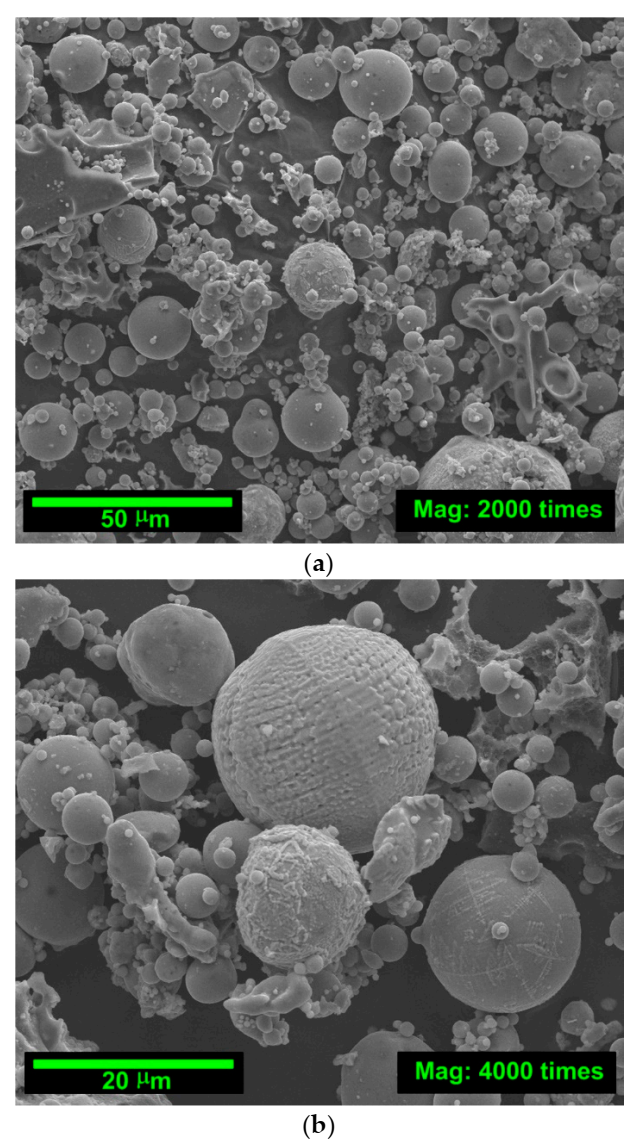

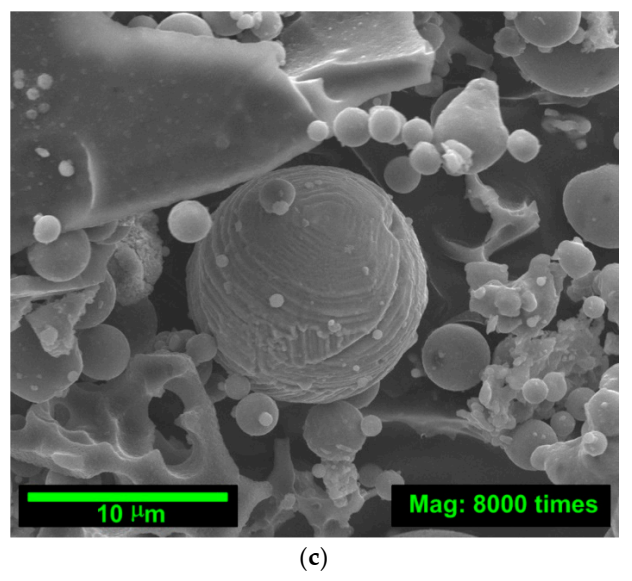

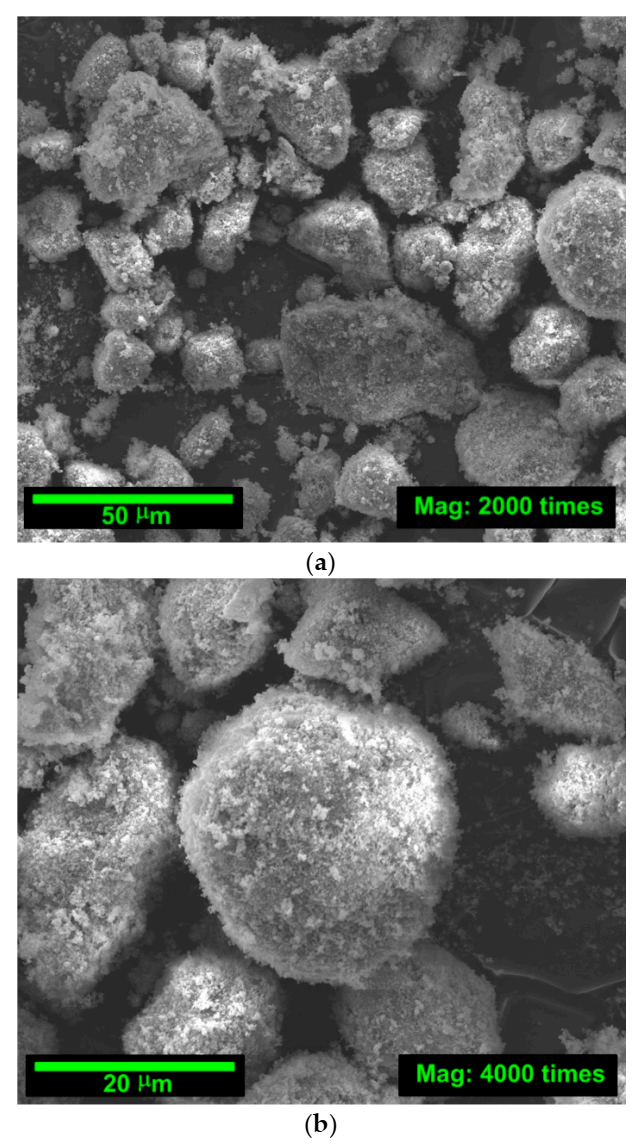

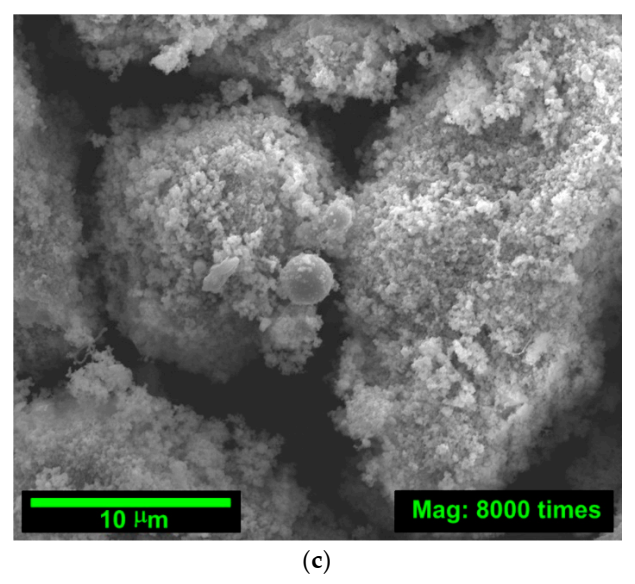

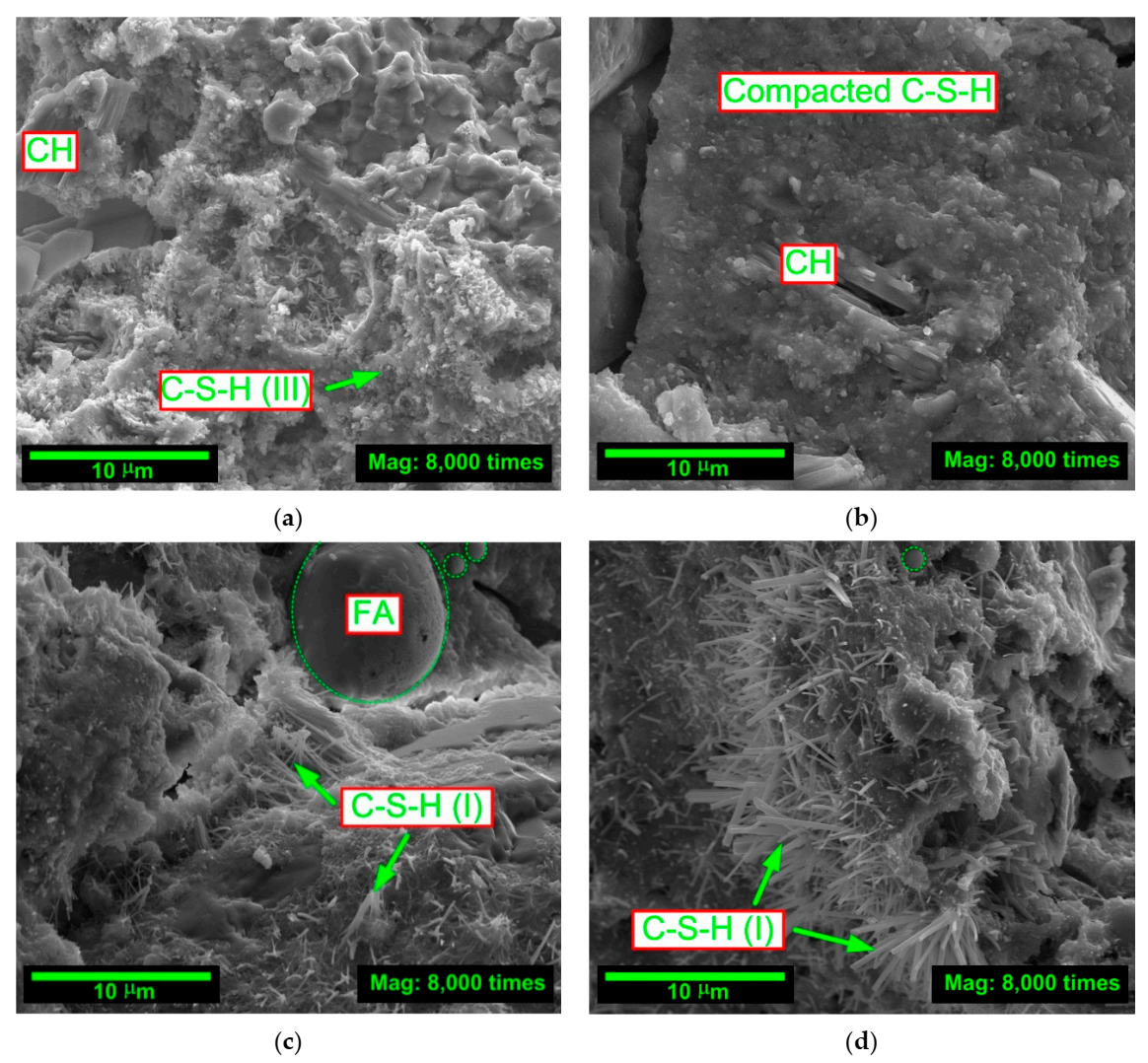

4.2. Microstructure of Composites

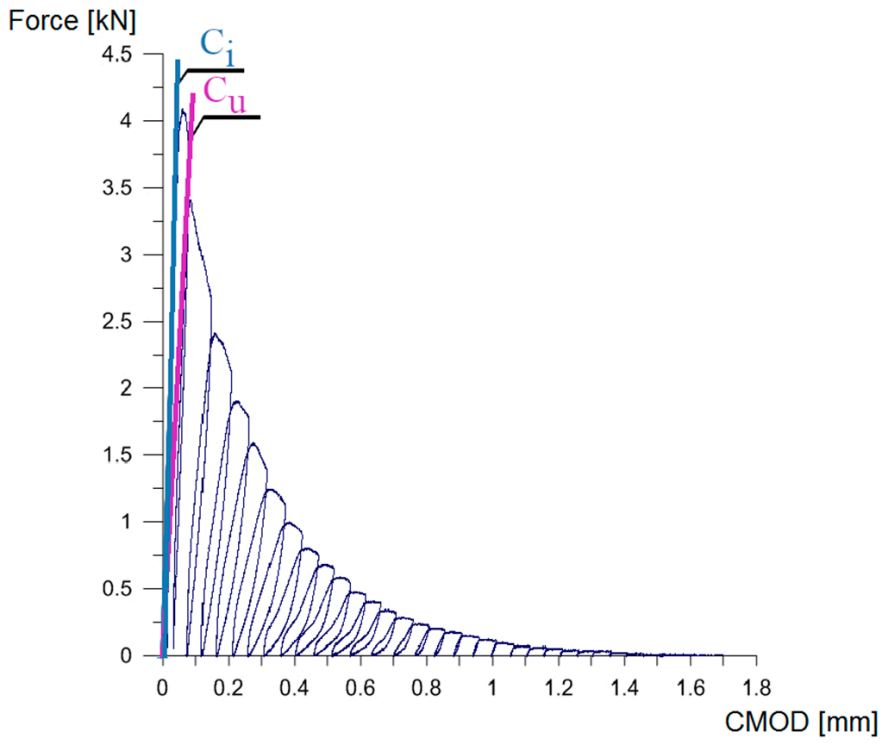

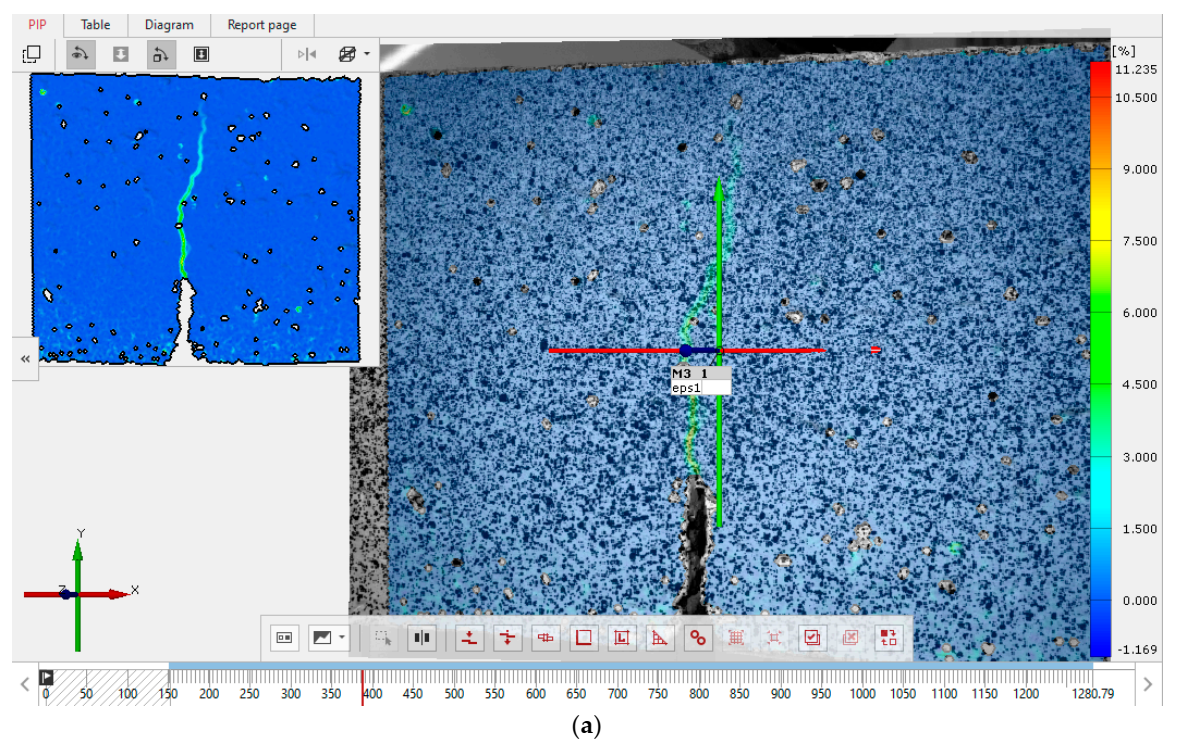

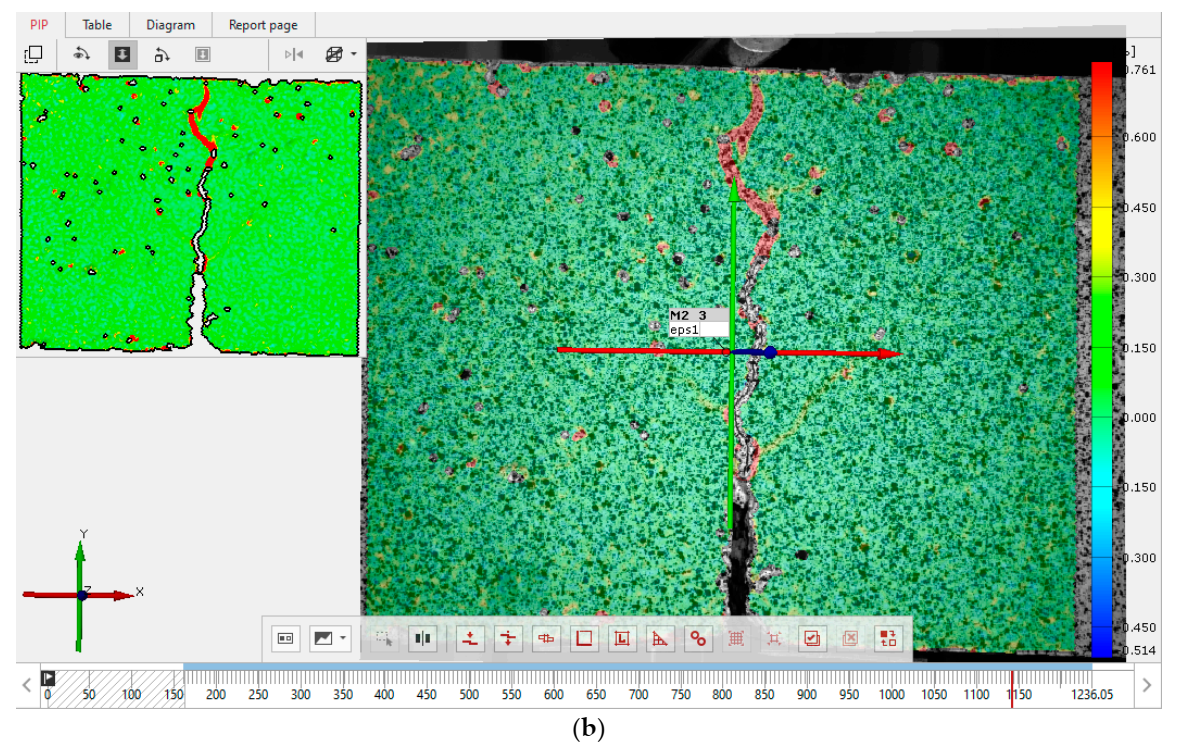

4.3. Toughness and Macrocrack Propagation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ikponmwosa, E.E.; Ehikhuenmen, S.O.; Irene, K.K. Comparative study and empirical modelling of pulverized coconut shell, periwinkle shell and palm kernel shell as a pozzolans in concrete. Acta Polytech. 2019, 59, 560–572. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of natural radioactivity of concrete with siliceous fly ash addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Protasio, F.N.M.; Ribeiro de Avillez, R.; Letichevsky, S.; De Adreade Silva, F. The use of iron ore tailings obtained from Germano dam in the production of a sustainable concrete. J. Clean. Prod. 2021, 278, 123929. [Google Scholar] [CrossRef]

