Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites

Abstract

:1. Introduction

2. Materials and Methods

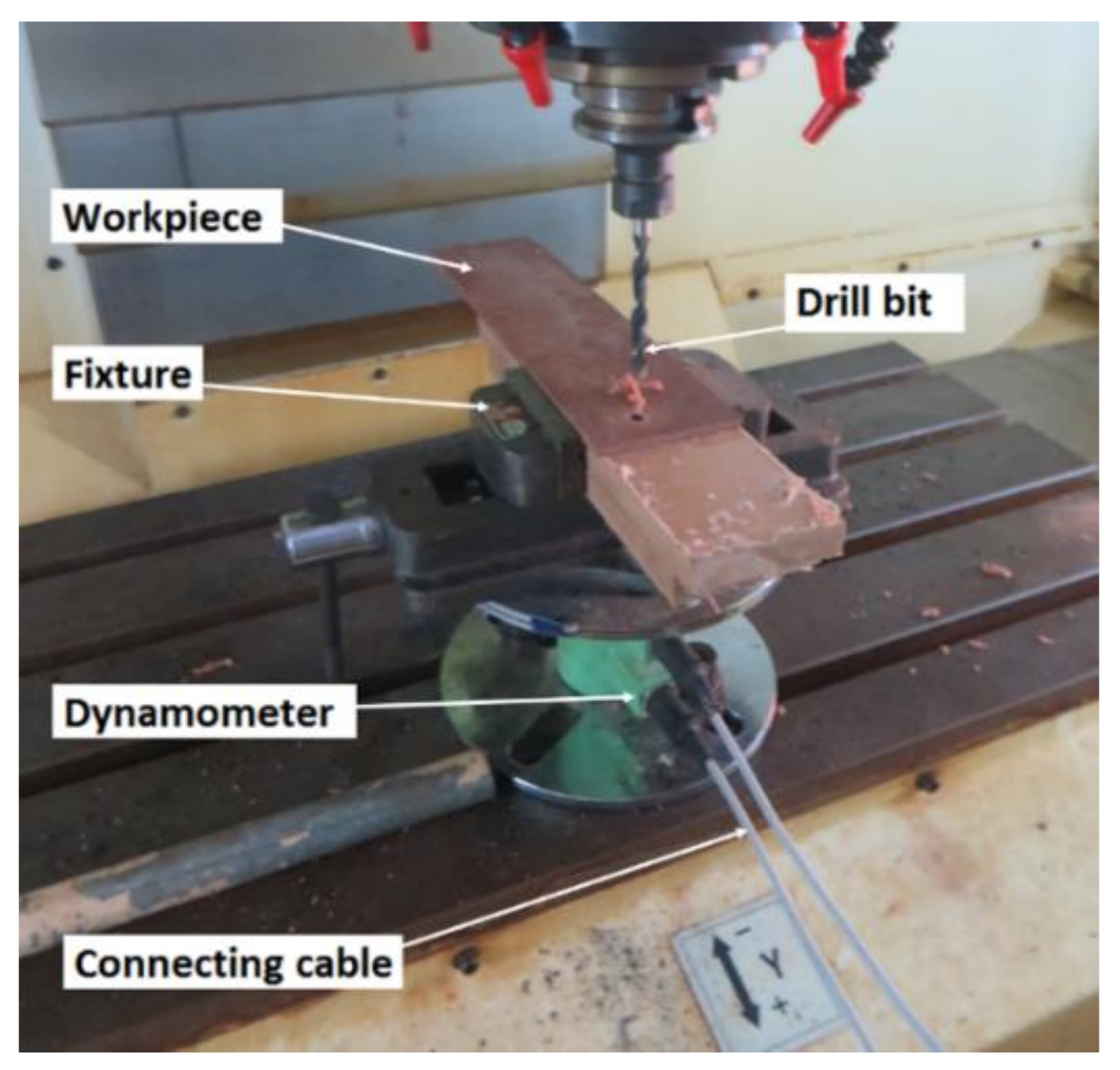

2.1. Drilling Experiment

2.2. Taguchi Experimental Design

3. Results and Discussion

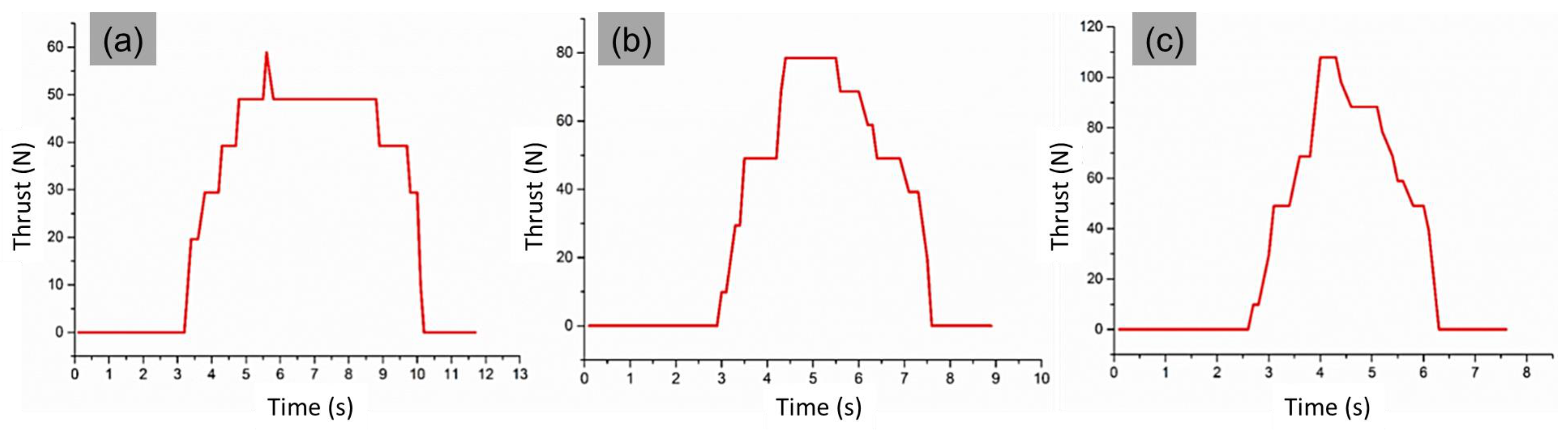

3.1. Thrust Force Analysis

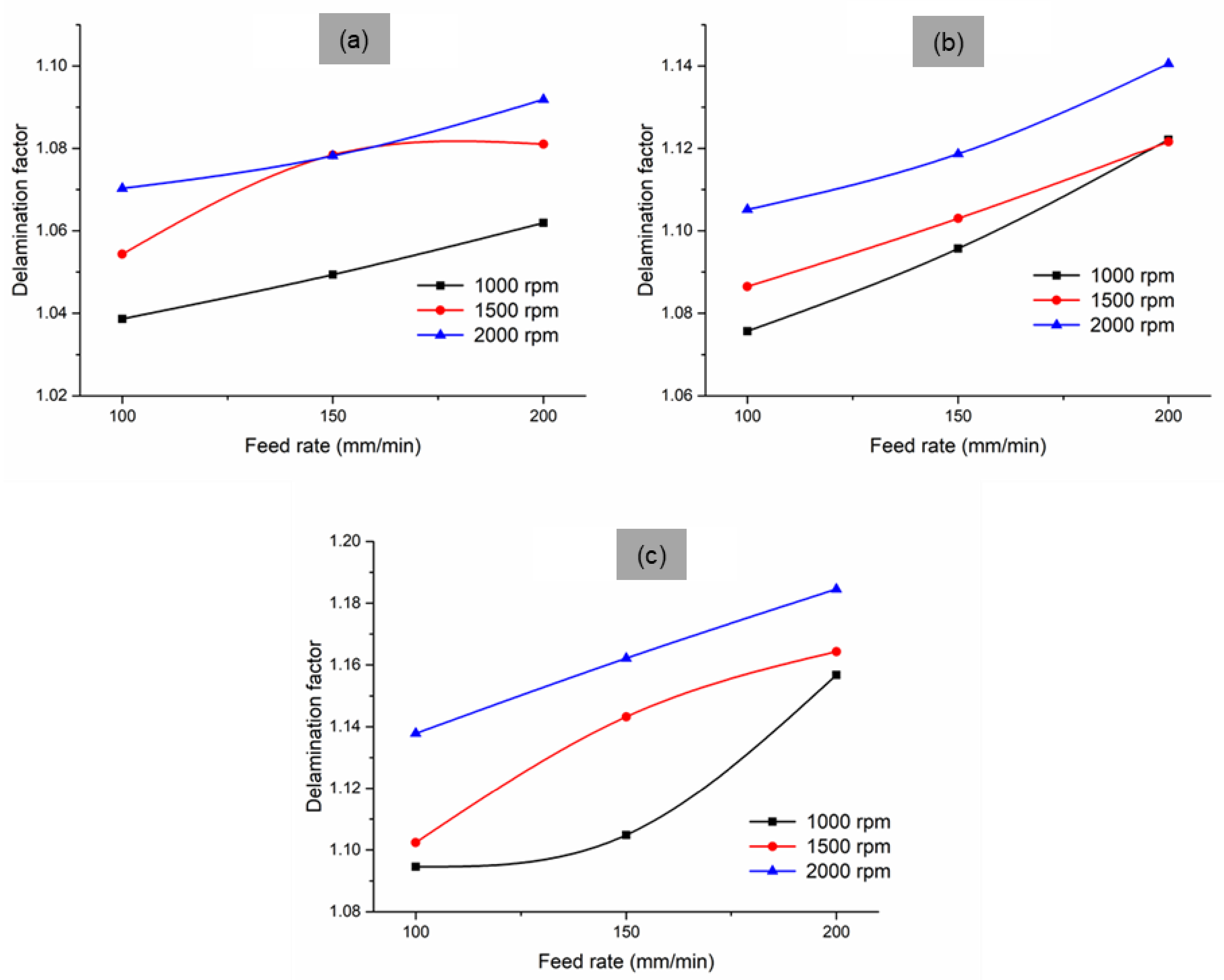

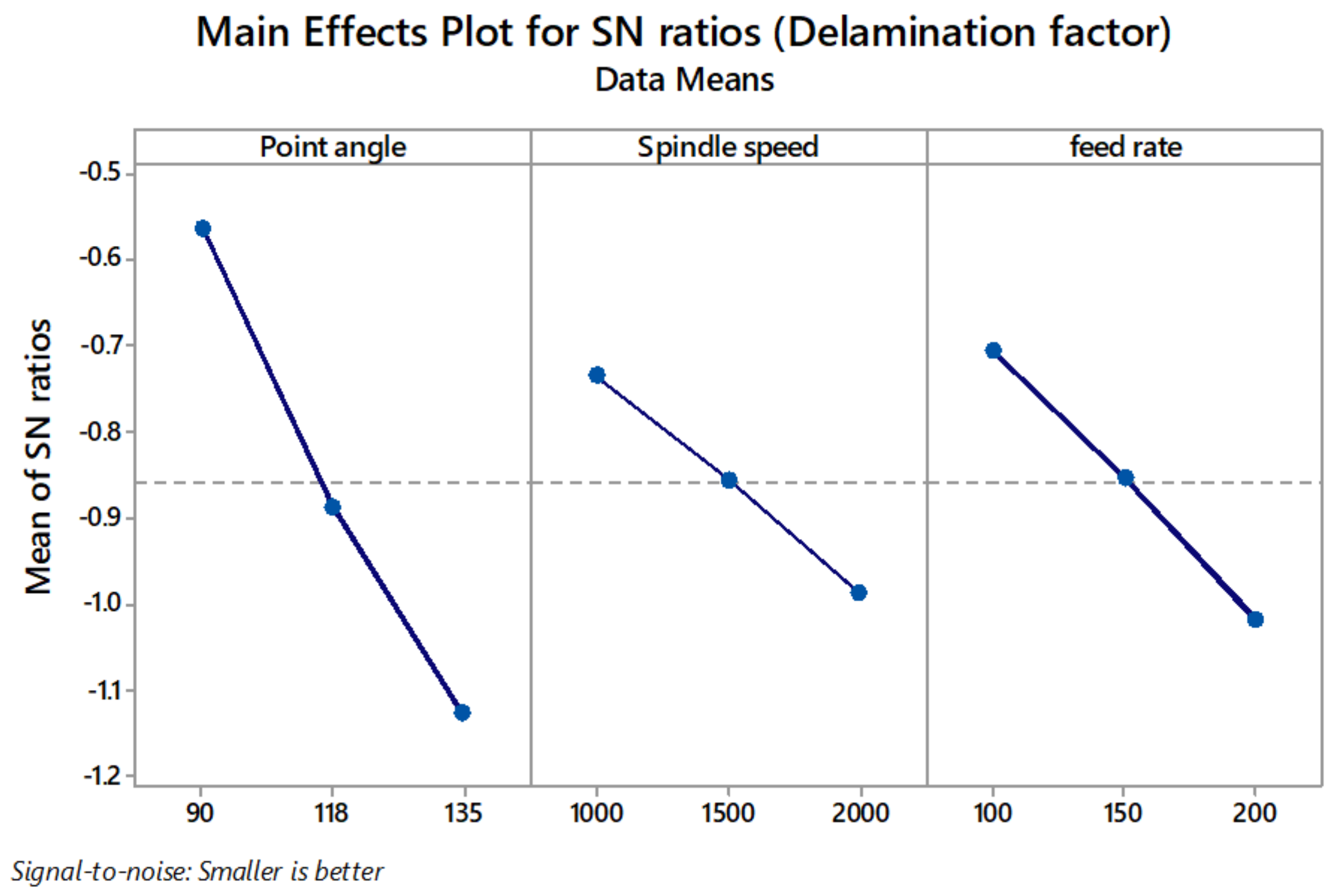

3.2. Delamination Analysis

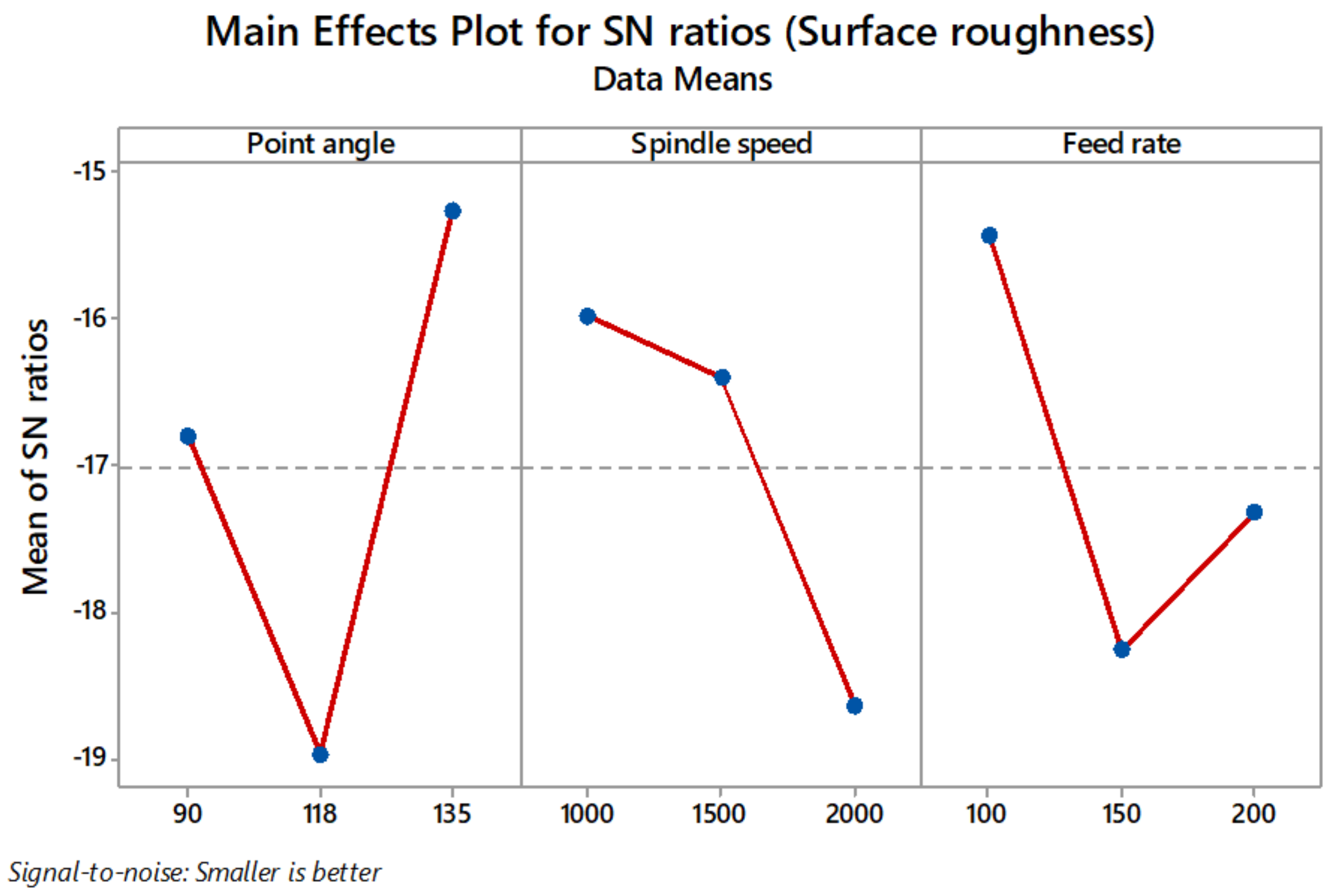

3.3. Surface Roughness (Ra) Analysis

4. Conclusions

- The thrust force increased with the increase in the feed rate and spindle speed. Compared to spindle speed, thrust force was highly influenced by feed rate. Drill tool with 118° point angle generated lower thrust force. ANOVA results showed that the spindle speed (39.23%) produced the maximum contribution affecting the thrust, followed by the feed rate (27.51%) and point angle (15.78%).

