Ultrasonic Vibration-Assisted Ball Burnishing Tool for a Lathe Characterized by Acoustic Emission and Vibratory Measurements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Setup

- -

- The maximum monitoring frequency allowed by the instrumentation should be applied.

- -

- All mechanical and electrical phenomena that occur during the process should be monitored and recorded.

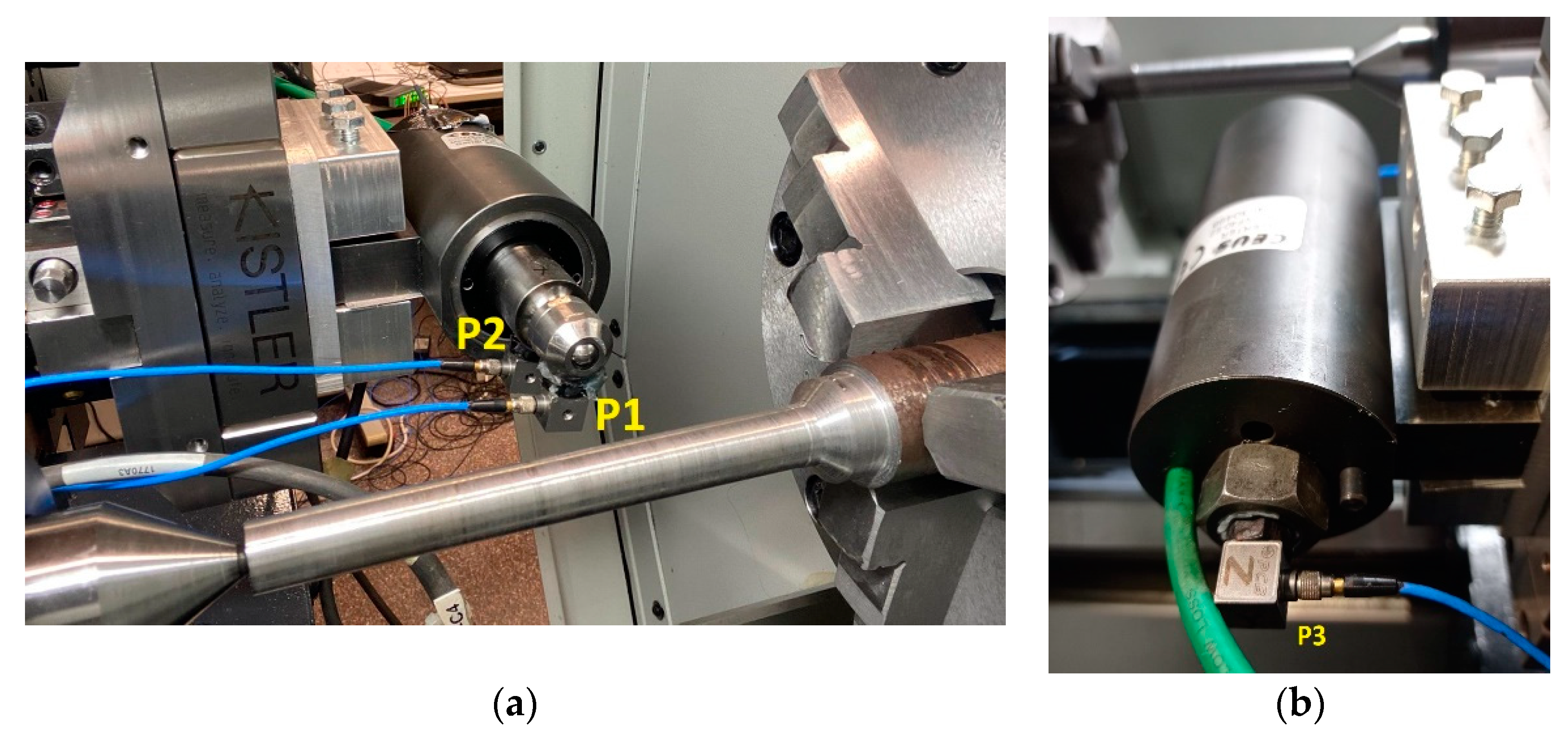

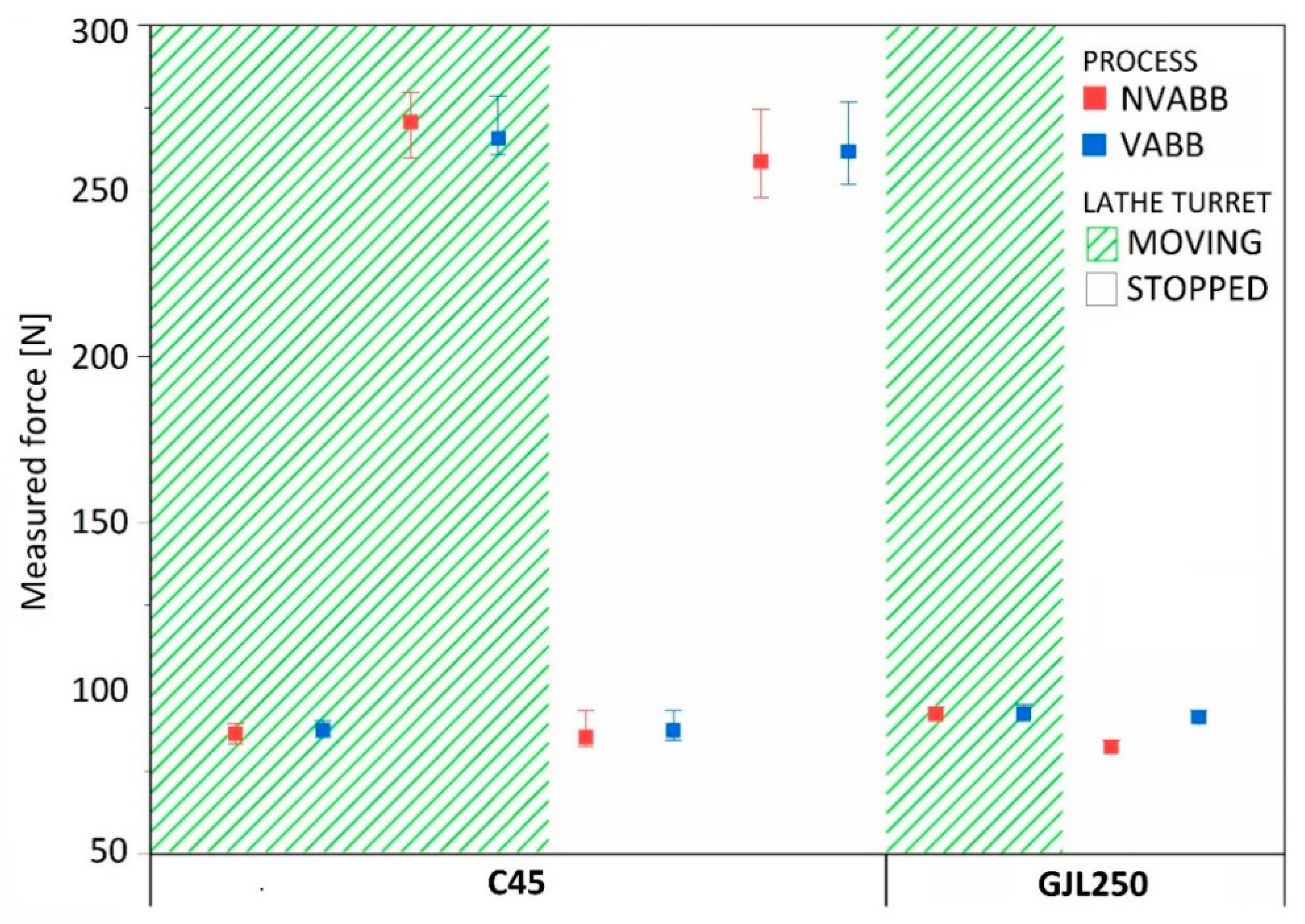

2.2. Burnishing Force Monitoring

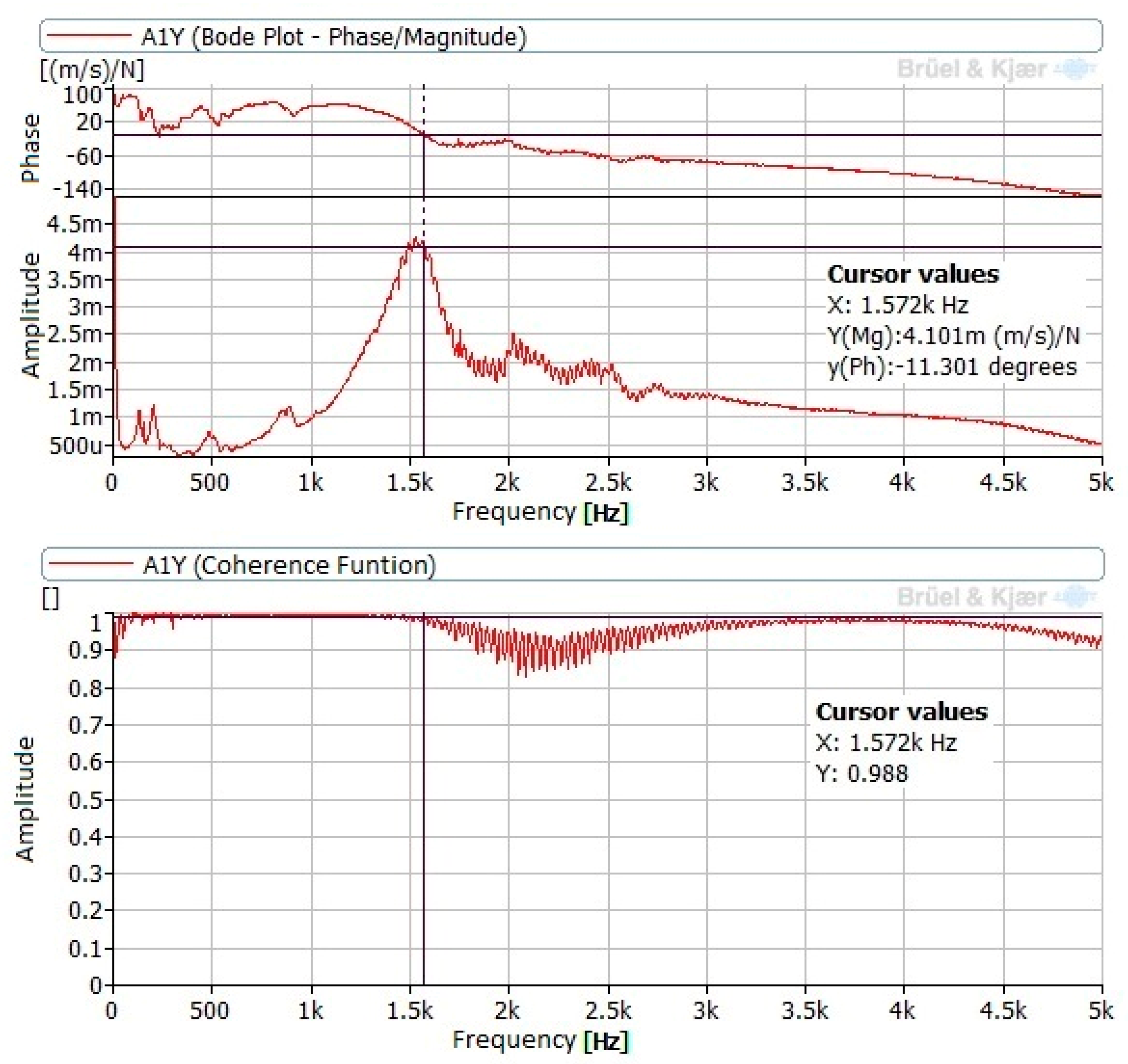

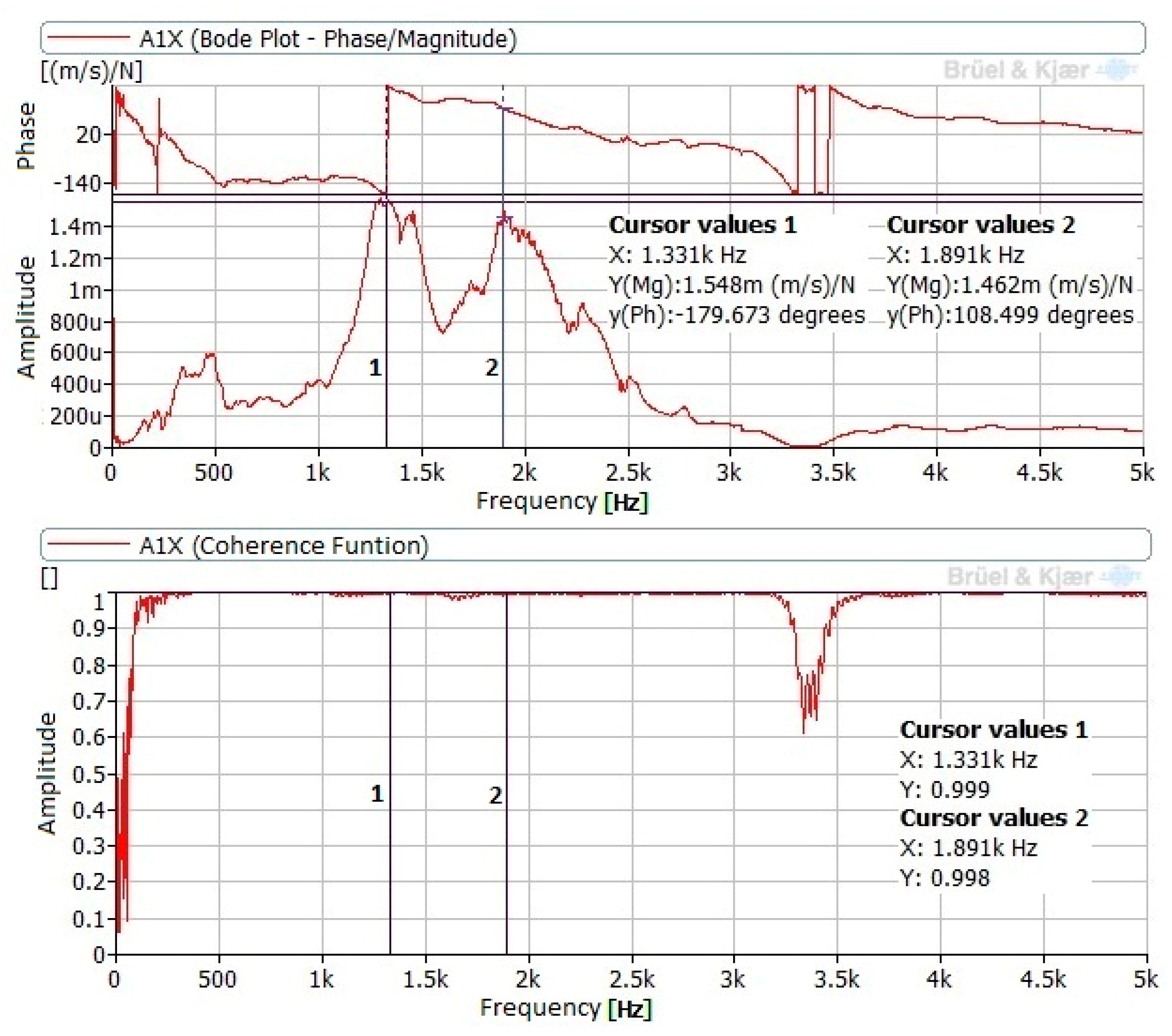

2.3. Impact Tests

- -

- Tool installed it its holder without any contact with the specimen (free tool).

- -

- Tool in contact with the specimen and forces between them of 90 N or 270 N, for the steel specimen, and a force of 90 N for the grey cast iron. These conditions were repeated with the tool in two positions: one near the plate and the other near the point.