- Golewski, G.L. Energy savings associated with the use of fly ash and nanoadditives in the cement composition. Energies 2020, 13, 2184. [Google Scholar] [CrossRef]

- Szeląg, M. Evaluation of cracking patterns in cement composites—From basics to advances: A review. Materials 2020, 13, 2490. [Google Scholar] [CrossRef]

- Bicer, A. Effect of production temperature on thermal and mechanical properties of polystyrene-fly ash composites. Adv. Compos. Lett. 2020, 29, 1–8. [Google Scholar]

- Freitas, E.; Louro, A.S.; Costa, H.; Cavaco, E.S.; Julio, E.; Pipa, M. Bond behavior between steel/stainless-steel reinforcing bars and low binder concrete (LBC). Eng. Struct. 2020, 221, 111072. [Google Scholar] [CrossRef]

- Szcześniak, A.; Zychowicz, J.; Stolarski, A. Influence of fly ash additive on the properties of concrete with slag cement. Materials 2020, 13, 3265. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Zhang, P.; Han, S.; Golewski, G.L.; Wang, X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv. Mech. Eng. 2020, 12, 1–4. [Google Scholar] [CrossRef]

- Góra, J.; Franus, M.; Barnat-Hunek, D.; Franus, W. Utilization of recycled liquid crystal display (LCD) panel waste in concrete. Materials 2019, 12, 2941. [Google Scholar] [CrossRef] [PubMed]

- Raheel, M.; Rahman, F.; Ali, Q. A stoichiometric approach to find optimum amount of fly ash needed in cement concrete. SN Appl. Sci. 2020, 2, 1100. [Google Scholar] [CrossRef]

- Szeląg, M. Fractal characterization of thermal cracking patterns and fracture zone in low-alkali cement matrix modified with microsilica. Cem. Concr. Compos. 2020, 114, 103732. [Google Scholar] [CrossRef]

- Szeląg, M. Development of cracking patterns in modified cement matrix with microsilica. Materials 2018, 11, 1928. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Chen, Y.; Shi, Y.; Ling, Y.-F. Durability of steel fiber-reinforced concrete containing SiO2 nano-particles. Materials 2019, 12, 2184. [Google Scholar] [CrossRef]

- Szymanowski, J.; Sadowski, L. The development of nanoalumina-based cement mortars for overlay applications in concrete floors. Materials 2019, 12, 3465. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. A study of mode III fracture toughness in young and mature concrete with fly ash additive. Solid State Phenom. 2016, 254, 120–125. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental investigation and numerical modeling fracture processes in fly ash concrete at early age. Solid State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Yunpeng, H.; Mingnian, W.; Zhilong, W.; Qiling, W.; Dagang, L. Mechanical behavior and constitutive model of shotcrete-rock interface subjected heat damage and variable temperature curing conditions. Constr. Build. Mater. 2020, 263, 120171. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, J.-X.; Dai, X.-B.; Zhang, T.-H. Fracture behavior of fly ash concrete containing silica fume. Struct. Eng. Mech. 2016, 59, 261–275. [Google Scholar] [CrossRef]