- Delamination was highly influenced by the feed rate (37.99%). Point angle 90° showed maximum delamination, while minimum delamination was noted at 118°. Variation in spindle showed minor variation in delamination.

- A quality hole with minimum thrust force was obtained at point angle 118°, spindle speed 1000 rpm, and feed rate 100 mm/min.

- The minimum delamination factor value was obtained at point angle 90°, spindle speed 1000 rpm, and feed rate 100 mm/min.

- The minimum surface roughness value was obtained at point angle 135°, spindle speed 1000 rpm, and feed rate 100 mm/min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Velmurugan, G.; Babu, K. Statistical analysis of mechanical properties of wood dust filled Jute fiber based hybrid composites under cryogenic atmosphere using Grey-Taguchi method. Mater. Res. Express 2020, 7, 065310. [Google Scholar] [CrossRef]

- Sanjeevi, S.; Shanmugam, V.; Kumar, S.; Ganesan, V.; Sas, G.; Johnson, D.; Shanmugam, M.; Ayyanar, A.; Naresh, K.; Neisiany, R.; et al. Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Das, O.; Loho, T.A.; Capezza, A.J.; Lemrhari, I.; Hedenqvist, M.S. A novel way of adhering PET onto protein (wheat gluten) plastics to impart water resistance. Coatings 2018, 8, 388. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; John, K.; Deepak, R.; Uthayakumar, M.; Arumugaprabu, V.; Kumaran, S. Conventional and unconventional machining performance of natural fibre-reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2021, 40, 553–567. [Google Scholar] [CrossRef]