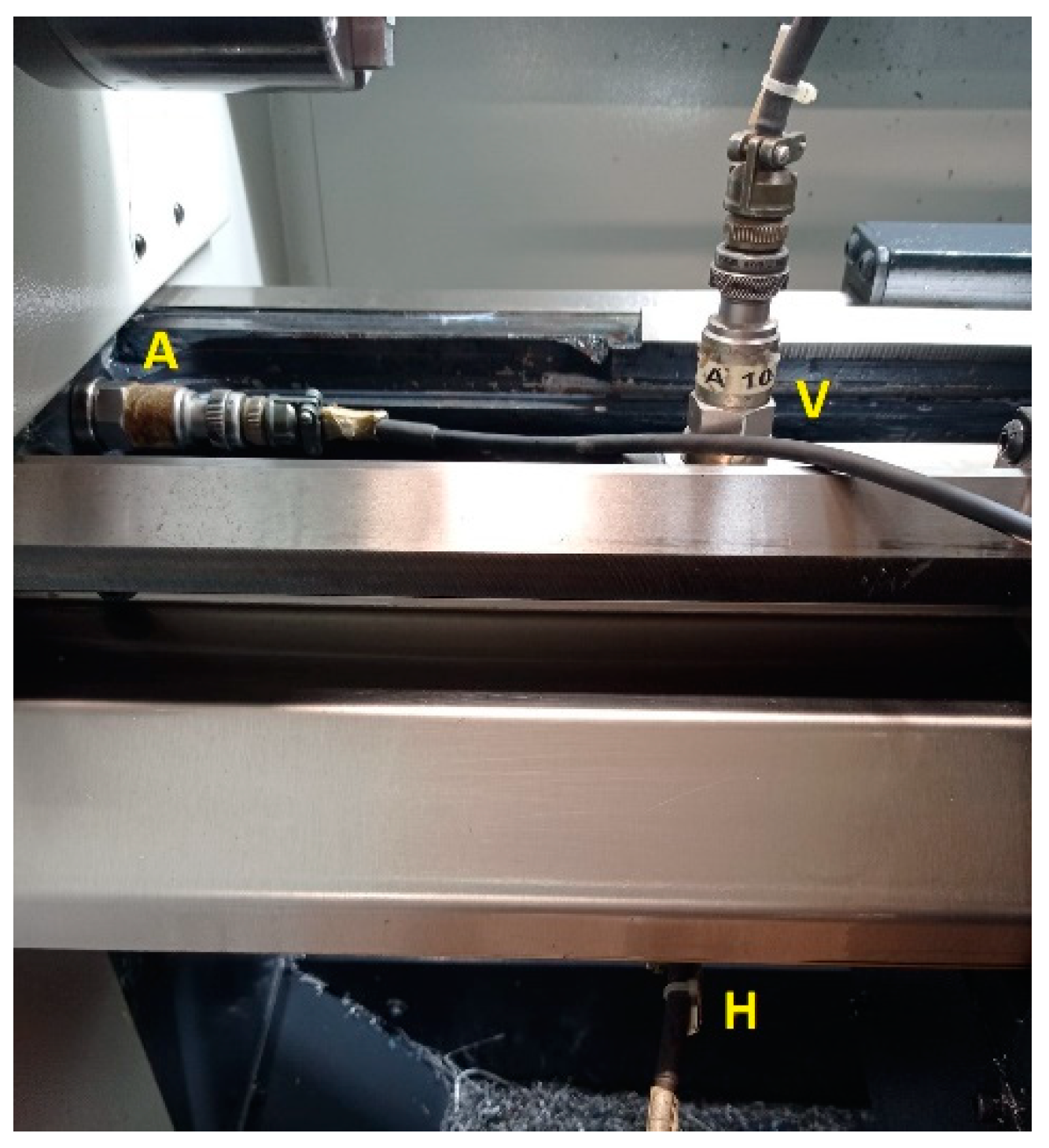

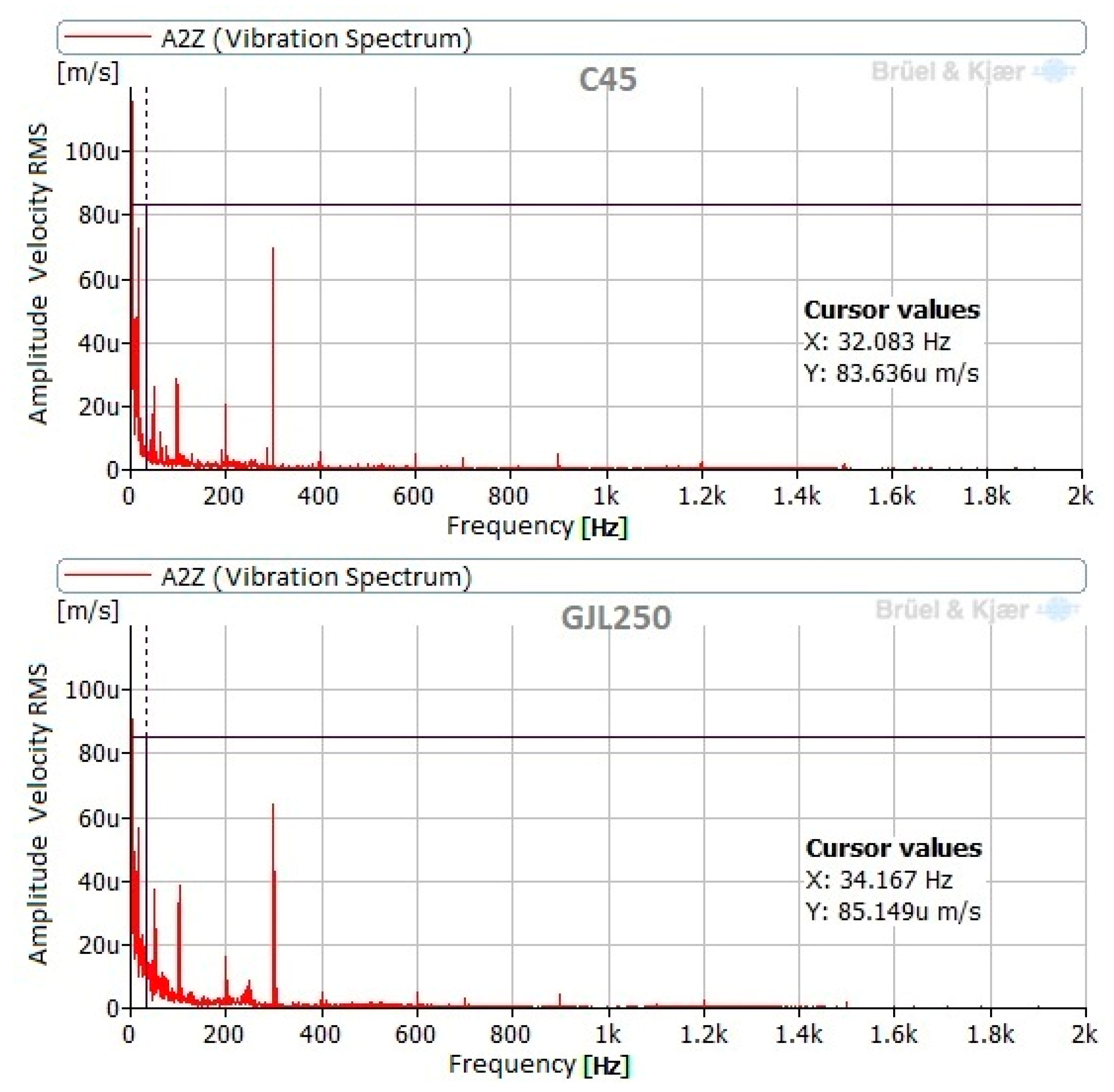

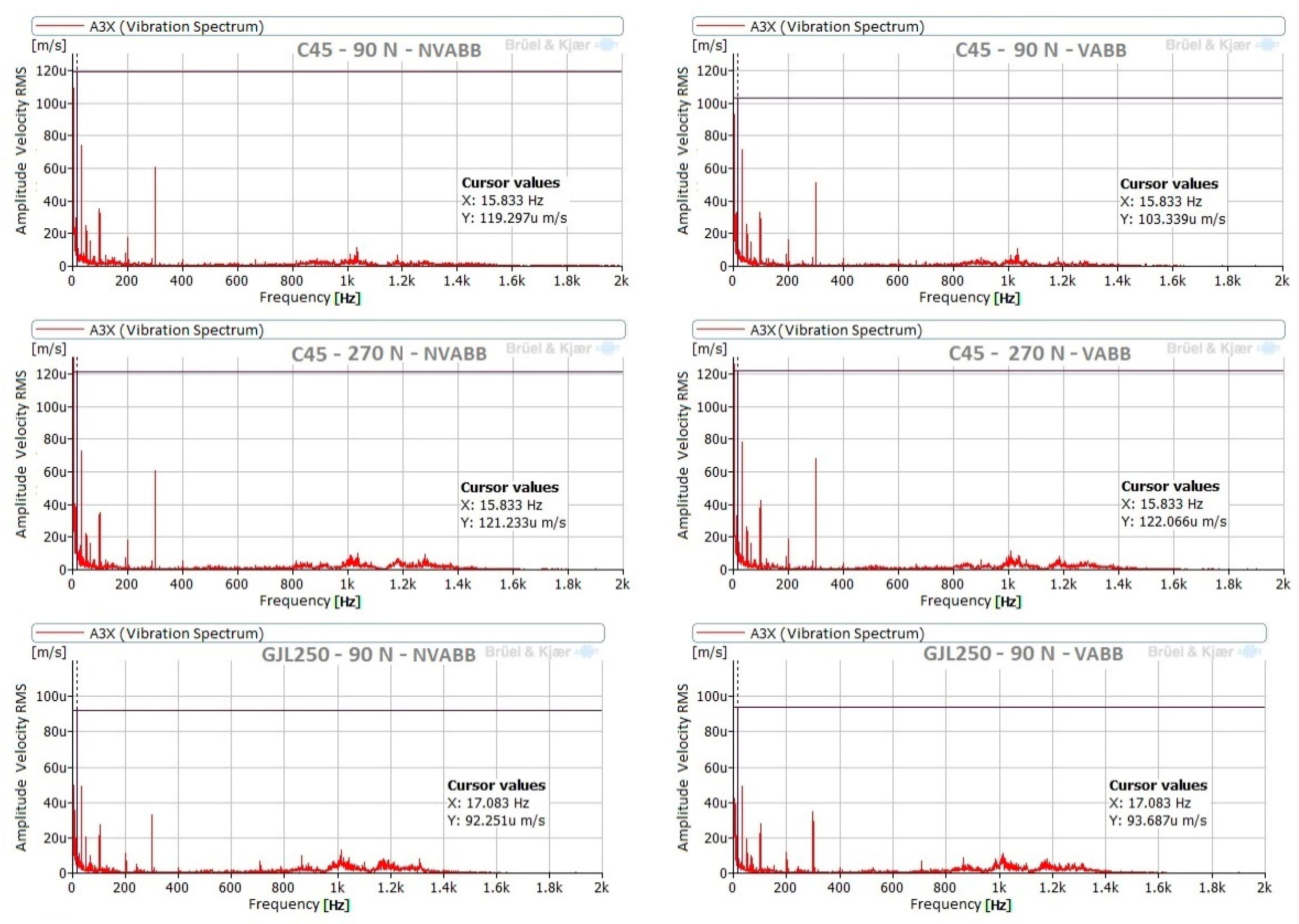

2.4. Vibration Monitoring during the Burnishing Process

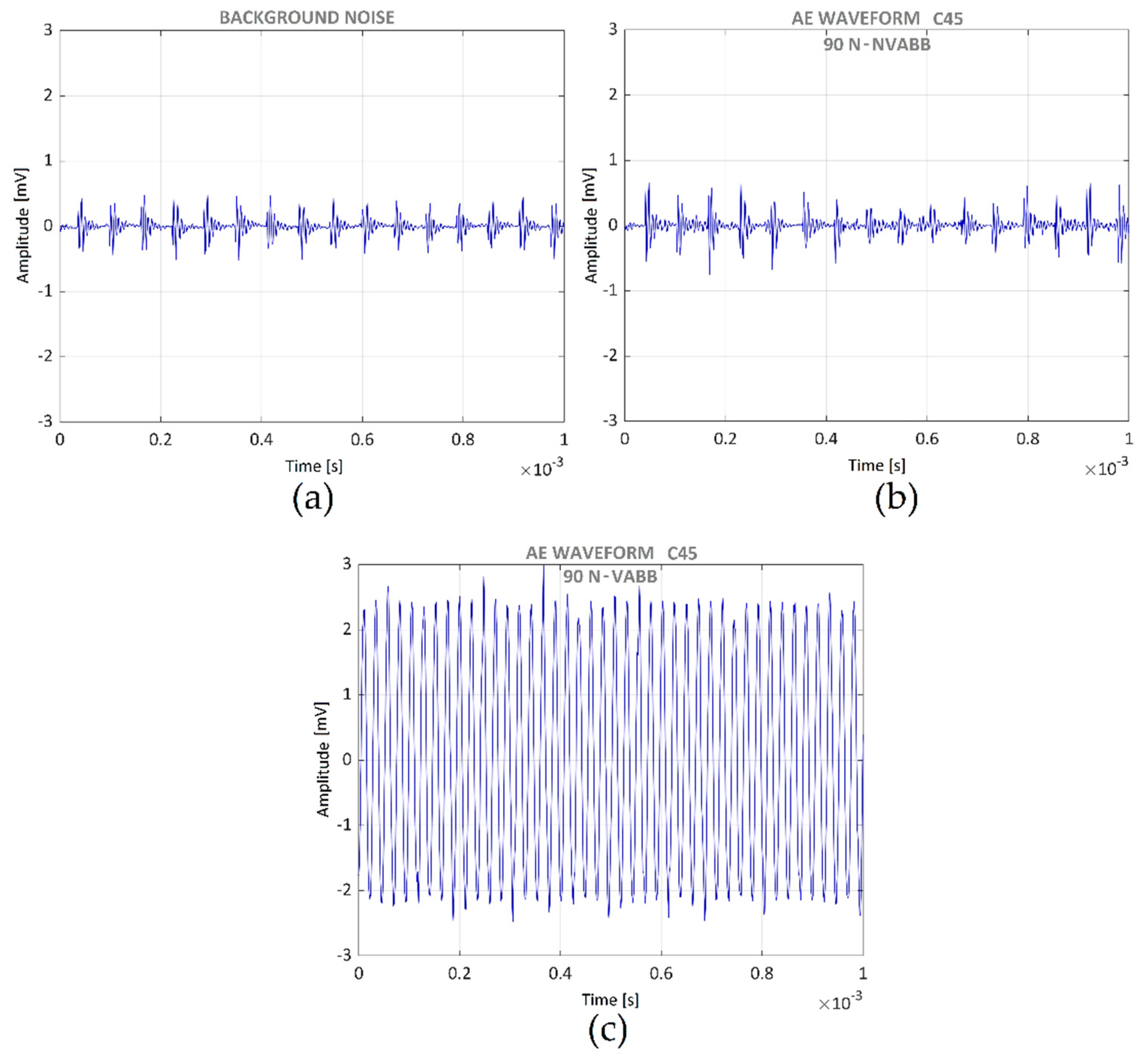

2.5. Acoustic Emission Measurements during the Burnishing Process

3. Results and Discussion

3.1. Impact Tests

3.2. Vibration Monitoring during the Burnishing Process

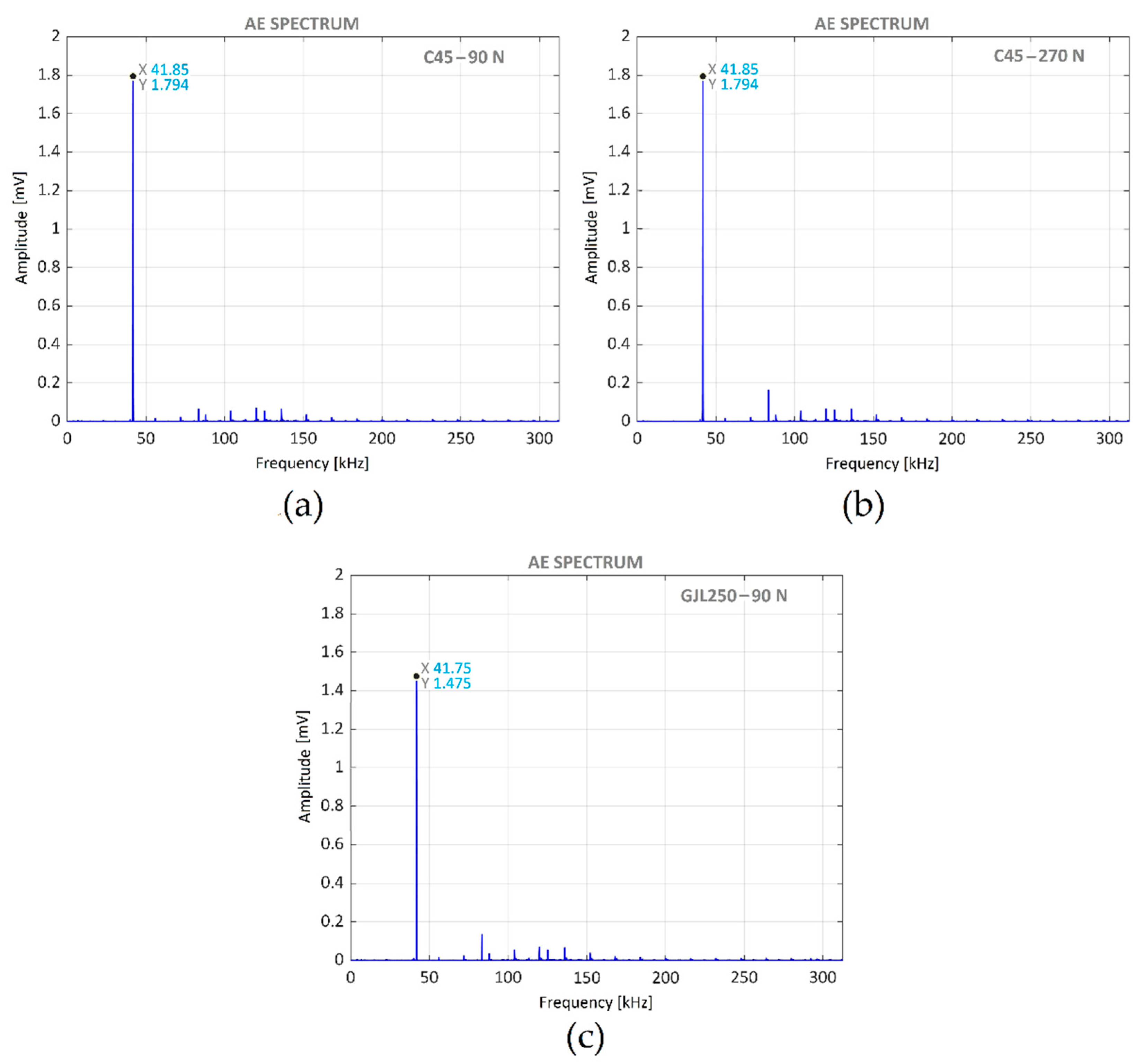

3.3. Acoustic Emission Monitoring during the Burnishing Process

3.4. Operating Deflection Shape

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martinez-Gonzalez, E.; Ramírez, G.; Romeu, J.; Casellas, D. Damage induced by a spherical indentation test in tool steels detected by using acoustic emission technique. Exp. Mech. 2015, 55, 449–458. [Google Scholar] [CrossRef]

- Feng, P.; Borghesani, P.; Smith, W.A.; Randall, R.B.; Peng, Z. A Review on the relationships between acoustic emission, friction and wear in mechanical systems. Appl. Mech. Rev. 2020, 72, 020801. [Google Scholar] [CrossRef]

- Maia, L.H.A.; Abrao, A.M.; Vasconcelos, W.; Sales, W.; Machado, Á. A new approach for detection of wear mechanisms and determination of tool life in turning using acoustic emission. Tribol. Int. 2015, 92, 519–532. [Google Scholar] [CrossRef]