- Kovacik, J.; Marsavina, L.; Linul, E. Poisson’s ratio of closed-cell aluminum foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [PubMed]

- Żebrowski, W.; Wolka, P.; Kurpinska, M. The influence of the aircraft operating fluids on the mechanical parameters of the airport. Materials 2020, 13, 3081. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Hu, C.; Chu, L. Microstructure, compressive strength and sound insulation property of fly ash-based geopolymeric foams with silica fume as foaming agent. Materials 2020, 13, 3215. [Google Scholar] [CrossRef] [PubMed]

- More, S.; Londhe, R.S. Experimental analysis of quaternary cement binder. Recent Trends Civ. Eng. Technol. 2020, 10, 12–17. [Google Scholar]

- Pipilikaki, P.; Katsioti, M. Study of the hydration process of quaternary blended cements and durability of the produced mortars and concretes. Constr. Build. Mater. 2009, 23, 2246–2250. [Google Scholar] [CrossRef]

- El-Chabib, H.; Ibrahim, A. The performance of high-strength flowable concrete made with binary, ternary, or quaternary binder in hot climate. Constr. Build. Mater. 2013, 47, 245–253. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Sharma, A.K.; Kaushik, S.K. Study on quaternary micro-structure, strength, durability considering the influence of multi-factors. Constr. Build. Mater. 2017, 139, 447–457. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of fly ash addition on the fracture toughness of plain concrete at third model of fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Experimental analysis of strength and durability properties of quaternary cement binder and mortar. Constr. Build. Mater. 2016, 107, 117–124. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Sharma, A.K.; Kaushik, S.K. Green quaternary concrete composites: Characterization and evaluation of the mechanical properties. Struct. Concr. 2018, 19, 1280–1289. [Google Scholar] [CrossRef]

- Dhrangadharia, S.; Vishwakarma, S.; Kumar, A.; Saran, B. Effect of quaternary binders systems on mechanical properties of concrete. Int. J. Eng. Sci. Res. 2018, 6, 1–10. [Google Scholar]

- Manju, R.; Premalatha, J. Binary, ternary and quaternary effect of pozzolanic binders and filler materials on the properties of self compacting concrete (SCC). Int. J. Adv. Eng. Technol. 2016, 7, 674–683. [Google Scholar]

- Manju, R.; Premalatha, J. Binary, ternary and quaternary effect of fillers on fresh and hardened properties of self compacting concrete (SCC). Int. J. Adv. Inf. Sci. Technol. 2014, 21, 12–19. [Google Scholar]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Development of a zero-cement binder using slag, fly ash, and rice husk ash with chemical activator. Adv. Mater. Sci. Eng. 2015, 247065. [Google Scholar] [CrossRef]

- Patel, N.; Dave, R.; Modi, S.; Joshi, C.; Vora, S.; Solanki, M. Effect of binary and quaternary blends on compressive strength. Int. J. Civ. Eng. Technol. 2016, 7, 242–246. [Google Scholar]

- Bassuoni, M.T.; Nehdi, M.L. Resistance of self-consolidating concrete of sulfuric acid attack with consecutive pH reduction. Cem. Concr. Res. 2007, 37, 1070–1084. [Google Scholar] [CrossRef]

- Chinnaraju, K.; Subramanian, K.; Senthil Kumar, S.R.R. Strength properties of HPC using binary, ternary and quaternary cementitious blends. Struct. Concr. 2010, 11, 191–198. [Google Scholar] [CrossRef]

- Papatzani, S.; Paine, K. Optimization of low-carbon footprint quaternary and quinary (37% fly ash) cementitious nanocomposites with polycarboxylate or aqueous nanosilica particles. Adv. Mater. Sci. Eng. 2019, 2019, 5931306. [Google Scholar] [CrossRef]

- Rathish Kumar, P.; Sumanth Reddy, C.; Saleem Baig, M. Cmpressive strength performance of high strength concretes using binary supplementary cementitious materials. Cem. Wapno Beton 2014, 1, 8–16. [Google Scholar]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–flyash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Leung, H.Y.; Kim, J.; Nadeem, A.; Jaganathan, J.; Anwar, M.P. Sorptivity of self-compacting concrete containing fly ash and silica fume. Constr. Build. Mater. 2016, 113, 369–375. [Google Scholar] [CrossRef]

- Shaikh, F.; Kerai, S.; Kerai, S. Effect of micro-silica on mechanical and durability properties of high volume fly ash recycled aggregate concretes (HVFA-RAC). Adv. Concr. Constr. 2015, 3, 317–331. [Google Scholar] [CrossRef]

- Van den Heede, P.; Maes, M.; De Belie, N. Influence of active crack width control on the chloride penetration resistance and global wrming potential of slabs made with fly ash + silica fume concrete. Constr. Build. Mater. 2014, 67, 74–80. [Google Scholar] [CrossRef]

- Mahamed, H.A. Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. Ain Shams Eng. J. 2011, 2, 79–86. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Effect of fly ash and silica fume on compressive and fracture behaviors of concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Swami, S.V. Effect of fly ash and silica fumes on compression and fracture behavior of concrete. J. Civ. Archit. Eng. 2016, 1, 2–7. [Google Scholar]