- Razavi, S.M.; Neisiany, R.E.; Razavi, M.; Fakhar, A.; Shanmugam, V.; Alagumalai, V.; Försth, M.; Sas, G.; Das, O. Efficient Improvement in Fracture Toughness of Laminated Composite by Interleaving Functionalized Nanofibers. Polymers 2021, 13, 2509. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Shanmugam, V.; Johnson, D.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test. 2020, 93, 106925. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.M.; Johnson, R.D.J.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent advancement in the natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Review on machinability of fiber reinforced polymers: A drilling approach. Silicon 2018, 10, 2295–2305. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K. Application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. Measurement 2013, 46, 1470–1481. [Google Scholar] [CrossRef]

- Jani, S.P.; Kumar, A.S.; Khan, M.A.; Kumar, M.U. Machinablity of hybrid natural fibre composite with and without filler as reinforcement. Mater. Manuf. Process. 2016, 31, 1393–1399. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Davim, J.P. Some studies on drilling of hybrid metal matrix composites based on Taguchi techniques. J. Mater. Process. Technol. 2008, 196, 332–338. [Google Scholar] [CrossRef]

- Kumar, S.; Chauhan, S.R.; Rakesh, P.K.; Singh, I.; Davim, J.P. Drilling of glass fibre/vinyl ester composites with fillers. Mater. Manuf. Process. 2012, 27, 314–319. [Google Scholar] [CrossRef]

- Rajmohan, T.; Vinayagamoorthy, R.; Mohan, K. Review on effect machining parameters on performance of natural fibre–reinforced composites (NFRCs). J. Thermoplast. Compos. Mater 2019, 32, 1282–1302. [Google Scholar] [CrossRef]