- Klocke, F.; Döbbeler, B.; Pullen, T.; Bergs, T. Acoustic emission signal source separation for a flank wear estimation of drilling tools. Procedia CIRP 2019, 79, 57–62. [Google Scholar] [CrossRef]

- Chethan, Y.; Ravindra, H.; Krishnegowda, Y. Optimization of machining parameters in turning Nimonic-75 using machine vision and acoustic emission signals by Taguchi technique. Measurement 2019, 144, 144–154. [Google Scholar] [CrossRef]

- Olufayo, O.; Abou-El-Hossein, K. Acoustic wear monitoring during the milling of tool steel for machining 4.0. In Lecture Notes in Mechanical Engineering, Proceedings of 8th International Conference on Fracture, Fatigue and Wear FFW 2020, Singapore, 26–27 August 2020; Abdel Wahab, M., Ed.; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Khripunov, N.V.; Gorshkov, B.M.; Samokhina, N.S. Machinability metallic materials estimation based on acoustic emission of turning. J. Phys. Conf. Ser. 2021, 1889, 042072. [Google Scholar] [CrossRef]

- Pandiyan, V.; Tjahjowidodo, T. Use of Acoustic emissions to detect change in contact mechanisms caused by tool wear in abrasive belt grinding process. Wear 2019, 436-437, 203047. [Google Scholar] [CrossRef]