- Zhang, P.; Li, Q.-F. Effect of silica fume on fracture properties of high-performance concrete containing fly ash. J. Mater. Des. Appl. 2012, 227, 336–342. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of siliceous fly ash and silica fume as a substitute of binder in cementitious concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Effect of silica fume and siliceous fly ash addition on the fracture toughness of plain concrete in mode I. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012065. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of curing time on the fracture toughness of fly ash concrete composites. Compos. Struct. 2018, 185, 105–112. [Google Scholar] [CrossRef]

- Golewski, G.L. An analysis of fracture toughness in concrete with fly ash addition, considering all models of cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef]

- Ikramullah; Rizal, S.; Nakai, Y.; Shiozawa, D.; Abdul Khalil, H.P.S.; Huzni, S.; Thalib, S. Evaluation on interfacial fracture toughness and interfacial shear strength of typha spp. fiber/polymer composite by double shear test method. Materials 2019, 12, 2225. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L.; Sadowski, T. The fracture toughness the KIIIc of concretes with fly ash (FA) additive. Constr. Build. Mater. 2017, 143, 444–454. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, G.L. A failure analysis of concrete composites incorporating fly ash during torsional loading. Compos. Struct. 2018, 183, 527–535. [Google Scholar] [CrossRef]

- Bicer, A. Effect of fly ash particle size on thermal and mechanical properties of fly ash-cement composites. Therm. Sci. Eng. Prog. 2018, 8, 78–82. [Google Scholar] [CrossRef]

- Latifi, H.; Amini, N. Effect of aggregate type on moisture susceptibility of modified cold recycled mix asphalt: Evaluation by mechanical tests and surface free energy method. Frat. Integrità Strutt. 2020, 52, 211–229. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, L.; Xiang, S.; Mo, Y.; Zhang, J.; Chen, J.; Cheng, G. Compressive performance evaluation of concrete confined by stirrups at elevated temperature using DIC technology. Constr. Build. Mater. 2020, 260, 119883. [Google Scholar] [CrossRef]

- Golewski, G.L. Estimation of the optimum content of fly ash in concrete composite based on the analysis of fracture toughness tests using various measuring systems. Constr. Build. Mater. 2019, 213, 142–155. [Google Scholar] [CrossRef]

- Panian, R.; Yazdani, M. Estimation of the service load capacity of plain concrete arch bridges using a novel approach: Stress intensity factor. Structures 2020, 27, 1521–1534. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Stolarski, A.; Cichorski, W.; Szcześniak, A. Non-classical model of dynamic behaviour of concrete. Appl. Sci. 2019, 9, 2590. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of Fracture Toughness in Concretes Containing Siliceous Fly Ash during Mode III Loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Golewski, G.L. A novel specific requirements for materials used in reinforced concrete composites subjected to dynamic loads. Compos. Struct. 2019, 223, 110939. [Google Scholar] [CrossRef]

- Golewski, G.L. A new principles for implementation and operation of foundations for machines: A review of recent advances. Struct. Eng. Mech. 2019, 71, 317–327. [Google Scholar]

- Khiem, N.T.; Tran, H.T.; Nam, D. Modal analysis of cracked continuous Timoshenko beam made of functionally graded material. Mech. Bas. Des. Struct. Mach. 2020, 48, 1–21. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Lotfi-Omran, O.; Nikbin, I.M. Influence of cement content and maximum aggregate size on the fracture parameters of magnetite concrete using WFM, SEM and BEM. Theor. Appl. Fract. Mech. 2020, 107, 102482. [Google Scholar] [CrossRef]

- Nogueira, C.L. A new method to test concrete tensile and shear strength with cylindrical specimens. ACI. Mater. J. 2018, 115, 909–923. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Q.; Guan, J.; Zhang, P.; Fang, H.; Hu, S. Numerical simulation on size effect of fracture toughness of concrete based on mesomechanics. Materials 2020, 13, 1370. [Google Scholar] [CrossRef]

- D’Antino, T.; Santandrea, M.; Carloni, C. Advances in knowledge of the fracture properties of cohesive materials: Fired-clay and tuff bricks. J. Eng. Mech. 2020, 146, 04020079. [Google Scholar] [CrossRef]

- Li, J.; Du, Z.-W.; Guo, Z.-P..; Ai, D.-C. Research on the size effect of unstable fracture toughness by the modified maximum tangential stress (MMTS) criterion. Adv. Civ. Eng. 2020, 2020, 3986367. [Google Scholar] [CrossRef]

- Yuan, F.; Cheng, L.; Shao, X.; Dong, Z.; Zhang, L.; Wu, G.; He, X. Full-field measurement and fracture and fatigue characterizations of asphalt concrete based on the SCB test and stereo-DIC. Eng. Fract. Mech. 2020, 235, 107127. [Google Scholar] [CrossRef]

- Golewski, G.L. An assessment of microcracks in the Interfacial Transition Zone of durable concrete composites with fly ash additives. Compos. Struct. 2018, 200, 515–520. [Google Scholar] [CrossRef]

- Farid, H.M.; Fakoor, M. Mixed mode I/II fracture criterion to anticipate behavior of the orthotropic materials. Steel Compos. Struct. 2020, 34, 671–679. [Google Scholar]

- Mehri Khansari, N.; Fakoor, M.; Berto, F. Probabilistic micromechanical damage model for mixed mode I/II fracture investigation of composite materials. Theor. Appl. Fract. Mech. 2019, 99, 177–193. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, R.C.; Sun, C.-Y.; Wang, Y.-J.; Zhang, X.; Fei, X.-D. A new test method for the complete load-displacement curve of concrete under mixed mode I-II fracture. Theor. Appl. Fract. Mech. 2020, 108, 102629. [Google Scholar] [CrossRef]