- Babu, G.D.; Babu, K.S.; Gowd, B. Optimization of machining parameters in drilling hemp fibre reinforced composites to maximize the tensile strength using design experiments. Ind. J. Eng. Mater. Sci. 2013, 20, 385–390. [Google Scholar]

- Chandramohan, D.; Marimuthu, K. Thrust force and torque in drilling the natural fibre reinforced polymer composite materials and evaluation of delamination factor for bone graft substitutes–a work of fiction approach. Int. J. Eng. Sci. Technol. 2010, 2, 6437–6451. [Google Scholar]

- Yallew, T.B.; Kumar, P.; Singh, I. A study about hole making in woven jute fabric-reinforced polymer composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 888–898. [Google Scholar] [CrossRef]

- Sridharan, V.; Raja, T.; Muthukrishnan, N. Study of the effect of matrix, fibre treatment and graphene on delamination by drilling jute/epoxy nanohybrid composite. Arab. J. Sci. Eng. 2016, 41, 1883–1894. [Google Scholar] [CrossRef]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajan, U.; Pazhanivel, B. Influence of alkali-treated fibres on the mechanical properties and machinability of roselle and sisal fibre hybrid polyester composite. Polym. Compos. 2010, 31, 723–731. [Google Scholar]

- Jayabal, S.; Natarajan, U. Drilling analysis of coir-fibre-reinforced polyester composites. Bull. Mater. Sci. 2011, 34, 1563–1567. [Google Scholar] [CrossRef]

- Jayabal, S.; Natarajan, U. Optimization of thrust force, torque, and tool wear in drilling of coir fibre-reinforced composites using Nelder–Mead and genetic algorithm methods. Int. J. Adv. Manuf. Syst. 2010, 51, 371–381. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Gonçalves, D.J.; Tavares, J.M.R.; de Albuquerque, V.H.C.; Panzera, T.H.; Silva, L.J.; Vieira, A.A.; Baptista, A.P.M. Drilling delamination outcomes on glass and sisal reinforced plastics. In Mater. Sci. Forum. 2013, 730, 301–306. [Google Scholar] [CrossRef]

- Vigneshwaran, S. Machining and Erosion Studies of Red Mud Based Polymer Composites; Kalasalingam Academy of Research and Education: Krishnankoil, India, 2020. [Google Scholar]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Development and sustainability of industrial waste-based redmud hybrid composites. J. Clean. Prod. 2019, 230, 862–868. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Gonçalves, D.J.; Tavares, J.M.R.; de Albuquerque, V.H.C.; Vieira, A.A.; Marques, A.T. Drilling tool geometry evaluation for reinforced composite laminates. Compos. Struct. 2010, 92, 1545–1550. [Google Scholar] [CrossRef]

| Property | Untreated Sisal Fibre/Redmud Composite | Silane Treated Sisal Fibre/Redmud Composite |

|---|---|---|

| Tensile strength (MPa) | 49 | 63 |

| Flexural strength (MPa) | 199 | 244 |

| Impact strength (J/m) | 20 | 26 |

| Hardness (shore D) | 78 | 90 |

| Density (g/cm3) | 1.4 | 1.5 |

| Voids (%) | 3.5 | 1.2 |

| Symbol | Process Variables | Levels | ||

|---|---|---|---|---|

| I | II | III | ||

| A | Point angle (°) | 90 | 118 | 135 |

| B | Spindle Speed (rpm) | 1000 | 1500 | 2000 |

| C | Feed rate (mm/min) | 100 | 150 | 200 |

| Ex. No | Point Angle (°) | Spindle Speed (rpm) | Feed Rate (mm/min) | Thrust (N) | S/N Ratio of Thrust | Fd | S/N Ratio of Fd | Ra (µm) | S/N Ratio of Ra |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 90 | 1000 | 100 | 29.43 | −29.38 | 1.039 | −0.329 | 5.332 | −14.538 |