- Lopes, W.N.; Junior, P.O.C.; Aguiar, P.R.; Alexandre, F.A.; Dotto, F.R.L.; da Silva, P.S.; Bianchi, E.C. An efficient short-time Fourier transform algorithm for grinding wheel condition monitoring through acoustic emission. Int. J. Adv. Manuf. Technol. 2021, 113, 585–603. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z. Acoustic emission signal analysis during chip formation process in high speed machining of 7050-T7451 aluminum alloy and Inconel 718 superalloy. J. Manuf. Process. 2017, 27, 114–125. [Google Scholar] [CrossRef]

- Zanger, F.; Kacaras, A.; Bächle, M.; Schwabe, M.; León, F.P.; Schulze, V. FEM simulation and acoustic emission based characterization of chip segmentation frequency in machining of Ti-6Al-4V. Procedia CIRP 2018, 72, 1421–1426. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. 1921, 221, 163–198. [Google Scholar]

- Shivalingappa, D. The influence of ball and roller burnishing process parameters on surface integrity of Al 2024 alloy. Mater. Today Proc. 2020, 27, 1337–1340. [Google Scholar] [CrossRef]

- Kalisz, J.; Żak, K.; Wojciechowski, S.; Gupta, M.; Krolczyk, G. Technological and tribological aspects of milling-burnishing process of complex surfaces. Tribol. Int. 2021, 155, 106770. [Google Scholar] [CrossRef]