- Berto, F.; Ayatollahi, M.; Marsavina, L. Mixed mode fracture. Theor. Appl. Fract. Mech. 2017, 91, 1. [Google Scholar] [CrossRef]

- Dehestani, A.; Hosseini, M.; Beydokhti, A.T. Effect of wetting-drying cycles on mode I and mode II fracture toughness of cement mortar and concrete. Theor. Appl. Fract. Mech. 2020, 106, 102448. [Google Scholar] [CrossRef]

- Linul, E.; Marsavina, L.; Stoia, D.I. Mode I and II fracture toughness investigation of laser-sintered polyamide. Theor. Appl. Fract. Mech. 2020, 106, 102497. [Google Scholar] [CrossRef]

- Fakoor, M.; Manafi Farid, H. Mixed-mode I/II fracture criterion for crack initiation assessment of composite materials. Acta Mech. 2019, 230, 280–301. [Google Scholar] [CrossRef]

- Golewski, G.; Sadowski, T. Fracture toughness at shear (mode II) of concretes made of natural and broken aggregates. Brittle Matrix Compos. 2006, 8, 537–546. [Google Scholar]

- Robalo, K.; Soldado, E.; Costa, H.; Carvalho, L.; Do Carmo, R.; Julio, E. Durability and time-dependent properties of low-cement concrete. Materials 2020, 13, 3583. [Google Scholar] [CrossRef] [PubMed]

- Suchorab, Z.; Franus, M.; Barnat-Hunek, D. Properties of fibrous concrete made with plastic fibers from E-Waste. Materials 2020, 13, 2414. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, E.; Sharbatdar, M.K.; Beygi, M.H.A. The effect of water-to-cement ratio on the fracture behaviors and ductility of Roller Compacted Concrete Pavement (RCCP). Theor. Appl. Fract. Mech. 2020, 109, 102753. [Google Scholar] [CrossRef]

- EN 12390-3: 2011+AC. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; British Standards Institution (BSI): London, UK, 2012. [Google Scholar]

- EN 12390-6. Testing Hardened Concrete—Part 6: Tensile Splitting Strenght of Test Specimens; British Standards Institution (BSI): London, UK, 2009. [Google Scholar]

- RILEM. 89-FMT Fracture Mechanics of Concrete Test Methods 1990 Determination of fracture parameters (KIc and CTODc) of plain concrete using three-point bend tests. RILEM Draft Recommendations. Mater. Struct. 1990, 23, 457–460. [Google Scholar]

- Wu, C.-H.; Huang, C.-H.; Kan, Y.-C.; Yen, T. Effect of fineness and dosage of fly ash on the fracture properties and strength of concrete. Appl. Sci. 2019, 9, 2266. [Google Scholar] [CrossRef]

- Golewski, G.L. Changes in the fracture toughness under mode II loading of low calcium fly ash (LCFA) concrete depending on ages. Materials 2020, 13, 5241. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; De Schutter, G.; Ezziane, K. Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Mater. Struct. 2010, 43, 665–673. [Google Scholar] [CrossRef]

- Regourd, M. Microstructure of cement blends containing fly ash, silica fume, slag and fillers. In Microstructural Development during Hydration of Cement; Struble, L.J., Brown, P.W., Eds.; MRS Online Proceedings Library Archive, Cambridge University: Cambridge, UK, 1986; Volume 85, pp. 187–200. [Google Scholar]

- Carette, G.; Malhotra, V.M. Early-age strength development of concrete incorporating fly ash and condensed silica fume. In Proceedings of the Use of Fly Ash, Silica Fume, Slag and Other Mineral by-Products in Concrete, Montebello, QC, Canada, 31 July 1983; ACI SP-79-41. Volume 2, pp. 765–784. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Effect of aggregate, cement and mineral admixture on the microstructure of the transition zone. MRS Proc. 1987, 114, 65–75. [Google Scholar] [CrossRef]

- Baalbaki, M.; Sarker, S.L.; Aitcin, P.C.; Isabelle, H. Properties and microstructure of high-performance concretes containing silica fume, slag and fly ash. ACI J. 1992, 132, 921–942. [Google Scholar]

- Kadri, E.H.; Duval, R.; Aggoun, S.; Kenai, S. Silica fume effect on hydration heat and compressive strength of high-performance concrete. ACI Mater. J. 2009, 106, 107–113. [Google Scholar]

- Golewski, G.L. The influence of microcrack width on the mechanical parameters in concrete with the addition of fly ash: Consideration of technological and economical benefit. Constr. Build. Mater. 2019, 197, 849–861. [Google Scholar] [CrossRef]

- Prokopski, G.; Langier, B. Effect of water/cement ratio and silica fume addition on the fracture toughness and morphology of fractured surfaces of gravel concretes. Cem. Concr. Res. 2000, 30, 1427–1433. [Google Scholar] [CrossRef]

- Brodersen, K.; Nilsson, K. Pores and cracks in cemented waste and concrete. Cem. Concr. Res. 1992, 22, 405–417. [Google Scholar] [CrossRef]

- Lilkov, V.; Dimitrova, E.; Petrov, O.E. Hydration process of cement containing fly ash and silica fume: The first 24 hours. Cem. Concr. Res. 1997, 27, 577–588. [Google Scholar] [CrossRef]

- Langan, B.W.; Weng, K.; Ward, M.A. Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem. Concr. Res. 2002, 32, 1045–1051. [Google Scholar] [CrossRef]