| 2 | 90 | 1000 | 150 | 49.05 | −33.81 | 1.049 | −0.419 | 7.521 | −17.526 |

| 3 | 90 | 1000 | 200 | 68.67 | −36.74 | 1.062 | −0.522 | 7.900 | −17.953 |

| 4 | 90 | 1500 | 100 | 49.05 | −33.81 | 1.054 | −0.459 | 6.538 | −16.308 |

| 5 | 90 | 1500 | 150 | 58.86 | −35.40 | 1.078 | −0.655 | 8.078 | −18.146 |

| 6 | 90 | 1500 | 200 | 78.48 | −37.90 | 1.081 | −0.677 | 3.961 | −11.956 |

| 7 | 90 | 2000 | 100 | 58.86 | −35.40 | 1.070 | −0.590 | 8.646 | −18.736 |

| 8 | 90 | 2000 | 150 | 78.48 | −37.90 | 1.078 | −0.653 | 8.191 | −18.267 |

| 9 | 90 | 2000 | 200 | 107.91 | −40.66 | 1.092 | −0.764 | 7.692 | −17.721 |

| 10 | 118 | 1000 | 100 | 19.62 | −25.85 | 1.076 | −0.634 | 5.341 | −14.553 |

| 11 | 118 | 1000 | 150 | 29.43 | −29.38 | 1.096 | −0.794 | 10.048 | −20.042 |

| 12 | 118 | 1000 | 200 | 39.24 | −31.87 | 1.122 | −1.001 | 8.824 | −18.913 |

| 13 | 118 | 1500 | 100 | 39.24 | −31.87 | 1.086 | −0.721 | 6.982 | −16.880 |

| 14 | 118 | 1500 | 150 | 49.05 | −33.81 | 1.103 | −0.851 | 9.124 | −19.204 |

| 15 | 118 | 1500 | 200 | 68.67 | −36.74 | 1.122 | −0.997 | 5.798 | −15.265 |

| 16 | 118 | 2000 | 100 | 49.05 | −33.81 | 1.105 | −0.868 | 12.726 | −22.094 |

| 17 | 118 | 2000 | 150 | 68.67 | −36.74 | 1.119 | −0.974 | 13.286 | −22.468 |

| 18 | 118 | 2000 | 200 | 88.29 | −38.92 | 1.141 | −1.142 | 11.672 | −21.343 |

| 19 | 135 | 1000 | 100 | 29.43 | −29.38 | 1.095 | −0.785 | 2.136 | −6.590 |

| 20 | 135 | 1000 | 150 | 39.24 | −31.87 | 1.105 | −0.866 | 6.630 | −16.430 |

| 21 | 135 | 1000 | 200 | 58.86 | −35.40 | 1.157 | −1.265 | 7.339 | −17.312 |

| 22 | 135 | 1500 | 100 | 49.05 | −33.81 | 1.102 | −0.847 | 4.442 | −12.952 |

| 23 | 135 | 1500 | 150 | 78.48 | −37.90 | 1.143 | −1.163 | 8.313 | −18.395 |

| 24 | 135 | 1500 | 200 | 107.91 | −40.66 | 1.164 | −1.321 | 8.447 | −18.534 |

| 25 | 135 | 2000 | 100 | 78.48 | −37.90 | 1.138 | −1.122 | 6.484 | −16.237 |

| 26 | 135 | 2000 | 150 | 127.53 | −42.11 | 1.162 | −1.305 | 4.958 | −13.906 |

| 27 | 135 | 2000 | 200 | 186.39 | −45.41 | 1.185 | −1.471 | 7.047 | −16.960 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Point angle | 2 | 5182.5 | 15.78% | 5182.5 | 2591.25 | 27.43 | 0.00 |

| Spindle speed | 2 | 12,881.4 | 39.23% | 12,881.4 | 6440.69 | 68.19 | 0.00 |

| Feed rate | 2 | 9031.9 | 27.51% | 9031.9 | 4515.97 | 47.81 | 0.00 |

| Point angle × Spindle speed | 4 | 2901.3 | 8.84% | 2901.3 | 725.34 | 7.68 | 0.008 |

| Point angle × Feed rate | 4 | 1040.8 | 3.17% | 1040.8 | 260.19 | 2.75 | 0.104 |

| Spindle speed × Feed rate | 4 | 1040.8 | 3.17% | 1040.8 | 260.19 | 2.75 | 0.104 |

| Error | 8 | 755.6 | 2.30% | 755.6 | 94.45 | - | - |

| Total | 26 | 32,834.3 | 100.00% | - | - | - | - |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Point angle | 2 | 0.023368 | 63.05% | 0.023368 | 0.011684 | 383.89 | 0.00 |