- Gomez–Gras, G.; Travieso–Rodriguez, J.A.; Jerez–Mesa, R.; Lluma-Fuentes, J.; De La Calle, B.G. Experimental study of lateral pass width in conventional and vibrations-assisted ball burnishing. Int. J. Adv. Manuf. Technol. 2016, 87, 363–371. [Google Scholar] [CrossRef] [Green Version]

- Amini, S.; Bagheri, A.; Teimouri, R. Ultrasonic-assisted ball burnishing of aluminum 6061 and AISI 1045 steel. Mater. Manuf. Process. 2017, 33, 1250–1259. [Google Scholar] [CrossRef]

- Kozlov, A.; Mordyuk, B.; Chernyashevsky, A. On the additivity of acoustoplastic and electroplastic effects. Mater. Sci. Eng. A 1995, 190, 75–79. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Landon, Y.; Travieso-Rodriguez, J.; Dessein, G.; Lluma-Fuentes, J.; Wagner, V. Topological surface integrity modification of AISI 1038 alloy after vibration-assisted ball burnishing. Surf. Coat. Technol. 2018, 349, 364–377. [Google Scholar] [CrossRef] [Green Version]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Gomez-Gras, G.; Lluma-Fuentes, J. Development, characterization and test of an ultrasonic vibration-assisted ball burnishing tool. J. Mater. Process. Technol. 2018, 257, 203–212. [Google Scholar] [CrossRef] [Green Version]