- Yajun, J.; Cahyadi, J.H. Simulation of of silica fume blended cement hydration. Mater. Struct. 2004, 37, 397–404. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Improvement of strength parameters of cement matrix with the addition of siliceous fly ash by using nanometric C-S-H seeds. Energies 2020, 13, 6734. [Google Scholar] [CrossRef]

- Radojicic, V.; Rudolovic, R.; Tarcic, M.; Jovic, S. The influence of the steel fibers on improvement of mechanical characteristic of concrete. Mech. Based Des. Struct. Mach. 2020, 48, 1–11. [Google Scholar] [CrossRef]

- Li, D.; Huang, P.; Chen, Z.; Yao, G.; Guo, X.; Zheng, X.; Yang, Y. Experimental study on fracture and fatigue crack propagation in concrete based on DIC technology. Eng. Fract. Mech. 2020, 235, 107166. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Macroscopic evaluation of fracture processes in fly ash concrete. Solid State Phenom. 2016, 254, 188–193. [Google Scholar] [CrossRef]

- Golewski, G.L. Measurement of fracture mechanics parameters of concrete containing fly ash thanks to use of Digital Image Correlation (DIC) method. Measurement 2019, 135, 96–105. [Google Scholar] [CrossRef]

- Ojdrovic, R.P.; Stojimirovic, A.L.; Petroski, H.J. Effect of age on splitting tensile strength and fracture resistance of concrete. Cem. Concr. Res. 1987, 17, 70–76. [Google Scholar] [CrossRef]

- Kim, J.K.; Lee, Y.; Yi, S.T. Fracture characteristics of concrete at early ages. Cem. Concr. Res. 2004, 34, 507–519. [Google Scholar] [CrossRef]

- Zoolinger, D.G.; Tang, T.; Yoo, R.H. Fracture toughness of concrete at early ages. ACI Mater. J. 1993, 90, 463–471. [Google Scholar]

| Chemical | Component (wt %) | ||

|---|---|---|---|

| OPC | FA | SF | |

| SiO2 | 15.00 | 55.27 | 91.90 |

| Al2O3 | 2.78 | 26.72 | 0.71 |

| Fe2O3 | 2.72 | 6.66 | 2.54 |

| CaO | 71.06 | 2.35 | 0.31 |

| K2O | 1.21 | 3.01 | 1.53 |

| SO3 | 4.56 | 0.47 | 0.45 |

| MgO | 1.38 | 0.81 | 1.14 |

| P2O5 | - | 1.92 | 0.63 |

| TiO2 | - | 1.89 | 0.01 |

| Ag2O | - | 0.10 | 0.07 |

| MnO | - | - | 0.26 |

| Cl | 0.08 | - | 0.28 |

| Property | Unit | Material | ||

|---|---|---|---|---|

| OPC | FA | SF | ||

| Specific density | (g/cm3) | 3.23 | 1.90 | 2.21 |

| Specific surface area | (cm2/g) | 4294 | 2944 | 26,230 |

| Loss of ignition | (%) | 3.64 | 4.66 | 3.83 |

| Color | - | Light gray | Dark gray | Black |

| Particle Size (μm) | Volume (%) | |

|---|---|---|

| SF | FA | |

| 0.01−2 | 68.38 | 1.87 |

| 2−20 | 23.11 | 23.84 |

| 20−50 | 8.06 | 23.15 |

| 50−100 | 0.45 | 26.28 |

| 100−250 | 0.00 | 21.70 |

| 250−500 | 0.00 | 3.13 |

| 500−1000 | 0.00 | 0.03 |

| 1000−2000 | 0.00 | 0.00 |

| Average particle diameter | 10.666 | 102.035 |

| Mix | Age (Days) | The Values of Analyzed Parameters Compared to FA00+SF00 (%) | ||

|---|---|---|---|---|

| fcm | fctm | |||

| FA00+SF00 | 3 | 100 | 100 | 100 |

| FA00+SF10 | 160.4 | 159.5 | 181.0 | |

| FA10+SF10 | 157.3 | 156.1 | 162.1 | |

| FA20+SF10 | 130.9 | 154.1 | 148.3 | |

| FA00+SF00 | 7 | 100 | 100 | 100 |

| FA00+SF10 | 143.8 | 148.9 | 164.6 | |

| FA10+SF10 | 133.2 | 130.3 | 159.5 | |

| FA20+SF10 | 110.5 | 120.5 | 154.4 | |

| FA00+SF00 | 28 | 100 | 100 | 100 |

| FA00+SF10 | 125.0 | 117.9 | 134.0 | |

| FA10+SF10 | 125.2 | 98.3 | 132.1 | |

| FA20+SF10 | 118.6 | 96.1 | 125.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, G.L.; Gil, D.M. Studies of Fracture Toughness in Concretes Containing Fly Ash and Silica Fume in the First 28 Days of Curing. Materials 2021, 14, 319. https://doi.org/10.3390/ma14020319

Golewski GL, Gil DM. Studies of Fracture Toughness in Concretes Containing Fly Ash and Silica Fume in the First 28 Days of Curing. Materials. 2021; 14(2):319. https://doi.org/10.3390/ma14020319

Chicago/Turabian StyleGolewski, Grzegorz Ludwik, and Damian Marek Gil. 2021. "Studies of Fracture Toughness in Concretes Containing Fly Ash and Silica Fume in the First 28 Days of Curing" Materials 14, no. 2: 319. https://doi.org/10.3390/ma14020319

APA StyleGolewski, G. L., & Gil, D. M. (2021). Studies of Fracture Toughness in Concretes Containing Fly Ash and Silica Fume in the First 28 Days of Curing. Materials, 14(2), 319. https://doi.org/10.3390/ma14020319