| Spindle speed | 2 | 0.004664 | 12.58% | 0.004664 | 0.002332 | 76.62 | 0.00 |

| Feed rate | 2 | 0.007187 | 19.39% | 0.007187 | 0.003594 | 118.07 | 0.00 |

| Point angle × pindle speed | 4 | 0.000451 | 1.22% | 0.000451 | 0.000113 | 3.7 | 0.054 |

| Point angle × Feed | 4 | 0.00086 | 2.32% | 0.00086 | 0.000215 | 7.06 | 0.01 |

| Spindle speed × Feed | 4 | 0.000291 | 0.78% | 0.000291 | 0.000073 | 2.39 | 0.137 |

| Error | 8 | 0.000243 | 0.66% | 0.000243 | 0.00003 | - | - |

| Total | 26 | 0.037065 | 100.00% | - | - | - | - |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Point angle | 2 | 46.191 | 27.91% | 46.191 | 23.0957 | 31.18 | 0 |

| Spindle speed | 2 | 27.685 | 16.73% | 27.685 | 13.8424 | 18.69 | 0.001 |

| Feed rate | 2 | 17.179 | 10.38% | 17.179 | 8.5893 | 11.59 | 0.004 |

| Point angle × Spindle speed | 4 | 31.124 | 18.80% | 31.124 | 7.781 | 10.5 | 0.003 |

| Point angle × Feed rate | 4 | 13.36 | 8.07% | 13.36 | 3.3401 | 4.51 | 0.034 |

| Spindle speed × Feed rate | 4 | 24.048 | 14.53% | 24.048 | 6.0119 | 8.12 | 0.006 |

| Error | 8 | 5.926 | 3.58% | 5.926 | 0.7408 | - | - |

| Total | 26 | 165.513 | 100.00% | - | - | - | - |

| Level | Thrust | Delamination Factor | Surface Roughness (Ra) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Point Angle | Spindle Speed | Feed | Point Angle | Spindle Speed | Feed | Point Angle | Spindle Speed | Feed | |

| 1 | −32.66 | −28.51 | −29.35 | 32.69 | 20.71 | 22.89 | −16.79 | −15.98 | −15.43 |

| 2 | −30.21 | −32.76 | −32.43 | 25.62 | 32.71 | 32.71 | −18.97 | −16.4 | −18.26 |

| 3 | −34.15 | −35.75 | −35.24 | 42.53 | 47.43 | 45.25 | −15.26 | −18.64 | −17.33 |

| Delta | 3.94 | 7.24 | 5.89 | 16.91 | 26.72 | 22.36 | 3.72 | 2.65 | 2.83 |

| Rank | 3 | 1 | 2 | 3 | 1 | 2 | 1 | 3 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shanmugam, V.; Marimuthu, U.; Rajendran, S.; Veerasimman, A.; Basha, A.M.; Majid, M.S.B.A.; Esmaeely Neisiany, R.; Försth, M.; Sas, G.; Razavi, N.; et al. Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites. Materials 2021, 14, 4468. https://doi.org/10.3390/ma14164468

Shanmugam V, Marimuthu U, Rajendran S, Veerasimman A, Basha AM, Majid MSBA, Esmaeely Neisiany R, Försth M, Sas G, Razavi N, et al. Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites. Materials. 2021; 14(16):4468. https://doi.org/10.3390/ma14164468

Chicago/Turabian StyleShanmugam, Vigneshwaran, Uthayakumar Marimuthu, Sundarakannan Rajendran, Arumugaprabu Veerasimman, Adamkhan Mahaboob Basha, Mohd Shukry Bin Abdul Majid, Rasoul Esmaeely Neisiany, Michael Försth, Gabriel Sas, Nima Razavi, and et al. 2021. "Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites" Materials 14, no. 16: 4468. https://doi.org/10.3390/ma14164468

APA StyleShanmugam, V., Marimuthu, U., Rajendran, S., Veerasimman, A., Basha, A. M., Majid, M. S. B. A., Esmaeely Neisiany, R., Försth, M., Sas, G., Razavi, N., & Das, O. (2021). Experimental Investigation of Thrust Force, Delamination and Surface Roughness in Drilling Hybrid Structural Composites. Materials, 14(16), 4468. https://doi.org/10.3390/ma14164468