- Arnau, A. Piezoelectric Transducers and Applications; Springer: Berlin, Germany, 2004; Volume 2004. [Google Scholar]

- Dornfeld, D.; Liu, J.B. Abrasive texturing and burnishing process monitoring using acoustic emission. CIRP Ann. Manuf. Technol. 1993, 42, 397–400. [Google Scholar] [CrossRef]

- Strömbergsson, D.; Marklund, P.; Edin, E.; Zeman, F. Acoustic emission monitoring of a mechanochemical surface finishing process. Tribol. Int. 2017, 112, 129–136. [Google Scholar] [CrossRef]

- Salahshoor, M.; Guo, Y.B. Contact Mechanics in low plasticity burnishing of biomedical magnesium-calcium alloy. In Proceedings of the STLE/ASME 2010 International Joint Tribology Conference, San Francisco, CA, USA, 17–20 October 2010; American Society of Mechanical Engineers: New York, NY, USA, 2010; Volume 44199, pp. 349–351. [Google Scholar]

- Hu, S.; Huang, W.; Shi, X.; Peng, Z.; Liu, X.; Wang, Y. Bi-Gaussian stratified effect of rough surfaces on acoustic emission under a dry sliding friction. Tribol. Int. 2018, 119, 308–315. [Google Scholar] [CrossRef]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Hase, A.; Mishina, H.; Wada, M. Correlation between features of acoustic emission signals and mechanical wear mechanisms. Wear 2012, 292, 144–150. [Google Scholar] [CrossRef]

- Geng, Z.; Puhan, D.; Reddyhoff, T. Using acoustic emission to characterize friction and wear in dry sliding steel contacts. Tribol. Int. 2019, 134, 394–407. [Google Scholar] [CrossRef] [Green Version]

- Travieso-Rodriguez, J.A.; Lluma-Fuentes, J.; Jerez-Mesa, R.; Dessein, G.; Wagner, V.; Landon, Y. Ultrasonic vibration assisted burnishing tool for lathe. In Spanish Utility Model; Spanish Intellectual Property Bulletin: Madrid, Spain, 2020; Publication number ES1253044. [Google Scholar]

- Ewins, D.J. Modal Testing: Theory and Practice; Research Studies Press: Letchworth, UK, 1984; Volume 15. [Google Scholar]

- Estevez-Urra, A.; Llumà, J.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A. Monitoring of Processing conditions of an ultrasonic vibration-assisted ball-burnishing process. Sensors 2020, 20, 2562. [Google Scholar] [CrossRef]

- Fernández, I.; Montané, F.X.; García, J.J.; Maureso, M. Advanced Analysis of In-Service Movements of Vehicle Closures; FISITA World Automotive Congress: Prague, Czech Republic, 2004; pp. 1–10. [Google Scholar]

- ISO 20816-1. Mechanical Vibration—Measurement and Evaluation of Machine Vibration—Part 1: General Guidelines; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Callister, W.D. Fundamentals of Materials Science and Engineering; Wiley: London, UK, 2000; Volume 471660817. [Google Scholar]

- Sales, W.F.; Becker, M.; Gurgel, A.G.; Júnior, J.L. Dynamic behavior analysis of drill-threading process when machining AISI Al-Si-Cu4 alloy. Int. J. Adv. Manuf. Technol. 2009, 42, 873–882. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Zhang, G.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

| Material | Initial Dimensions | Cutting Parameters | Final Dimensions | |||||

|---|---|---|---|---|---|---|---|---|

| D [mm] | L [mm] | Cutting Speed [m/min] | Feed [mm/rev] | Cutting Depth [mm] | D [mm] | L [mm] | Roughness Ra [μm] | |

| C45 | 15 | 133 | 70.7 | 0.15 | 0.2 | 14.8 | 133 | 1.187 |

| GJL250 | 15 | 185 | 29.4 | 0.15 | 0.4 | 14.0 | 185 | 2.310 |

| Measurement Position | Accelerometer | Frequency Range [Hz] |

|---|---|---|

| Tool (P1, P2 y P3) | PCB 356A32/NC | 1 ÷ 4000 ± 5% 0.7 ÷ 5000 ± 10% |

| Lathe bed, directions A, V y H | KISTLER Type 8752A50 | 0.5 ÷ 5000 ± 5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Osete, I.; Estevez-Urra, A.; Velázquez-Corral, E.; Valentin, D.; Llumà, J.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A. Ultrasonic Vibration-Assisted Ball Burnishing Tool for a Lathe Characterized by Acoustic Emission and Vibratory Measurements. Materials 2021, 14, 5746. https://doi.org/10.3390/ma14195746

Fernández-Osete I, Estevez-Urra A, Velázquez-Corral E, Valentin D, Llumà J, Jerez-Mesa R, Travieso-Rodriguez JA. Ultrasonic Vibration-Assisted Ball Burnishing Tool for a Lathe Characterized by Acoustic Emission and Vibratory Measurements. Materials. 2021; 14(19):5746. https://doi.org/10.3390/ma14195746

Chicago/Turabian StyleFernández-Osete, Ismael, Aida Estevez-Urra, Eric Velázquez-Corral, David Valentin, Jordi Llumà, Ramón Jerez-Mesa, and J. Antonio Travieso-Rodriguez. 2021. "Ultrasonic Vibration-Assisted Ball Burnishing Tool for a Lathe Characterized by Acoustic Emission and Vibratory Measurements" Materials 14, no. 19: 5746. https://doi.org/10.3390/ma14195746

APA StyleFernández-Osete, I., Estevez-Urra, A., Velázquez-Corral, E., Valentin, D., Llumà, J., Jerez-Mesa, R., & Travieso-Rodriguez, J. A. (2021). Ultrasonic Vibration-Assisted Ball Burnishing Tool for a Lathe Characterized by Acoustic Emission and Vibratory Measurements. Materials, 14(19), 5746. https://doi.org/10.3390/ma14195746